Polishing wheel for processing hard and brittle material and preparation method thereof

A technology of hard and brittle materials and polishing wheels, which is applied to wheels with flexible working parts, metal processing equipment, grinding/polishing equipment, etc., which can solve the problem of inability to prepare fine-grained abrasive polishing pads and low porosity of polishing pads. , easy to block and other problems, to achieve the effect of easy implementation and promotion, low subsurface damage, and uniform removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

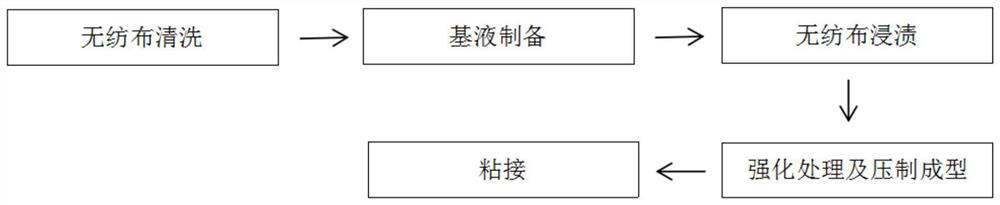

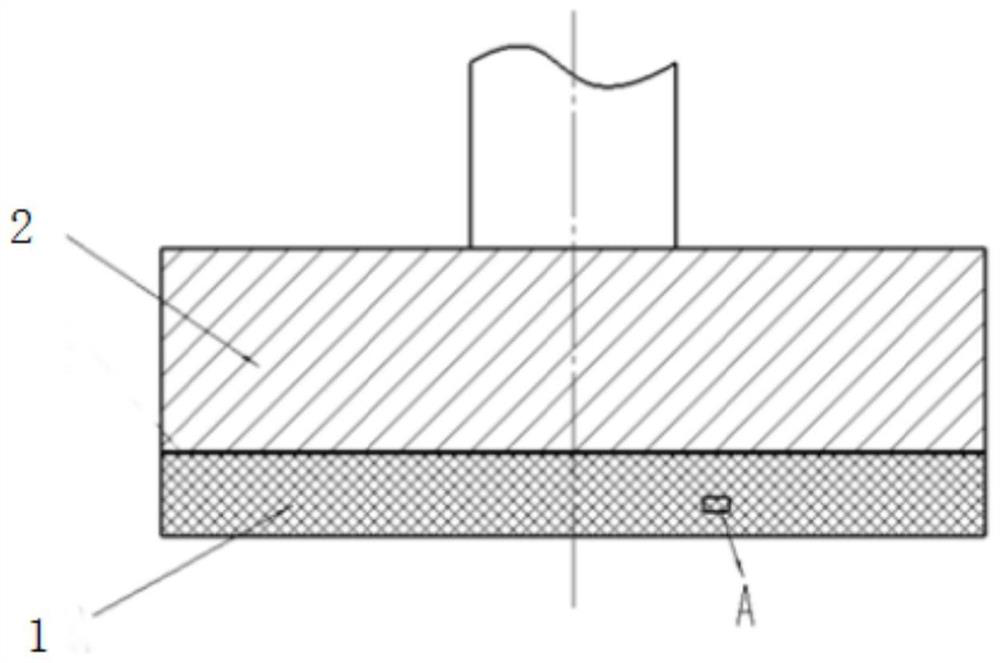

[0031] S1. Cleaning of non-woven fabric: Take a piece of nylon non-woven fabric 4 and use surfactant to clean the non-woven fabric, then wash it with deionized water, anhydrous ethanol, and finally dry it in a hot oven;

