Charpy beam type straddle type monorail vehicle two-axle power bogie

A simply supported beam type straddle type, power bogie technology, applied to bogies, locomotives, railway car body parts, etc., can solve the problems of cumbersome tire replacement operations, tire partial wear, short maintenance cycle, etc. The effect of eccentric wear problem, improvement of tire eccentric wear problem, and improvement of stress situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

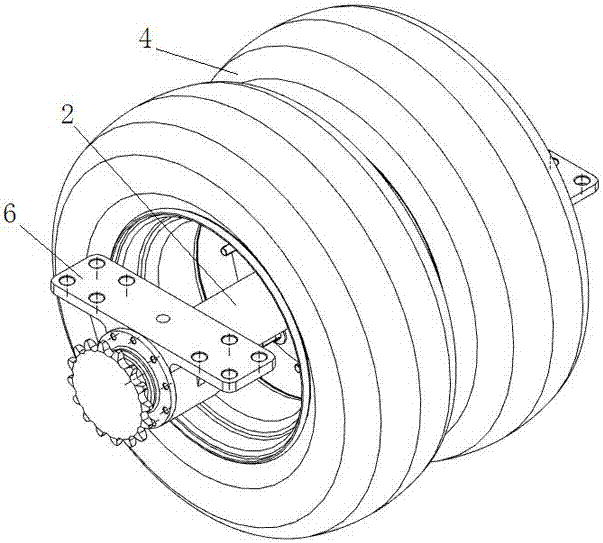

[0011] A simply supported beam type straddle type monorail vehicle dual-axle power bogie, comprising a support frame 1 and a running wheel assembly, the support frame 1 is provided with a running wheel installation cavity, and the running wheel assembly is arranged in the running wheel installation cavity Inside, the innovation is that the running wheel assembly includes a support shaft 2, two rims, two wheels 4 and two sets of bearings 5, and the middle part of the support shaft 2 is provided with a disc-shaped protrusion 2 with a T-shaped shaft section. -1, the outer diameter of the left section on the disc-shaped protrusion 2-1 is larger than the outer diameter of the right section; the rim is composed of a support part 3-1, a connecting disc 3-2 and a cone section 3-3, and the connecting disc The middle part of 3-2 is provided with a mounting hole, and the inner diameter of the mounting hole matches the outer diameter of the right section on the disc-shaped protrusion 2-1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com