Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Increased torsional rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

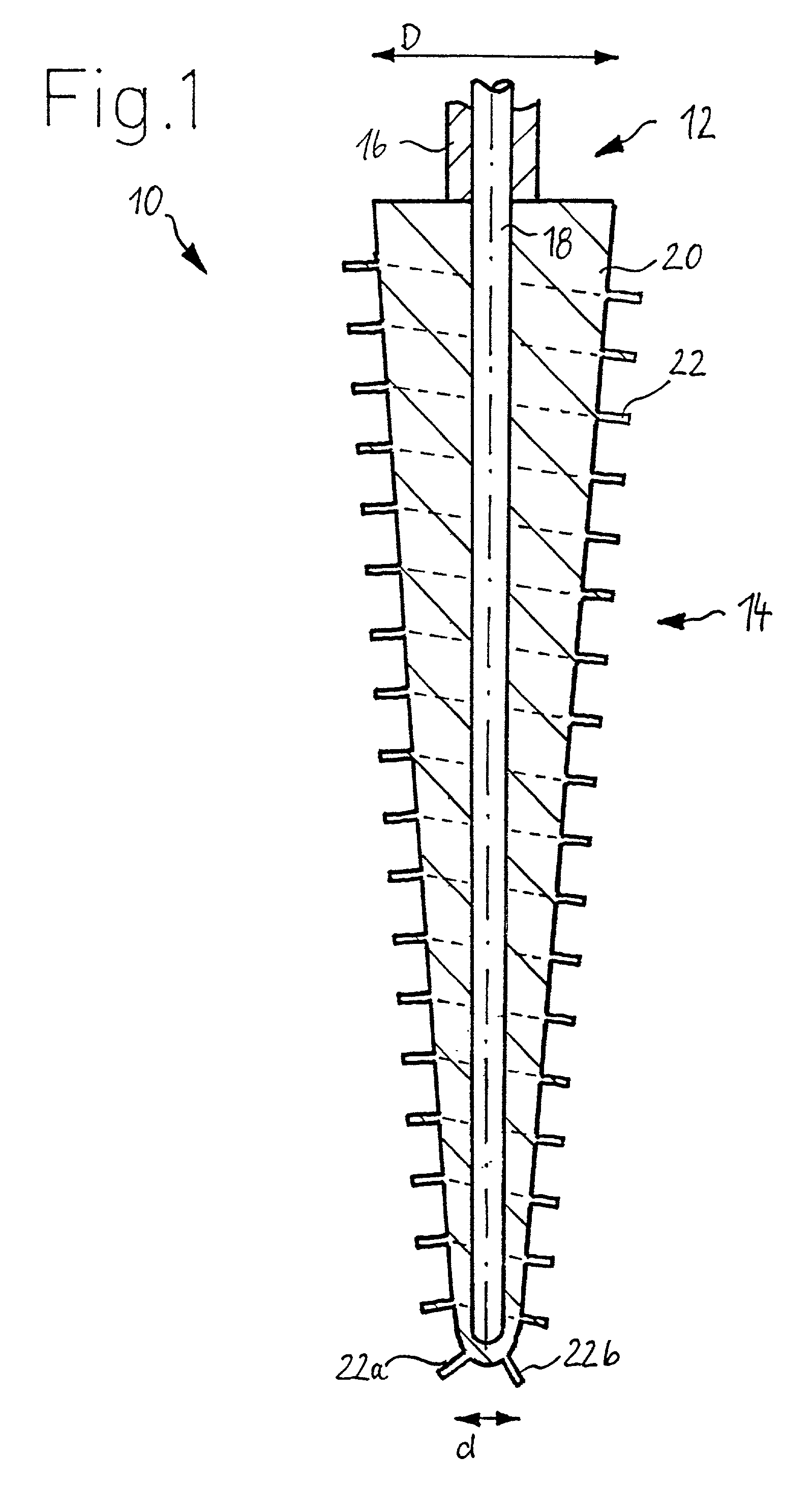

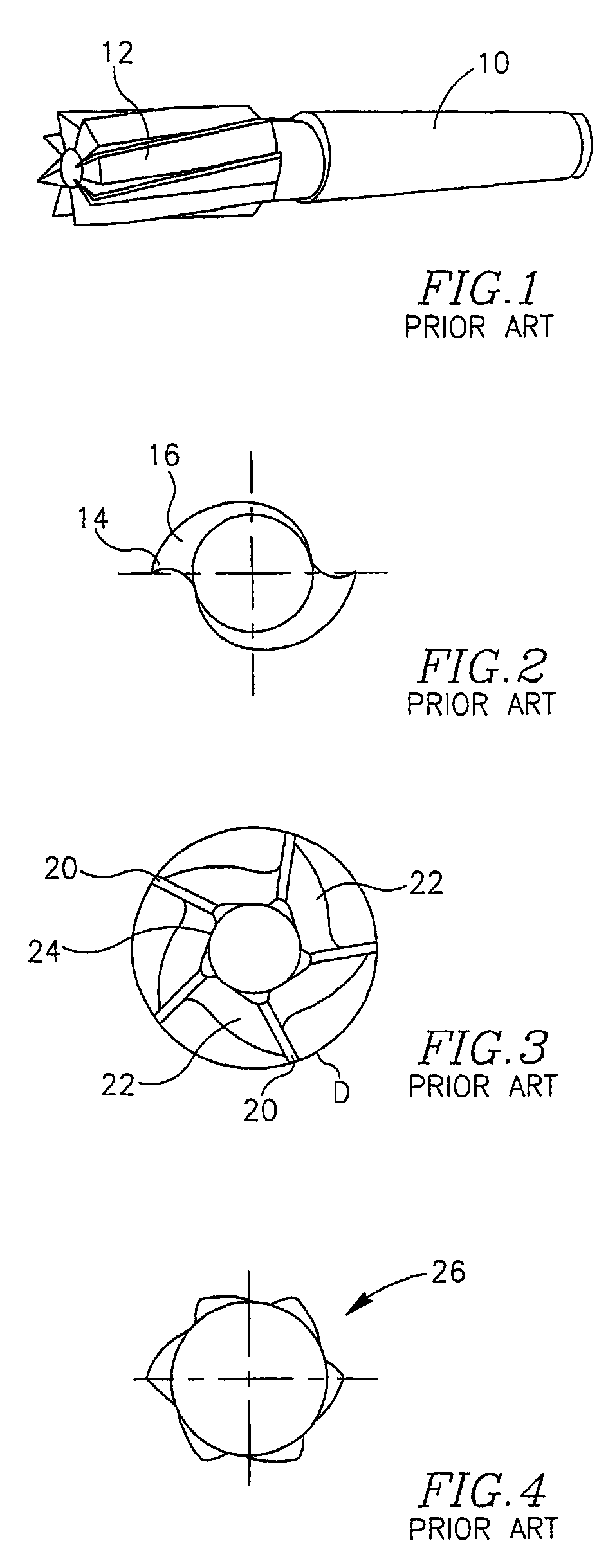

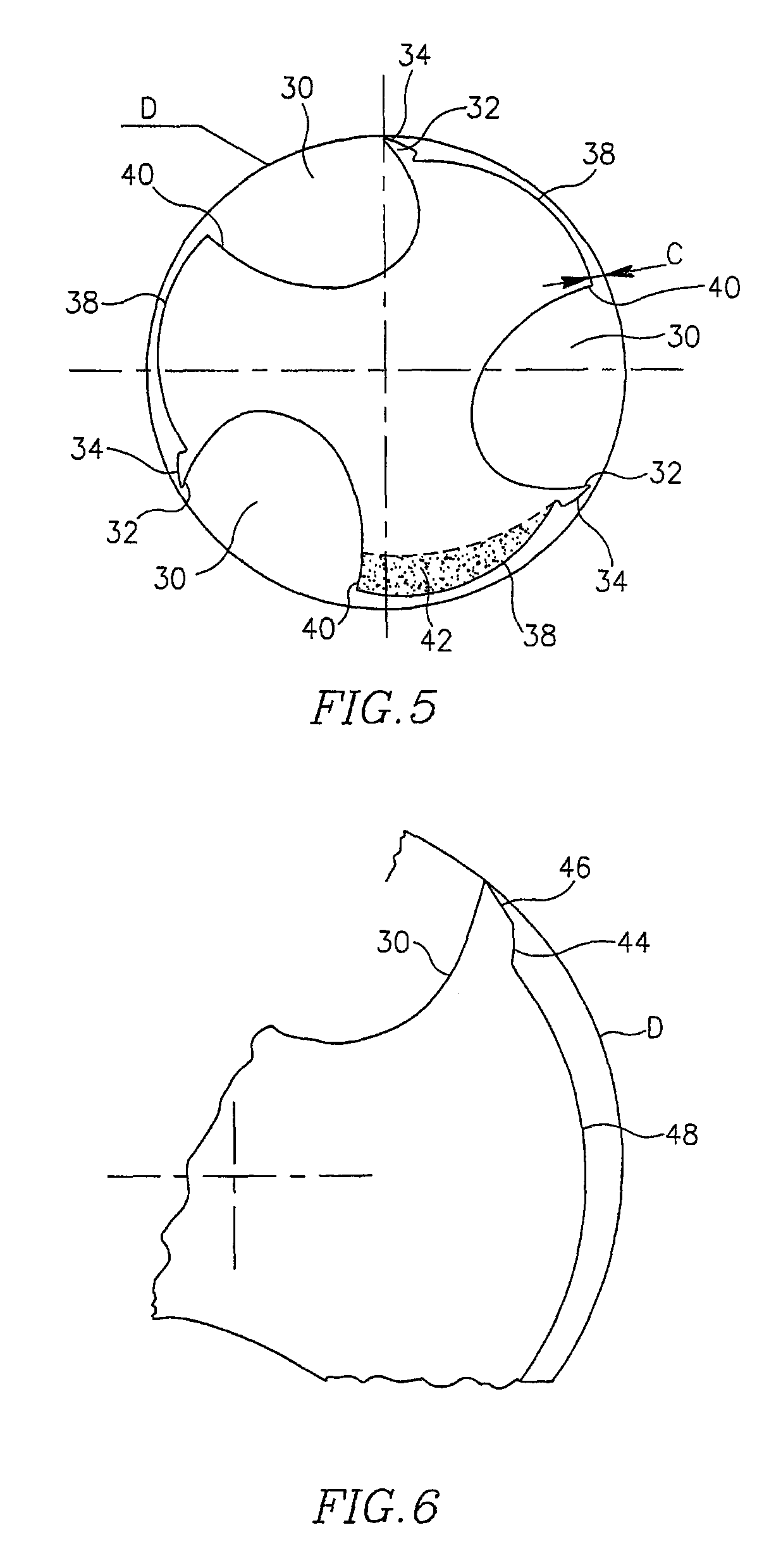

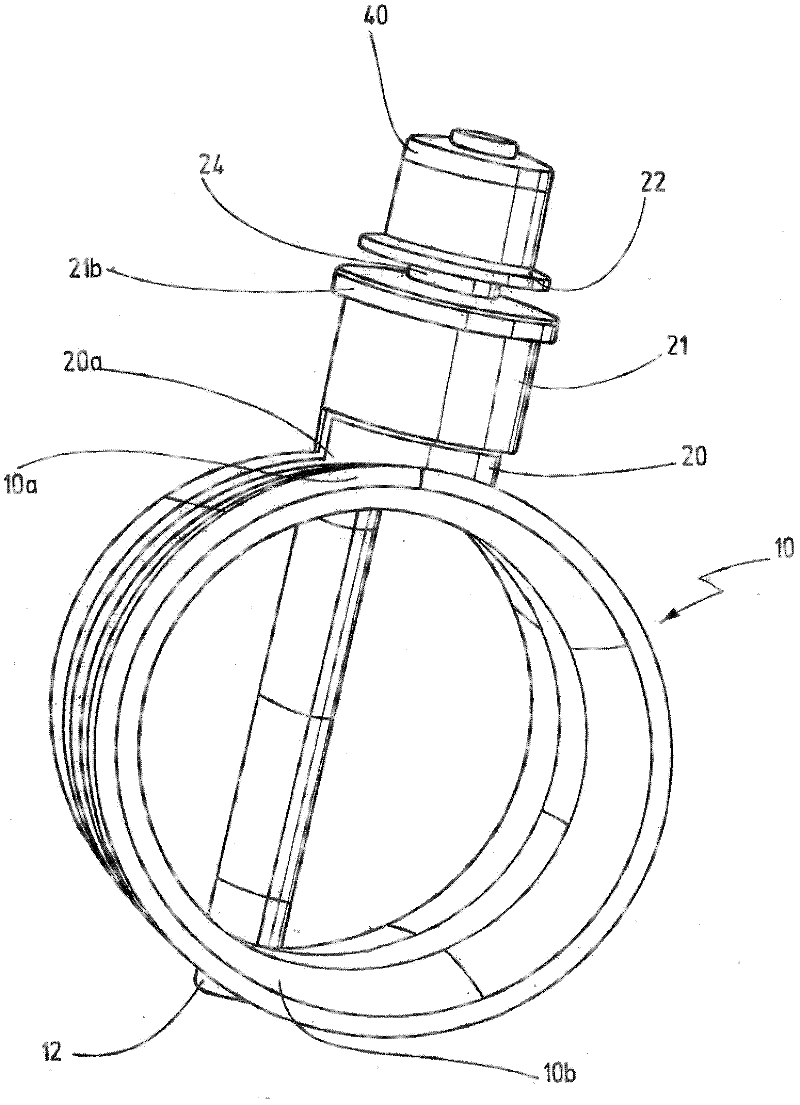

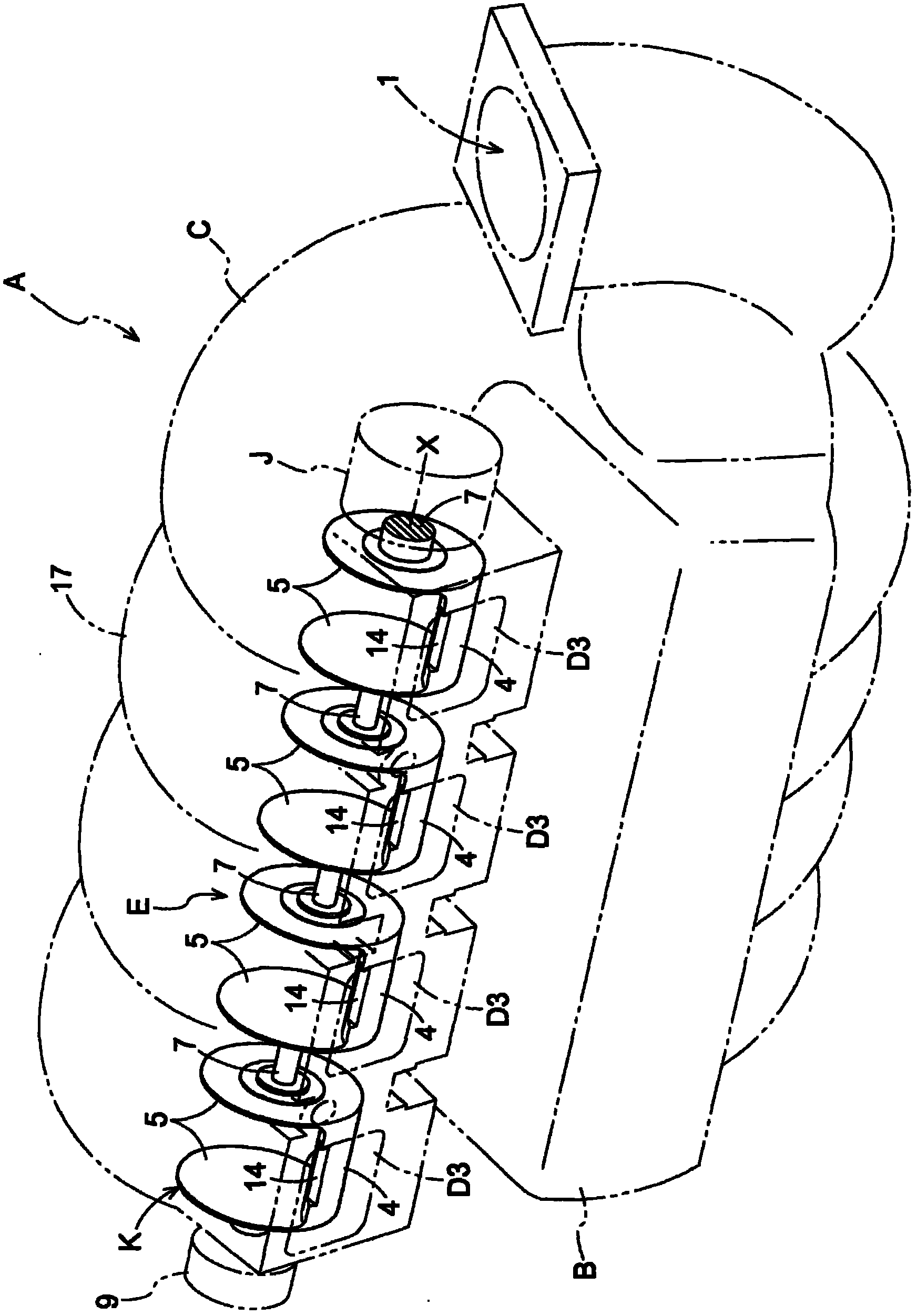

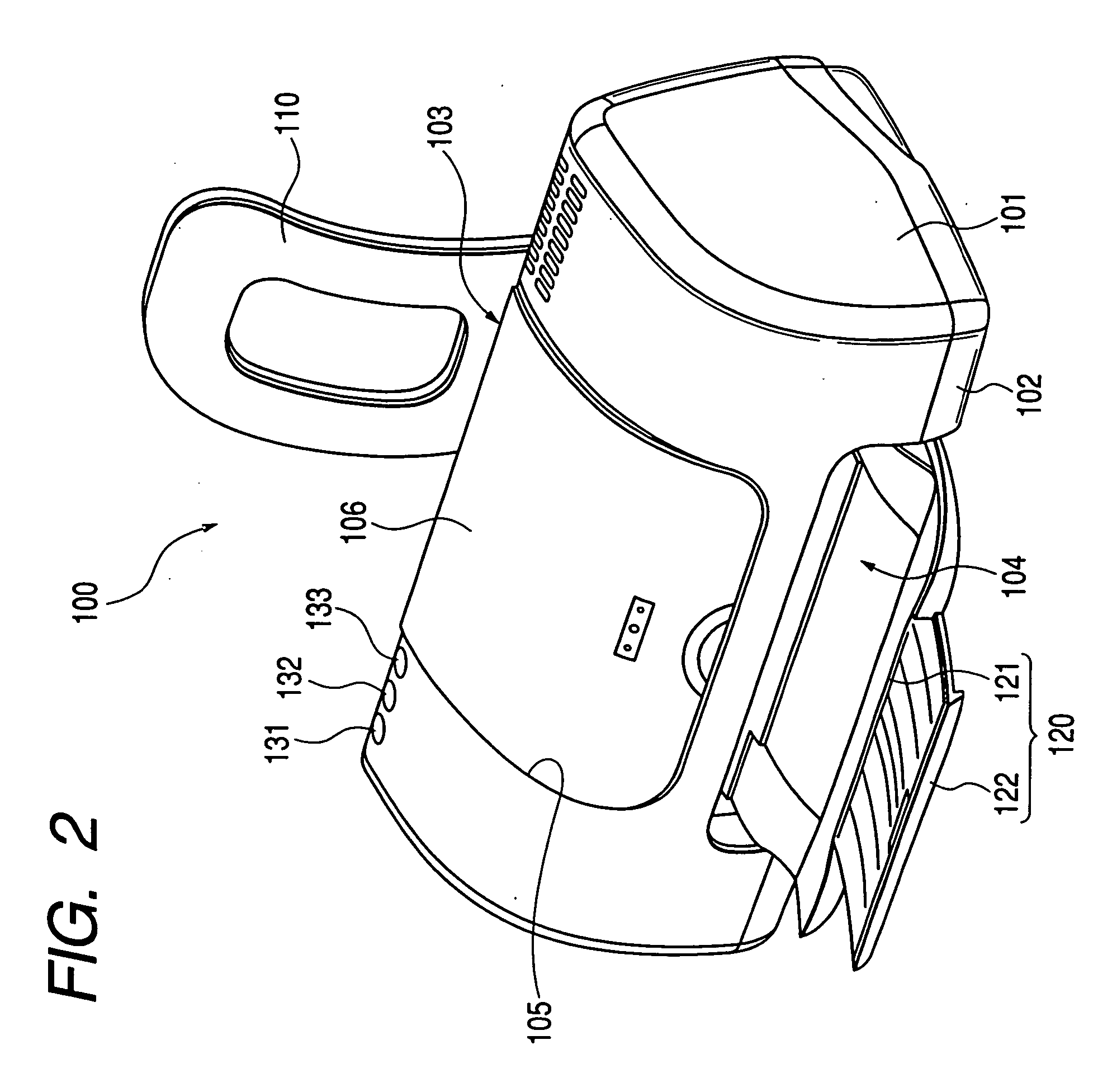

Cleaning instrument for a tooth root canal

InactiveUS20020172922A1Easy to cleanIncreased torsional rigidityGum massageBrush bodiesBristleEngineering

The cleaning instrument (10) comprises a head portion (10) and, adjacent thereto, a cleaning portion (14) having a shank (20), which is provided with bristles (22) on its external surface. In order that especially the tooth root canal or also a tooth interstice can be reliably cleaned using the cleaning instrument (10), the shank (20) is of integral construction with the bristles (22).

Owner:ROEKO & DENTALERZEUGNISSE

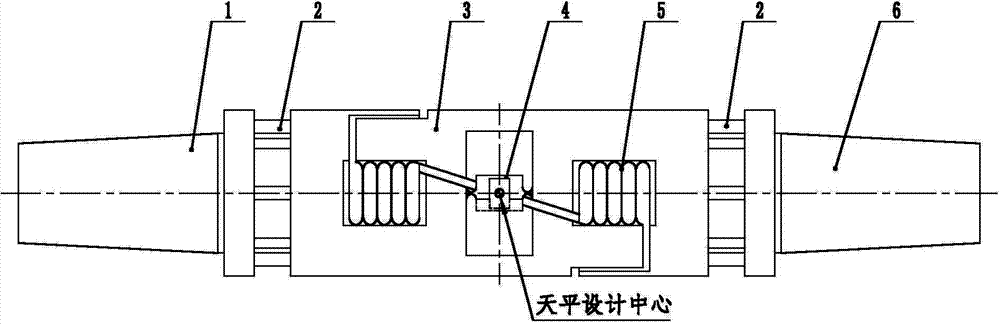

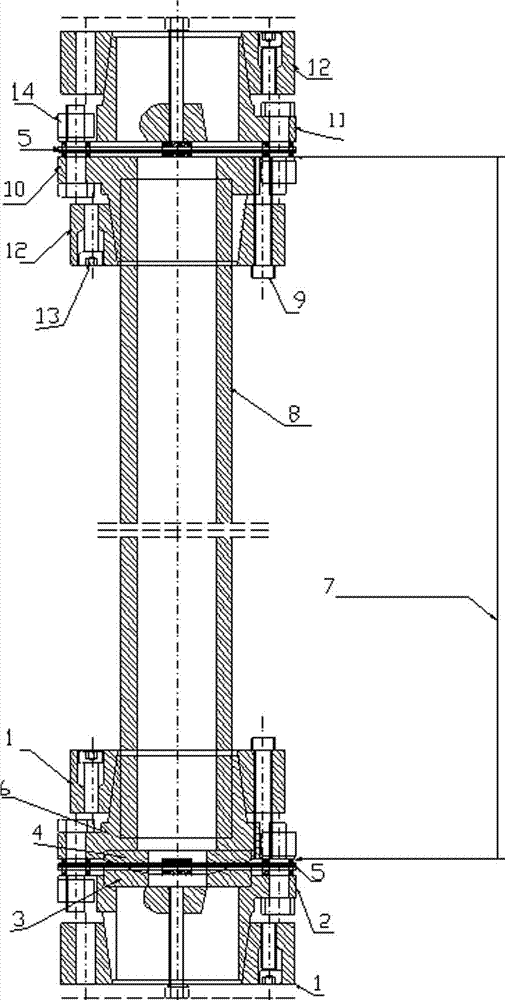

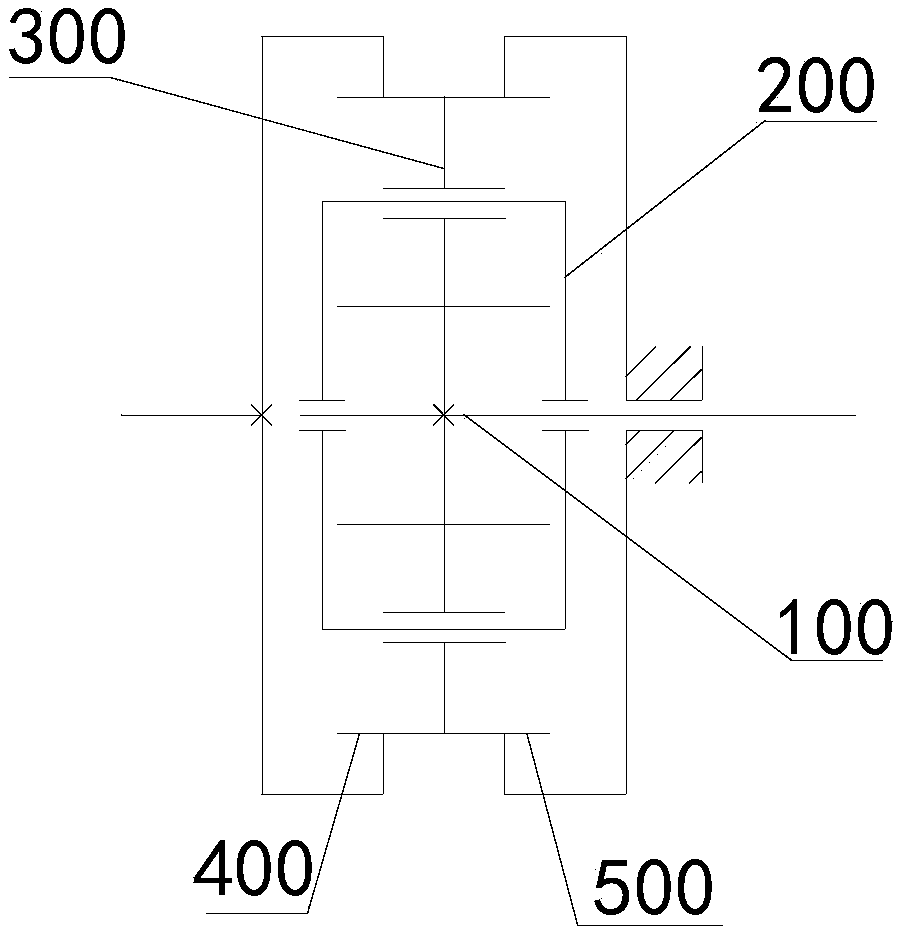

High-lift-to-drag ratio balance applied to low-speed wind tunnel

ActiveCN104713694AImprove testing capabilitiesHigh measurement accuracyAerodynamic testingShaped beamLow speed

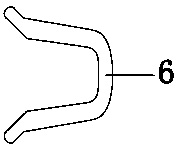

The invention provides a high-lift-to-drag ratio balance applied to a low-speed wind tunnel. The high-lift-to-drag ratio balance comprises a test model connecting cone, combined force measuring elements, a balance base body, resistance measuring elements, support sheets and a support rod connecting cone, wherein two ends of the balance base body are connected with the model connecting base and the support rod connecting cone through the combined force measuring elements; the balance base body is divided into an upper part and a lower part by an inclined groove which penetrates through the design center of the balance and runs through back and forth; the upper part and the lower part of the balance base body are connected into a whole through front, rear, left and right four groups of support sheets which are symmetrical about the design center of the balance; grooves are formed in the front part and the rear part of the balance base body symmetrically about the design center of the balance; the resistance measuring elements are arranged in the two grooves; and the resistance measuring elements are n-shaped beams (described in the specification); two ends of each n-shaped beam are connected with the balance base body through flexible hinges; and every two adjacent n-shaped beams are arranged anti-symmetrically about a longitudinal symmetric shaft in an up-front and down-back manner. The high-lift-to-drag ratio balance is high in high-lift-to-drag ratio balance, strong in antijamming capability and good in torsion resisting stiffness.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

