Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Improve partial wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

tire

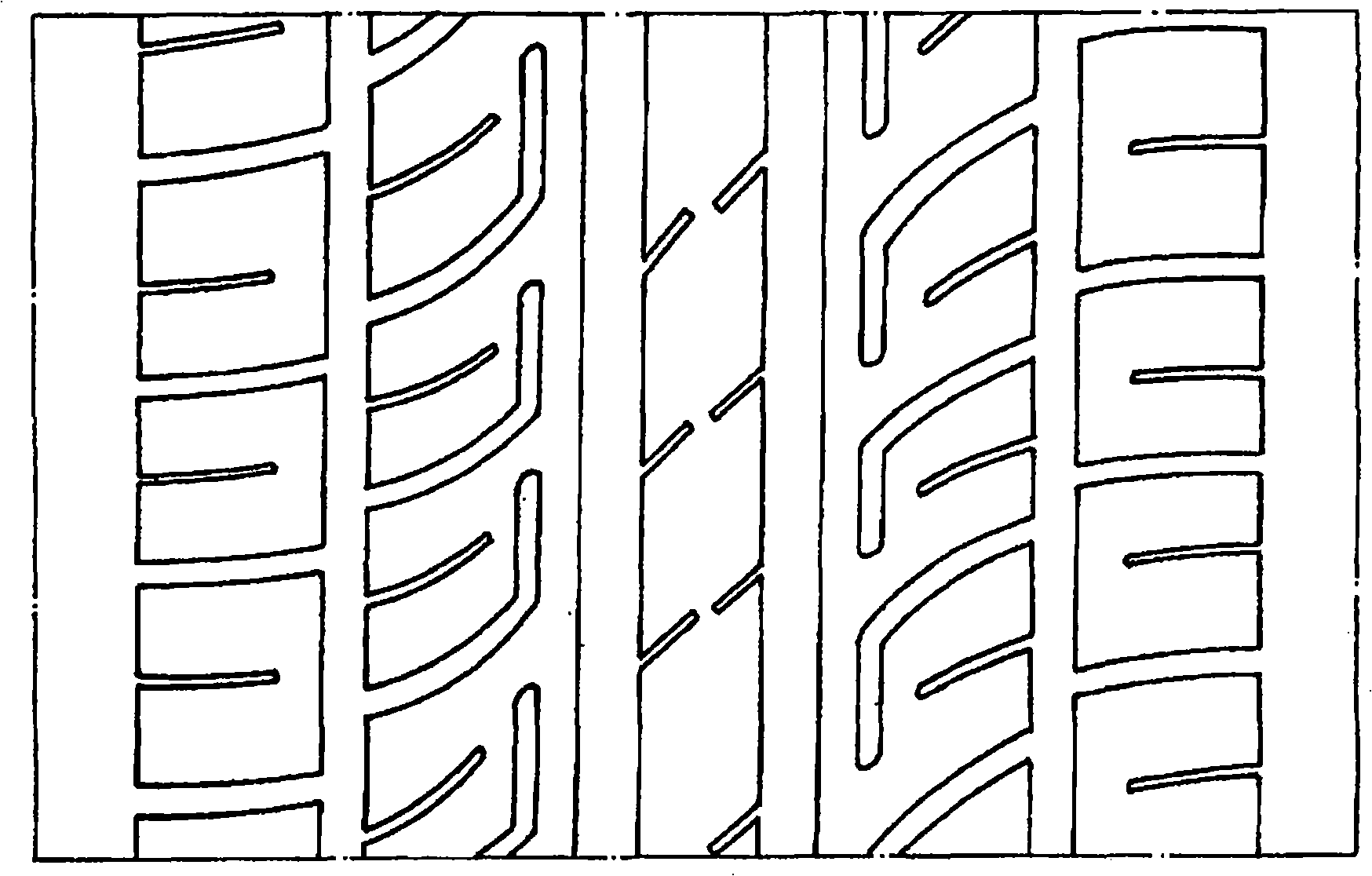

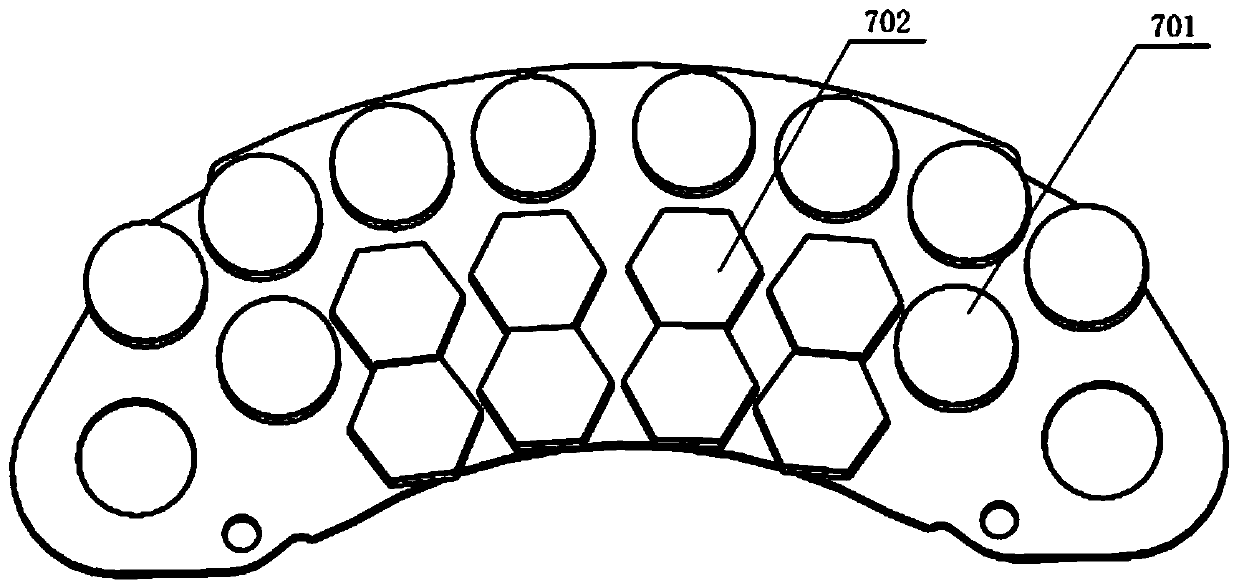

ActiveUS20120216931A1Improve partial wearReduce noiseHeavy duty tyresHeavy duty vehicleGround contactEngineering

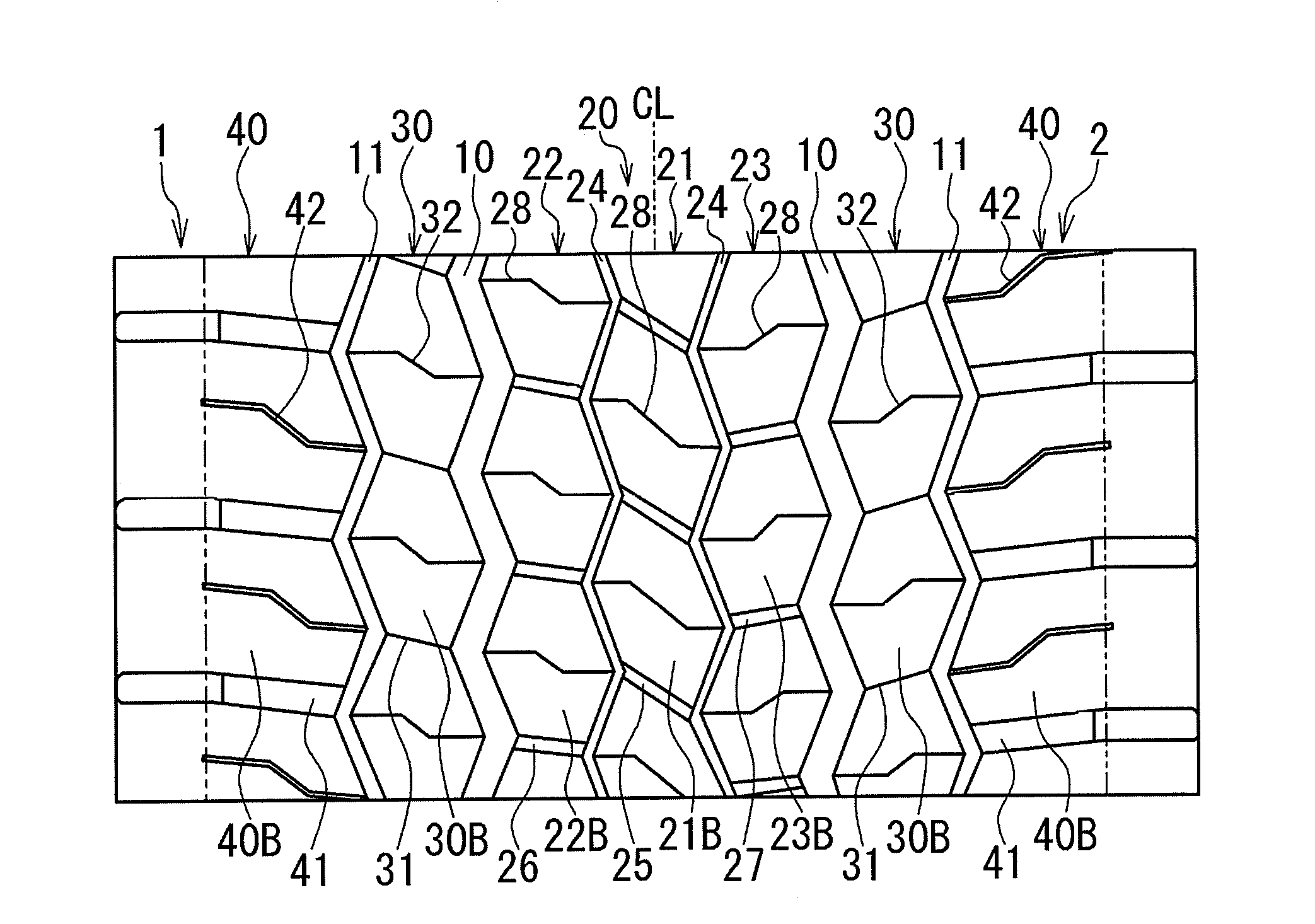

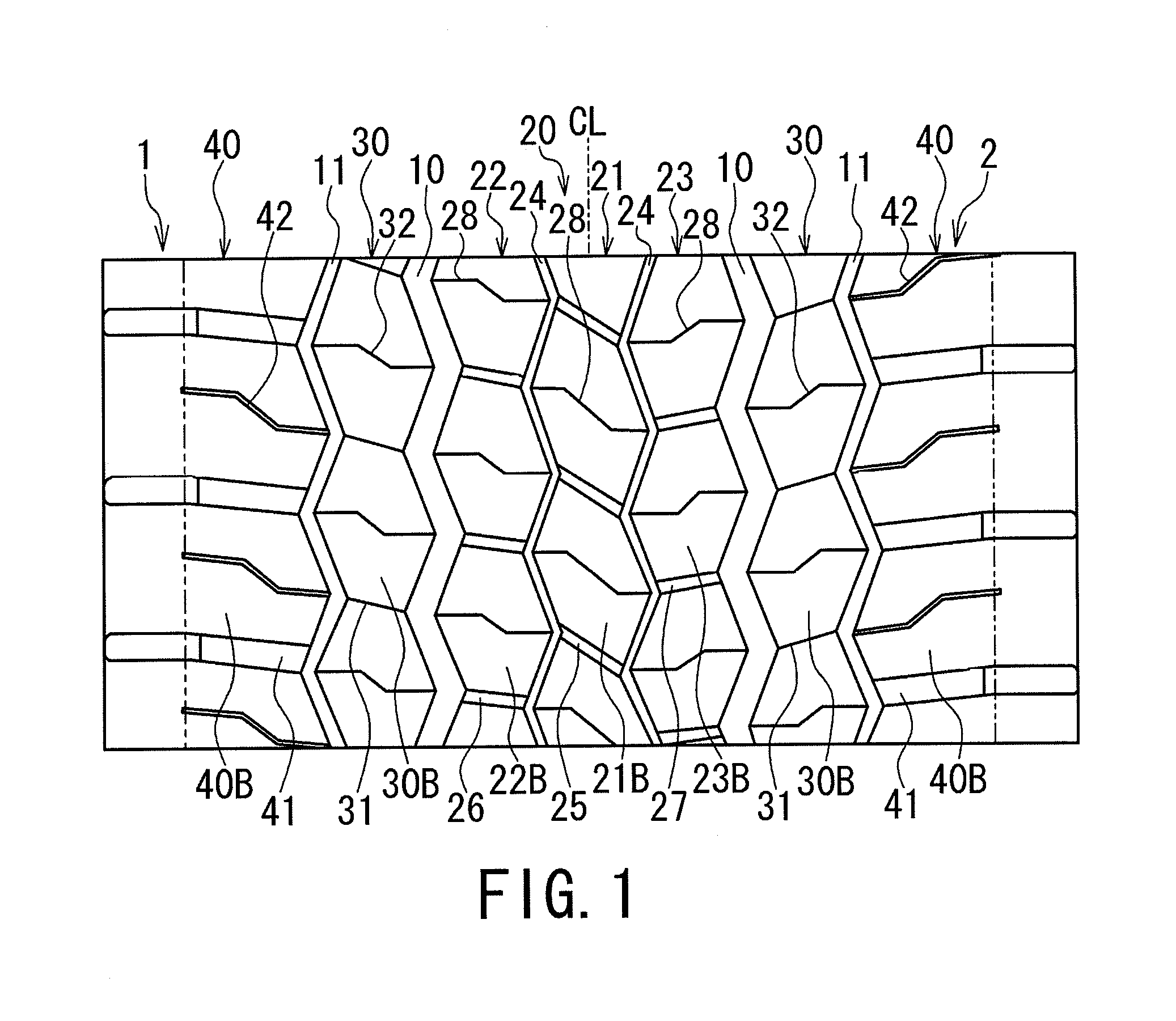

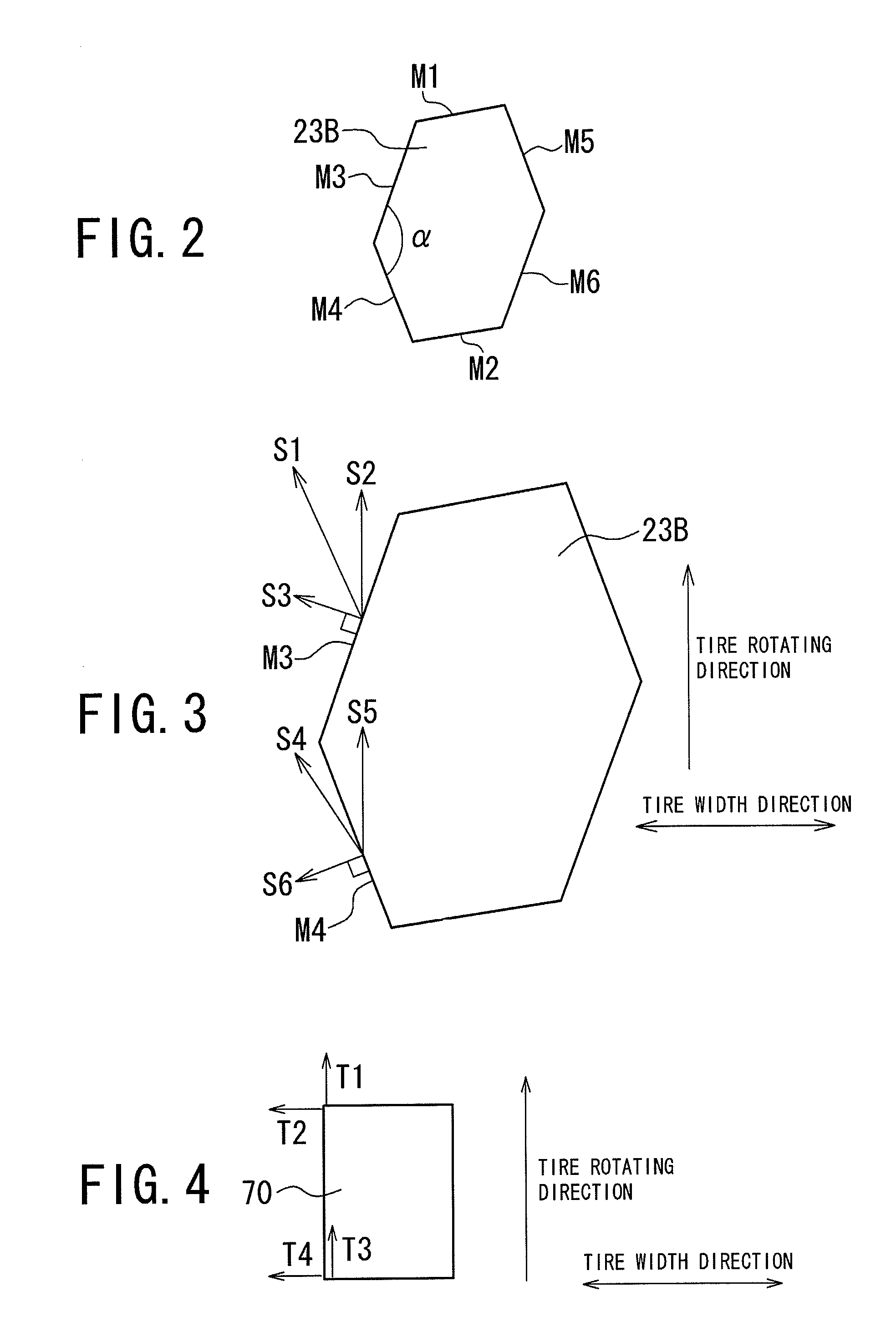

Wet performance and partial wear resistance of a tire are improved, and a noise generated during running of the tire is reduced.At a tread portion 2, a plurality of land portions 20, 30, and 40 is defined by circumferential main grooves 10 and 11 extending in a zig-zag manner in a tire circumferential direction. In the center land portion 20 and the second land portion 30, a plurality of hexagonal blocks 21B, 22B, 23B, and 30B is provided, each gradually expanding to the both sides in the tire width direction from the both end portions in the tire circumferential direction toward the center. In the center land portion 20, the plurality of hexagonal blocks 21B, 22B, and 23B is arranged so as to be brought close to each other in the tire width direction while sandwiching a circumferential thin groove 24 extending in a zig-zag manner in the tire circumferential direction and to be defined by lug grooves 25, 26, and 27 in the tire circumferential direction. In the second land portion 30, the plurality of hexagonal blocks 30B is arranged so as to continue in the tire circumferential direction while sandwiching a sipe 31, and formed in a rib shape continuous in a ground-contacting surface.

