Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "High dynamic stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

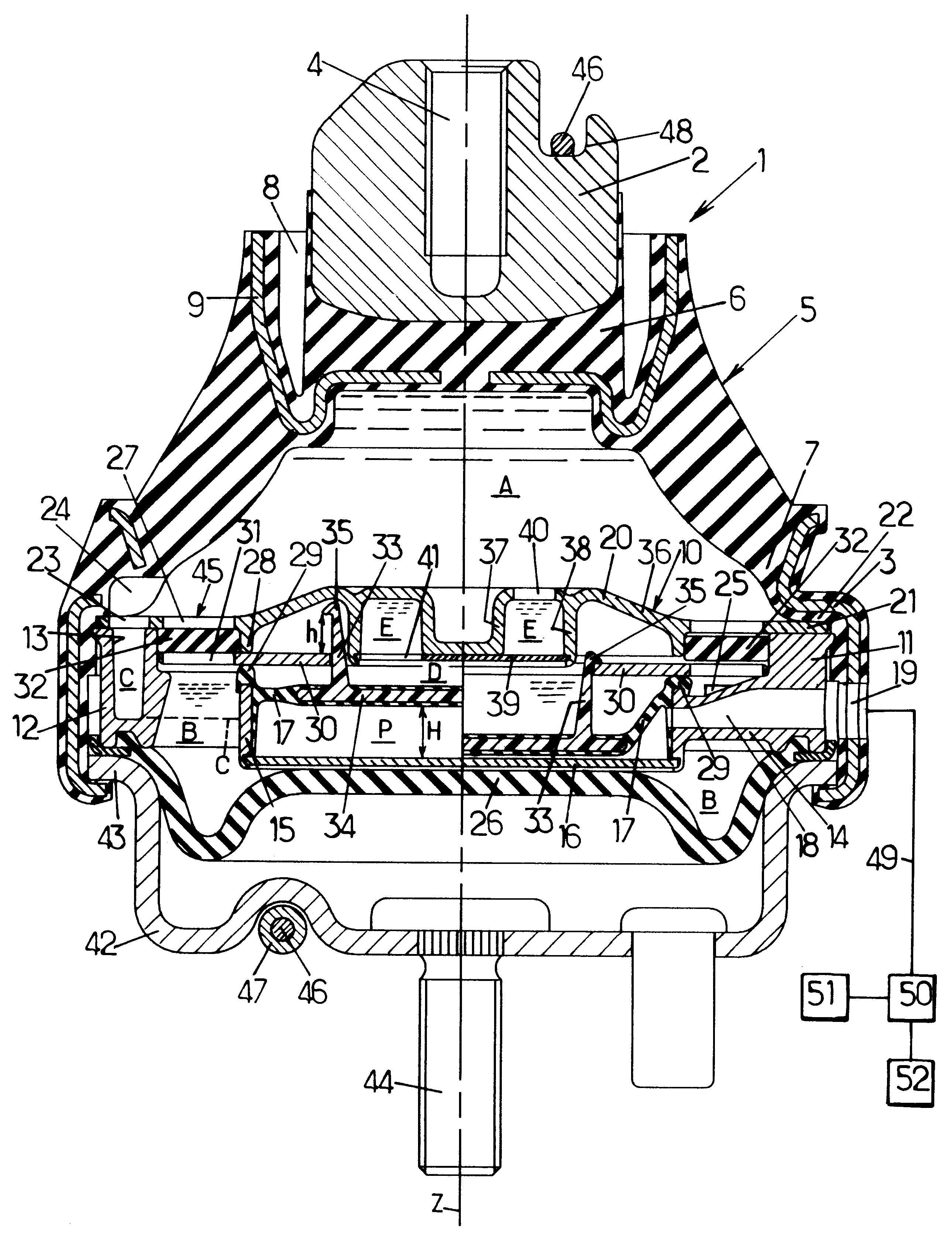

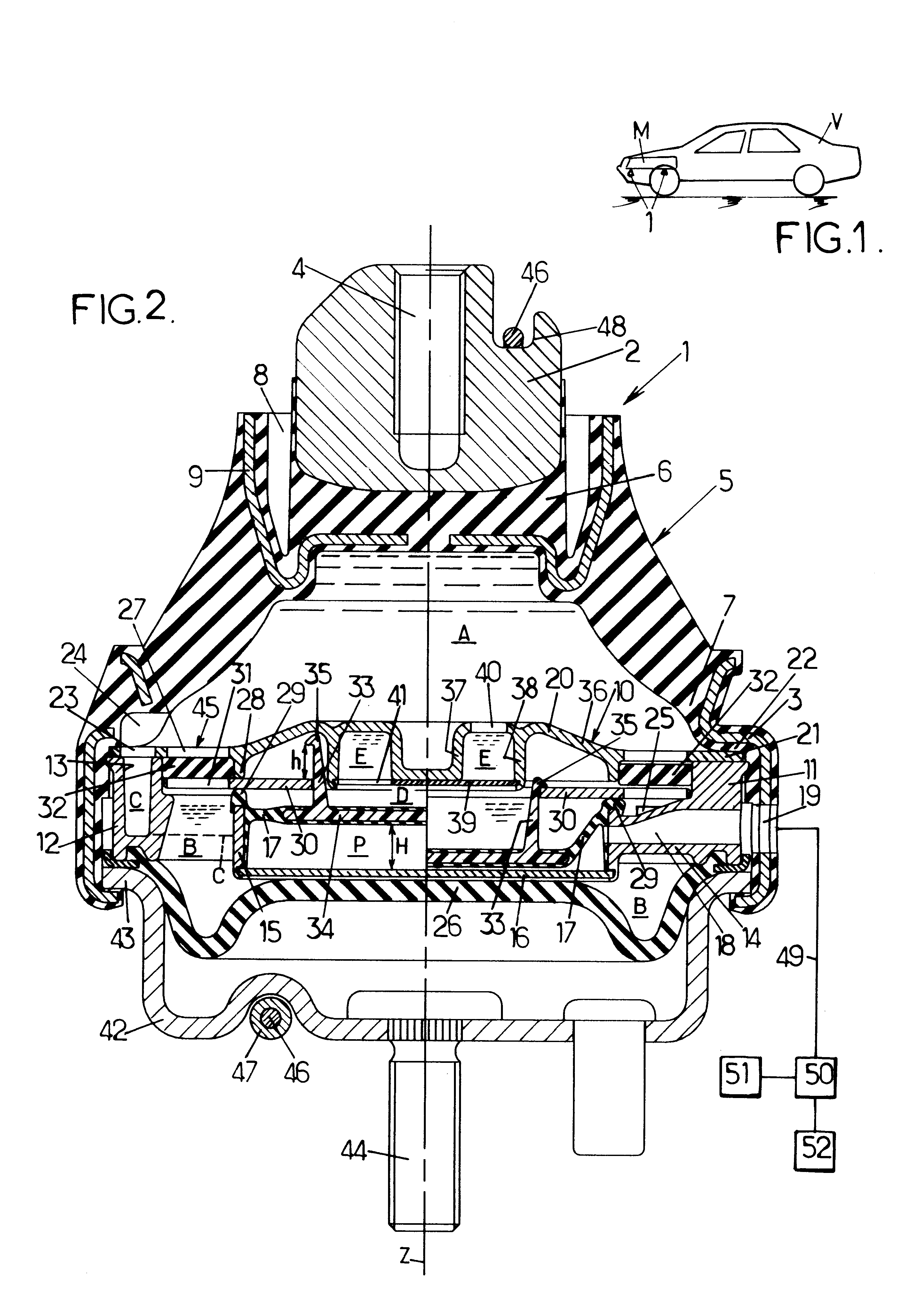

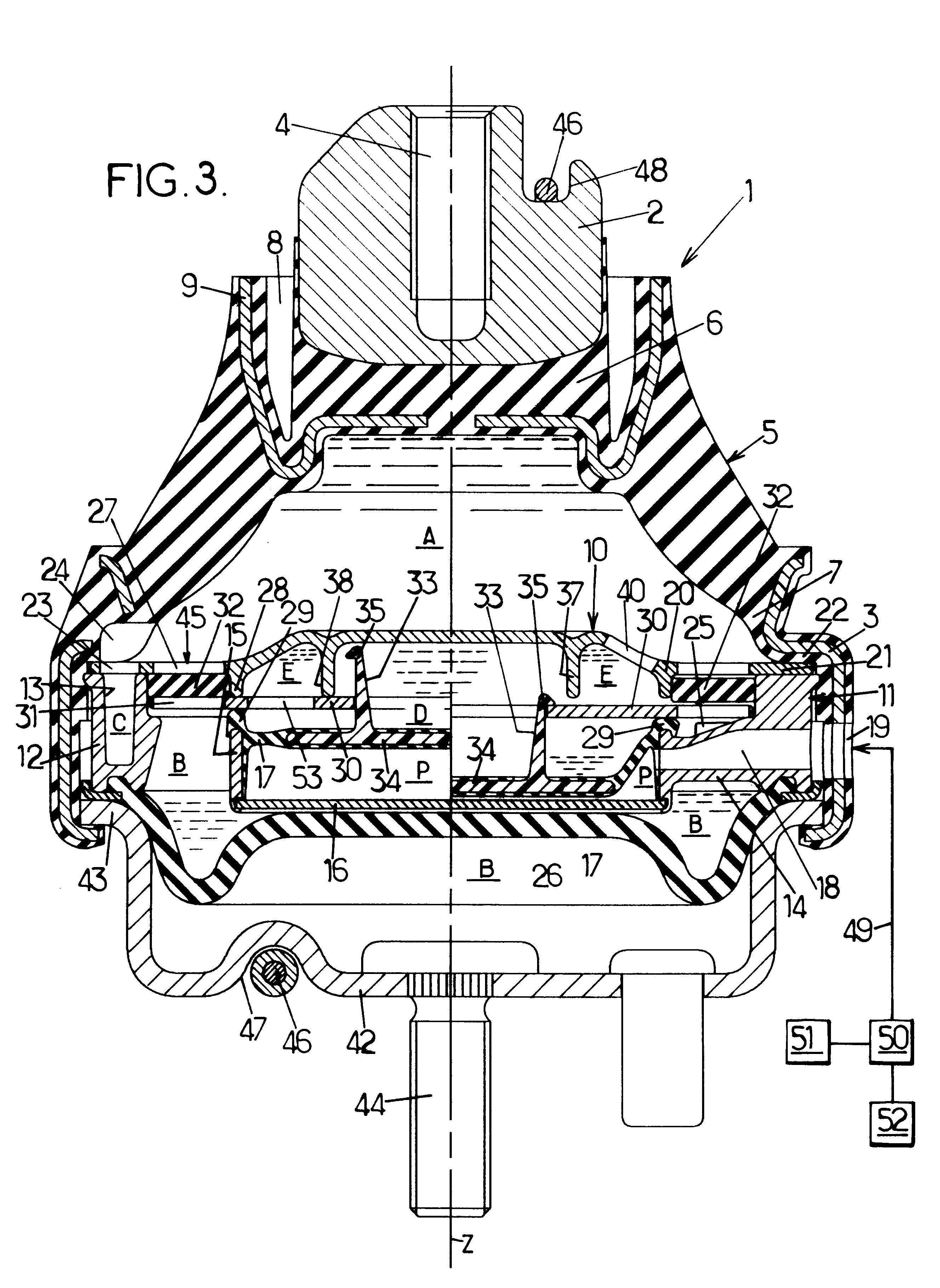

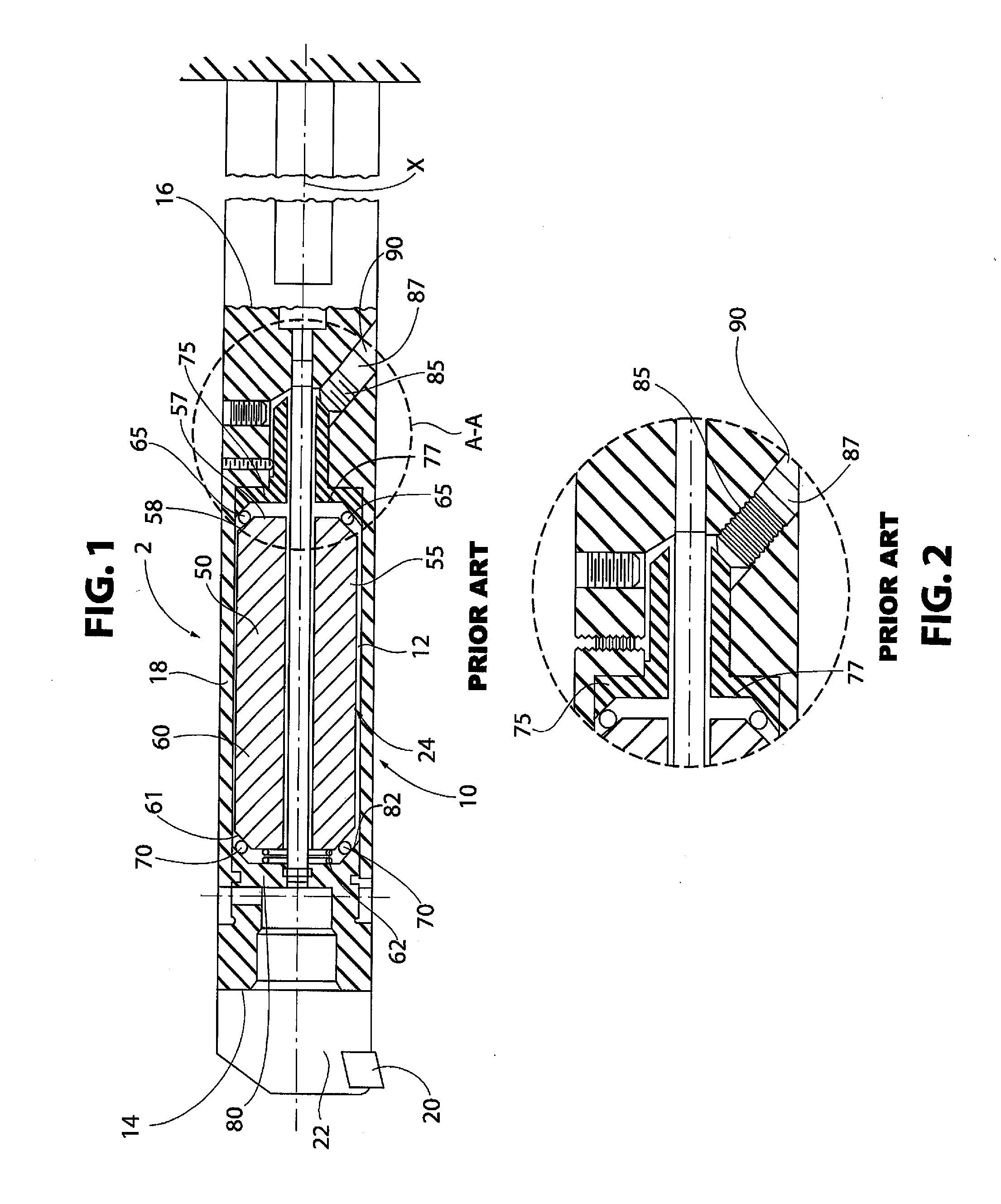

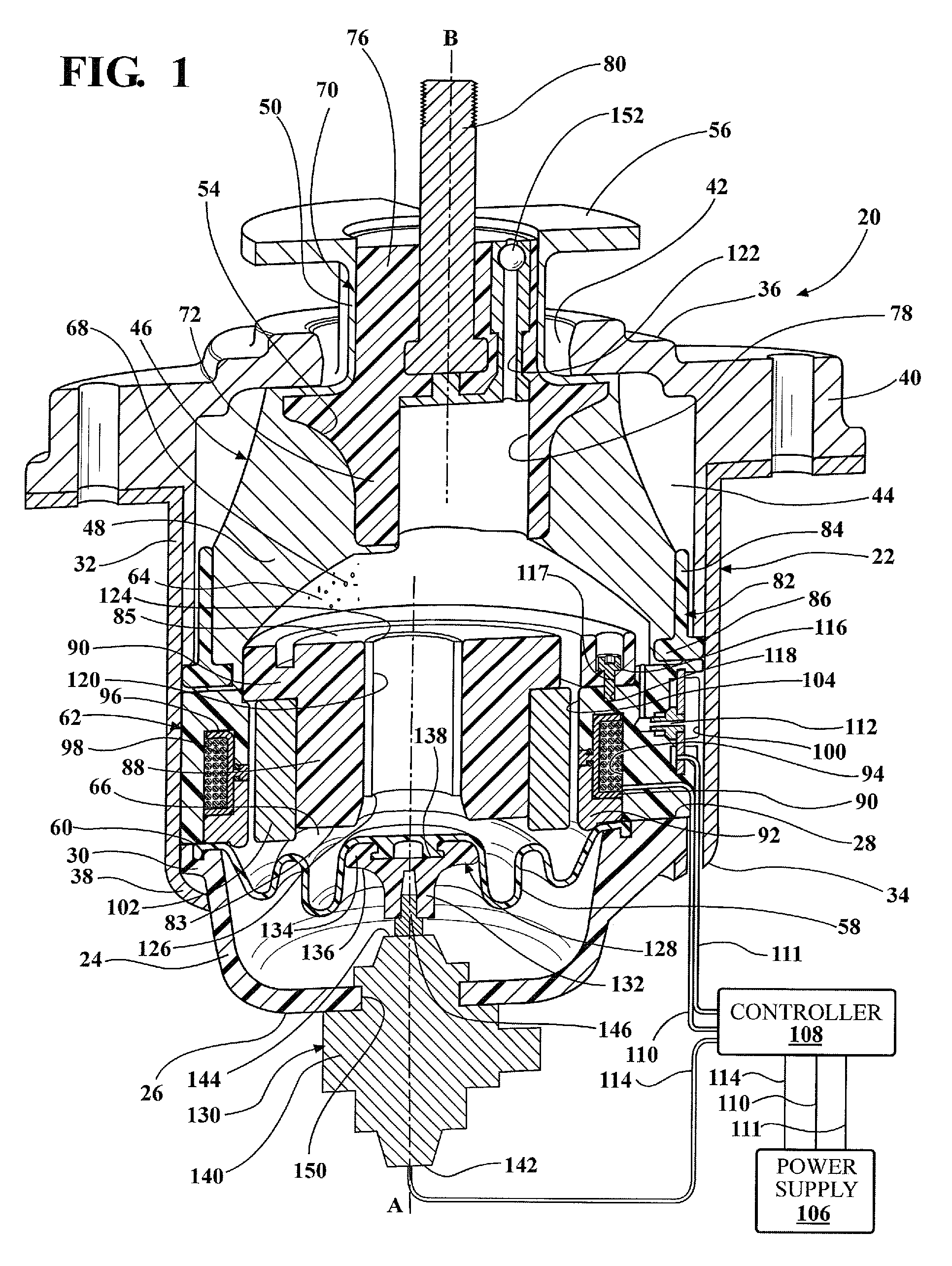

Method of damping vibration, active hydraulic anti-vibration mount and vehicle including such a mount

InactiveUS6523816B1Reduce disadvantagesHigh dynamic stiffnessMachine framesLiquid springsElastomerControl theory

Active hydraulic anti-vibration mount comprising two support elements connected by an elastomer body partially delimiting a working chamber filled with liquid, this working chamber communicating by a throttled passage with a compensation chamber separated from said working chamber by a rigid partition. The rigid partition is penetrated by a first regulating nozzle closed by a movable exciting device, and a second regulating nozzle closed by a valve the movements of which are limited to correspond to an amplitude of variation in the volume of the working chamber which is less than 20% of the amplitude of the variations in volume generated by the exciting device.

