Exhaust brake valve for engine

An exhaust brake valve, engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of easy failure of the control mechanism, easy eccentric wear and hairpin of the piston push rod, and eccentric wear of the piston push rod, etc. Achieve the effect of improving eccentric wear and card issuance, solving eccentric wear and card issuance, and improving stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

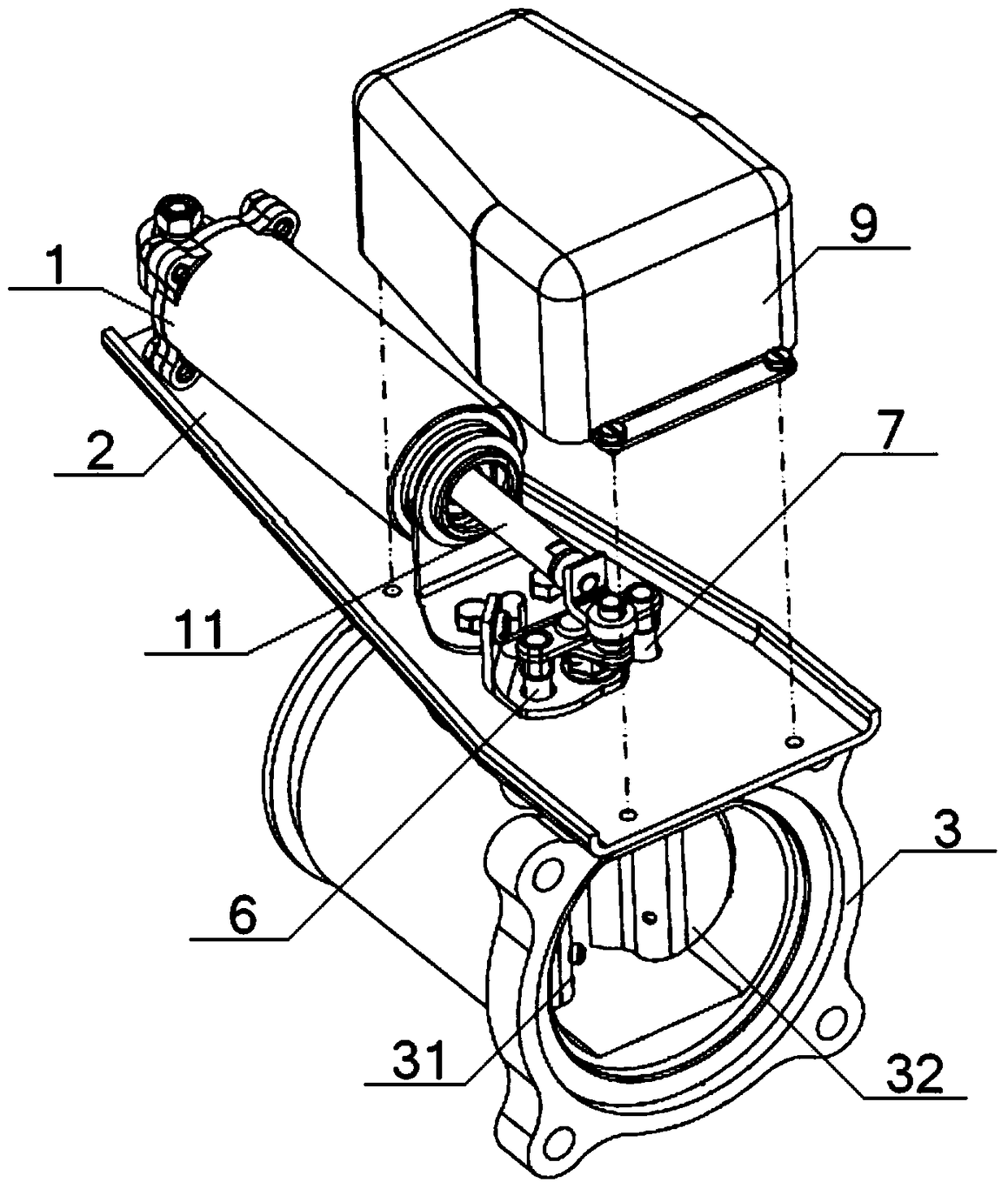

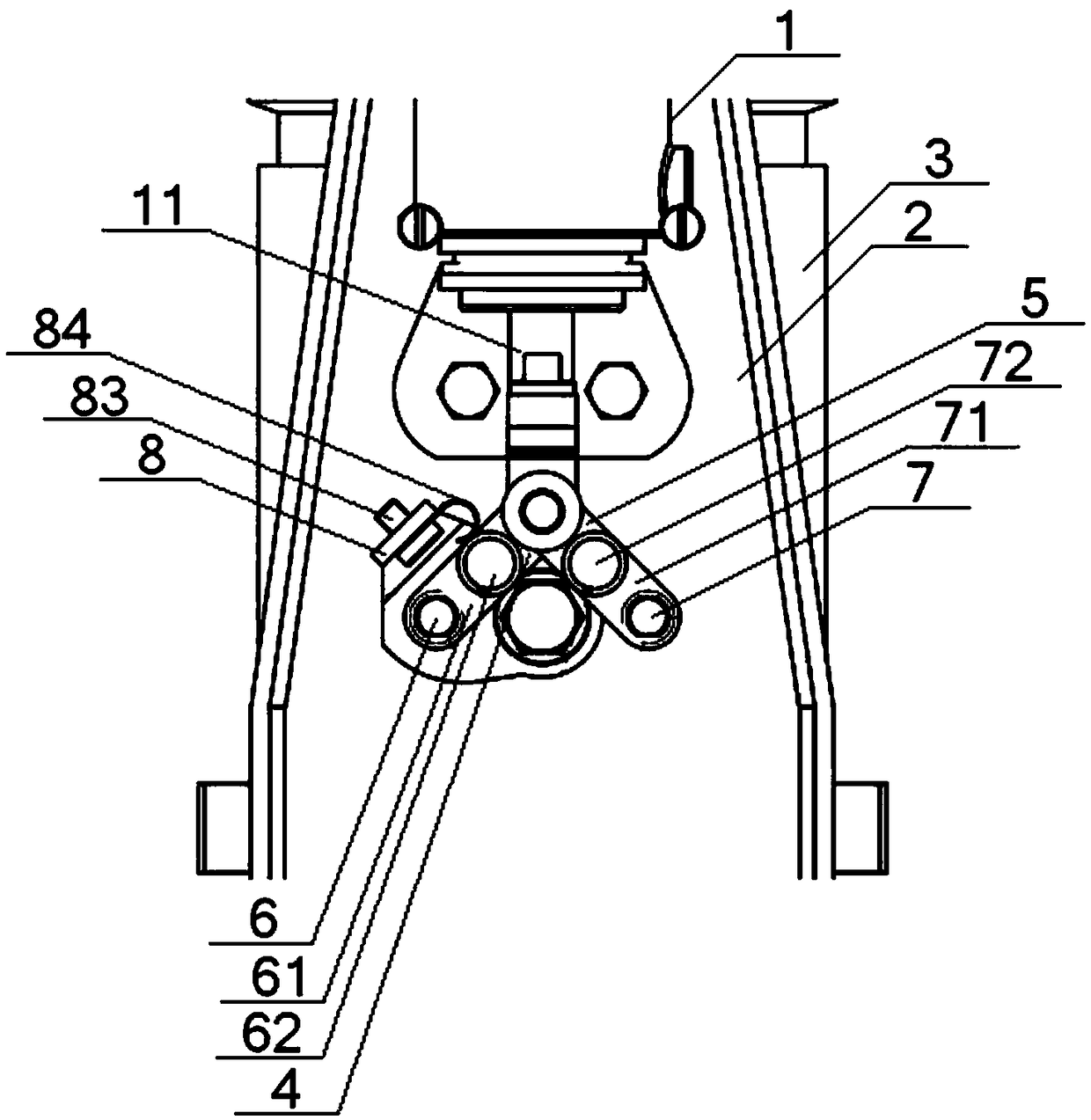

[0043] see Figure 1 to Figure 6 , an engine exhaust brake valve, comprising a manipulation cylinder 1, a support plate 2, a valve body 3, and a cover 9, the manipulation cylinder 1 is mounted on the upper end surface of the support plate 2, and the valve body 3 is mounted on a support On the lower end surface of the plate 2, the piston push rod 11 of the operating cylinder 1 is connected with the valve plate in the valve body 3 through the operating mechanism, and the valve plate includes the first valve plate 31 and the second valve plate 32. The operating mechanism includes No. 1 connecting rod 4, No. 2 connecting rod 5, No. 1 rotating shaft 6, and No. 2 rotating shaft 7. The No. 1 rotating shaft 6 and No. 2 rotating shaft 7 are arranged symmetrically with respect to the piston push rod 11. The No. 1 rotating shaft One end of 6 is equipped with a No. 1 rocker arm 61, and No. 1 rocker arm 61 is connected with one end of No. 1 connecting rod 4 through No. 1 movable pin 62, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com