Owner:BRIDGESTONE CORP

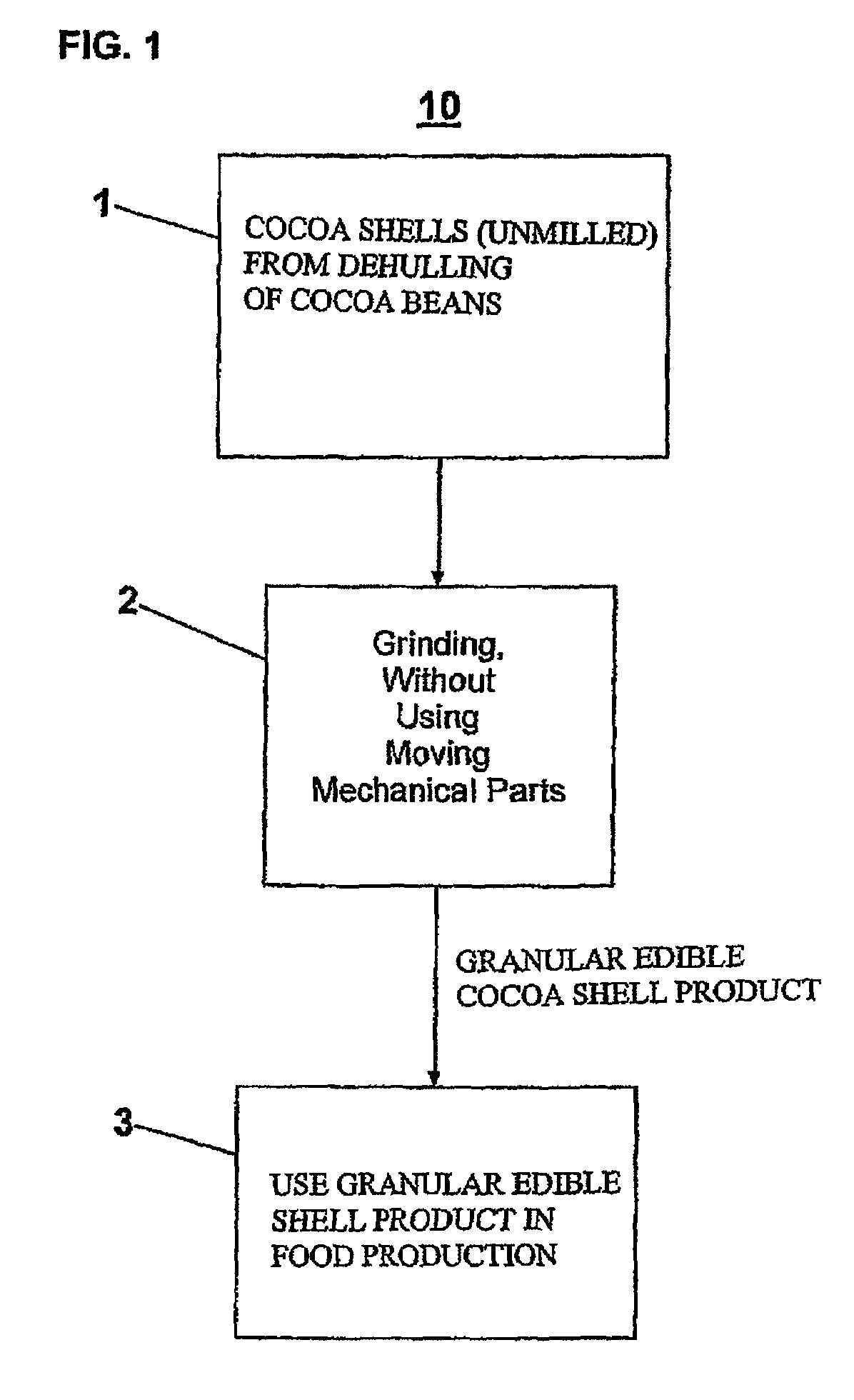

Process for Milling Cocoa Shells and Granular Edible Product Thereof

A process for preparation of milled cocoa shell including grinding cocoa shell in a single unit operation in a short-duration manner without the need for moving mechanical parts. The milled cocoa shell product obtained from the grinding treatment has reduced heat degradation and avoids equipment maintenance concerns otherwise associated with mechanical milling of the cocoa shells while providing an edible granular product useful for food manufacture such as chocolate food production.

