Brazed super abrasive band saw and preparation method thereof

A super-hard abrasive, band saw technology, used in grinding/polishing equipment, grinding devices, manufacturing tools, etc., can solve the problems that do not involve the production process and method of the band saw, the high requirements for the riveting process, and the difficulty in achieving Ultra-thin and other problems, to achieve a major role and economic benefits, guaranteed strength, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Take the preparation of conventional brazed diamond band saws as an example. The size of the band saw is: width 38mm, substrate thickness 0.8mm, and the total length of the band saw is 1600mm. A segmented diamond abrasive area is arranged on the band saw, and the size of the area is: length × width = 10mm × 5mm. There are 80 sections in the diamond cloth area.

[0038] The specific implementation method is as follows:

[0039] 1. Prepare a thin steel sheet, the material is stainless steel, the thickness of the thin steel sheet is 0.2mm, the length of the sheet is 10mm, and the width is 11mm.

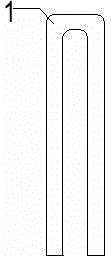

[0040] 2. If figure 1 As shown, the thin steel sheet 1 is equally bent, and the gap in the middle after bending is set to 0.3 mm.

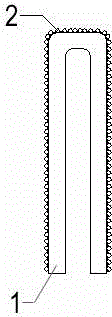

[0041] 3. If figure 2 As shown, superabrasive grains 2 are arranged on the thin steel sheet 1 above. In this embodiment, diamond abrasives are used, and the grain size of the abrasives is 80-100 mesh.

[0042]4. Spread solder on the thin steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com