Owner:HUTCHINSON SA

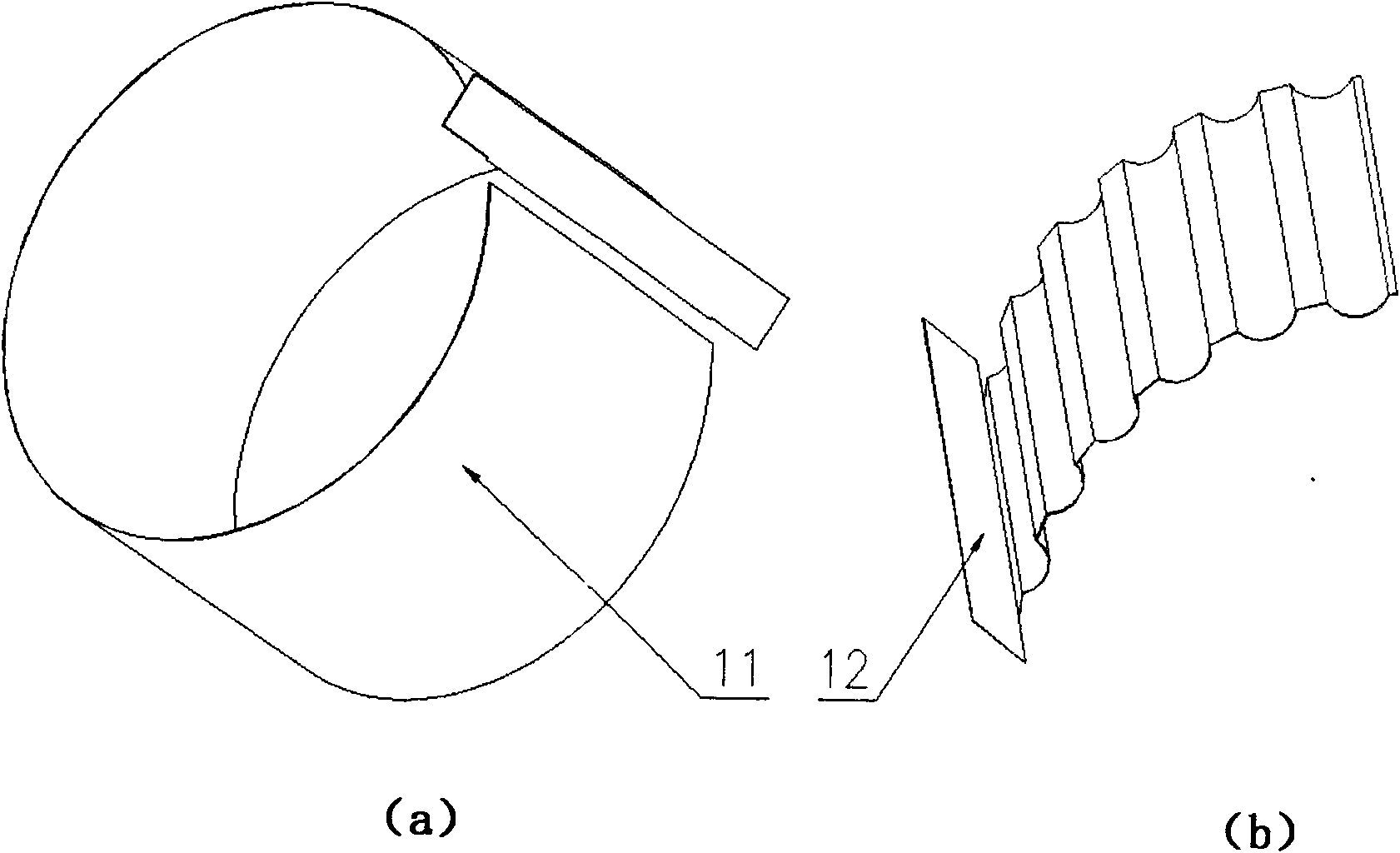

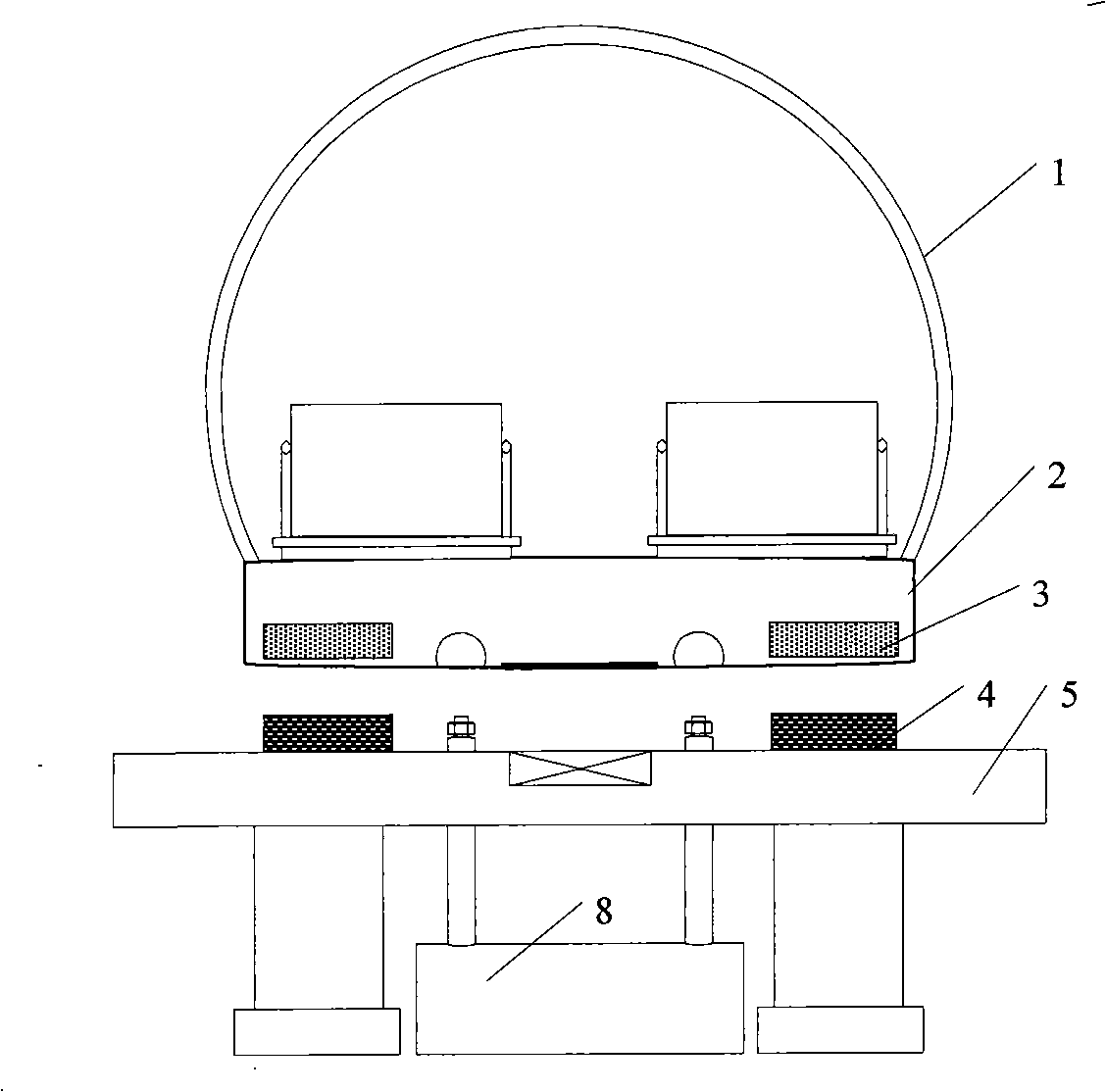

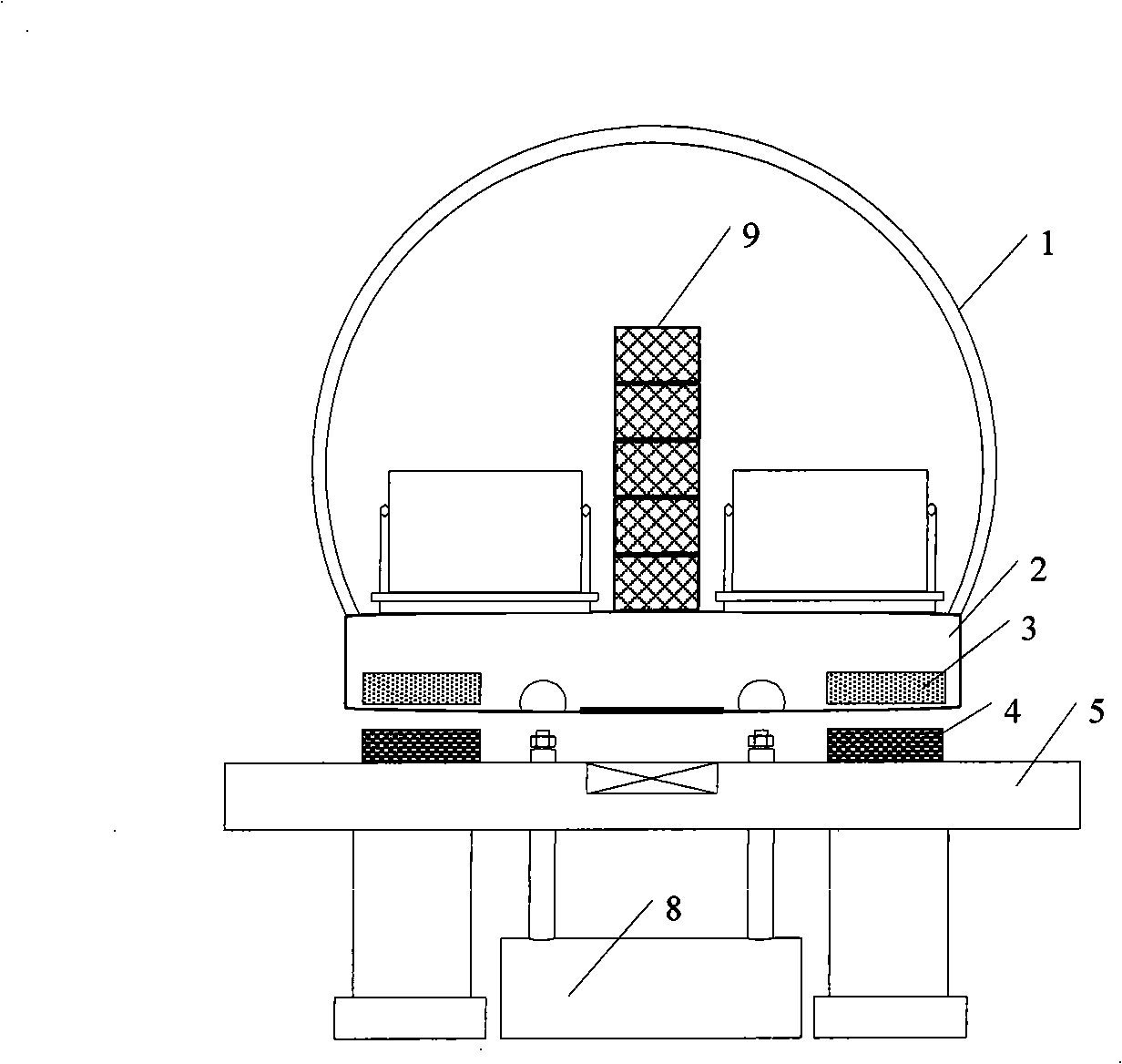