Owner:KRAFT FOODS SCHWEIZ HLDG AG

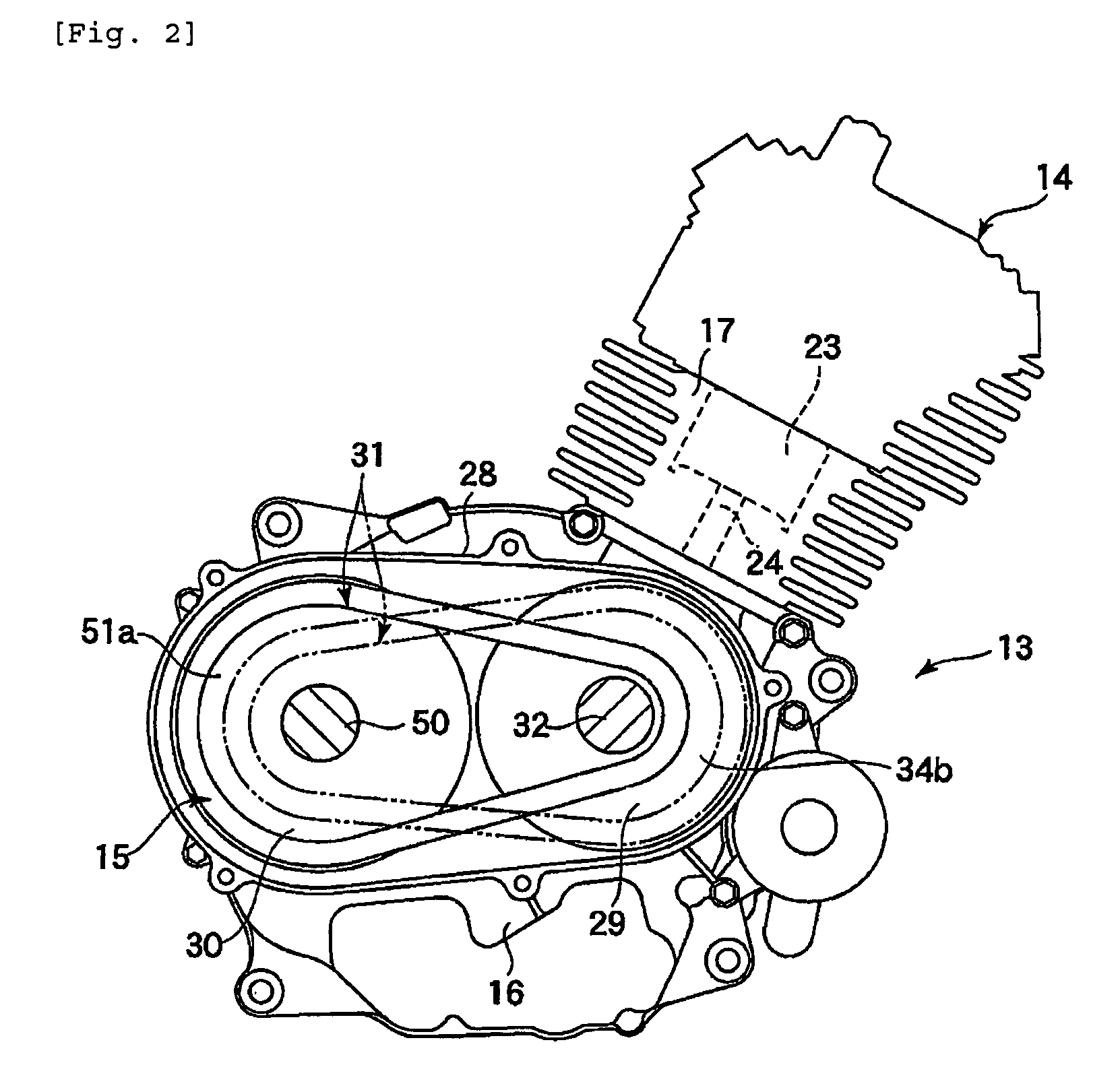

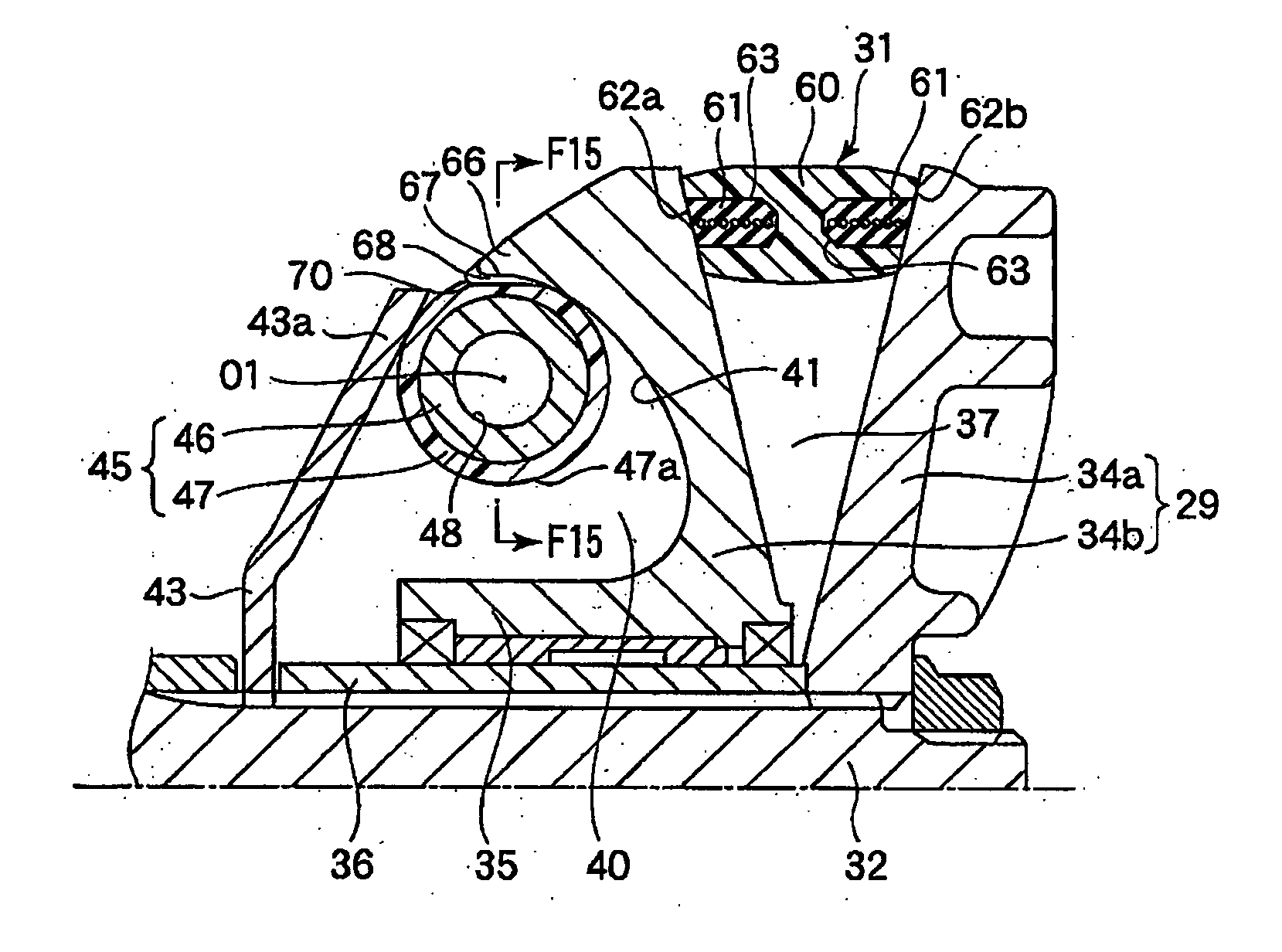

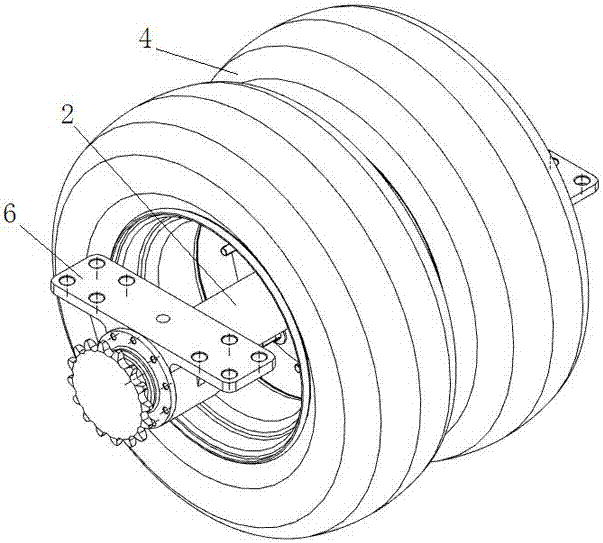

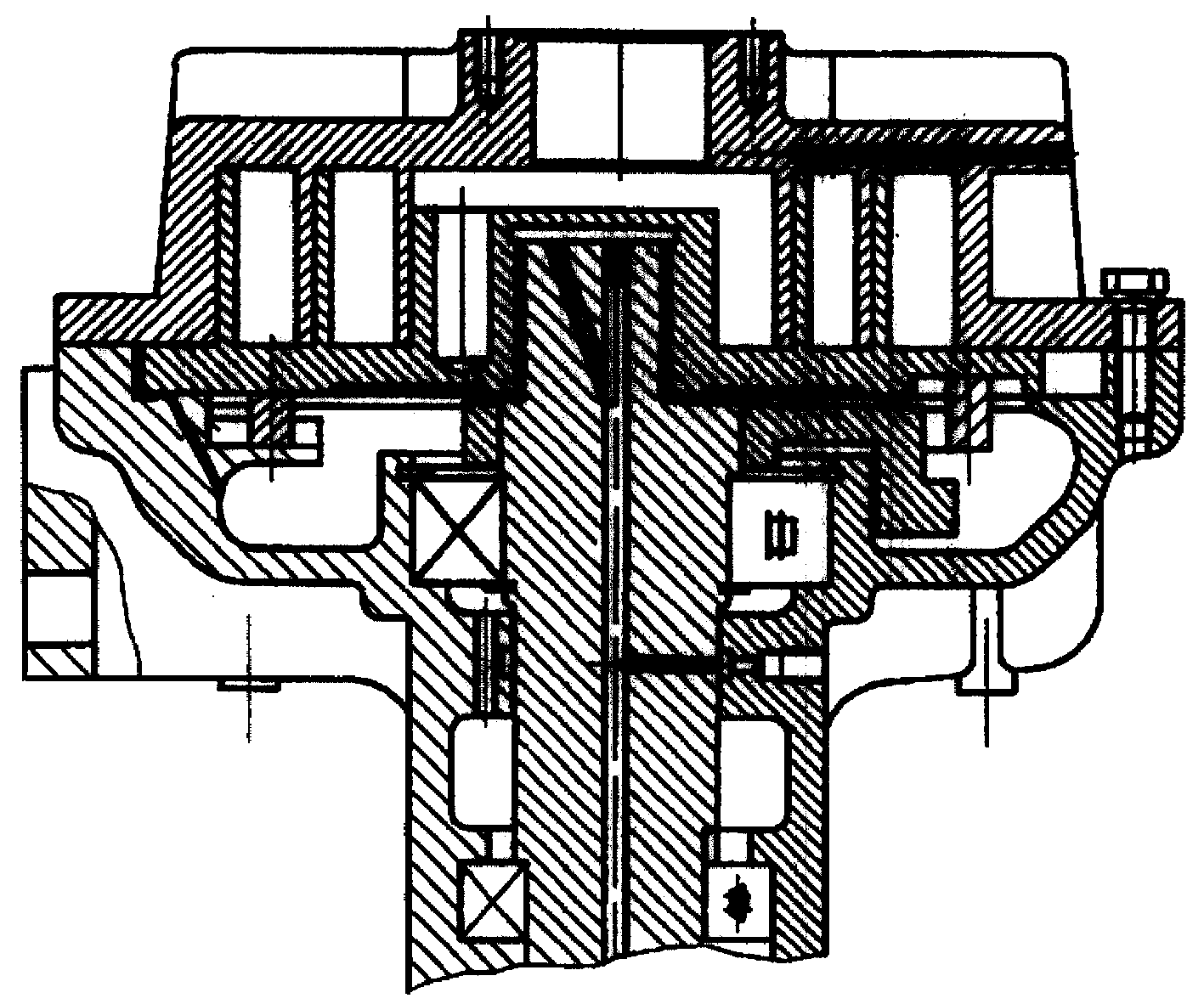

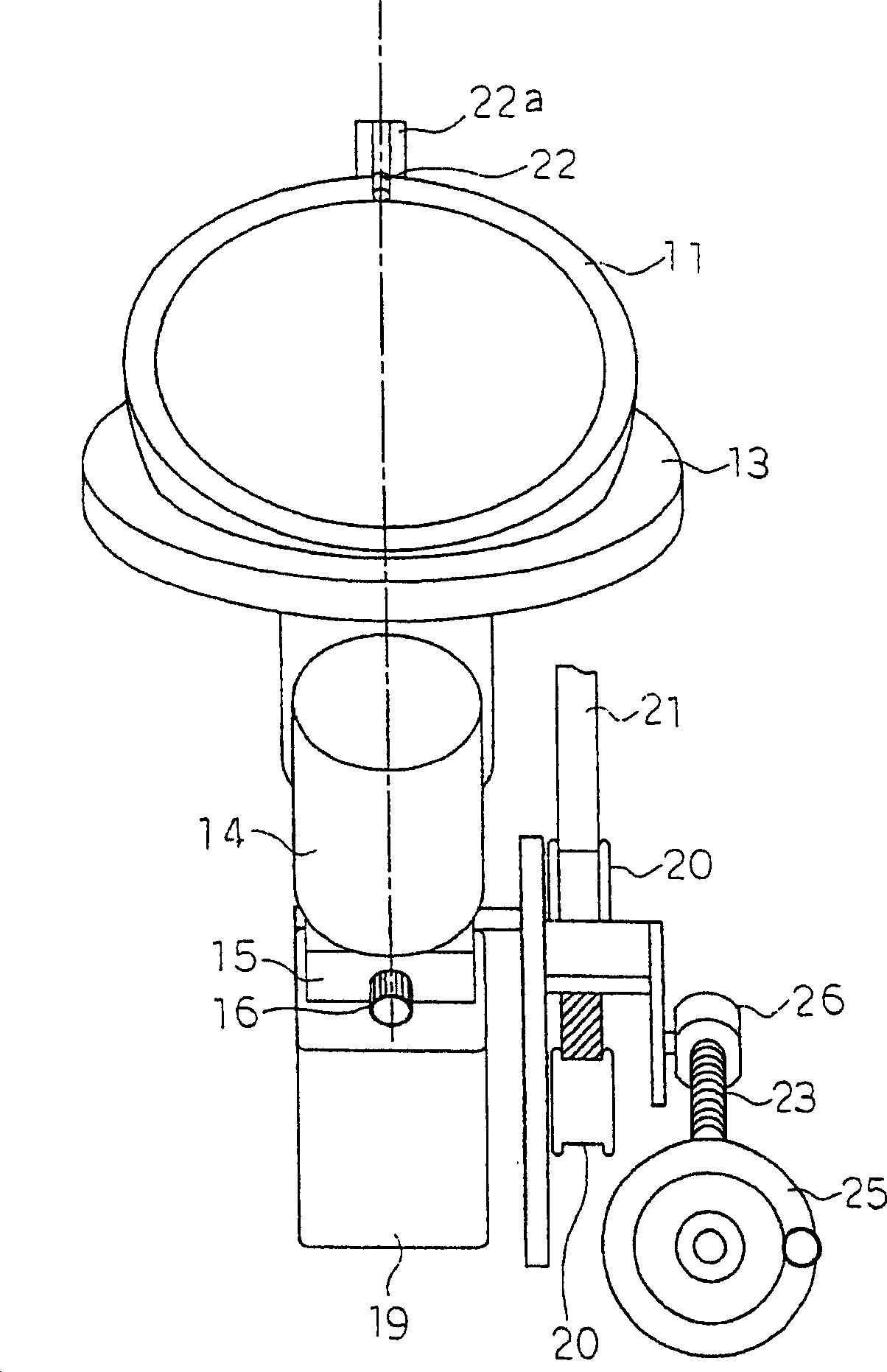

Belt type continuous variable transmission, power unit having the belt type continuous variable transmission, vehicle mounting thereon the belt type continuous variable transmission, and sheave for continuous variable transmission

A belt type continuous variable transmission comprises a primary sheave, a secondary sheave, and a belt. The primary sheave comprises a first sheave body, a second sheave body that forms between it and the first sheave body a belt groove, about which a belt is entrained, a plurality of push bodies that slide the second sheave body according to centrifugal forces to change a width of the belt groove, and a plurality of stoppers that restrict movements of the push bodies by contacting with outer surfaces of the push bodies when the second sheave body reaches a position of minimum transmission gear ratio, in which the belt groove is made smallest in width. The stoppers are shaped to accelerate partial wear of the outer surfaces of the push bodies.

Owner:YAMAHA MOTOR CO LTD

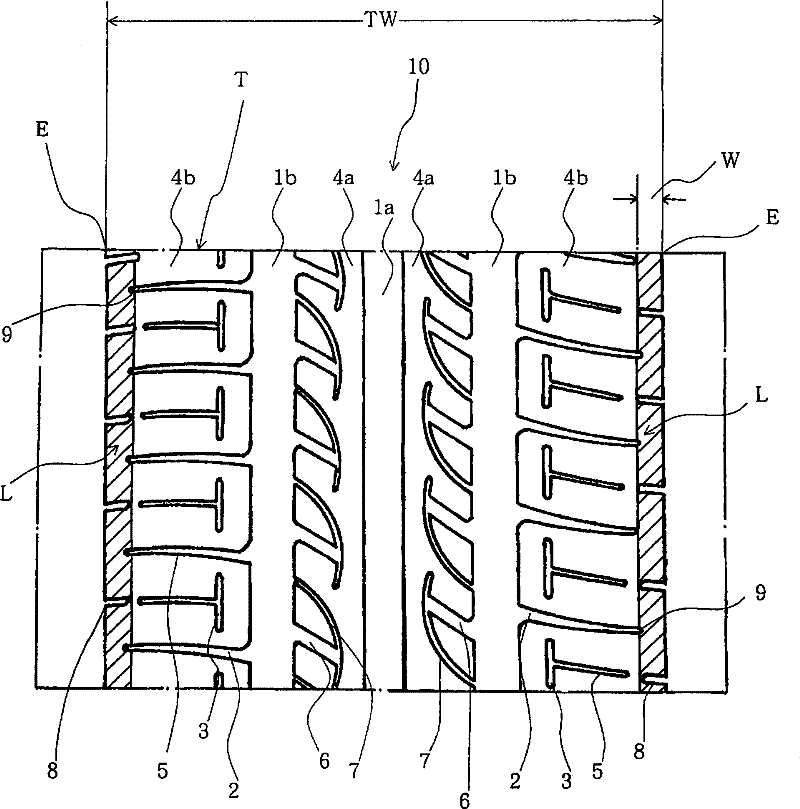

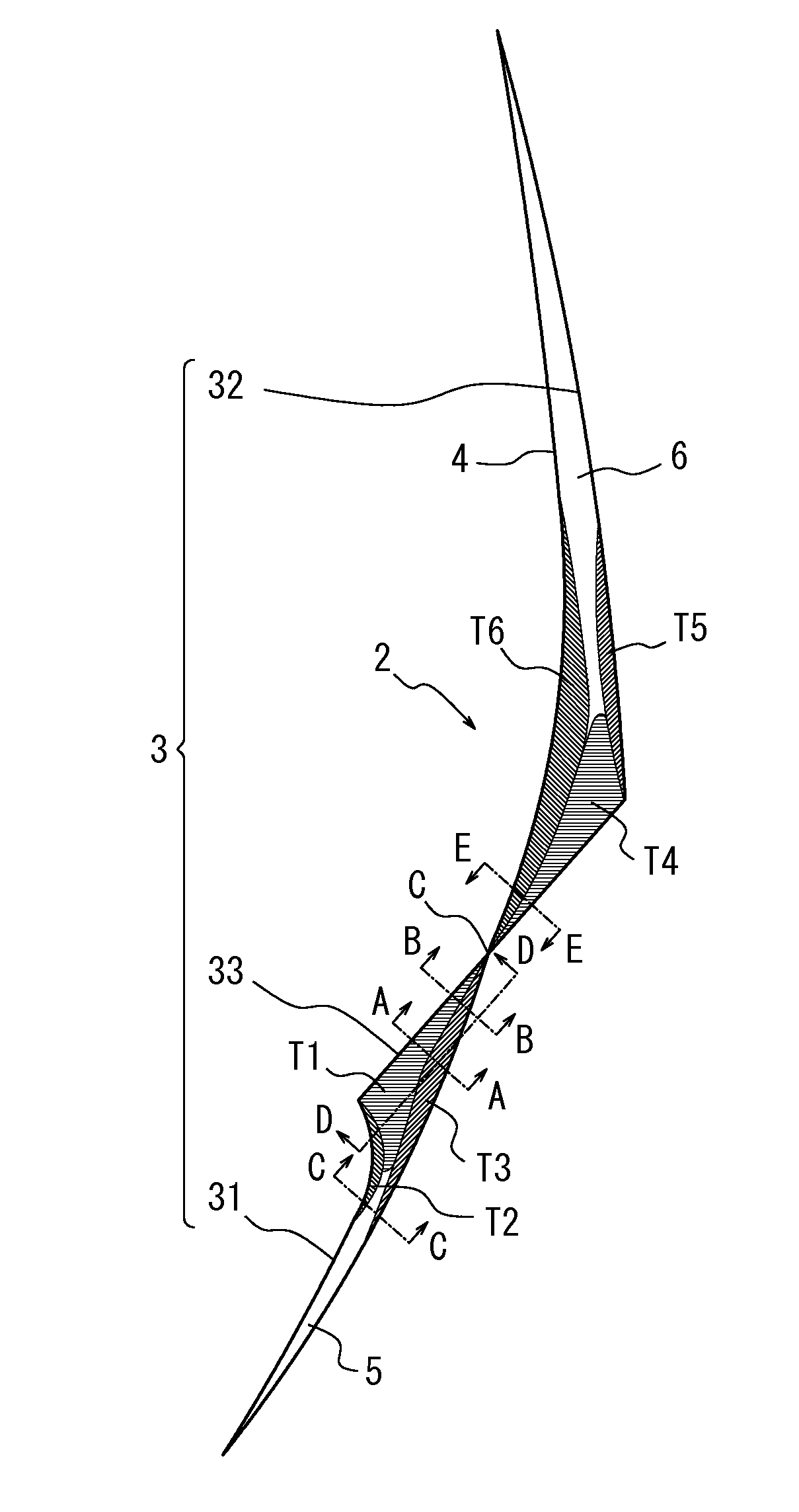

Pneumatic belt tire

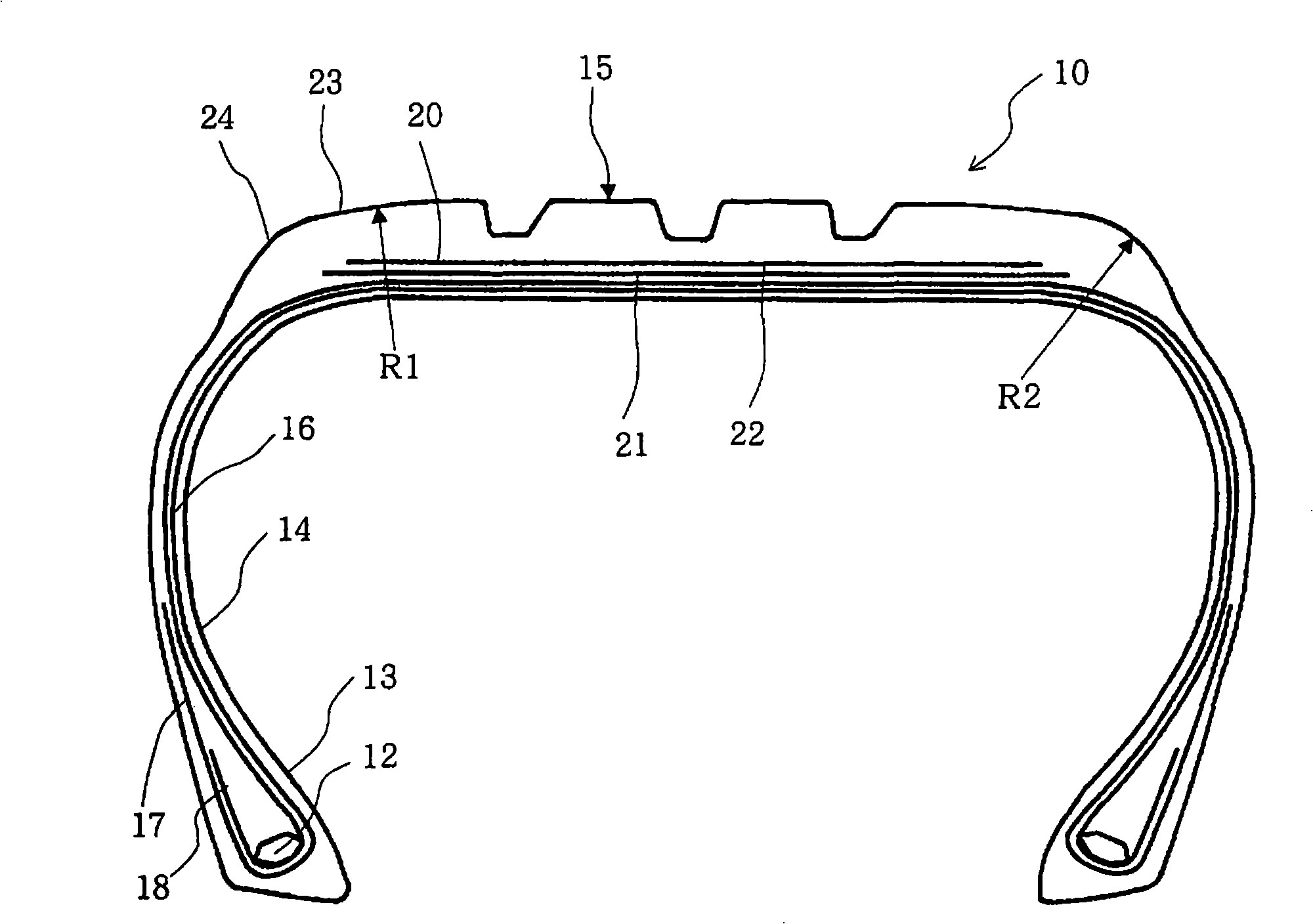

InactiveCN101306631AImprove partial wearMaintain cost competitivenessPneumatic tyre reinforcementsTyre tread bands/patternsCost competitivenessGrounding line

The invention provides a pneumatic radial tire having cost competition and improving the bias abrasion performance to the tire shoulder by seeking for the optimization of the ground shape and the ground pressure. The pneumatic radial tire has a translot (2) having a plurality of circumferential main slots (1a, 1b) at the tread portion of the tire and extending along the width direction of the tire and a tread pattern for forming a plurality of ground lines (4a, 4b). In the tier shoulder ground line (4b) comprising ground end (E), a translot (2) extending from the circumferential main slots (1b) nearest to the ground end to the ground end (E) is stopped near the ground end, and continuous ground portions (L) are formed near the ground end. Side of the main slots (1b) of the tier shoulder ground line (4b) is approximately parallel to the intermittent slit auxiliary slot (3).

