Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Increase chip removal space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

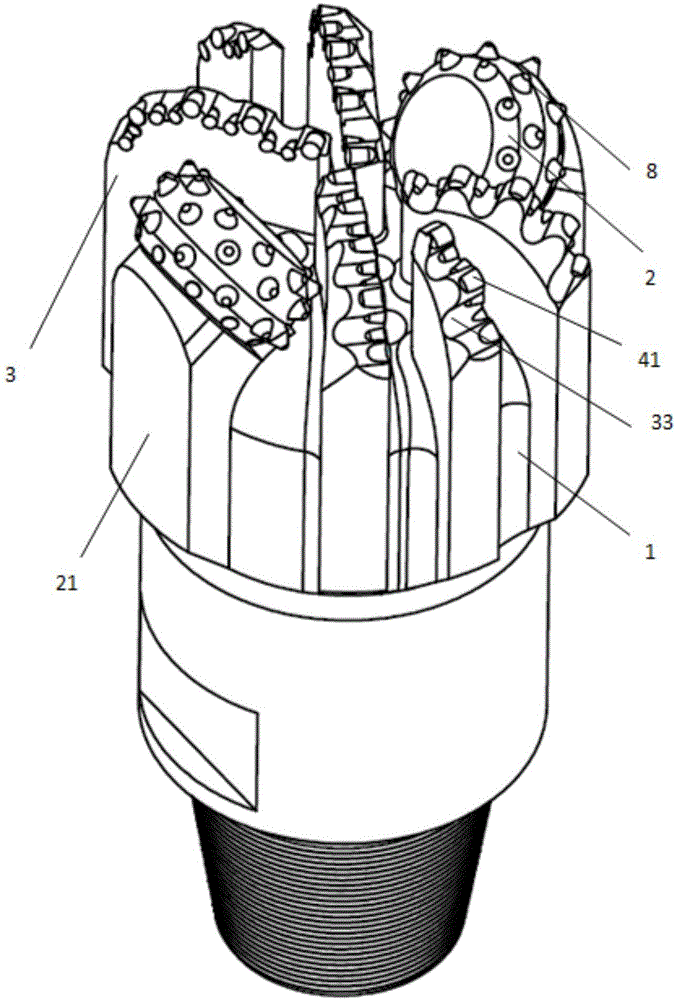

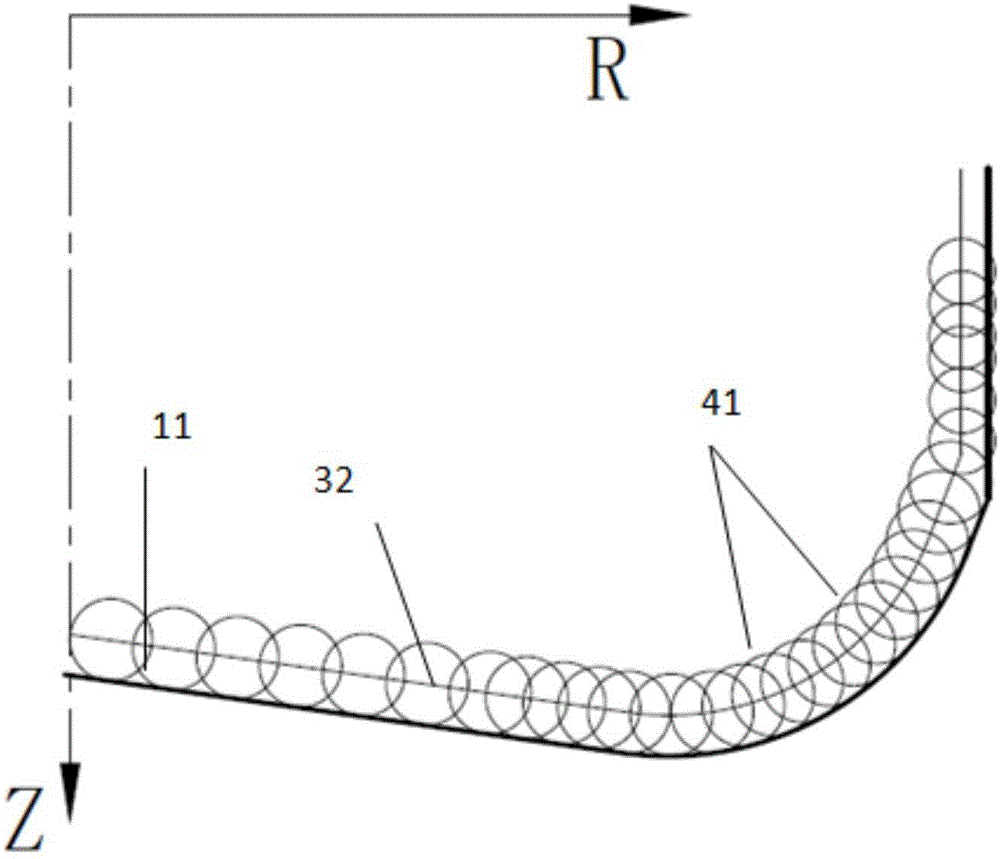

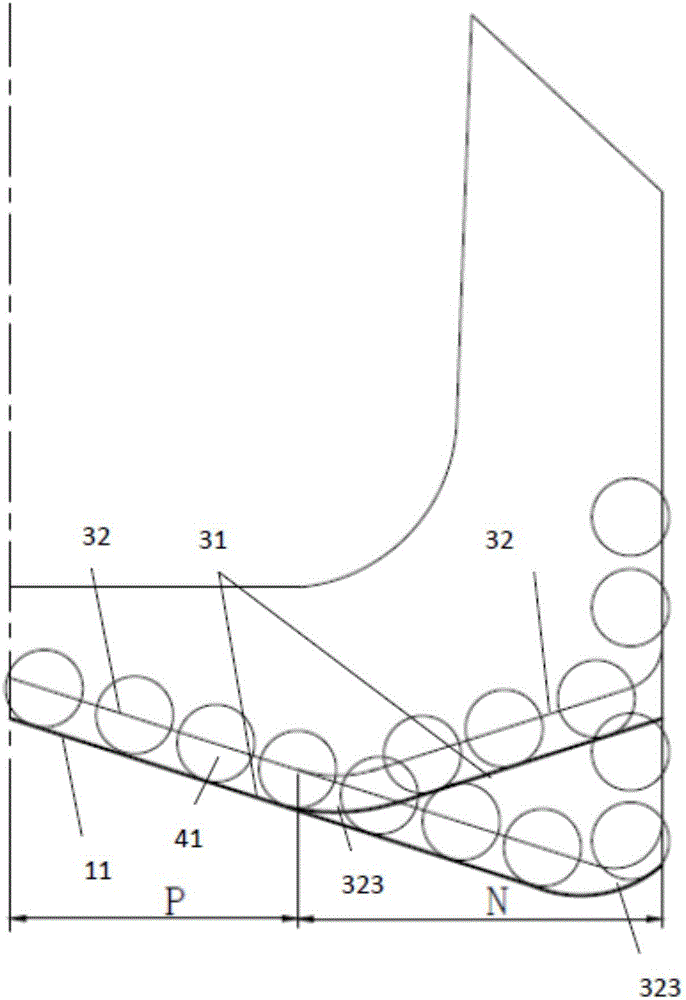

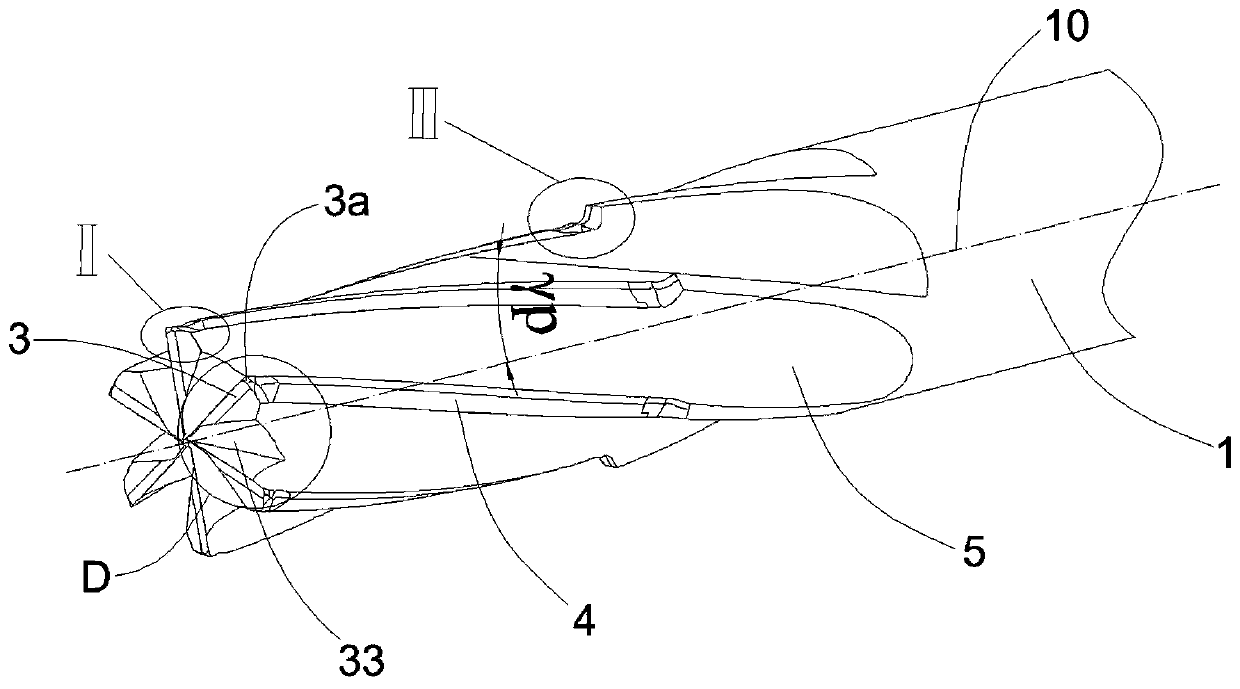

Composite drill bit suitable for stratum difficult to drill

ActiveCN106437525AAdjust the tooth densityIncreased axial wear volumeDrill bitsConstructionsDrill bitPetroleum engineering

