Ring-shaped superhard abrasive wire and manufacturing method thereof

A technology of superhard abrasives and production methods, which is applied in the direction of manufacturing tools, fine working devices, stone processing tools, etc. It can solve problems such as difficult discharge, small chip space, and wire saws cannot work, and achieves simple methods and mass production. Fast, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail, to better understand content of the present invention.

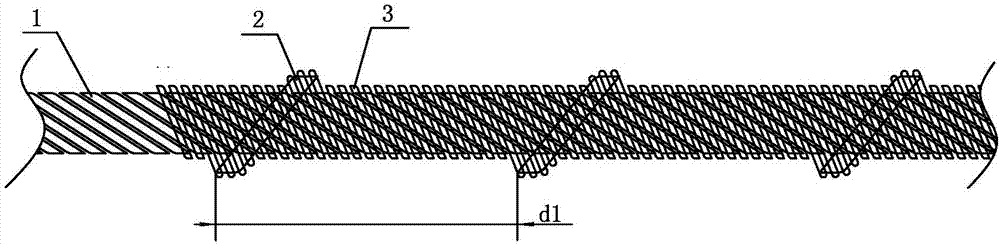

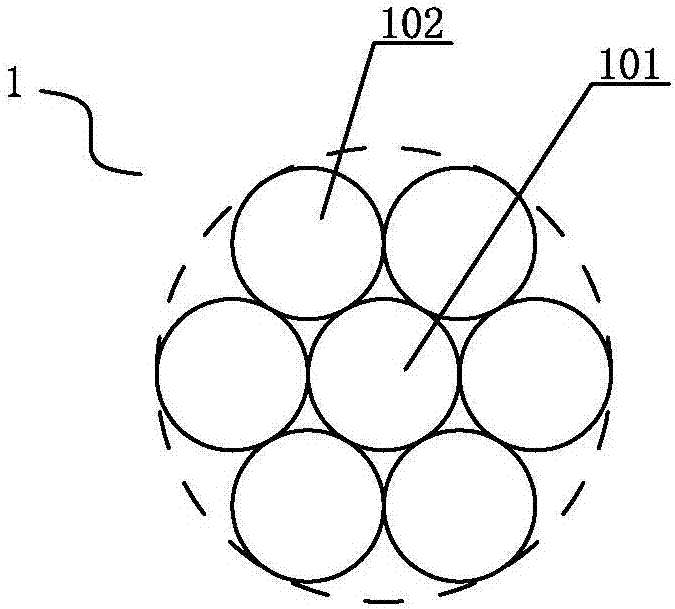

[0034] figure 1 It is a structural schematic diagram of an embodiment of the annular superabrasive wire of the present invention, the matrix of the annular superabrasive wire is a silk rope 1 with a diameter of 0.1 mm to 6 mm, and a silk thread 2 is sparsely wound on the silk rope 1, The exposed part of the silk rope 1 and the silk thread 2 are tightly wound with an abrasive silk thread 3; wherein the pitch d1 of two adjacent sections of the silk thread 2 on the silk rope 1 is greater than or equal to 3 times the diameter of the abrasive silk thread 3; in the silk rope 1 or on the wire 2, two adjacent sections of the abrasive wire 3 are arranged sequentially without overlapping each other, and at the same time, the peripheral walls of the adjacent two sections of the abrasive wire 3 are in contact with each other;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com