Owner:BRIDGESTONE CORP

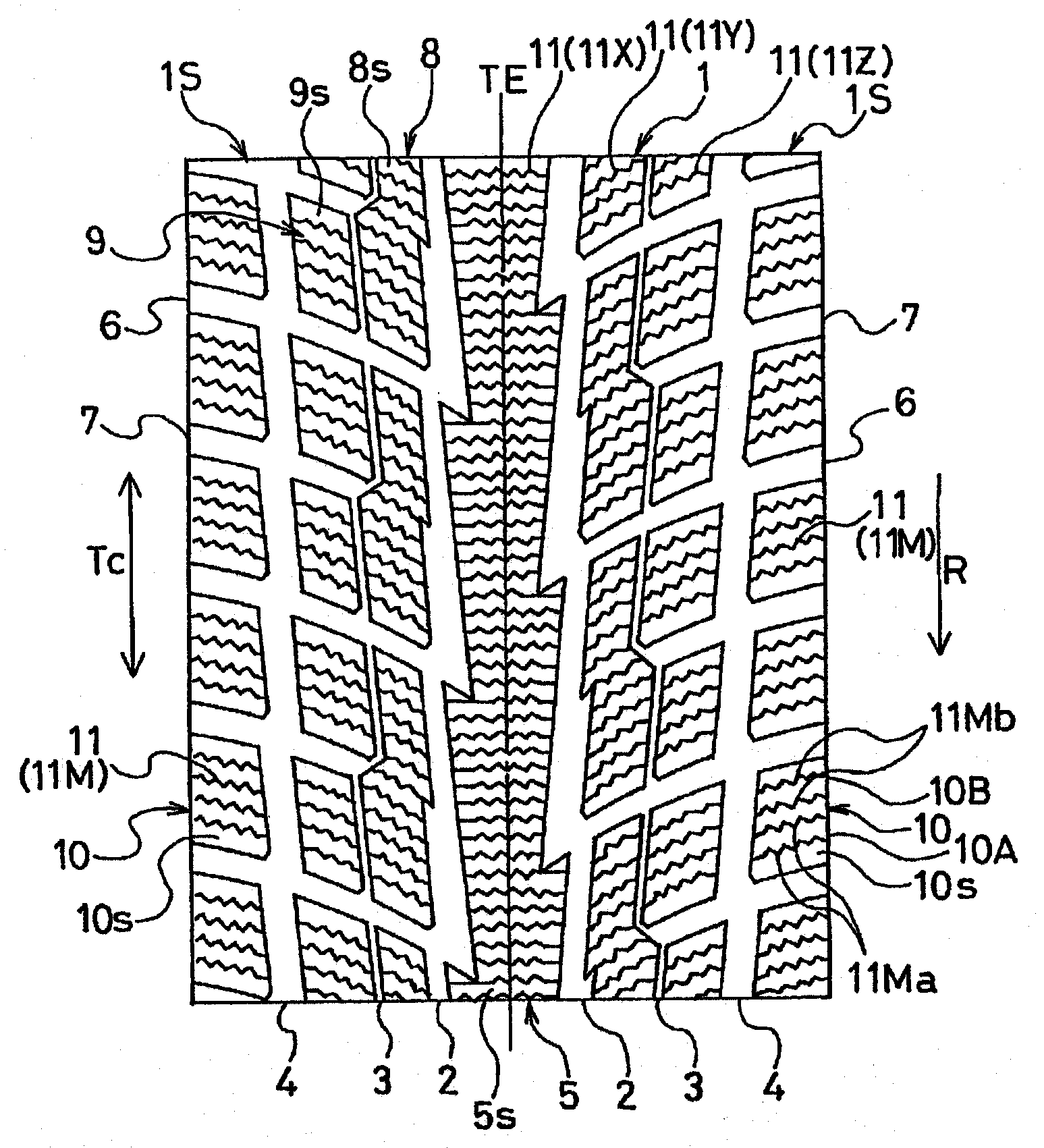

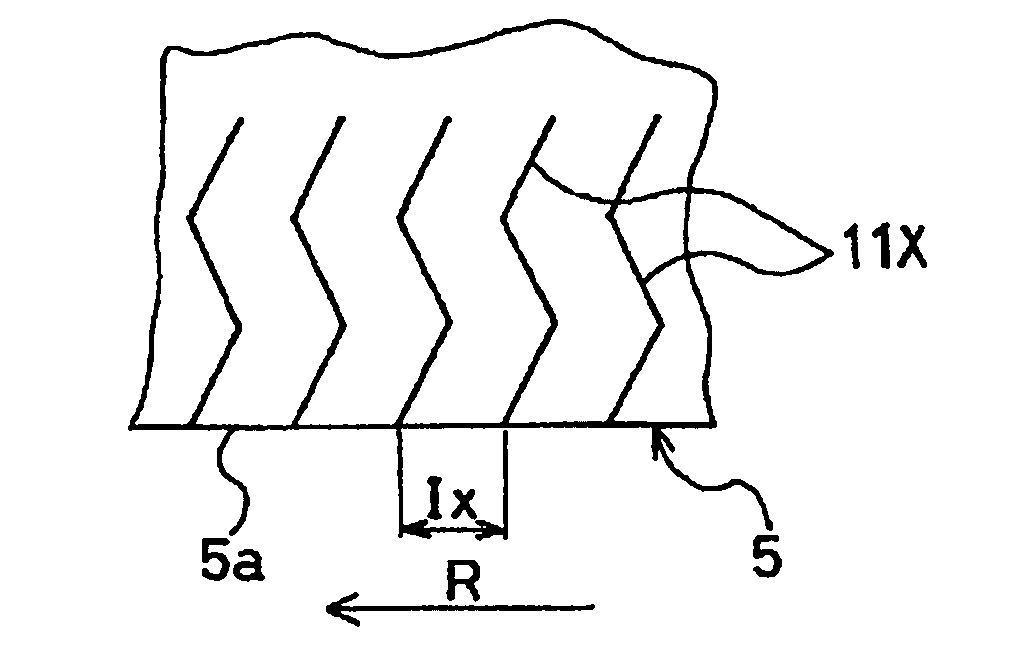

Pneumatic tire

ActiveCN102083639AImprove partial wearReduce the difference in rigidity in the circumferential directionTyre tread bands/patternsShoulder regionThree dimensional shape

Provided is a pneumatic tire which can improve the braking performance on ice and the partial-wear resistance. Sipes (11X) provided in a rib (5) on the tire equatorial plane (TE) are arranged in a three-dimensional shape where the amount of collapse of the rib (5) by the external force becomes smaller in one rotational direction of the tire than in the other rotational direction of the tire. In the block (10) of a shoulder region (1S), the sipes (11Ma) on the block tread-in side (10A) have a three-dimensional shape where the amount of collapse of the block by the external force when the sipes(11Ma) are provided entirely in the block (10) becomes smaller in one rotational direction of the tire than in the other rotational direction of the tire, and the sipes (11Mb) on the block kick-out side (10B) have a three-dimensional shape where the amount of collapse of the block by the external force when the sipes (11Mb) are provided entirely in the block (10) becomes smaller in the other rotational direction of the tire than in one rotational direction of the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

Fuel gas supply device for gas engine

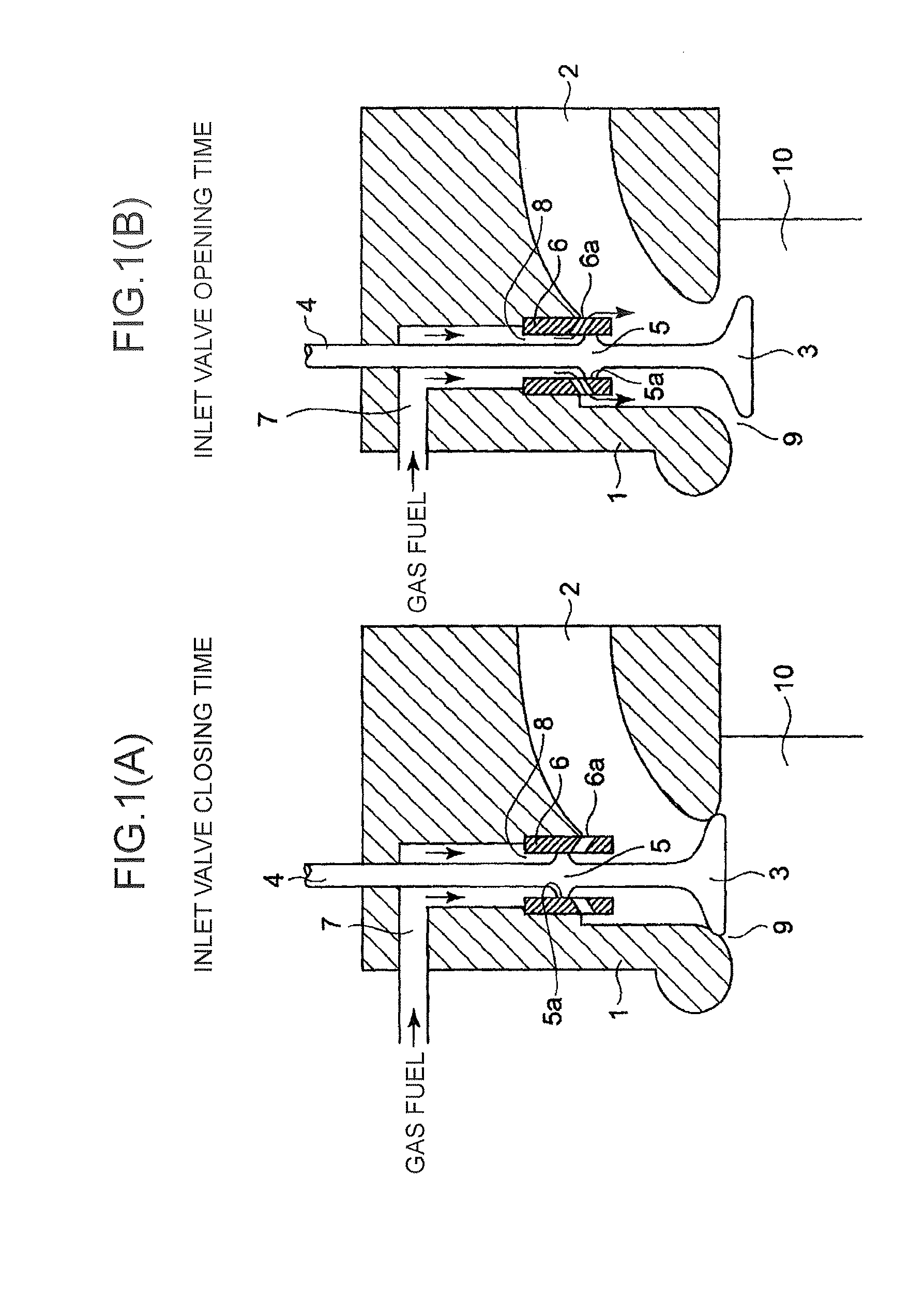

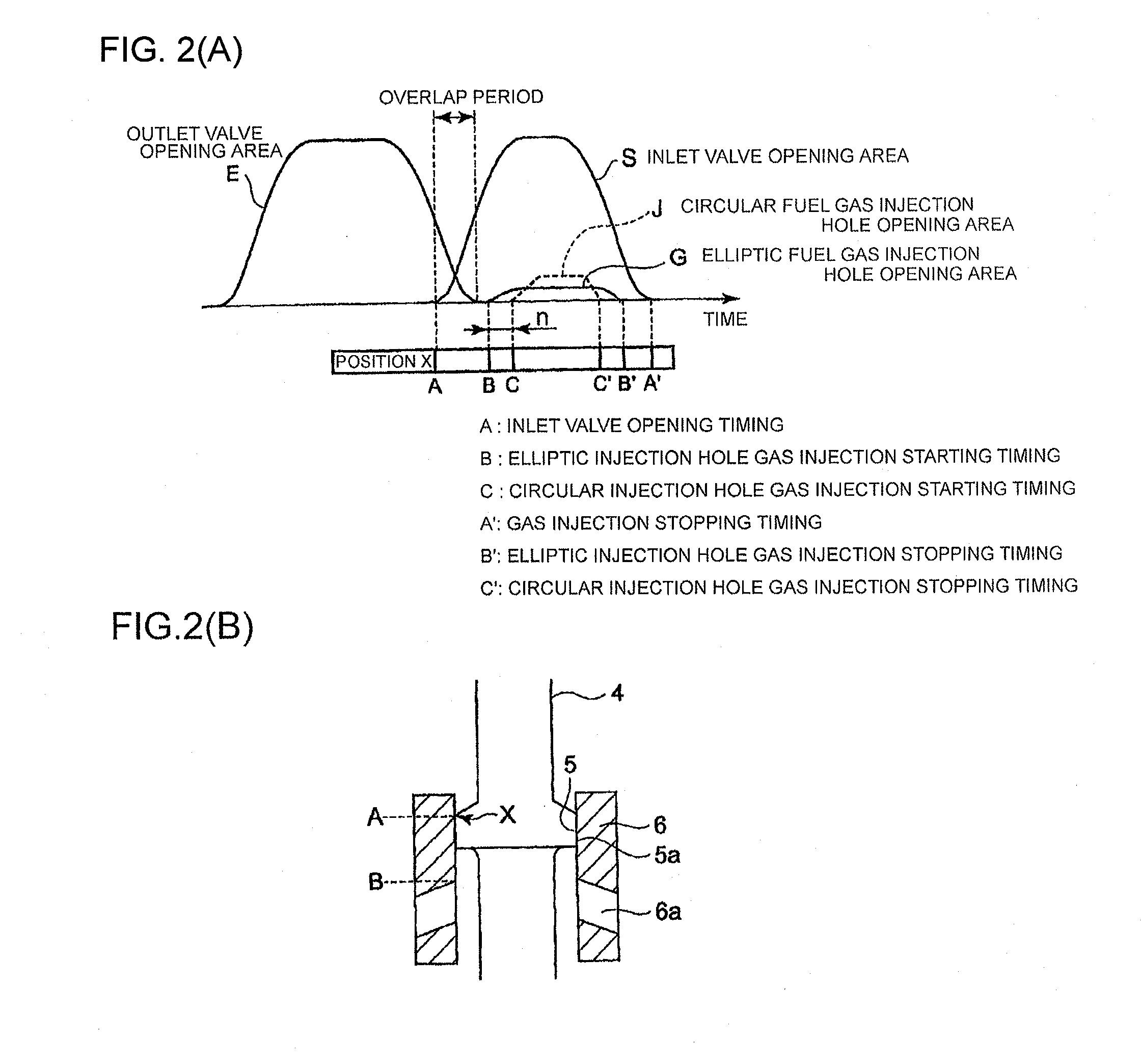

InactiveUS20130333667A1Avoid damageImprove partial wearInternal combustion piston enginesFuel supply apparatusEllipseCylinder head

There is provided a fuel gas supply device for a gas engine in which a fuel gas flows along the axial direction on the outer circumferential side of an inlet valve rod, and is supplied to an inlet path in a cylinder head. The device is characterized in that fuel gas injection holes to be opened and closed with the movement of a projection are provided in the inner circumferential surface of a sleeve into which the projection is slidably fitted, the projection being provided at the inlet valve rod, having a larger outer diameter than the inlet valve rod and having a portion concentric with and in parallel with the inlet valve rod, and in that the fuel gas injection holes are each formed in an ellipse, and the opening upper and lower end region part of the ellipse is situated within the movement region of the projection.

Owner:MITSUBISHI HEAVY IND LTD

Belt Type Continuous Variable Transmission, Power Unit Having He Type Continuous Varible Transmission, Vehicle Mounting Thereon The Belt Type Continuous Variable Transmission, And Sheave For Continuous Variable Transmission

InactiveUS20080047772A1Reduce gear ratioSuppress change in speed ratioV-beltsGearingEngineeringCentrifugal force

A belt type continuous variable transmission comprises a primary sheave, a secondary sheave, and a belt. The primary sheave comprises a first sheave body, a second sheave body that forms between it and the first sheave body a belt groove, about which a belt is entrained, a plurality of push bodies that slide the second sheave body according to centrifugal forces to change a width of the belt groove, and a plurality of stoppers that restrict movements of the push bodies by contacting with outer surfaces of the push bodies when the second sheave body reaches a position of minimum transmission gear ratio, in which the belt groove is made smallest in width. The stoppers are shaped to accelerate partial wear of the outer surfaces of the push bodies.

Owner:YAMAHA MOTOR CO LTD

Pneumatic tire

InactiveUS20130186535A1Shorten the lengthImprove partial wearMotorcycle tyresTyre tread bands/patternsAcute angleEngineering

The present invention has an object of providing a pneumatic tire having a tread pattern capable of providing both excellent drivability and a high partial wear resistance. The pneumatic tire of the present invention includes, in a tread surface, a compound groove partitioned into a first groove portion and a second groove portion by a first groove side and a second groove side, the first groove side having an oblique side portion diagonally disposed relative to a tire circumferential line in plan view, the second groove side intersecting with the oblique side portion of the first groove side at an acute angle in plan view, in which: the first groove portion and the second groove portion both have a groove depth that gradually reduces in an extending direction of the groove toward an intersection between the oblique side portion and the second groove side; and a groove wall extending from the first groove side is formed as a tapered surface mildly-sloped toward a groove bottom on the intersection side when viewed in the groove transverse direction. Further, the pneumatic tire of the present invention includes, in a tread surface, a groove partitioned by at least three groove sides in plan view, in which: one or more of groove walls extending from one of the at least three groove sides that extends in the longitudinal direction of the groove is formed as a tapered surface at least in part thereof; and the tapered surface forms an angle with a plane perpendicular to the tread surface, which varies in the extending direction of the groove side.

