Assembled integral shear wall and construction method thereof

A shear wall, integral technology, applied in the direction of walls, building materials, building components, etc., can solve the problems of complexity, short service life, and lack of overall assembly, and achieve the effect of small constraints and reduced workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings.

[0060] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

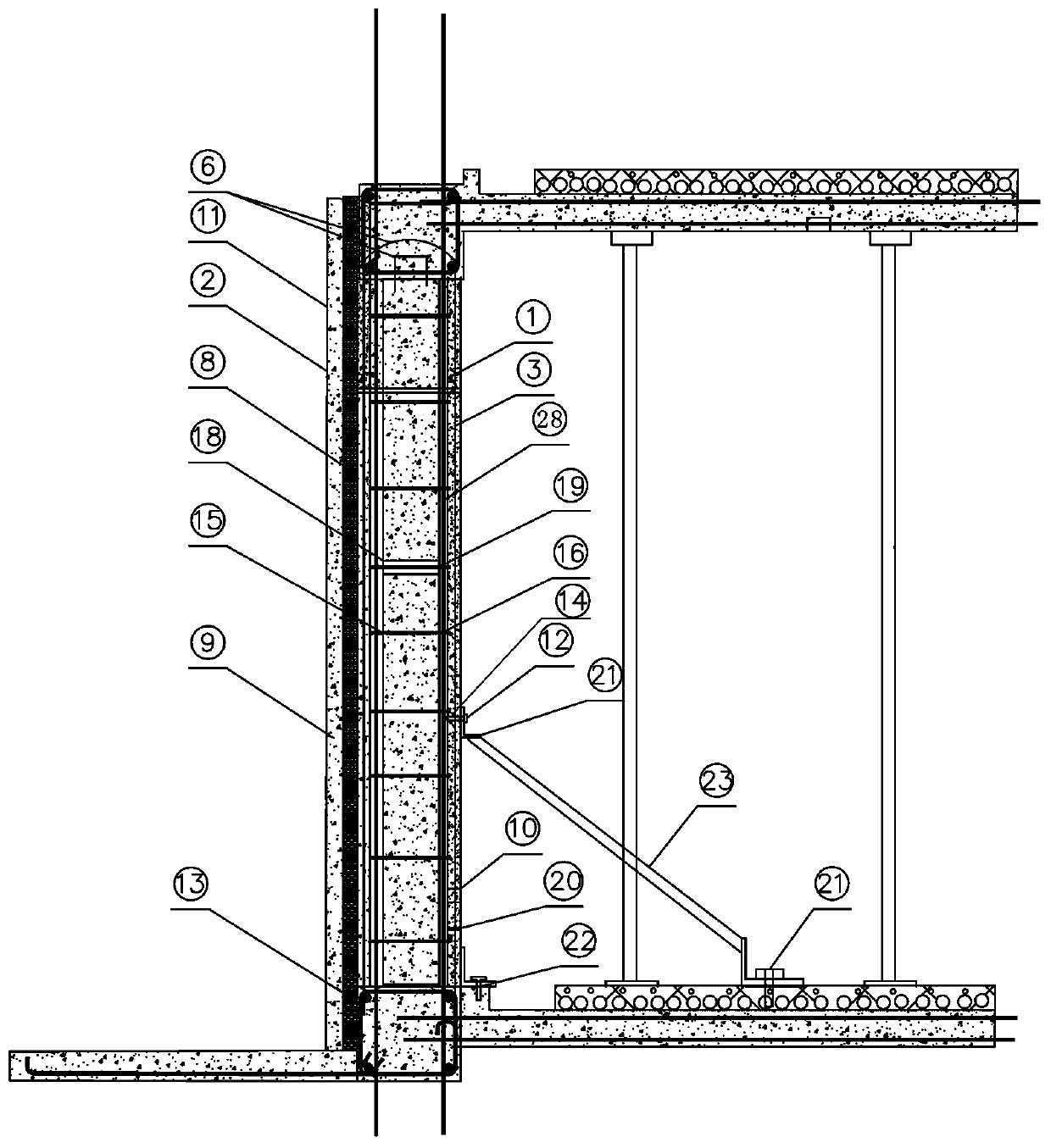

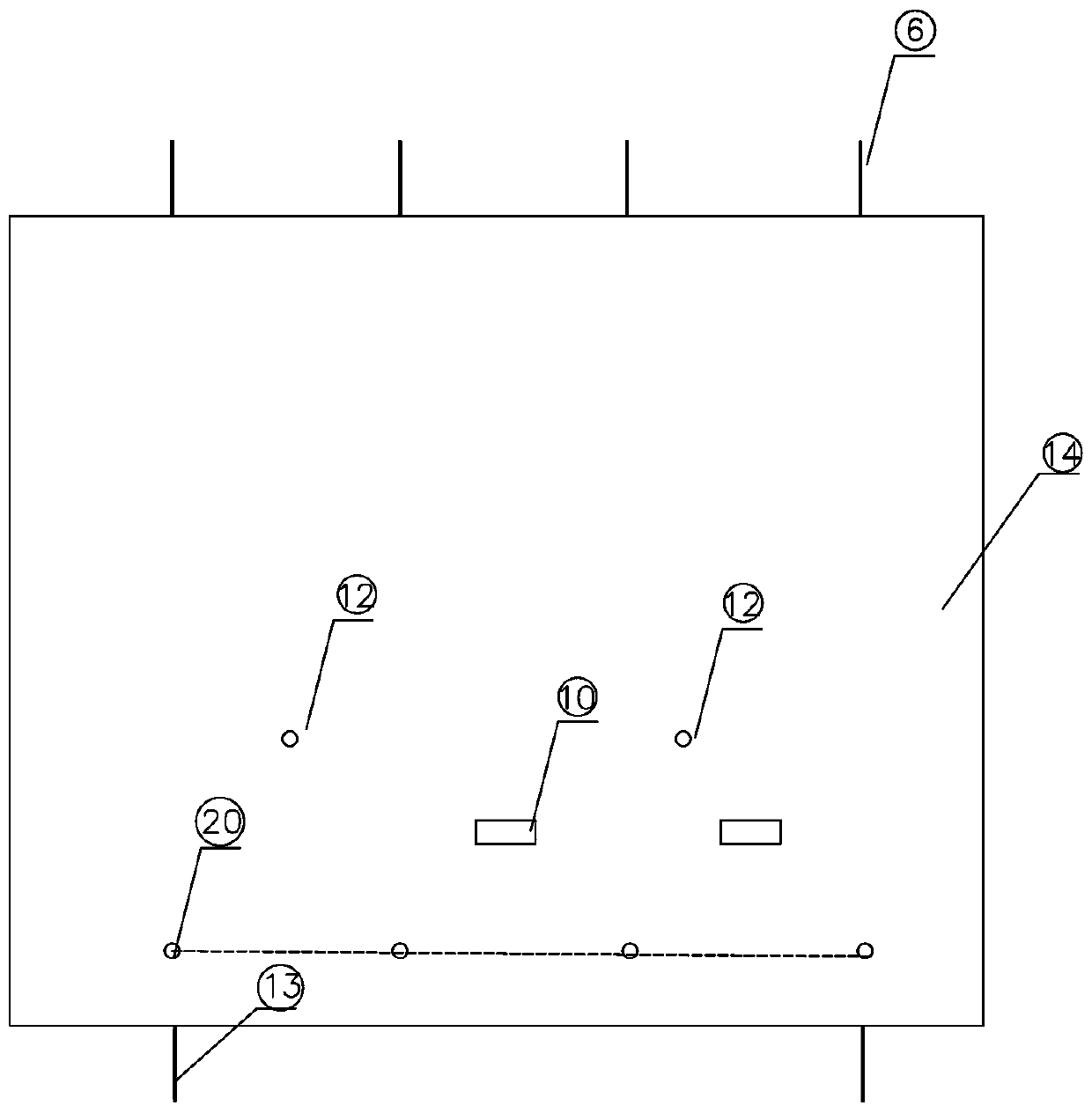

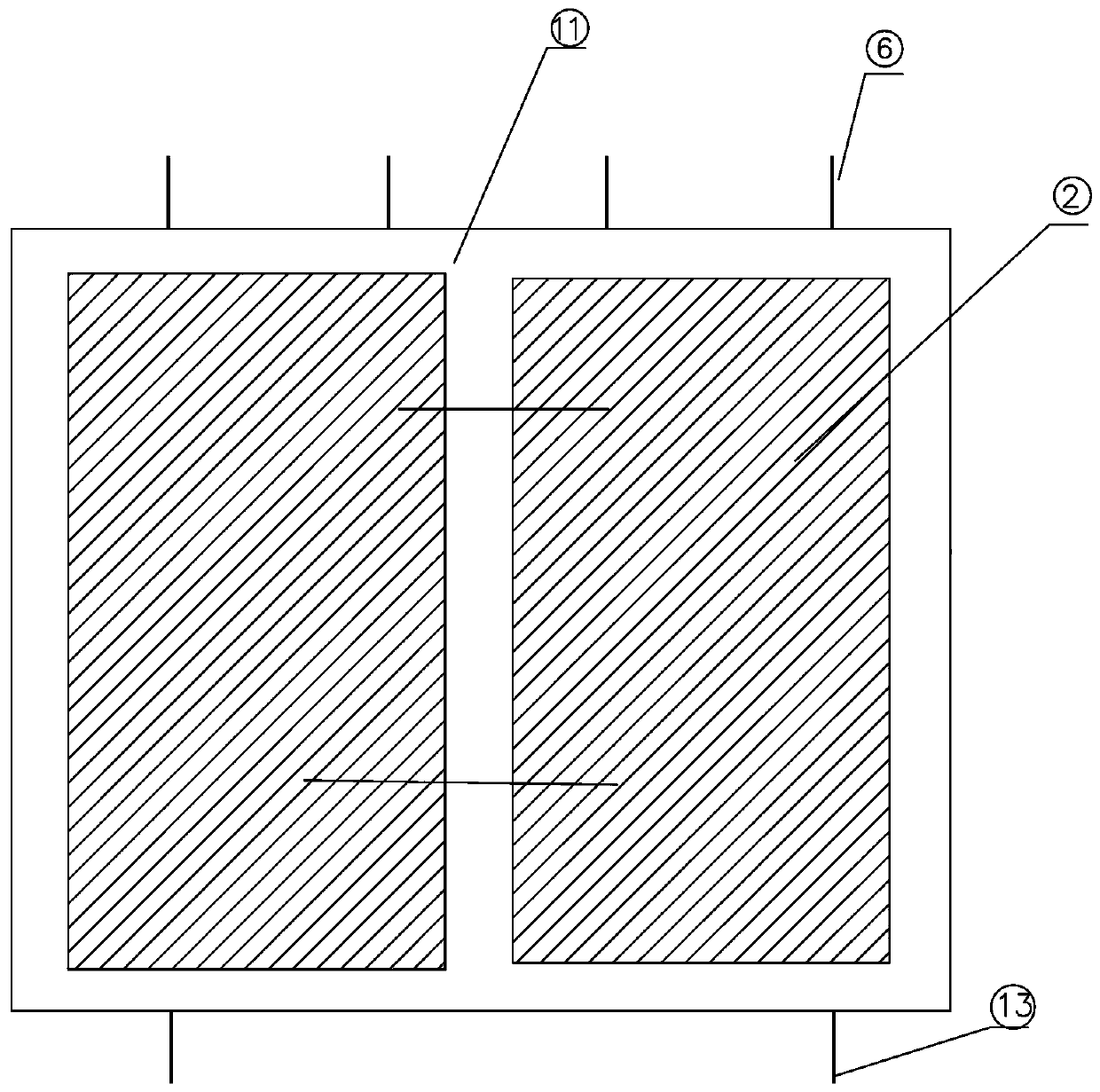

[0061] like Figure 1 to Figure 5 As shown, the present invention provides an assembled integral shear wall, comprising a shear wall formwork 1 and a square concrete block 17 inside the shear wall formwork, the bottom of the shear wall formwork 1 is provided with a filling opening 20, The internal gap is filled by injecting cement slurry into the filling port 20 . Reinforcement grooves 25 are left on both sides of the concrete block 17 for reserving a position for the reinforced reinforcement 16 inside the formwork. A word stirrup reserved hole 18 is reserved on the concrete block 17, and the word stirrup 19 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com