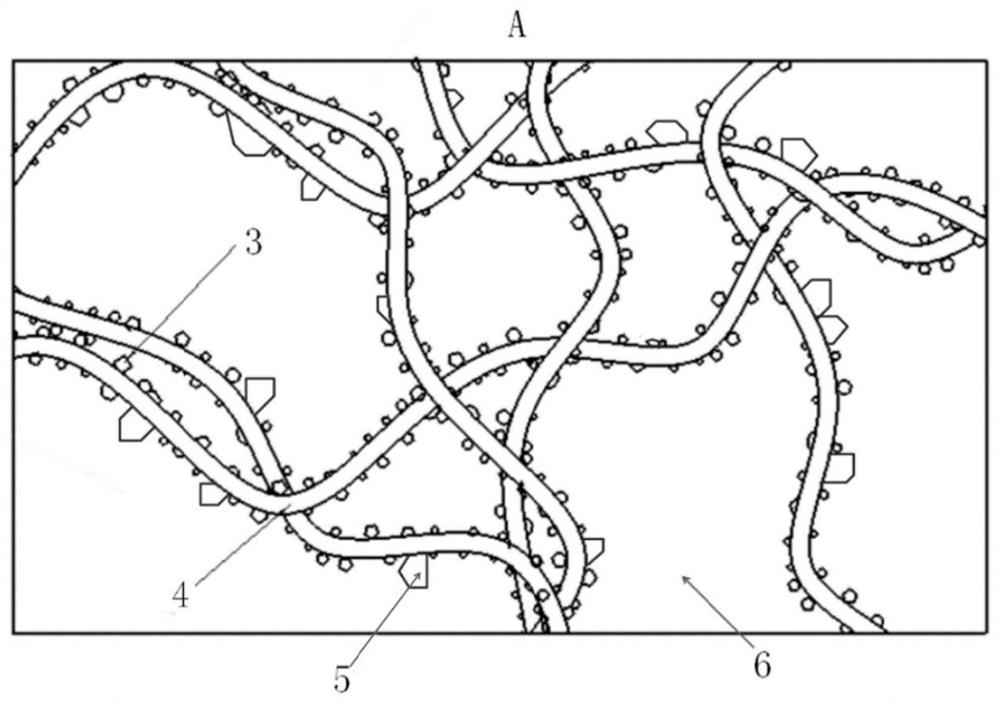

[0032] S2, base liquid preparation: get 25g abrasive material 3 particle diameters and be the diamond of 5 micrometers, 1g potassium tripolyphosphate dispersant, 100g deionized water, 5g sodium carbonate additive 5 are mixed evenly, add 3g titanate coupling agent, then in Continuous vibration and stirring in a water bath at 20°C;

[0033] S3. Impregnation of non-woven fabric: put the base liquid prepared in S2 into a water bath at 20°C, then put the non-woven fabric 4 obtained in the first step into the base liquid, dip it and stir it slowly and uniformly for 10 minutes, and dry it in a hot oven;

[0034] S4. Press molding: put the nylon non-woven fabric 4 impregnated in S3 into a mold, and press at a temperature of 150° C. and a pressure of 50 kg for 5 minut...

Embodiment 2

[0037] S1. Cleaning of non-woven fabric: Take a piece of wool non-woven fabric 4 and use surfactant to clean the non-woven fabric, then wash it with deionized water, anhydrous ethanol, and finally dry it in a hot oven;

[0038] S2. Preparation of base liquid: Take 35g of abrasive 3, silica abrasive with a particle size of 200nm, 5g of sodium hexametaphosphate dispersant, 150g of deionized water, and 10g of potassium permanganate additive 5, mix well and add 3g of titanate coupling agent, then vibrate and stir continuously in a water bath at 40°C;

[0039] S3. Impregnation of non-woven fabrics: put the base liquid obtained in S2 into a water bath at 30°C, then put the wool non-woven fabric 4 obtained in the first step into the base liquid, dip it and stir it slowly and evenly for 10 minutes, and dry it in a hot oven ;

[0040] S4. Press forming: the wool non-woven fabric 4 impregnated in S3 is put into a mold, and pressed at a temperature of 180° C. and a pressure of 30 kg for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com