Precise injection machine

An injection molding machine, a precise technology, applied in the field of injection molding machines, can solve the problems of inability to precisely close the mold, unbalanced accuracy of the processing object, and negligible mold clamping, etc., and achieve the effect of precise stroke and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

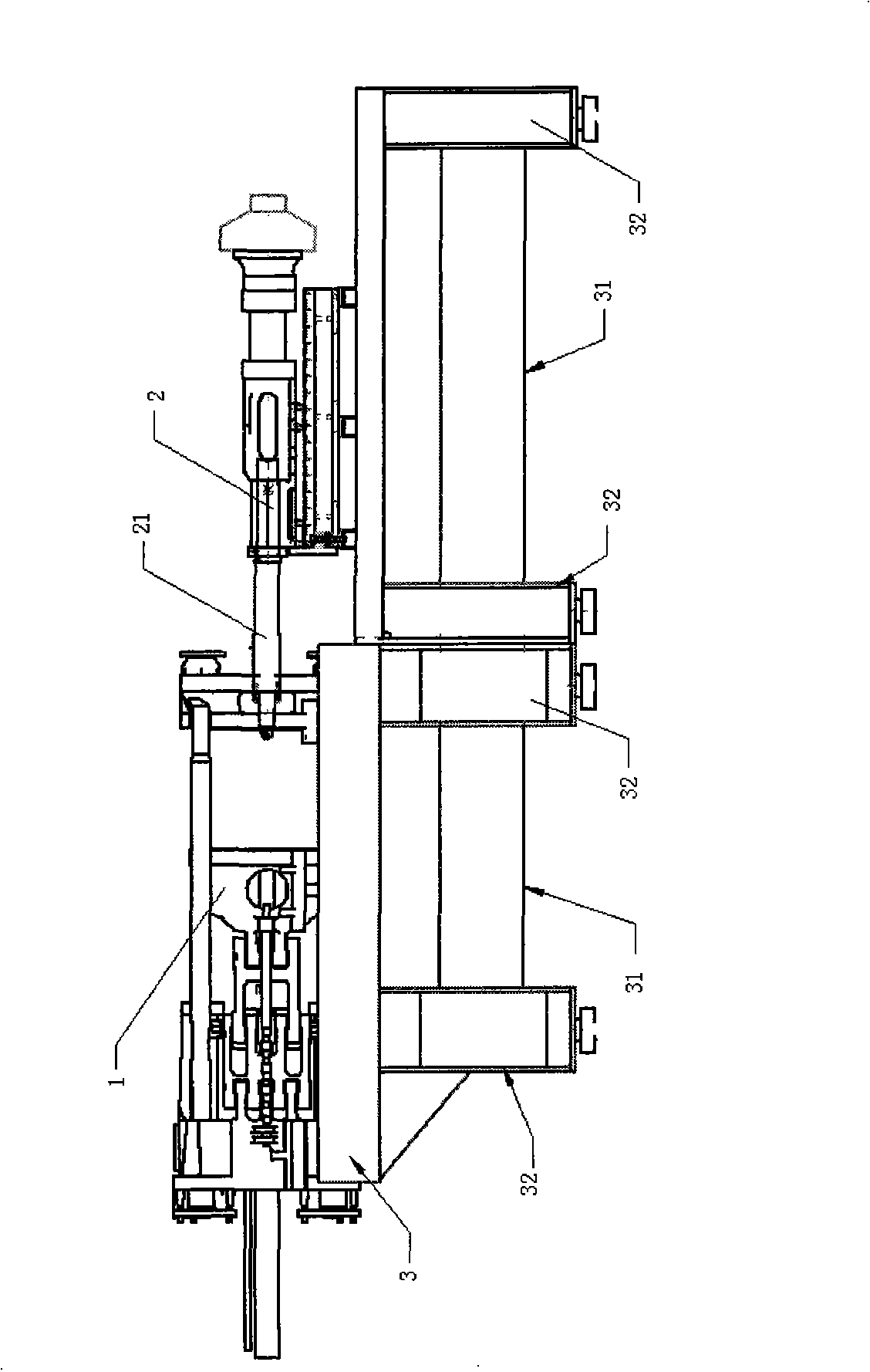

[0014] With reference to accompanying drawing, further illustrate the present invention:

[0015] A precision injection molding machine comprising a mold clamping mechanism 1 and a headstock 2. The headstock 2 includes a material pipe 21, a screw, a feeding device, and a screw driving device. The mold clamping mechanism 1 and the headstock 2 are arranged on a machine platform 3. It is characterized in that: the machine platform 3 is fixed with a circular tube 31 that can resist torsion deformation, and the circular tube 31 runs through the machine platform 3 longitudinally.

[0016] The machine table 3 is composed of two side substrates for supporting the mold clamping mechanism 1 and the headstock 2, and the end seats 32 at the longitudinal ends are connected, and the above-mentioned round pipes are provided between the two end seats 32 31.

[0017] A supporting seat for assisting in fixing the circular pipe 31 is erected on the base plate between the two ends 32 of the mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com