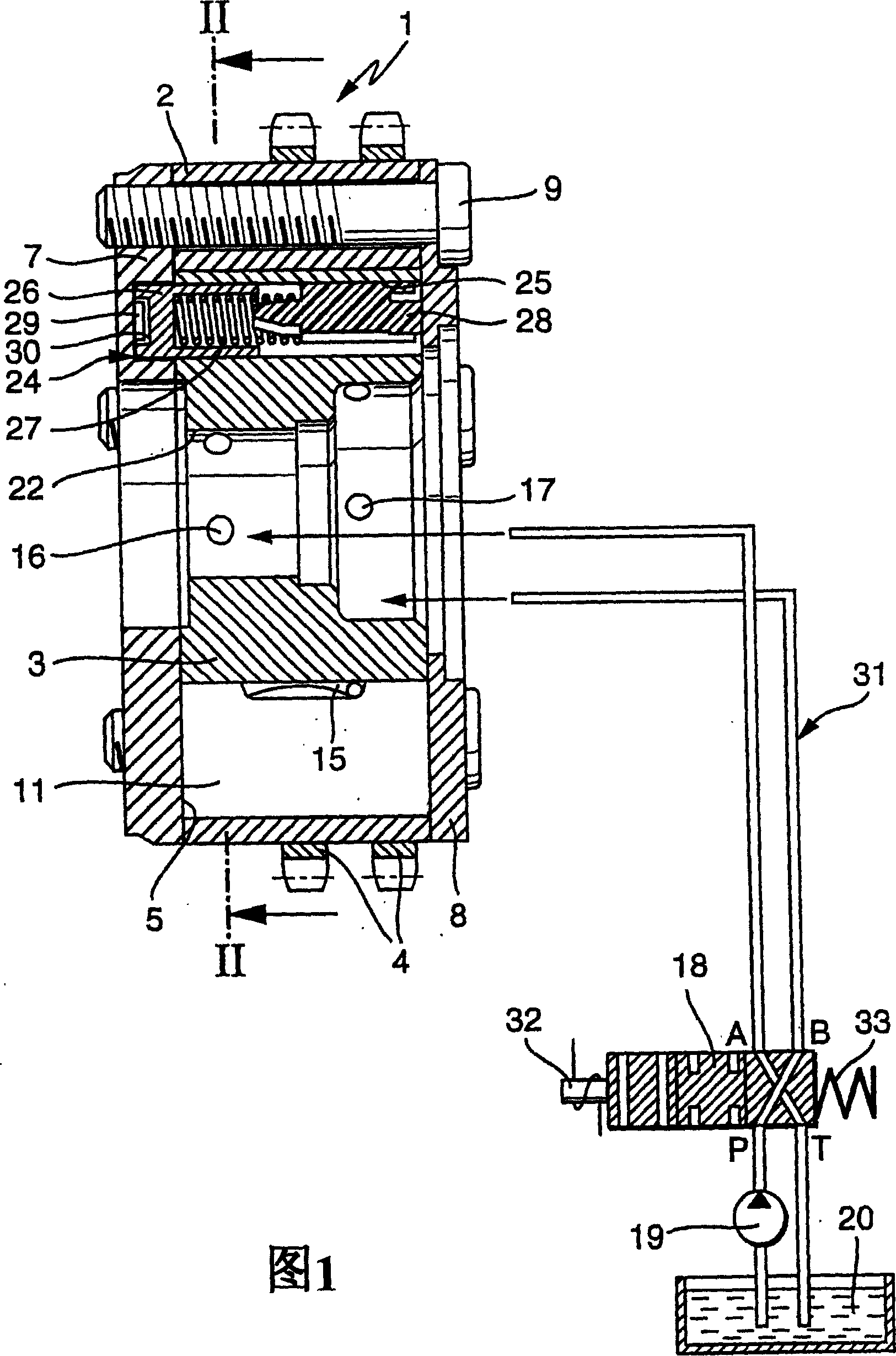

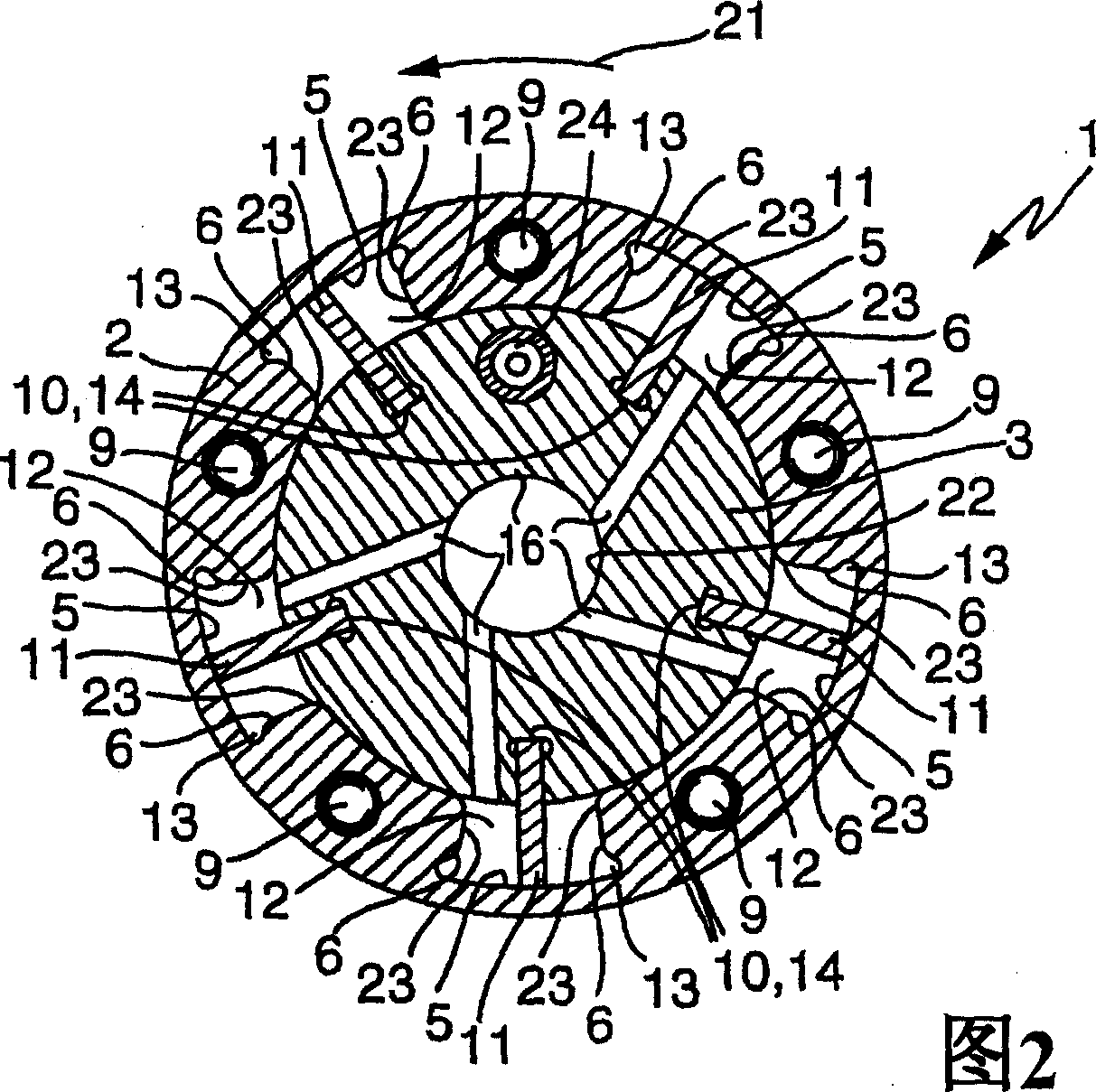

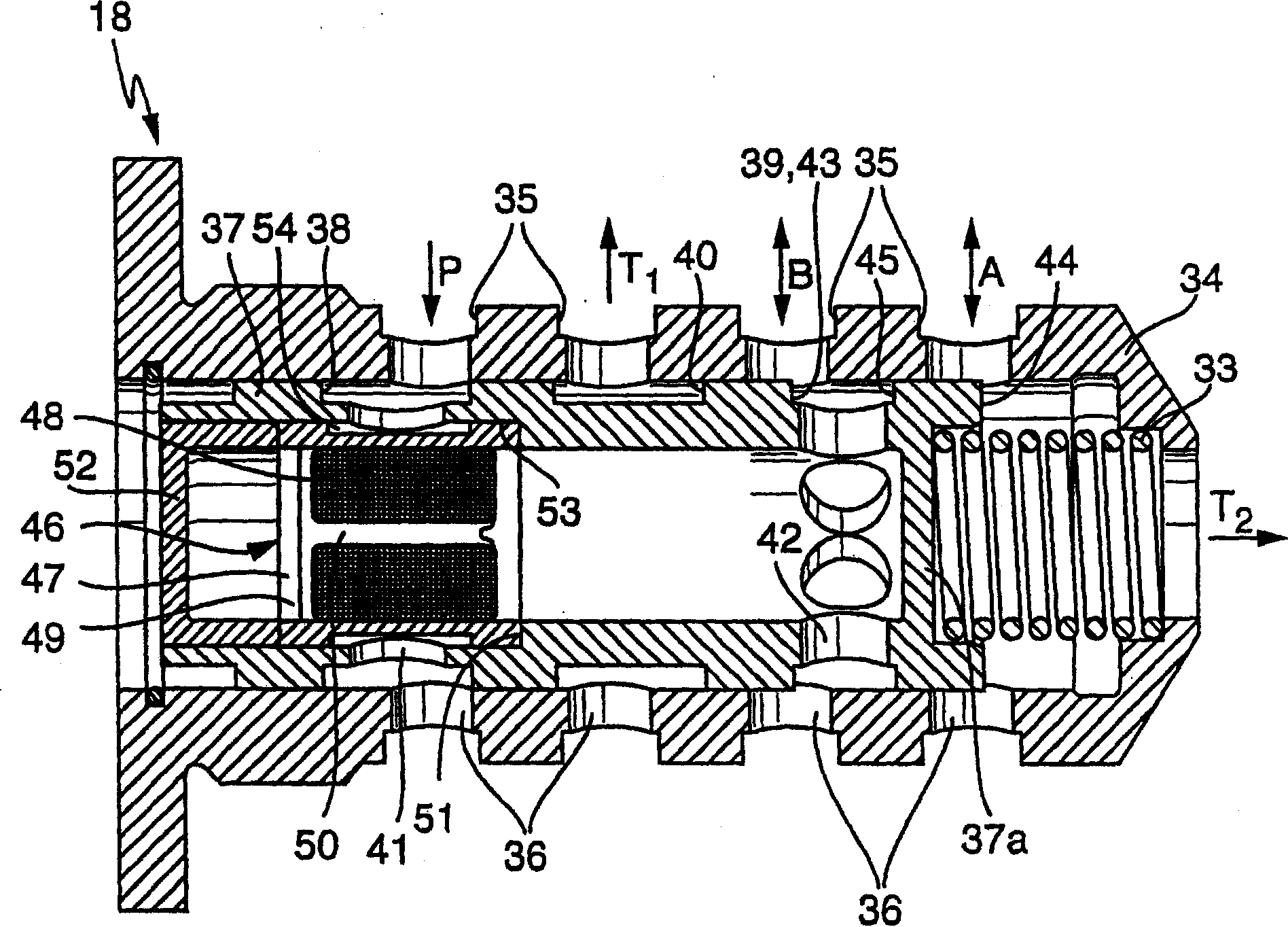

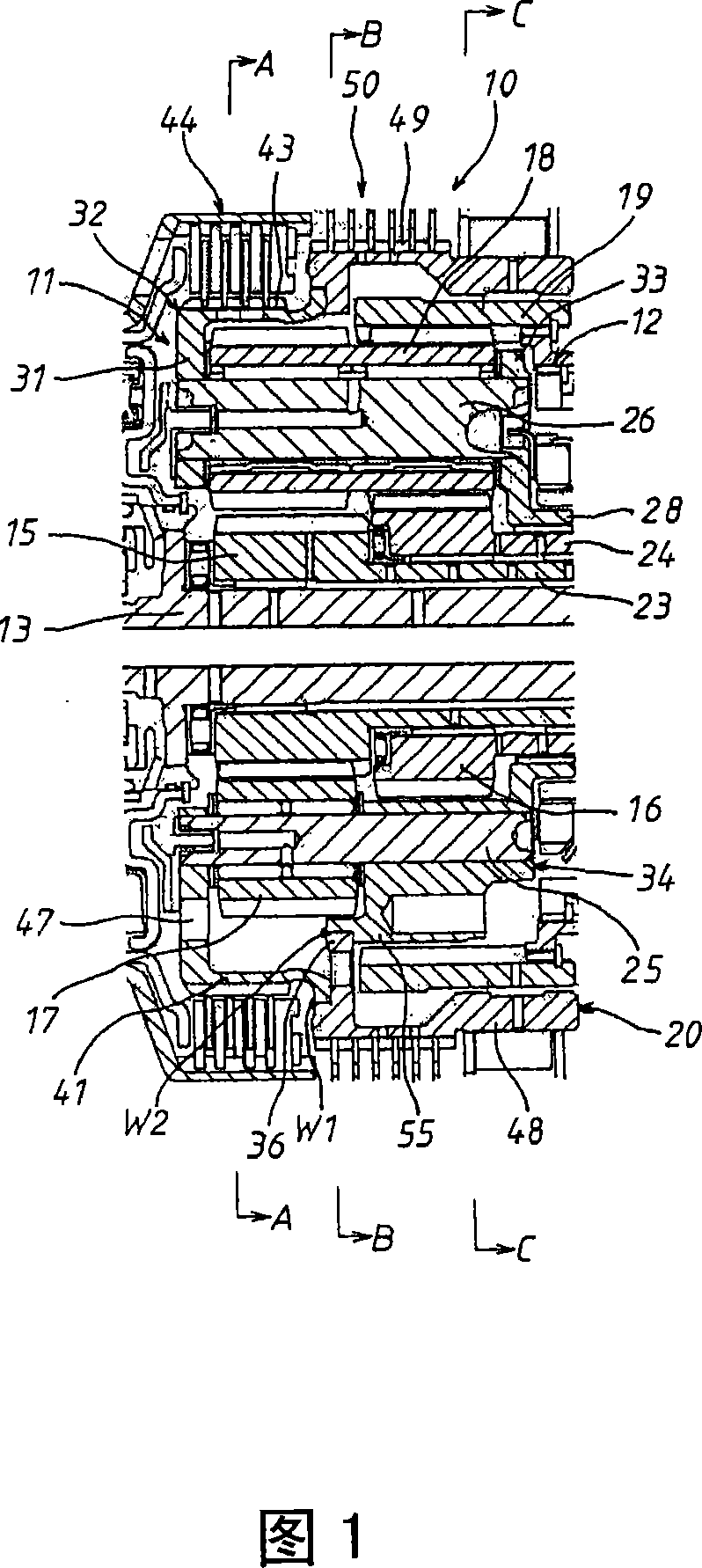

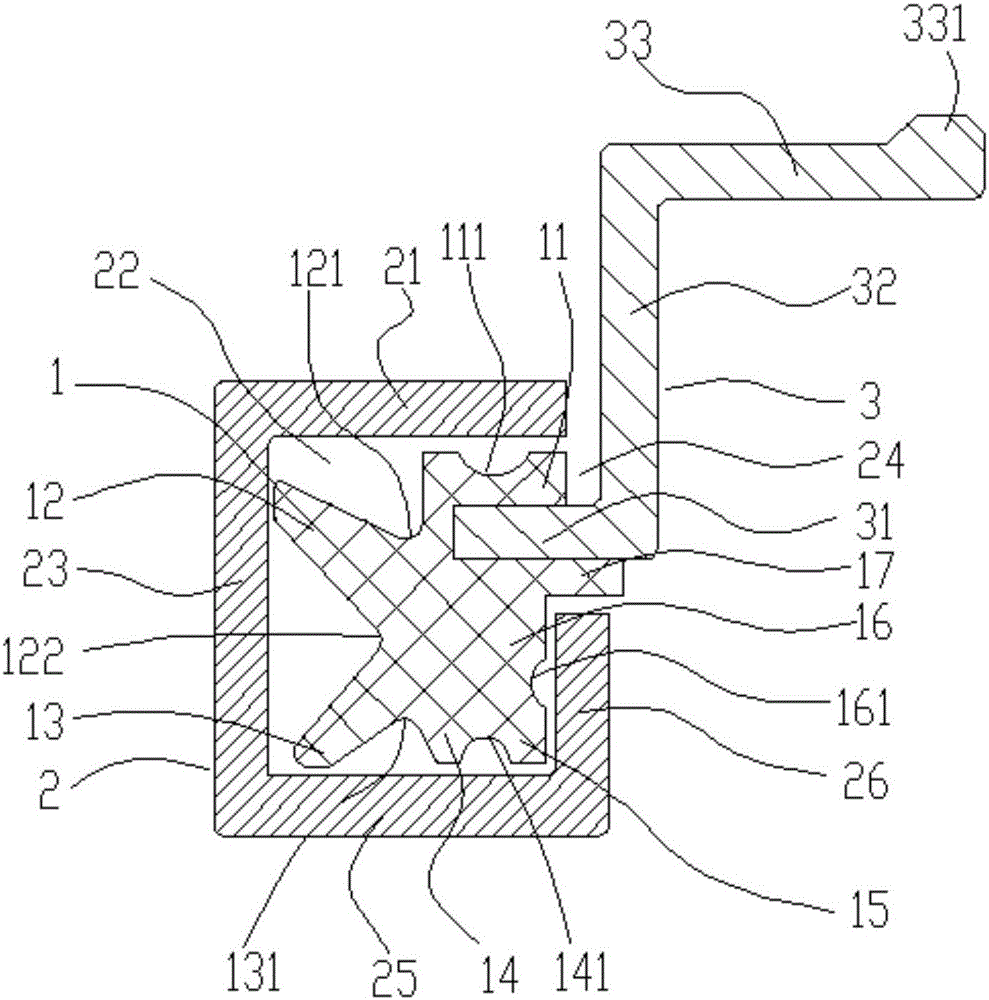

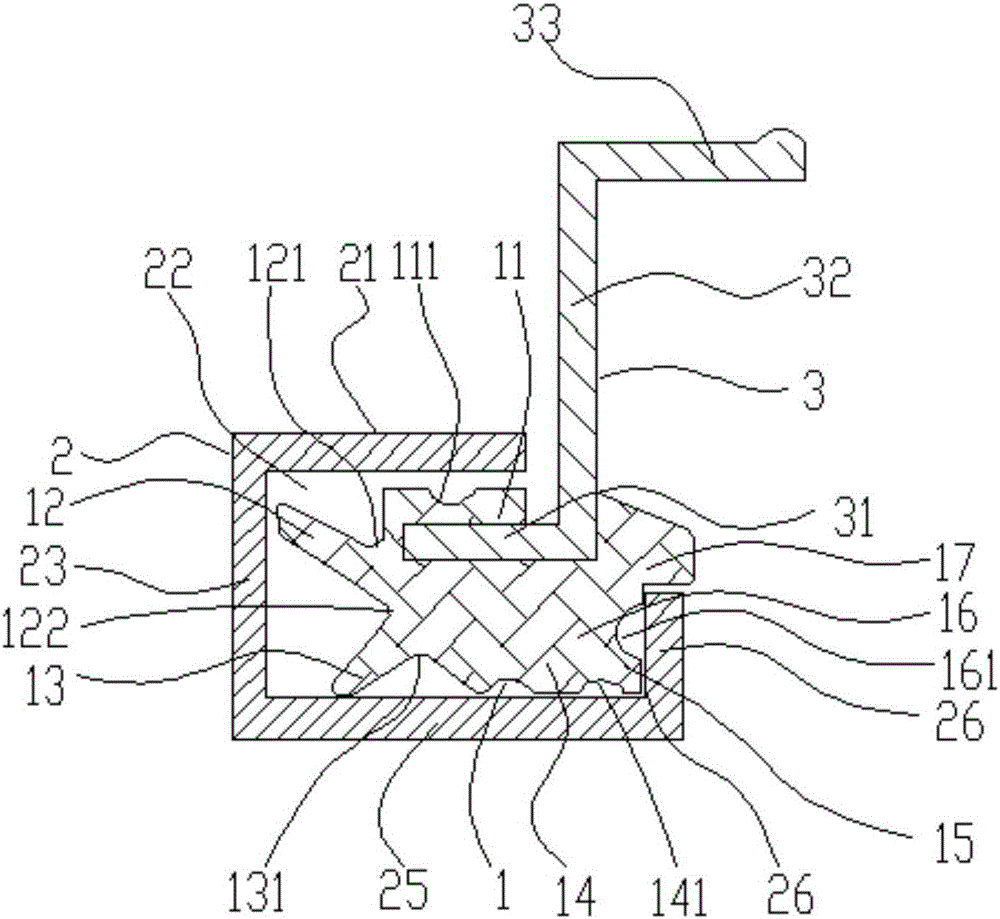

Control valve for a device to modify the timing of an internal combustion engine

InactiveCN1724852APrevent mobilityBlocker openOperating means/releasing devices for valvesServomotor componentsExternal combustion engineFuel tank

The invention relates to a control valve (18) of a device (1) for varying the control time of an internal combustion engine. In this case, a targeted rotation of the camshaft relative to the crankshaft can be achieved by means of a hydraulic actuator. A control valve (18) with a working connection (A, B), a pressure oil connection (P) and at least one tank connection (T, T1, T2) controls the pressure oil supply or pressure oil discharge of the hydraulic actuator. The invention proposes to arrange a filter (46) between the pressure oil connection (P) and the working connections (A, B).