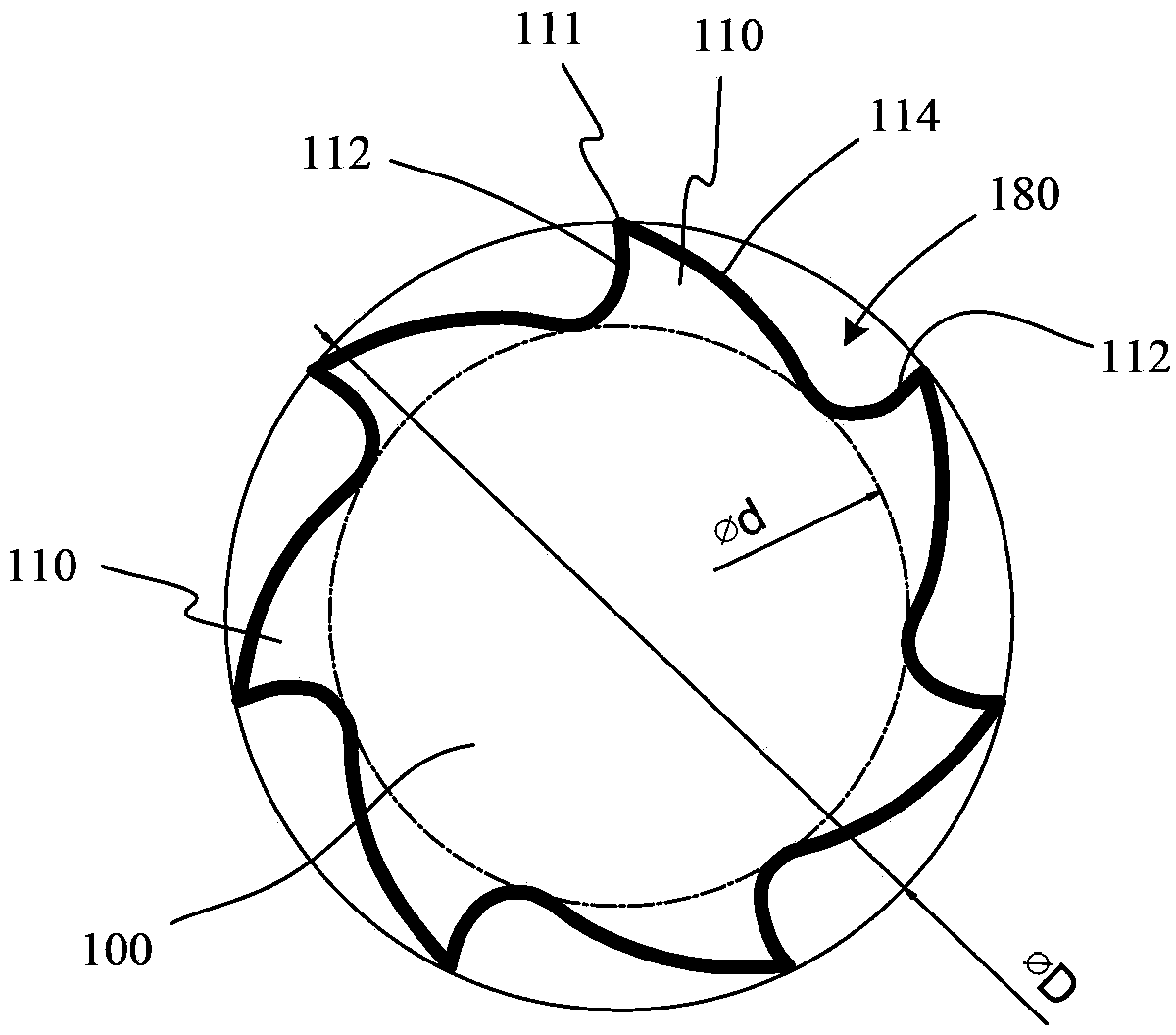

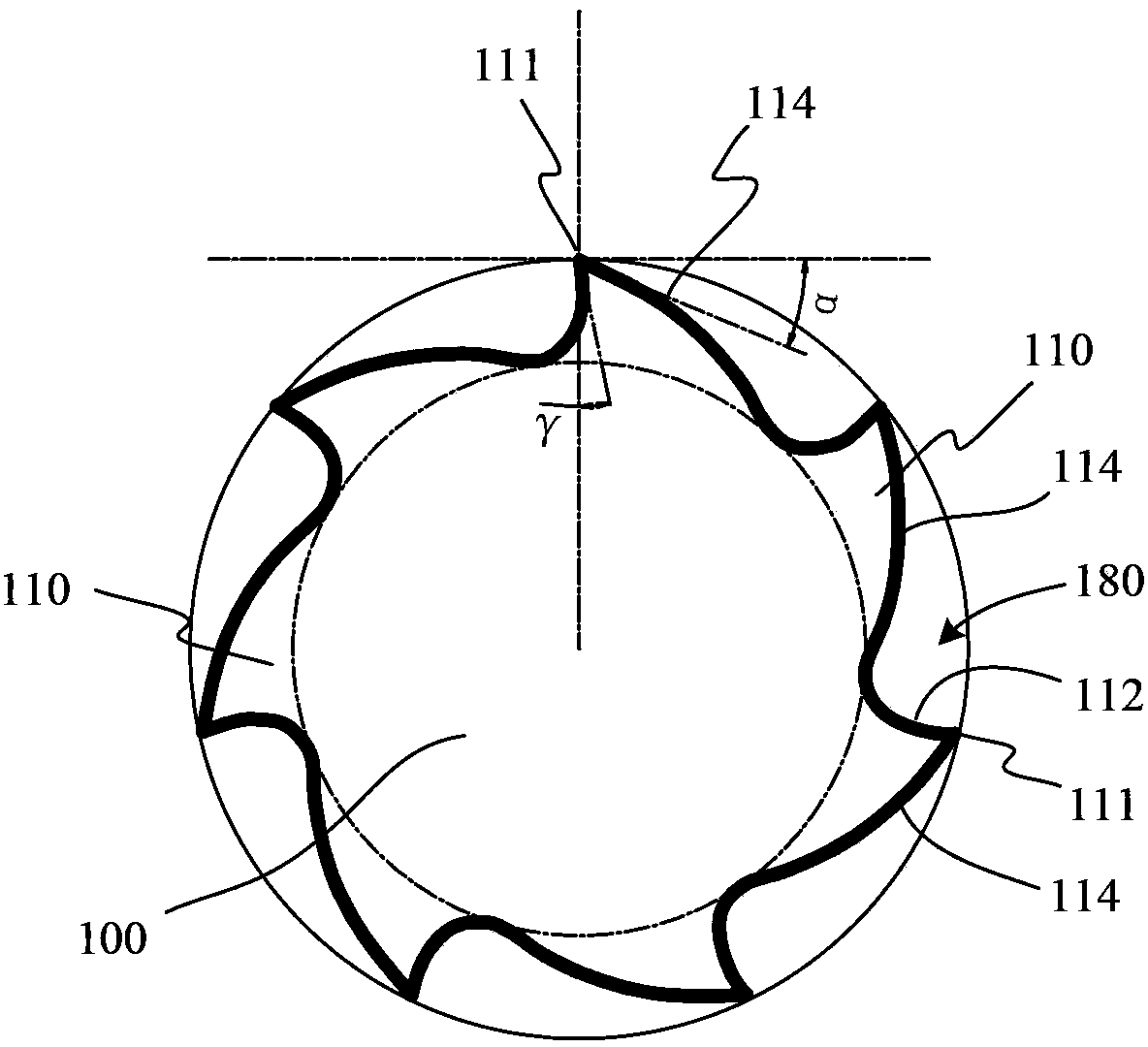

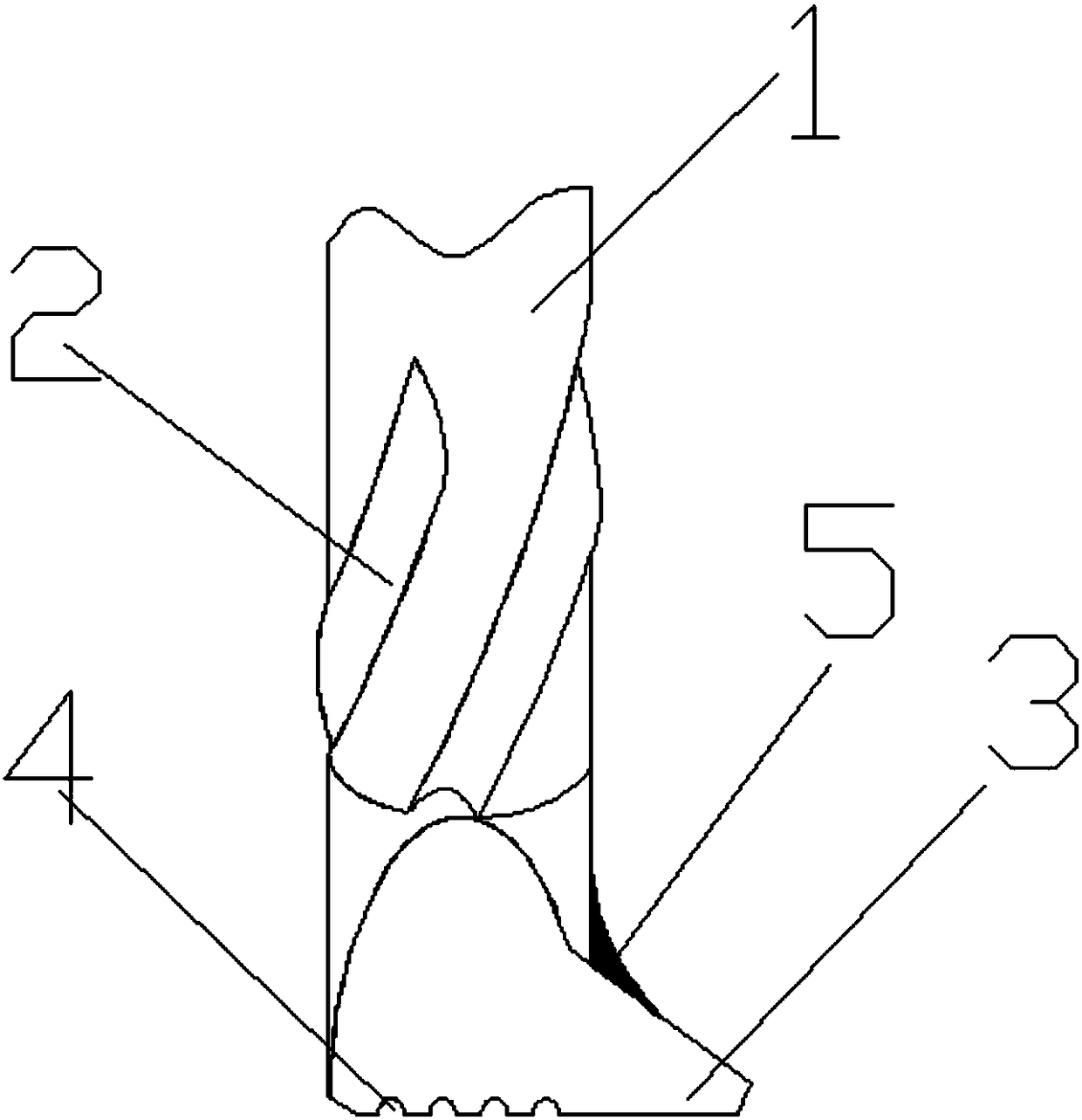

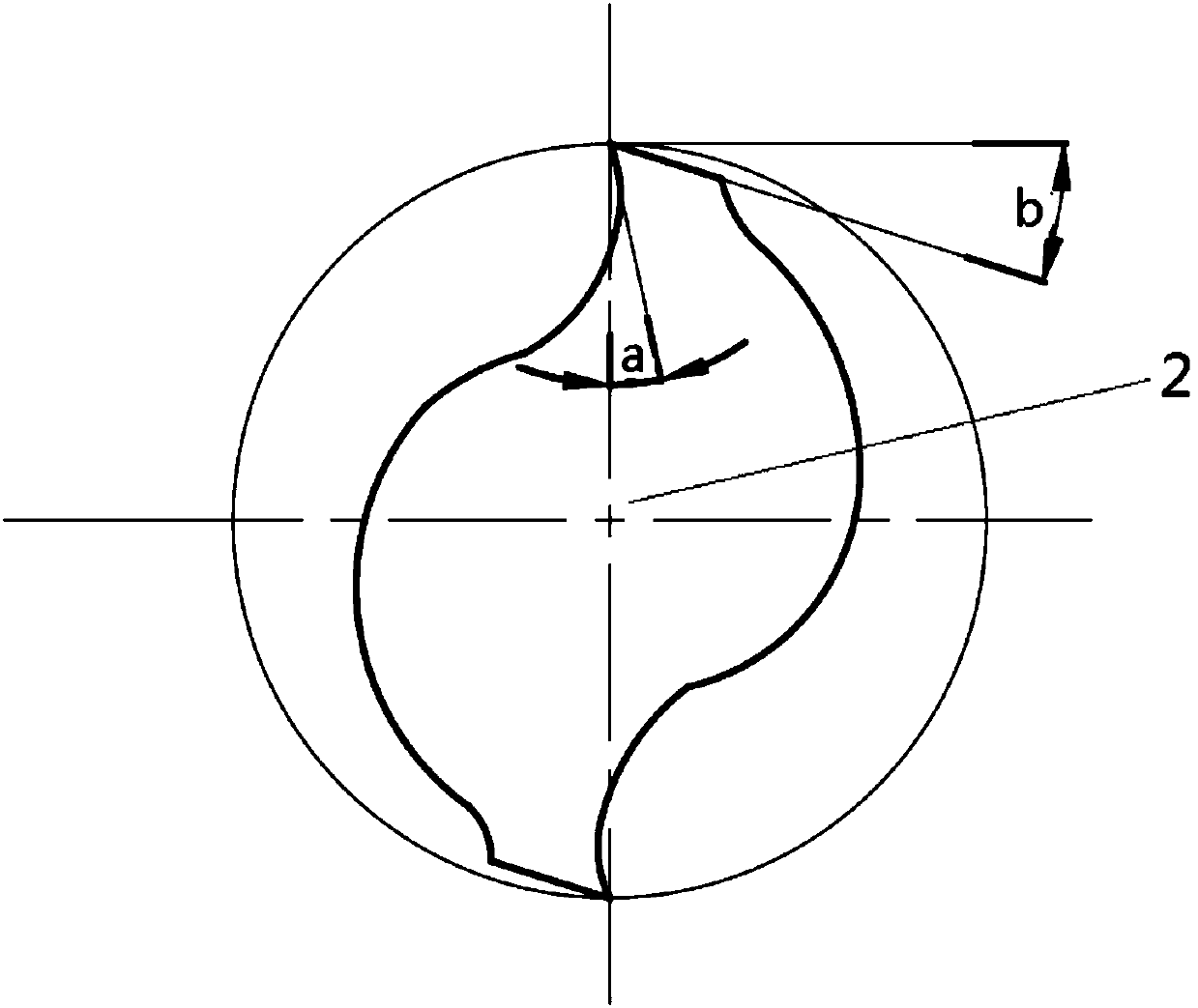

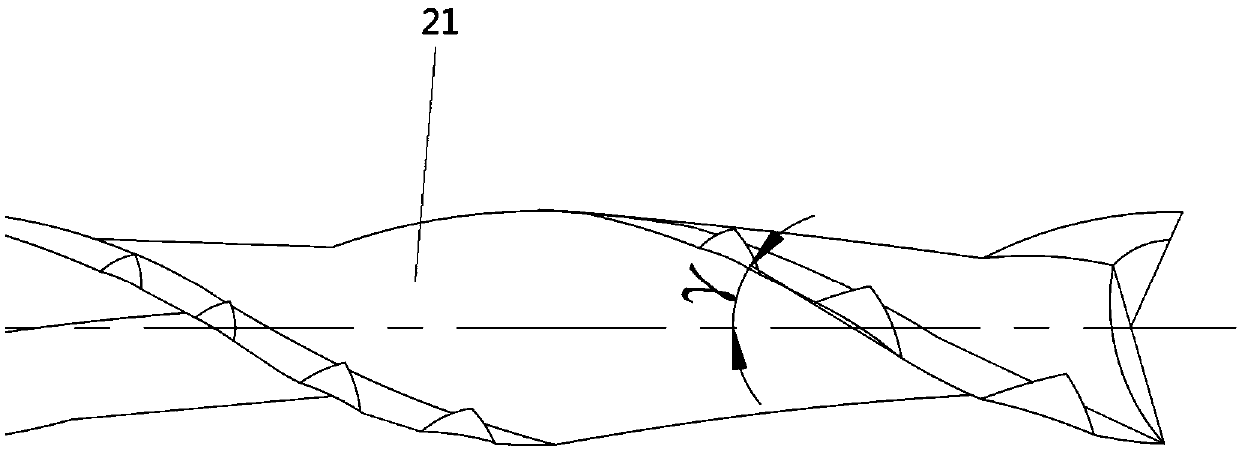

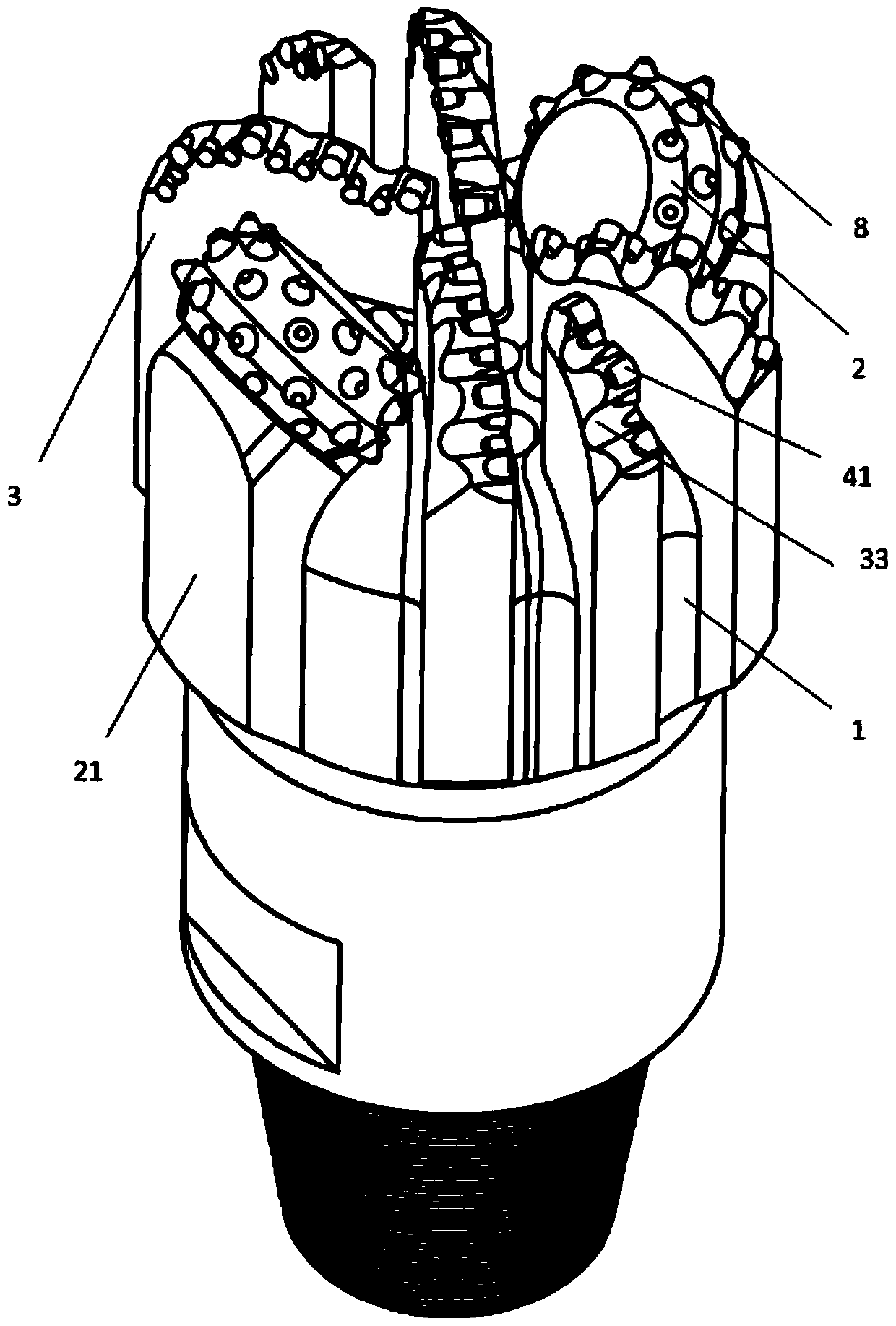

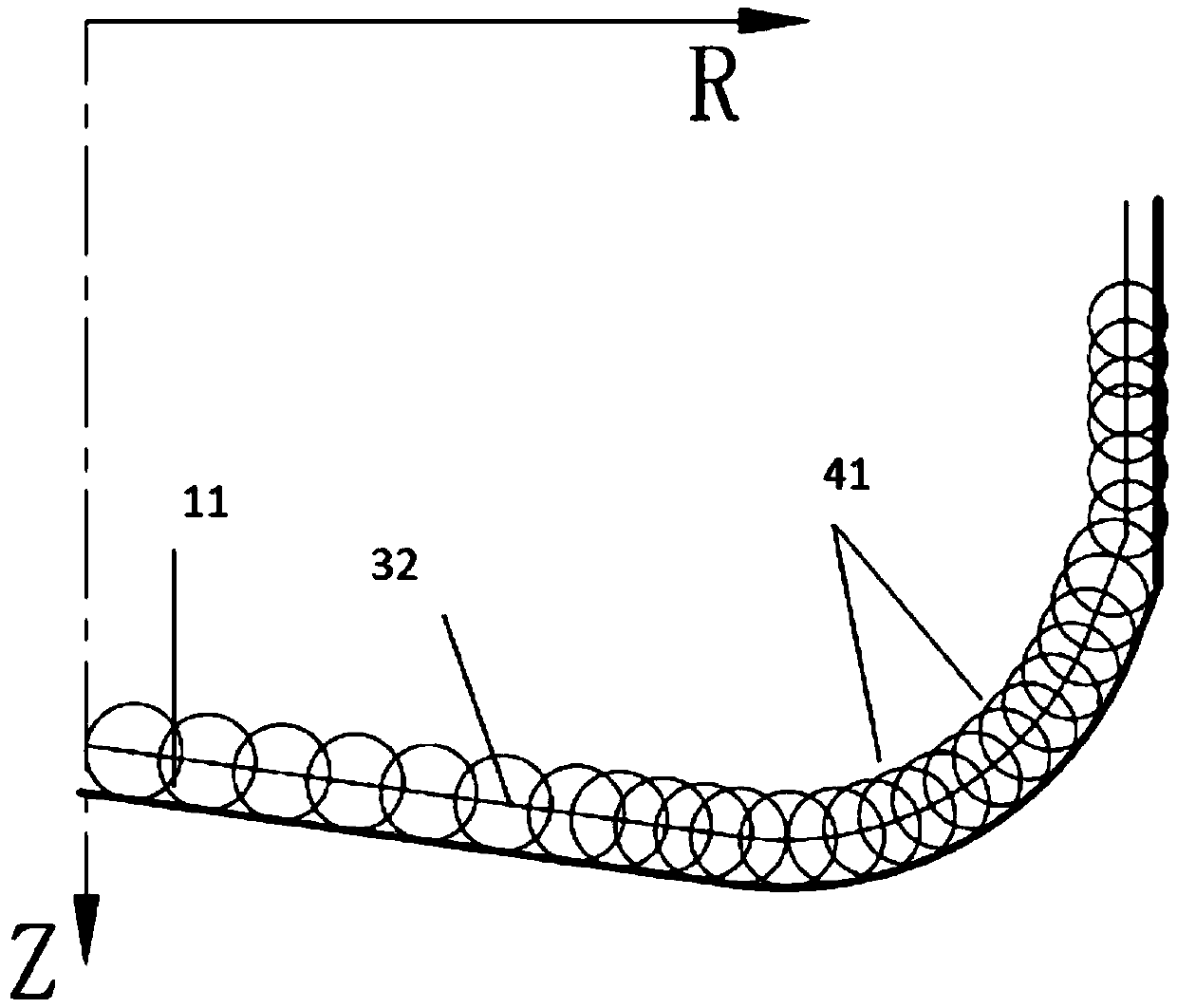

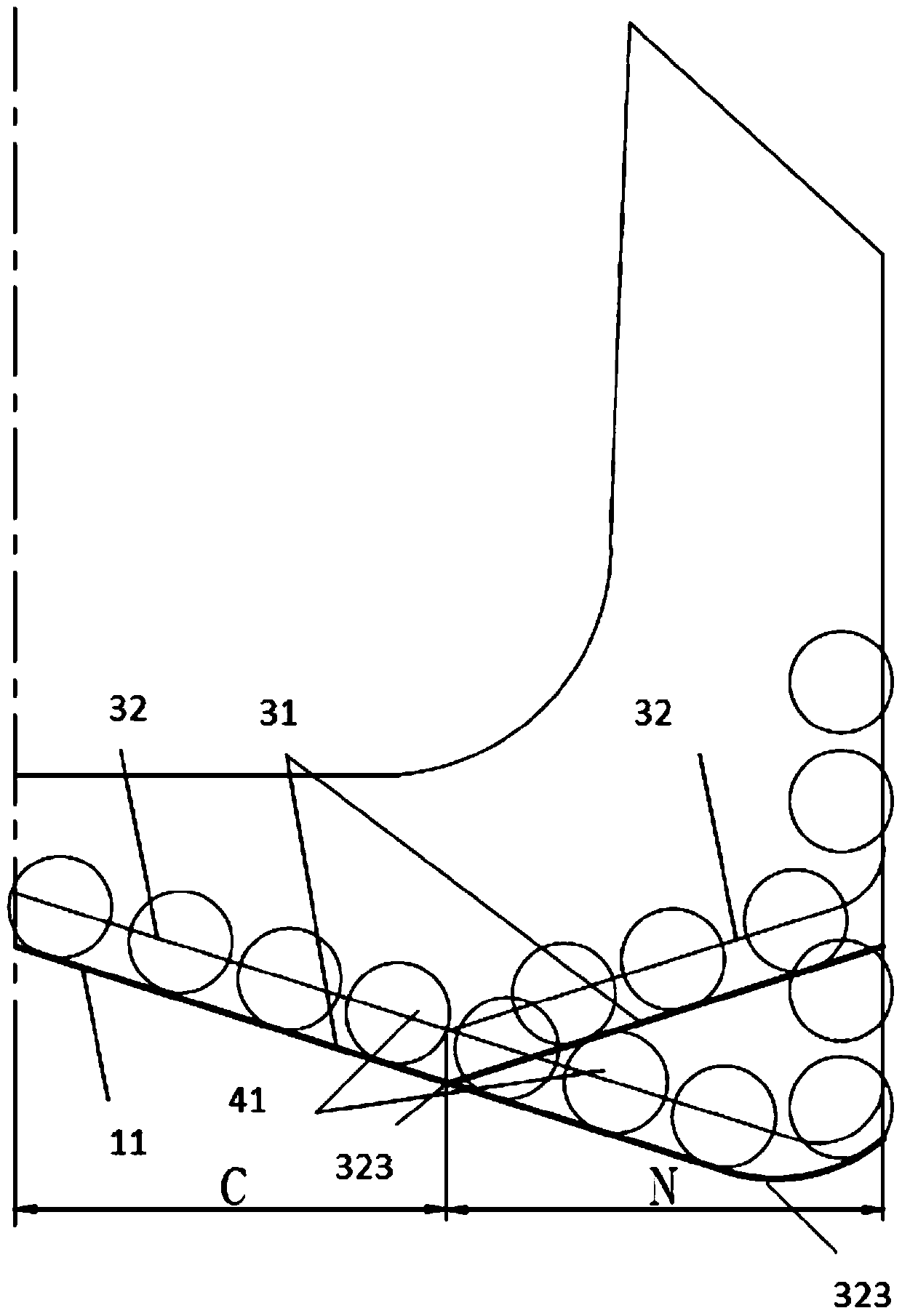

The invention discloses a composite drill bit suitable for a stratum difficult to drill. The composite drill bit suitable for the stratum difficult to drill comprises a drill bit body, cutter wings which are fixedly connected with the drill bit body, tooth wheels which are rotatably connected with the drill bit body, and water holes or nozzles which are arranged on the drill bit body. A plurality of first sets of cutting teeth are arranged on each cutter wing. Pits are formed in the sides, provided with the teeth, of the cutter wings and used for fixing the first sets of cutting teeth. The tooth wheels are rotatably connected with the drill bit body through tooth palms. Teeth are mounted on the tooth wheels. In the common coverage area of the body contour line of at least one cutter wing and the body contour line of at least another cutter wing, at least one non-overlapping area and at least one overlapping point or overlapping area exist. Through the structure characteristic, the drill bit can operate in an asynchronous cutting mode, the longitudinal abrasion length of the drill bit can be increased, and the service life of the drill bit can be prolonged; and the drill bit is in a high-specific-pressure drilling state in the whole drilling process, the capacity to intrude into rocks of the drill bit is improved, the drilling speed of the drill bit in the stratum difficult to drill is increased accordingly, and the service life of the drill bit in the stratum difficult to drill is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +1

