Milling cutter for machining carbon fiber composite material

A composite material and carbon fiber technology, used in milling cutters, metal processing equipment, tools for milling machines, etc., can solve the problems of edge splitting or burrs on carbon fiber composite boards, splitting or burrs on composite boards, and avoid carbon fiber. The effect of powder accumulation and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

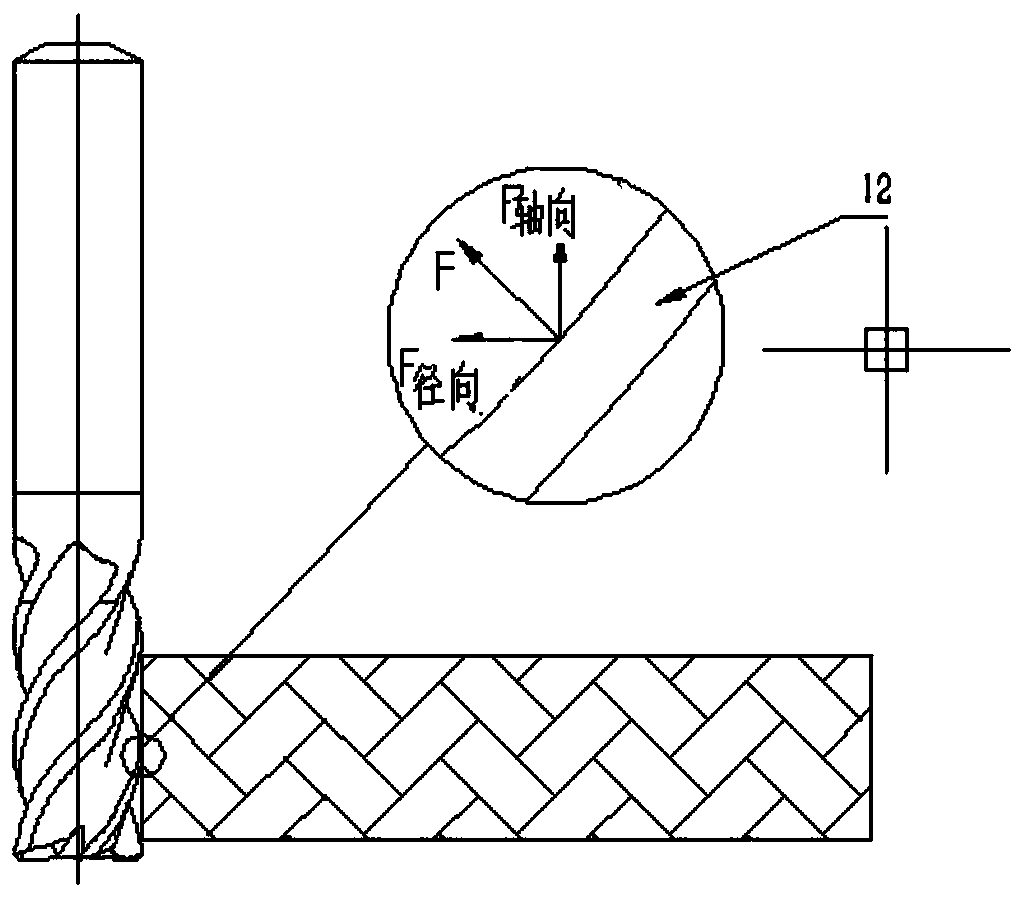

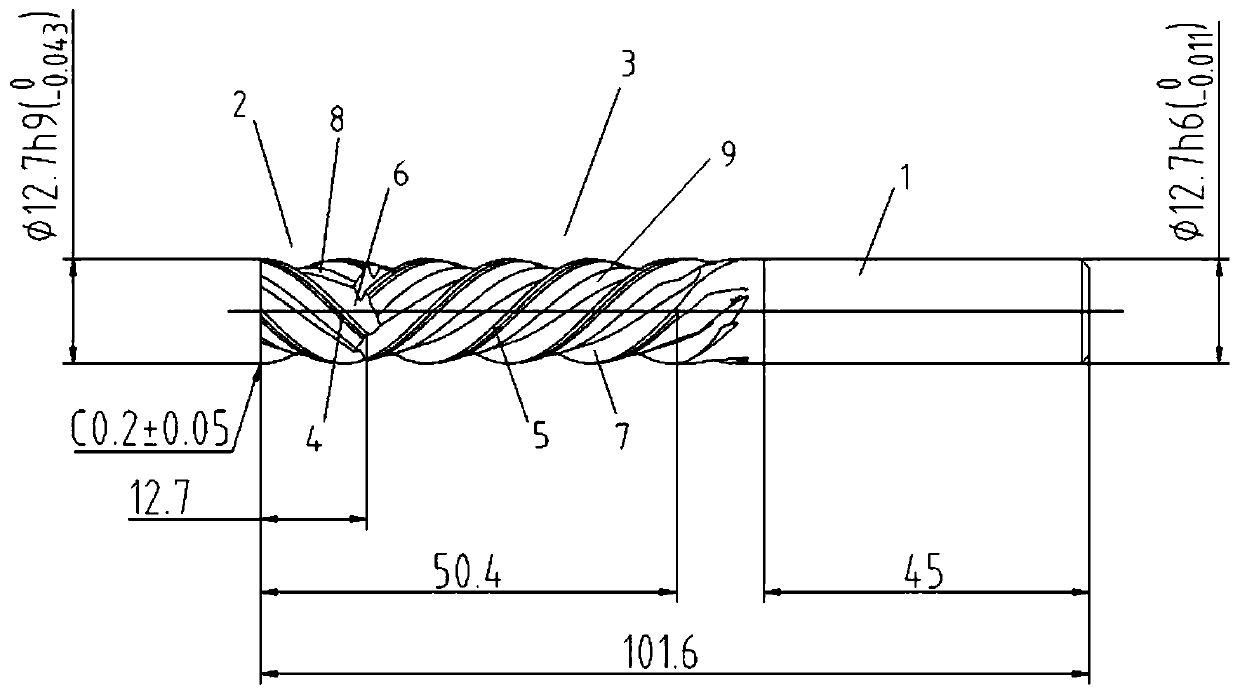

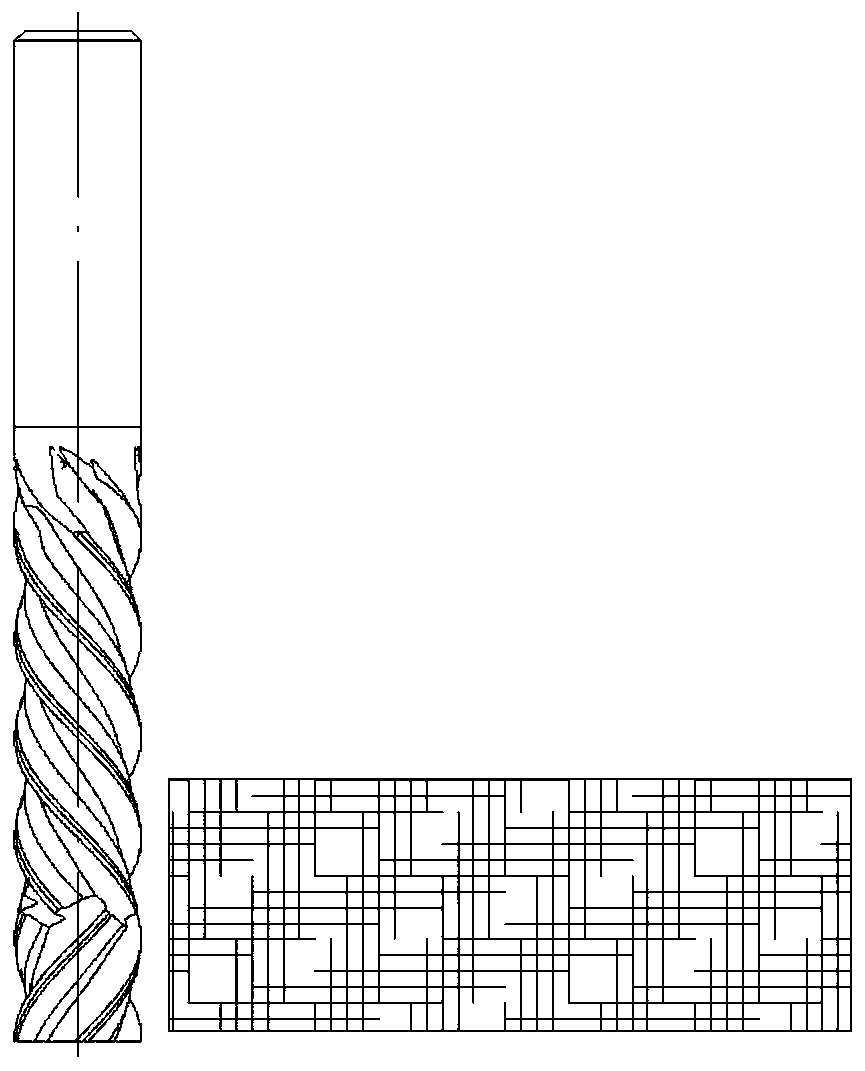

[0033] like Figure 2-8 As shown, a milling cutter for processing carbon fiber composite materials includes a cylindrical shank 1 with a diameter of 12.7mm. Shaft, the right blade part 2 includes several right-handed teeth 4 arranged in a rightward helical direction along the circumferential direction, and the left blade part 3 includes several left-handed teeth 5 arranged in a reverse helical manner with the right-handed teeth 4 along the circumferential direction, for To prevent no cutting ability between the right-handed teeth 4 and left-handed teeth 5, the right-handed teeth 4 and left-handed teeth 5 are alternately distributed and the surfaces of the two are coated with diamond super wear-resistant coating, the distance between the end of the right-handed teeth 4 and the front end of the left-handed teeth 5 The distance is denoted as L, and the value range of L is 0.6-0.8mm. The right-handed teeth 4 form right-handed flutes a6 with each other, and the left-handed teeth 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com