Owner:SCHAEFFLER TECH AG & CO KG

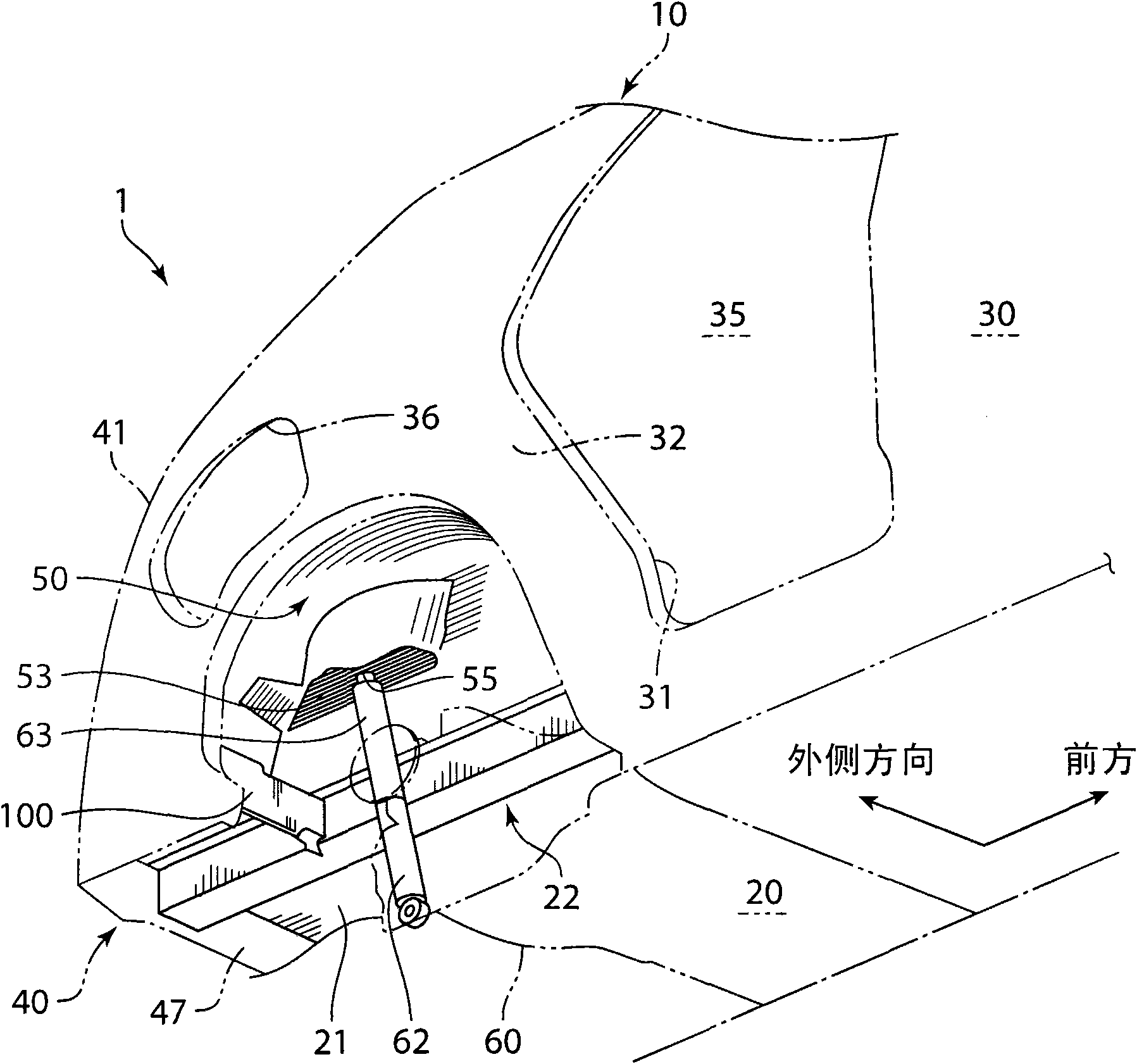

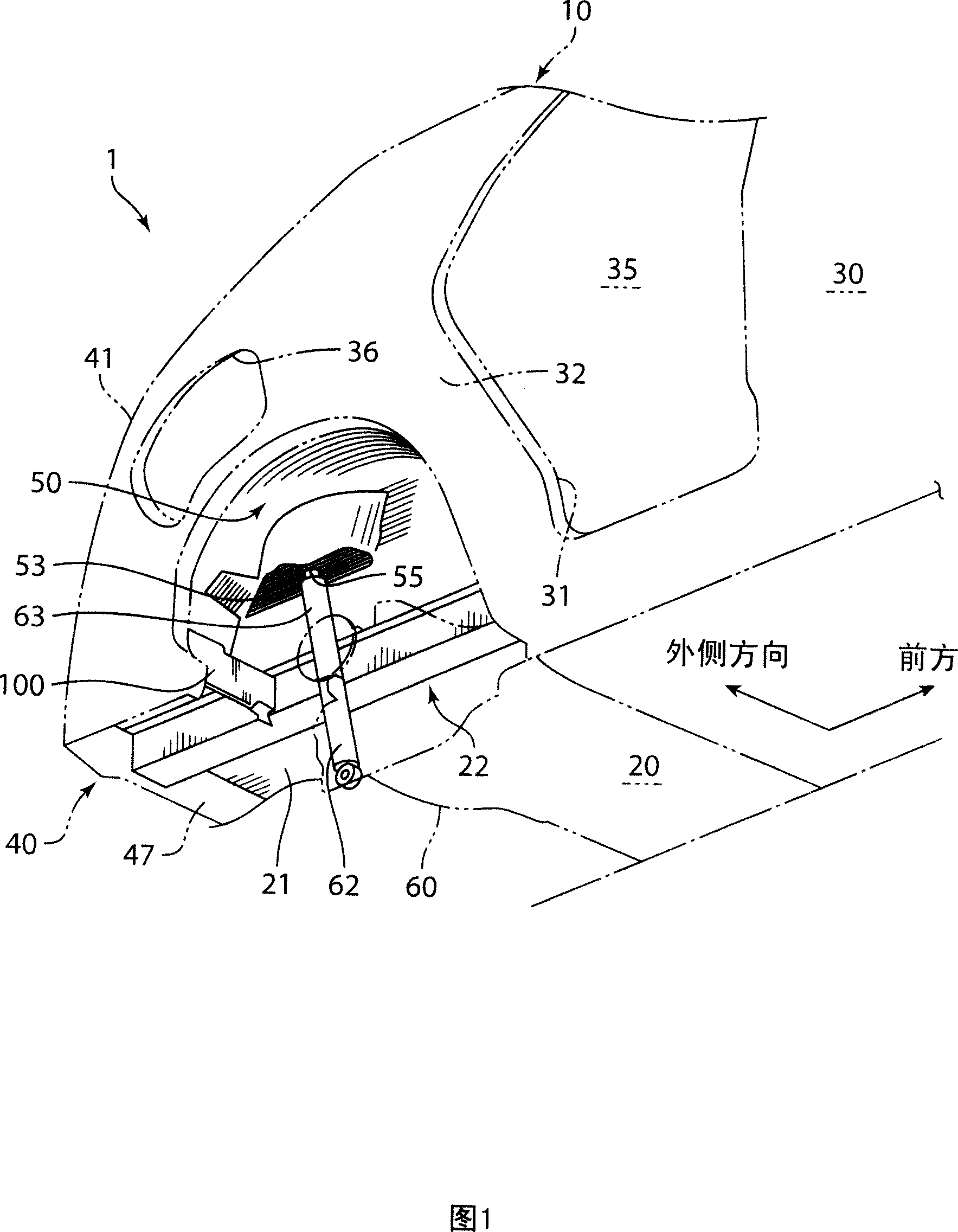

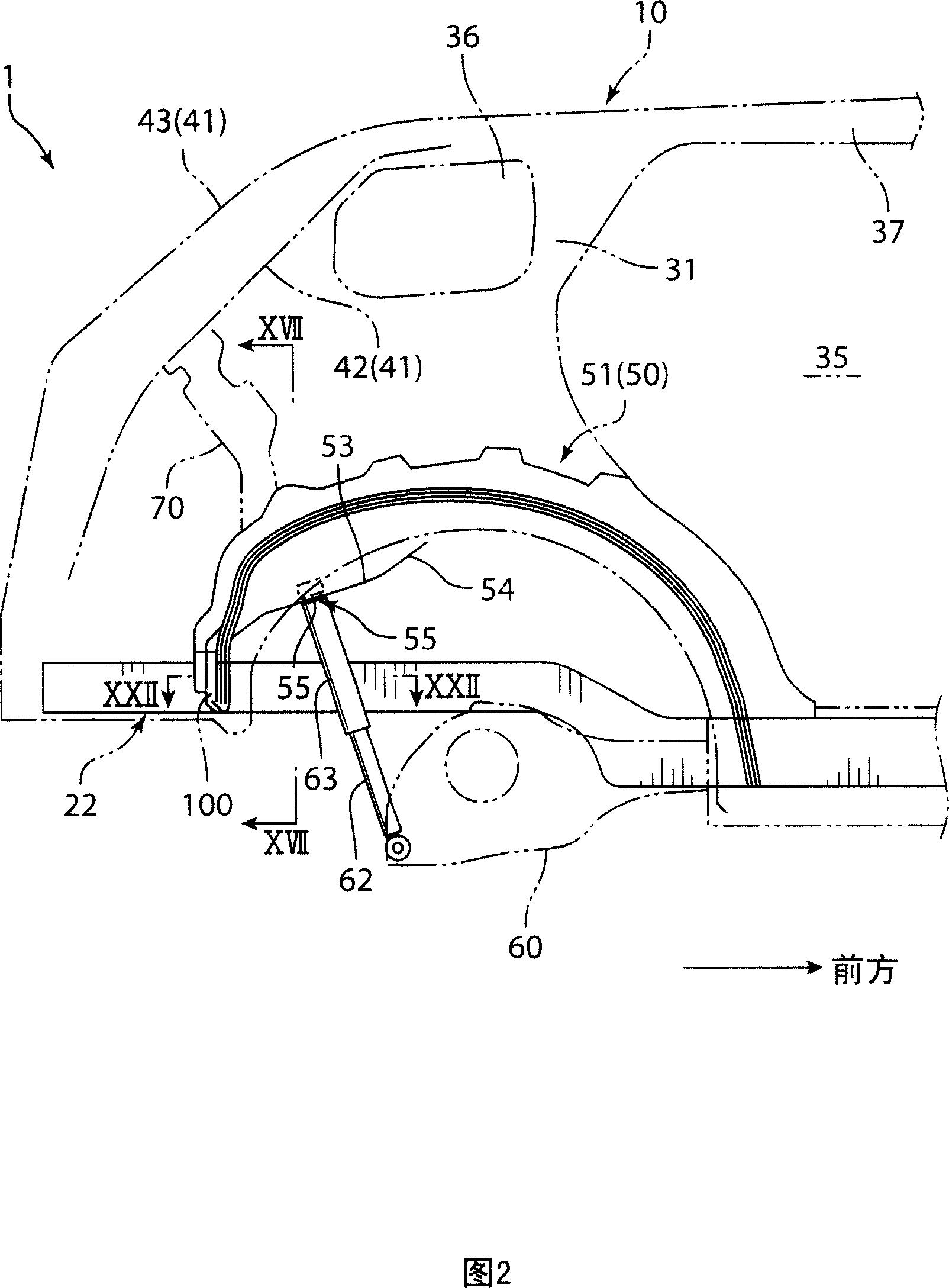

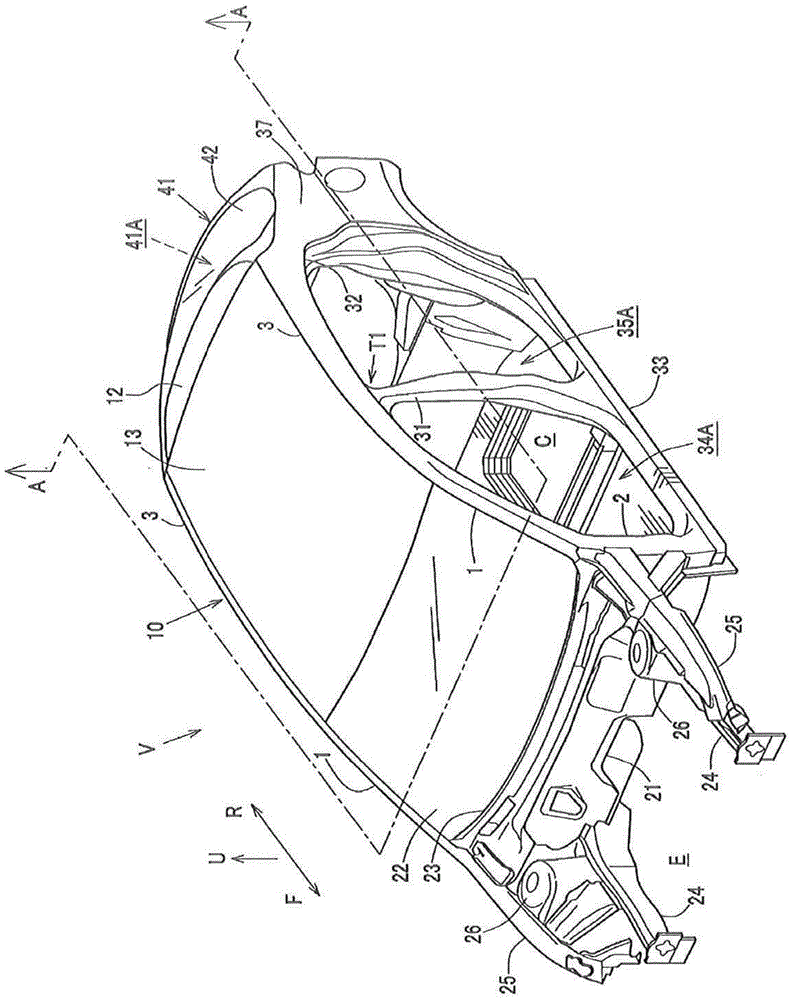

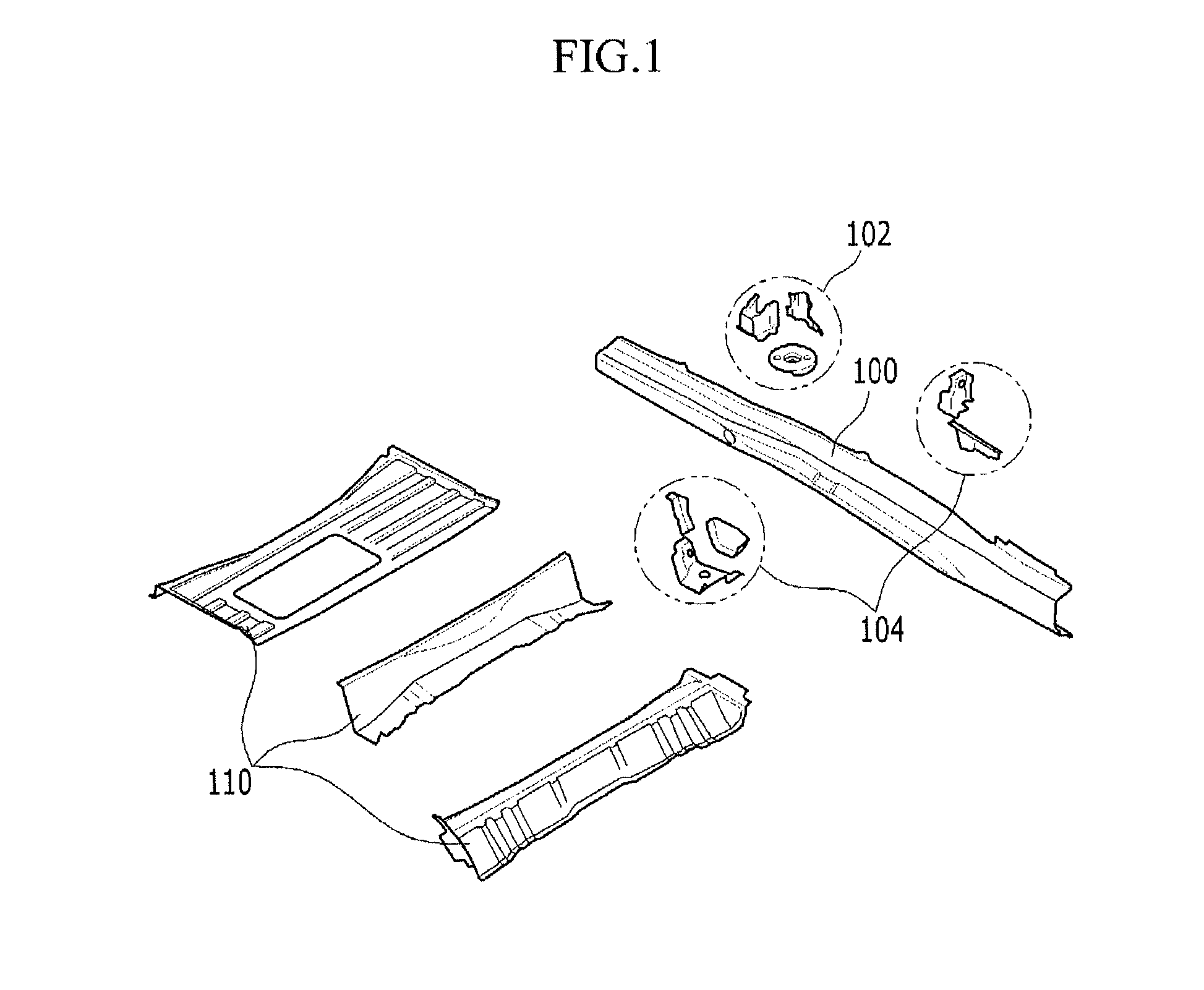

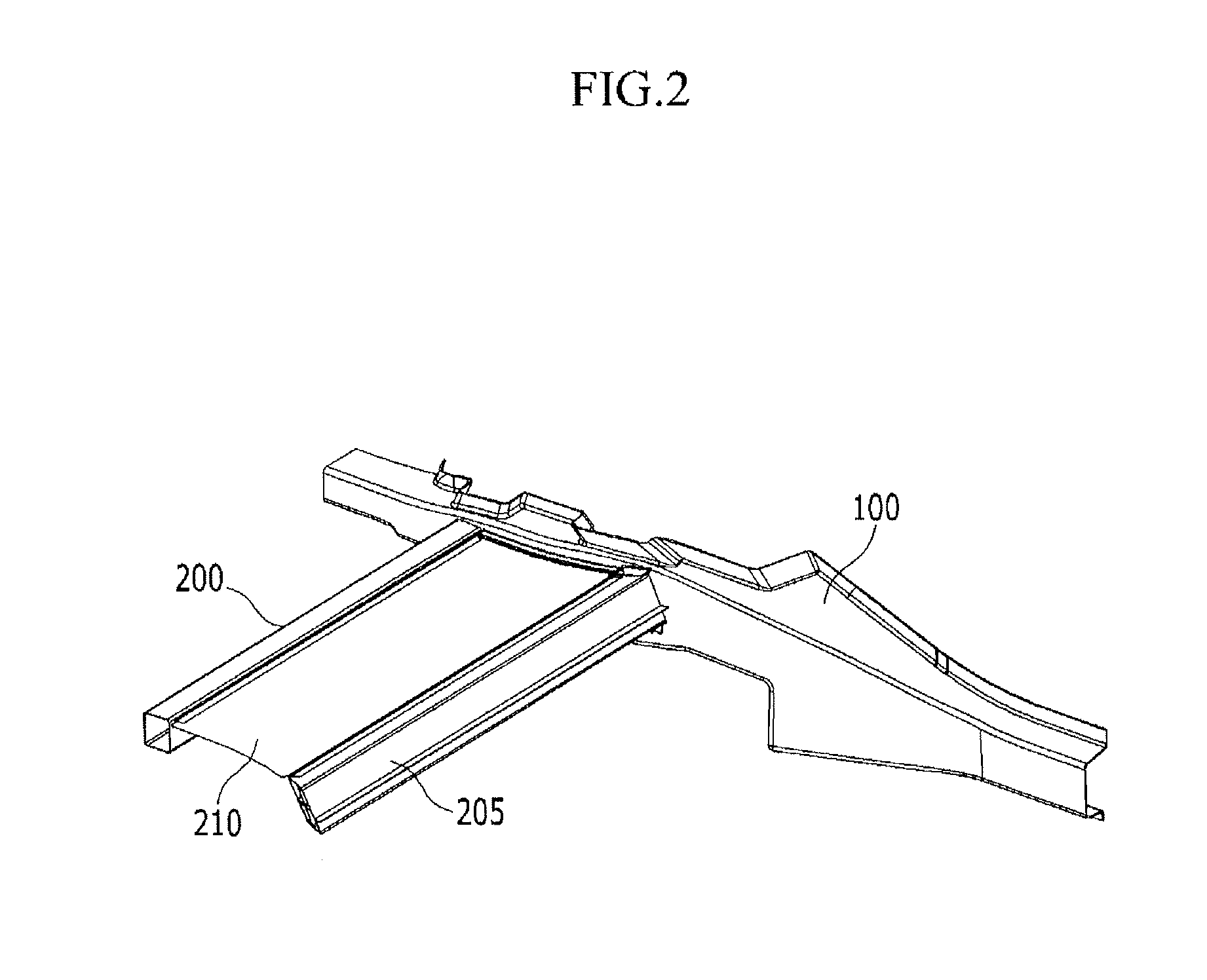

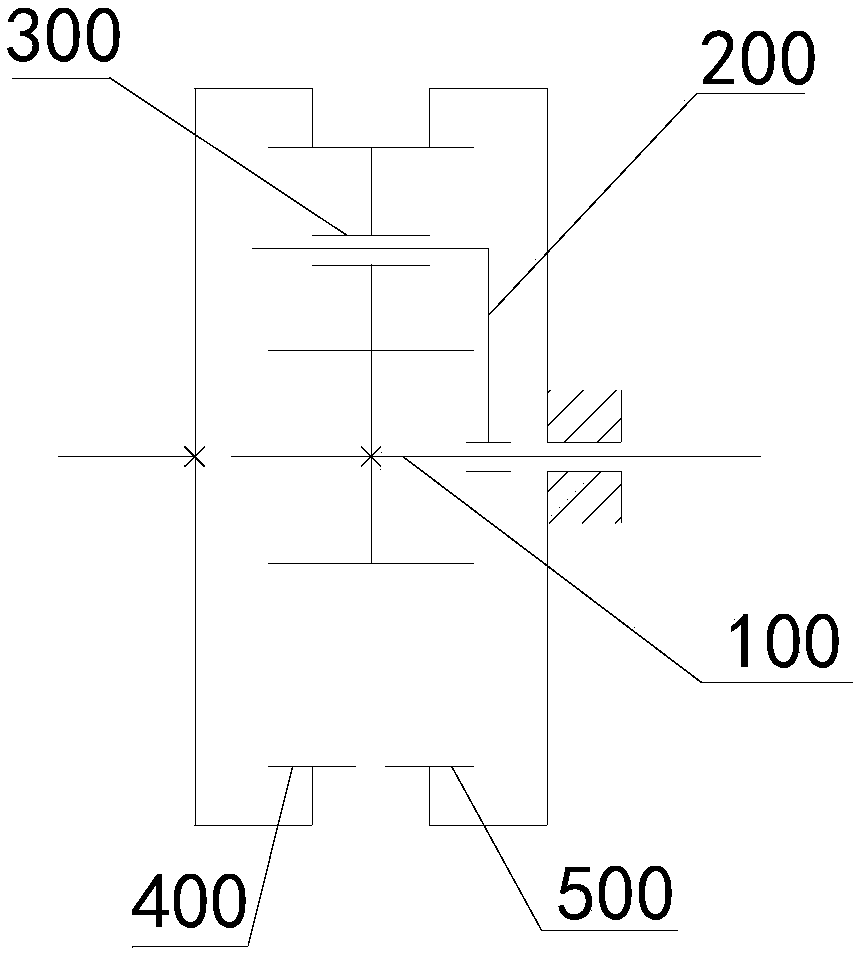

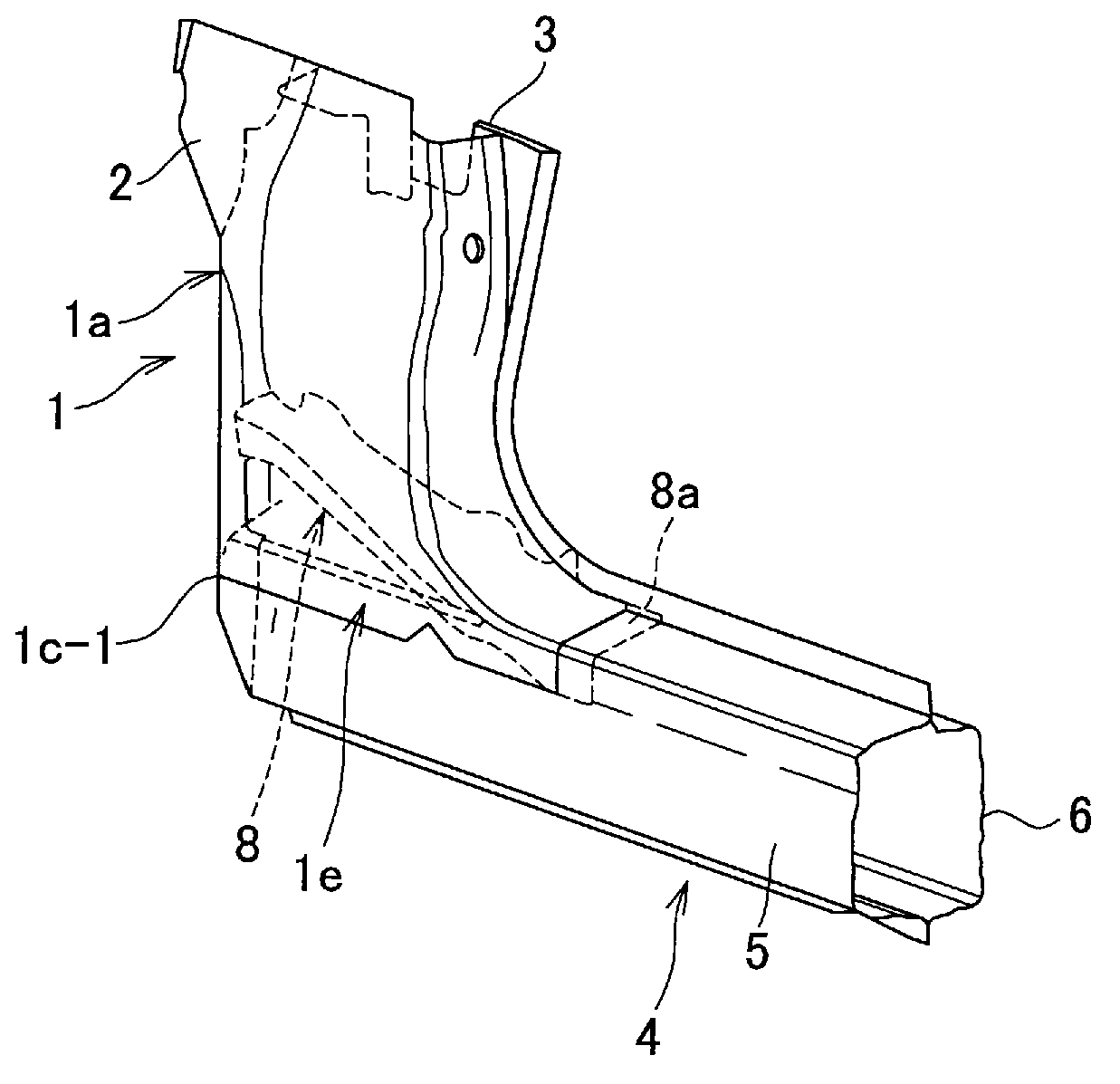

Vehicle body structure

ActiveCN101823506AIncreased torsional rigiditySuperstructure subunitsEngineeringMechanical engineering

Disclosed is a vehicle body structure, which comprises a body sidewall (30) which forms a side portion of a vehicle body, a wheel house (50) formed on a lower side of the body sidewall and provided with a mounting portion (53) on which a rear suspension system mounts, a side pillar (33) which is above the wheel house (50), a rear pillar (41) which is provided behind the vehicle or behind the vehicle body of the side pillar (33); and a connection gusset (70) which connects the rear pillar (41) with the peripheral part of an installation part (53) of the wheel house (50); wherein, the installation part (53) is formed behind the wheel house (50), and the extension direction of the connection gusset (70) is approximately same with a main load transfer direction of the rear suspension system.

Owner:MAZDA MOTOR CORP

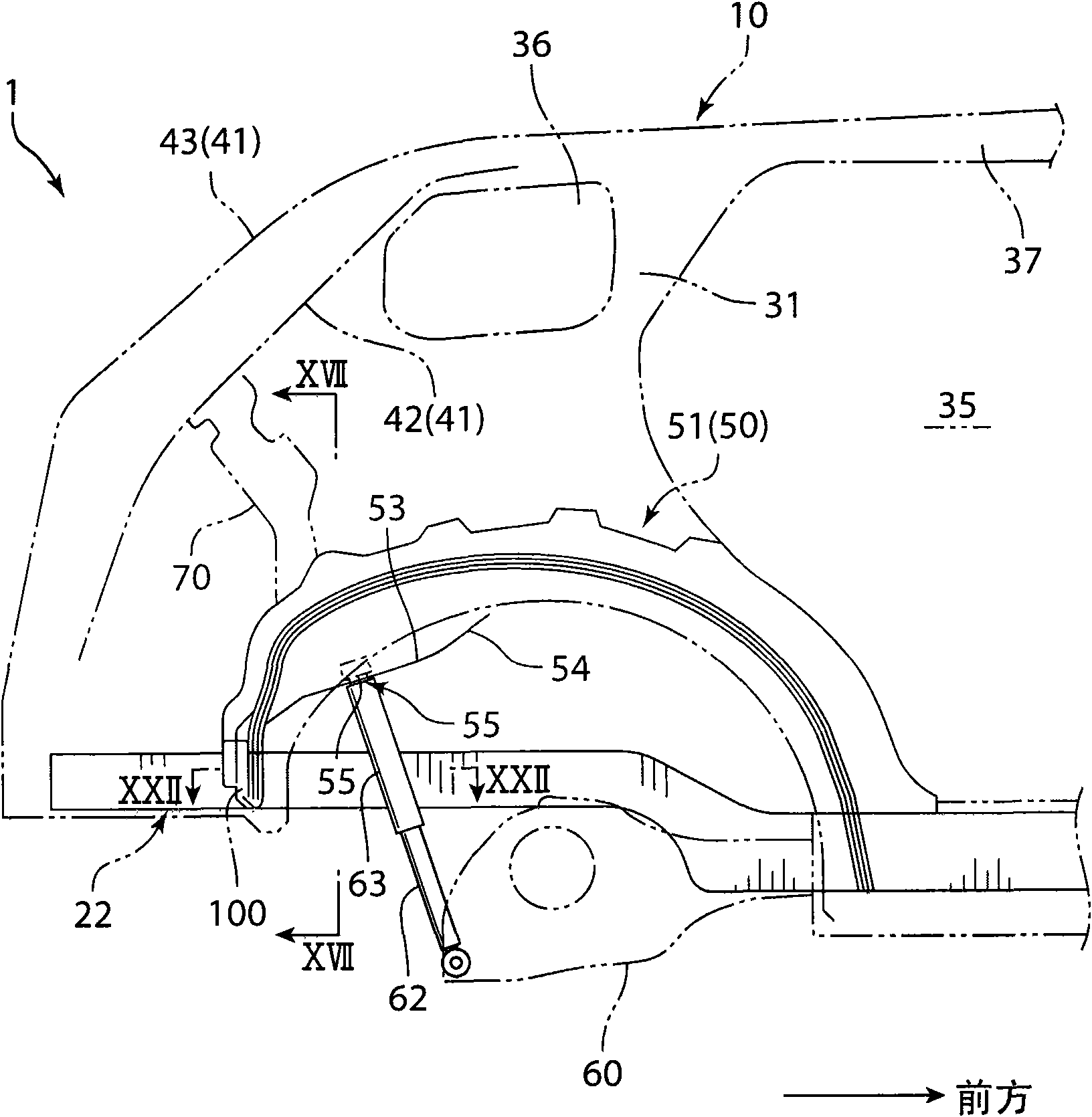

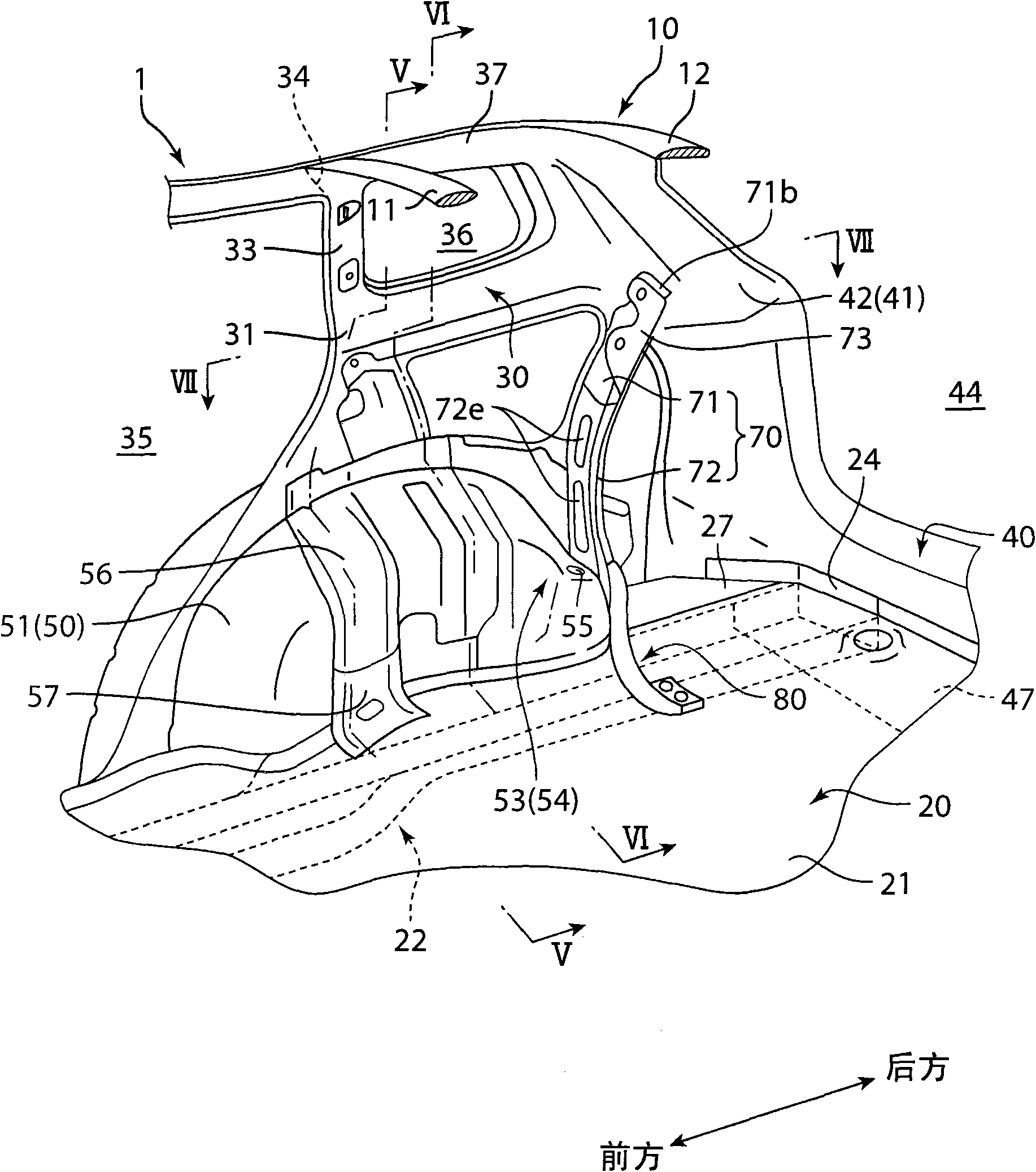

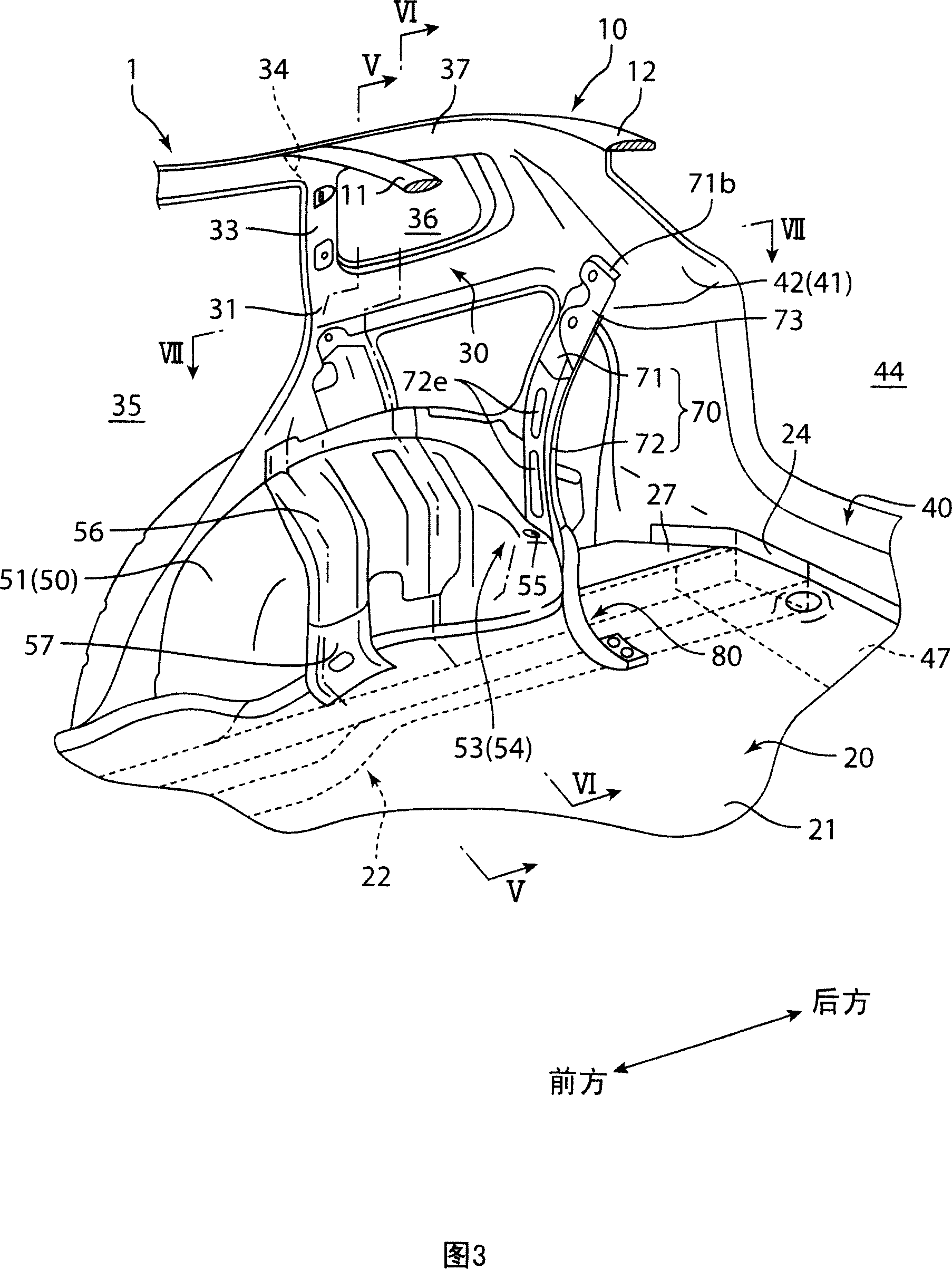

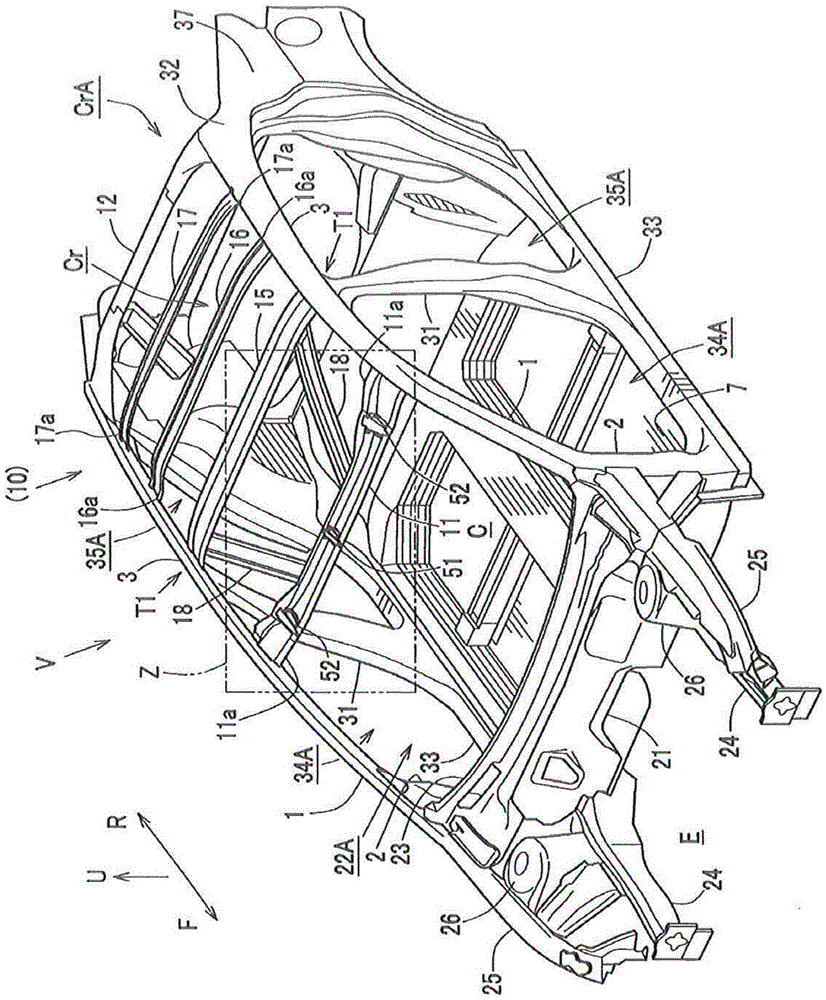

Vehicle body structure of vehicle

ActiveCN1982139AIncreased torsional rigidityPrevent collapseSuperstructure subunitsAutomotive engineeringTorsional rigidity