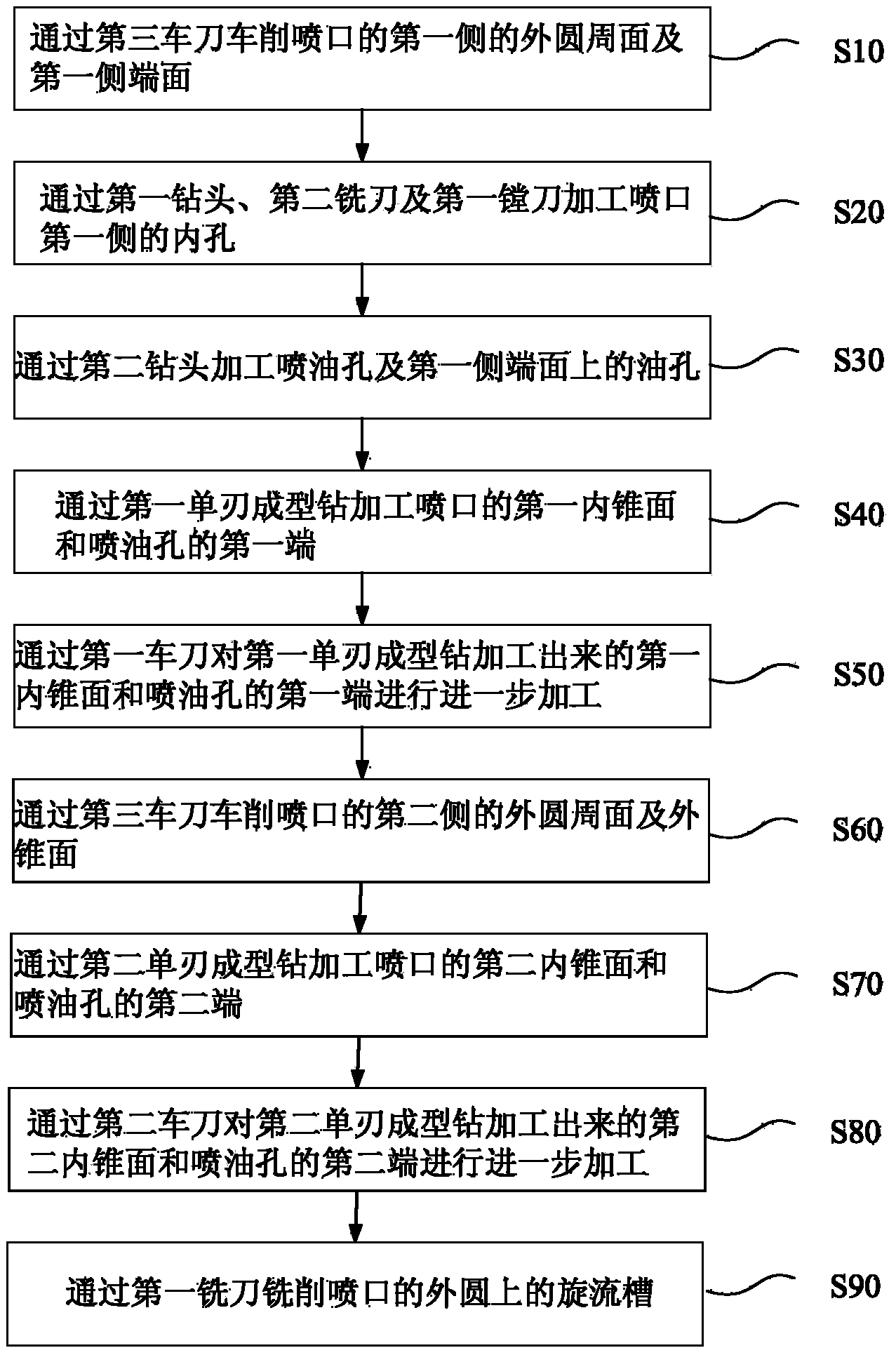

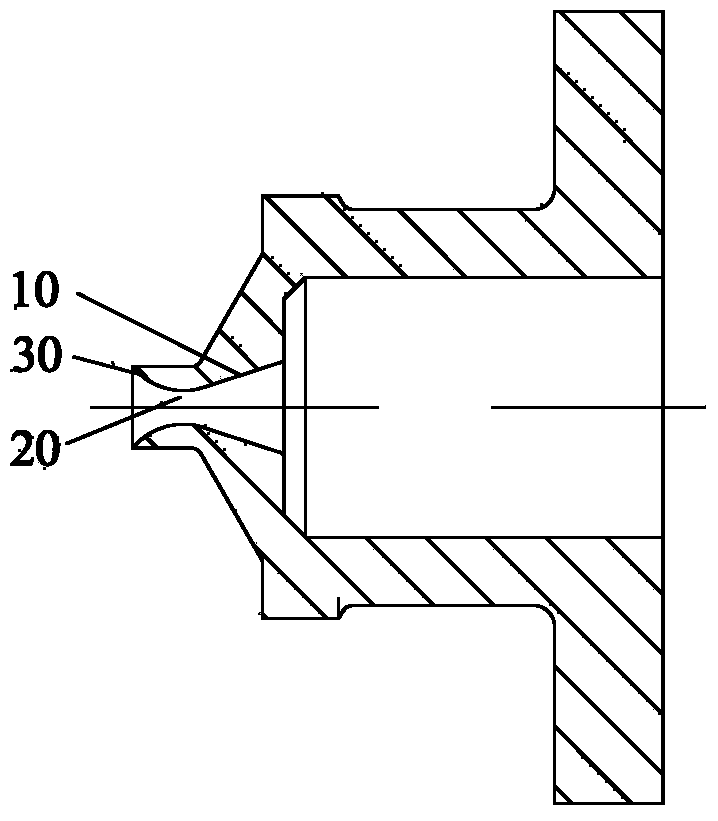

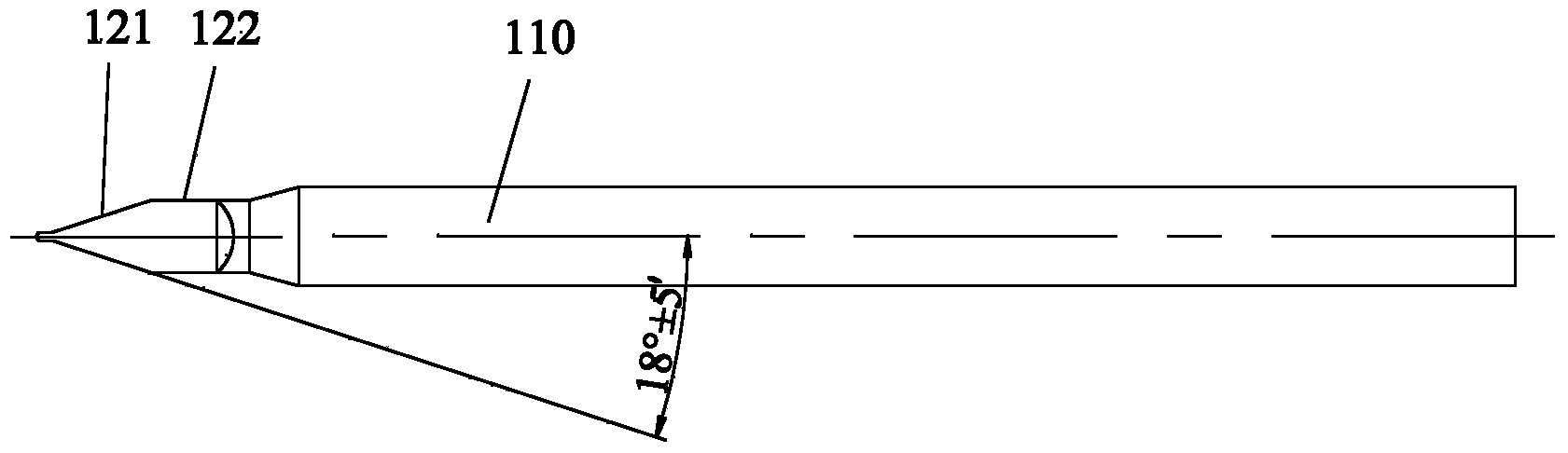

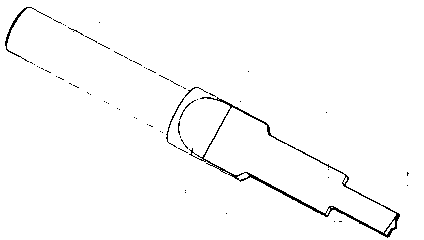

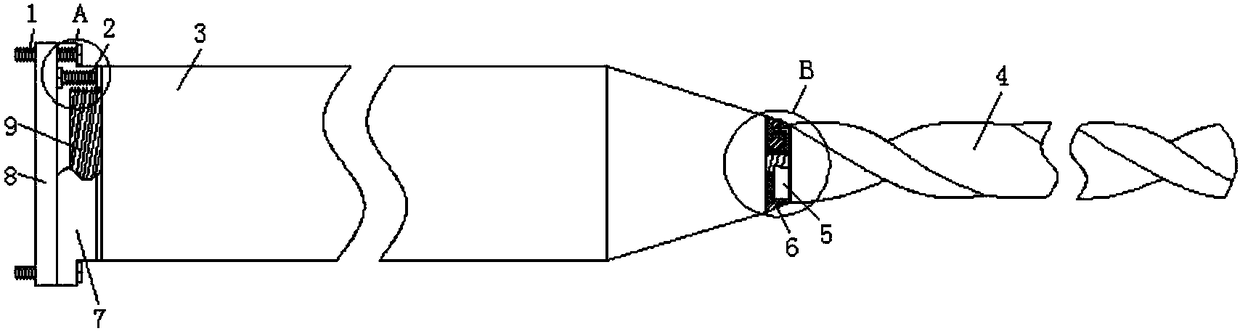

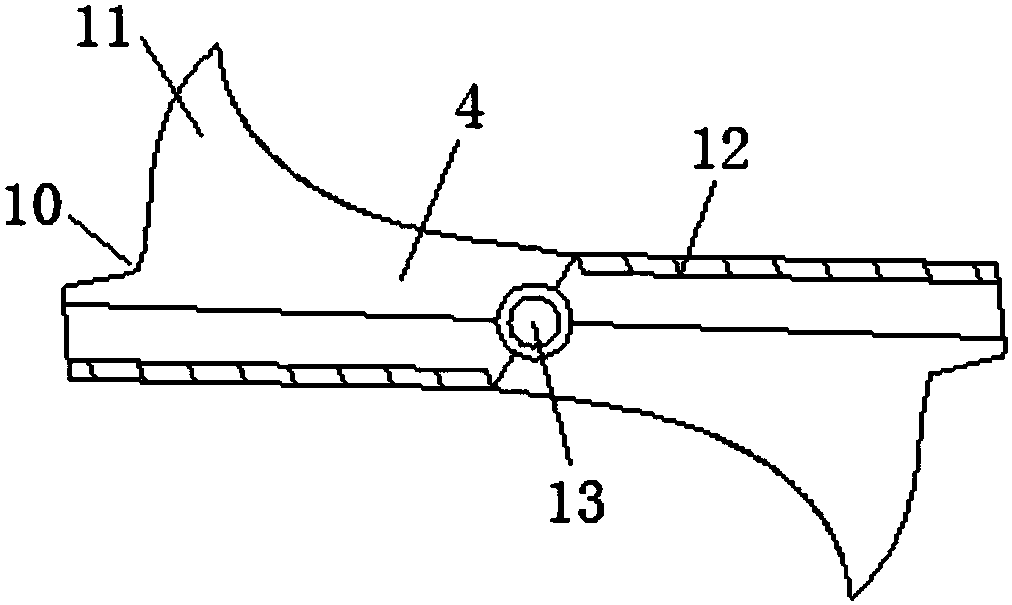

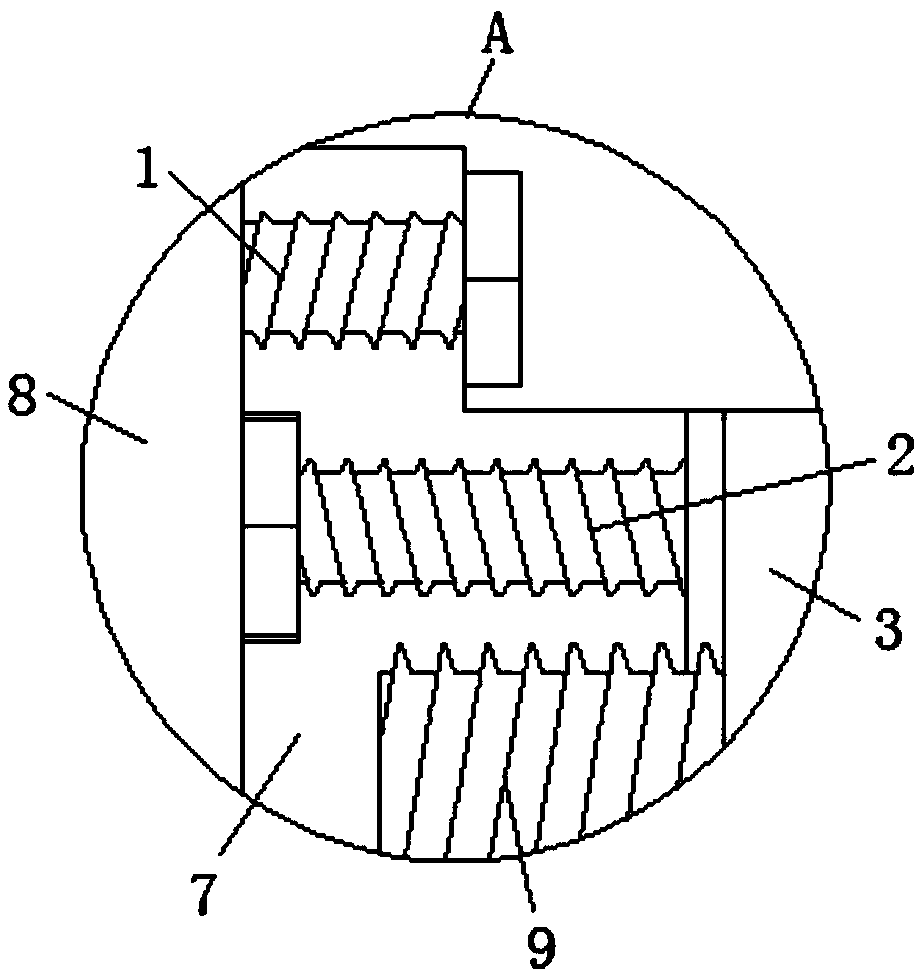

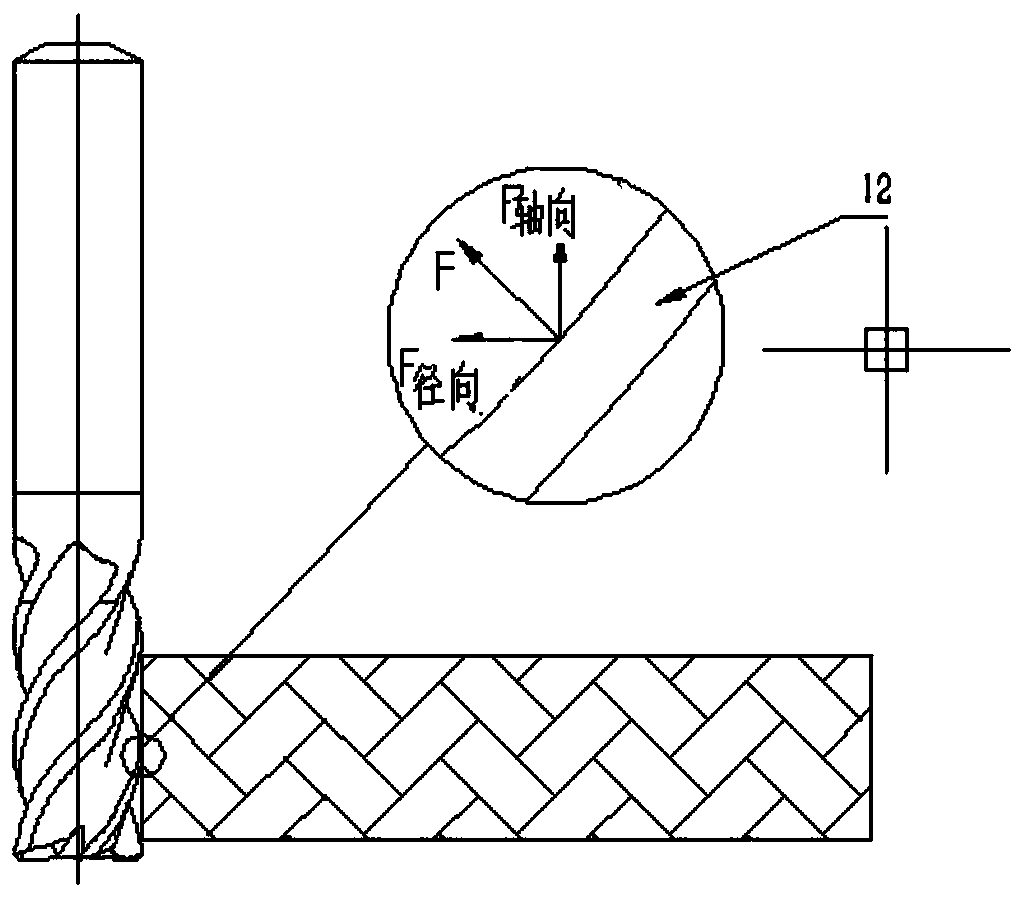

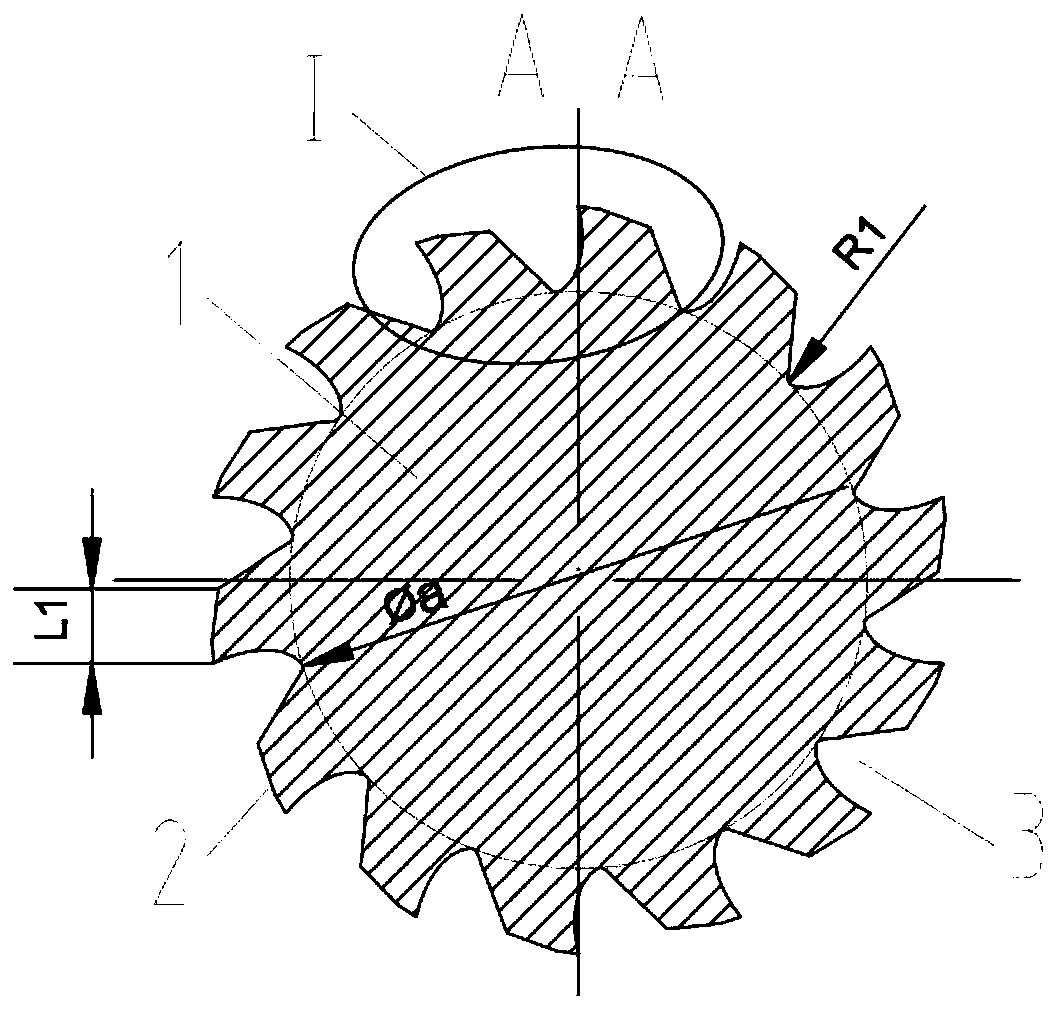

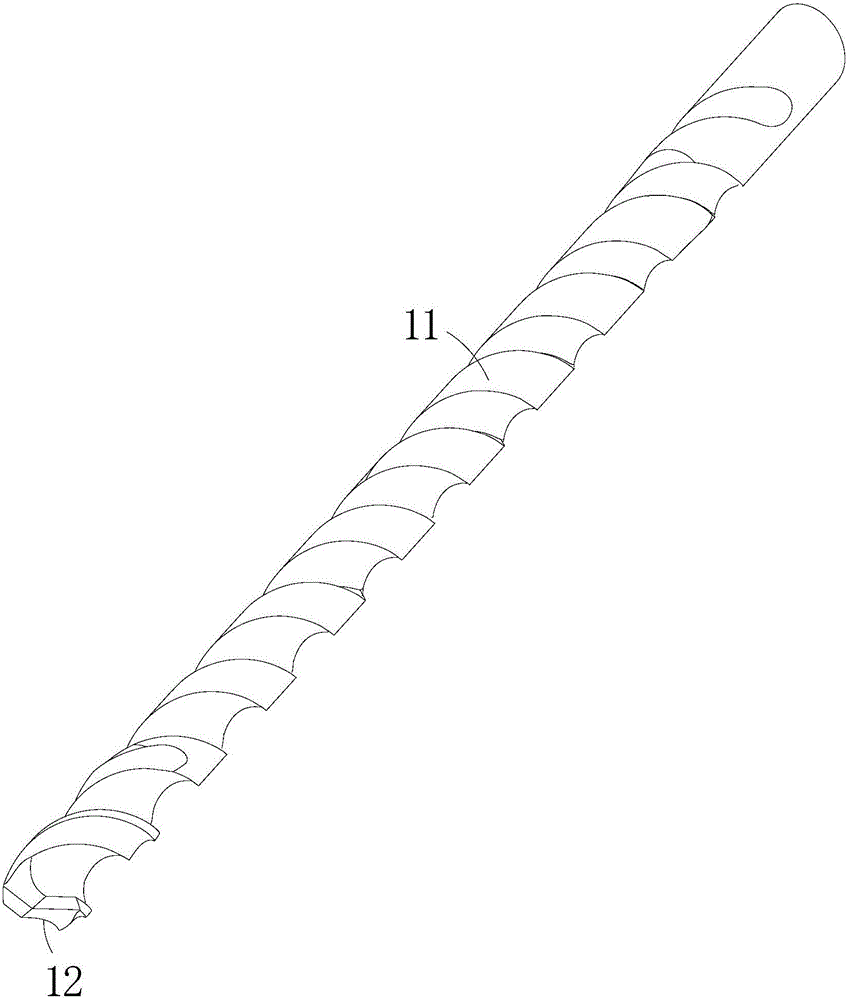

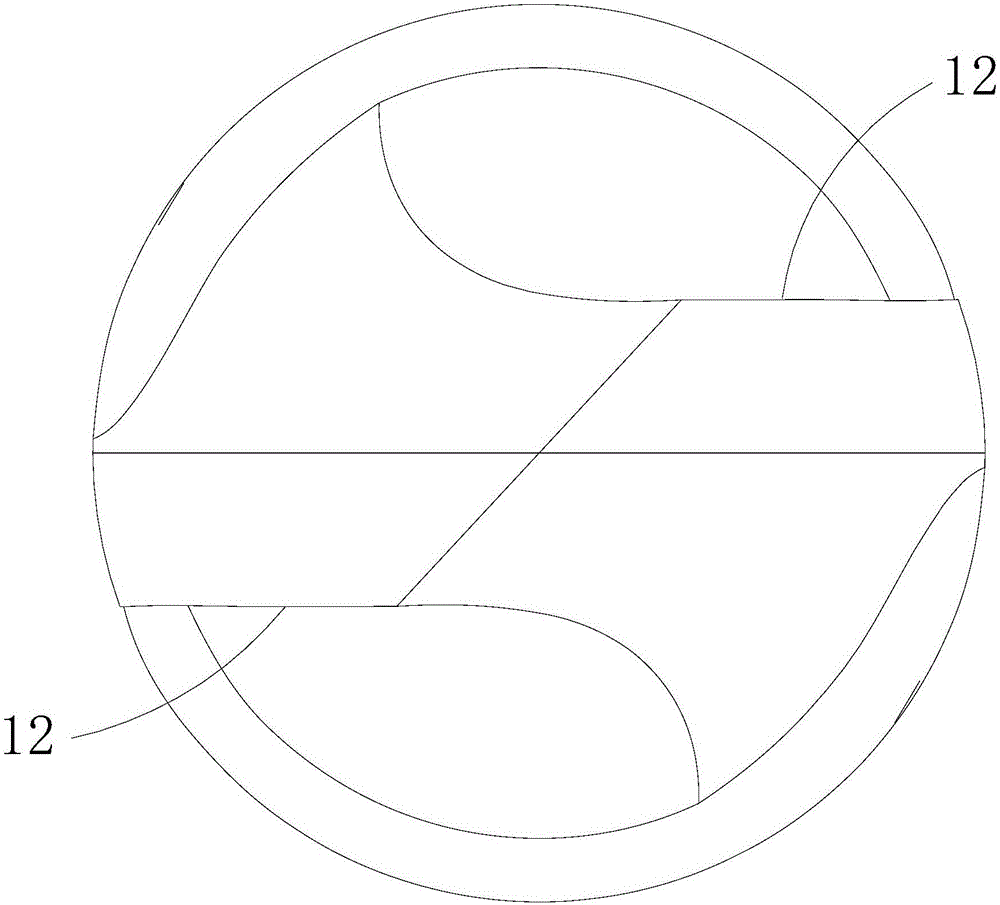

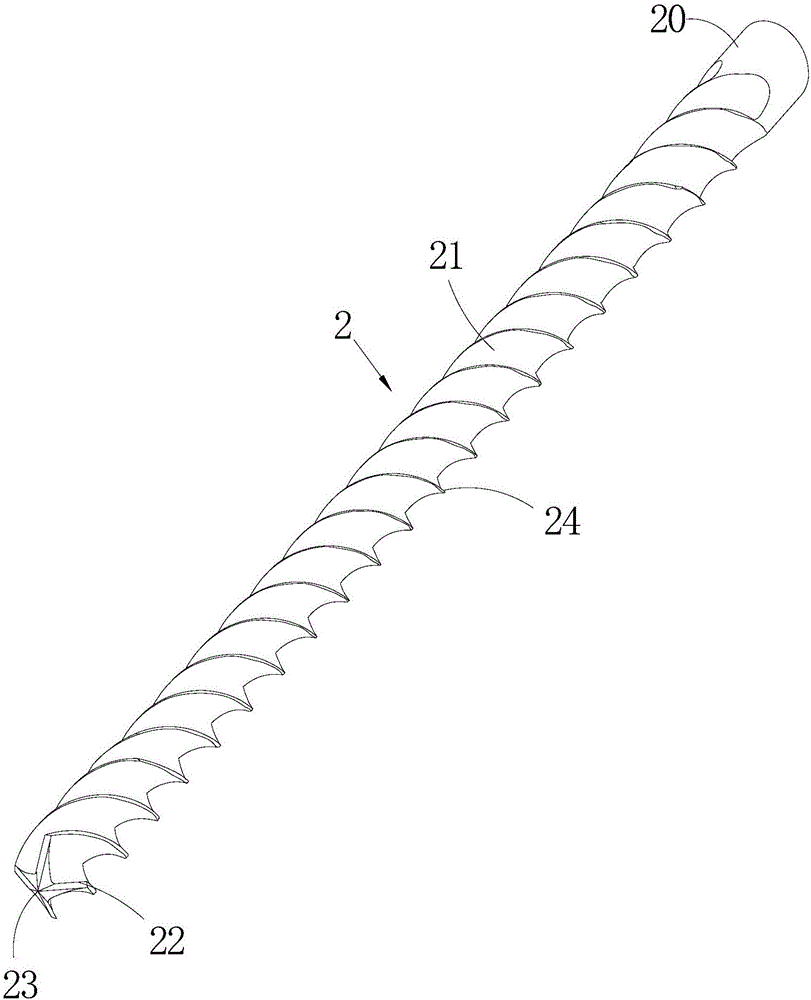

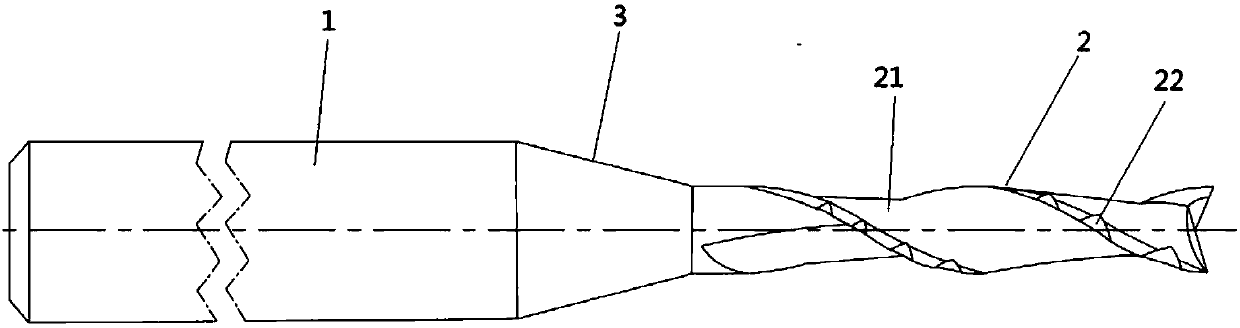

Machining method and machining device of jet nozzle

ActiveCN103586636AIncrease chip removal spaceImprove cooling effectTransportation and packagingMilling cuttersFistEngineering

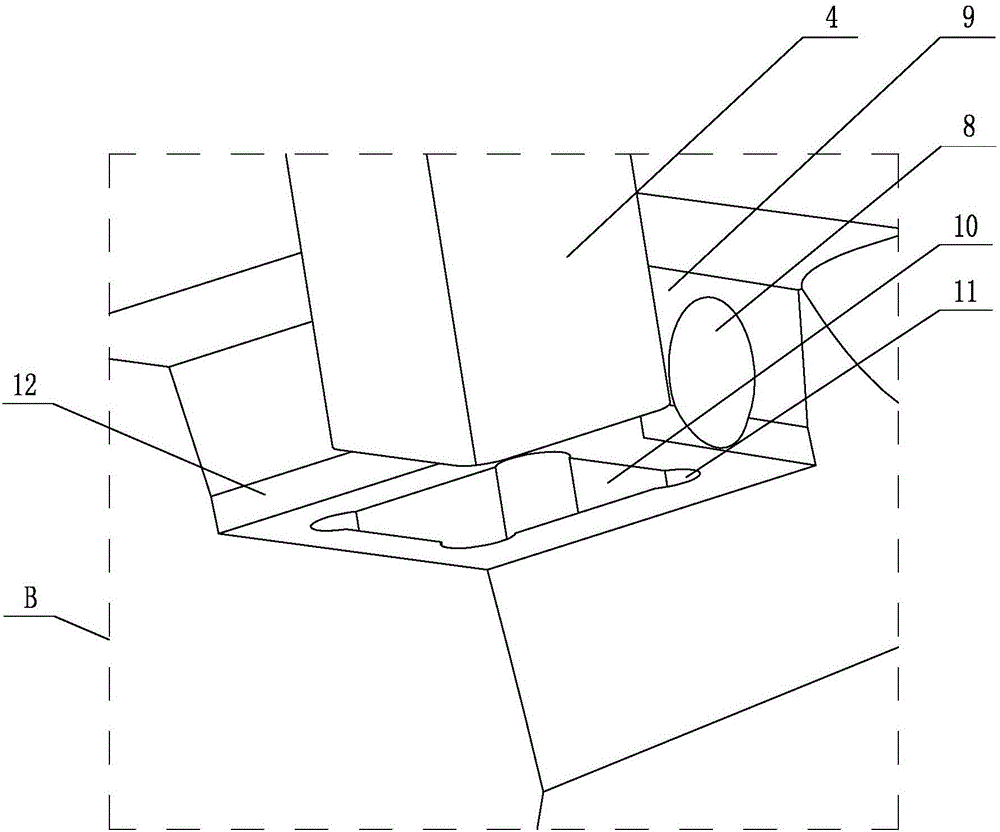

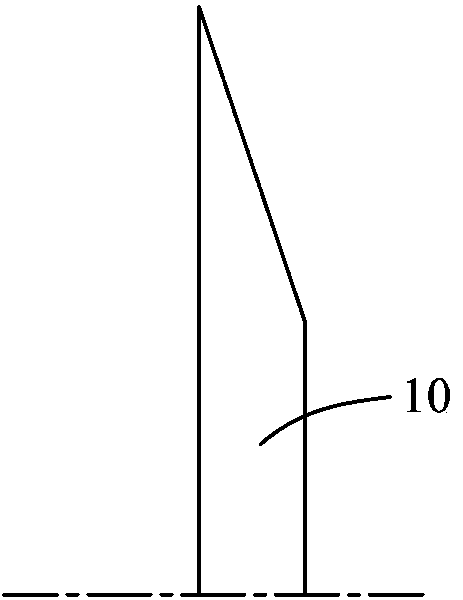

The invention provides a machining method and a machining device of a jet nozzle. The machining method of the jet nozzle comprises the following steps that S40, the first end of a first inner conical surface (10) and the first end of an oil jet hole (20) of the jet nozzle are machined through a first single-blade forming drill; S70, the second end of a second inner conical surface (30) and the second end of the oil jet hole (20) of the jet nozzle are machined through a second single-blade forming drill; the first single-blade forming drill and the second single-blade forming drill respectively comprise a first cutter handle (110) and a first cutter head (120), each first cutter head (120) comprises a first conical section (121), each first conical section (121) is gradually contacted and extends outwards, a first cutting surface (1211) is formed on each first conical section (121) and provided with a fist scrap discharging portion, and one of two edges of each first cutting surface (1211) forms a cutting blade. According to the technical scheme, the machining method and the machining device effectively solve the problem that the inner conical surfaces of the jet nozzle are difficult to machine in the prior art.