Owner:BRIDGESTONE CORP

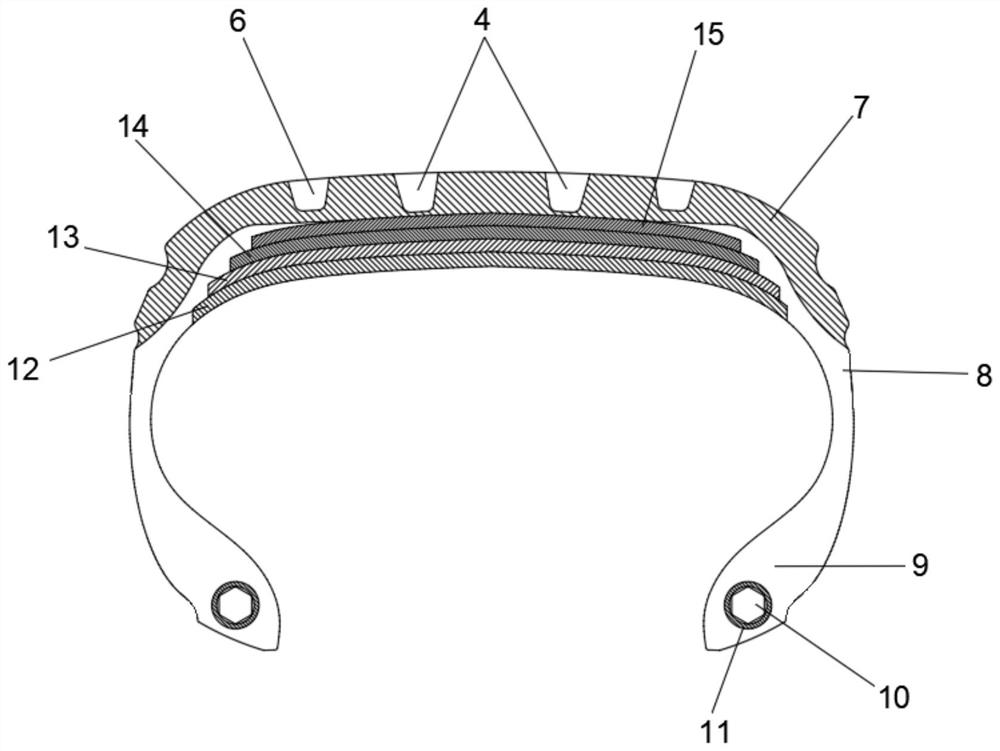

High-speed train brake pad for optimizing friction particle combination and installation modes

ActiveCN111396474AEnsure braking reliability and safetyReduce noise pollutionNoise/vibration controlFriction liningPhysicsHeat distribution

The invention belongs to the technical field of friction braking, and particularly relates to a high-speed train brake pad for optimizing friction particle combination and installation modes. The problems of simplex shape of friction particles, eccentric wear, high braking noise and non-uniform heat distribution on a brake interface of an existing brake pad are solved. The technical scheme is as follows: the idea of combining friction particles of different shapes and materials is put forward, and the advantages of the friction particles of various shapes and materials are comprehensively utilized by flexibly arranging the friction particles of various shapes and materials in different areas; a fixing mode of the friction particles is optimized; and an anti-rotation mode of the friction particles is optimized, and a guide shaft and a mounting hole are optimized to be cylinders with a non-circular section shape. The advantages of the friction particles of different shapes and materialsare organically combined, and the reliability, safety and comfortableness of a brake system are improved.

Owner:SOUTHWEST JIAOTONG UNIV

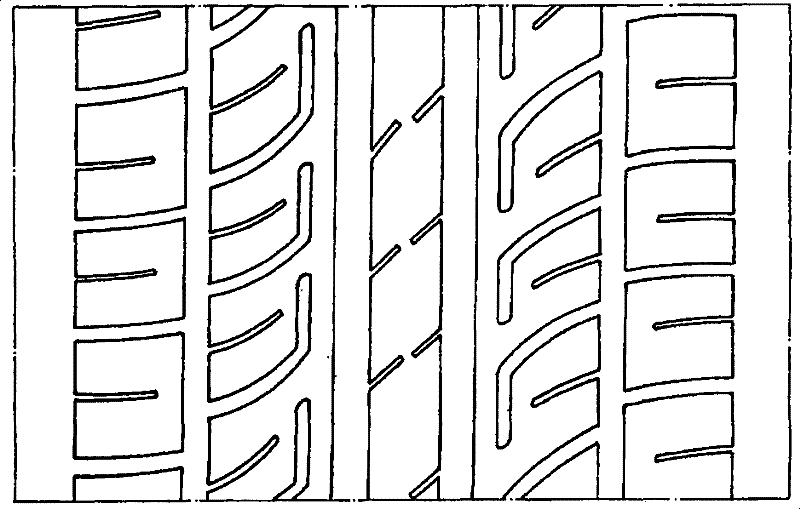

Pneumatic tire

ActiveCN1720151AEven distribution of ground pressureImprove partial wearTyre tread bands/patternsShoulder regionMechanical engineering

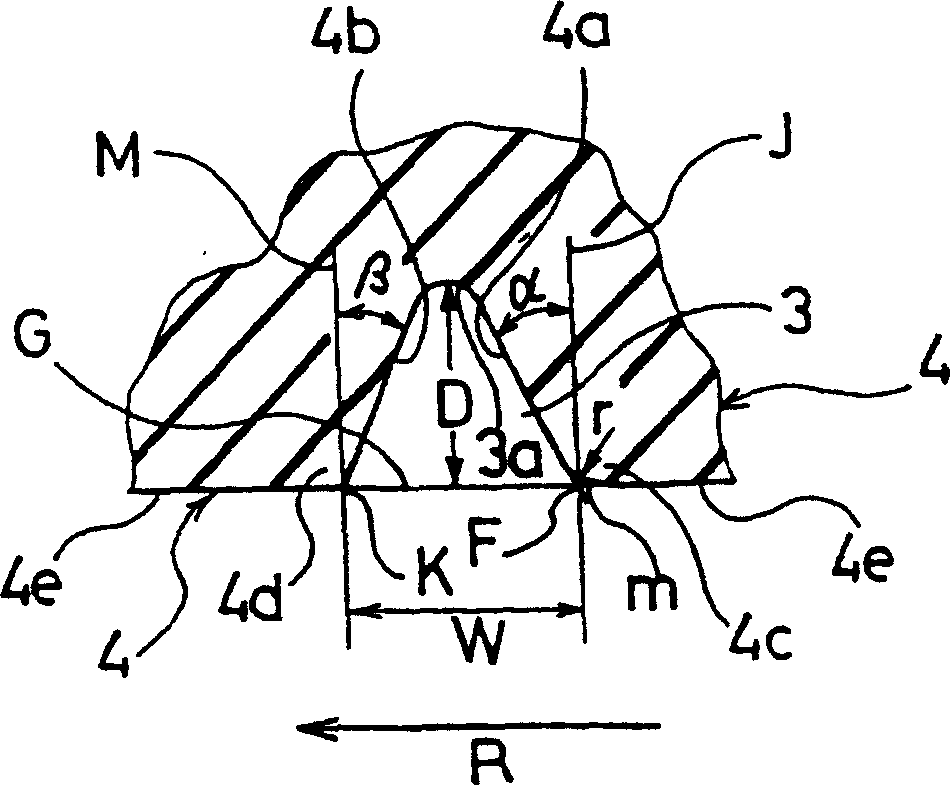

A tread surface the tire rotational direction of which is specified in one direction has a center region and shoulder regions on both sides of the center region. Blocks are defined in at least one of the shoulder regions by at least one first circumferential groove which extends in a circumferential direction of the tire, and first lateral grooves which extend in a widthwise direction of the tire and are disposed at predetermined intervals in the tire circumferential direction. Each block includes a tire rotational direction side groove wall surface having an inclination angle alpha , and a tire reverse rotation direction side groove wall surface having an inclination angle beta , and the inclination angle beta is greater than the inclination angle alpha . Each block has a tire rotational direction side edge portion which is chamfered.

Owner:YOKOHAMA RUBBER CO LTD

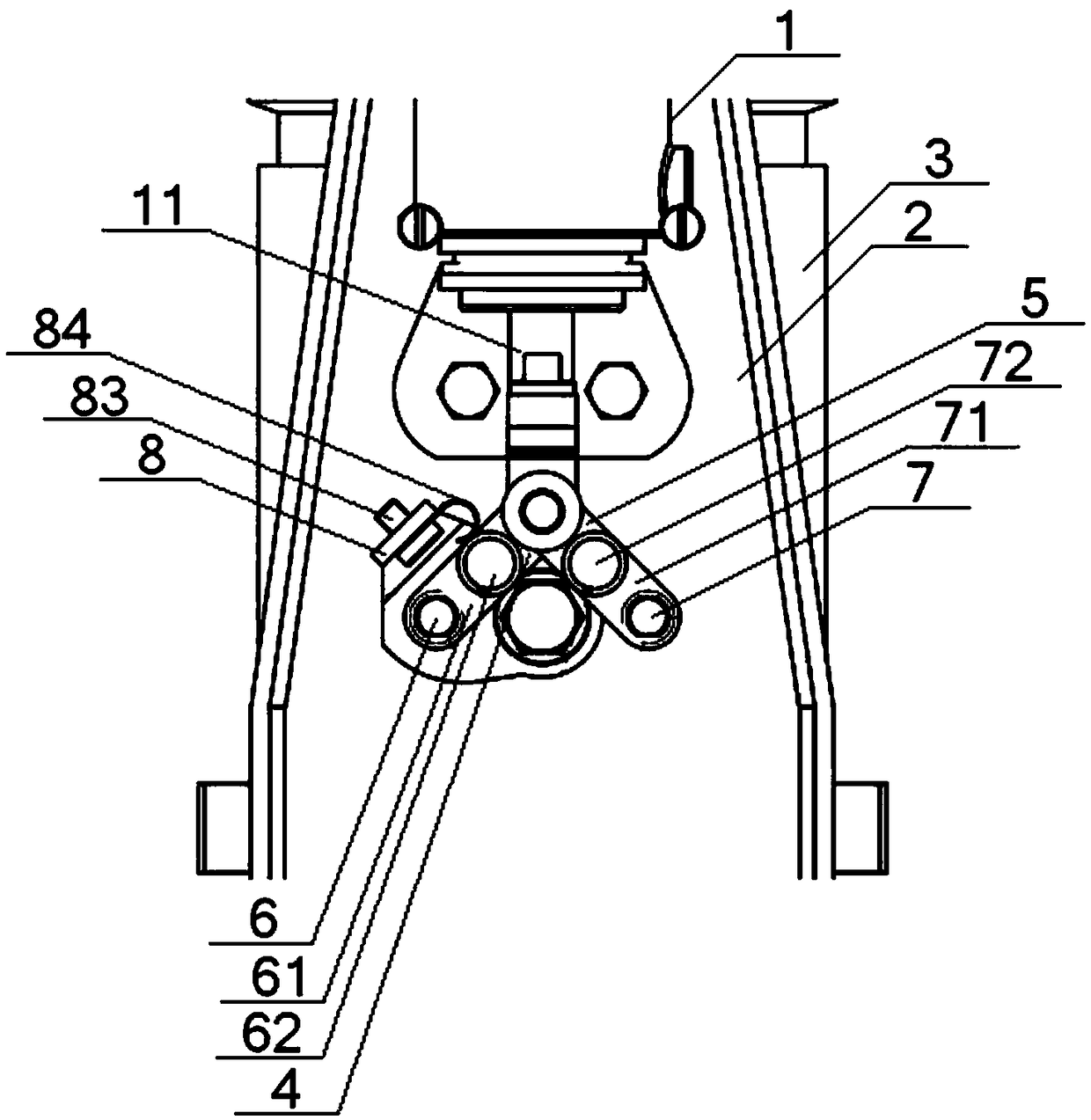

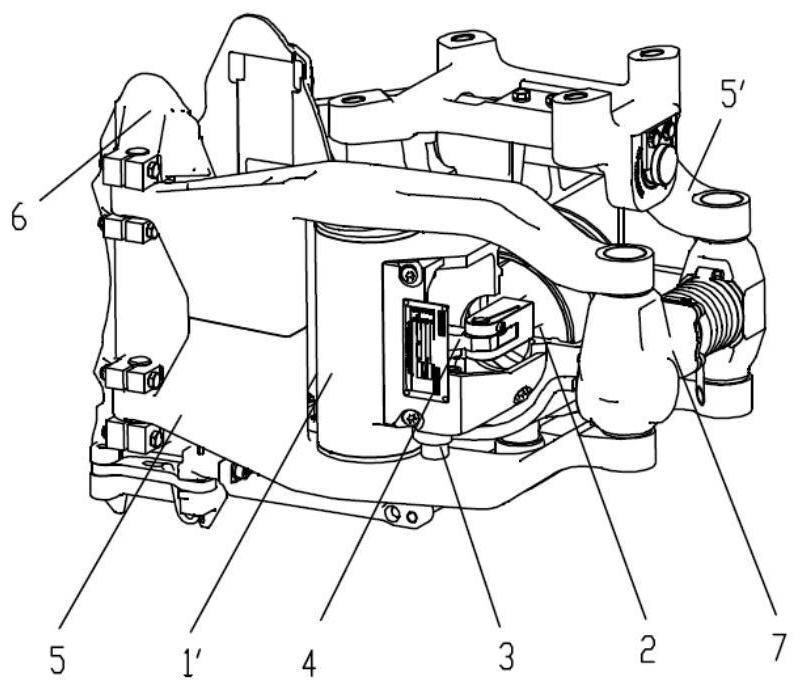

Charpy beam type straddle type monorail vehicle two-axle power bogie

Owner:CHONGQING CHANGXING TECH DEV CO LTD

Process for milling cocoa shells

A process for preparation of milled cocoa shell including grinding cocoa shell in a single unit operation in a short-duration manner without the need for moving mechanical parts. The milled cocoa shell product obtained from the grinding treatment has reduced heat degradation and avoids equipment maintenance concerns otherwise associated with mechanical milling of the cocoa shells while providing an edible granular product useful for food manufacture such as chocolate food production.

