Device for grinding lens sphere

A grinding device and lens technology, which is applied in the direction of grinding drive devices, optical surface grinders, grinding machines, etc., can solve the problems of lens wall thickness changes, difficulty in rapid adjustment, and inability to stop cutting immediately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described below with reference to the drawings.

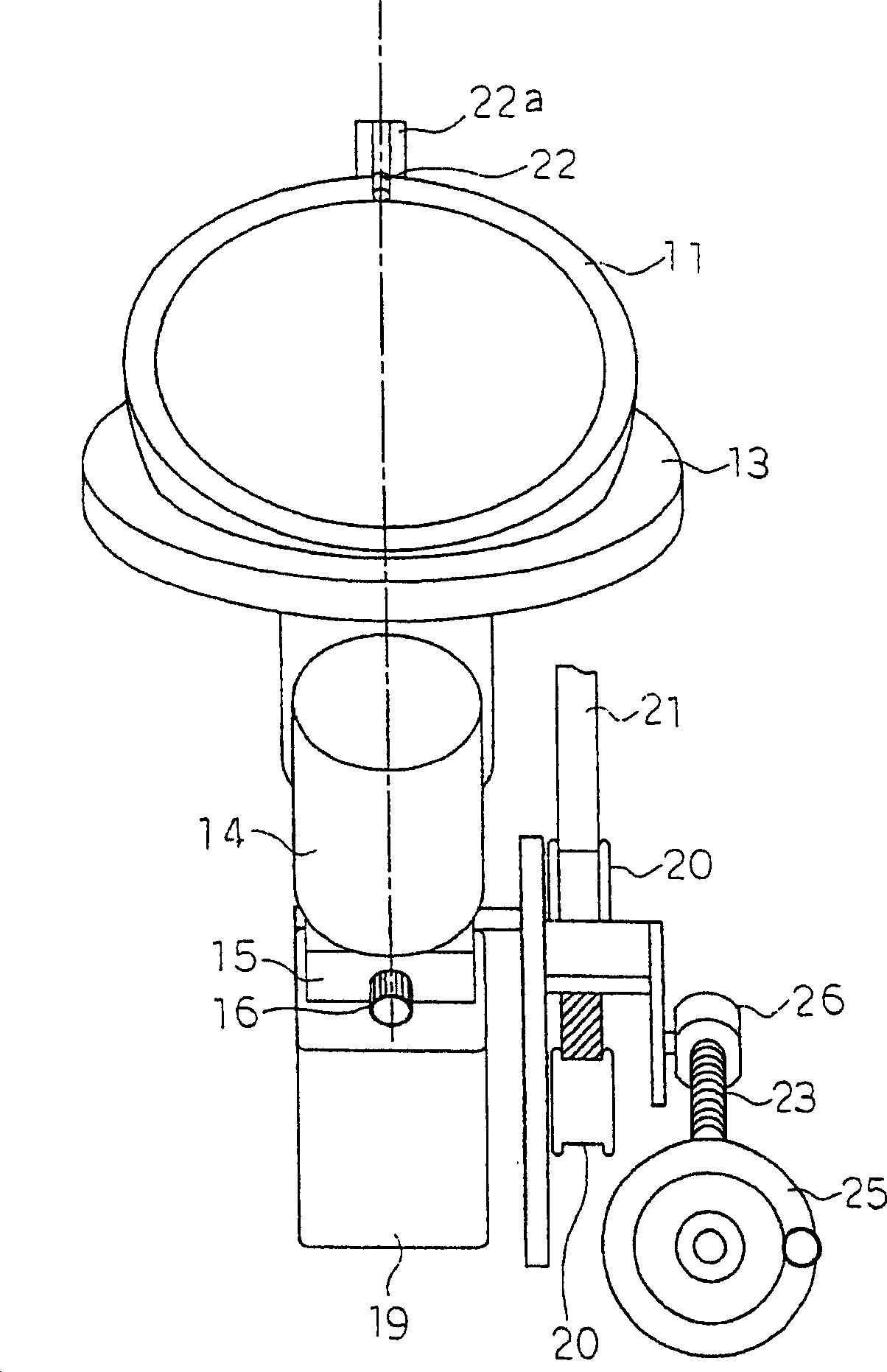

[0019] figure 1 and figure 2 To represent the figure of lens spherical grinding device of the present invention, figure 1 is a cross-sectional view showing the side, figure 2 It is a front view showing a swing part.

[0020] In the figure, 1 is a lens to be processed, 2 is a holder holding the lens to be processed 1 , 3 is a shaft supporting the holder 2 , and 4 is a measurement arm connected to the shaft 3 . The shaft 3 presses the processed lens 1 on the tool plate 9 from the axis passing through the center O of the spherical surface with the use of the pressure spring 5. Since the measuring arm 4 on one side is connected to the shaft 3, it can correspond to the cutting amount of the processed lens 1. Press the probe of the scale gauge 10. The scale 10 outputs a signal based on a preset value of the scale 10 , and is set to output a signal when the processed lens 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com