Owner:CHINA HANGFA SOUTH IND CO LTD

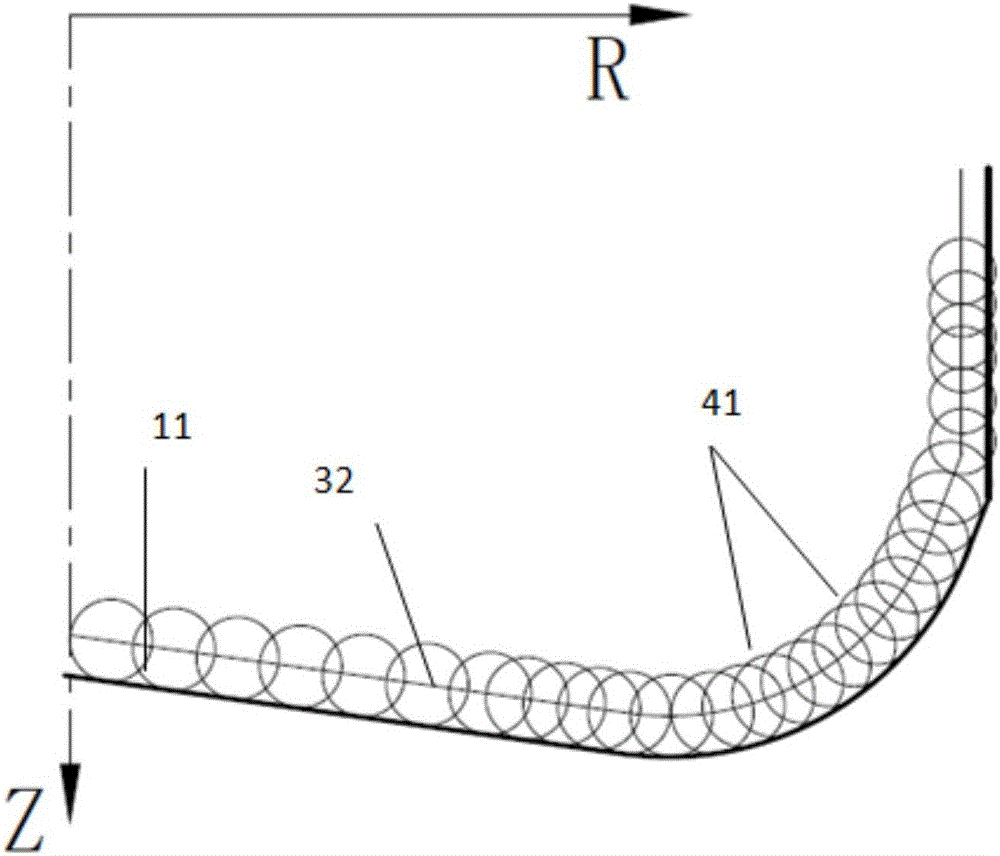

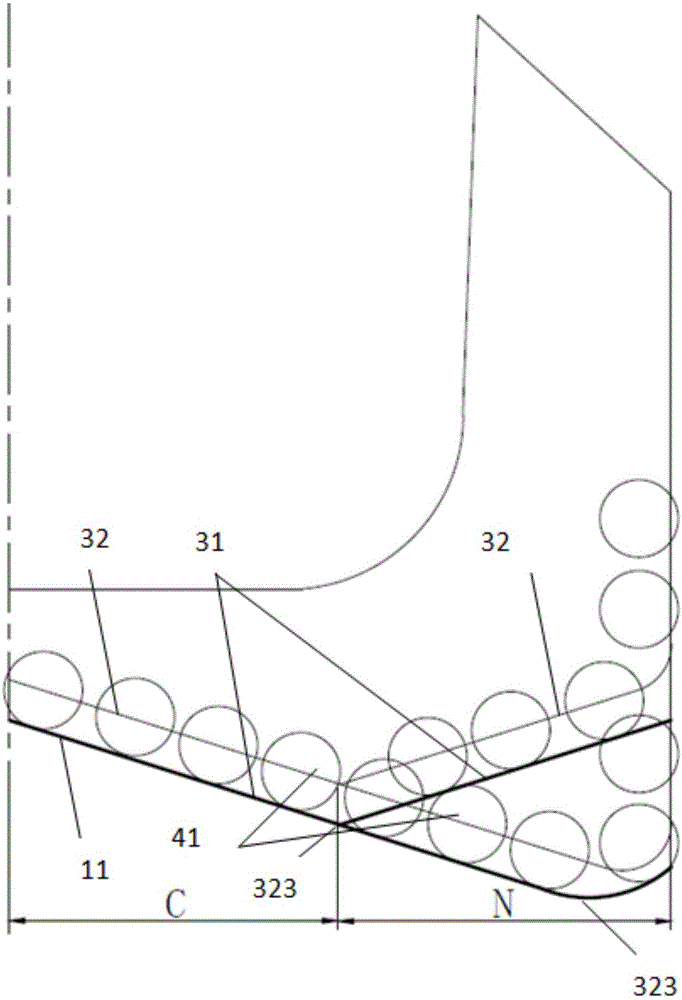

Disc cutter type multiple drill bit suitable for hard-to-drill stratum

The invention discloses a disc cutter type multiple drill bit suitable for a hard-to-drill stratum. The disc cutter type multiple drill bit comprises a drill bit body, a plurality of cutter wings extending to the drill bit body, a disc cutter rotatably connected relatively to the drill bit body, and a water hole or a nozzle formed in the drill bit body; a plurality of first groups of cutting teeth are formed in the cutter wings, a slot is formed in the tooth surface of the cutter wing to fix the first group of cutting teeth, the disc cutter comprises a disc cutter body and disc cutter teeth arranged on the disc cutter body, the contour line of a body of at least one cutter wing and the contour line of a body of at least another cutter wing have at least one mismatched area in the common coverage area and at least one matched point or matched area. The structural feature enables the drill bit to work in an asynchronous cutting manner, so that the longitudinal abrasion length of the drill bit is increased, the service life of the drill bit is prolonged, in addition, the drill bit is kept in a high specific pressure drilling state in the whole drilling process, and the capability of the drill bit drilling in a rock is strengthened. Therefore, and the drilling speed and the service life of the drill bit in the hard-to-drill stratum are increased and prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +1

Punching composite drill bit suitable for difficult-to-drill stratums

ActiveCN106089087AAdjust the tooth densityEffective intakeDrill bitsConstructionsPunchingBody contour

The invention discloses a punching composite drill bit suitable for difficult-to-drill stratums. The drill bit comprises a drill bit body, blades and water holes or nozzles arranged in the drill bit body, wherein each blade is provided with a plurality of first cutting teeth, the tooth arranging face of each blade is provided with sockets for fixing the first cutting teeth, the drill bit body is further provided with punching structures and an impact force transmission mechanism, the punching structures are provided with punching teeth, and the body contour line of at least one blade and the body contour line of at least another blade are provided with at least one non-overlap area and at least one overlap point or area in a joint covering area. By the structure, the drill bit can work in an asynchronous cutting manner, the longitudinal abrasion length of the drill bit can be increased, the service life of the drill bit can be prolonged, the drill bit can be allowed to be in a high-specific-pressure drilling state during the whole drilling process, the rock drilling ability of the drill bit is enhanced, the drilling speed of the drill bit in the difficult-to-drill stratums is increased, and the service life of the drill bit in the difficult-to-drill stratums is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +1

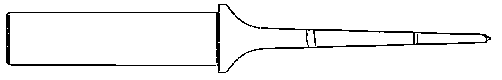

Tungsten steel flat drill

InactiveCN102837034AIncrease chip removal spaceSmooth chip removalTransportation and packagingTrepanning drillsRound tableKnife blades

The invention relates to a tungsten steel flat drill, which comprises a tool blade and a tool handle that are formed integrally. The tungsten steel flat drill is characterized in that the tungsten steel flat drill is made of a tungsten steel material, the tool handle is a cylindrical straight handle; the tool blade is in a step shape; a transition part is arranged between the tool blade and the tool handle; a round table is arranged at the bottom end of the transition part; a cambered chip discharge groove is formed from the round table to a rake face of the tool blade; the tool blade is in a two-stage type; the first-stage tool blade is positioned at the front end of the tool blade; the width of the first-stage tool blade increases stage by stage; cutting edges of the first-stage tool blade and the second-stage tool blade are arranged at the edge of the tool blade; an edge point is arranged at the top end of the first-stage tool blade; and a 45 DEG cutting edge is arranged at a connection part between the second-stage tool blade and the transition part. The tungsten steel flat drill has a large chip discharge area and is long in service life; chips are discharged smoothly; as the tool blade of the tungsten steel flat drill is in a step shape, two step holes in different diameters and outer hole chamfers can be processed once without aligning a tool; and the processing precision and the working efficiency are improved greatly.

Owner:WUXI YUTIAN PRECISION TOOL

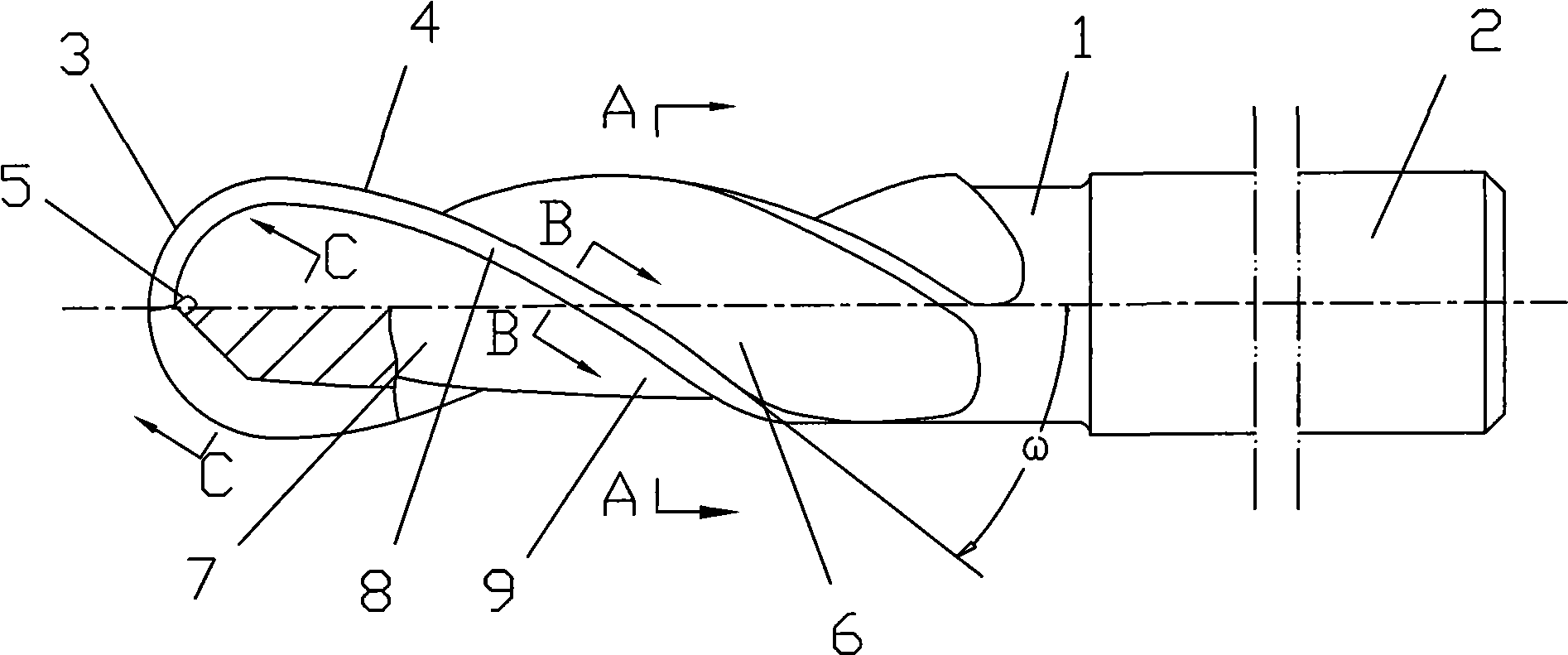

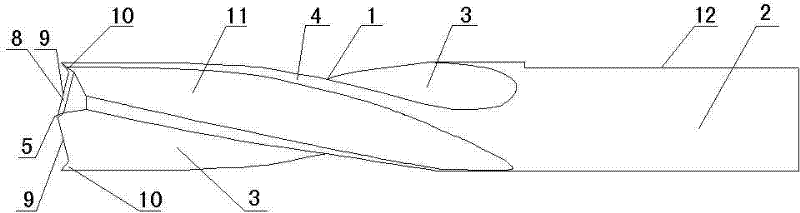

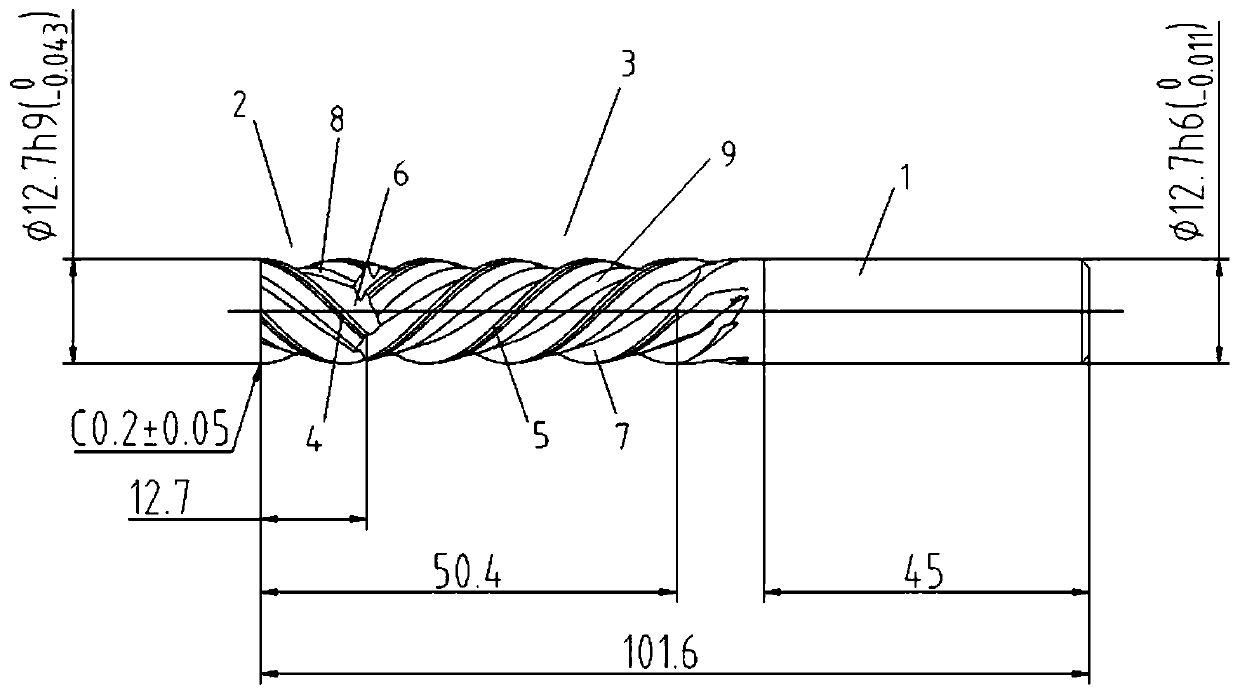

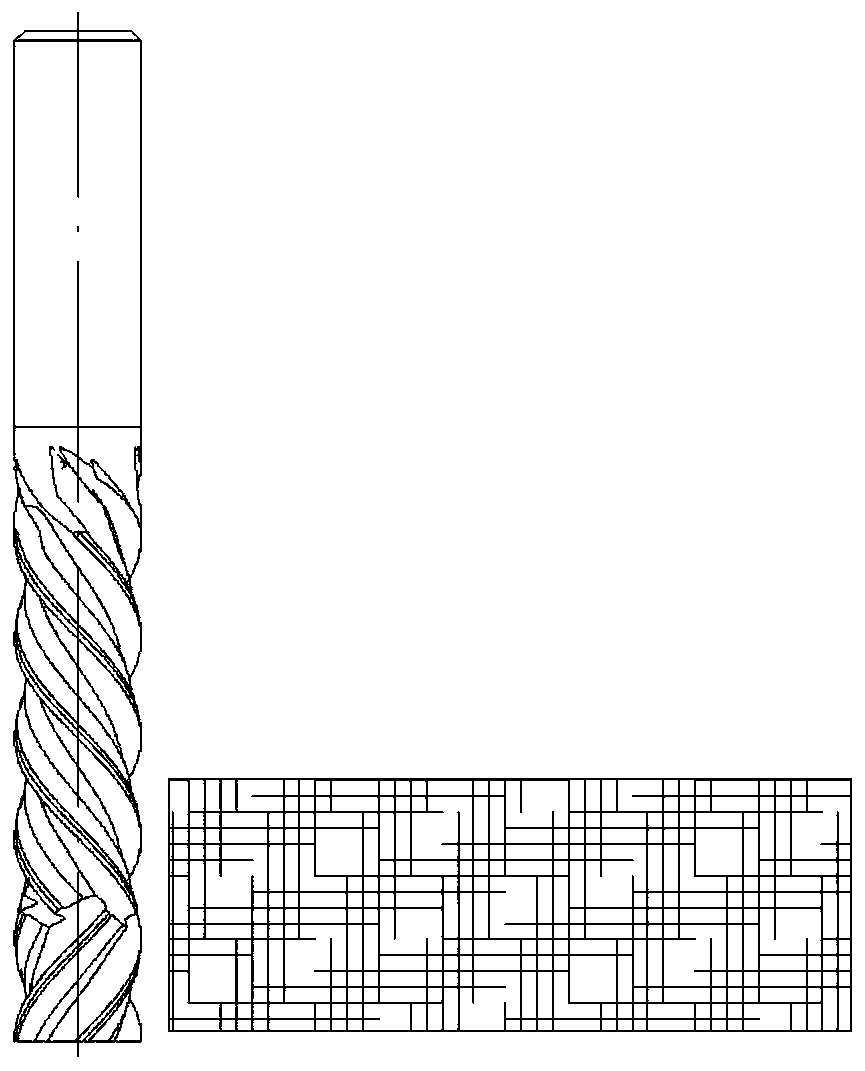

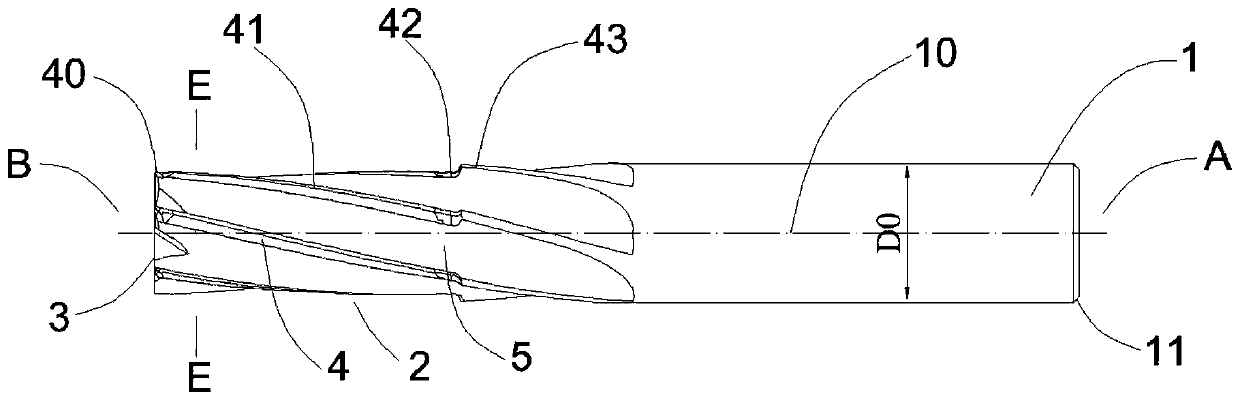

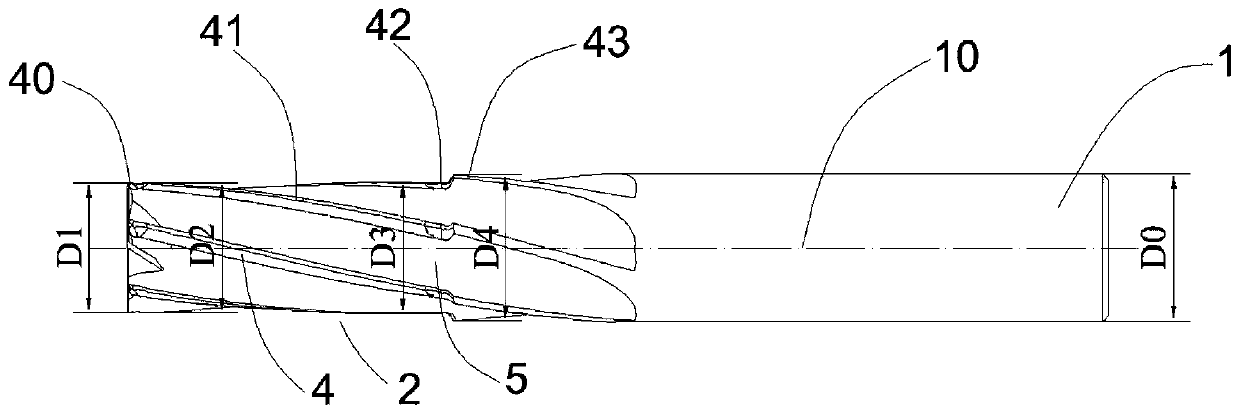

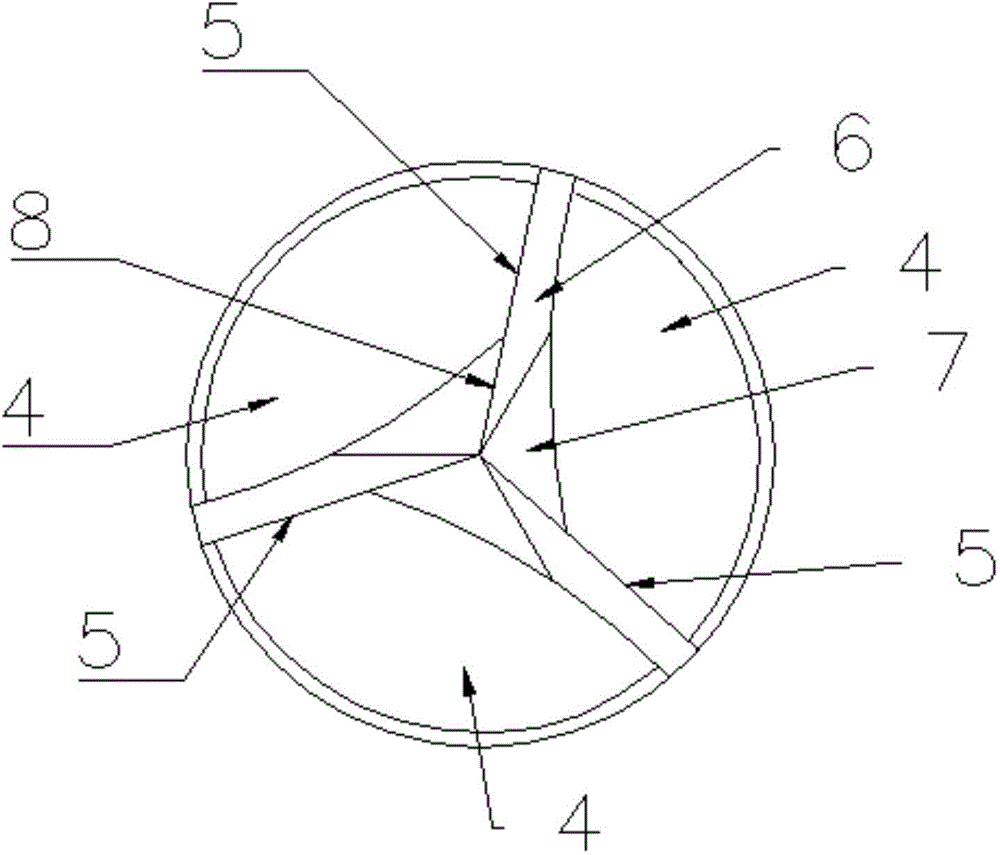

Milling cutter for high speed machining of non-metallic material

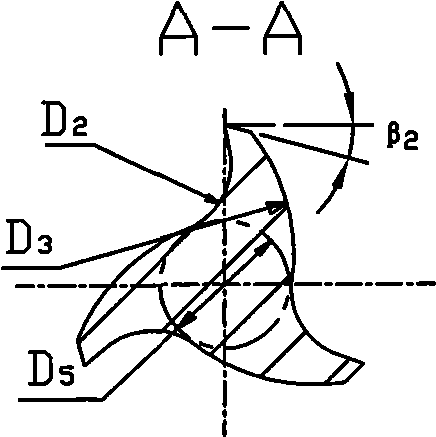

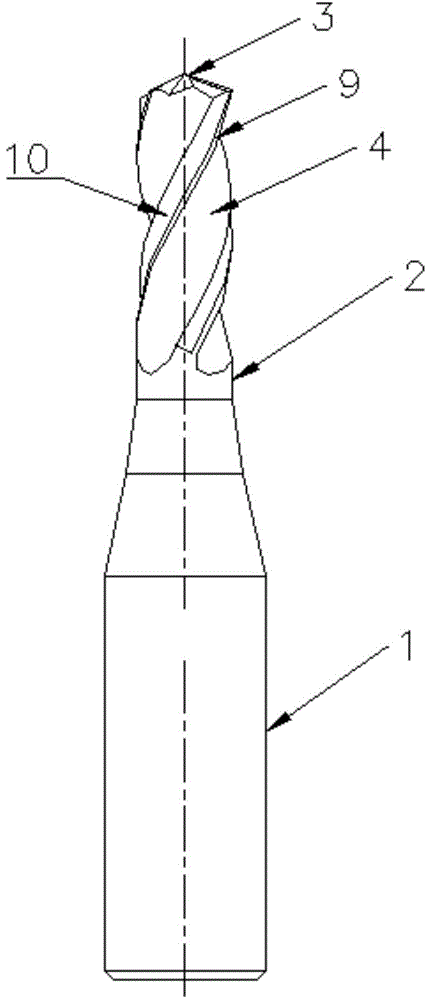

The invention discloses a milling cutter used for processing non-metal materials at high speed. Transitional groove edges (5) are arranged between adjacent main cutting edges (3); the helical angle omega of an minor cutting edge (4) is 50 to 60 degrees; the front angle alpha1 and the rear angle of beta1 of the main cutting edges (3) are 15 degrees; the front angle alpha2 of the minor cutting edge (4) is 12 degrees and the rear angle is 15 degrees; circular arc groove radii D4 of the main cutting blades (3) are 1.5mm to 3.5mm; the radial section of a helical groove of a rake face (6) is a circular arc with radius D2 of 3.5mm to 6mm; a flank (7) consists of a main flank (8) with width D1 of 1.5mm and a minor flank (9) with radial section being an circular arc with 7.5mm to 15mm of radius D3; the diameter D of the cutter is 20 to 50mm. The invention with the advantages of high cutting efficiency, small cutting resistance, smooth chip removal, light body and good intensity is applicable to the high-speed coarse and fine milling of foam, resin, plastic, organic glass and other non-metal chemical materials.