Owner:KRAFT FOODS SCHWEIZ HLDG AG

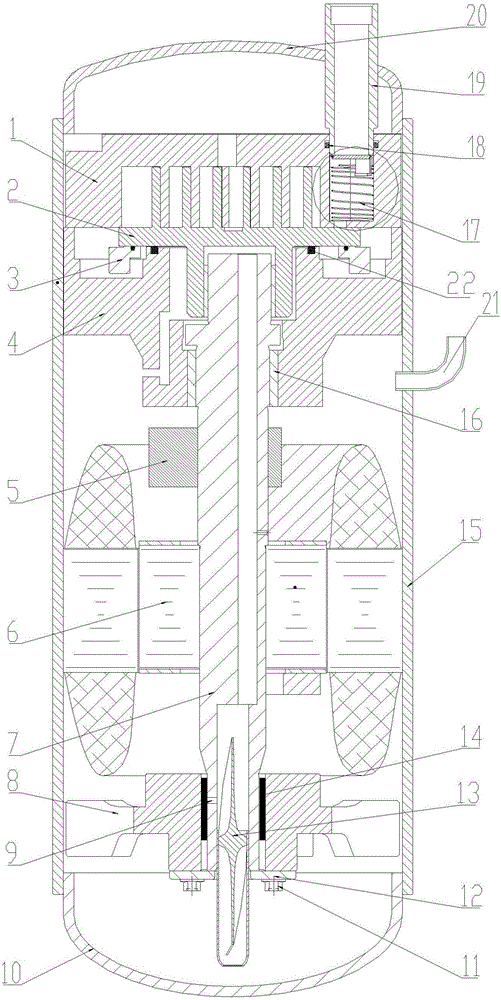

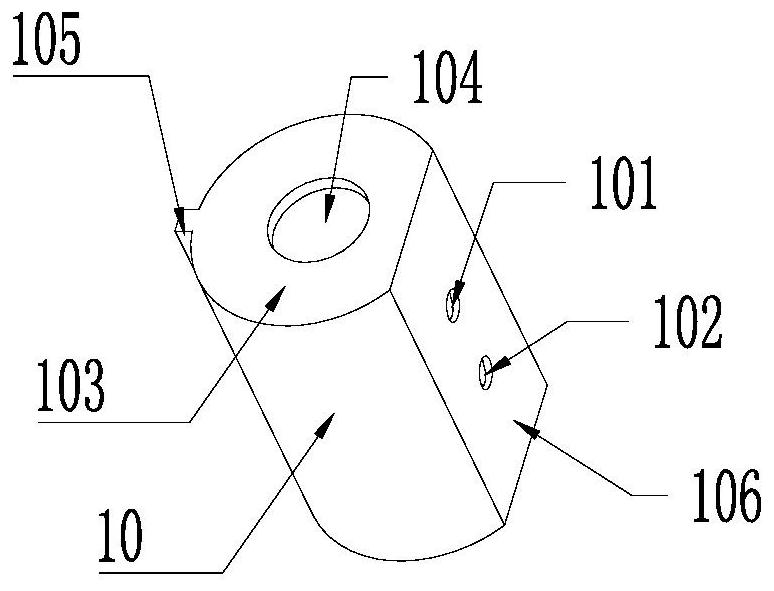

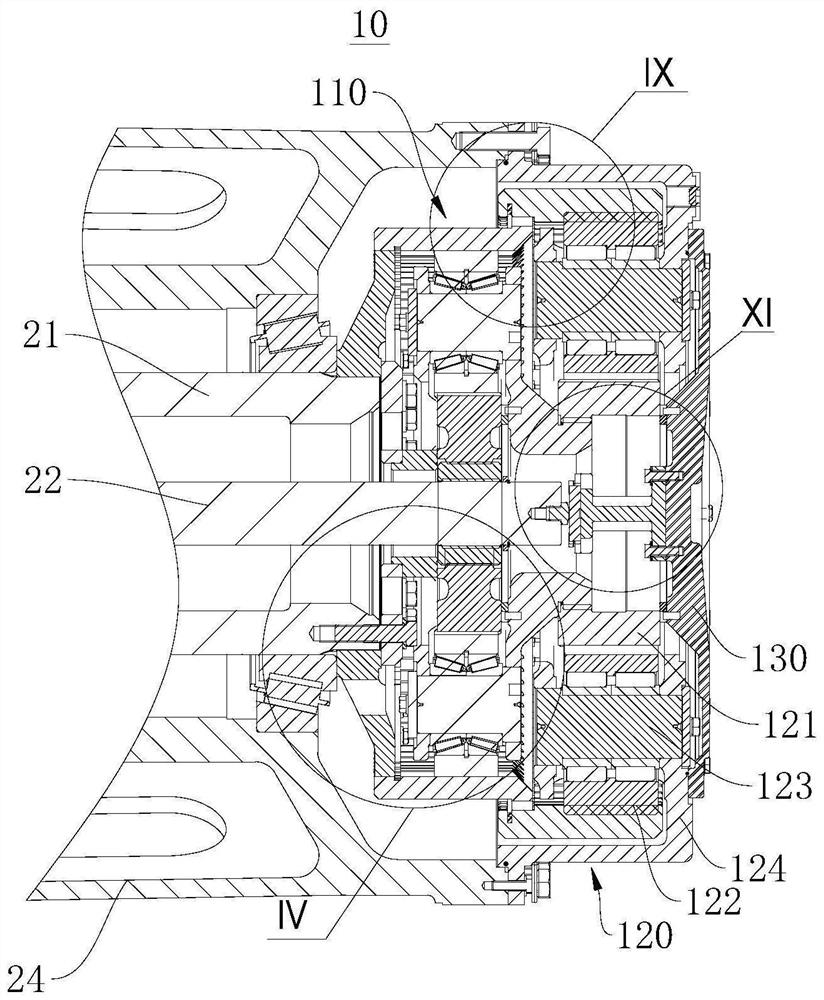

Scroll compressor and cross slip ring thereof

InactiveCN106481559AImprove serious wear and tear problemsReduce friction lossRotary piston pumpsRotary piston liquid enginesRolling resistanceFriction loss

The present invention discloses a cross slip ring which is arranged between a movable scroll plate and an upper bracket to support the floating of the movable scroll plate. A rolling friction mechanism is assembled on a fitting surface f the cross slip ring, the movable scroll plate and the upper bracket, so that the friction loss between parts is reduced. The rolling friction mechanism can reduce the friction loss between the cross slip ring and the movable scroll plate through a mode of the rolling friction instead of the sliding friction by specifically assembling a ball on an end face where the cross slip ring is cooperated with the movable scroll plate. The ball is instead of the end face of the cross slip ring, and processing procedures are reduced. The structure of the scheme is simple and the assembling is easy. The invention also discloses a scroll compressor using the cross slip ring. The friction between the cross slip ring and the movable scroll plate and the upper bracket is effectively reduced. The contact friction mode between the parts is changed, and the friction loss between the parts is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

