Molded package for light-emitting device and light-emitting device using the same

A technology of light-emitting devices and molded bodies, applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems of aesthetic damage, etc., and achieve the effects of inhibiting intrusion, inhibiting the occurrence of burrs, and inhibiting the formation of burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

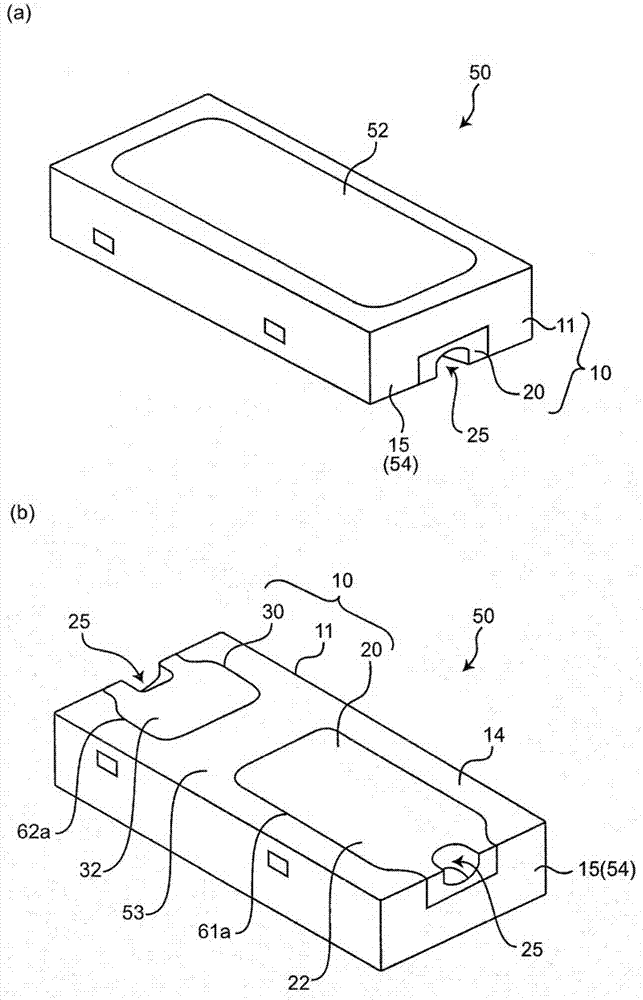

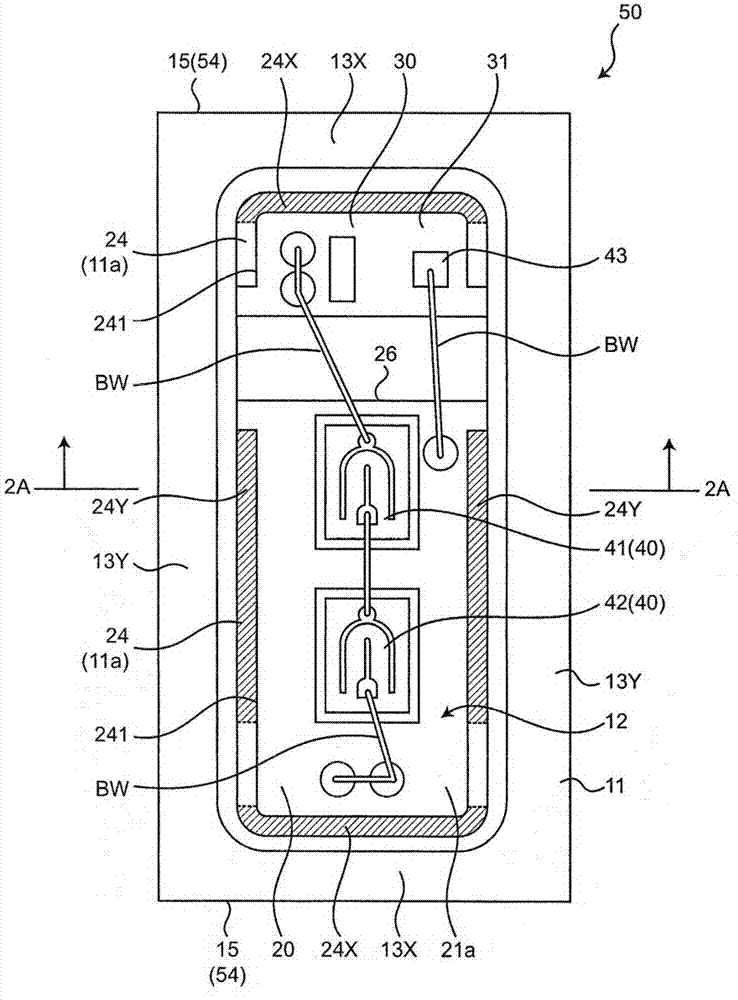

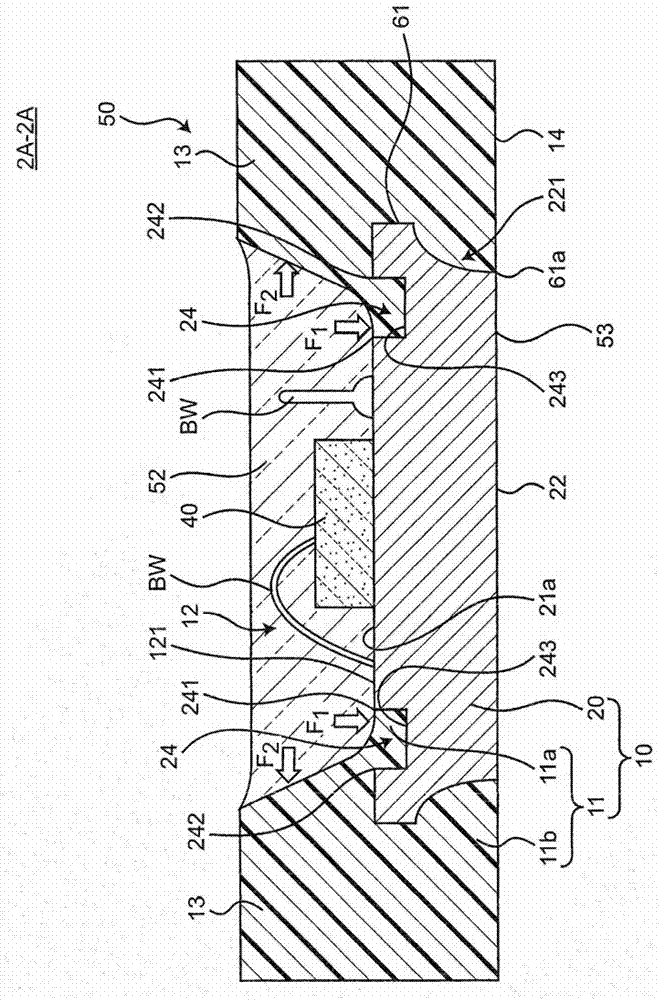

[0062] like Figure 1~3 As shown, a light-emitting device 50 of the present invention includes a molded package 10 , a light-emitting component 40 and an encapsulating resin 52 .

[0063] The so-called "light-emitting component 40" in this specification refers to a component including a light-emitting element, including a light-emitting element (such as an LED) itself, or a component composed of a light-emitting element and a submount (submount: submount). In this embodiment, the light emitting component 40 is constituted by a light emitting element.

[0064] As for the encapsulating resin 52 , it encapsulates the concave portion 12 of the resin molded body 11 containing the light emitting component 40 and protects the light emitting component 40 from the external environment.

[0065] The molded package 10 of the present invention includes a molded resin 11 and at least one lead (in this embodiment, two leads 20 and 30 ).

[0066] The resin molded body 11 has a recessed por...

Embodiment 1

[0142] As an example of the present invention, the molded package 10 and the molded package 100 for comparison were produced, and the presence or absence of the burr 80 was confirmed.

[0143] The manufacturing process of the molded package 10 of the present invention is as follows. First, wet etching is performed on the lead frame LF in which the first lead 20 and the second lead 30 are connected by the tie bar TB, and after forming the groove portion 24 at a predetermined position, the lead frame LF is clamped by the mold 90, and the resin is injected into the mold 90. Then, an assembly of the molded package 10 is formed. Next, the molded resin body 11 and the tie bar TB are cut by dicing along predetermined positions to separate the molded package 10 into individual pieces.

[0144] The molded package 100 for comparison is the same as the manufacturing process of the molded package 10 of the present invention except that the process of forming the groove portion 24 at a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com