Owner:HUNAN UNIV

Particle reinforcement metal-matrix composite machining device and machining method

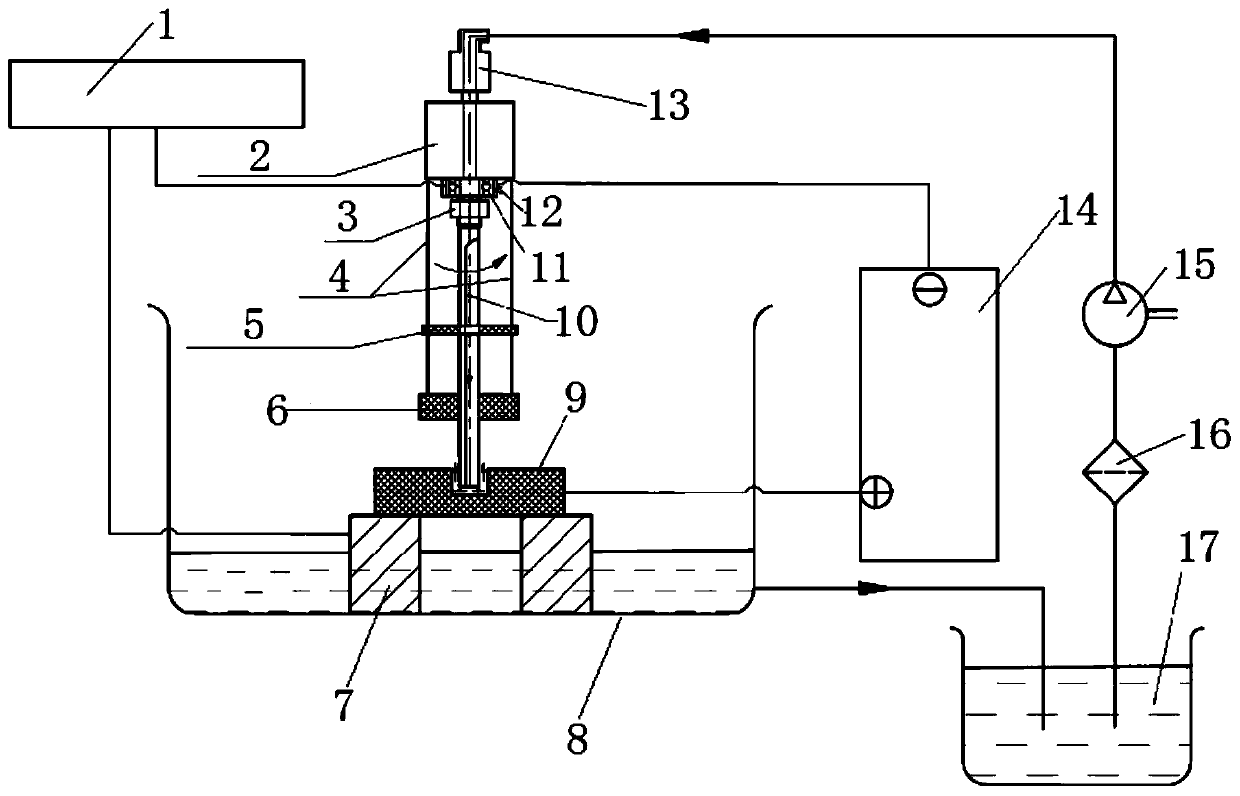

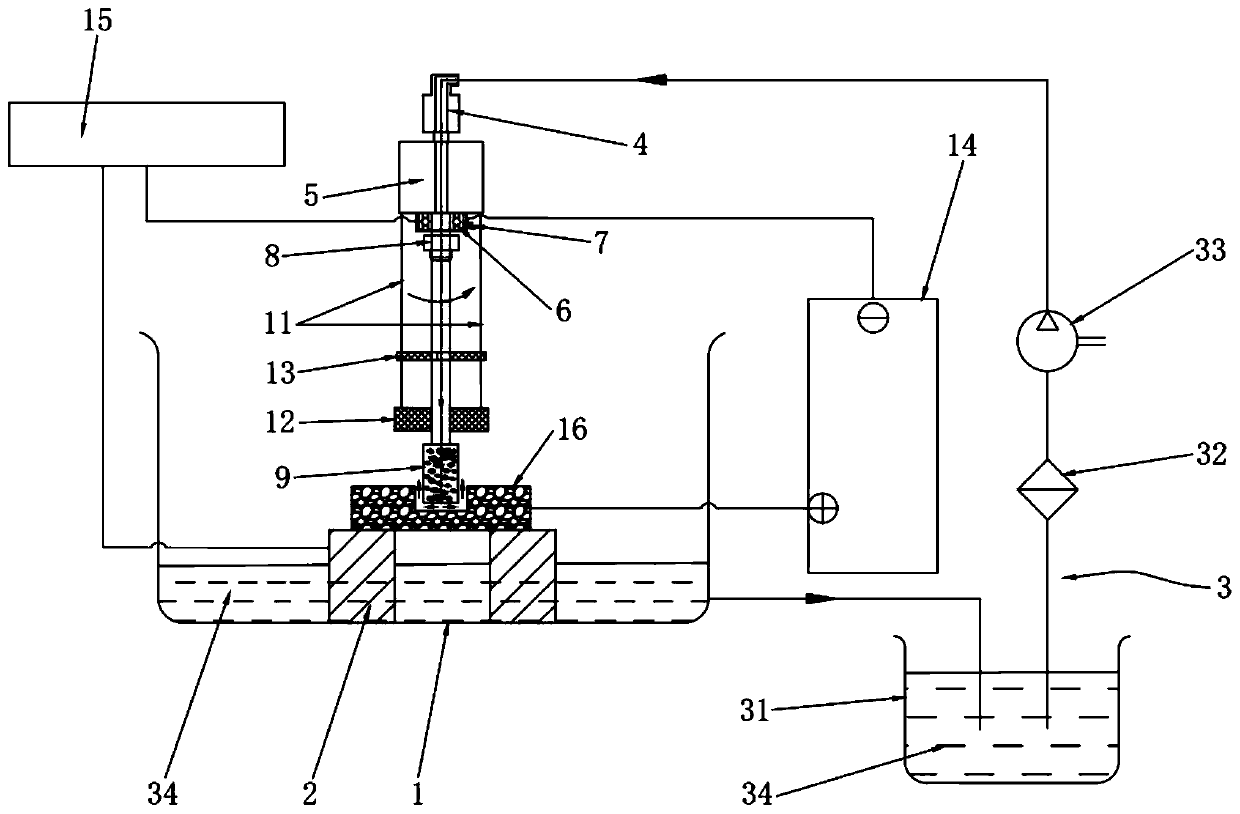

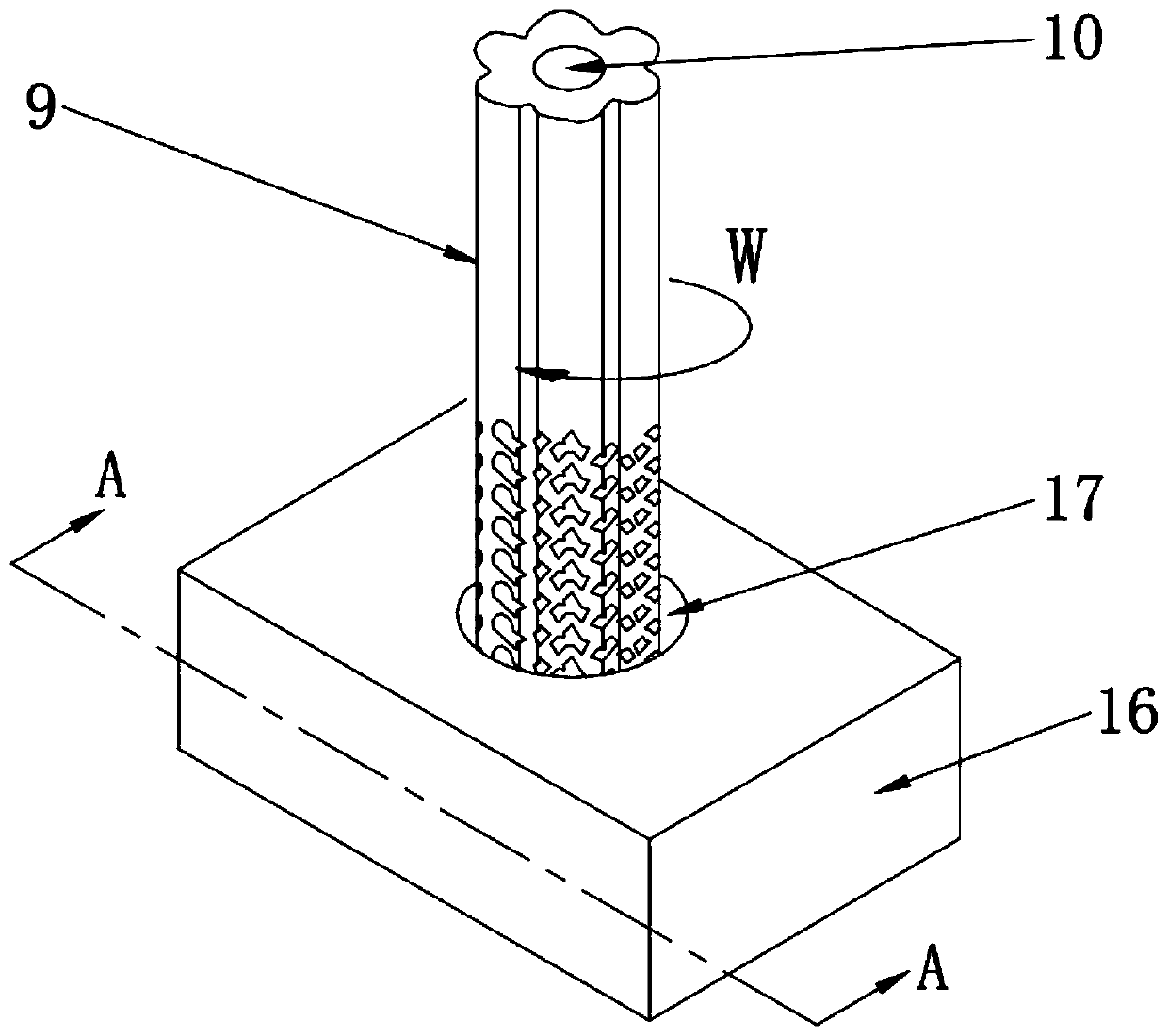

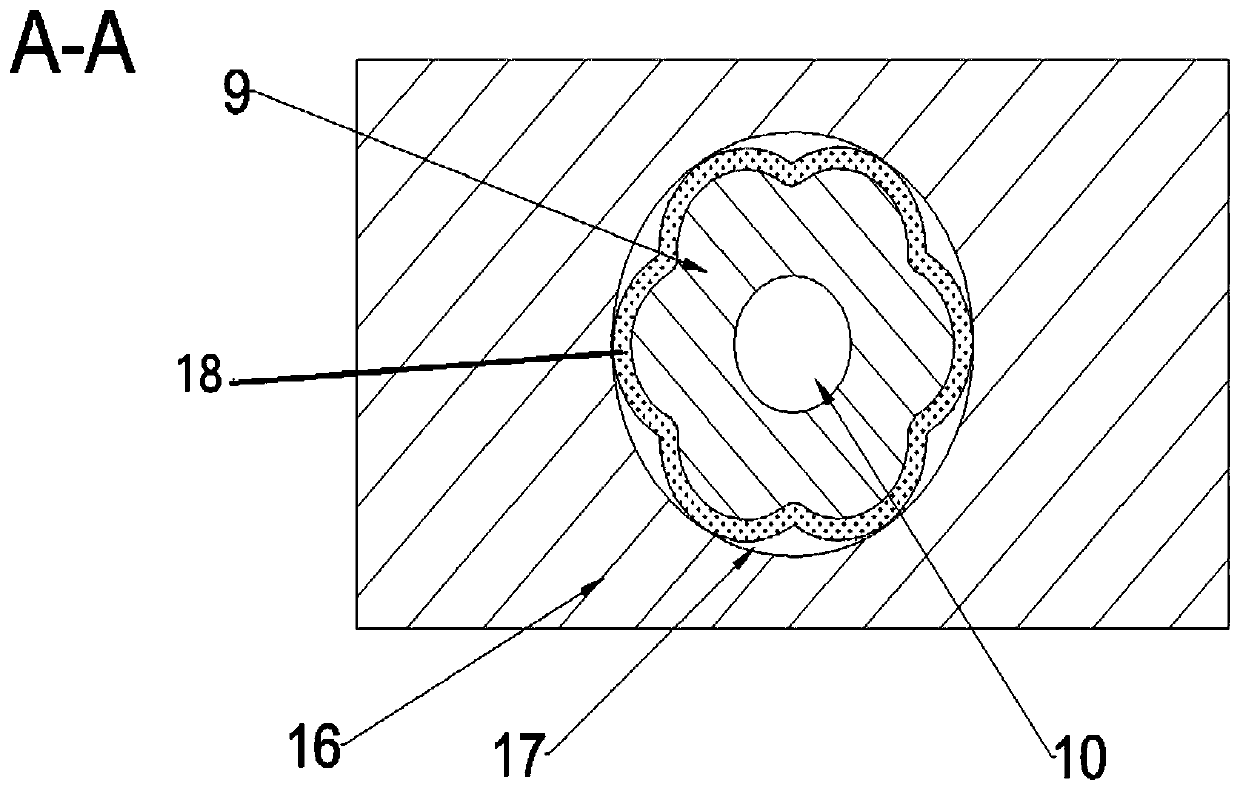

PendingCN110102840AImprove flushing abilityImprove processing statusElectrical-based auxillary apparatusMetal matrix compositeMachining process

The invention discloses a particle reinforcement metal-matrix composite machining device and machining method. The particle reinforcement metal-matrix composite machining device and machining method comprises a machining tank, a spindle motor, a chuck, a guide column, a fixed base, a guide device, a workpiece placing base, a workpiece and a tool electrode; work liquid in the machining tank entersa liquid storage tank through a liquid guide pipe, circular flowing of the work liquid is achieved, the interpolar workpiece liquid can be updated in time, machining stability in the discharge machining process can be effectively improved, machining efficiency is improved, machining quality is improved, in the deep small hole machining process, compared with a traditional chip removal manner, themachining effect is more obvious, meanwhile, when work liquid is replaced with an electrolyte with conductivity, the chip removal manner is used for electrolytic machining, electrochemical discharge machining and the like, the device is suitable for high-precision and high-quality deep small hole machining of various materials, the guide device and the fixed base are arranged, and the rotating precision of a tool electrode during high-speed rotation is ensured.

Owner:GUANGDONG UNIV OF TECH +1

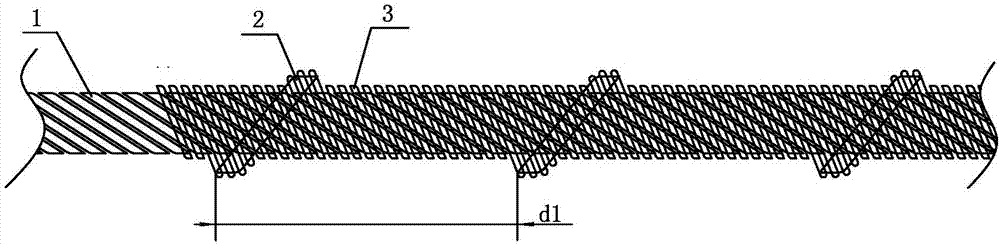

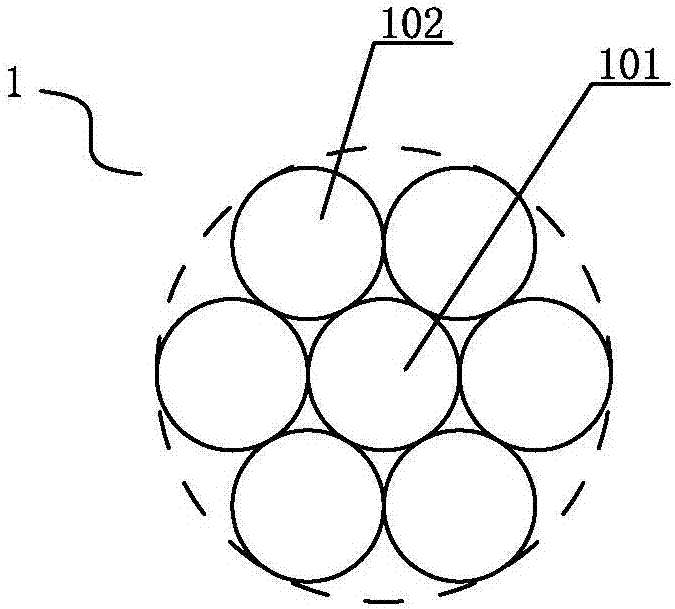

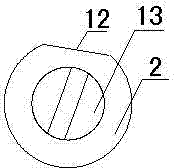

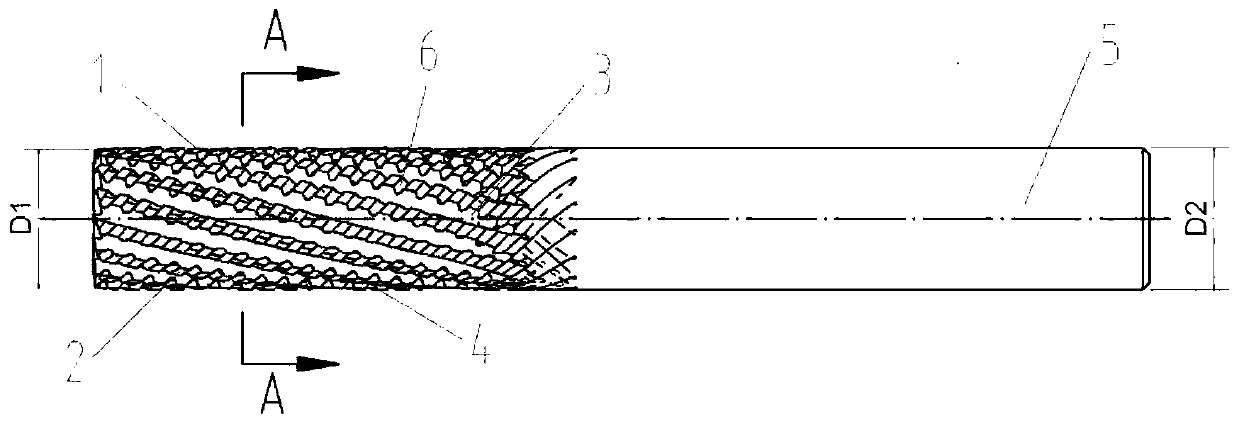

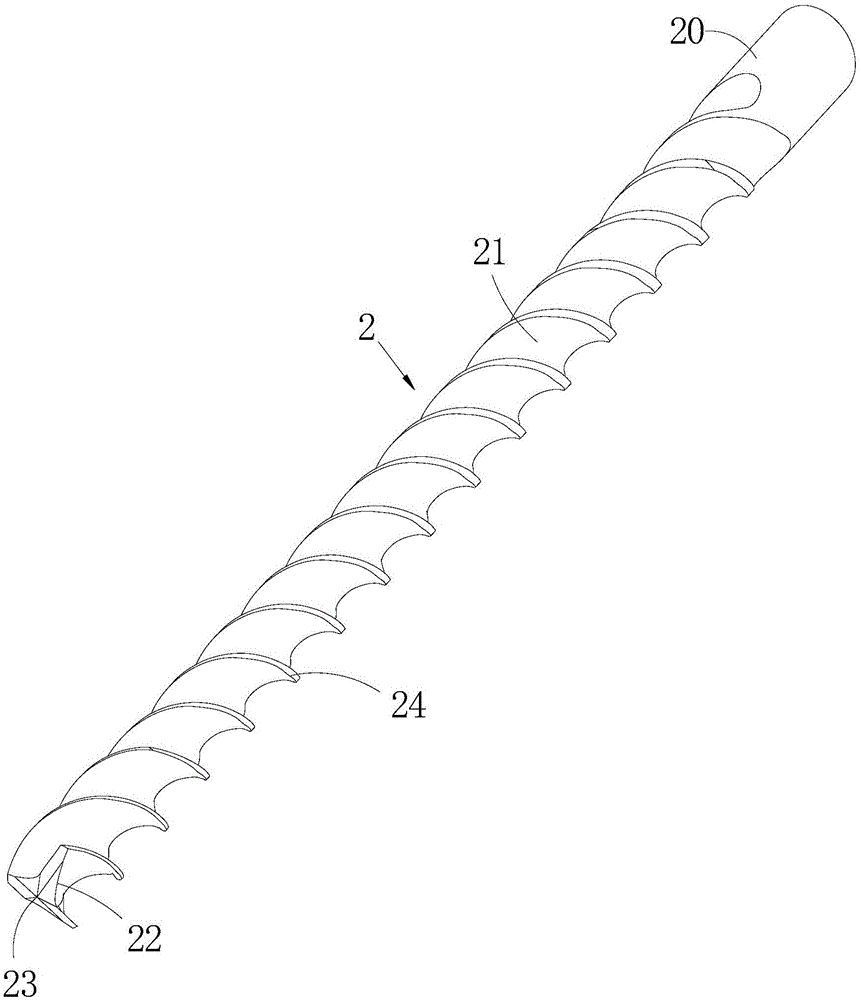

Ring-shaped superhard abrasive wire and manufacturing method thereof

ActiveCN108000735AIncrease chip removal spaceImprove cutting abilityFine working devicesStone-like material working toolsConductor CoilMaterials science

The invention discloses a ring-shaped superhard abrasive wire and a manufacturing method of the ring-shaped superhard abrasive wire. A base body of the ring-shaped superhard abrasive wire is a wire rope. The wire rope is connected end to end into a ring shape. Silk threads are loosely wound around the wire rope. Silk threads with abrasive are tightly wound around the exposed part of the wire ropeand the silk threads. The pitch between every two joints of adjacent silk threads on the wire rope is larger than or equal to 3 times the diameter of the silk threads with the abrasive. Every two joints of silk threads with the abrasive on the wire rope or the silk threads are sequentially arranged and not mutually pressed and stacked, and meanwhile the peripheries of every two joints of adjacentsilk threads with the abrasive are in contact with each other. The ends of the silk threads with the abrasive are buried under the winding-finished silk threads with the abrasive. The ring-shaped superhard abrasive wire has the ultra-high chipping discharge space and the higher cutting capacity, the manufacturing method is simple and easy to implement, and mass production is fast.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