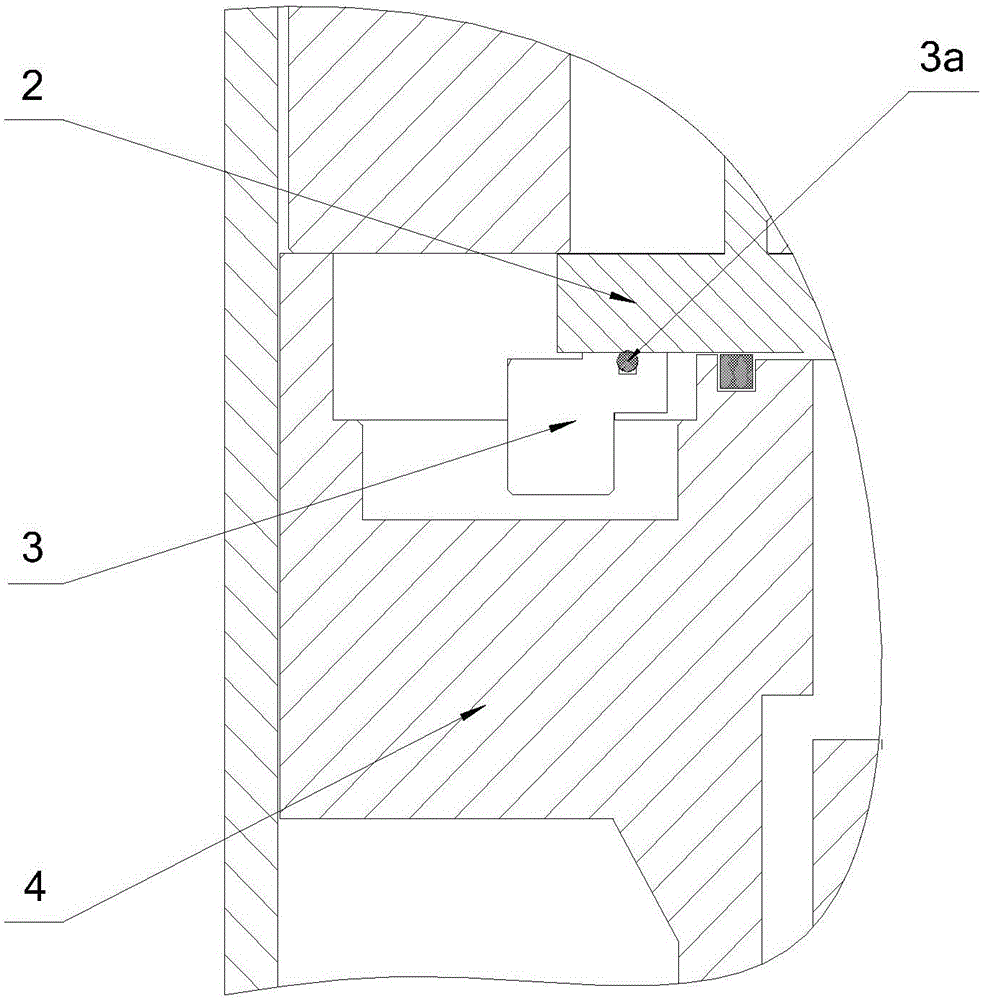

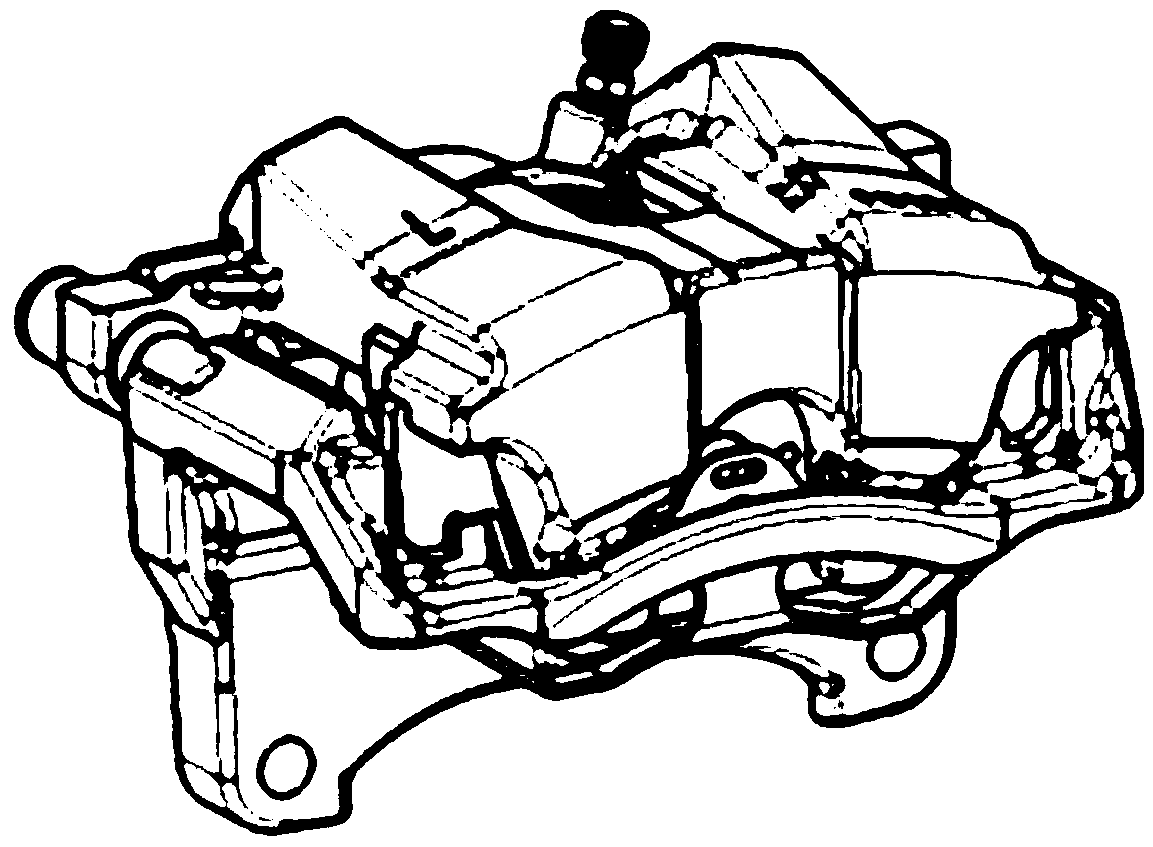

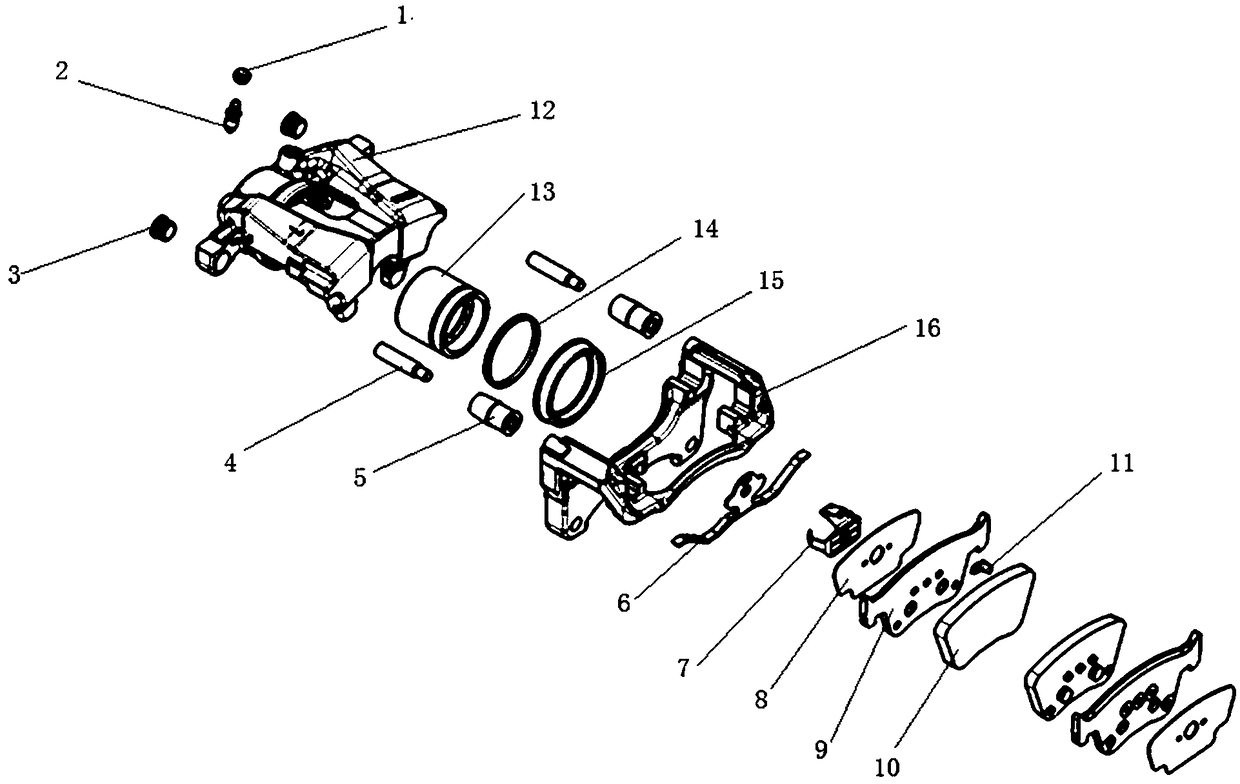

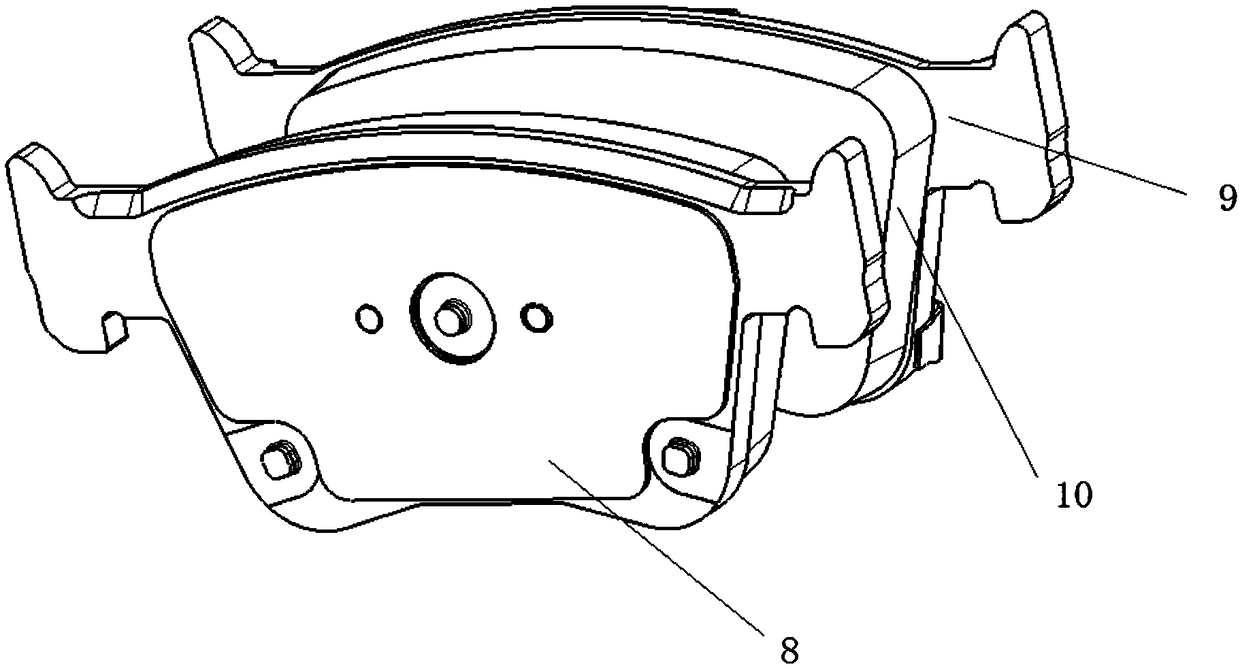

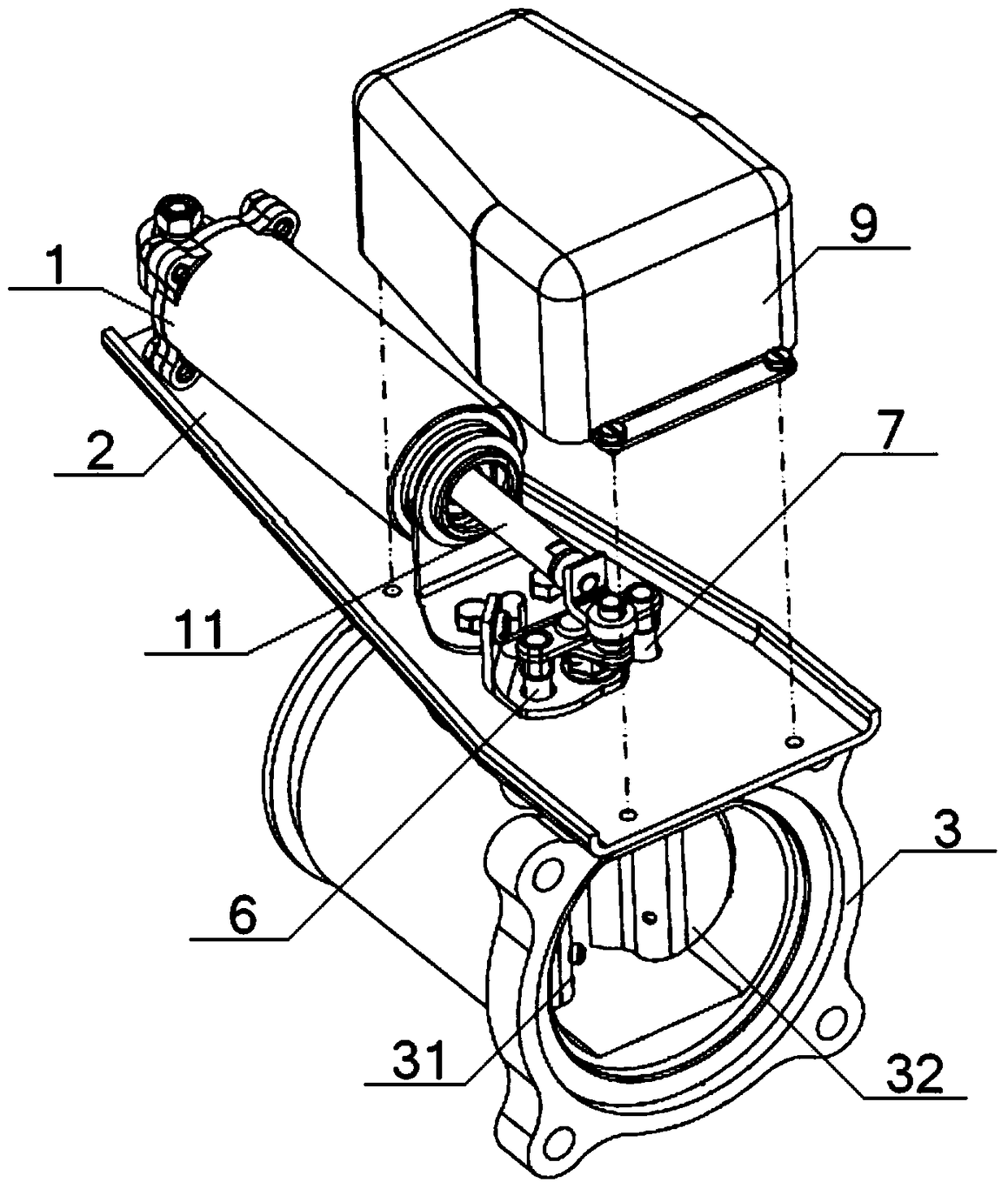

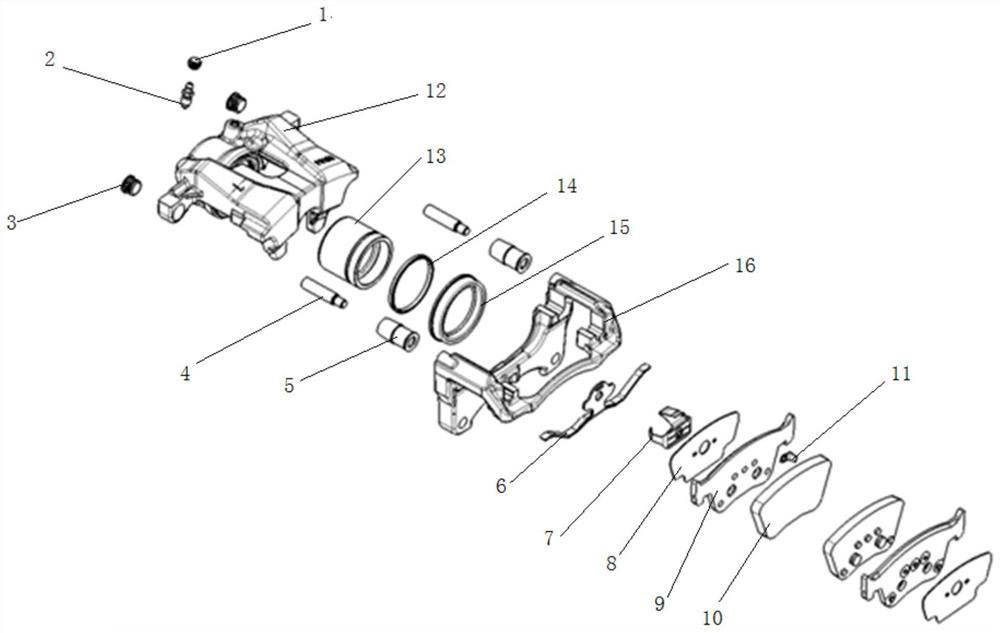

Eccentric only-pull structure type hydraulic brake callipers

ActiveCN108953424AImprove partial wearImprove noiseBraking membersFriction liningCalipersStructure type

The invention relates to the technical field of brake calipers and in particular relates to a pair of eccentric only-pull structure type hydraulic brake calipers. The pair of eccentric only-pull structure type hydraulic brake calipers comprises a guide pin, a buffer sleeve, holding springs, an inner friction block, an outer friction block, an eccentric shell, a piston and an only-pull structure bracket. Two sides of the eccentric shell and the only-pull structure bracket are connected through the guide pin and the buffer sleeve, the eccentric shell and the outer friction block are connected through the holding spring, and the inner friction block and the piston are connected through the other holding spring. Compared with the prior art, the only-pull structure bracket with an outer beam isdesigned, so that the integral rigidity is improved, the machining stability is improved greatly, and the tolerance zone is reduced greatly, and therefore, more favorable support is provided to improve eccentric wear, noise and drag. The eccentric shell is matched with the only-pull structure bracket, so that the eccentric wear of a friction plate is reduced to the maximum extent, and low frequency and knock abnormal sound noises are improved. The drag, eccentric wear and noise conditions of the hydraulic brake calipers are also improved well.

Owner:上海大陆汽车制动系统销售有限公司 +1

Embedded hub vortex compressor

InactiveCN1231674CReduce eccentric wearImprove stress conditionRotary piston pumpsRotary piston liquid enginesStress conditionsCoupling

A hub embedded vortex compressor is disclosed. The second spiral vortex circles extended from end plate is mutually inserted with the first ones on the non-revolving vortex part. The revolving vortexpart is driven by crankshaft to revolve relatively to the non-revolving one. A rotation preventer is composed of said revolving vortex part and cross coupling. A hub integrated with the second spiralvortex circle is embedded in the cavity of non-revolving vortex part. It can greatly decrease the tilt force moment generated by acting on the fluid in working cavity, so improving the stress condition of bearing on crankshaft and sealing condition of end face.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

A vehicle adaptive rear suspension control system and control method

ActiveCN109455053BImprove partial wearImprove escape performanceSteering partsResilient suspensionsSteering wheelSteering angle

The invention relates to a self-adaptive rear suspension control system and method for a vehicle. The system comprises a steering wheel steering angle sensor, a wheel speed sensor, an MCU processing module, an image acquisition module, a mode selection module, a micro electric steering pull rod motor and a power source; the steering wheel steering angle sensor, the wheel speed sensor, the image acquisition module, the mode selection module and the micro electric steering pull rod motor are in electric signal connection with the MCU processing module; the power source provides power for the whole control system. According to the technical scheme, on the basis of a multi-link rear suspension structure of the existing vehicle, a toe-in pull rod is replaced with a micro electric steering pullrod, and when the speed of the vehicle is high, the eccentric abrasion of tires is relieved by detecting the abrasion condition of the tires and adjusting the toe-in value of rear wheels; for the rear-drive or four-drive vehicle, when the vehicle is trapped, the angles of the rear wheels can be greatly changed, and the capability of the vehicle of getting out of a trap or steering is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Shaft sleeve pressing system and sleeve pressing machine

PendingCN110450099AImprove the shaft sleeve that is prone to slippingImprove the problem of shaft sleeve interferenceMetal-working hand toolsOil pressurePressure sensor

The embodiment of the invention provides a shaft sleeve pressing system and a sleeve pressing machine, relates to the technical field of shaft sleeve installation, and aims at solving the problem thatin the existing operation that a shaft sleeve is pressed into a shaft sleeve hole, shaft sleeve playing or shaft sleeve interference is likely to happen. The shaft sleeve pressing system comprises athree-position four-way valve, a sleeve pressing oil cylinder and a first branch. A pressure sensor is arranged on the first branch, a controller is used for receiving pressure signals which representthe oil pressure value and are sent by the pressure sensor, and the three-position four-way valve is in any state of the right position and the middle position. When the three-position four-way valveis located at the right position and oil enters a rod cavity of the sleeve pressing oil cylinder, the shaft sleeve is pressed in the shaft sleeve hole, the pressure sensor detects the oil inlet oil pressure of the rod cavity of the sleeve pressing oil cylinder, and when the oil pressure value is in the reasonable range, the controller controls the three-position four-way valve to be continuouslylocated at the right position, the shaft sleeve is continuously pressed in the shaft sleeve hole. When the oil pressure value exceeds the reasonable range, it is shown that the shaft sleeve and the shaft sleeve hole are not matched, the controller controls the three-position four-way valve to be located at the middle position, continuous pressing of the shaft sleeve into the shaft sleeve hole is stopped, and the fool-proof function is achieved.

Owner:SANY HEAVY MACHINERY

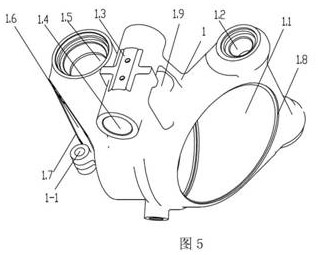

A sealing device for a micro rotor engine

ActiveCN106401786BReduce air leakageReduce wearSealing arrangements for enginesMachines/enginesEngineeringEngine power

The invention discloses a sealing device used for a micro-miniature rotor engine, relates to a sealing device used for a micro-miniature rotor engine and adopting a combined type of leaf springs and sealing pieces and belongs to the field of micro-miniature rotor engines. The sealing device comprises the sealing pieces and the leaf springs; each leaf spring is in a shape of an arc; and the middle portions of the two ends in the up-down direction are provided with grooves used for being in clearance fit with rib plates. The top end of each sealing piece is in a shape of an arc; the middle portion of each sealing piece is rectangular; the upper end and the lower end of the back portion of each sealing piece are provided with convex tables preventing the leaf springs from moving; and the rib plates reducing the gas leakage area are machined in the middles of the back portions of the sealing pieces. The rib plates are in clearance fit with the grooves formed in the end portions of the leaf springs, and the grooves in the upper sides and the lower sides of the leaf springs can stride cross the two sides of each rib plate. During installation, the back portions of the leaf springs make contact with the portions of the bottoms of rotor sealing grooves, and the tops of the sealing pieces make contact with the inner wall of a cylinder. By means of the sealing device, the abrasion amount of the sealing pieces can be reduced, eccentric abrasion of the sealing pieces in the working process can be improved, the power and the service life of the micro-miniature rotor engine are improved, and installing is convenient.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Pneumatic belt tire

InactiveCN101306631BImprove partial wearMaintain cost competitivenessPneumatic tyre reinforcementsTyre tread bands/patternsCost competitivenessGrounding line

The invention provides a pneumatic radial tire having cost competition and improving the bias abrasion performance to the tire shoulder by seeking for the optimization of the ground shape and the ground pressure. The pneumatic radial tire has a translot (2) having a plurality of circumferential main slots (1a, 1b) at the tread portion of the tire and extending along the width direction of the tire and a tread pattern for forming a plurality of ground lines (4a, 4b). In the tier shoulder ground line (4b) comprising ground end (E), a translot (2) extending from the circumferential main slots (1b) nearest to the ground end to the ground end (E) is stopped near the ground end, and continuous ground portions (L) are formed near the ground end. Side of the main slots (1b) of the tier shoulder ground line (4b) is approximately parallel to the intermittent slit auxiliary slot (3).