A vehicle body structure of the invention, comprises: a body side wall part (30) configured a vehicle body side part; a wheel cover (50) provided down the body side wall part (30) has an assembly part for mounting a rear suspension; a side column enhancing component (34), for enhancing the side column, arraged on the side column over the wheel cover, extending along the vehicle body up and down; a posterior column enhancing component (45) for enhancing the posterior column, arraged on the posterior column behind the vehicle body of the wheel cover, extending along the vehicle body up and down; a first connecting component (56) for connecting the side column enhancing component and the lower end of the wheel cover; a second connecting component (70, 80) for connecting the posterior column enhancing component and neighborhood parts of the assembly part of the wheel cover; and a third connecting component (39) for connecting the side column enhancing component and the posterior column enhancing component. According to the invention, torsional rigidity of the body side wall part behind the vehicle body can be improved.

Owner:MAZDA MOTOR CORP

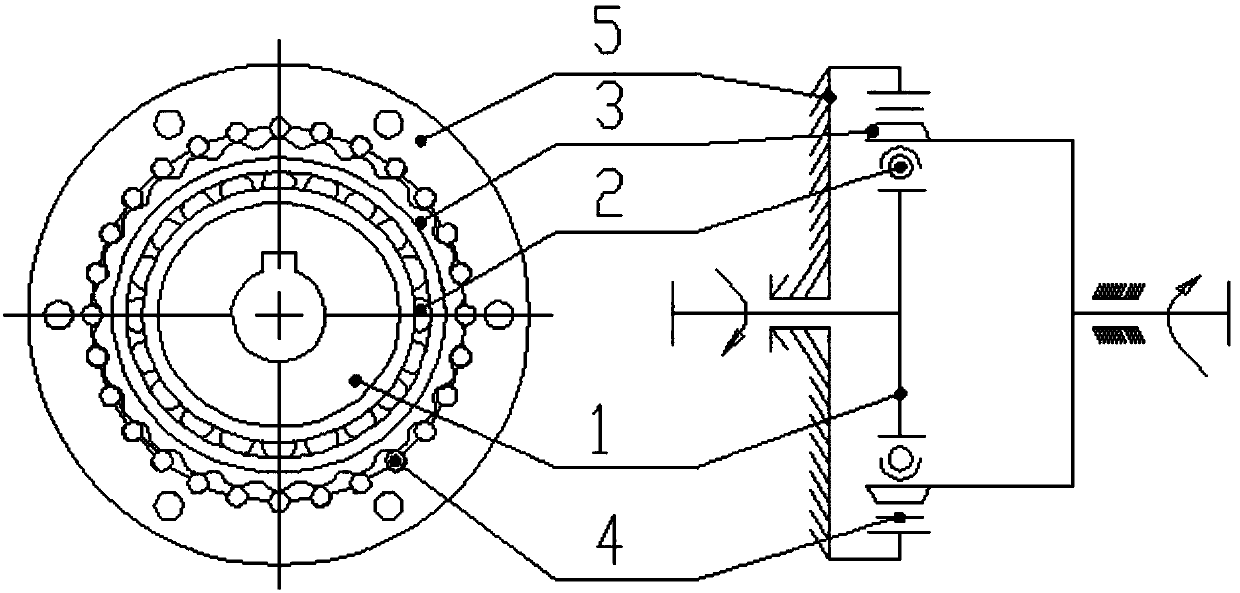

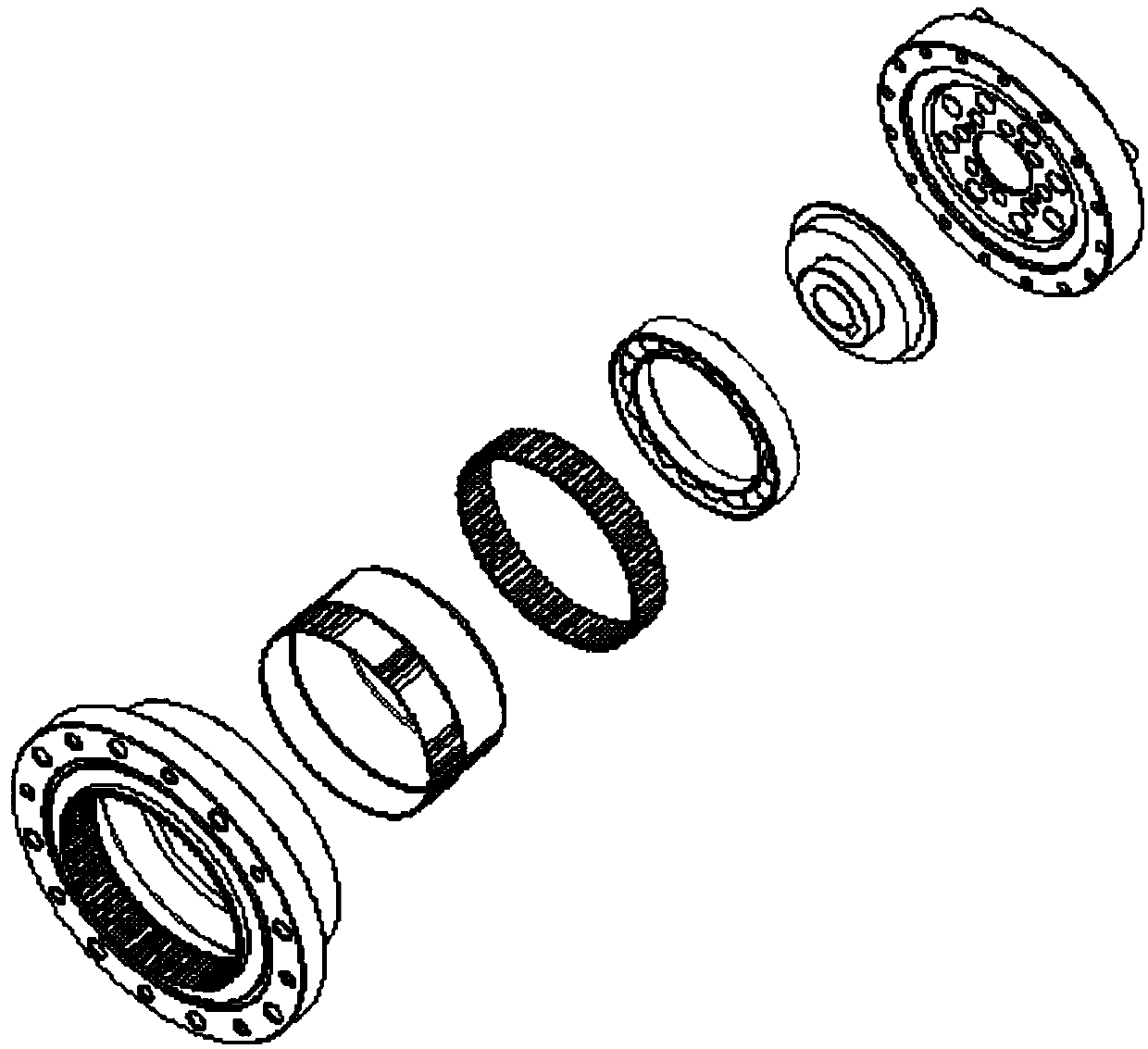

Harmonic transmission device for cycloidal-pin wheel

The invention discloses a harmonic transmission device for a cycloidal-pin wheel. The device comprises a cam shaft, a flexible bearing, a flexible gear, roller pins and a rigid wheel, the flexible bearing is arranged on the elliptic cam shaft, and the inner circle of the flexible gear is matched with the outer circle of the flexible bearing; the outer tooth surface of the flexible gear is in contact with each roller pin, the roller pins are evenly distributed in a semicircle groove of the rigid wheel, the inner circle of a main bearing is fixedly connected with the flexible gear, and the outercircle of the main bearing is fixedly connected with the rigid wheel. According to the harmonic transmission device for the cycloidal-pin wheel, the high tooth root of a harmonic transmission gear ofthe cycloidal-pin wheel is in a cycloidal tooth profile, the risk of fracture and failure is reduced, the large meshing amount can be obtained without the need of extremely deep meshing distance, thetooth width is large, and all teeth are involved in meshing; the specific pressure of the tooth surface is small, the gear can bear extremely large torque, deformation of the flexible gear is also small, the service life of the flexible gear can be greatly prolonged, and the intensity of the flexible gear can be improved.

Owner:SHENZHEN LLMACHINECO LTD

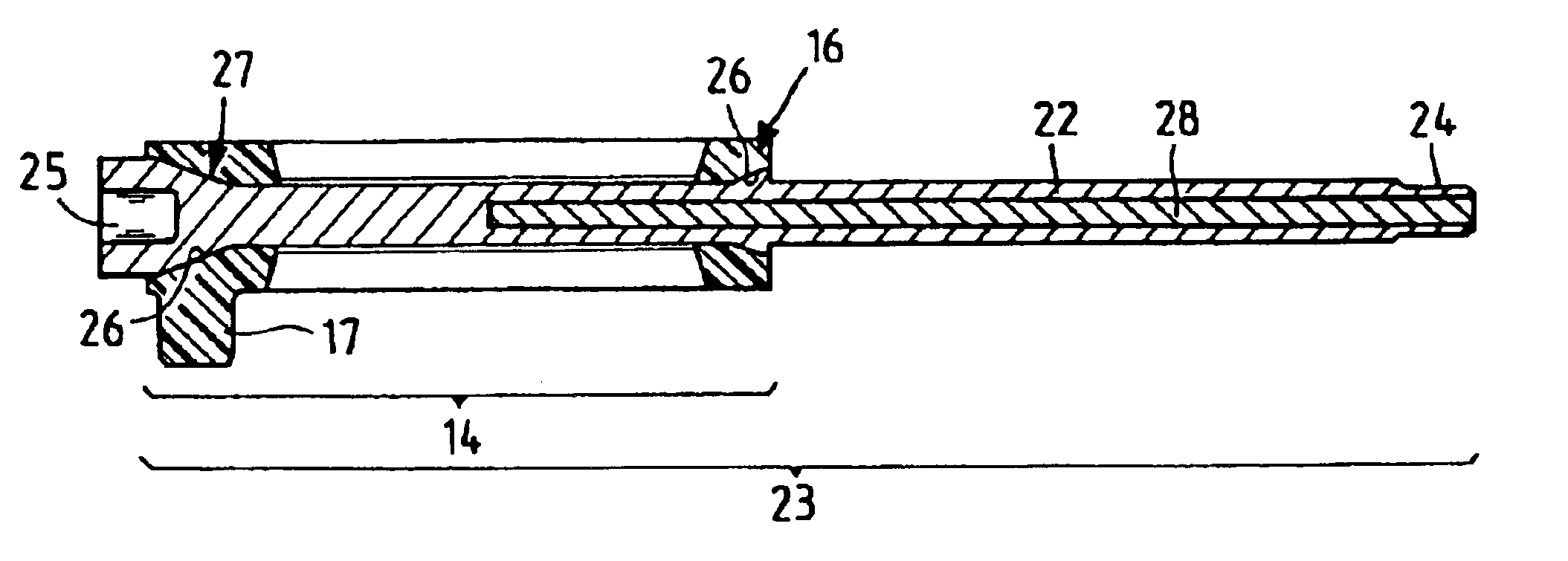

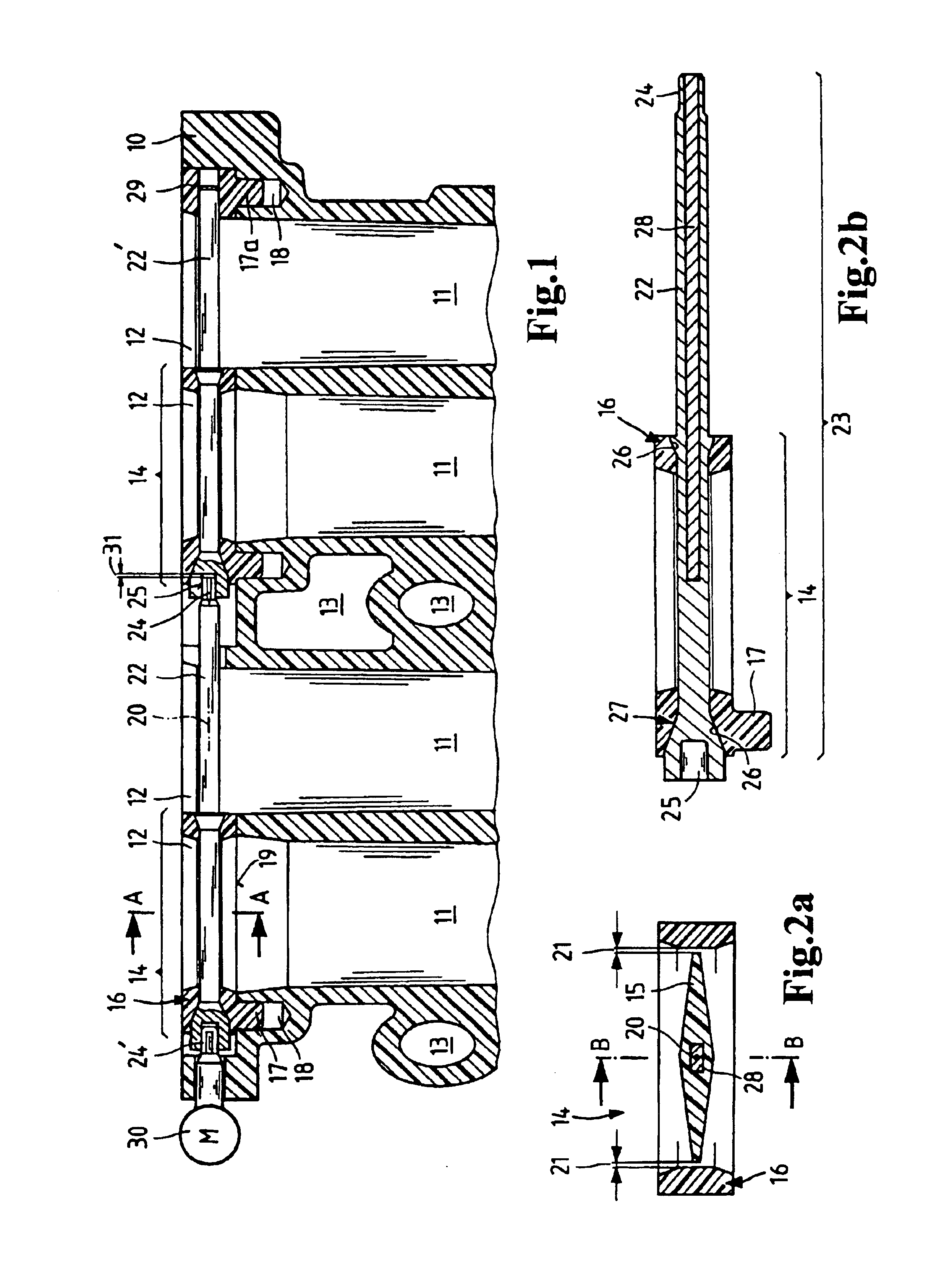

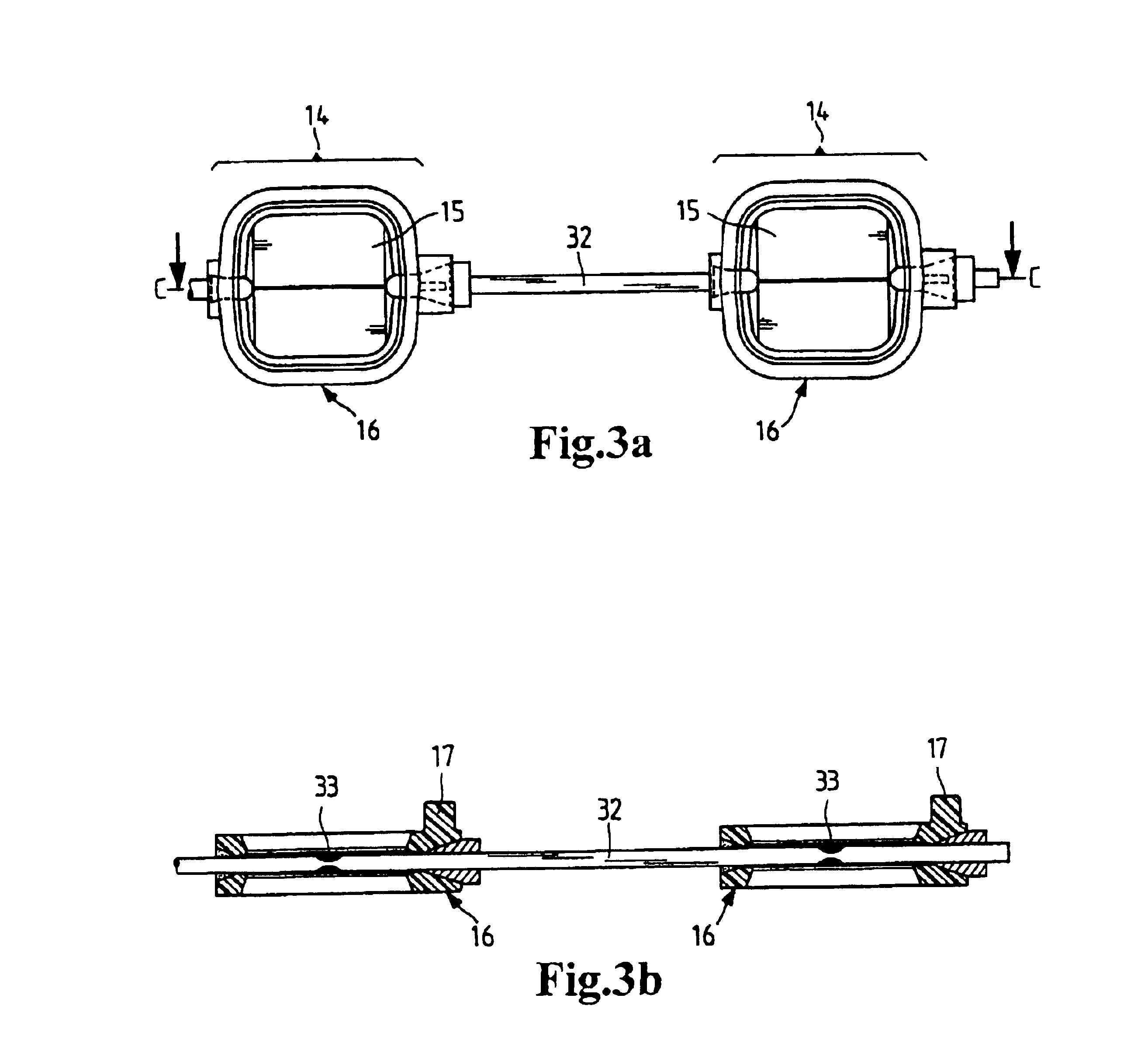

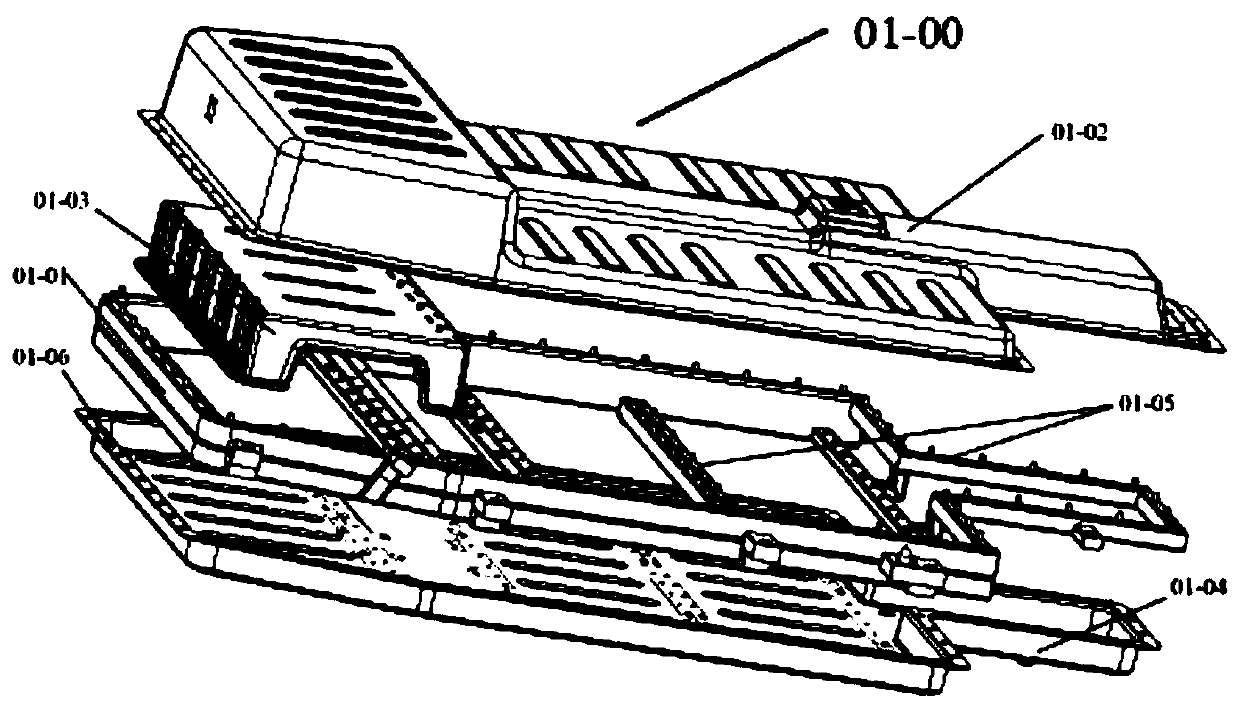

Control valve assembly of valve assembly-injection-molded control valves or modules

InactiveUS6837261B2Good torsional rigidityIncreased torsional rigidityRotary bearingsOperating means/releasing devices for valvesInjection molding processEngineering

A control valve assembly comprising at least two control valves which may be used, for example, to throttle the air intake of an internal combustion engine. The assembly is provided with a centrally arranged, force-transmitting shaft (32). The control valves are formed by blades (15) in frames (16) produced by an assembly injection molding process. The control valve blades (15) can be molded onto the force-transmitting shaft (32). The resulting assembly can be mounted or installed as a unit. Alternatively, instead of using a single continuous shaft, shaft projections can be injection molded on the valve blades, which terminate in lugs which engage in a rotationally secure manner in sockets in an adjacent valve assembly so that the two assemblies rotate together as a unit. The resulting control valve assembly is easy to install and advantageously takes up only a little space.

Owner:MANN HUMMEL GMBH

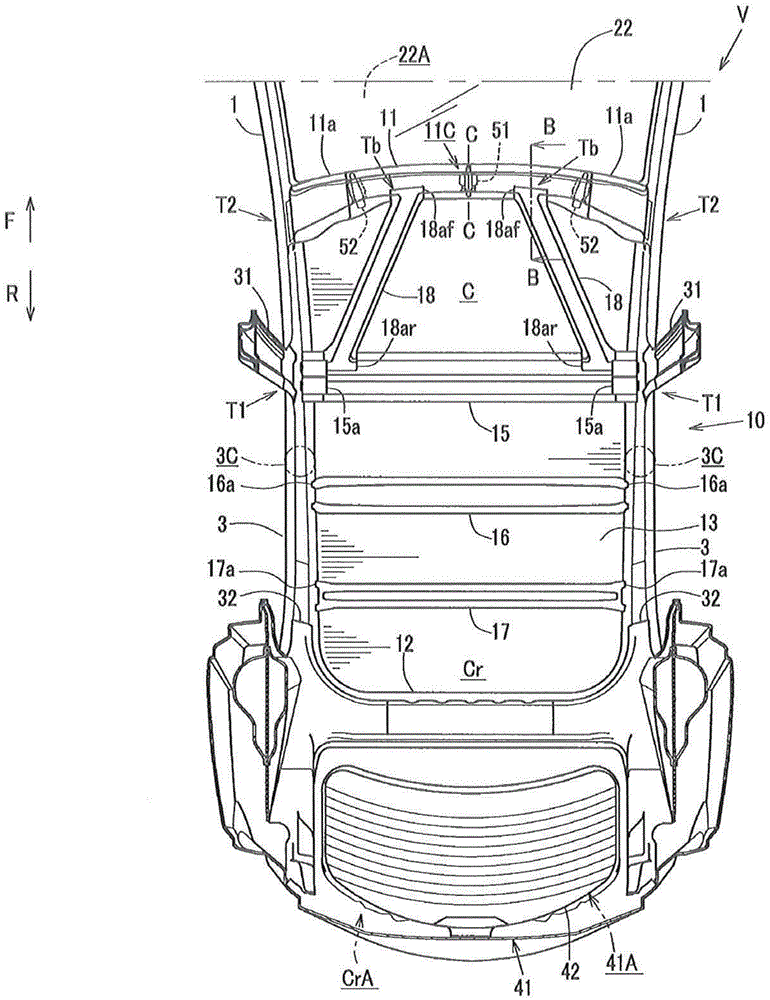

Upper vehicle-body structure of vehicle

InactiveCN105882760AAvoid deformationIncreased torsional rigiditySuperstructure subunitsMechanical engineeringTorsional rigidity

There are provided a pair of roof rails, a roof panel, a front header, a pair of front pillars, and a pair of center pillars, and a pair of front inclination roof reinforcements provided at a lower face of the roof panel. Each of the front inclination roof reinforcements is configured to extend obliquely from its front portion which is joined to the front header to its rear portion which is positioned on an outward side, in a vehicle width direction, relative to the front portion and joined to a portion located in the vicinity of a joint portion of the center pillar and the roof rail. Thereby, the torsional rigidity of a vehicle body can be properly improved, so that the maneuverability / stability of a vehicle can be improved.

