High-lift-to-drag ratio balance applied to low-speed wind tunnel

A technology with high lift-to-drag ratio and balance, which is used in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problems that force-measuring balances are difficult to meet the requirements of high lift-drag ratio and start late, so as to improve measurement accuracy and anti-interference. ability, improve torsional stiffness, and improve the effect of test ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

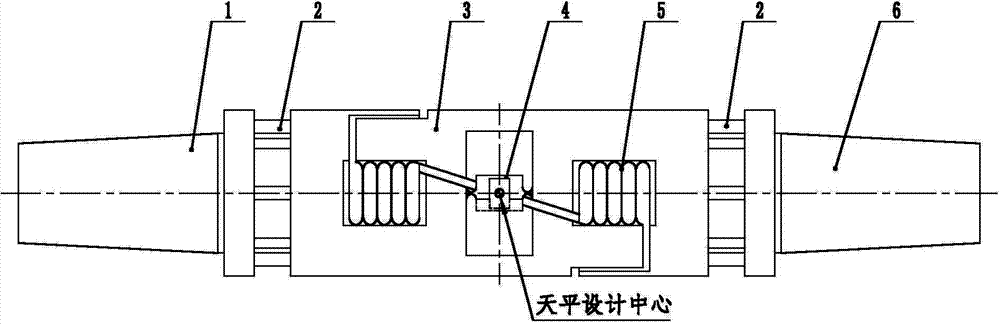

[0021] According to the distribution characteristics of the aerodynamic force of the UAV with a large aspect ratio, the resistance (X) and lateral force (Z) in the design load of the balance are small, and the lift (Y), rolling moment (Mx) and pitching moment (Mz) Larger, according to traditional design principles, the design load of the balance does not match. In order to solve the above problems, the present invention utilizes the antisymmetric arrangement The structure of the shape resistance measuring element and the flexible hinge is used to amplify the resistance output signal and reduce the interference of other components on the resistance. The eight-column beam combined force measuring element is used to replace the traditional four-column beam combined force measuring element, and the torsional stiffness is increased while the lateral bending stiffness is reduced, so as to ensure that the lateral force of the balance has a larger output signal and a smaller output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com