Grindstone guide, production line and production method pertaining to rechargeable battery core production

A secondary battery and guide technology, applied in secondary battery manufacturing, manufacturing tools, final product manufacturing, etc., can solve problems such as breakage and protrusion of separators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Next, embodiments of the present invention will be described in detail with reference to the drawings as appropriate. However, the present invention is not limited to the following embodiments.

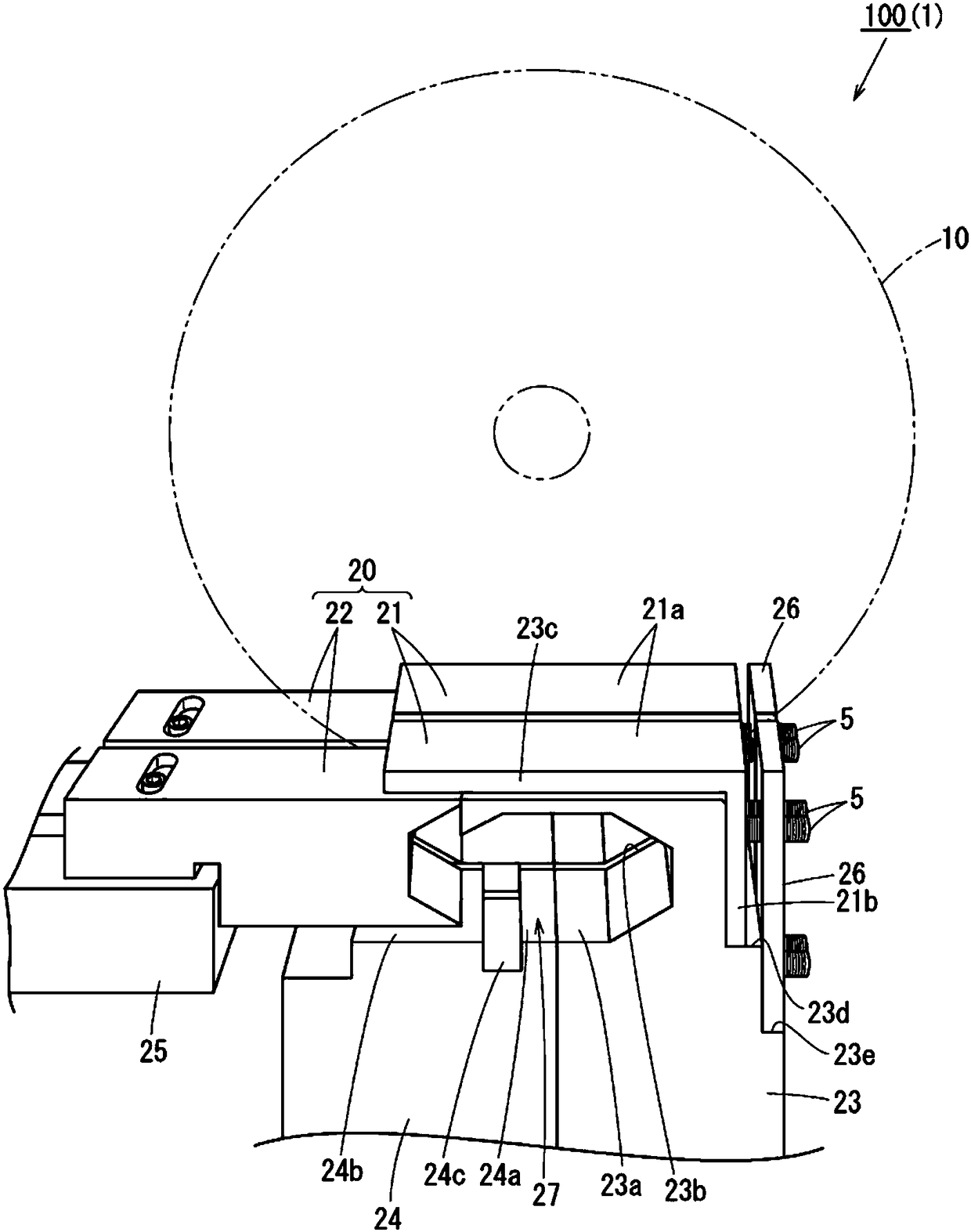

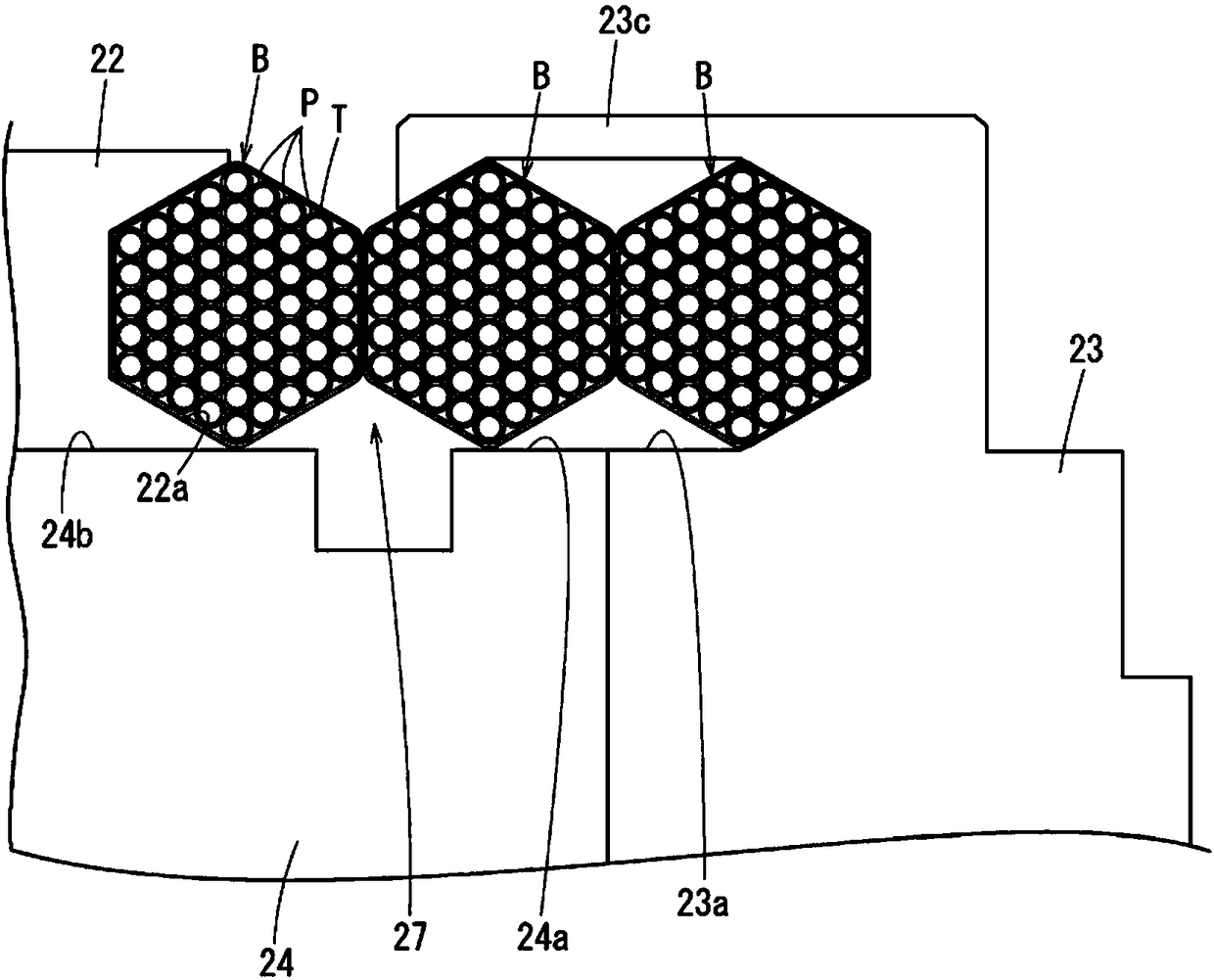

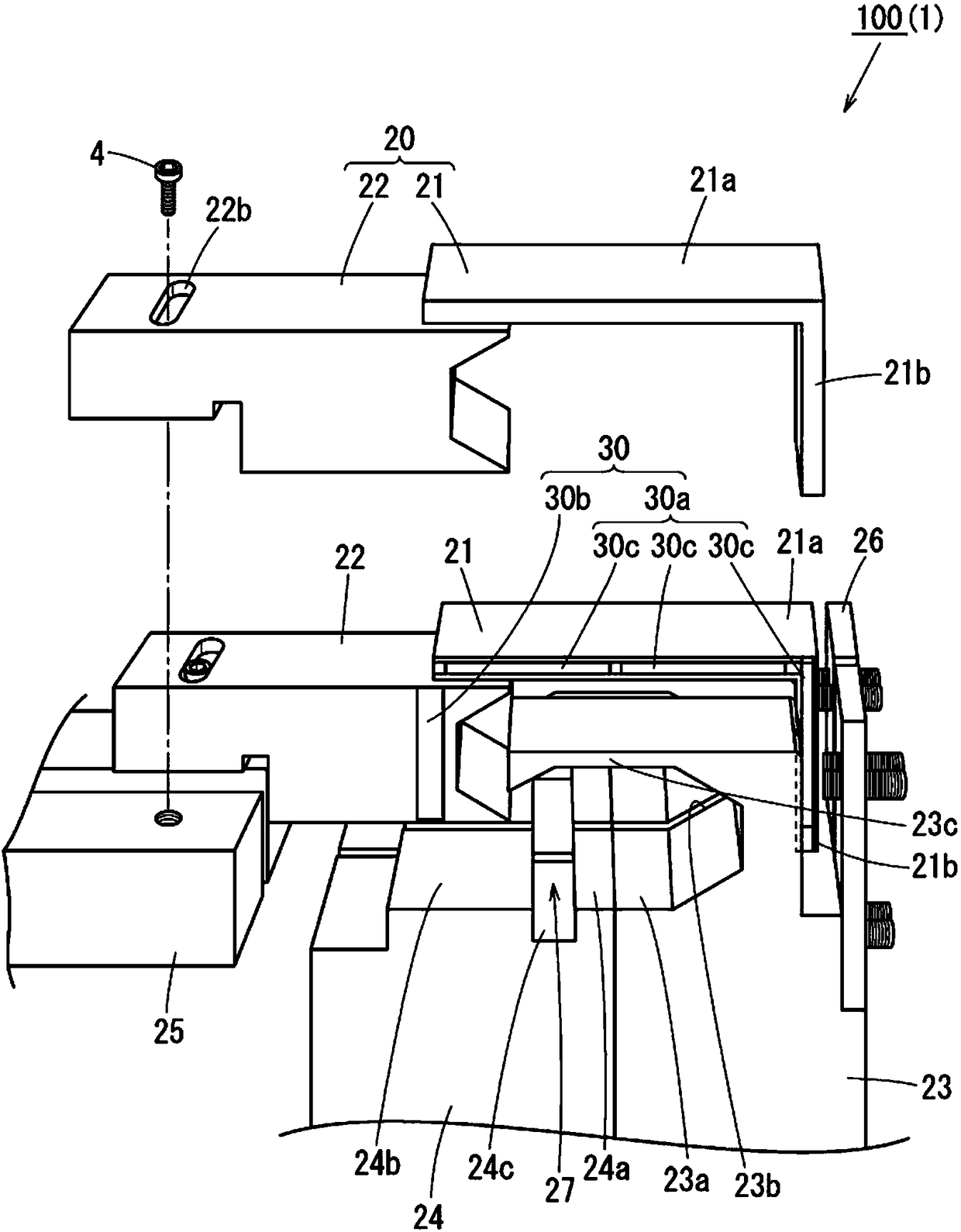

[0038] figure 1 The cutting device 100 of the production line 1 of the central core body C of the lithium ion secondary battery according to an embodiment of the present invention is shown, Picture 9 The surface cutting device 200 in the production line 1 is shown (the overall view of the production line 1 is not shown). Production line 1 is used for manufacturing Picture 11 A tubular central core C as shown.

[0039] In addition, in figure 1 , image 3 , Picture 9 Here, the symbols 100(1) and 200(1) indicate that both the cutting device 100 and the noodle cutting device 200 are included in the production line 1.

[0040] Such as figure 2 As shown, the cutting device 100 is used to cut a raw material pipe P to form a work pipe (not shown) A of a predetermined length, and a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com