Owner:BRIDGESTONE CORP

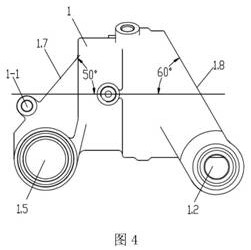

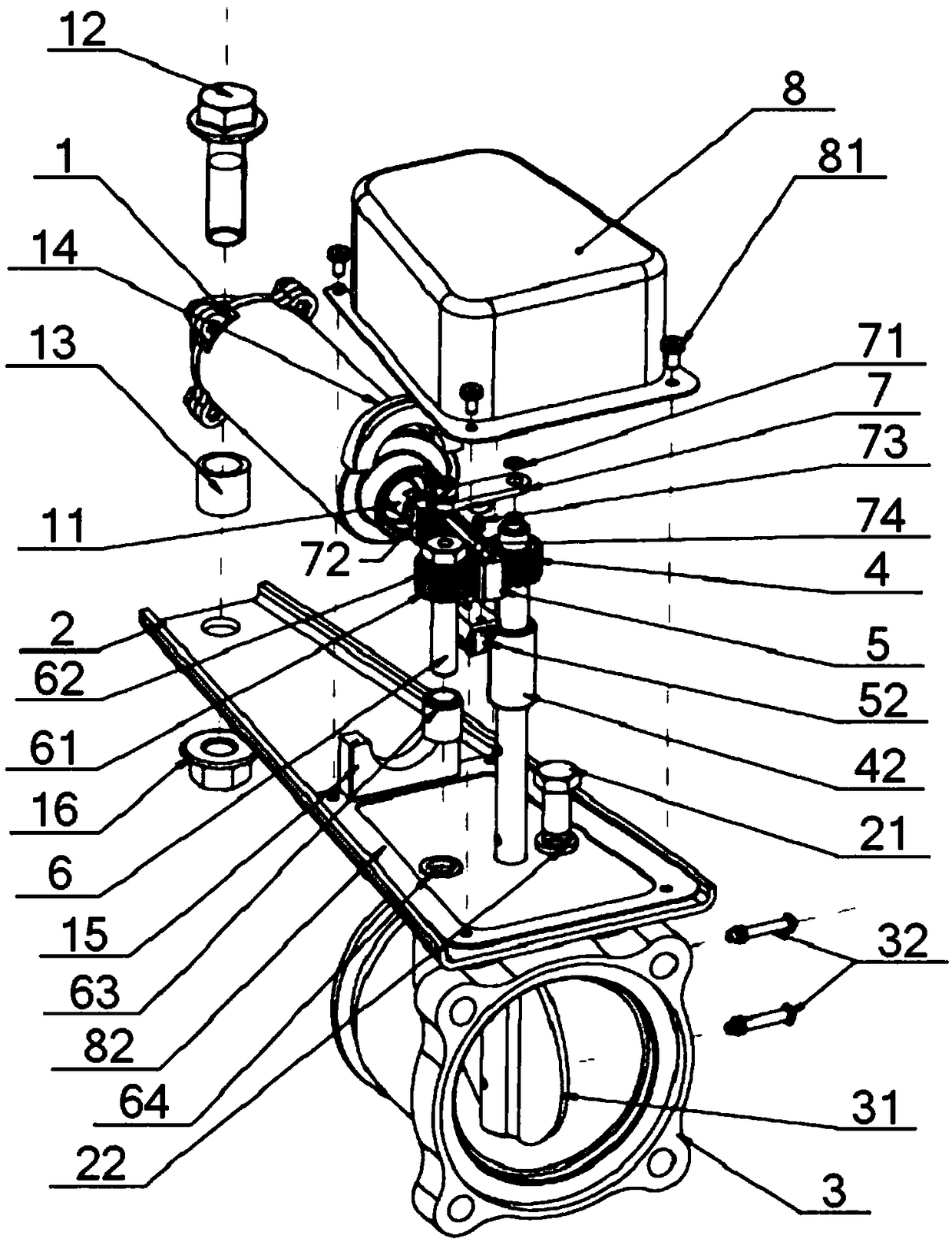

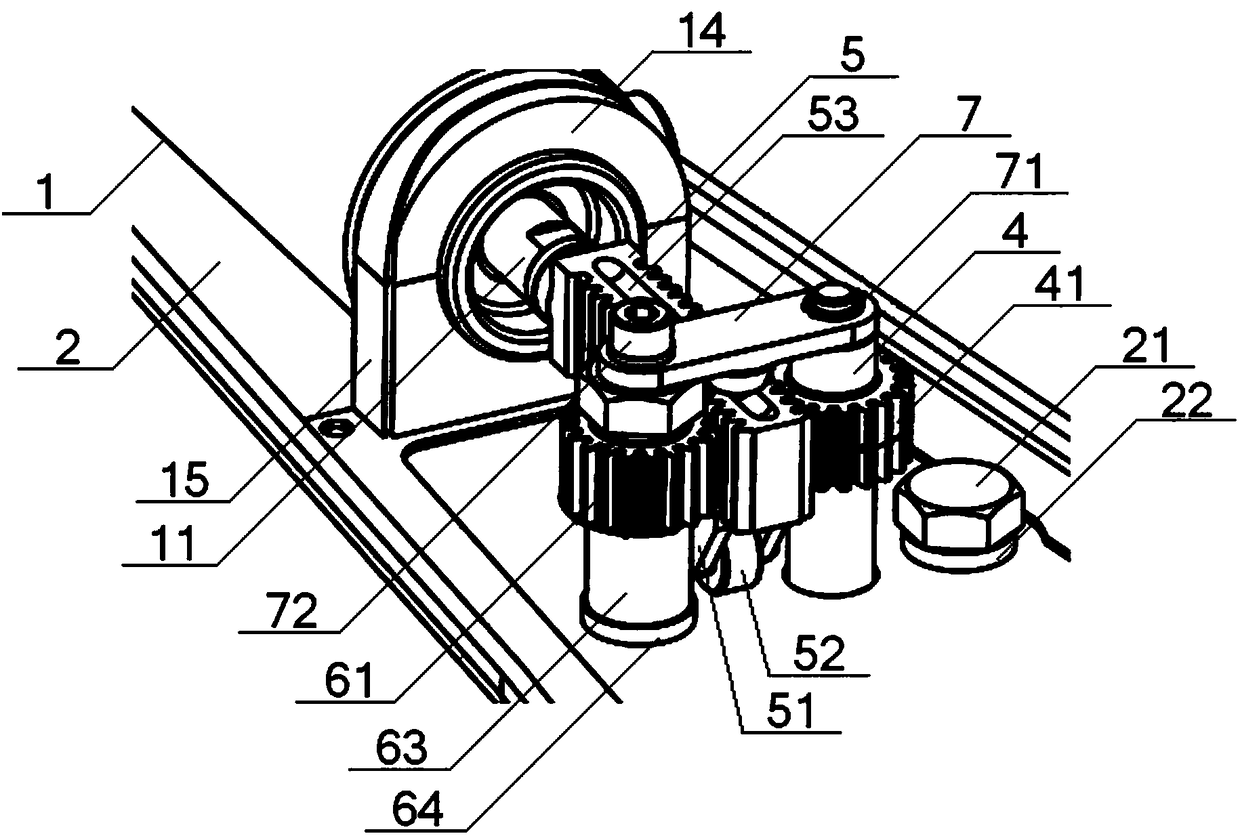

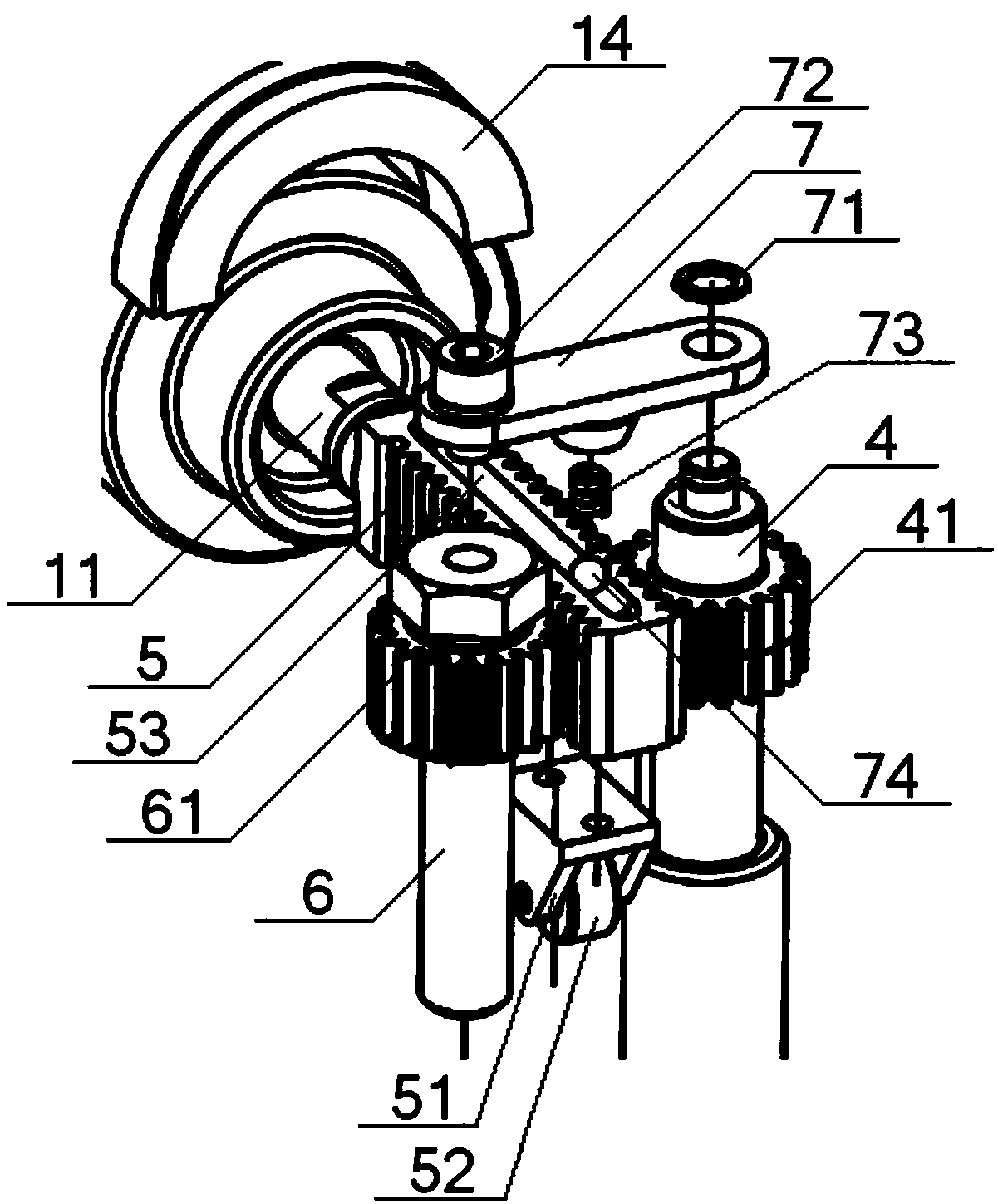

Exhaust brake valve for engine

PendingCN108317013AReduce failureImprove partial wearEngine controllersMachines/enginesAgricultural engineeringExhaust brake

Owner:DONGFENG COMML VEHICLE CO LTD

Compact brake clamp unit shell

PendingCN114215866AEasy to disassembleAvoid the influence of assembly accuracyBraking elementsBrake arrangement with pressed braking surfaceBrakeEngineering

The invention relates to a compact brake clamp unit shell, and belongs to the technical field of rail transit. The shell is provided with a brake cylinder piston assembly mounting hole and a push rod assembly cavity communicated with one end of the mounting hole; the outer end of the push rod assembly cavity is a side cover mounting surface inclined to the axis of the mounting hole; one end, far away from the push rod assembly cavity, of the mounting hole is an end cover mounting surface; and one end of the side cover mounting surface is provided with a push rod assembly hinging structure. With the adoption of the invention, the positioning and movement precision of the push rod assembly can be fully ensured, and the adverse effect on the positioning and movement precision of the push rod assembly caused by vibration or looseness of fastening connection between the shell and the brake cylinder side cover is avoided; accurate and stable transmission of the required clearance adjustment amount during clamp braking is effectively guaranteed, and then the braking reliability and the operation safety are guaranteed. And the brake cylinder side cover can be conveniently disassembled, so that the action condition of each part in the shell can be conveniently checked, and great convenience is brought to detection and maintenance.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Control mechanism of exhaust brake valve

ActiveCN108386277AReduce failureImprove the state of stressInternal combustion piston enginesEngine controllersGear wheelExhaust brake

A control mechanism of an exhaust brake valve comprises a control cylinder, a supporting plate, a valve body, a rotary shaft, a rack, an idler shaft and a hood; one end of the rotary shaft is providedwith a gear in a sleeved mode, and the other end of the rotary shaft penetrates through the supporting plate and the valve body in sequence to be connected with a valve plate in the valve body; one end of the idler shaft is connected with the supporting plate, and an idler is arranged at the other end of the idler shaft; one end of the rack is connected with a piston push rod of the control cylinder, the other end of the rack is located between the rotary shaft and the idler shaft, and the rack is engaged with the gear and the idler; a roller support with a roller is installed on the lower end face of the rack; and a pressing plate is arranged above the rack, the end parts of the pressing plate are fixed to the rotary shaft and the idler shaft correspondingly, a spring and a ball are installed on the lower end face of the pressing plate, a groove is formed in the upper end face of the rack, and the ball is pressed in the groove through the spring. By means of the control mechanism ofthe exhaust brake valve, the problems that a control mechanism loses efficacy and a piston push rod is eccentrically worn and gets stuck can be effectively solved, and the control mechanism is long inservice life, high in reliability and good in smoothness.

Owner:DONGFENG COMML VEHICLE CO LTD

Composite rigid body train line and its production method

A composite rigid body train line and its production method, which has a sliding contact rail sliding contact with collector shoe and a rail support for fixing the sliding contact rail which includes a central plate and a lateral plate bending ductility from two sides of the central plate, said rail support has a mounting slot embeded and riveted for fixing said lateral plate, the ratio W1 / W2 of the width W1 of the central plate and the width W2 of the lateral plate, is more than 3.0, the whole surface of the central plate is contacted with said rail support in width direction virtually, so the conjugation of the sliding contact rail and rail support is improved.

Owner:SUMITOMO ELECTRIC IND LTD

Ultra-low section all-steel radial giant tire

InactiveCN113246662AIncrease ground areaImprove partial wearTyre tread bands/patternsGround contactCat's claw

The invention discloses an ultra-low section all-steel radial giant tire, and relates to the field of tire manufacturing, the ultra-low section all-steel radial giant tire comprises a tire body integrally formed with a hub, the tire body comprises an airtight layer, a tire body layer, a steel wire cord layer, a belted layer, a tire tread and a tire sidewall which are sequentially distributed from inside to outside, and a tire shoulder of an arc-shaped structure is formed between the tire tread and the tire sidewall; and the crown arc of the tire shoulder adopts a bionic cat claw palm pad structure design. The tire shoulder with the arc-shaped structure is formed between the tire tread and the tire side wall, the tire crown arc of the tire shoulder adopts the bionic cat-claw palm pad structure design, and the cat-claw palm pad arc curve fitting is carried out by utilizing the similar principle and is applied to the tire crown design, so that the ground contact area of the tire can be effectively increased, the tire eccentric wear phenomenon is improved, and the service life of the tire is prolonged. And the cooperative improvement of the tire ground gripping performance and the wear performance is achieved.

Owner:山东新豪克轮胎有限公司

Pneumatic tire

InactiveCN100348431CEven distribution of ground pressureImprove partial wearTyre tread bands/patternsShoulder regionEngineering

A tread surface the tire rotational direction of which is specified in one direction has a center region and shoulder regions on both sides of the center region. Blocks are defined in at least one of the shoulder regions by at least one first circumferential groove which extends in a circumferential direction of the tire, and first lateral grooves which extend in a widthwise direction of the tire and are disposed at predetermined intervals in the tire circumferential direction. Each block includes a tire rotational direction side groove wall surface having an inclination angle alpha , and a tire reverse rotation direction side groove wall surface having an inclination angle beta , and the inclination angle beta is greater than the inclination angle alpha . Each block has a tire rotational direction side edge portion which is chamfered.

Owner:THE YOKOHAMA RUBBER CO LTD

Device for grinding lens sphere

InactiveCN1301181CImprove partial wearEliminate Wall Thickness VariationsOptical surface grinding machinesGrinding drivesFree rotationAir bearing

The present invention provides a kind of spherical lens grinding apparatus improved from a kind of common lens grinding apparatus. The solving method provides the spherical tool tray with the function which can compress the under-processing lens in the direction of the axis through the center of the spherical tool tray and the capacity which can move in the direction parallel with the above-mentioned axis. The spherical oscillating body which can oscillate freely supports the above-mentioned tool tray with free rotation and has the same center with the tool tray. The above-mentioned oscillating body is supported by the spherical air bearings which has the same center with the above-mentioned tool tray. The lens grinding apparatus also provides the stop-rotation component in the axis parallel with the surface which the above-mentioned oscillating body and tool tray rotate on and through the sphere center of the above-mentioned tool tray. The center-adjusting mechanism for oscillating angle adopts the arched cam to set the center of oscillating angle.

Owner:HARUCHIKA

Eccentric only pull structure hydraulic brake calipers

ActiveCN108953424BImprove partial wearImprove noiseBraking membersFriction liningStructural engineeringMechanical engineering

The invention relates to the technical field of brake calipers and in particular relates to a pair of eccentric only-pull structure type hydraulic brake calipers. The pair of eccentric only-pull structure type hydraulic brake calipers comprises a guide pin, a buffer sleeve, holding springs, an inner friction block, an outer friction block, an eccentric shell, a piston and an only-pull structure bracket. Two sides of the eccentric shell and the only-pull structure bracket are connected through the guide pin and the buffer sleeve, the eccentric shell and the outer friction block are connected through the holding spring, and the inner friction block and the piston are connected through the other holding spring. Compared with the prior art, the only-pull structure bracket with an outer beam isdesigned, so that the integral rigidity is improved, the machining stability is improved greatly, and the tolerance zone is reduced greatly, and therefore, more favorable support is provided to improve eccentric wear, noise and drag. The eccentric shell is matched with the only-pull structure bracket, so that the eccentric wear of a friction plate is reduced to the maximum extent, and low frequency and knock abnormal sound noises are improved. The drag, eccentric wear and noise conditions of the hydraulic brake calipers are also improved well.

Owner:上海大陆汽车制动系统销售有限公司 +1

Pneumatic tire

ActiveUS20150090384A1Shorten the lengthImprove partial wearMotorcycle tyresTyre tread bands/patternsAcute angleEngineering

The present invention has an object of providing a pneumatic tire having a tread pattern capable of providing both excellent drivability and a high partial wear resistance. The pneumatic tire of the present invention includes, in a tread surface, a compound groove partitioned into a first groove portion and a second groove portion by a first groove side and a second groove side, the first groove side having an oblique side portion diagonally disposed relative to a tire circumferential line in plan view, the second groove side intersecting with the oblique side portion of the first groove side at an acute angle in plan view, in which: the first groove portion and the second groove portion both have a groove depth that gradually reduces in an extending direction of the groove toward an intersection between the oblique side portion and the second groove side; and a groove wall extending from the first groove side is formed as a tapered surface mildly-sloped toward a groove bottom on the intersection side when viewed in the groove transverse direction. Further, the pneumatic tire of the present invention includes, in a tread surface, a groove partitioned by at least three groove sides in plan view, in which: one or more of groove walls extending from one of the at least three groove sides that extends in the longitudinal direction of the groove is formed as a tapered surface at least in part thereof; and the tapered surface forms an angle with a plane perpendicular to the tread surface, which varies in the extending direction of the groove side.

Owner:BRIDGESTONE CORP

Valve, air cylinder, compressor and air conditioner

PendingCN111852872AChange the way you workTwo-way rotation realizationRotary/oscillating piston combinations for elastic fluidsCompressorEngineeringMechanical engineering

The invention provides a valve, an air cylinder, a compressor and an air conditioner, and relates to the technical field of air conditioners. The technical problem that in the prior art, a compressorpump body only allows a roller to rotate in a single direction to realize air suction and exhaust operation of the air cylinder can be solved. The device comprises a first plug body (10) and a secondplug body (11), the second plug body (11) is arranged in the first plug body (10), and the second plug body (11) can be matched with the first plug body (10) at an air suction port and an air exhaustport of the air cylinder to form a channel for air to enter or be exhausted out of the air cylinder. The valve can work in two directions to alternately form an air inlet channel and an exhaust channel of the air cylinder, so that the air cylinder allows the roller to rotate in two directions to achieve air suction and exhaust operation, the single-direction working mode of the air cylinder is changed, and the two-direction rotating working mode of the roller in the air cylinder is achieved.

Owner:ZHUHAI LANDA COMPRESSOR +1

Ring gear structure and planetary gear transmission device

ActiveCN111692313ASatisfy floating needsReduce eccentric wearPortable liftingToothed gearingsGear wheelEngineering

The embodiment of the invention provides a ring gear structure and a planetary gear transmission device, and relates to the technical field of mechanical equipment. The ring gear structure provided bythe embodiment of the invention includes a first-class ring gear and a second-class ring gear, the first-class ring gear is used for meshing with a first-class planetary gear, and the second-class gear ring is used for meshing with a second-class planetary gear. The first stage ring gear and the second stage ring gear are actively connected with each other, and a gap is formed between the first-class ring gear and the second-class ring gear. Therefore, in the process of use, the second-class ring gear can float relative to the first-class ring gear, correspondingly, the first-class ring gearcan float relative to the second-class ring gear, that is, the first stage ring gear and the second stage ring gear can be relatively independent floating by separately arranging the first stage ringgear and the second stage ring gear. At the same time, floating effect is achieved, and uniform load effect is good. Noise is reduced, eccentric wear phenomenon is reduced, and then use effect is improved.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com