Floor slab hole plugging device and method

A technology for plugging devices and holes, applied in building maintenance, building components, building insulation materials, etc., can solve problems such as large safety hazards, low construction efficiency, unfavorable turnover, etc., to improve construction safety, ensure construction quality, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

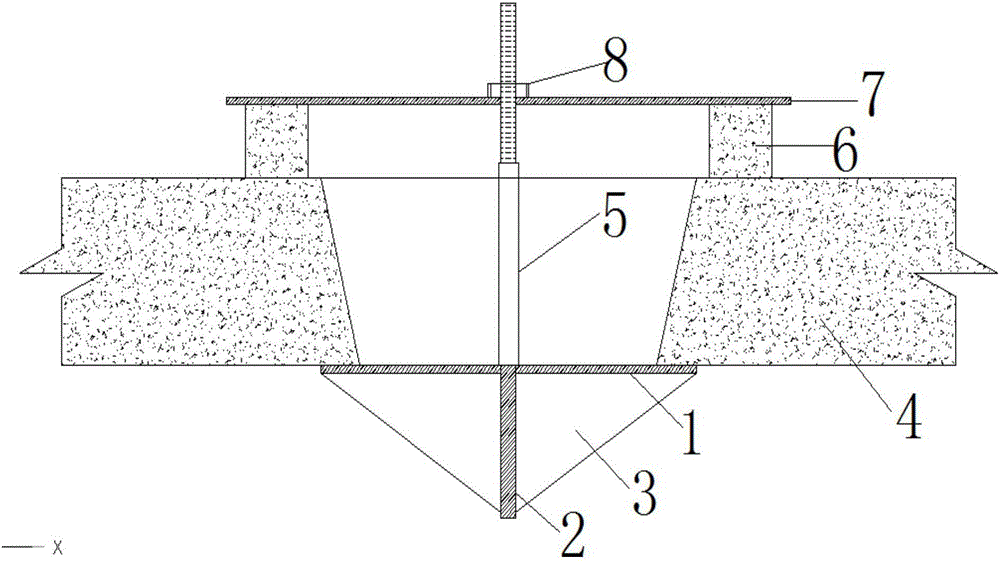

[0028] refer to figure 1 As shown, the floor hole plugging device in an embodiment provided by the present invention includes a supporting plate 1, a tie rod 2 and a fixing plate 7, the supporting plate 1 and the fixing plate 7 are horizontally arranged in parallel, and are distributed on the pulling rod 2 in turn from bottom to top , the tie rod 2 is provided with a sleeve, the length of the sleeve is longer than the thickness of the floor slab, the sleeve is arranged between the supporting plate 1 and the fixing plate 7, the supporting plate 1 is connected and fixed with the pull rod 2 by welding, and the fixing plate 7 Connected with the pull rod 2 through threads, the fixed plate 7 can be adjusted up and down along the pull rod 2 through the threads. The lower end surface of the fixed plate 7 is also provided with a plurality of pads, and the mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com