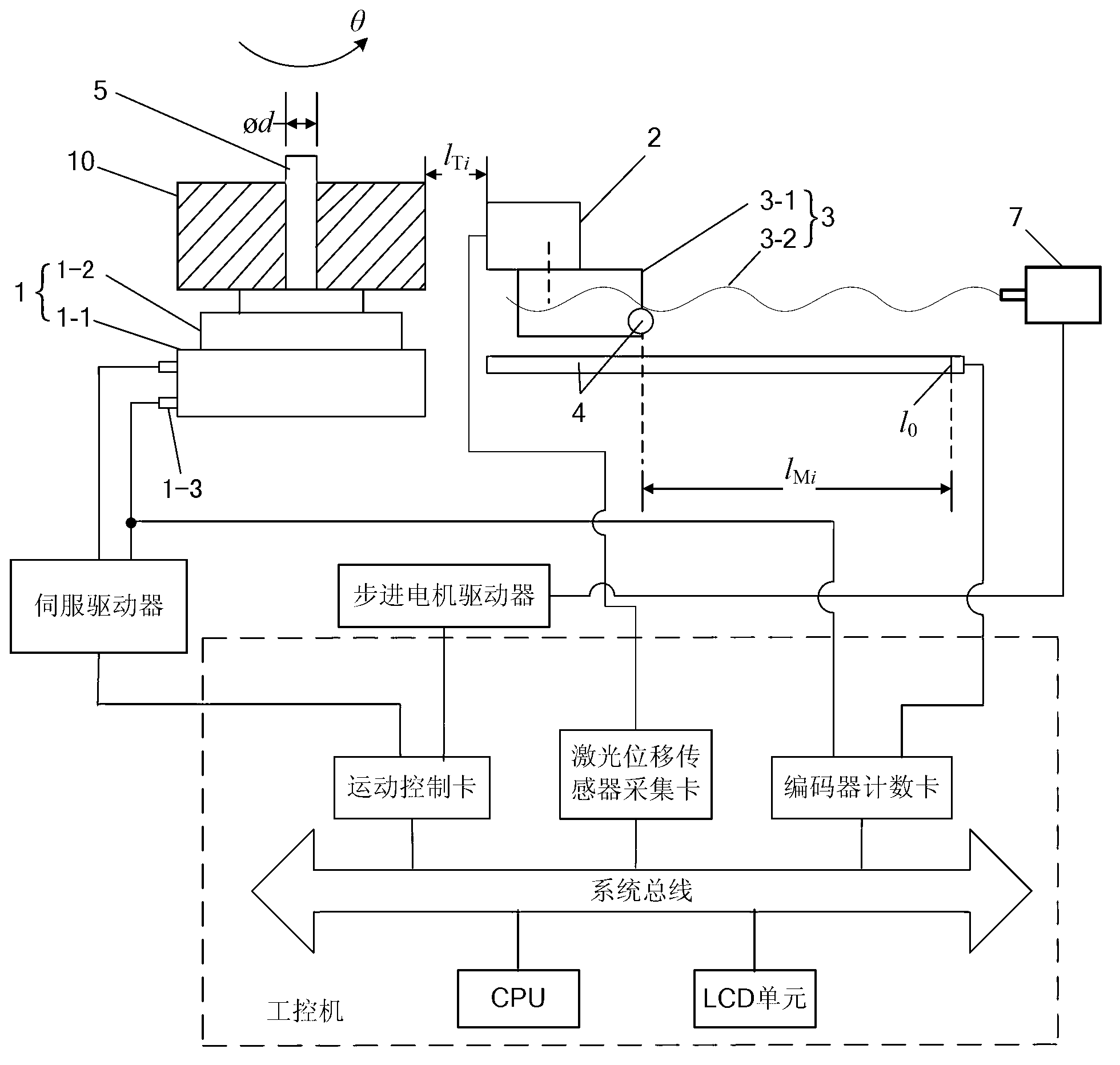

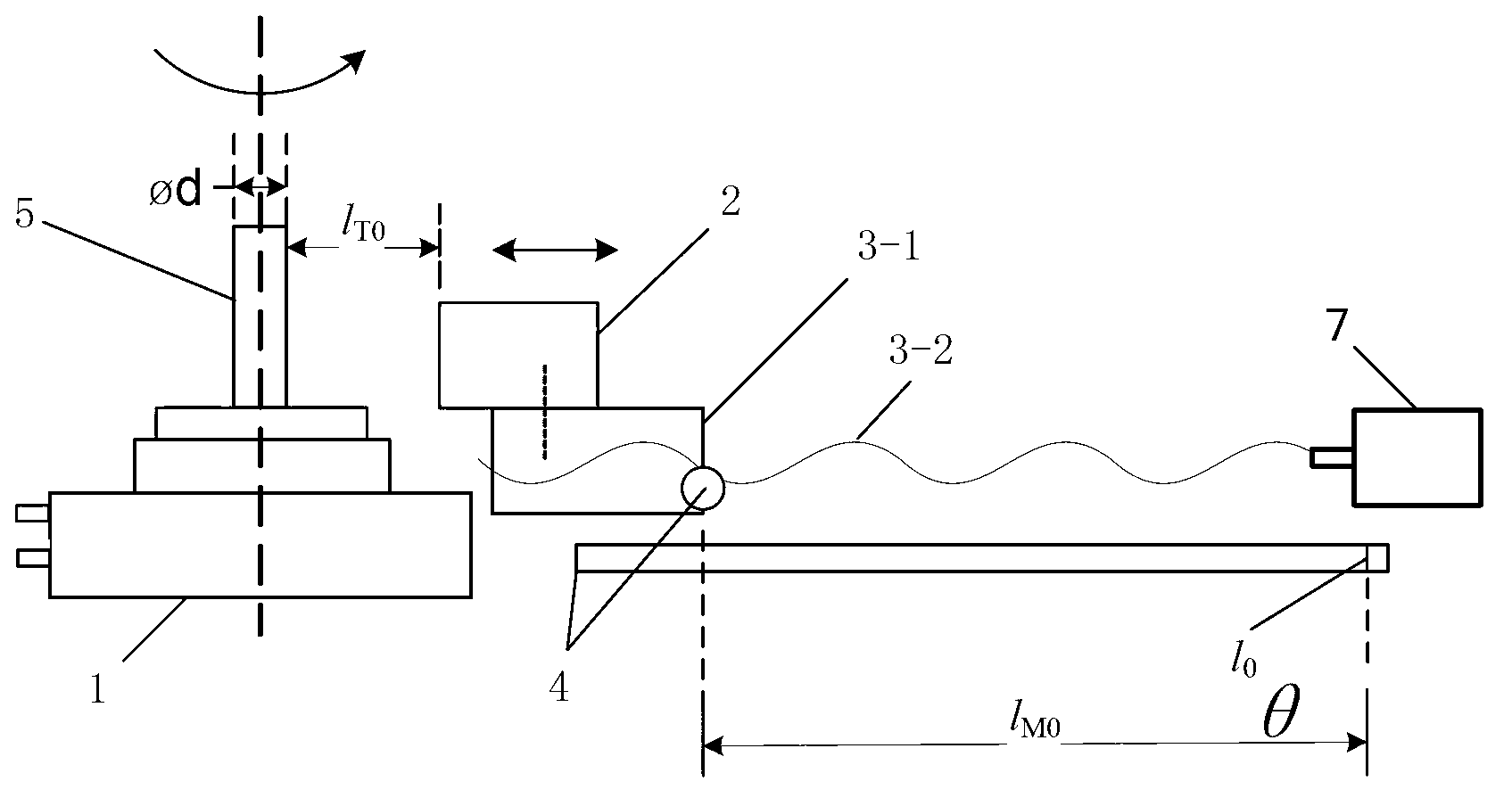

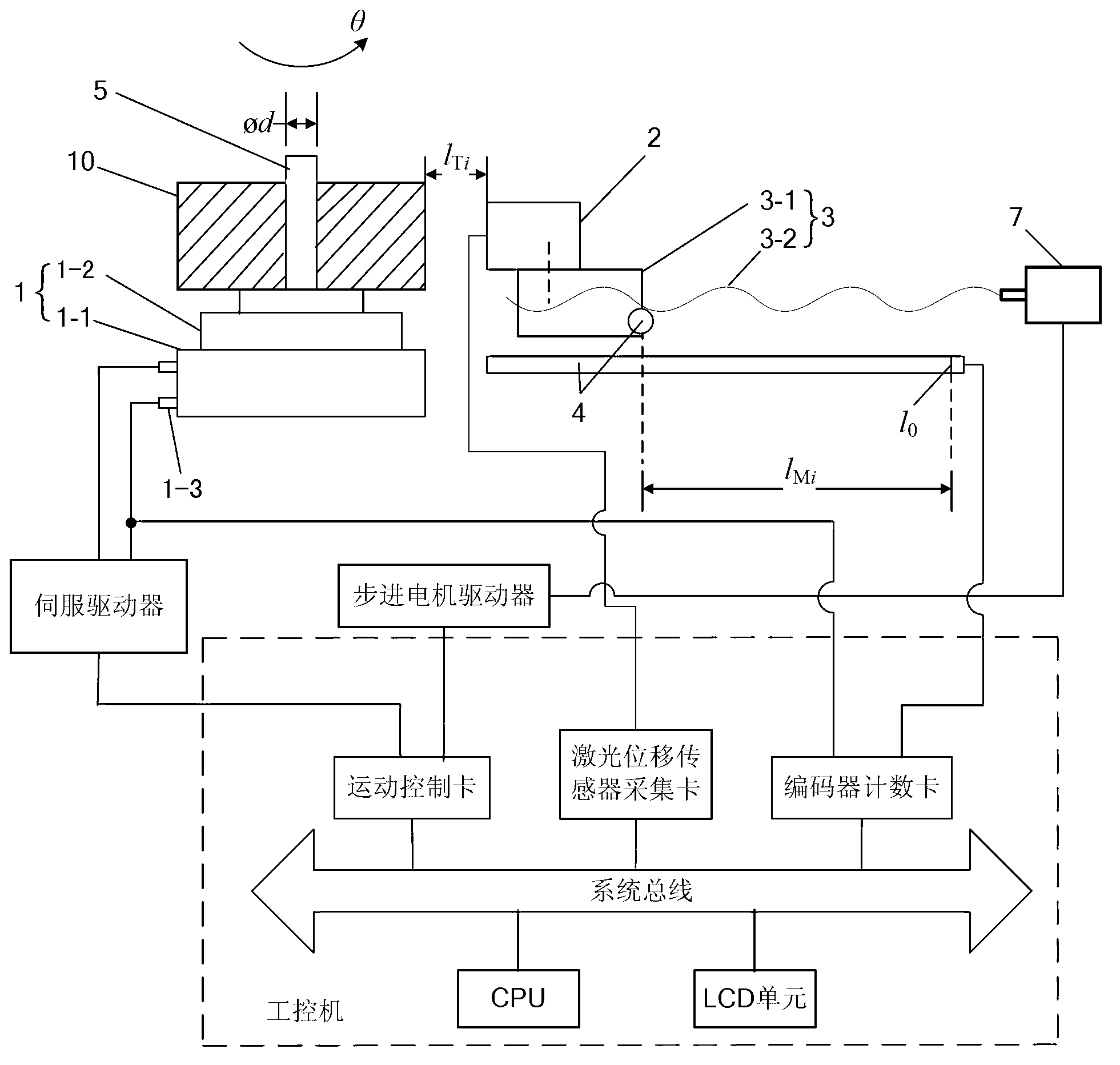

Device for detecting cam profile

InactiveCN102147238AThere is no transmission gapHigh dynamic stiffnessUsing optical meansNumerical controlElectric machine