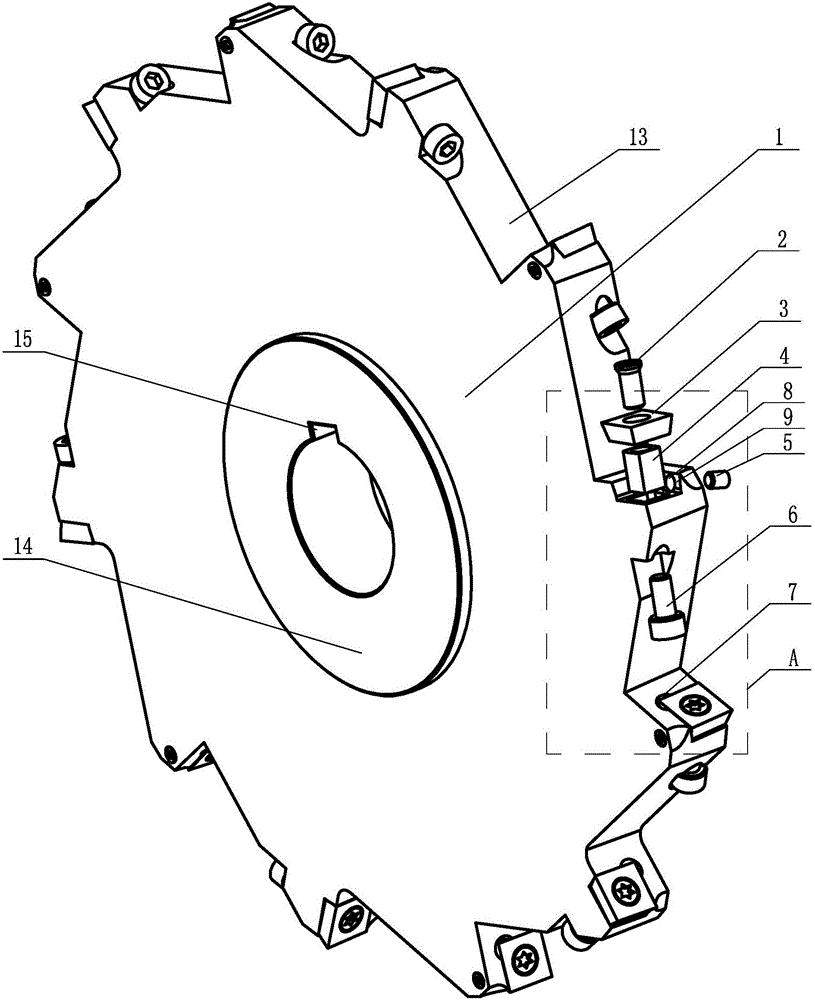

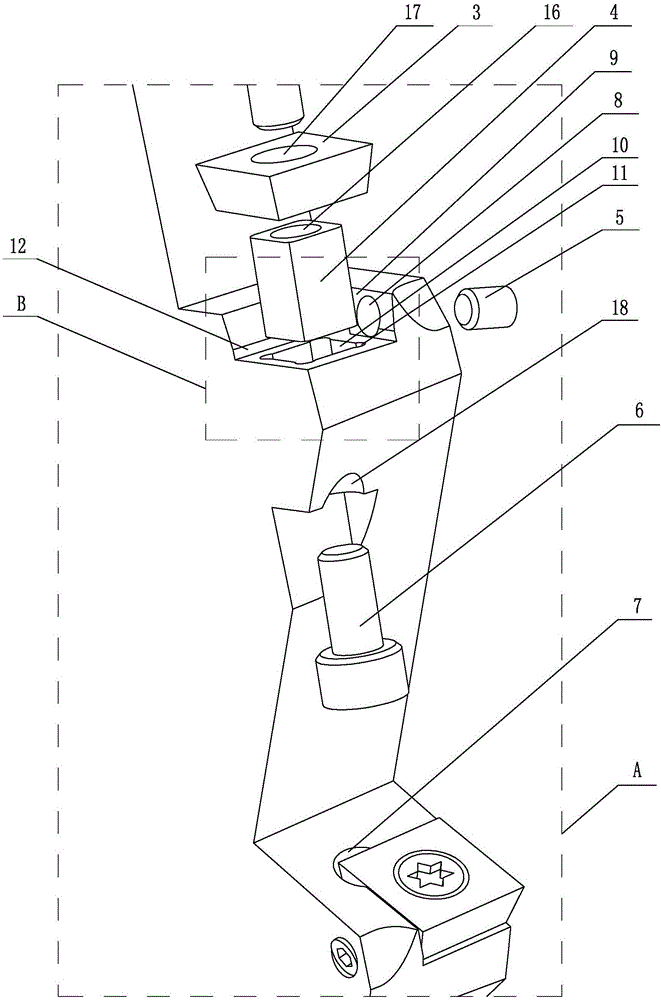

Disc milling cutter adopting flatly staggered teeth and variable cutting width and applied to slotting rough machining of blisk channel

The invention provides a disc milling cutter adopting flatly staggered teeth and variable cutting width and applied to slotting rough machining of a blisk channel and belongs to the technical field of cutters for cutting machining. Multiple L-shaped chip removal slots are uniformly distributed and formed in an outer circumferential surface of a cutter body, a cutter slot is formed in the short slot side surface of each L-shaped chip removal slot, every two adjacent cutter slots are staggered in the axial direction of the cutter body, a slider slot is formed in the bottom surface of each cutter slot, a slider is arranged in each slider slot, and a blade is arranged in each cutter slot and detachably and fixedly connected with the corresponding slider; the slider is arranged in each slider slot, a gap is formed between each slider slot and the slider in the axial direction, a tightening screw penetrates into a second through hole in each slider slot and is in fastening connection with a first threaded hole in the slider, a second threaded hole is formed in the slot side wall, perpendicular to the axial direction, of each cutter slot, a set screw is tightened in each second threaded hole, and each set screw is propped against the corresponding blade in the axial direction. The disc milling cutter is applied to milling machining of a blisk.

Owner:HARBIN UNIV OF SCI & TECH

Minisize drill bit for PCB plate drilling hole

ActiveCN101176930AReasonable groove widthImprove borehole wall qualityTransportation and packagingTrepanning drillsBiochemical engineeringHelix angle

The invention discloses a PCB-drilling micro-bit, comprising an base line at the bottom of the groove and two side lines respectively arranged at both sides of the groove and smoothly connected with the base line, which is characterized in that: a spiral winding groove is arranged on the prismatic face; the cross-section profile vertical to the spiral line of the groove is U-shaped with wide bottom on the whole; wherein, the base line is a straight line segment or a circular arc line segment with large curvature radius; the two side lines are respectively straight line segment or circular arc line segment with small curvature radius. Optimally, Helix angle of the groove is 42 to 45 degrees. The invention has the advantages of having bigger space for removing chips and bigger core radius synchronously through optimizing the groove, not decreasing the width of the groove with the groove becoming shallower, having more reasonable groove amplitude ratio of the rear part in the drill bit, improving the quality of drill wall, the hole accuracy, lowering rod-breaking performance synchronously; by increasing the helix angle to 42 to 45 degrees, the invention improves the dust exhausting ability of the drill bit and the quality of hole wall.

Owner:SHENZHEN JINZHOU PRECISION TECH

Novel electrode compound electric machining device and machining method

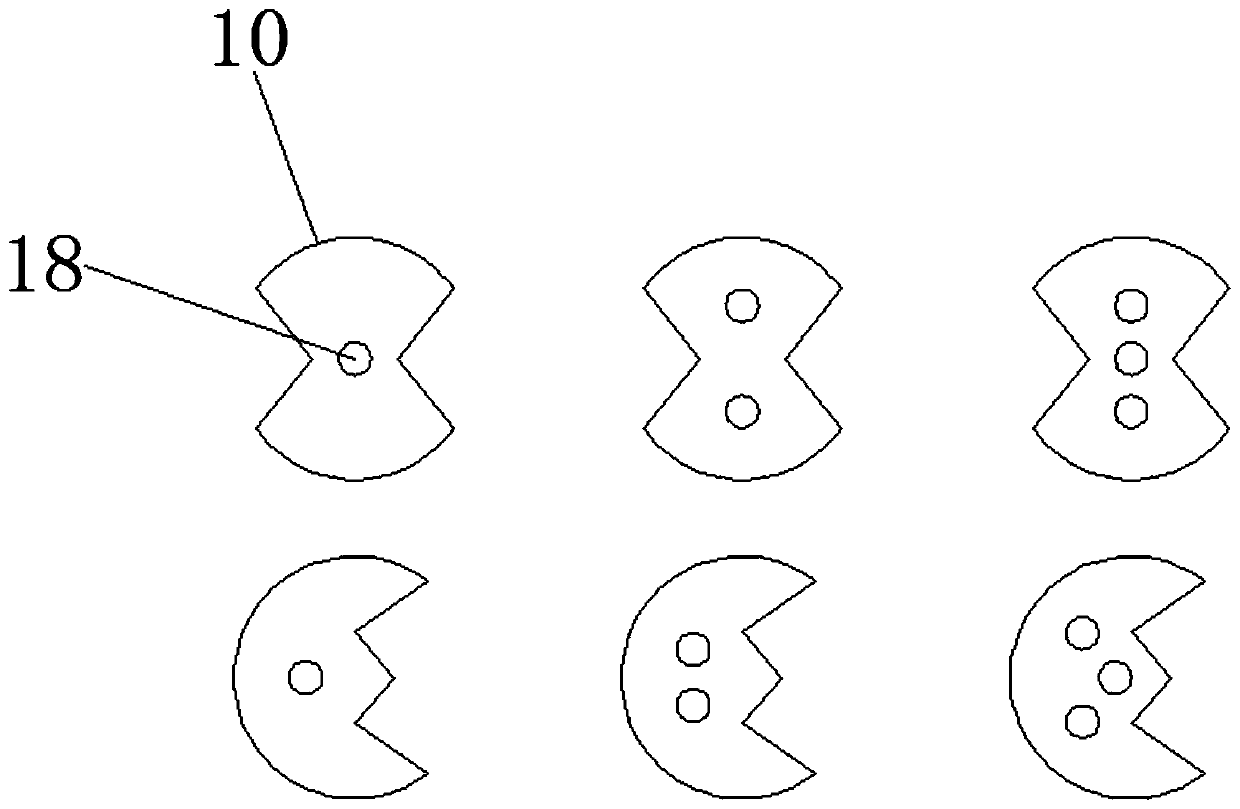

InactiveCN111215709AImprove machined surface qualityIncrease chip removal spaceElectrical-based machining electrodesRotational axisWorking fluid

The invention discloses a novel electrode compound electric machining device and machining method. The novel electrode compound electric machining device comprises a machining tank, the inner side ofthe machining tank is provided with workpiece supporting seats for placing a workpiece, one side of the machining tank is provided with a working fluid system, the working fluid system comprises a working tank, a filter and a high-pressure pump, the working tank is internally provided with a fluid guide pipe immersed in working fluid, the bottom side of a rotating connection head is provided witha main shaft motor, the output end of the main shaft motor is provided with a high-speed rotary bearing, the high-speed rotary bearing is provided with an electric lead bolt, the output end of the main shaft motor is connected with one end of a tool electrode through a clamping head, the outer side of the tool electrode is wrapped with a grinding material layer, and the cross section of the tool electrode is in an annular wave shape. According to the novel electrode compound electric machining device and the machining method, the tool electrode of the novel electrode compound electric machining device has a grinding effect in the machining process and the wave-shaped cross section of the tool electrode makes the tool electrode have a larger chip discharge space, meanwhile, in coordinationwith a fluid rushing hole and the rushing pressure formed under the action of the high-pressure pump, the rushing ability between poles is improved, and the novel electrode compound electric machiningdevice has strong chip discharge ability and is especially suitable for machining of particle reinforced metal matrix composite materials.

Owner:GUANGDONG UNIV OF TECH

Precision milling cutter and processing method thereof

ActiveCN103433542ASpiral groove space increasedIncrease chip removal spaceLayered productsMilling cuttersEngineeringMilling cutter

The invention discloses a precision milling cutter and a processing method thereof. The milling cutter comprises a cutter body and a plurality of cutter teeth at the periphery of the cutter body, wherein a flat section is arranged between every two cutter teeth to form a flat bottom surface on the bottom of a spiral groove between the two cutter teeth, the flat bottom surfaces and the spiral grooves are arranged on the cutter body according to the same helical angle, and all points on the flat bottom surfaces are equally far away from an axis of the milling cutter. According to the precision milling cutter, by virtue of the flat sections, the distance between every two cutter teeth increases, so that a chip removal space of the milling cutter is enlarged, and chips can be discharged smoothly. By virtue of the flat sections, the distance between every two cutter teeth increases, so that rake angles of cutting edges can be large to allow the cutting edges to be sharp, while back angles of the cutting edges can be reduced correspondingly to ensure the thickness of the cutter teeth so as to avoid tooth breakage. Moreover, by virtue of the flat sections, the bottoms of the spiral grooves are flattened, so that the core diameter of the milling cutter can be enlarged to improve the strength of the milling cutter, and further, the rate of cutter breakage can be lowered.

Owner:SHENZHEN JINZHOU PRECISION TECH

Integrated milling-rutter

The invention is a kind of single-blade hobbing with sharp spiral blade and big row swarf slot, and it comprises colter arm, cutter body, the body is made up of side blade which has a ª‰spiral lifting angle, correspondent bottom blade, fore cutter face which is made up of spiral slots, several spiral aft cutter faces, the side blade and the bottom blade are all only one; the fore angle ª†is 25~30íÒ; the cross-sectional of fore blade face slot is a round arc, the volume of the slots accounts 35%~48%; the back cutter is made up of spiral main blade face, several assistant blade faces.

Owner:SHENZHEN JINZHOU PRECISION TECH

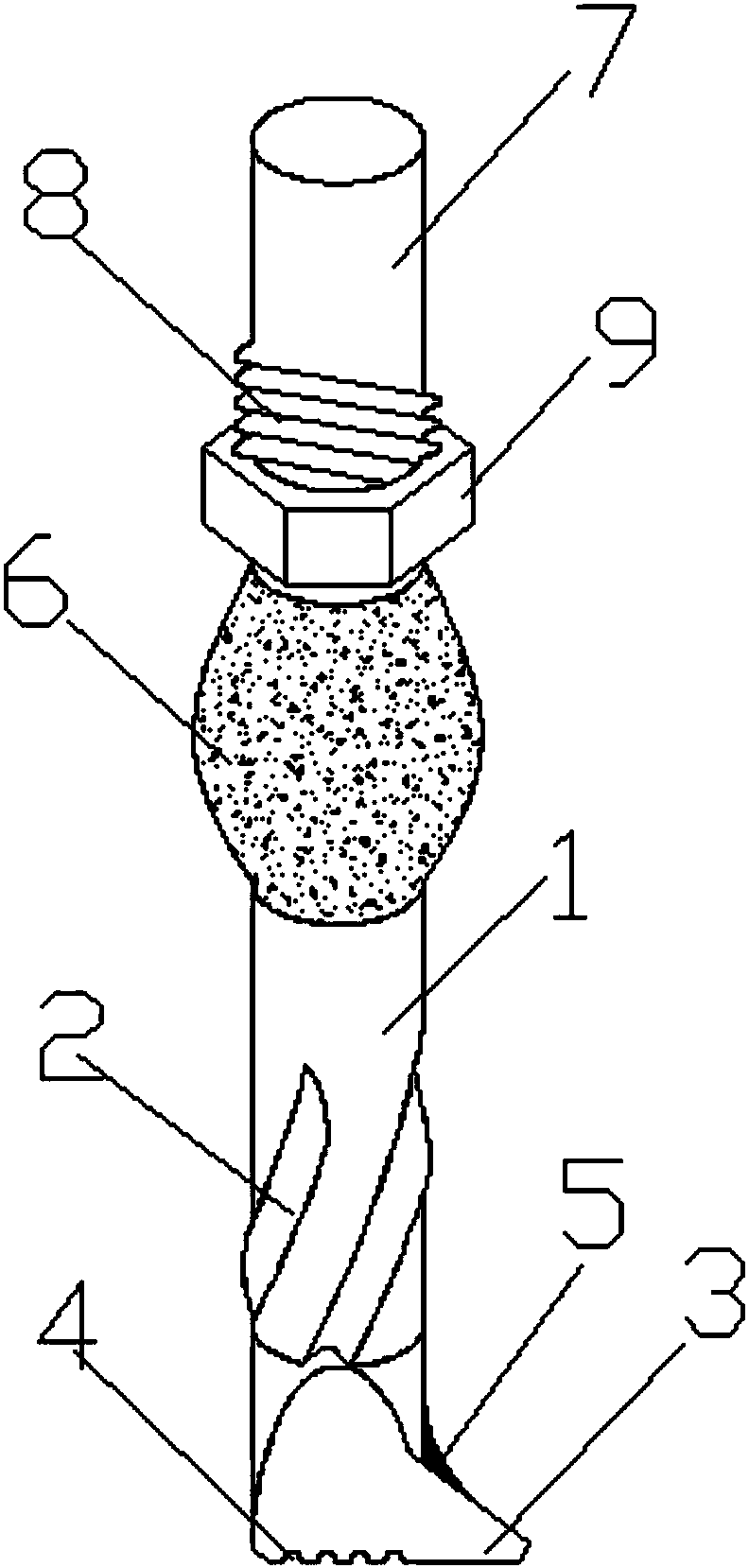

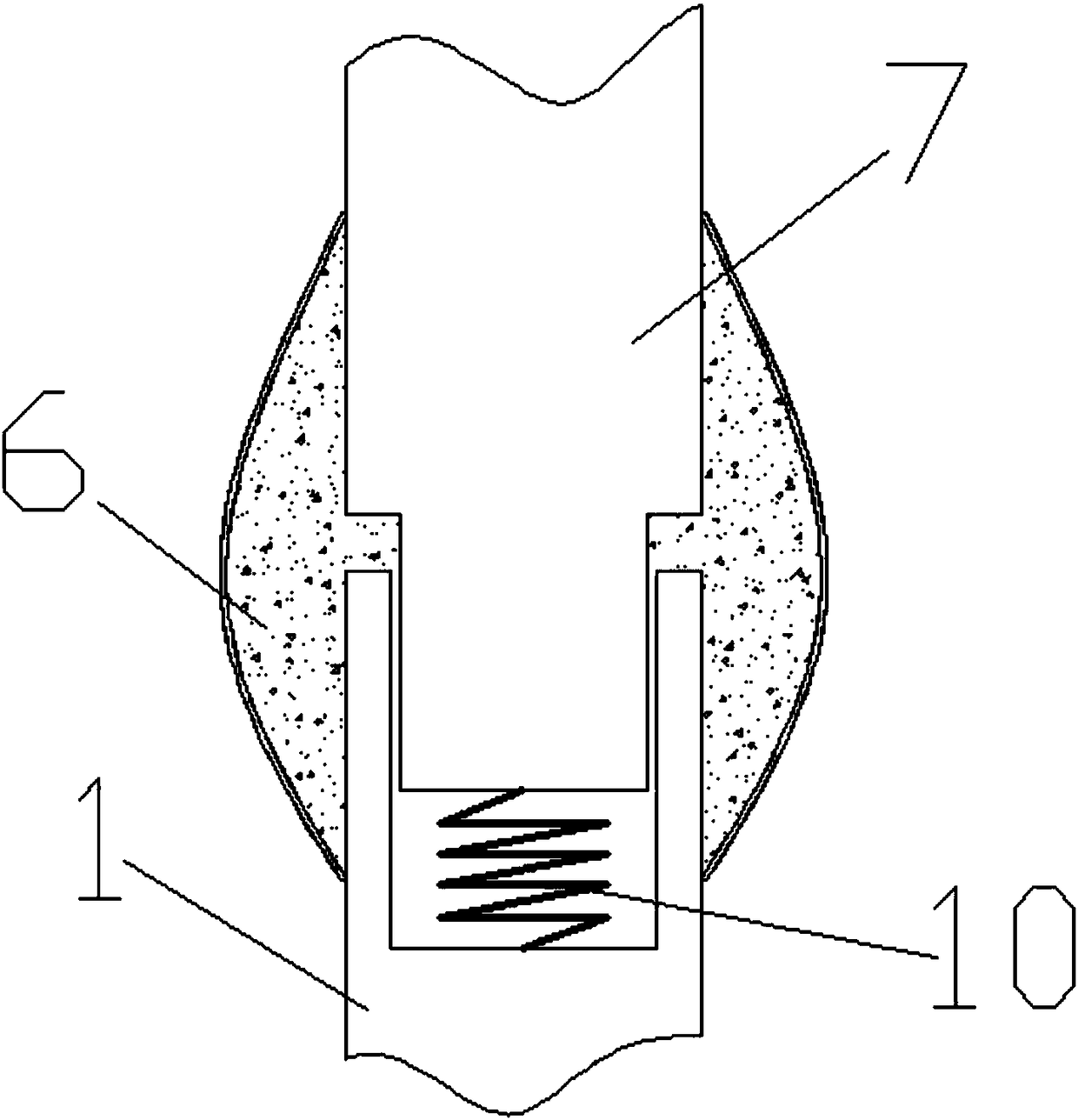

Boring cutter with arc structure

InactiveCN108380912ACompact connectionEasy to useCutting insertsTurning toolsTool bitStress strength

The invention discloses a boring cutter with an arc structure. The boring cutter comprises a connecting rod, chip removing grooves, a tool bit, pressure relief ports, reinforcing ribs, a protective rubber block, a knife handle, threads, an extrusion nut and a spring. The boring cutter with the arc structure has the beneficial effects that the bottom of the tool bit is uniformly provided with a plurality of inward-concave arc-shaped pressure relief ports, and the impact force borne by the tool bit when boring hole is carried out and when the tool bit makes contact with a workpiece can be reasonably dispersed, the vibration of the tool bit is reduced, so that the process of the hole boring is stable; the connecting part between the connecting rod and the tool bit is fixedly provided with thereinforcing ribs with the arc surfaces on the surfaces, so that the pressure borne by the tool bit can be dispersed to the connecting rod through the reinforcing ribs, and the stress strength of thetool bit can be improved; the number of the chip removal grooves are symmetric four, and the tangent plane of each chip removal groove is of the inward-concave arc shape which is provided with a largechip removal space, so that the chip removal effect of the boring cutter is good; the knife handle can move up and down inside the connecting rod, the knife handle is provided with a certain deformability, so that the large impact force cannot be generated between the tool bit and the workpiece when the tool bit is just in contact with the workpiece.

Owner:常州思智行睿精密机械有限公司

Chip discharging structure of machine tool

PendingCN107825217AIncrease widthAvoid cloggingMaintainance and safety accessoriesEngineeringMachine

The invention provides a chip discharging structure of a machine tool, and belongs to the technical field of machinery. The chip discharging structure solves the problem that an existing machine toolis not smooth in chip discharging. In the chip discharging structure of the machine tool, the machine tool comprises a tool body and a spindle box arranged on the tool body, one side of the spindle box is provided a mounting platform which is in a long strip shape and is used for mounting of guiding rails, and the mounting platform and the tool body are of an integrated structure; the chip discharging structure comprises a chip discharging groove formed in the tool body, the lower side of the mounting platform is located in the chip discharging groove, the bottom wall of the chip discharging groove is a first bevel, and the inclination angle of the first bevel is 30 degrees to 35 degrees; the first bevel is in a U shape and is composed of two first guiding surfaces and a second guiding surface, the two first guiding surfaces are correspondingly located on the two sides of the mounting platform, the second guiding surface is located between the two first guiding surfaces and is connected with the two first guiding surfaces, and the first guiding surfaces and the second guiding surface are each in a rectangular shape; and a circular-arc-shaped notch is formed in the lower side, awayfrom one end of the spindle box, of the mounting platform, the axis of the notch extends in the width direction of the mounting platform, and the notch directly faces the second guiding surface. The chip discharging structure of the machine tool has the advantages of smooth chip discharging.

Owner:TAIZHOU EASTERN CNC EQUIP CO LTD

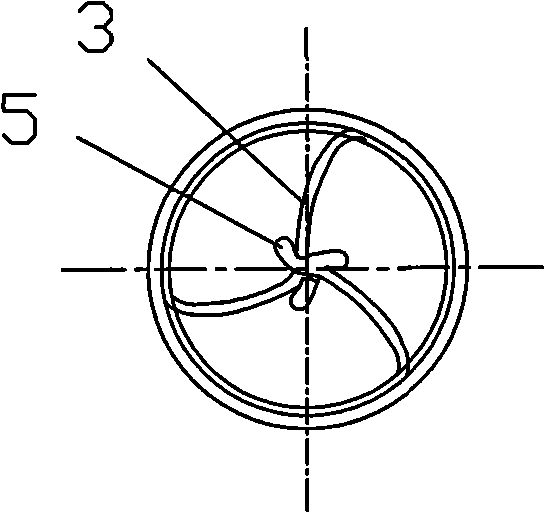

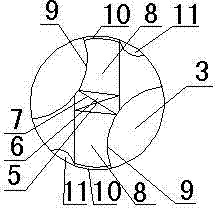

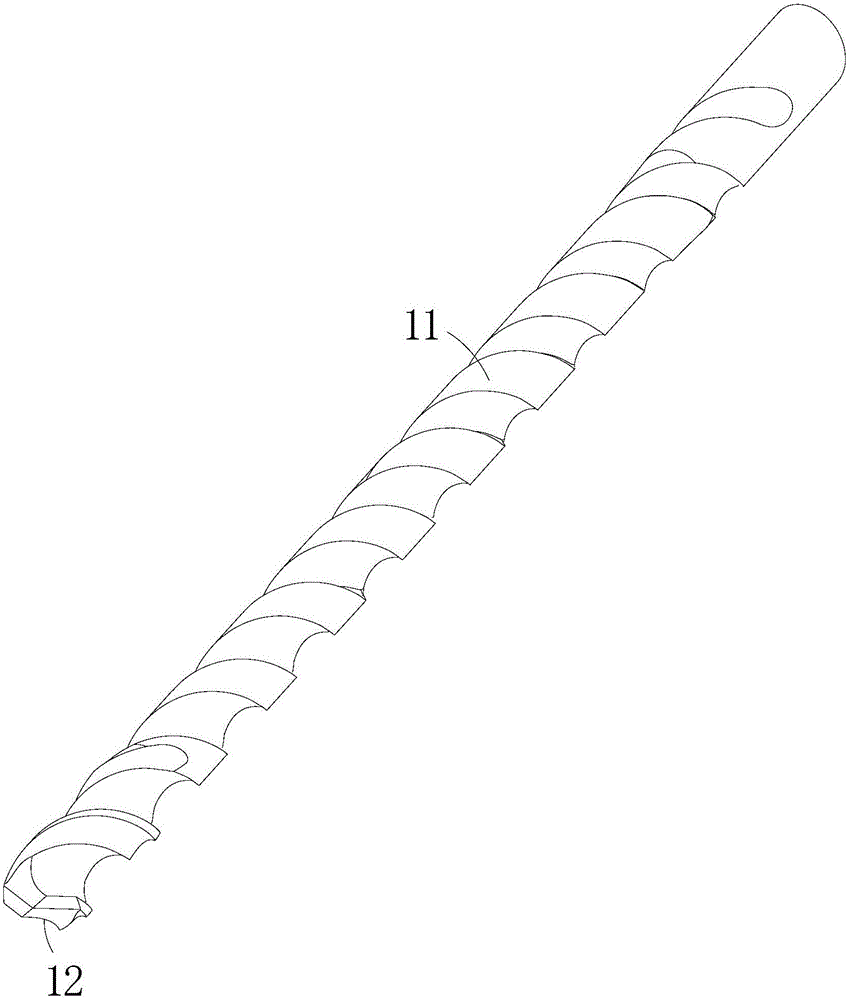

Four-groove gang drill

InactiveCN102490213AIncrease the effective cutting areaQuality improvementStationary drilling machinesWood turning toolsEngineeringDrill

The invention discloses a four-groove gang drill which comprises a cutting part (1) and a shank (2) that are connected in sequence. Two spiral chip grooves (3) are formed on the cutting part (1), the part between the spiral chip grooves (3) forms a cutter body (4), a positioning tip (5) is protruded from the center at the front end of the cutting part (1) and formed by four inclined positioning surfaces (6), the prismatic intersection of the four inclined positioning surfaces (6) forms a positioning edge (7), two downwardly sheer inclined surfaces (8) in outward symmetry are formed on the positioning tip (5), the inclined surfaces (8) and the groove bottoms of the spiral chip grooves (3) form end edges (9), the end edges (9) and the peripheral surface of the cutting part (1) form two outer side tips (10), and spiral auxiliary chip grooves (11) are formed on the cutter body (4). The invention has the following benefits: chip removal effect is good, and processing surface quality is improved; service life is prolonged; positioning is accurate, and drill offset is avoided; and assembly and disassembly are simple and convenient.