Owner:MAZDA MOTOR CORP

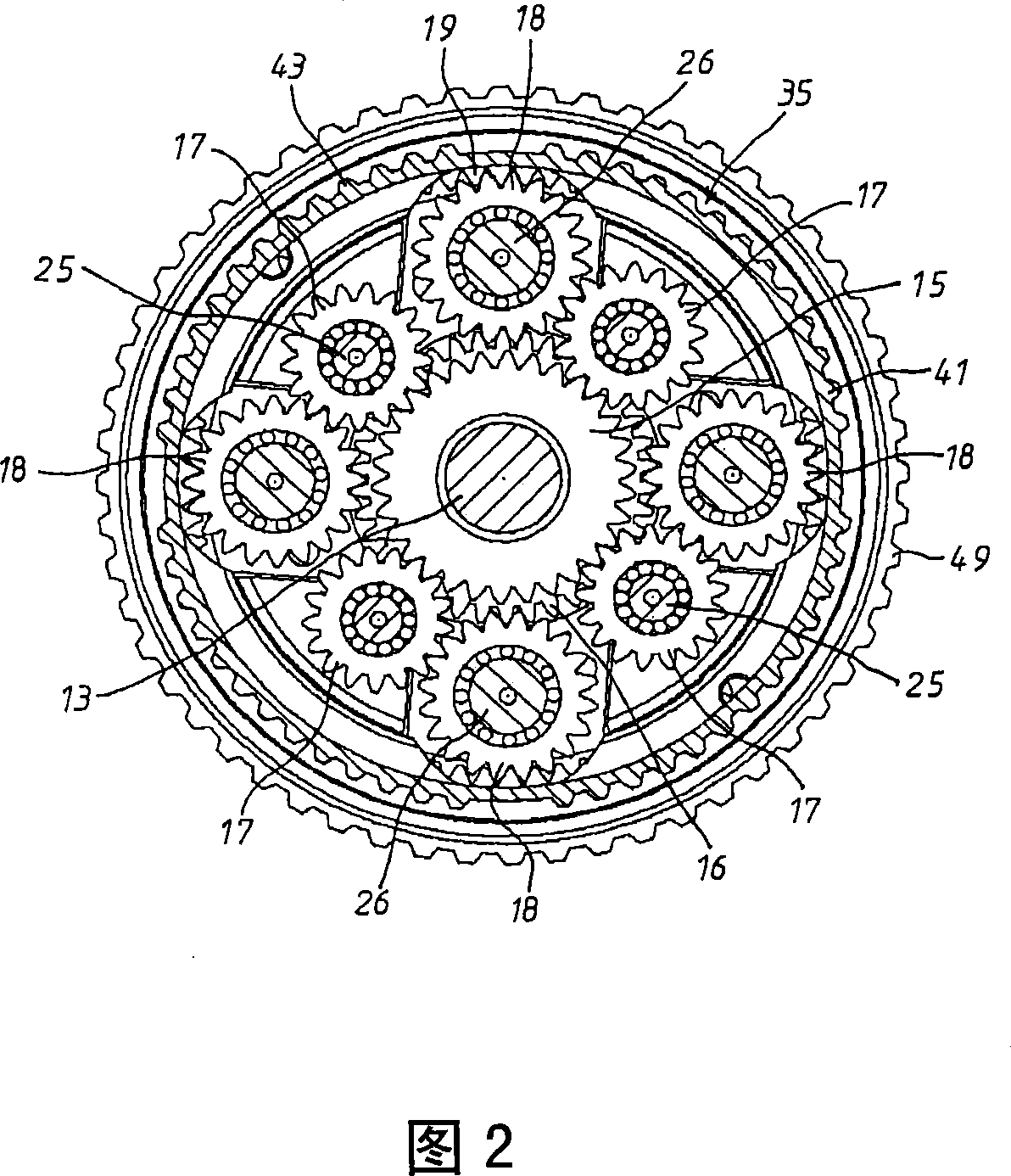

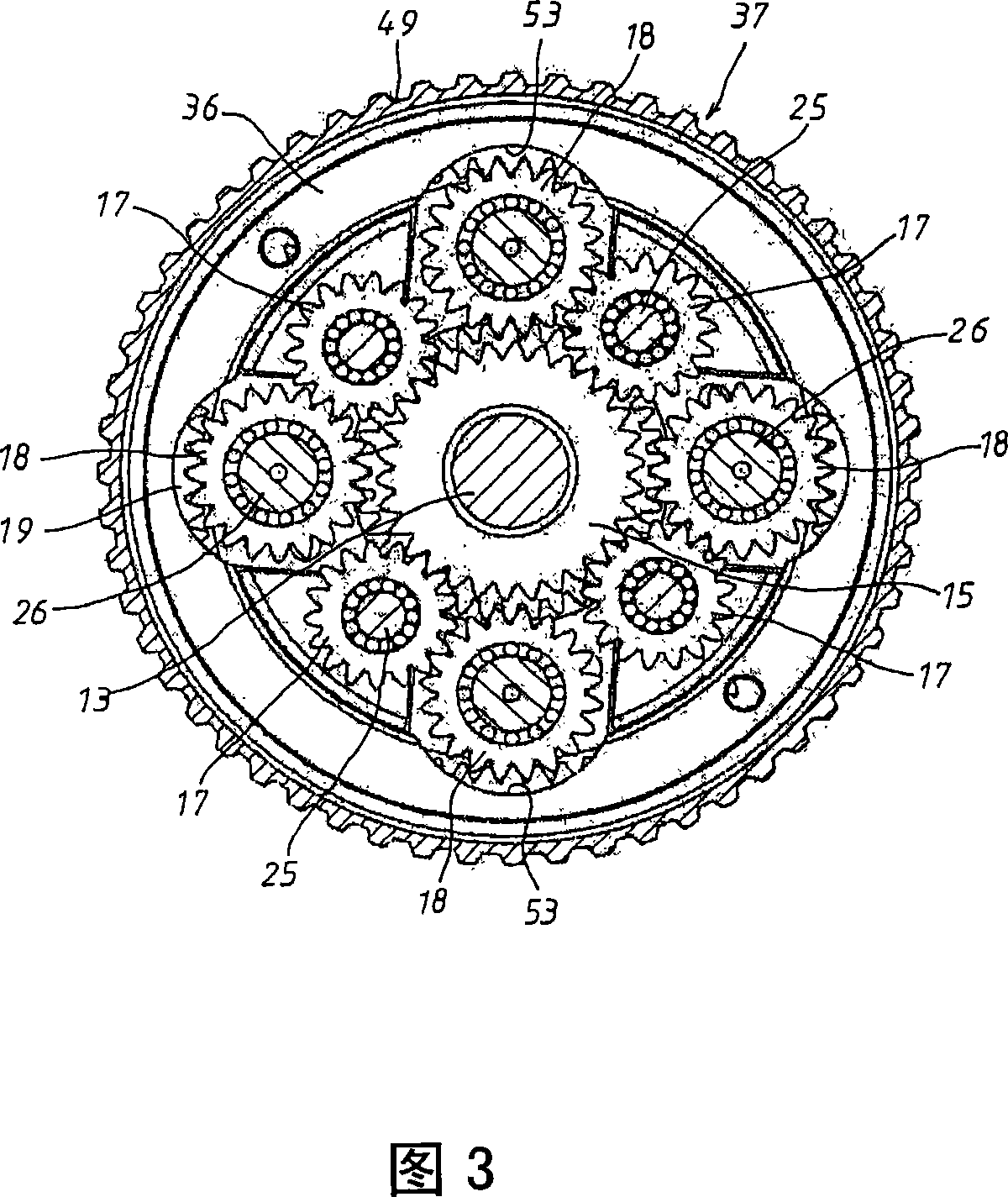

Planetary gear apparatus

InactiveCN1993571AIncreased torsional rigidityReduce processing costsGearboxesToothed gearingsTransmission ratioEpicyclic gearing

Because spiral cable is needed for arranging the current transmission ratio-variable mechanism on the steering column, additional time is needed, and the probability of the accidents caused by cable breaking-off and so on still exists. The housing 21 fixed to the steering column 13 rotatablely supports an operation shaft 11 and an output shaft 22 on which opposite ends a first and a second sun gears 45, 46 are provided. A first and a second planetary gears 53, 54, which respectively engage with the first and the second sun gears, are supported by a planetary gear bracket 47, and are arranged at the motor 43 arranged on the housing along a direction which is vertical to the rotary shaft lines of the operation shaft and the output shaft to rotate a worm shaft 58 which engages with a worm wheel 57 rotatablely connected to the planetary gear bracket. Therefore, spiral cable can be abandoned, and a space-saving transmission ratio-variable steering device 10 can be obtained.

Owner:AISIN AW CO LTD

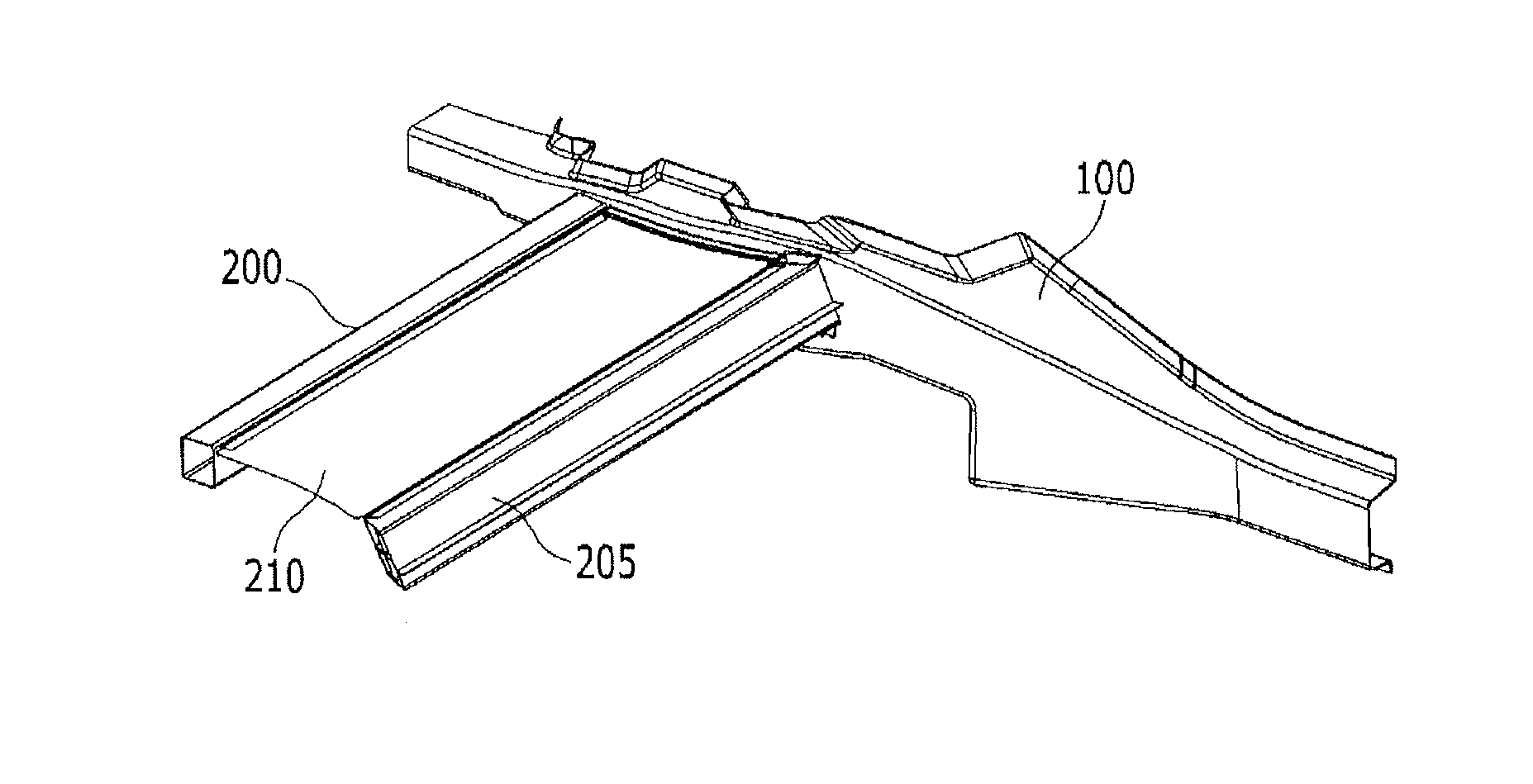

Vehicle body having rear side member

ActiveUS20150042129A1Increased flexural rigidityIncreased torsional rigidityVehicle seatsUnderstructuresEngineeringMechanical engineering

Owner:HYUNDAI MOTOR CO LTD

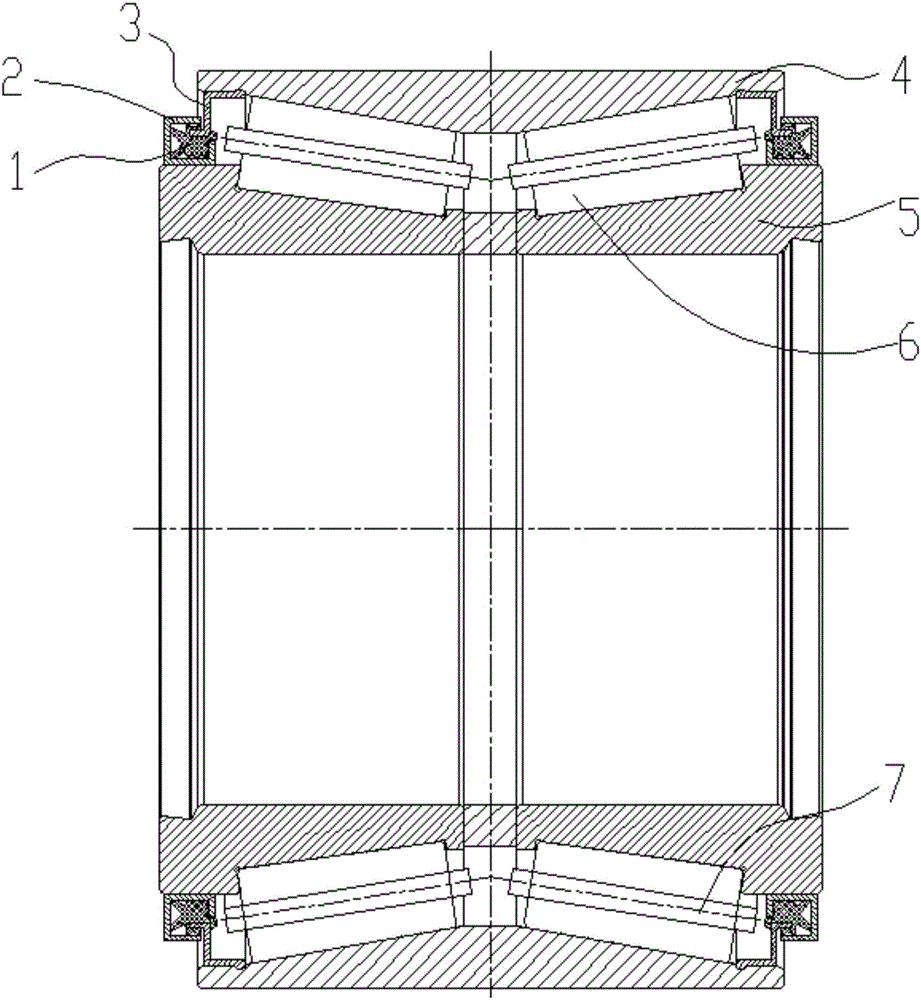

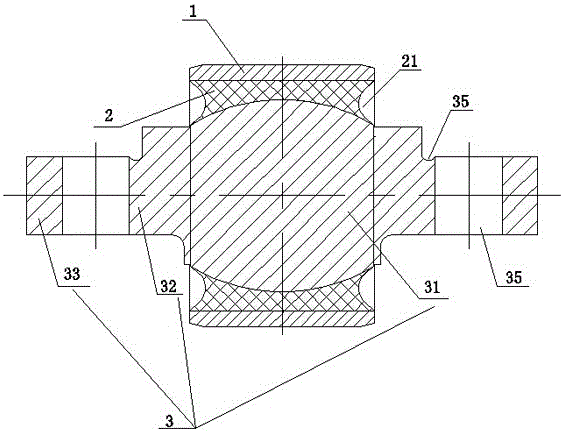

Hub bearing sealing ring of railway wagon and bearing equipped with same

The invention relates to a hub bearing sealing ring of a railway wagon. The hub bearing sealing ring of the railway wagon comprises an outer framework which is fixed to an outer ring of a bearing, an inner framework which is fixed to an inner ring of the bearing, and a maze type sealing part which is arranged between the inner framework and the outer framework, wherein the inner framework comprises an inner ring which fixedly sleeves the periphery of the inner ring of the bearing, an outer ring which is annularly arranged at the periphery of the inner ring of the inner framework, an outer annular plate which is fixedly connected between the outer end of the inner ring of the inner framework and the outer end of the outer ring of the inner framework, and an inner annular plate which is fixedly connected to the inner end of the inner ring of the inner framework and radially outwards extends; the maze type sealing part comprises a sealing body, and a plurality of lip parts which extend from the sealing body and form maze gaps with the wall surfaces of an inner chamber of the inner framework; lubricating grease fills each maze gap to form a lubricating grease sealing ring. According to the hub bearing sealing ring of the railway wagon, the inner framework box design is adopted, so that vulcanized rubber is not exposed in air; the added maze structure can effectively prevent outside foreign materials and liquid from invading as well as prevent the inside lubricating grease from leaking.

Owner:FUJIAN YONGAN BEARING

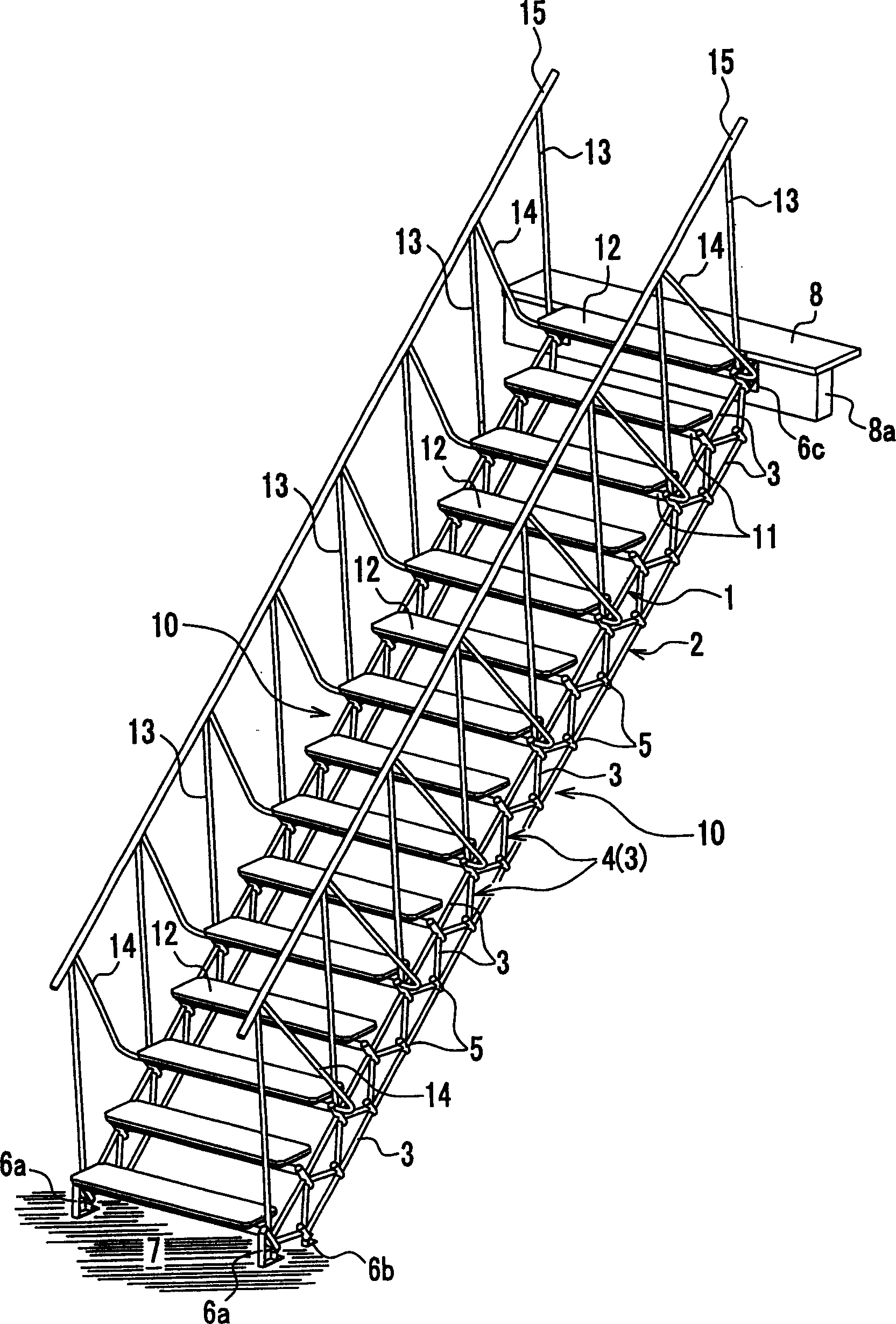

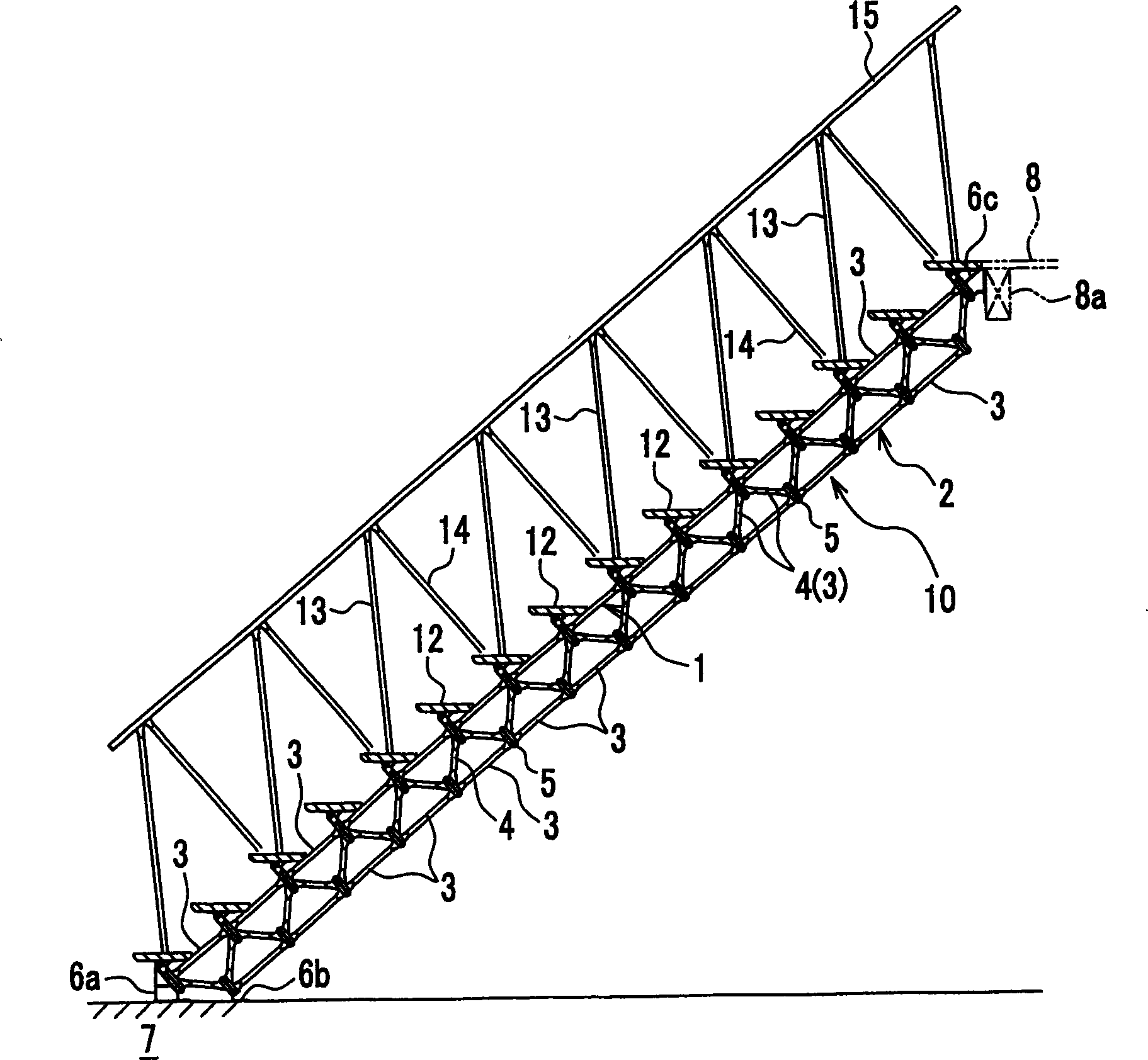

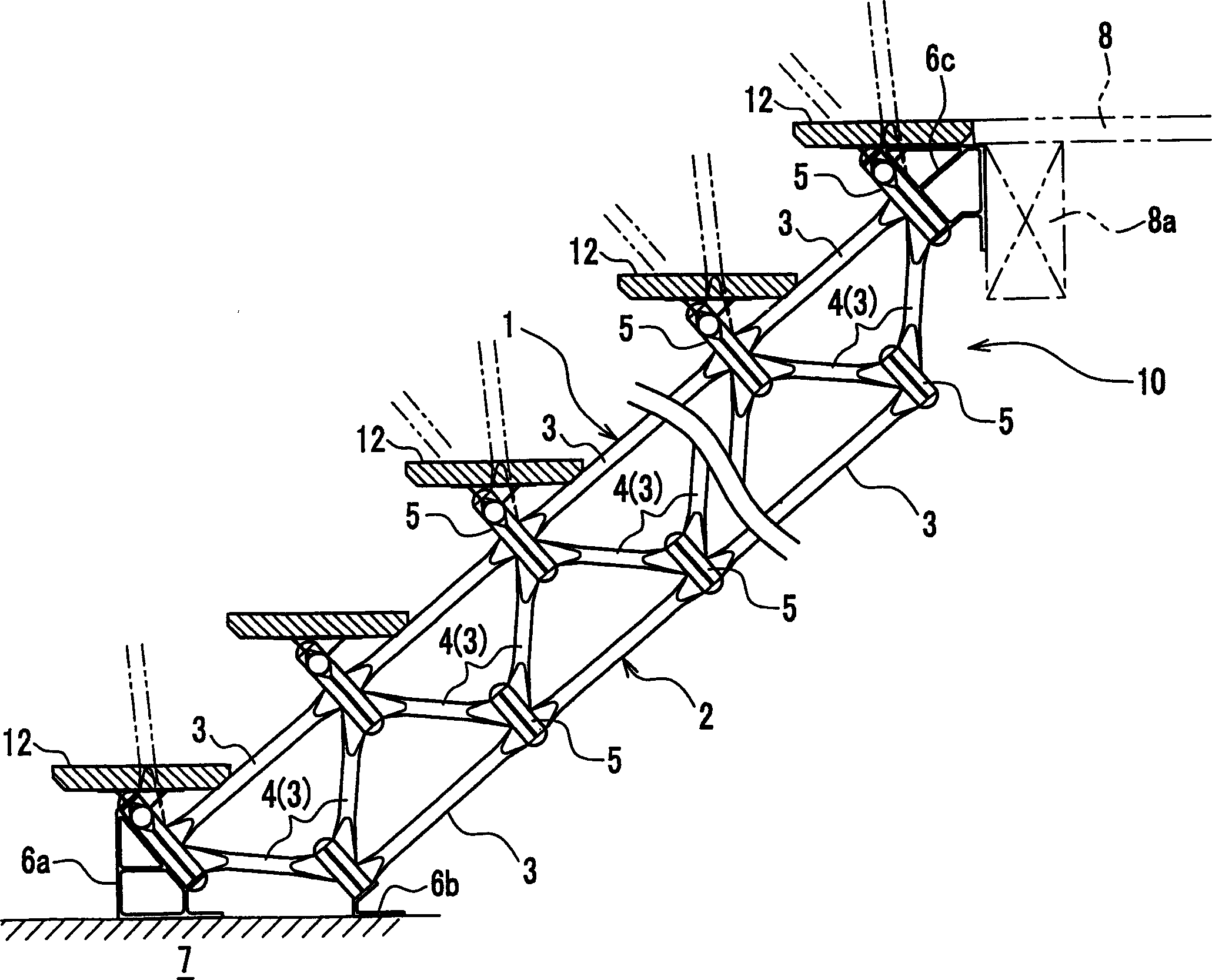

Stairway

InactiveCN1608162AIncreased torsional rigidityImprove bending rigidityTreadsLaddersEngineeringStep height

The invention provides a staircase with a light structure, high production and construction efficiency, and a sense of lightness. The staircase comprises a pair of left and right inclined beams and pedals (12) formed by truss structural parts (10). The truss structure part (10) comprises: an upper chord member (1) and a lower chord member (2) inclined with the gradient of the stairs; a plurality of grids for connecting the upper chord member (1) and the lower chord member (2) structural parts (4), between the truss structural parts (10), a plurality of connection parts (11) arranged horizontally according to each step height are fixed to connect these truss structural parts (10), and the pedals (12) are fixedly supported on these connection parts (11).

