Compact brake clamp unit shell

A brake caliper and unit housing technology, applied in the field of rail transit, can solve the problem that the vibration, impact and wear of rail vehicles and rail systems cannot be improved more effectively, which is detrimental to the braking reliability of the brake caliper unit of rail vehicles. Operational safety, restricting the stability of rail vehicles, reducing comfort and operating costs, etc., to achieve the effect of being conducive to effective transmission, improving eccentric wear, and eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

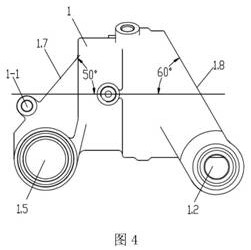

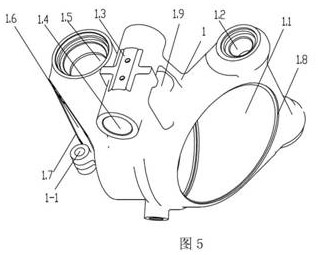

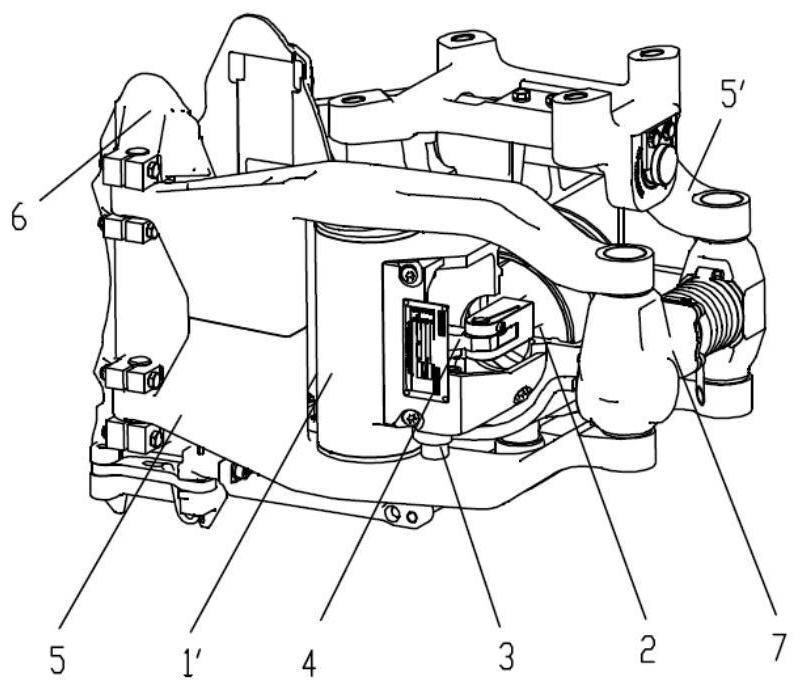

[0030] The compact brake caliper unit housing 1 of the present embodiment is as Figure 4 and Figure 5 As shown, there is an installation hole 1.1 of the brake cylinder piston assembly 2, a push rod assembly cavity 1.6 communicating with one end of the installation hole 1.1, a transmission mechanism assembly hole 1.5, a lever pin assembly hole 1.2, and a horizontal suspension assembly hole 1.4. The axis of the mounting hole 1.1 is coaxial with the piston of the brake cylinder piston assembly 2, and the mounting hole 1.1 provides a relatively sufficient space for the brake cylinder piston assembly 2 to move laterally in the housing, and the movement of the piston is smoother. The axes of the mounting holes 1.1 are generally arranged along the transverse direction. The axes of the transmission mechanism assembly hole 1.5 and the lever pivot assembly hole 1.2 are respectively arranged vertically, and the axes of the horizontal suspension assembly hole 1.4 are arranged roughly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com