The invention provides a device for detecting cam profiles, which has the advantages of simple structure, high detection precision and higher efficiency. The device comprises a numerical control turntable, a linear motor, a laser measuring head, a grating scale displacement sensor, an encoder and an industrial personal computer, wherein the numerical control turntable is used for driving the cam to horizontally and coaxially rotate around a vertical mandrel; the linear motor is horizontally arranged on one side of the numerical control turntable; the laser measuring head is arranged on the active cell of the linear motor and at one side of the cam; the grating scale displacement sensor is used for measuring the horizontal displacement of the active cell; the encoder is used for detecting the rotation angle of the cam; and the industrial personal computer controls the numerical control turntable and the linear motor to act and obtains the outer profile data of the cam according to data measured by the laser measuring head, the grating scale displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

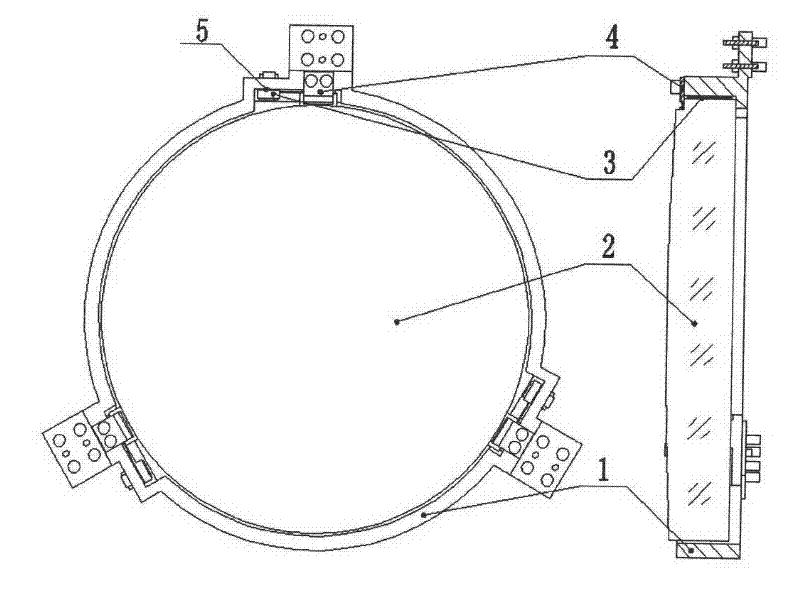

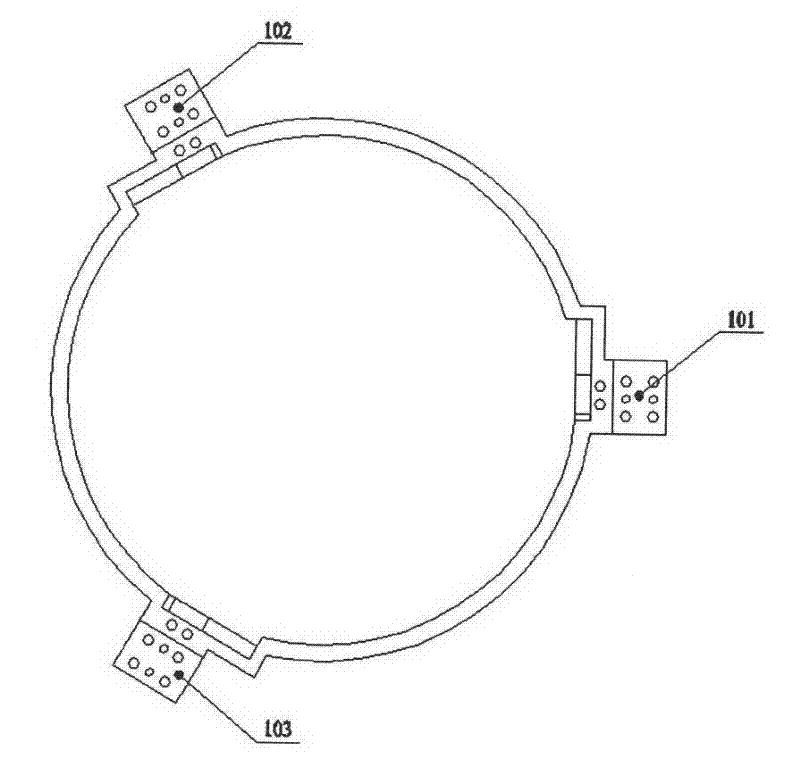

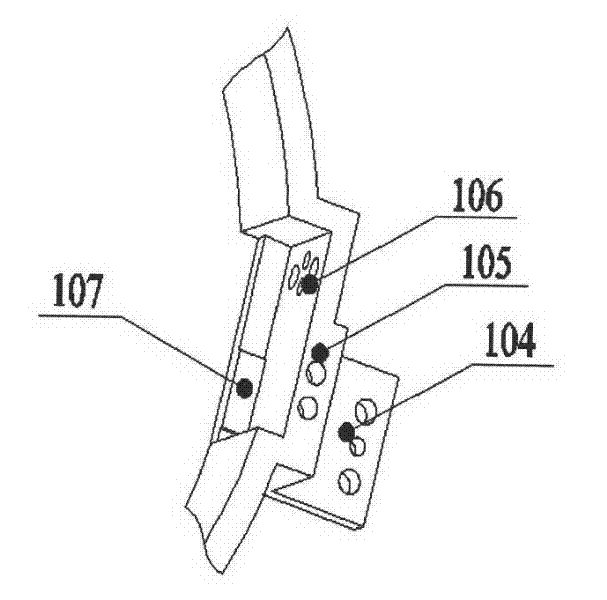

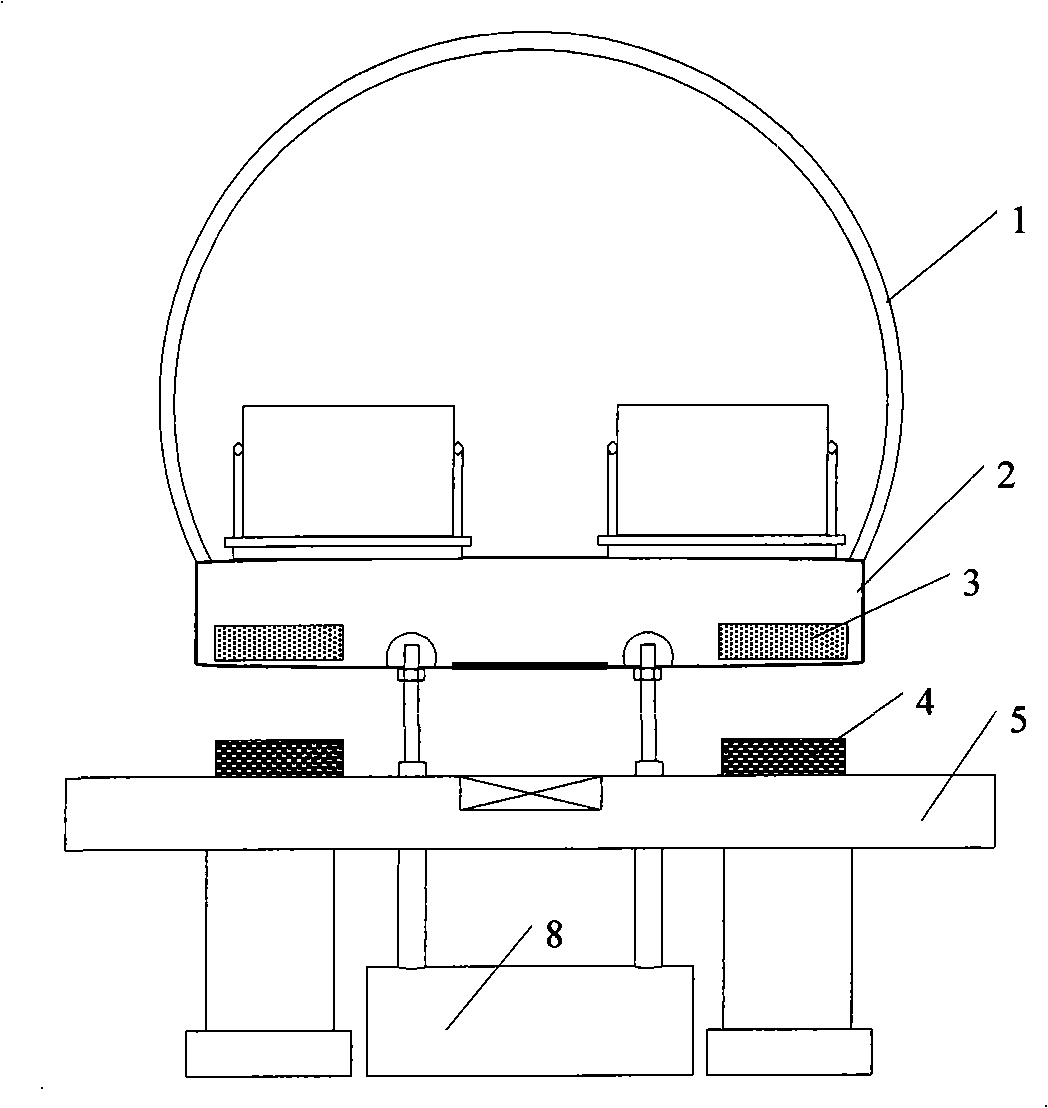

Flexible supporting method of large-aperture lens

InactiveCN102243359ANo destructive deformationAvoid curvature of fieldMountingsOptical aberrationMechanical engineering