Owner:NIPPON LIGHT METAL CO LTD

End mill and a method of operating an end mill

ActiveUS7322774B2Increased torsional stiffnessImprove the immunityMilling cuttersWorkpiecesTrademarkEngineering

Owner:KENNAMETAL INC

Pipe fitting connecting device

ActiveCN107131187ASimple structureEasy to installRod connectionsPipe fittingArchitectural engineering

The invention relates to a pipe fitting connecting device. The device is characterized by comprising an upper connecting piece, a lower connecting piece, a positioning column, a connecting nut, two support pieces, a slide rod and a fastening nut; the outer sides of the upper connecting piece and the lower connecting piece are respectively connected with one ends of two connected pipe fittings; the two support pieces are respectively mounted in the upper connecting piece and the lower connecting piece; the lower end of the positioning column is fixed with the upper end of the lower connecting piece; the upper end of the positioning column is inserted in the upper connecting piece; the connecting nut is mounted at the external of the positioning column; one end of the slide rod is fixed with one support piece, and the other end penetrates through the positioning column to fixed with the support piece mounted in the lower connecting piece; the upper connecting piece and the lower connecting piece are in threaded connection through the connecting nut and the fastening nut; the upper connecting piece is a hollow structure; and the upper end of the upper connecting piece is an upper connecting piece circular table structure capable of being supported by the support pieces.

Owner:HEBEI UNIV OF TECH

Novel combined type bidirectional flexible diaphragm coupling with tubular long shaft and method for manufacturing novel combined type bidirectional flexible diaphragm coupling with tubular long shaft

ActiveCN103899667AGood torsional rigidityImprove manufacturing precisionYielding couplingTorsional rigidityEngineering

The invention discloses a novel combined type bidirectional flexible diaphragm coupling with a tubular long shaft. The novel combined type bidirectional flexible diaphragm coupling with the tubular long shaft comprises a first assembly, a second assembly and the tubular middle long shaft (8), wherein the first assembly and the second assembly are connected to the two ends of the tubular middle long shaft (8) in a split type combined middle joint (7) respectively. The novel combined type bidirectional flexible diaphragm coupling with the tubular long shaft has the advantages that metal diaphragm elements are adopted, no tooth space exists, the torsional rigidity is good, the coupling is suitable for high-temperature occasions, the manufacturing accuracy is high, the dynamic balance accuracy is high, the operation speed is high, vibration is small, and the noise is low; compared with other couplings which can transmit the same torque as the novel combined type bidirectional flexible diaphragm coupling, the novel combined type bidirectional flexible diaphragm coupling has the advantages that the structure is compact, the radial size is small, the radial length can reach 2000 mm-2500 mm, the transmitted torque is large, the performance is stable, and the service life is long.

Owner:WUHAN KEXIN TECH

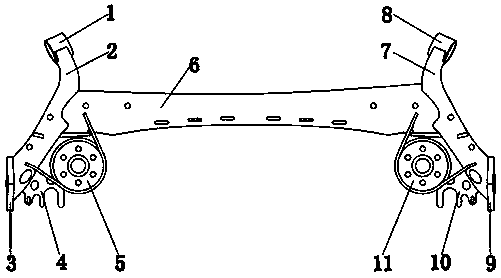

U-shaped variable cross-section rear torsion beam assembly

PendingCN107914533AMeet functional requirementsEnsure stabilityInterconnection systemsPivoted suspension armsClassical mechanicsDamper

The invention discloses a U-shaped variable cross-section rear torsion beam assembly of the technical field of automobiles. A left longitudinal arm is installed at the bottom of a left casing pipe, aleft wheel hub plate is installed at the bottom of the left longitudinal arm, a left damper support is installed at the bottom of the right side of the left longitudinal arm, a left spring plate is installed at the top of the left damper support, the left side of the left spring plate is connected with the left longitudinal arm, a torsion beam is installed on the right side of the left longitudinal arm, the top of the left spring plate is connected with the bottom of the torsion beam, a right longitudinal arm is installed at the right end of the torsion beam, a right casing pipe is installed at the top of right longitudinal arm, a right wheel hub plate is installed at the bottom of the right longitudinal arm, and a right damper support is installed at the bottom of the left side of the right longitudinal arm. The U-shaped variable cross-section rear torsion beam assembly has strong rigidity, can satisfy functional requirements of targets well, has a simple forming process and light weight, increases advantages of the torsion beam, and guarantees stability of a roll center.

Owner:安徽万安汽车零部件有限公司

Close out bracket

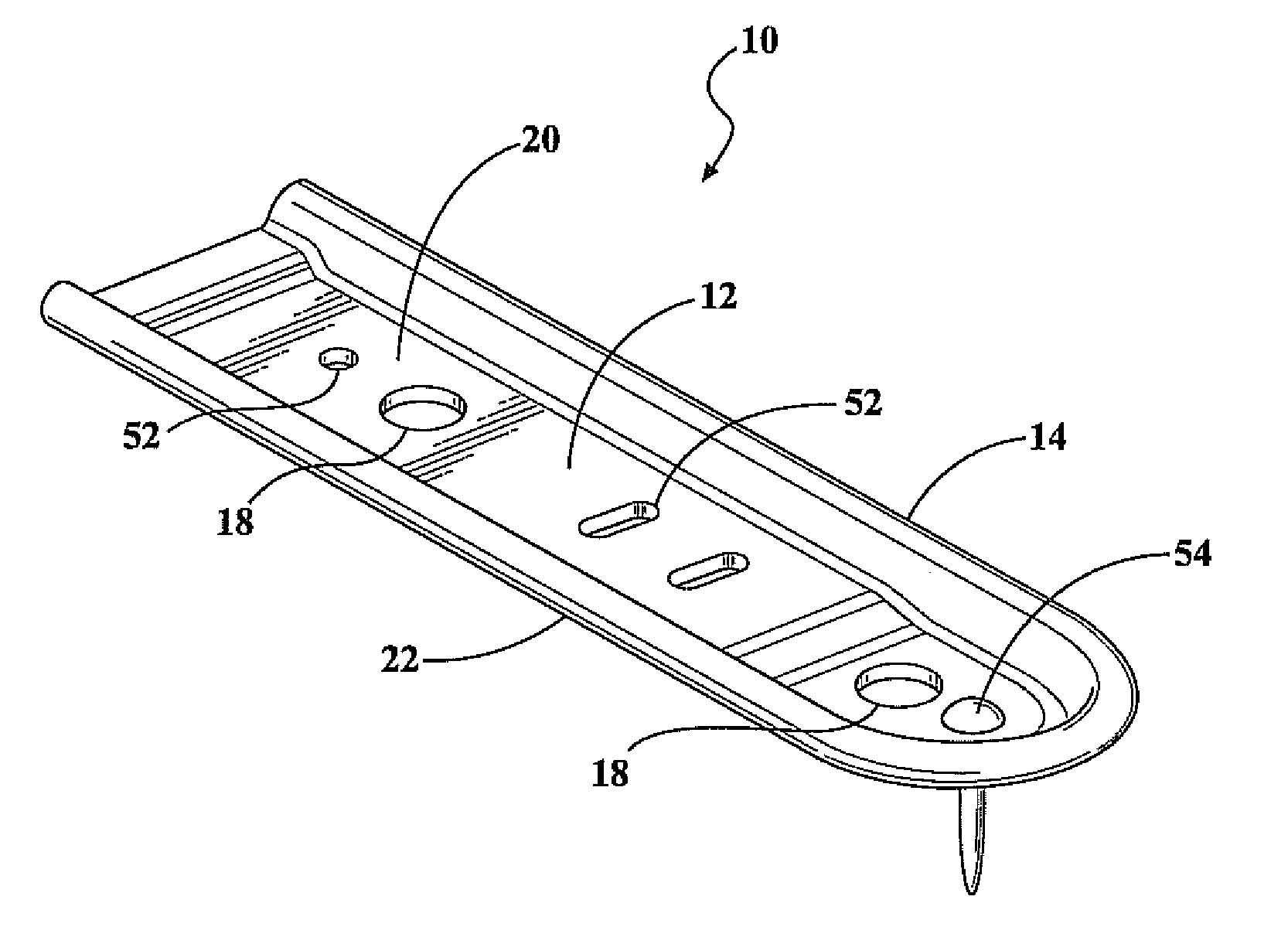

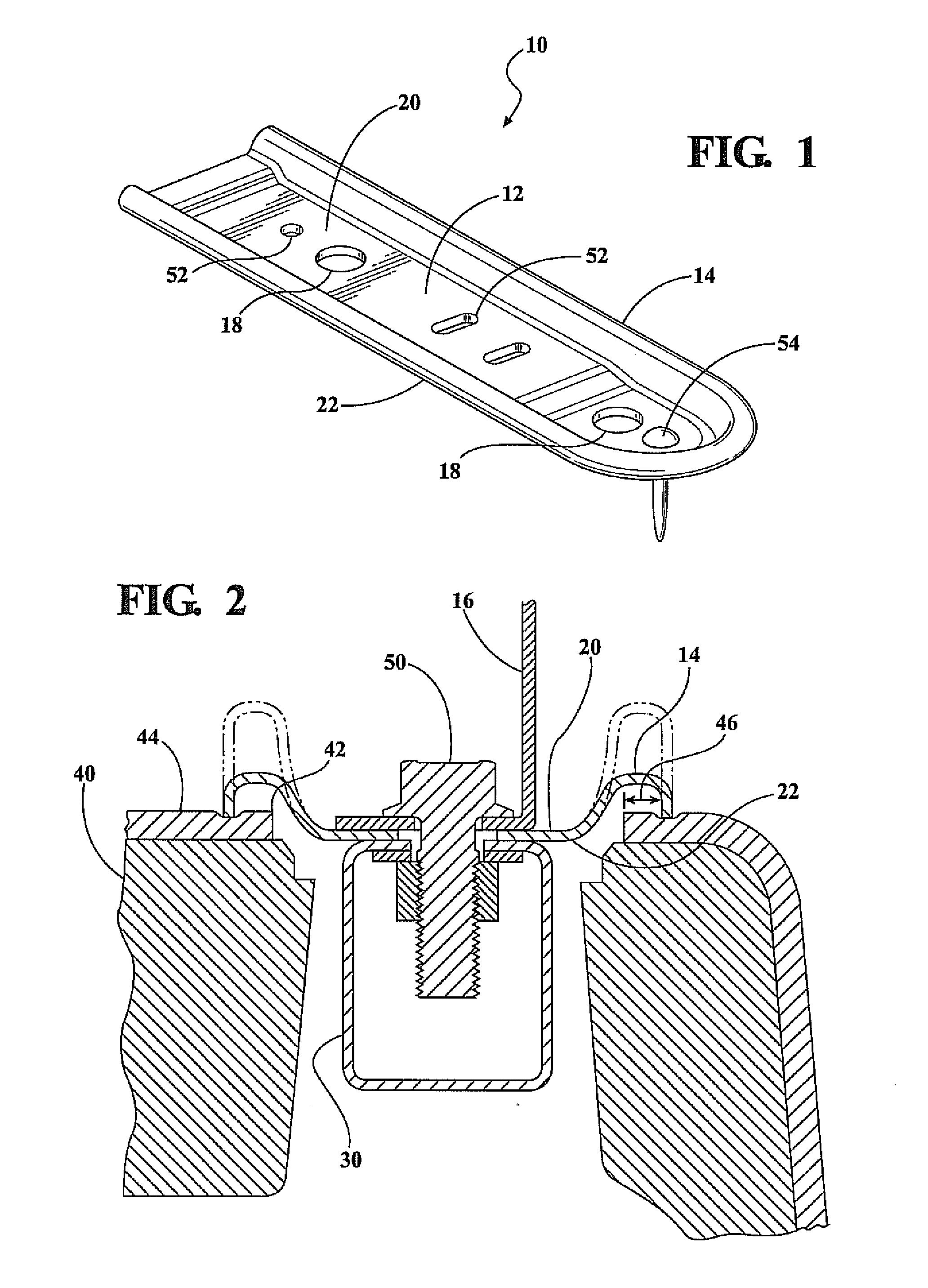

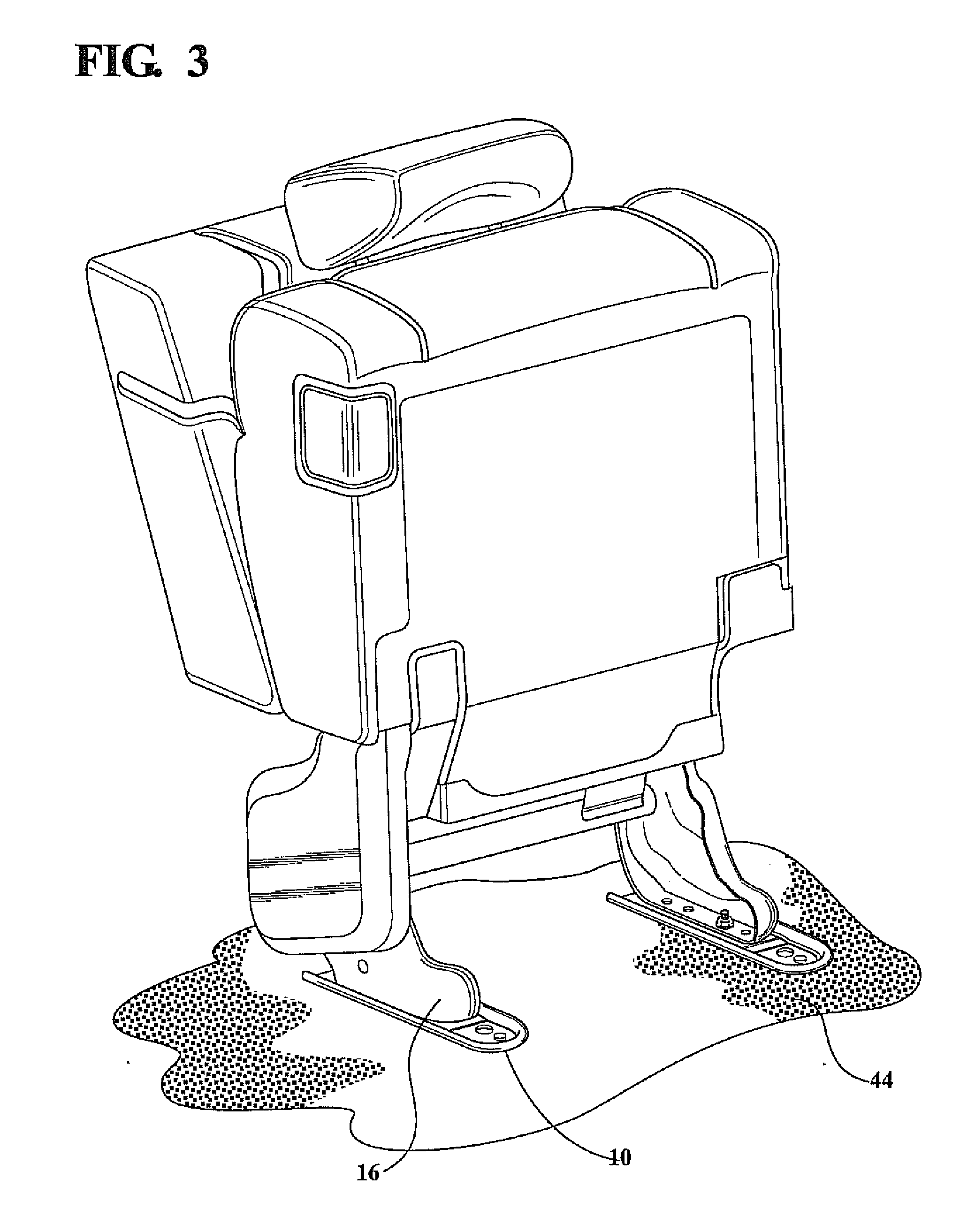

ActiveUS20140166842A1Increased torsional rigidityAvoid damageVehicle seatsFurniture partsEngineeringMechanical engineering

The present invention relates to a close out bracket for securing a seat mounting structure to a support rail in a floor of a vehicle. The bracket has a generally flat center portion that is rigidly engaged between the seat mounting structure and the support rail. The bracket also has a curved portion extending radially outward from the center portion. The curved portion has a generally inverted U shape and extends along the perimeter of the center portion. The bracket serves as a finish trim piece by closing out along the edge of the floor covering that was cut to expose the support rail below.

Owner:TOYOTA JIDOSHA KK

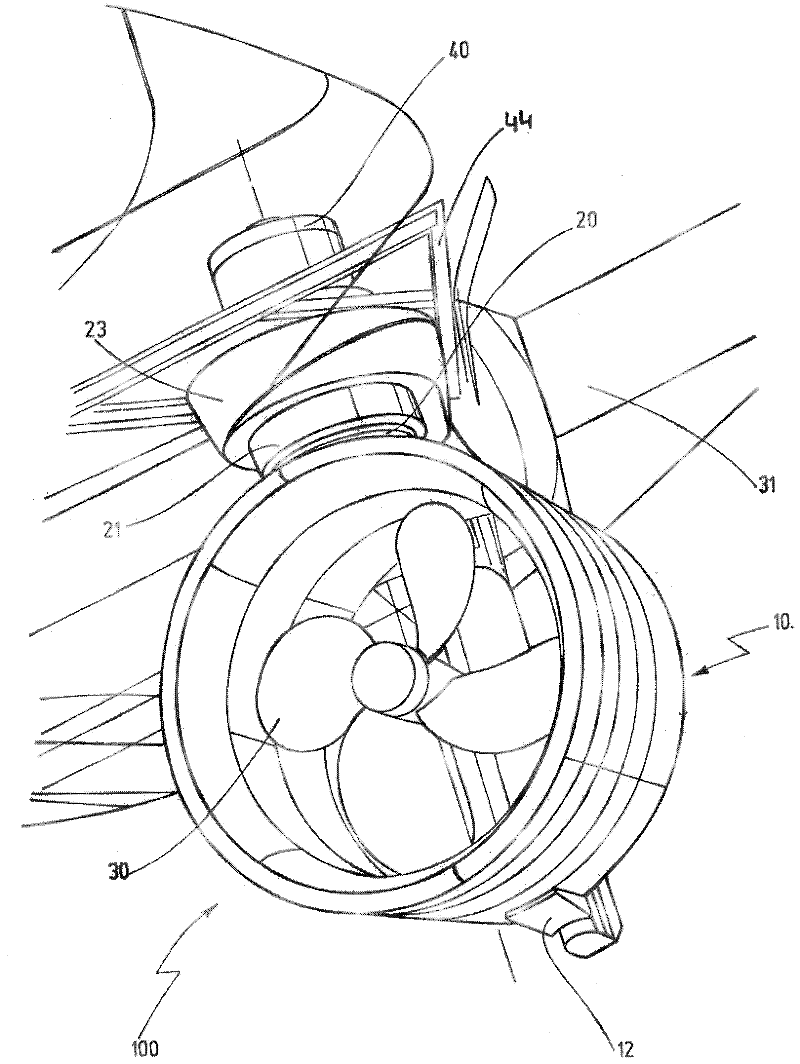

Pivotable propeller nozzle for a watercraft

ActiveCN102470913AHigh bending momentStable and simpler to makeSteering ruddersSteering by jetsPropellerWatercraft

In order to achieve a connection between a nozzle shaft (20) and a nozzle ring (10) that has the simplest design possible, while at the same time being stable, in a propeller nozzle (100) for a watercraft which comprises a fixed propeller (30) and a nozzle ring (10) surrounding the propeller (30), said nozzle ring being pivotable by means of a nozzle shaft (20), the nozzle shaft (20) is designed as a hollow body.

Owner:BECKER MARINE SYST

Rubber joint for rail vehicle oil pressure damper and rubber formula thereof

ActiveCN106337891AStrong torqueExtended service lifeSprings/dampers design characteristicsRubber-like material springsEngineeringStearic acid

The invention discloses a rubber joint for a rail vehicle oil pressure damper. The rubber joint comprises a coat layer, a rubber layer and a central spindle. The middle portion of the central spindle is sleeved with the rubber layer, the rubber layer is closely bonded with the central spindle, the rubber layer is sleeved with the coat layer, the section of the contact surface of the coat layer and the rubber layer is rectangular, and the side face of the rubber layer is in a concave arc shape. A rubber formula of the rubber layer comprises, by mass, 80-90 parts of natural rubber, 10-20 parts of synthetic rubber, 0.6-1 part of sulfur, 0.8-1.2 parts of benzothiazole-2-thiol, 2.2 parts of 2,2'-dithio-dibenzo thiazole, 0.8-1.2 parts of diphenyl guanidine, 0.4-0.8 part of hexamethylene tetramine, 4-8 parts of hardening resin, 3 parts of zinc oxide, 1 part of stearic acid, 1 part of N-phenyl-N'-cyclohexyl-P-phenylenediamine, 1 part of 2-benzothiazolethiol, 1 part of poly(1,2-dihydro-2,2,4-trimethylquinoline), 1 part of paraffin and 30-50 parts of carbon black. The rubber joint with the rubber layer produced through the formula has strong torsion, radial rigidity, axial rigidity, deflection rigidity and torsion rigidity, and is high in product performance and long in service life.

Owner:南通市弘达轨道交通配件有限公司

Metal and composite material combined battery box

PendingCN111439106ALow costContinuous/automated productionEngine sealsNon-rotating vibration suppressionMechanical engineeringBattery cell

The invention discloses a metal and composite material combined battery box in the technical field of automobile parts. The battery box is composed of a high-strength metal frame, an upper shell madeof a composite material, a middle shell made of a composite material, a lower shell made of a composite material, a sealing rubber layer and a sealing rubber strip. According to the structural characteristics and technical requirements of the battery box, different materials are applied to different positions of the battery box, and the advantages of the materials are brought into full play, so the production cost is reduced, the rigidity requirement of the battery box is met, meanwhile, the frame weight is reduced to the maximum extent, the local stress is dispersed, and the connection reliability is improved.

