Multi-edge super-small-diameter drill point

A technology of small diameter and drill needle, which is applied in the direction of repairing drills, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of low life and broken needles, etc., and achieve the effect of long service life, reduced broken needles and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

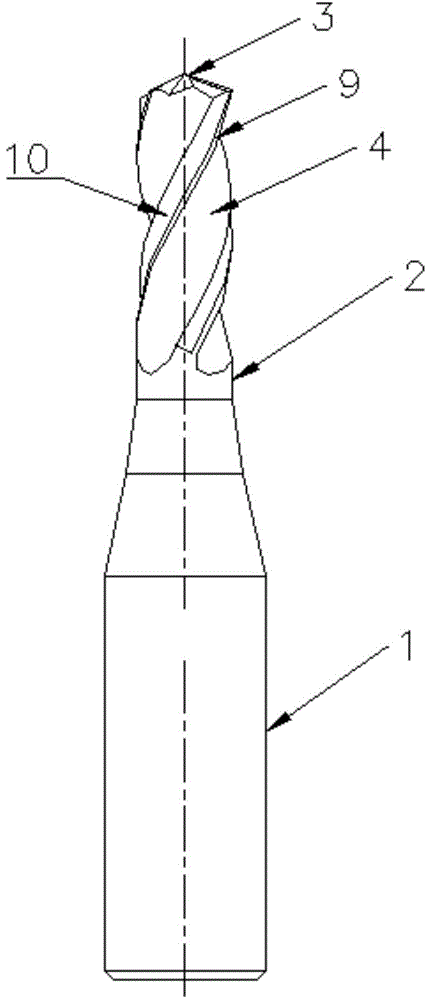

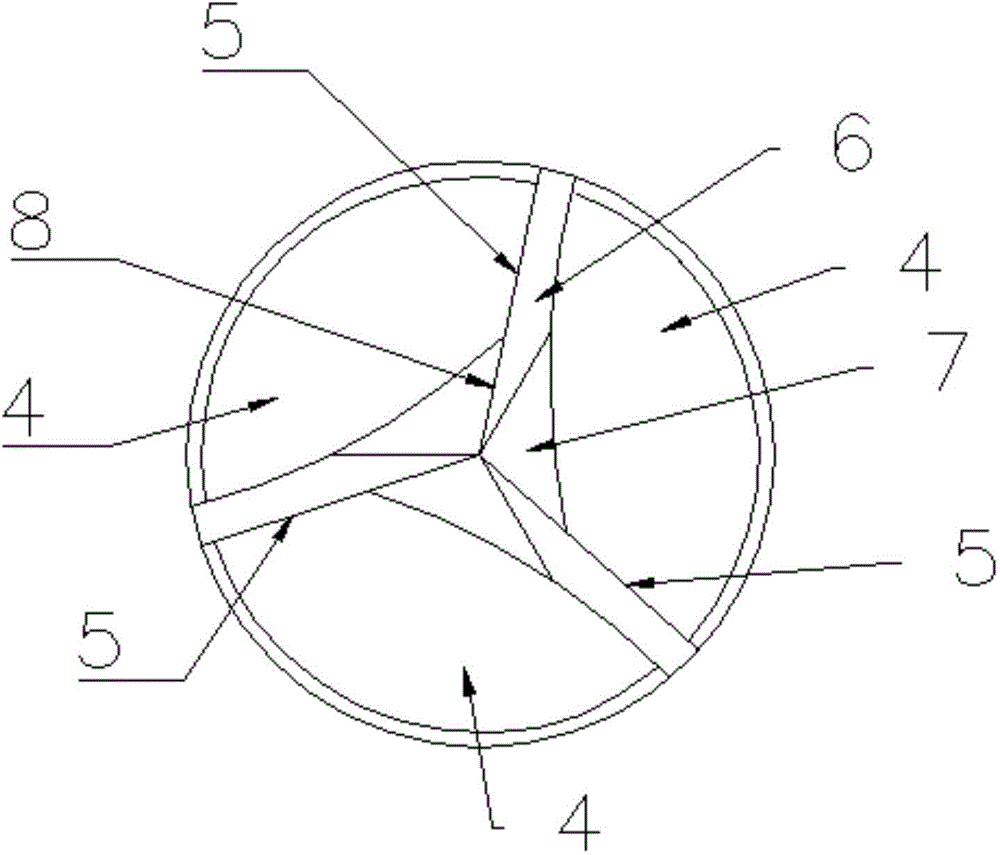

[0019] Such as figure 1 , 2 As shown, a multi-edged ultra-small-diameter drill includes a needle handle 1 and a needle body 2 arranged at one end of the needle handle. The end of the needle body away from the needle handle is a tip 3. Several helical chip removal grooves 4 are provided from the axis direction of the needle body to the tip, and several helical chip removal grooves are arranged at equal intervals and divide the tip into several identical sub-points; each row The cutting edge 5 is formed at the junction of the chip f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com