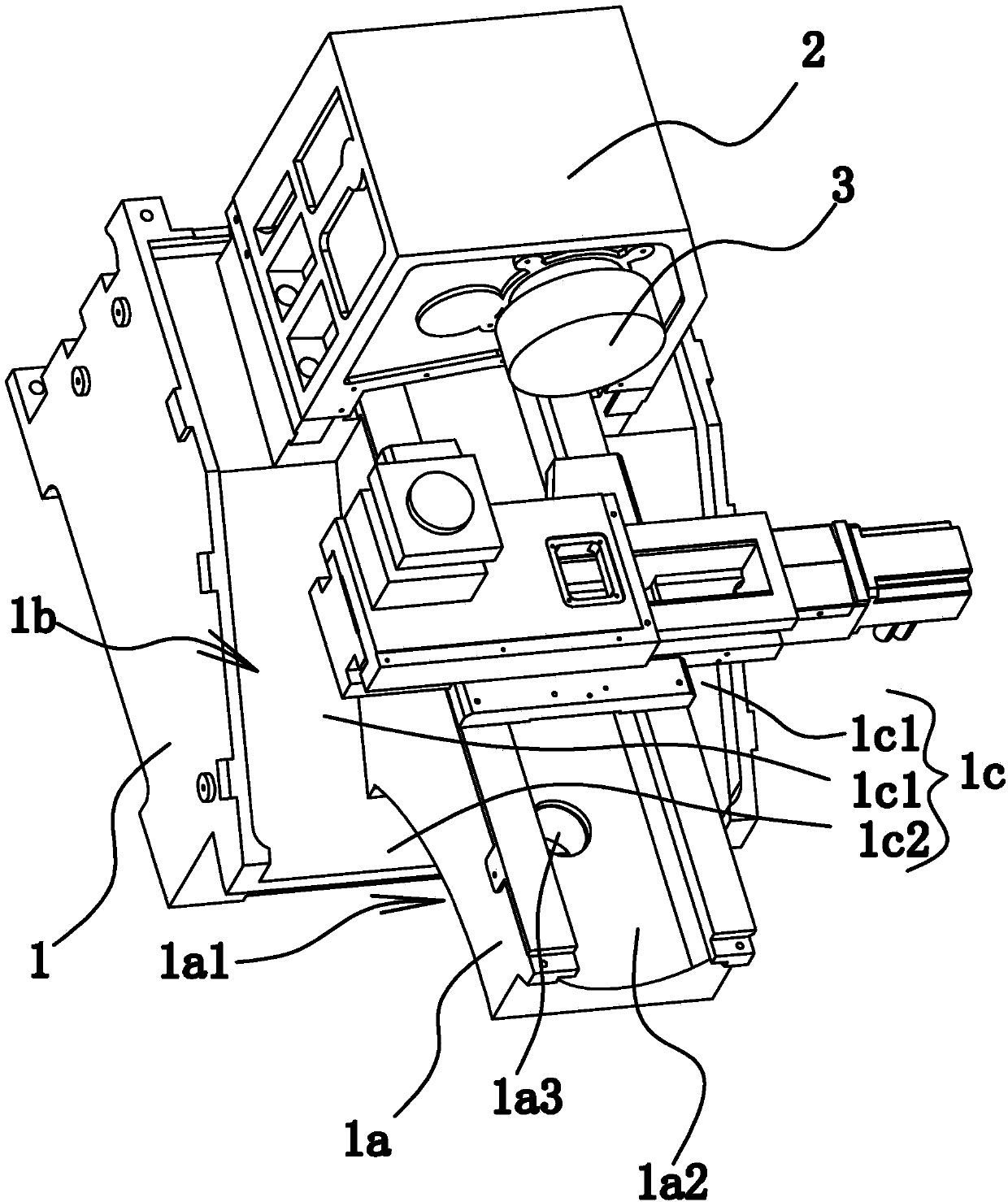

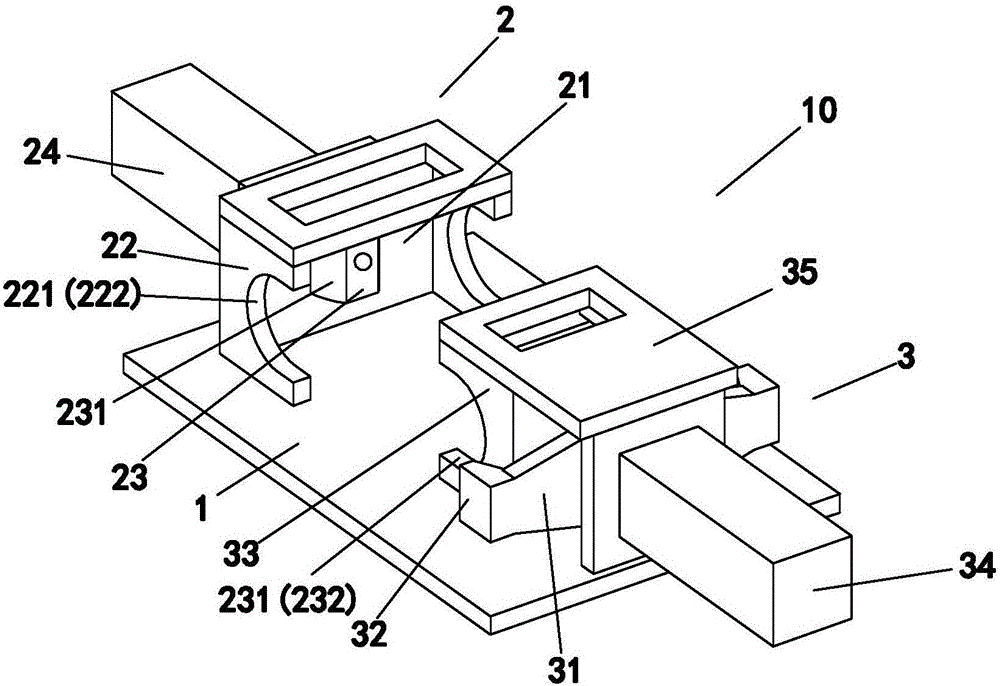

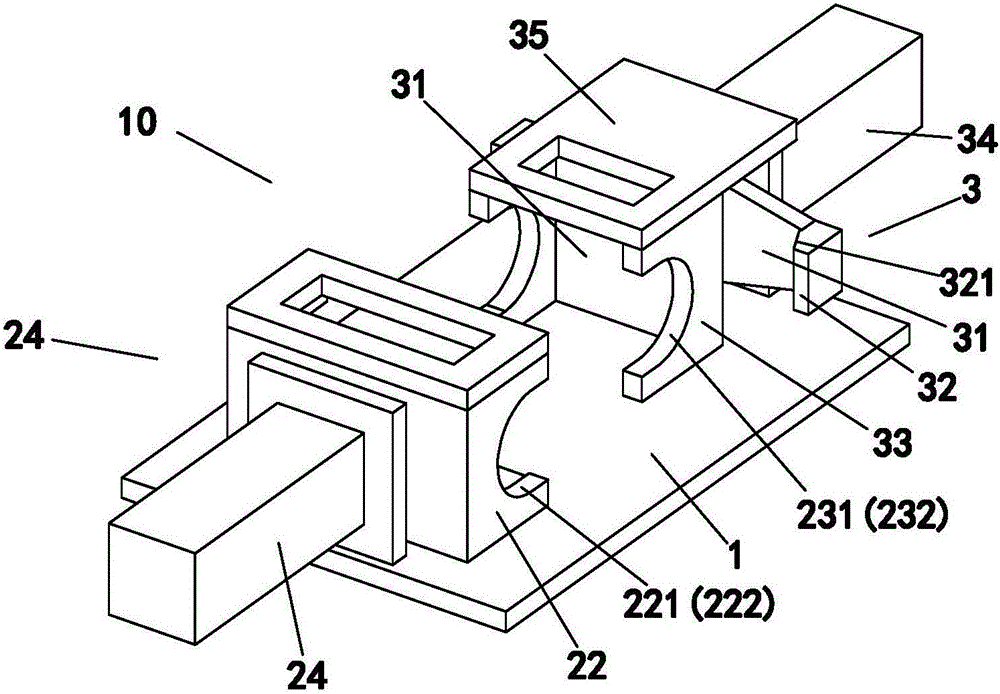

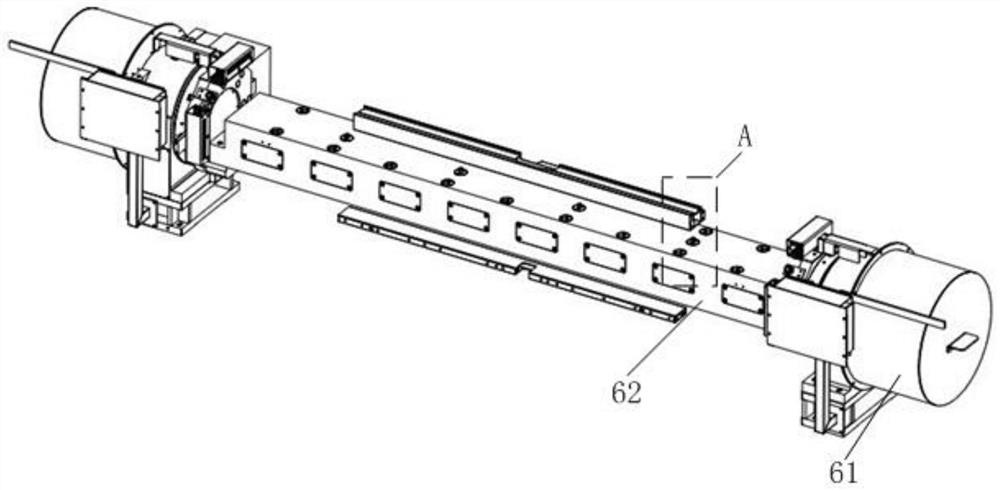

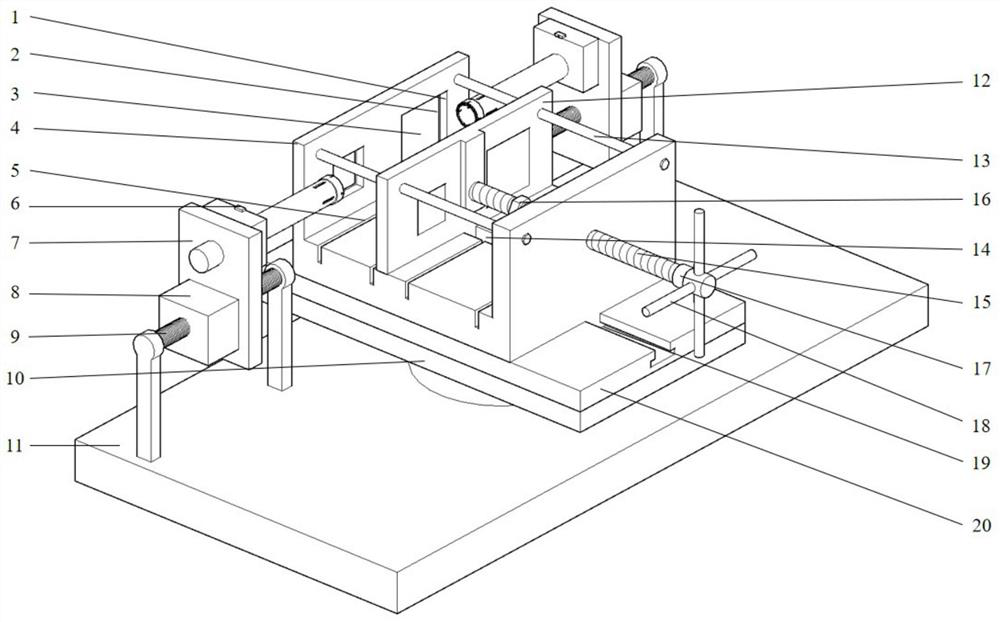

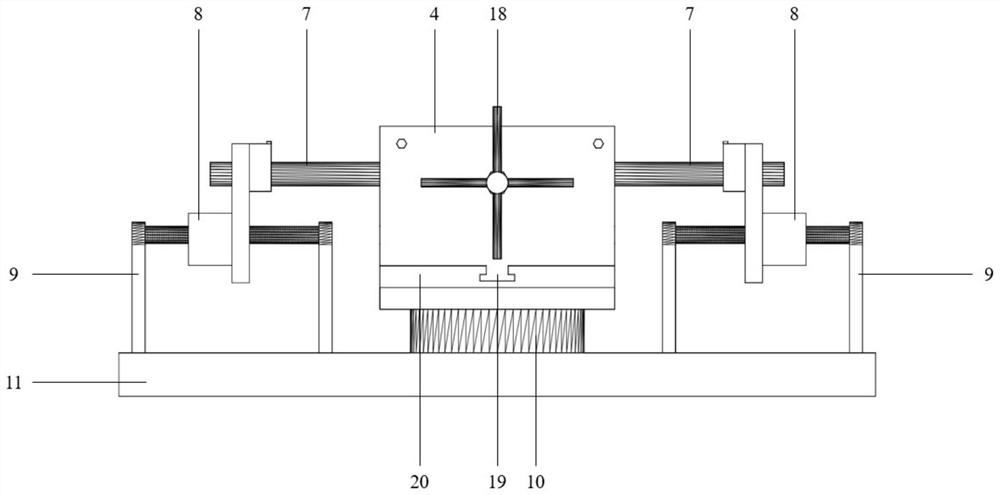

Chain sheet clamping device and chain sheet machining equipment with same

ActiveCN106002267AEasy to put inImprove machining accuracyOther manufacturing equipments/toolsPositioning apparatusEngineeringMachining

The invention discloses a chain sheet clamping device and chain sheet machining equipment with the chain sheet clamping device, and relates to the field of clamping devices for clamping chain sheets and chain sheet machining equipment. The chain sheet clamping device comprises an installation base, a first end jacking mechanism and a second end jacking mechanism. The first end jacking mechanism comprises a baffle, first side edge baffles arranged on the side faces of the baffle and a check block. The second end jacking mechanism comprises a movable baffle, second side edge baffles arranged on the side faces of the movable baffle and third side edge baffles. Different holes can be machined through one-time clamping of the chain sheet clamping device, and therefore machining precision and production efficiency are improved. The chain sheet machining equipment comprises a machine base, the chain sheet clamping device arranged on the machine base and a first machining cutter set, wherein the first machining cutter set is arranged on the machine base, and the chain sheet clamping device and the first machining cutter set are perpendicularly and correspondingly arranged. By means of the chain sheet machining equipment, multiple chain sheets can be simultaneously machined, clamping is stable, machining precision can be improved, and machining production efficiency can also be greatly improved.

Owner:QUANZHOU LIANTUO MACHINERY CO LTD

Drill needle for FPC board

ActiveCN108422018AEasy to install and removeEasy to replaceTransportation and packagingPrinted circuit manufactureBiomedical engineeringEngineering

The invention discloses a drill needle for an FPC board. The drill needle for the FPC board comprises a needle handle, wherein a needle head mounting base is welded to one end of the needle handle; and a threaded hole is formed in the middle position of the needle head mounting base, a positioning groove is formed in the outer wall of one side, far away from the needle handle, of the needle head mounting base, and a mounting hole is formed in the position, located on one side of the positioning groove, inside the needle head mounting base. According to the drill needle for the FPC board, the needle handle, a needle head, a positioning ring, the needle head mounting base, a fixed screw rod, the positioning groove, the threaded hole and an unlocking button are arranged; when the needle headis installed, the needle head is fixed on one side of the needle head mounting base through the fixed screw rod and the positioning ring, the needle head mounting base is welded to one end of the needle handle, so that the connection between the needle handle and the needle head is completed, and the positioning ring and the fixed screw rod are used for enabling the needle head and the needle headmounting base to be effectively fixed; and meanwhile, the installation position of the needle head can be effectively limited by a lock rod in the positioning ring, the phenomenon that the needle head of the drill needle is loosened in the rotating process is avoided, and therefore the fixation stability of the needle head is ensured.

Owner:深圳市金峰环保科技有限公司

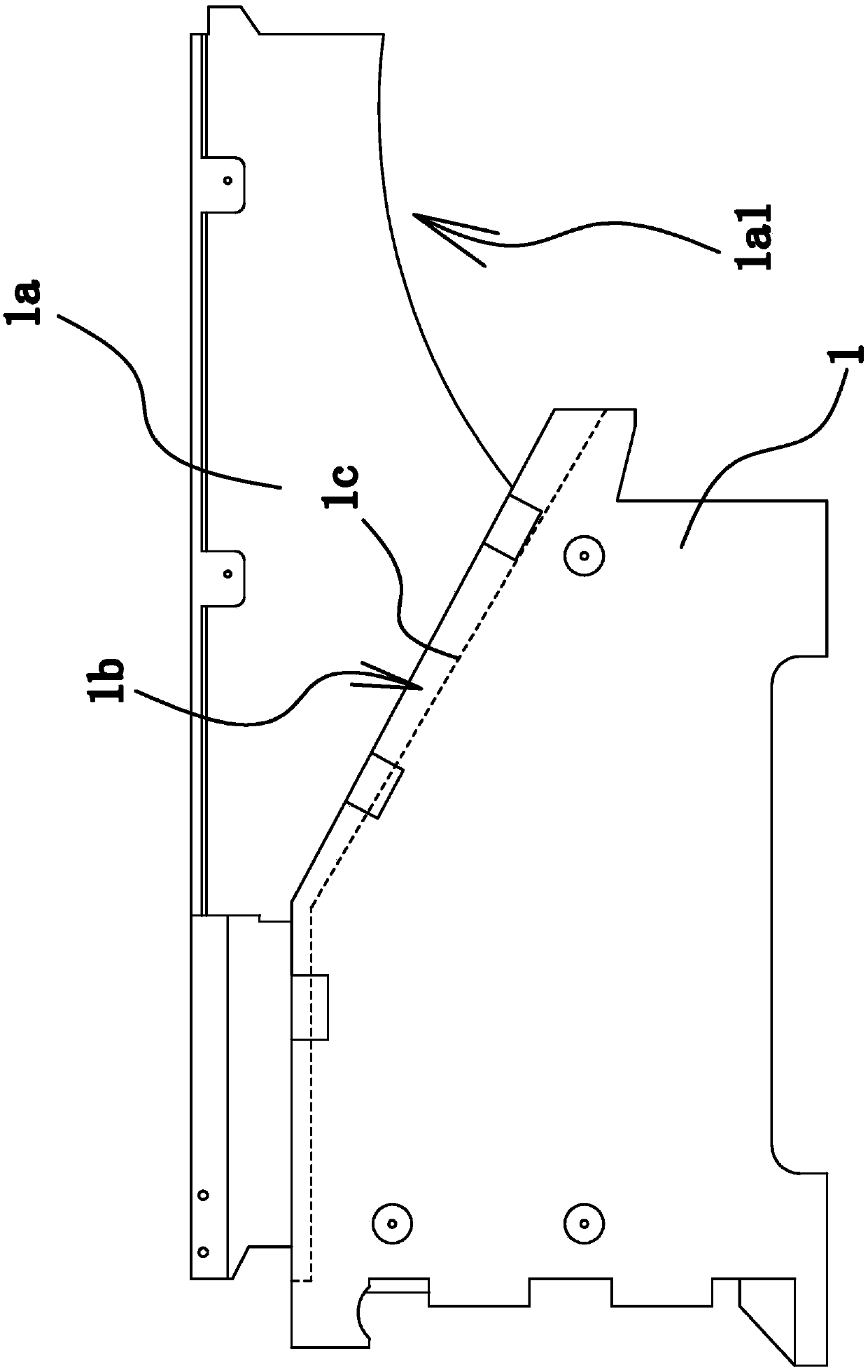

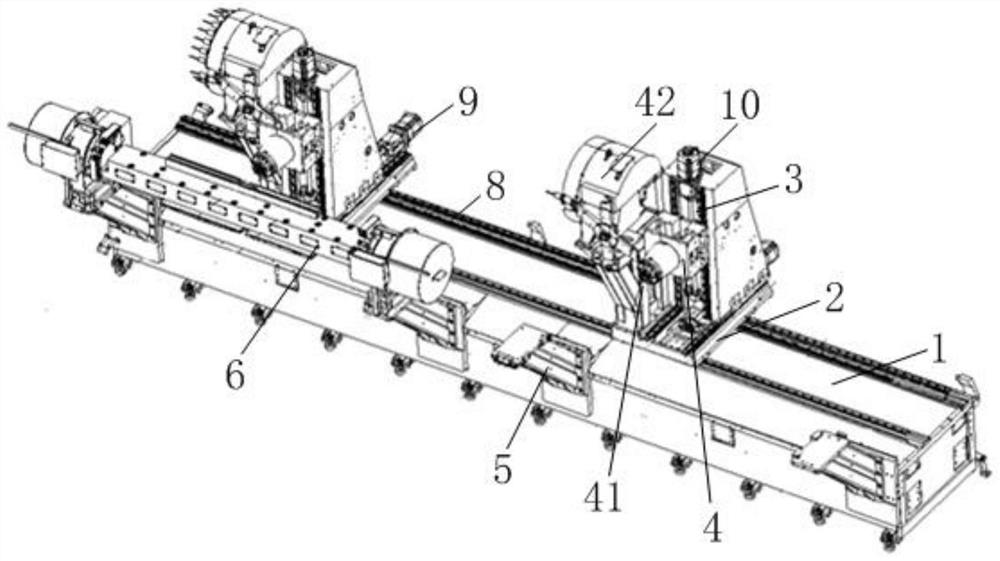

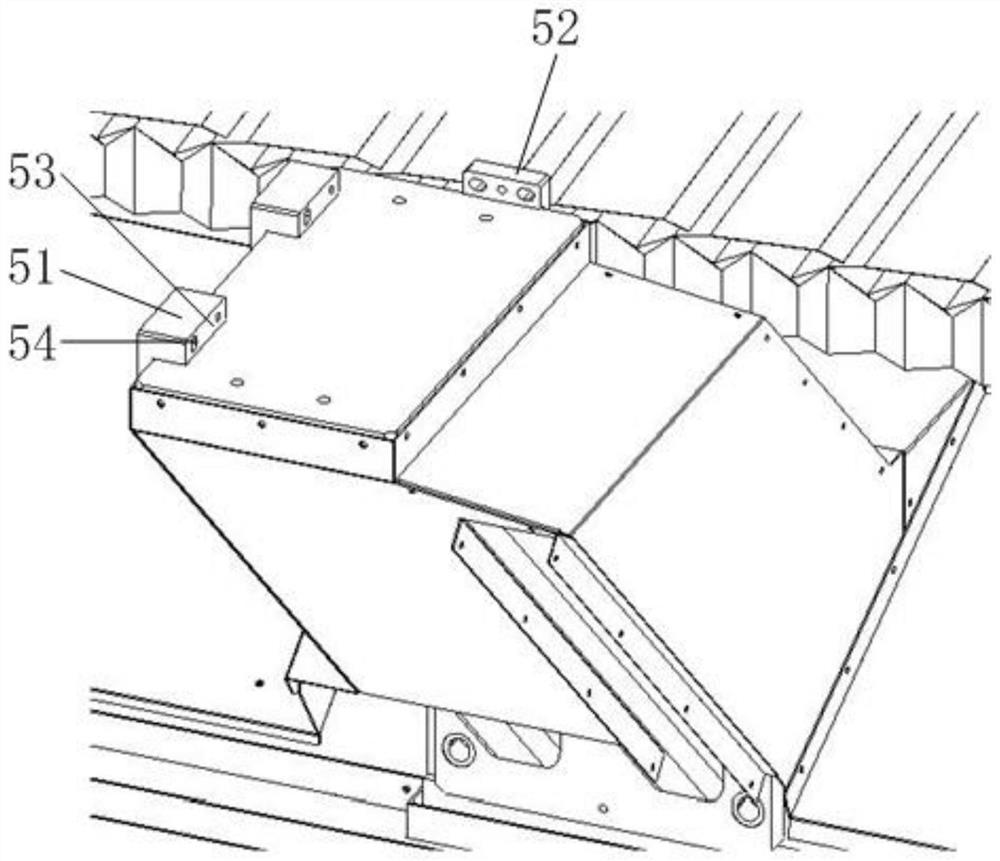

Special double-machine-head horizontal machining center for new energy automobile accessory machining

PendingCN114346705AAchieve impactAvoid accumulationSolid waste disposalLarge fixed membersNew energyCantilever

The embodiment of the invention discloses a double-machine-head horizontal machining center special for new energy automobile accessory machining. The double-machine-head horizontal machining center comprises a lathe bed, a saddle, a stand column, machine heads, a cantilever supporting workbench, a clamp mounting table and a scrap recycling system. The saddle is arranged on the lathe bed and can slide along the lathe bed; the stand column is arranged on the saddle, and the machine head is arranged on the stand column and can move up and down along the stand column; the cantilever supporting workbench is obliquely arranged on one side of the lathe bed and used for installing the clamp installing table. The chipping recycling system is used for recycling chippings generated by machining. The clamp mounting table is mounted on the cantilever supporting workbench obliquely arranged on one side of the lathe bed, the problem of difficulty in chip removal can be solved in cooperation with the chip recovery system, automatic chip removal is achieved, clamping is convenient, and the machining efficiency is high.