Owner:上海瓴荣材料科技有限公司 +1

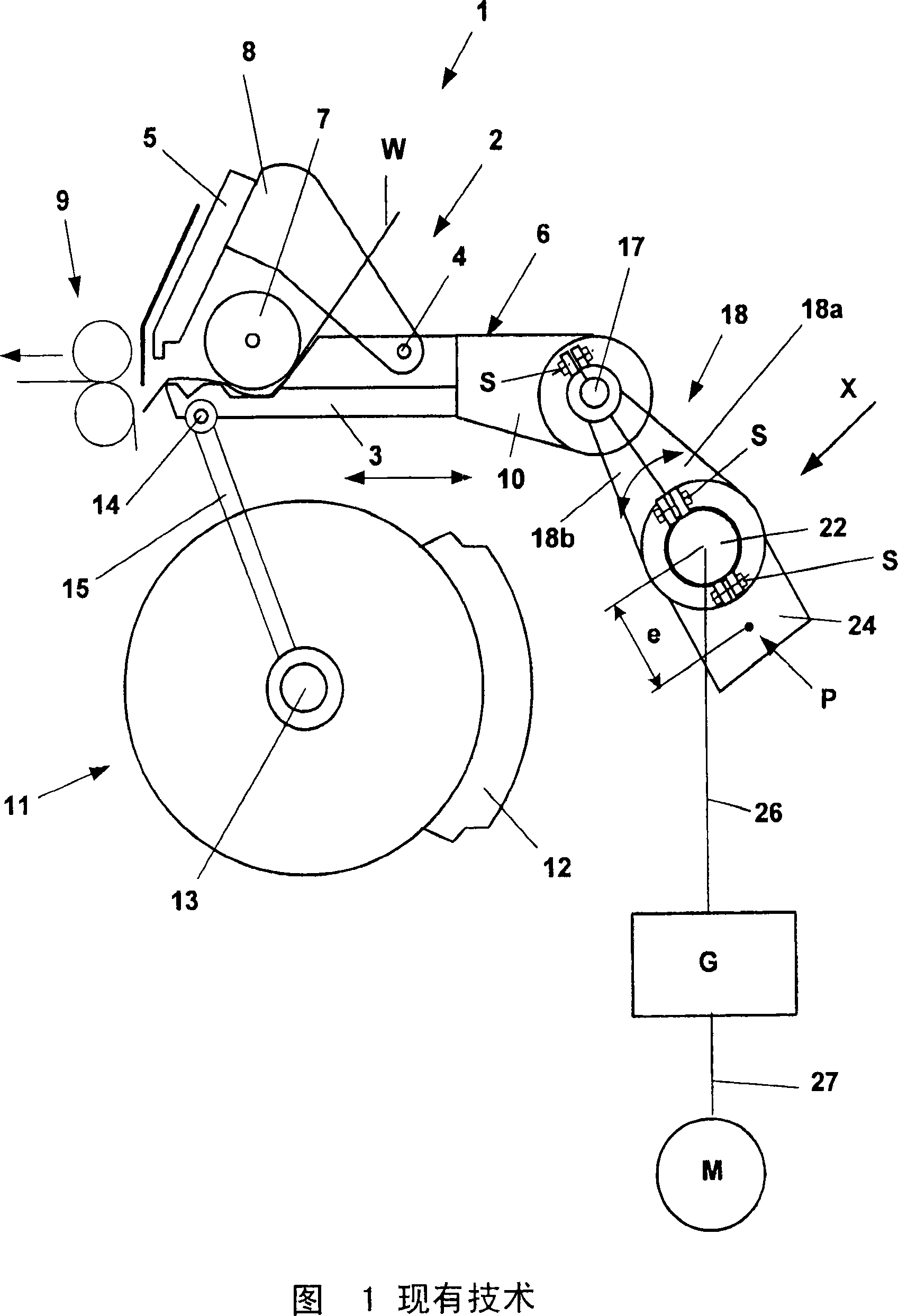

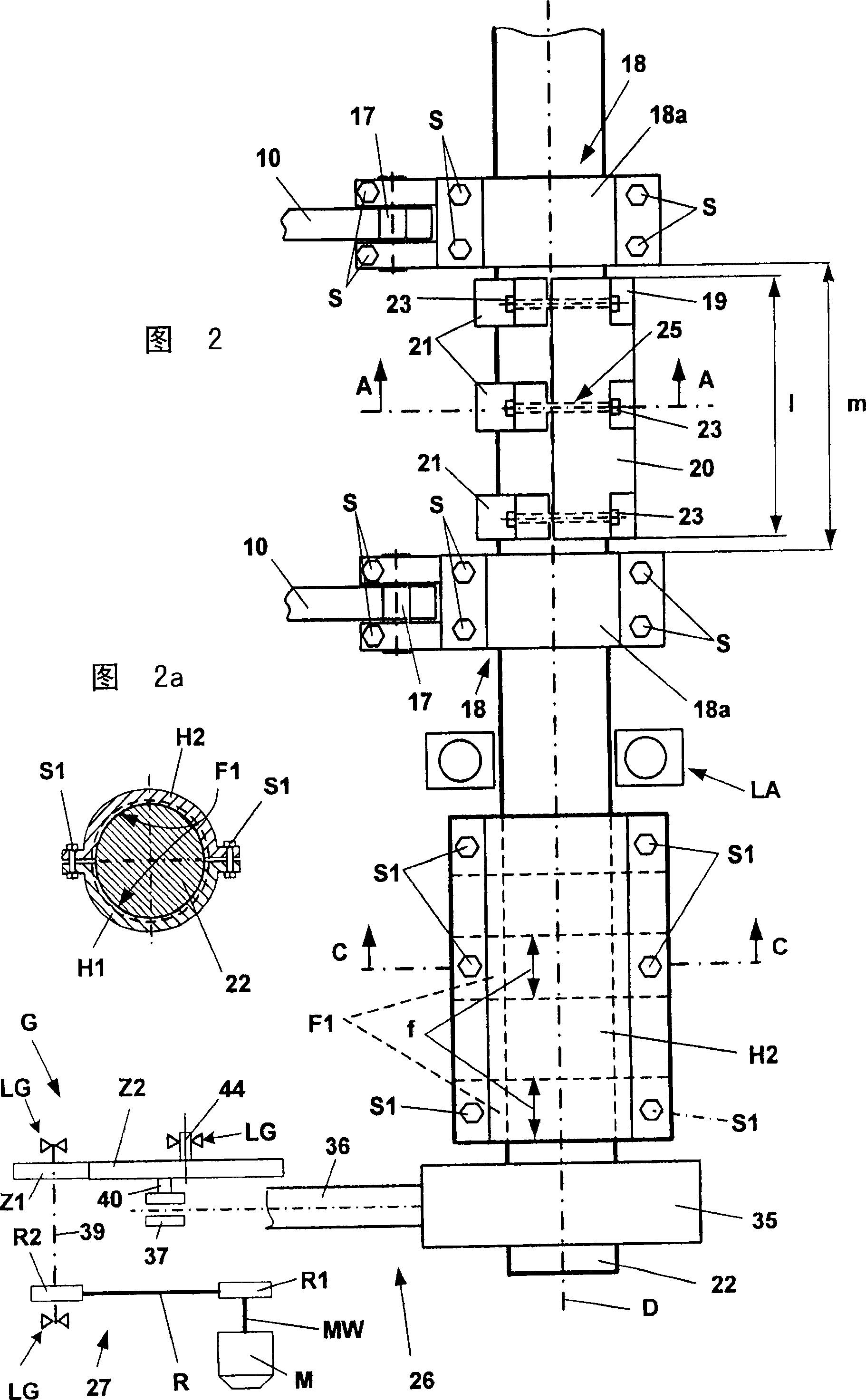

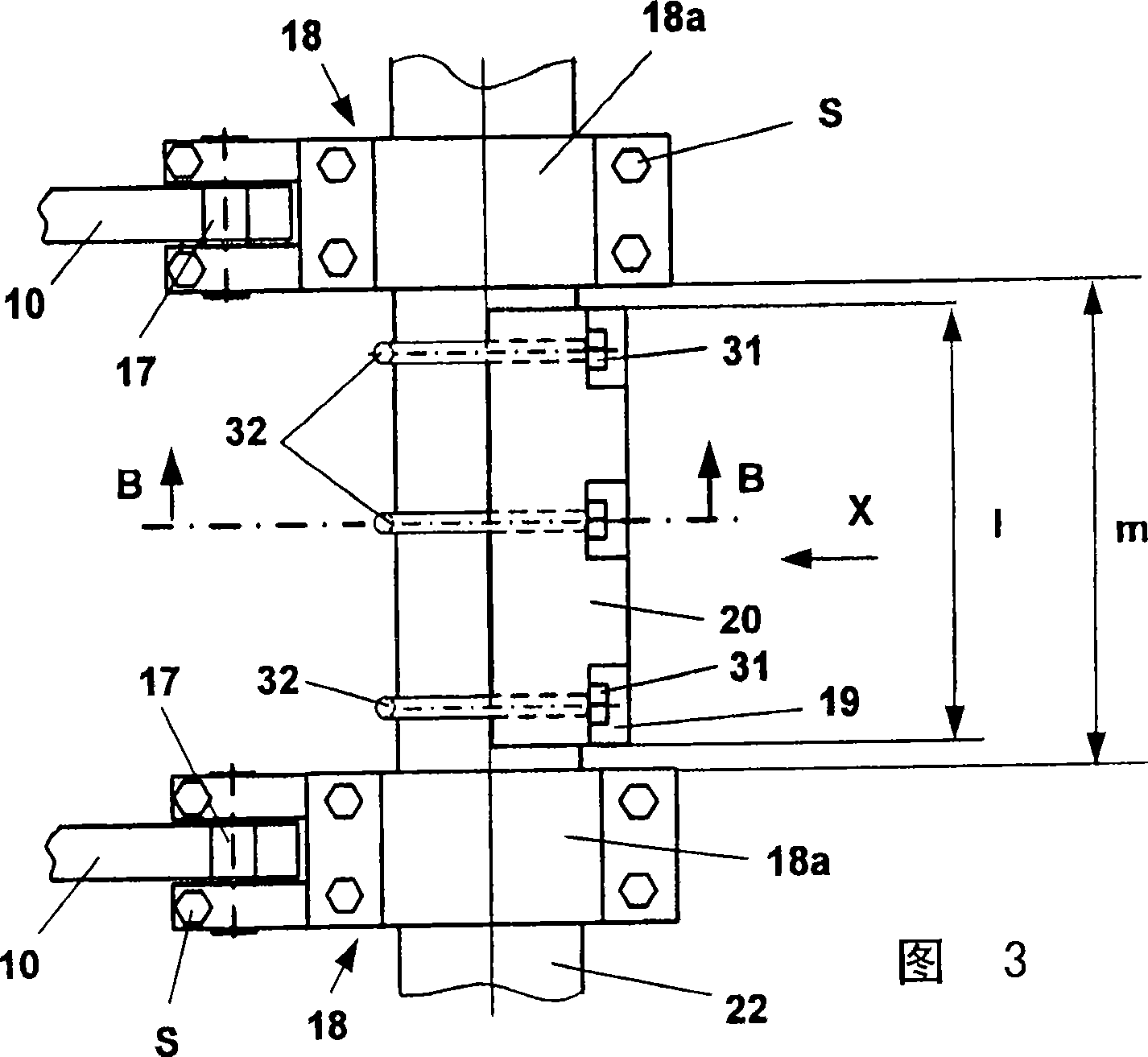

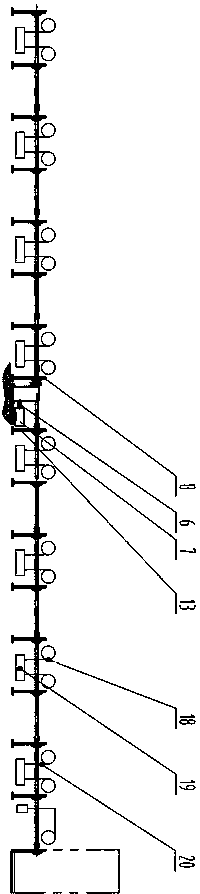

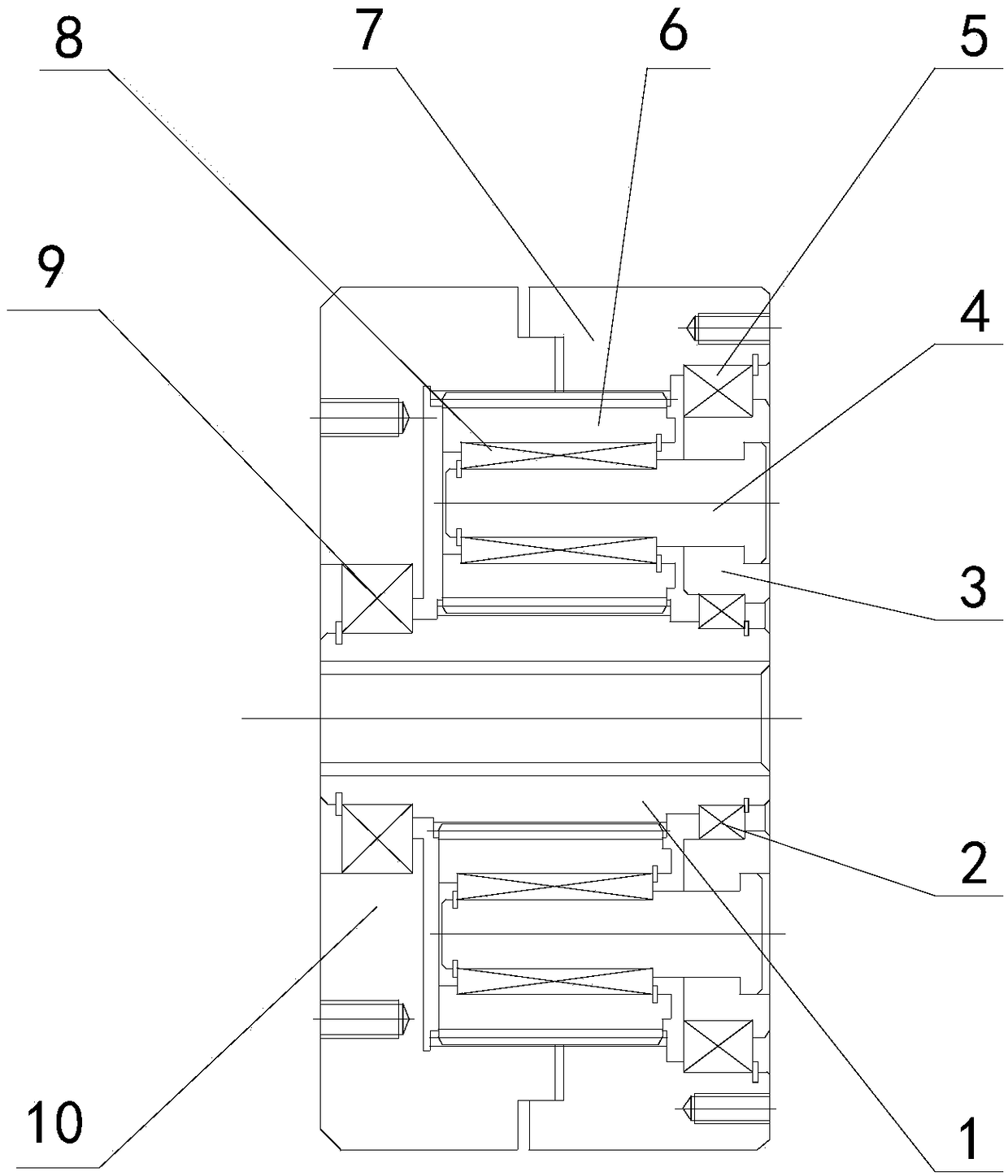

Balancing a nipper mechanism in a combing machine

The invention relates to a combing machine comprising at least one comb head (1) with a pincers unit (2) under any circumstances, which is pivotably mounted around at least one axis (13) for the implementation of a back and forth motion and with a rotatably-mounted pincers shaft (22), which runs parallel to the axis and to which at least one swivel arm (18) is non-rotatably secured, which is drive-connected with the pincer unit (2) via corresponding device(17), and balance weights intended in the area of the swivel arms (18) and the pincers shaft (22) for the compensation of the flywheel mass of the pincer unit. In order to reduce the inertial moment of the balance weights, carding circulation of higher numbers can be realized without exceeding critical moment limit. The balance weights (20, 30) are formed or attached in such a manner that the distances (e1, e2) of the centers of gravity (P1, P2) of the respective balance weight to the rotation axis (D) of the pincer shaft (22) are 35mm-60 mm.

Owner:MASCHINENFABRIK RIETER AG

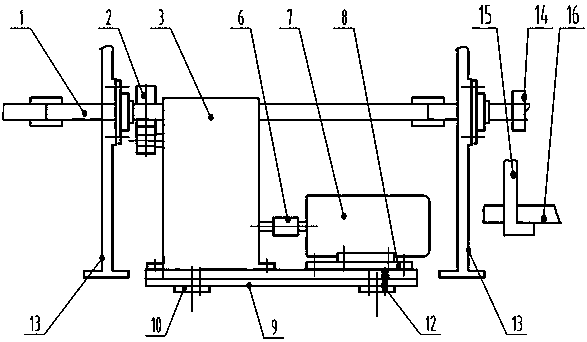

Roving frame transmission device

The invention discloses a roving frame transmission device. A lifting transmission shaft horizontally penetrates through a headstock and a tailstock machine frame of a roving frame and is driven to perform forward and reverse rotation by a transmission shaft driving device installed between two adjacent wallboards, a gear is installed on the lifting transmission shaft extending out of one side of a wall, a keel is installed at the bottom end of a keel supporting foot rack meshed with the gear, the bottom of the keel is connected with one end of a keel lever, the other end of the keel lever is provided with a supporting point, and a balance mechanism enabling the keel lever to be balanced is lifted on the keel lever. The roving frame transmission device can provide invariable balance force large in weight to act on the lever, stable balancing moment is generated, on one hand, torque borne by the lifting transmission shaft in the keel lifting process can be shared, on the other hand, balance and stability in the lifting process can be guaranteed, keel shaking caused by increase of spindles on the keel is avoided, the roving frame keel lifting transmission shaft is good in torsional rigidity, the torque borne by the lifting transmission shaft is small, and rough yarn is formed and packaged well.

Owner:WUXI HONGYUAN ELECTROMECHANICAL TECH

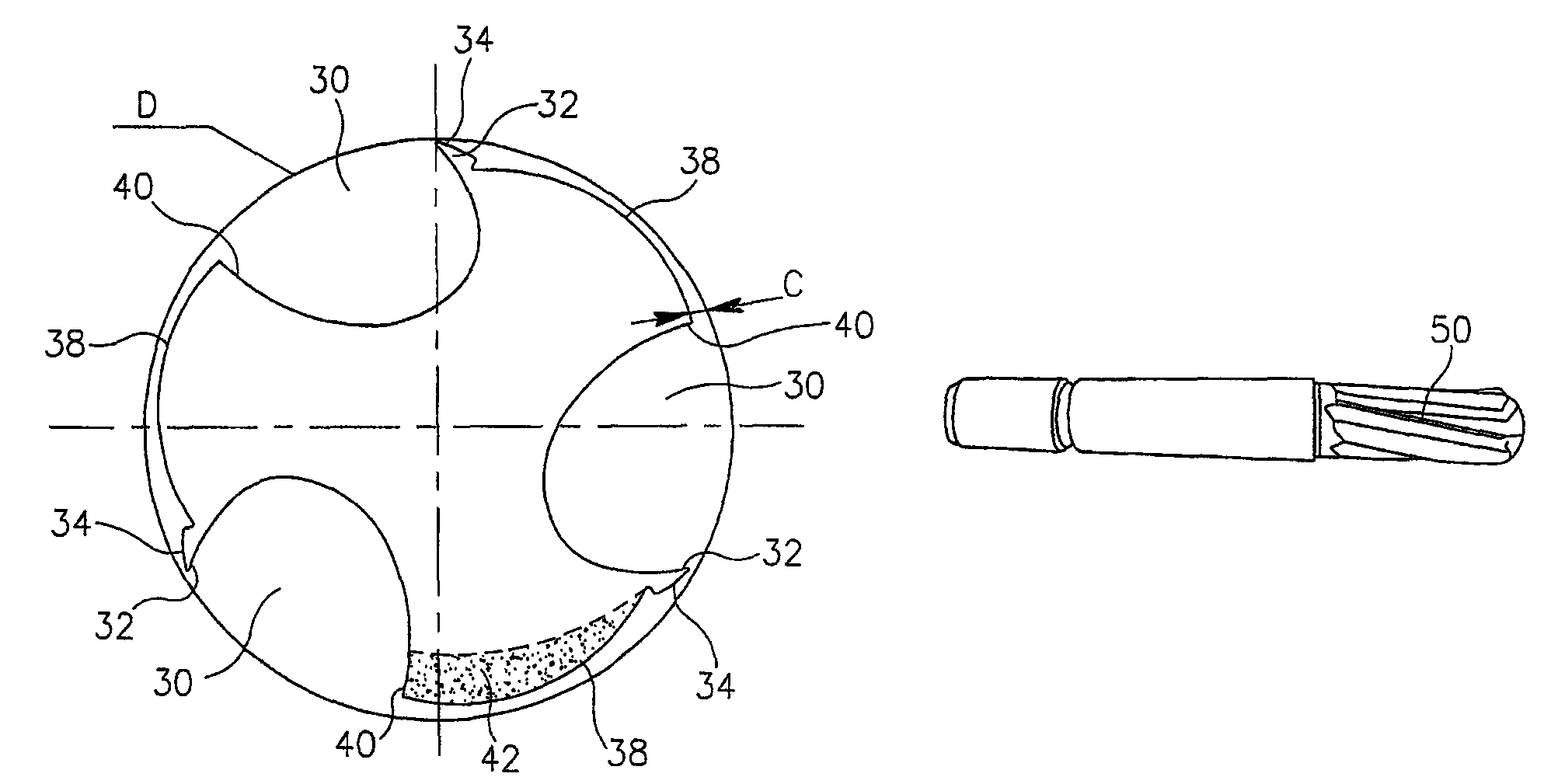

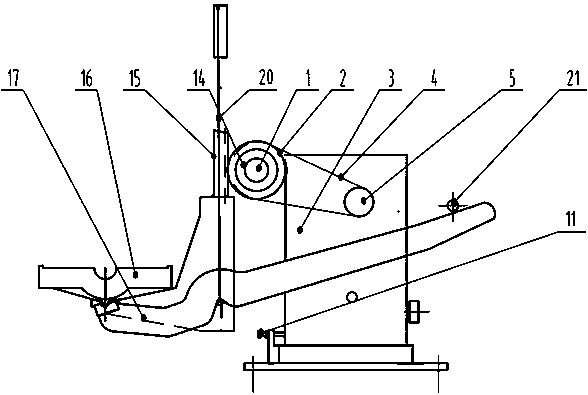

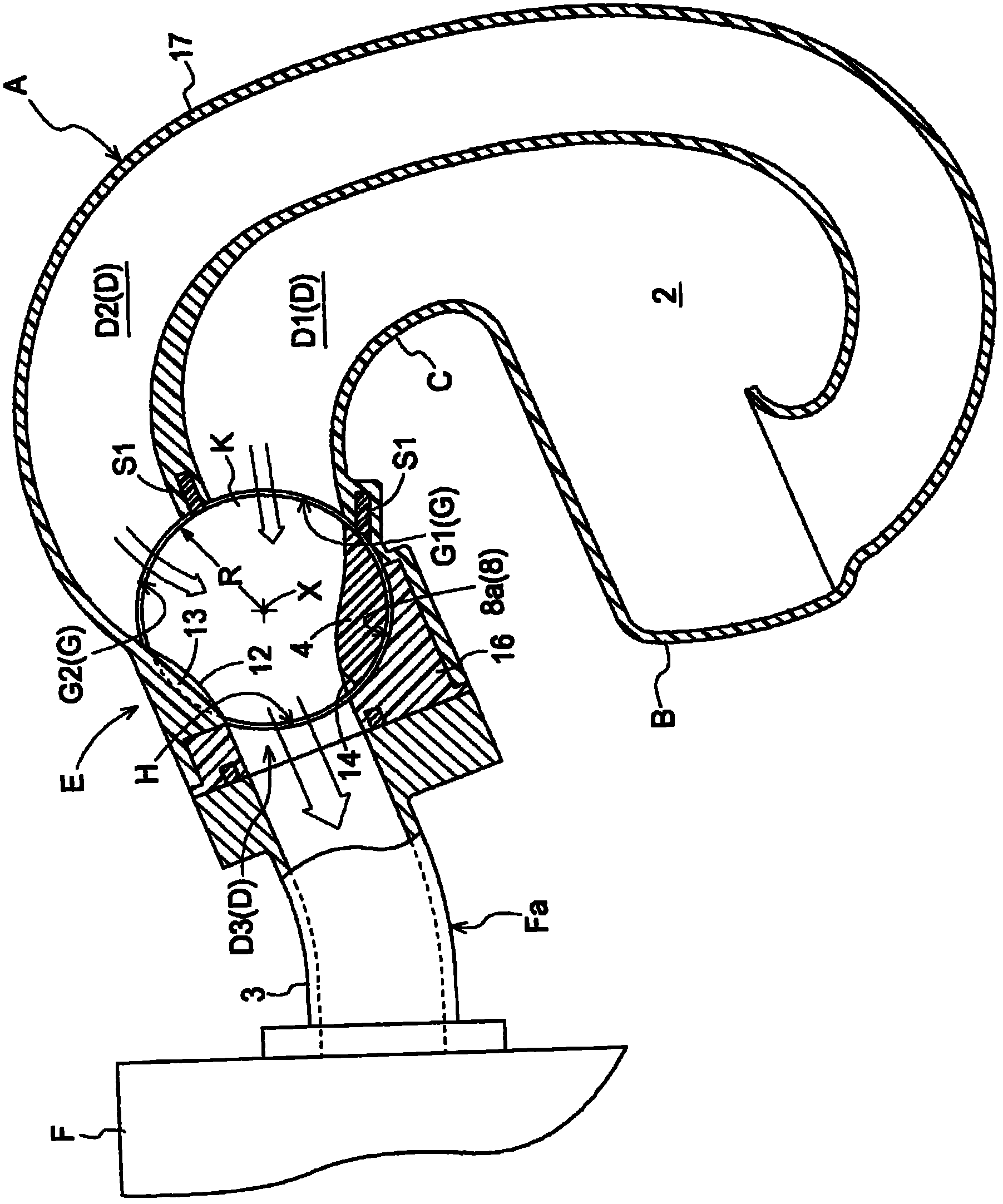

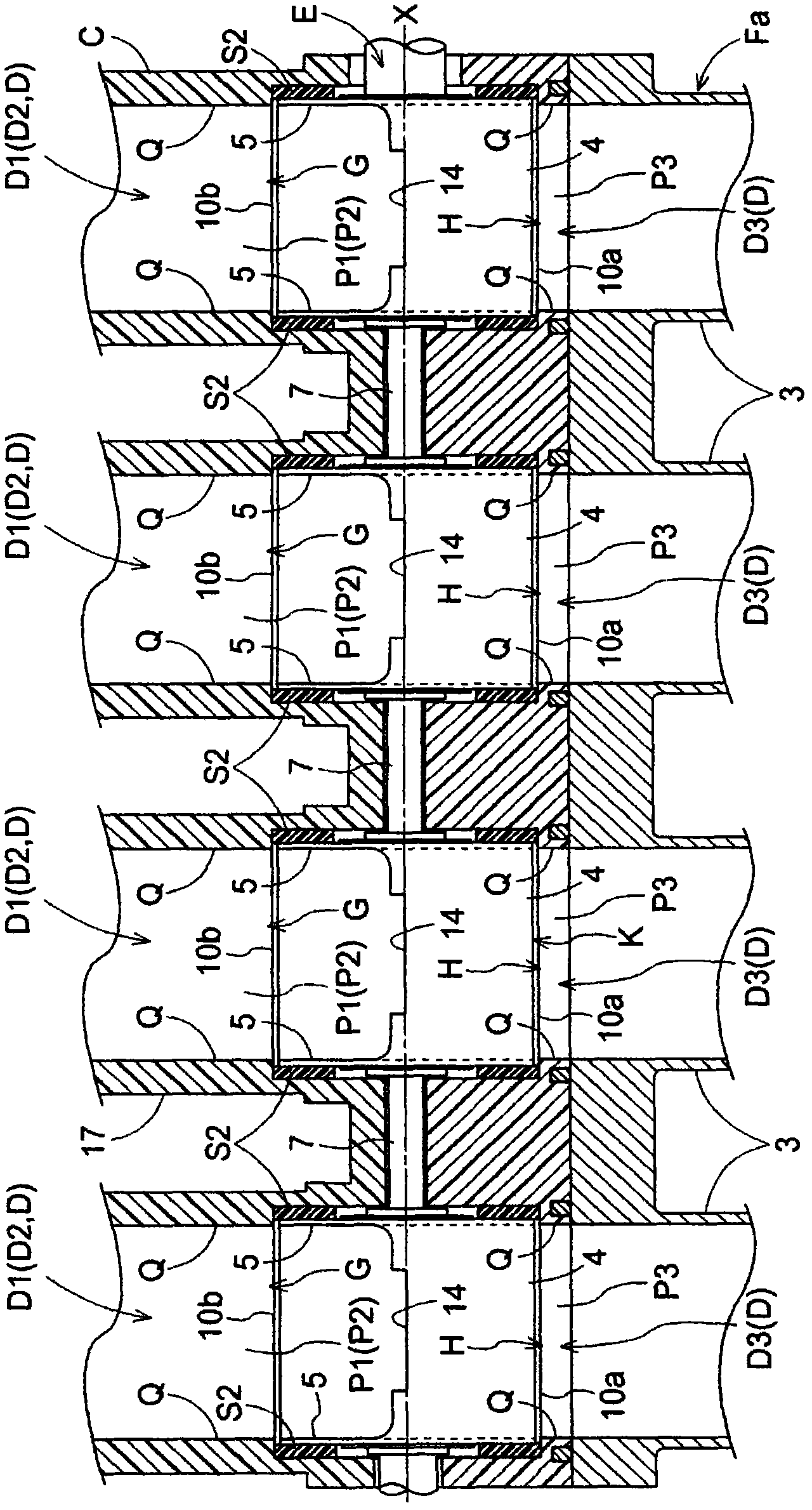

Air intake apparatus for internal combustion engine

InactiveCN102072056AHigh strengthIncreased torsional rigidityInternal combustion piston enginesCombustion-air/fuel-air treatmentRotational axisRotary valve

An air intake apparatus for an internal combustion engine includes a casing (C) including an intake port (G) and a discharge port (H), a rotary valve (E) rotatable around a rotational axis (X) within the casing (C) and including a valve element (4) that controls a connecting state between the intake port (G) and the discharge port (H), and an inner surface forming portion (13) formed at an inner surface (12) of the casing (C) along the rotational axis (X) of the rotary valve (E) and defined from the intake port (G) to the discharge port (H), a distance of the inner surface (12) from the rotational axis (X) being shorter than a maximum rotational radius (R) of the valve element (4).

Owner:AISIN SEIKI KK

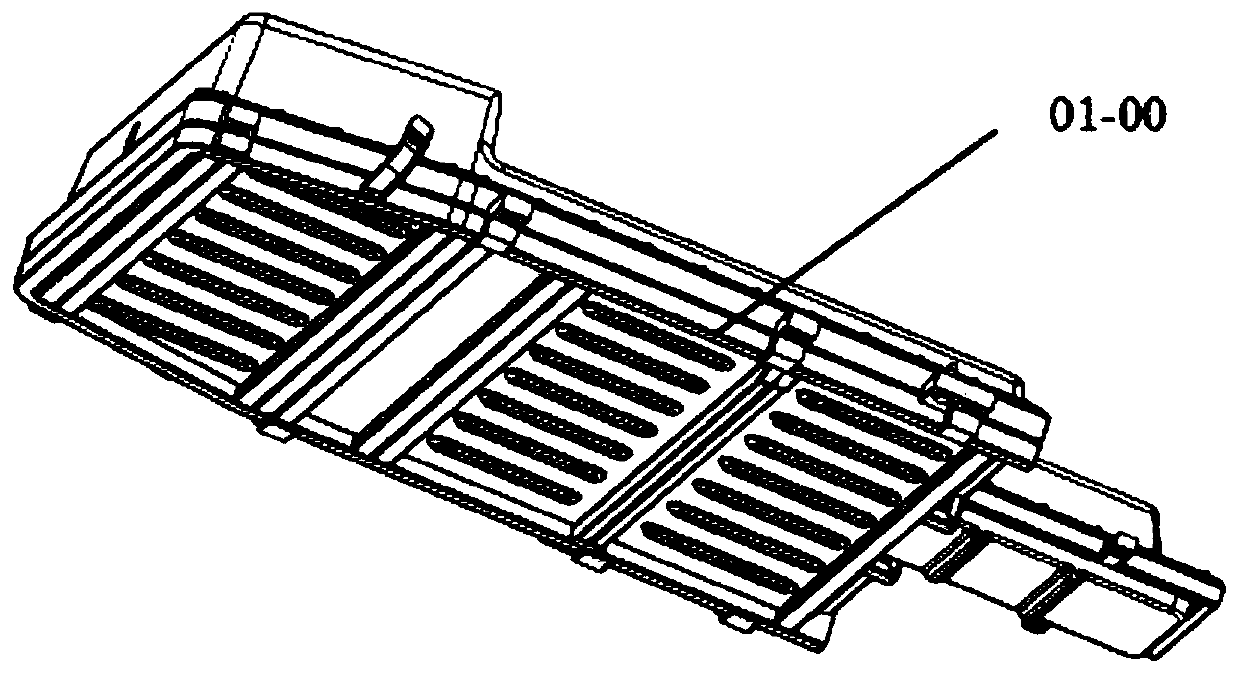

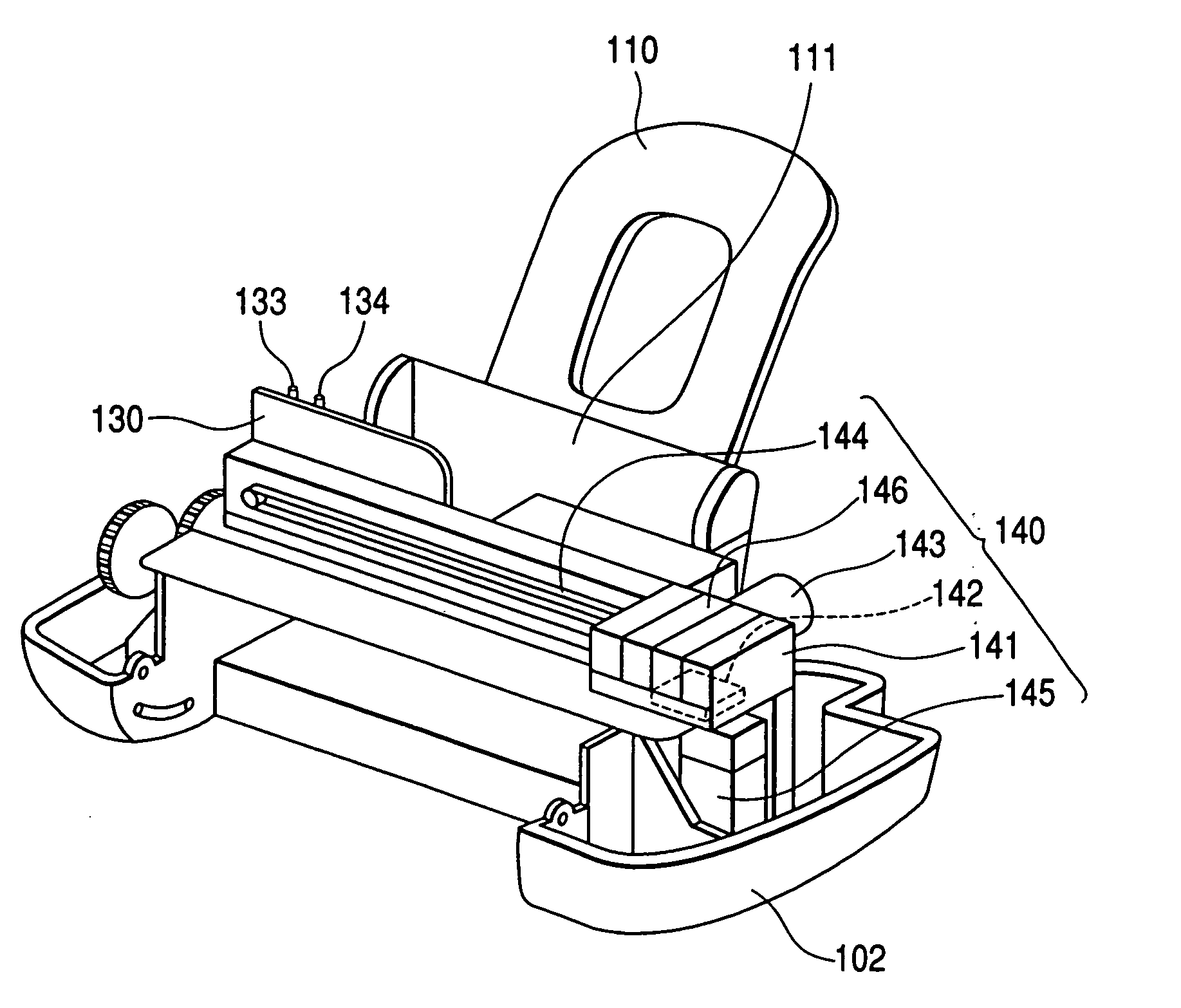

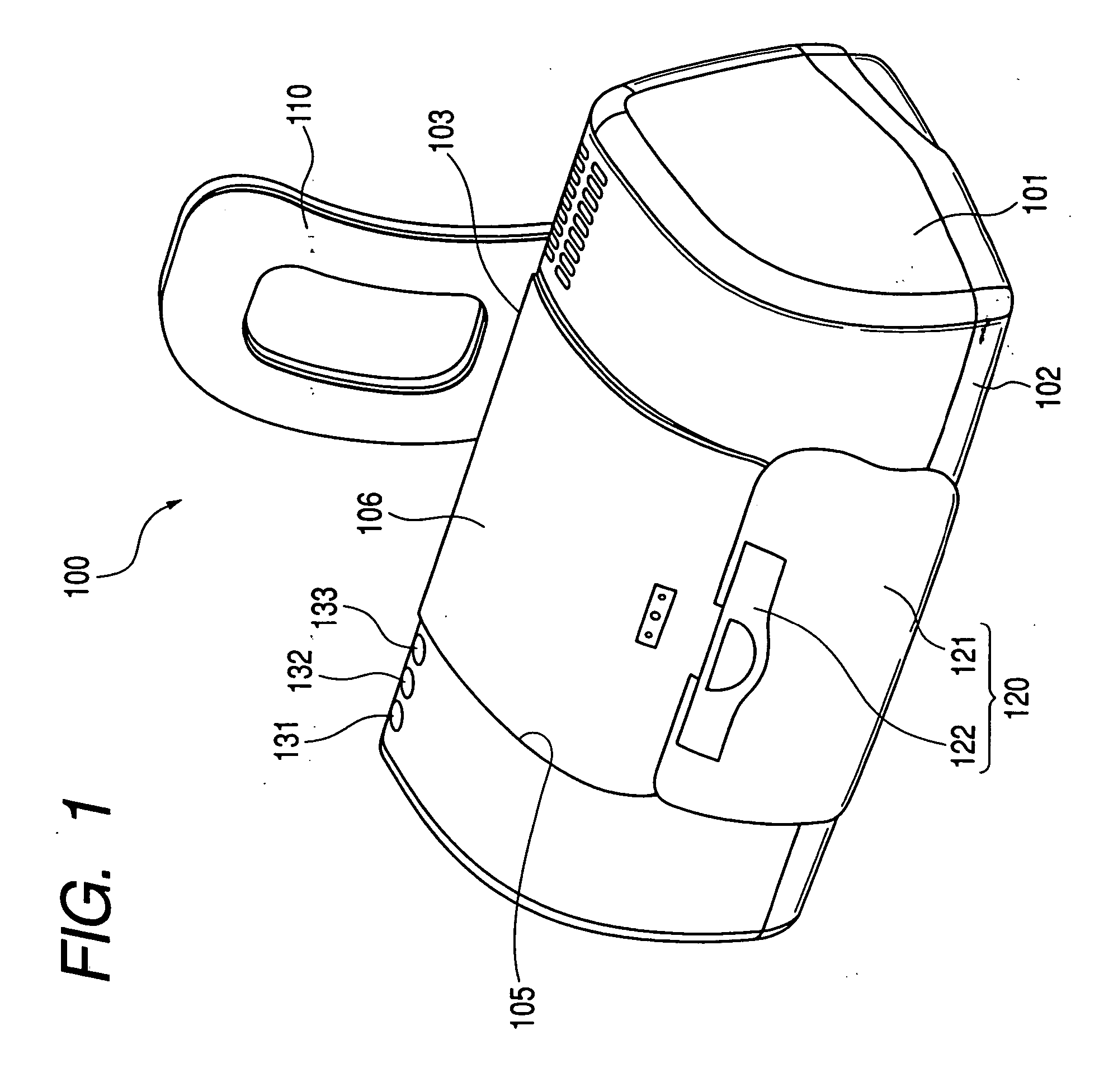

Recording apparatus

InactiveUS20060050127A1Increased flexural rigidityIncreased torsional rigidityOther printing apparatusArticle separationMechanical engineeringSynthetic resin

A feeding roller is adapted to feed a recording medium to a recording section provided in a recording apparatus. A shaft portion of the feeding roller is made of synthetic resin and formed with a hollowed portion. A roller portion is formed on an outer periphery of the shaft portion. A hopper is adapted to support the recording medium to be fed to the recording apparatus. The body of the hopper is made of synthetic resin and formed with a hollowed portion extending in a longitudinal direction of the recording apparatus.

Owner:SEIKO EPSON CORP

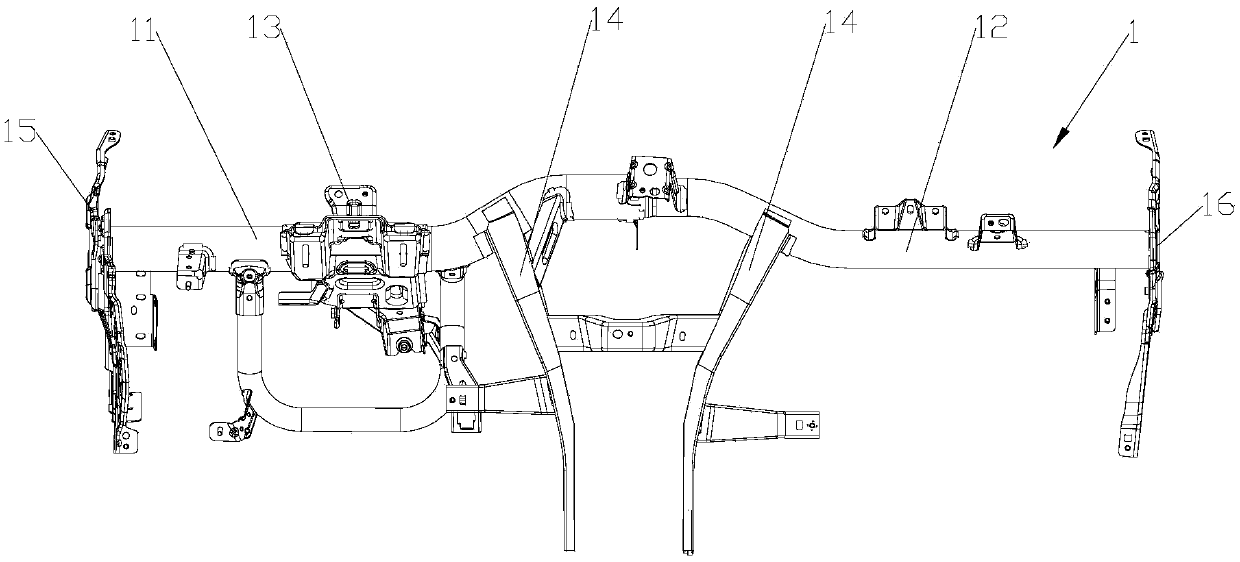

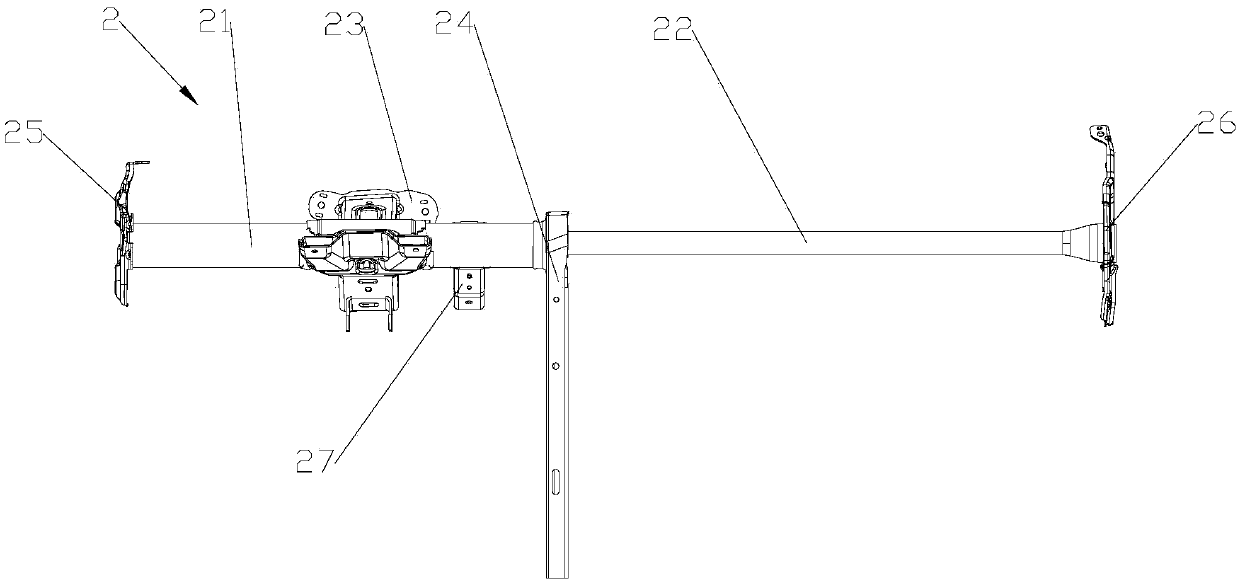

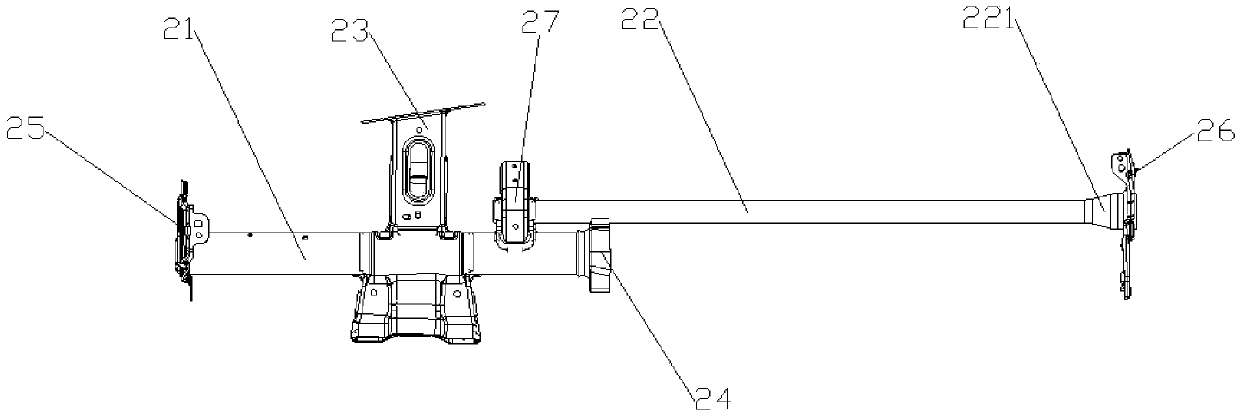

Beam structure and cross car beam assembly

InactiveCN110733577AStructural advantageIncrease stiffnessSuperstructure subunitsStructural engineeringMechanical engineering

The invention relates to the field of vehicle body structures, and provides a beam structure and a cross car beam assembly. The beam structure comprises a first beam body and a second beam body whichare sequentially arranged, wherein the tail end of the first beam body and the head end of the second beam body are staggered and connected through a connector. According to the beam structure disclosed by the invention, the tail end of the first beam body and the head end of the second beam body are staggered and connected through the connector, so that the adjustment of the position of the second beam body relative to the first beam body can be more flexible. In addition, bent beam bodies and expansion and contraction beam bodies are avoided or reduced so as to enable the whole beam structure to be designed in a flat and straight manner, and eliminate the reduction in structural stiffness and strength caused by a bent structure. Moreover, the anti-torsion stiffness of the whole beam structure can be improved by avoiding a same axis, and the overall stiffness of the beam structure is improved.

Owner:GREAT WALL MOTOR CO LTD

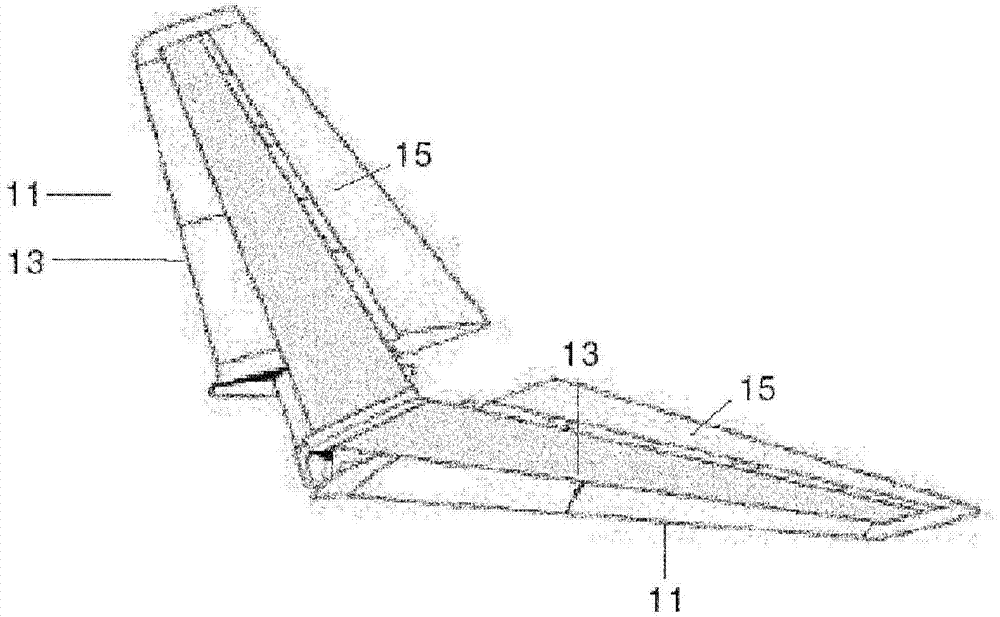

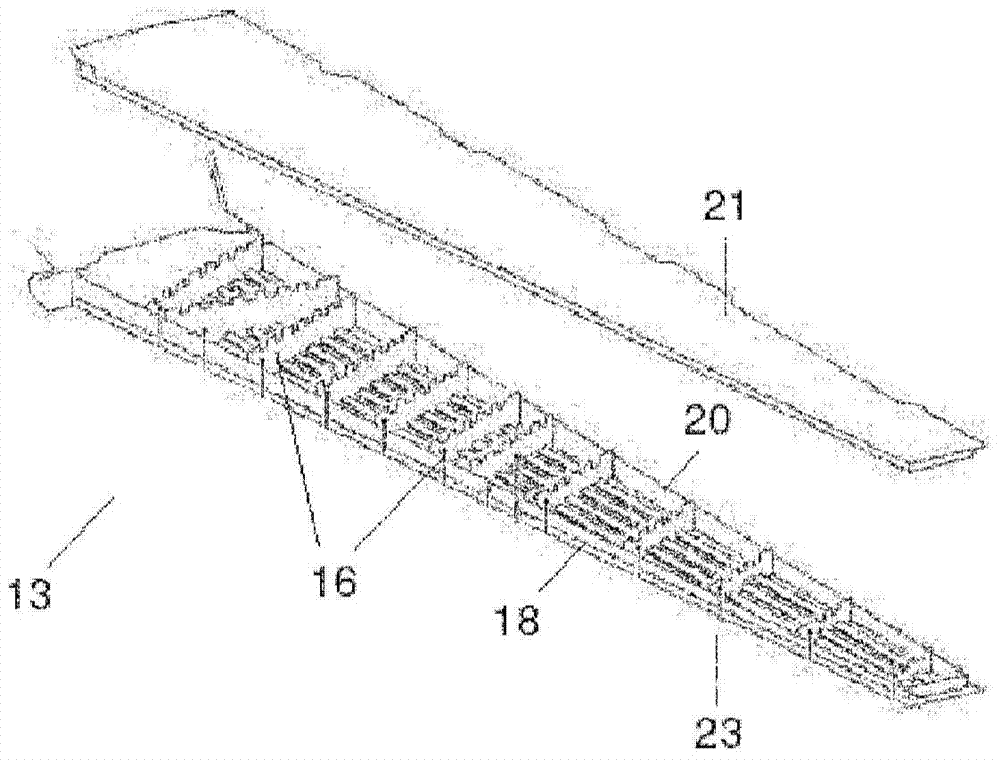

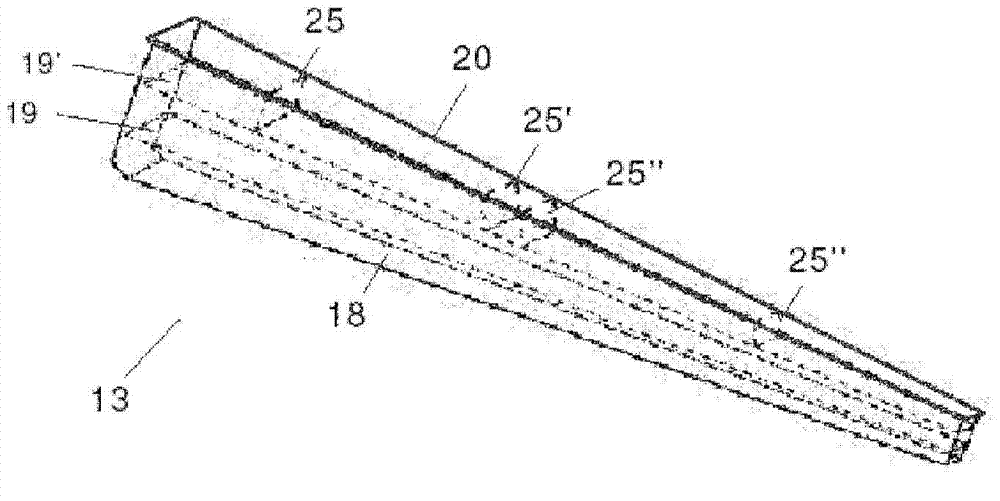

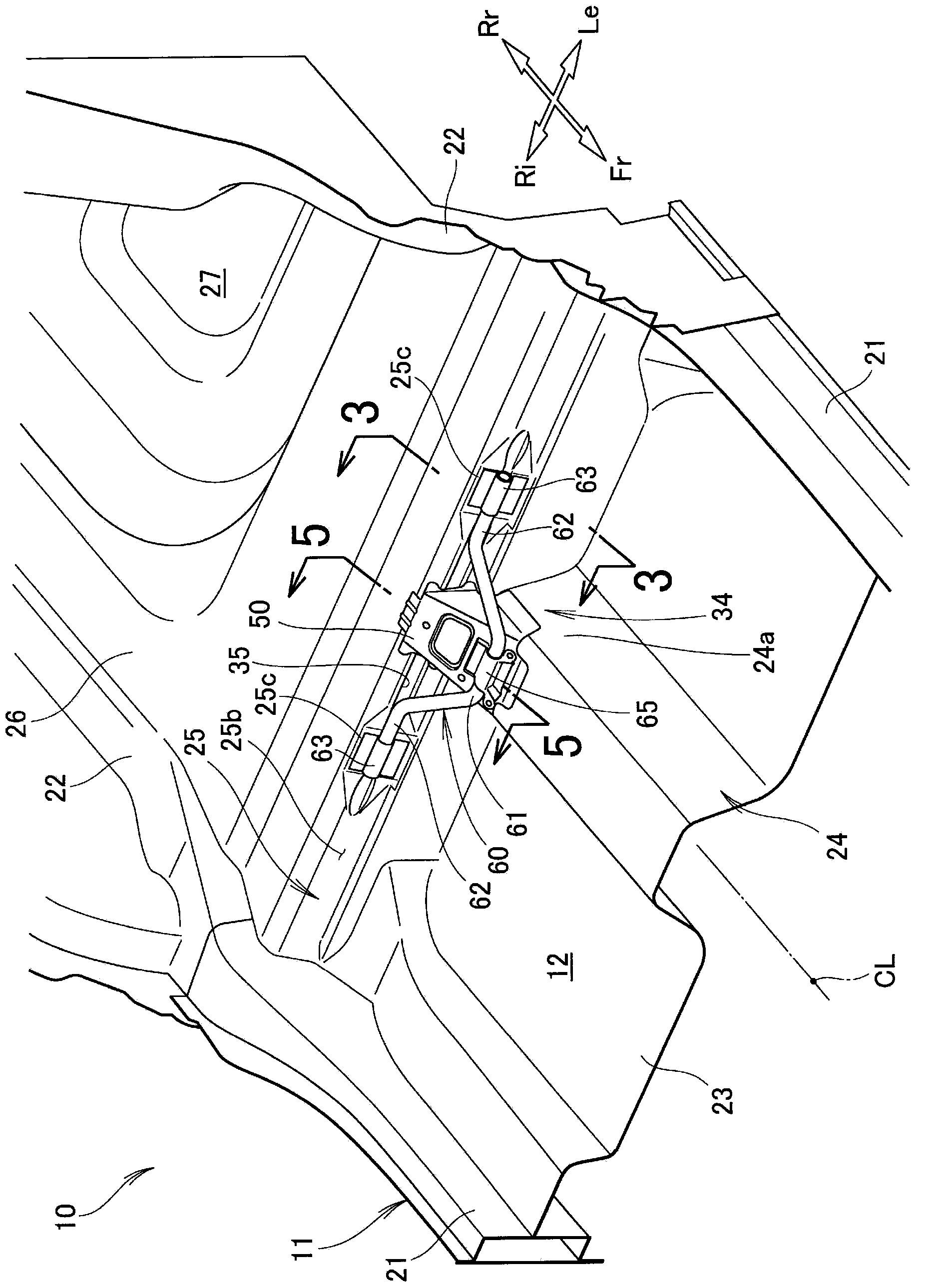

Optimized torsion box for an aircraft

ActiveCN103832574AIncreased torsional rigidityAvoid huge deformationFuselage framesSpars/stringersEngineering

Owner:AIRBUS OPERATIONS SL

Vehicle body structure

ActiveCN104108424AImprove bending rigidityImprove rigidityUnderstructuresSuperstructure subunitsMechanical engineeringEngineering

A vehicle body structure can further improve the rigidity of a rear panel bulk head and a whole vehicle body around the rear panel bulk head. A vehicle body (11) comprises a bottom panel (23), the rear panel bulk head (25) erected at the rear end of the bottom panel, a trunk bottom plate (26) extending rearward from the upper end of the rear panel bulk head and a central channel (24) extending in the front-back direction of the vehicle body. The rear end portion of the central channel is joined to the rear panel bulk head. The rear panel bulk head is provided with a bulk head reinforcing member (60) extending in the vehicle width direction. At least two ends (62, 62) in the vehicle width direction of the bulk head reinforcing member are joined to the rear panel bulk head. The vehicle width center portion (61) of the bulk head reinforcing member is joined to the central channel.

Owner:HONDA MOTOR CO LTD

Improved planetary reducer

InactiveCN108425997ASimple structureWide reduction ratio rangePortable liftingToothed gearingsReduction driveAgricultural engineering

The invention discloses an improved planetary reducer, which comprises a center wheel, a stationary wheel circumferentially arranged along one end of the center wheel, at least one planetary gear mechanism arranged between the stationary wheel and the center wheel, and an output wheel circumferentially arranged at the other end of the center wheel, wherein the planetary gear mechanism comprises aplanetary carrier rotatably arranged on the stationary wheel, a planetary shaft arranged on the planetary carrier, and a planetary gear rotatably arranged on the planetary shaft, and the stationary wheel, the output wheel and the center wheel are coaxially arranged; the axis of the planetary wheel is parallel to the axis of the center wheel, and the planetary gear is meshed with the center wheel,the stationary wheel, and the output wheel; the tooth number of the stationary wheel is different from that of the output wheel. The improved planetary reducer provided by the invention has the advantages of simple structure, low cost and high precision.

Owner:吴永德

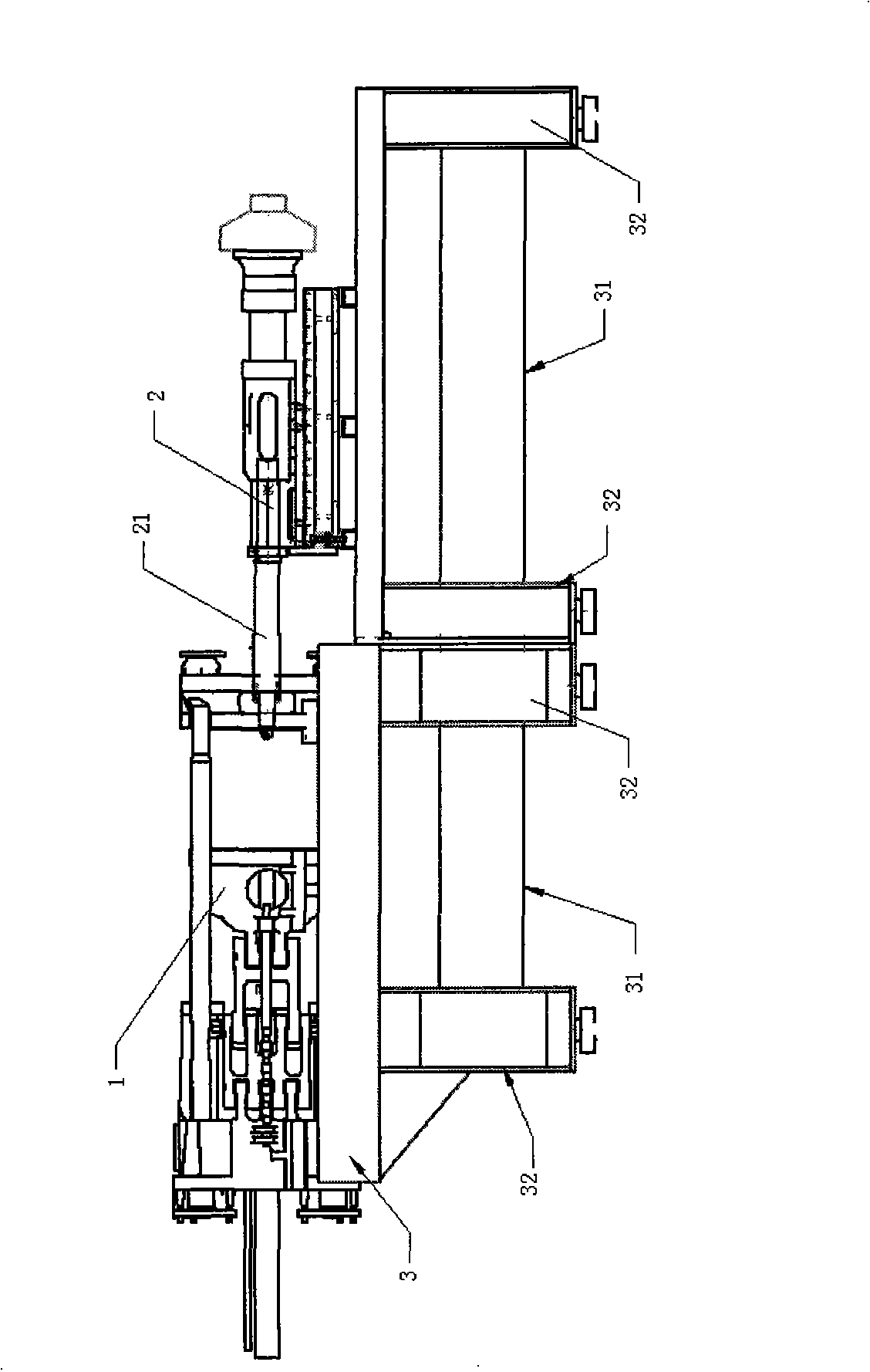

Precise injection machine

The invention discloses a precise injection machine, comprising a mould-closing mechanism and a headstock, wherein the headstock comprises a material tube, a screw, a feeding device and a screw driving device, the mould-closing mechanism and the headstock are arranged on the machine, a torsional deformation resistant round pipe is fixed in the machine, the round pipe penetrates through the machine longitudinally. The invention has the advantage: the motion parts such as the mould-closing mechanism, the ejaculation mechanism and the like have precise stroke, thus the precision is high.

Owner:UNION PLASTIC HANGZHOU MACHINERY +2

Coupling Structure Between Front Pillar And Side Sill Of Automobile

ActiveCN102858622AImprove handling stabilityIncreased torsional rigiditySuperstructure subunitsSuperstructure connectionsCouplingEngineering

Provided is a coupling structure between a front pillar and a side sill of an automobile, in which the handling stability of the automobile is improved while high productivity is also achieved. A reinforcement (8) is arranged so as to extend in a closed section shape of a front pillar (1) in the front-rear direction of an automobile, a reinforcement extension (8a) is formed by coupling the reinforcement (8) to a front pillar outer (2) together with extending the automobile rear-end side of the reinforcement (8) to a side sill (4) side, and the reinforcement extension (8a) is coupled to a side sill outer (5) side.

Owner:UNIPRES CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com