Owner:FOSHAN PRATIC CNC SCI & TECH

Milling cutter for machining carbon fiber composite material

The invention discloses a milling cutter for machining a carbon fiber composite material. The milling cutter comprises a handle part, a right blade part and a left blade part are sequentially arrangedat the front end of the handle part from left to right, the right blade part comprises a plurality of right-handed teeth spirally arranged rightwards in the circumferential direction, the left bladepart comprises a plurality of left-handed teeth spirally arranged in the direction opposite to the right-handed teeth in the circumferential direction, wherein the right-handed teeth and the left-handed teeth are distributed in a staggered mode, the surfaces of the right-handed teeth and the surfaces of the left-handed teeth are coated with diamond super-wear-resistant coatings correspondingly, the distance between the tail ends of the right-handed teeth and the front ends of the left-handed teeth is 0.6-0.8 mm, right-handed chip discharge grooves a are formed among the right-handed teeth, andleft-handed chip discharge grooves b are formed among the left-handed teeth. According to the milling cutter for machining the carbon fiber composite material, fiber splitting or burrs and the like on the upper edge and the lower edge of a carbon fiber composite plate are restrained at the same time through the opposite axial force of the right blade part and the left blade part, the chip containing space is large, larger milling cutting width can be achieved, the rigidity is good, the machined powdery carbon fiber material can be smoothly discharged, and carbon fiber powder accumulation caused by unsmooth chip discharge is avoided.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

Drilling and coring device for early-age concrete

InactiveCN113008612AIncrease chip removal spaceImprove precision controlAnalysing solids using sonic/ultrasonic/infrasonic wavesWithdrawing sample devicesLaser rangingClassical mechanics

The invention relates to a drilling and coring device for early-age concrete. The device is composed of a positioning groove, a wave velocity measuring probe, a fixed support, a drainage tank, a laser range finder, a coring drill bit device, a motor, a thread fixing assembly, a hydraulic jack, a base, a movable fixing plate, an auxiliary positioning rod, a propelling screw, an electronic torque measuring meter, a torque measuring meter handle, a T-shaped sliding groove plate, a notch, a chip removal opening and carborundum particles. According to the wave velocity condition of the cubic sample measured by the wave velocity measuring probe, the sample is subjected to stage treatment under different wave velocity levels, so that double-end-face coring is realized, and the coring efficiency is greatly improved; the coring bit device is subjected to nickel plating treatment, the bit part is provided with the chip removal opening, and the notch part is electroplated with carborundum, so that a larger chip removal space is provided in the early-age concrete drilling and coring process, and the problems are solved that the internal cementing capacity of the early-age concrete is poor, the gelation structure strength is low, and the friction force between the inner wall of the drill bit and the core sample is too large, so that the core sample is broken and has unfilled corner.

Owner:ANHUI UNIV OF SCI & TECH

Brazed super abrasive band saw and preparation method thereof

ActiveCN104589226AGuaranteed StrengthSolve application problemsGrinding devicesMetal working apparatusHigh volume manufacturingEconomic benefits

The invention relates to a brazed super abrasive band saw and a preparation method thereof. The band saw comprises a band saw substrate and a super abrasive, wherein the super abrasive is brazed on a U-shaped sleeve; the U-shaped sleeve is adhered to the edge of the band saw substrate. The preparation method comprises the following steps: bending a thin steel sheet; arranging the abrasive and a solder; feeding in a furnace to braze; adhering and fixing to the outer edge of the band saw substrate in a thermosetting manner and the like. The process and the method for preparing the brazed super abrasive band saw have the characteristics of simple processes, convenience in operation, stable quality and suitability for batch production. The prepared band saw has the advantages of high exposure and high chip removal space of the brazed super abrasive, the strength of the band saw substrate is also guaranteed, and the application problem of a super abrasive brazing technology in the band saw field is perfectly solved. The band saw and the method have a significant effect and economic benefit on promotion of development of the band saw field.

Owner:NANJING HUICHENG TOOL MFG

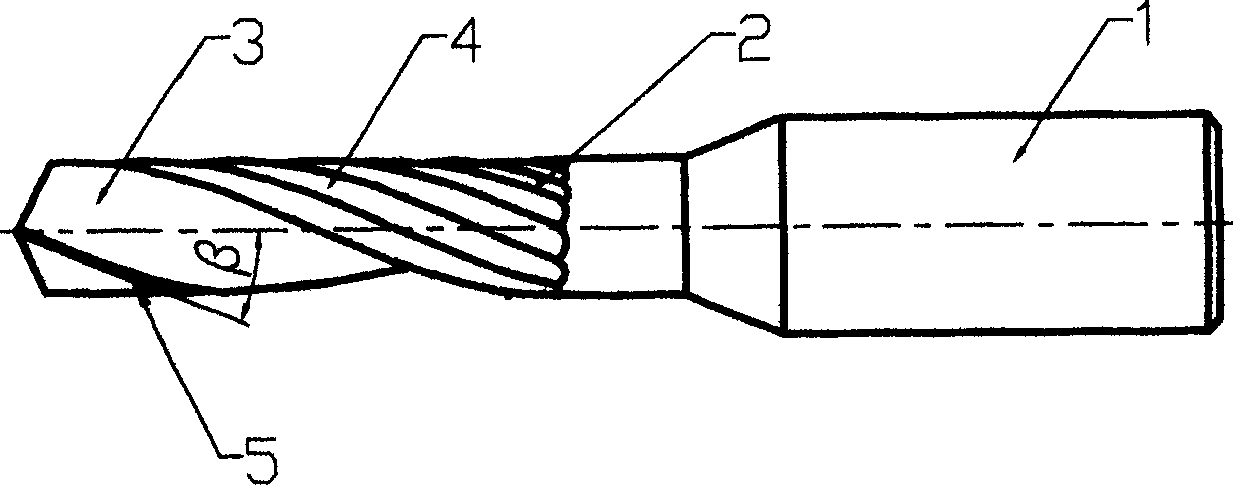

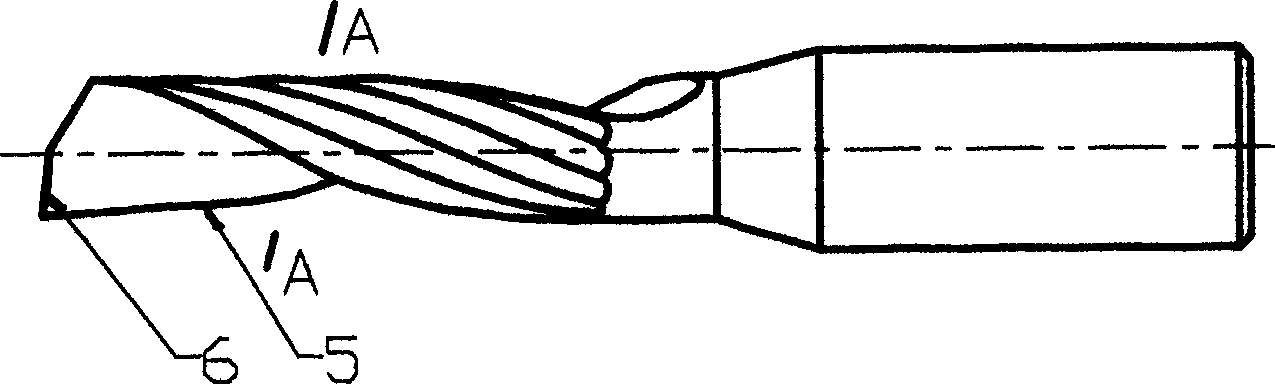

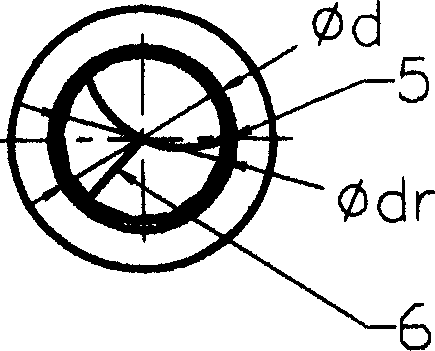

Multi-step forming reamer

The invention discloses a multi-step forming reamer. The multi-step forming reamer comprises a shank (1) and a reamer body (2), wherein the reamer body (2) comprises a plurality of end cutting edges (3), peripheral cutting edges (4) connected between the end cutting edges (3) and the shank (1), and chip removal grooves (5) correspondingly formed between the peripheral cutting edges (4); each of the peripheral cutting edges (4) is of a right hand spiral structure and is provided with at least two steps; rake angles of the steps are positive rake angles; and the closer the steps are to the shank(1), the larger the diameters and rake angles of the steps are. In the multi-step forming reamer, the step with the largest diameter adopts a large rake angle, and the rake angle of the step with thesmallest diameter can be ensured to be the positive rake angle so as to enhance the sharpness of the cutting edges, reduce the cutting resistance, and significantly improve the surface quality and roughness of inner walls of holes.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

Scale-like dense-tooth diamond coating milling cutter for composite material

InactiveCN111136313AGuaranteed smoothIncrease chip removal spaceMilling cuttersWorkpiecesMilling cutterSurface smoothness

The invention relates to a scale-like dense-tooth diamond coating milling cutter for composite material. A plurality of circumferential cutting edges are arranged on a cutter body in the circumferential direction, right spiral chip removal grooves are formed among the circumferential cutting edges, protective cutter edges with shallow-groove-shaped structures are arranged on the right spiral chipremoval grooves, circumferential cutting edge backs are formed on the cutter body through the right spiral chip removal grooves, left-handed left spiral chip removal grooves are formed in the circumferential cutting edge backs, a plurality of end cutting edges are arranged at the front end of the cutter body, and chip containing grooves are formed among the end cutting edges. According to the scale-like dense-tooth diamond coating milling cutter for the composite material, a left spiral and right spiral crossed scale-like structure is adopted, the groove bottoms of the left spiral chip removalgrooves and the right spiral chip removal grooves are arc-shaped, the chip removal space is enlarged, the flowing speed of chips is increased, the chips are cut off and extruded through the right-handed sharp face and the left-handed sharp-breaking face, machined surface smoothness is guaranteed, burrs and delamination phenomena are avoided, the material removal amount of each tooth is reduced, multiple layers of diamond coatings are coated, so that the hardness of the surface of the cutter is enhanced, the abrasion of the cutter is reduced, and the machining cutting speed and the material removal efficiency are improved.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

Micro three-wing bit and processing method thereof

The invention relates to the technical field of drill bits, and discloses a micro three-wing bit and a processing method thereof. The micro three-wing bit comprises a drill stem. The bottom end of the drill stem is provided with a drill end portion. The center of the drill end portion is provided with a drill tip. The periphery of the drill stem is provided with three chip pockets respectively arranged in a spiral manner along the drill stem. The three chip pockets are arranged at interval in sequence. The side edge of the drill end portion is provided with three main cutting edges. The three main cutting edges are arranged around the drill tip in sequence. The drill end portion is provided with three chisel edges, and the three chisel edges surround the drill tip in sequence, and are intersected at the drill tip. The side edge of the drill end portion is provided with three main cutting edges. When the drill tip is drilling, the drill end portion forms three support points, thereby increasing balance of the drill tip and reducing wearing of the main cutting edges. The three chip pockets increase chip removal time, and the length of the chisel edge is enough, thereby increasing core thickness and greatly improving rigidity of the drill tip. Therefore, for the drill tip, in a process of drilling, probability of drill broken phenomenon is greatly reduced.

Owner:GUANGZHOU PANYU POLYTECHNIC

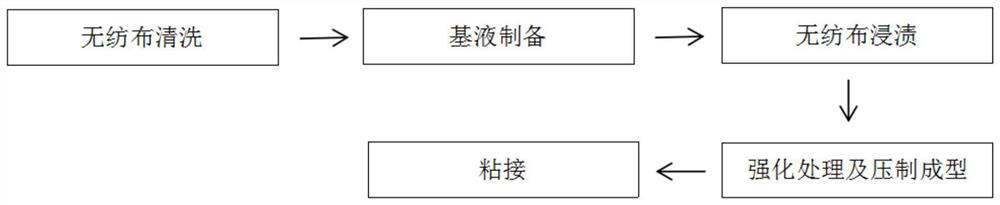

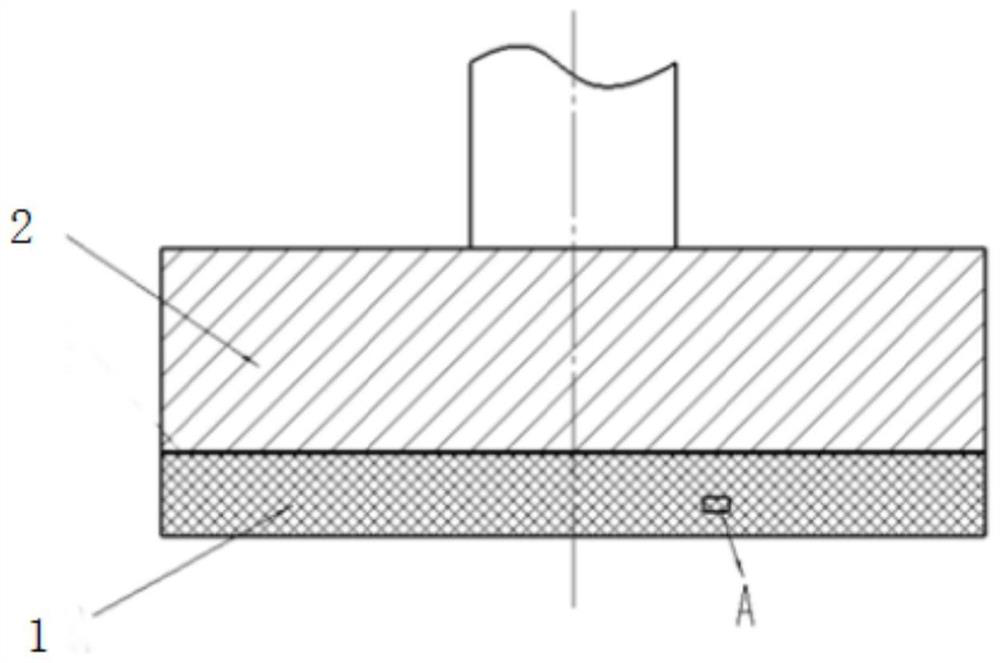

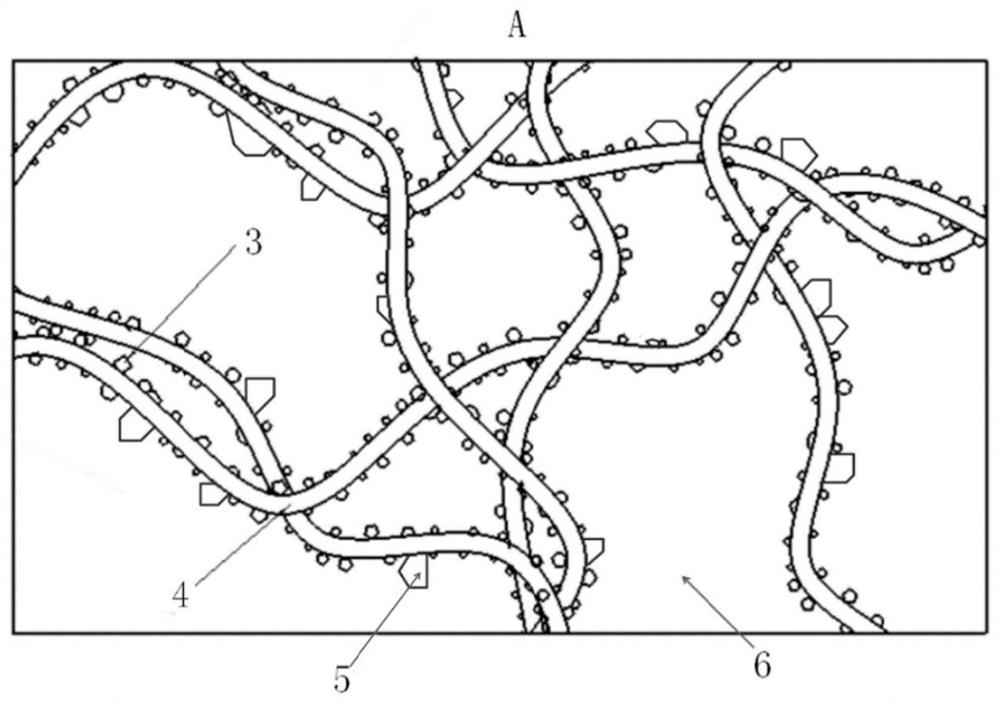

Polishing wheel for processing hard and brittle material and preparation method thereof

ActiveCN111775071AAvoid scratchesLow subsurface damageFlexible-parts wheelsGrinding devicesAlcoholNonwoven fabric

The invention provides a polishing wheel for processing a hard and brittle material and a preparation method thereof. The method comprises the following steps of taking a non-woven fabric as a polishing layer matrix, cleaning the non-woven fabric with a surfactant, then washing the non-woven fabric with deionized water and absolute ethyl alcohol successively, and finally drying the non-woven fabric; mixing and stirring screened abrasive particles, a dispersant, an additive and deionized water and adding a coupling agent, and placing the mixture in a water bath at a certain temperature to be stirred and vibrated continuously; placing the dried non-woven fabric in a base solution to be impregnated, slowly and uniformly stirring the non-woven fabric in the water bath at a certain temperaturefor a certain time, and drying the non-woven fabric; and placing the dried non-woven fabric in a die, and pressing the non-woven fabric for a certain time to prepare a polishing layer. The method is simple in process, low in cost and easy to implement and popularize.

Owner:DALIAN UNIV OF TECH

Miniature four-blade drill bit and machining method thereof

InactiveCN105127487AImprove balanceImprove rigidityTransportation and packagingTrepanning drillsSupport pointDrill bit

The invention relates to the technical field of drill bits, and discloses a miniature four-blade drill bit and a machining method thereof. The miniature four-blade drill bit comprises a drill rod. A drill end is formed at the bottom end of the drill rod, and a drill point is formed in the center of the drill end. Four chip containing grooves spirally formed in the axial direction of the drill rod are sequentially formed in the outer circumference of the drill rod at intervals. Four main cutting blades are formed on the lateral side of the drill end and sequentially surround the drill point. Four transverse blades are formed at the drill end, sequentially surround the drill point and are intersected at the drill point. As the four main cutting blades are formed on the lateral side of the drill end, when drilling is carried out through the drill bit, four supporting points are formed at the drill end, the balance of the drill bit is improved, and abrasion of the main cutting blades is reduced; the four chip containing grooves can increase chip discharging space, and the length of the transverse blades is sufficient, the core thickness can be increased accordingly, and the rigidity of the drill bit is greatly improved accordingly; in this way, in the drilling process of the drill bit, the drill bit breaking probability is greatly reduced.

Owner:GUANGZHOU PANYU POLYTECHNIC

Milling cutter provided with groove width gradual change type chip breaker groove

PendingCN107824855AGuaranteed space for chip removalIncrease chip removal spaceMilling cuttersGroove widthMilling cutter

The invention is applicable to the technical field of milling cutters, and discloses a milling cutter provided with a groove width gradual change type chip breaker groove. The milling cutter comprisesa milling cutter body; the milling cutter body comprises a cutter handle part and a cutting edge part connected with the cutter handle part; the cutting edge part is provided with at least two main spiral grooves and at least one chip breaker groove; the spiral direction of the at least one chip breaker groove is opposite to those of the at least two main spiral grooves; the width of the at leastone chip breaker groove is reduced from the edge point direction to the edge root direction of the cutting edge part; the range of the spiral angle of each main spiral groove is 20-45 degrees; and the range of the spiral angle of the at least one chip breaker groove is 20-85 degrees. According to the milling cutter provided with the groove width gradual change type chip breaker groove, the widthof the chip breaker groove of the milling cutter is reduced from the front to the back gradually, so that a dust exhaust space of the tip of the milling cutter is expanded emphatically on the condition that an overall chip removal space of the milling cutter is ensured, the dust blocking problem of the cutter tip is solved, the plate edge processing quality is good, the abrasion to the milling cutter can be reduced, and the service life of the milling cutter can be prolonged advantageously.

Owner:SHENZHEN JINZHOU PRECISION TECH

A Composite Drill Bit Suitable for Difficult-Drilling Formation

ActiveCN106437525BAdjust the tooth densityIncreased axial wear volumeDrill bitsConstructionsPetroleum engineering

The invention discloses a composite drill bit suitable for a stratum difficult to drill. The composite drill bit suitable for the stratum difficult to drill comprises a drill bit body, cutter wings which are fixedly connected with the drill bit body, tooth wheels which are rotatably connected with the drill bit body, and water holes or nozzles which are arranged on the drill bit body. A plurality of first sets of cutting teeth are arranged on each cutter wing. Pits are formed in the sides, provided with the teeth, of the cutter wings and used for fixing the first sets of cutting teeth. The tooth wheels are rotatably connected with the drill bit body through tooth palms. Teeth are mounted on the tooth wheels. In the common coverage area of the body contour line of at least one cutter wing and the body contour line of at least another cutter wing, at least one non-overlapping area and at least one overlapping point or overlapping area exist. Through the structure characteristic, the drill bit can operate in an asynchronous cutting mode, the longitudinal abrasion length of the drill bit can be increased, and the service life of the drill bit can be prolonged; and the drill bit is in a high-specific-pressure drilling state in the whole drilling process, the capacity to intrude into rocks of the drill bit is improved, the drilling speed of the drill bit in the stratum difficult to drill is increased accordingly, and the service life of the drill bit in the stratum difficult to drill is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV +1

Multi-edge super-small-diameter drill point

InactiveCN104668636AReduced service lifeImprove rigidityTransportation and packagingTrepanning drillsEngineeringMachining process

The invention discloses a multi-blade super-small-diameter drill point, comprising a point handle and a point body arranged at one end of the point handle, wherein one end, far away from the point handle, of the point body is a tip part, the surface of the point body is provided with a plurality of spiral chip grooves to the tip part along the axial direction of the point body, the plurality of spiral chip grooves are evenly spaced and divide the tip part into a plurality of identical branch tip parts, a cutting edge is formed at the junction of each chip groove and the corresponding branch tip part, each branch tip part is provided with a first rear cutter surface and a second rear cutter surface in sequence outside the side, far away from the corresponding chip groove, of the corresponding cutting edge, and a chisel edge is formed at the junction of the first and second rear cutter surfaces of every two adjacent branch tip parts. According to the multi-blade super-small-diameter drill point, each cutting edge is formed by the corresponding equant symmetric edges; different from the existing cutter machining mode, the drill point has the advantages that wear in a stainless steel machining process is favorably reduced, and the machining problems of point breakage, short service life, and the like during stainless steel drilling within the diameter range between 0.1mm and 0.5 mm can be solved.

Owner:HPTEC CHINA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com