The invention discloses a flexible supporting method of a large-aperture lens, which comprises the steps of; firstly, machining three bosses on the excircle of a circular lens base with a certain thickness at intervals of 120 DEG , machining a connecting part with a cuboid structure on the outer side of each boss, machining an installing hole and a pin hole on the outer side of each boss along the radial direction of the lens base, machining an installing hole and a pin hole on the connecting part along the axial direction of the lens base, machining an installing hole on each boss along the axial direction of the lens base, and machining a small boss with a step on the inner side of each boss; secondly, machining three corresponding installing surfaces on the excircle of the lens at intervals of 120 DEG, and machining radial flexible elements and axial press plates; thirdly, bonding the radial flexible elements with the lens, and fixing the bonded assembly in the lens base through the installing holes and the pin holes; and finally, tightly pressing the lens through the axial press plates, and fixing the axial press plates through the installing holes. According to the supporting method disclosed by the invention, positioning precision of the lens is integrally improved, stress environment of the lens under an assembling condition is improved, and optical aberration such as field curvature, astigmatism and the like can be eliminated.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

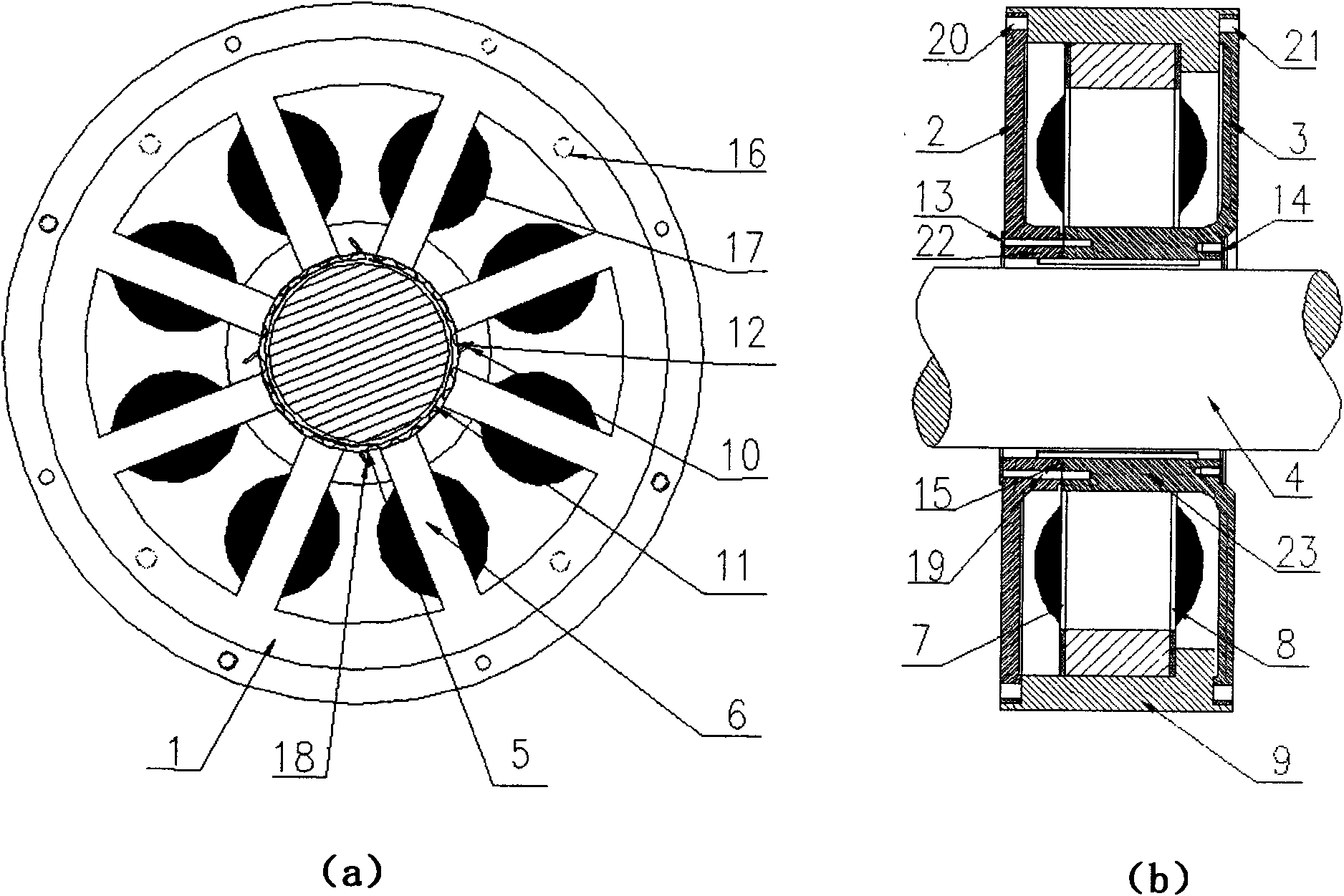

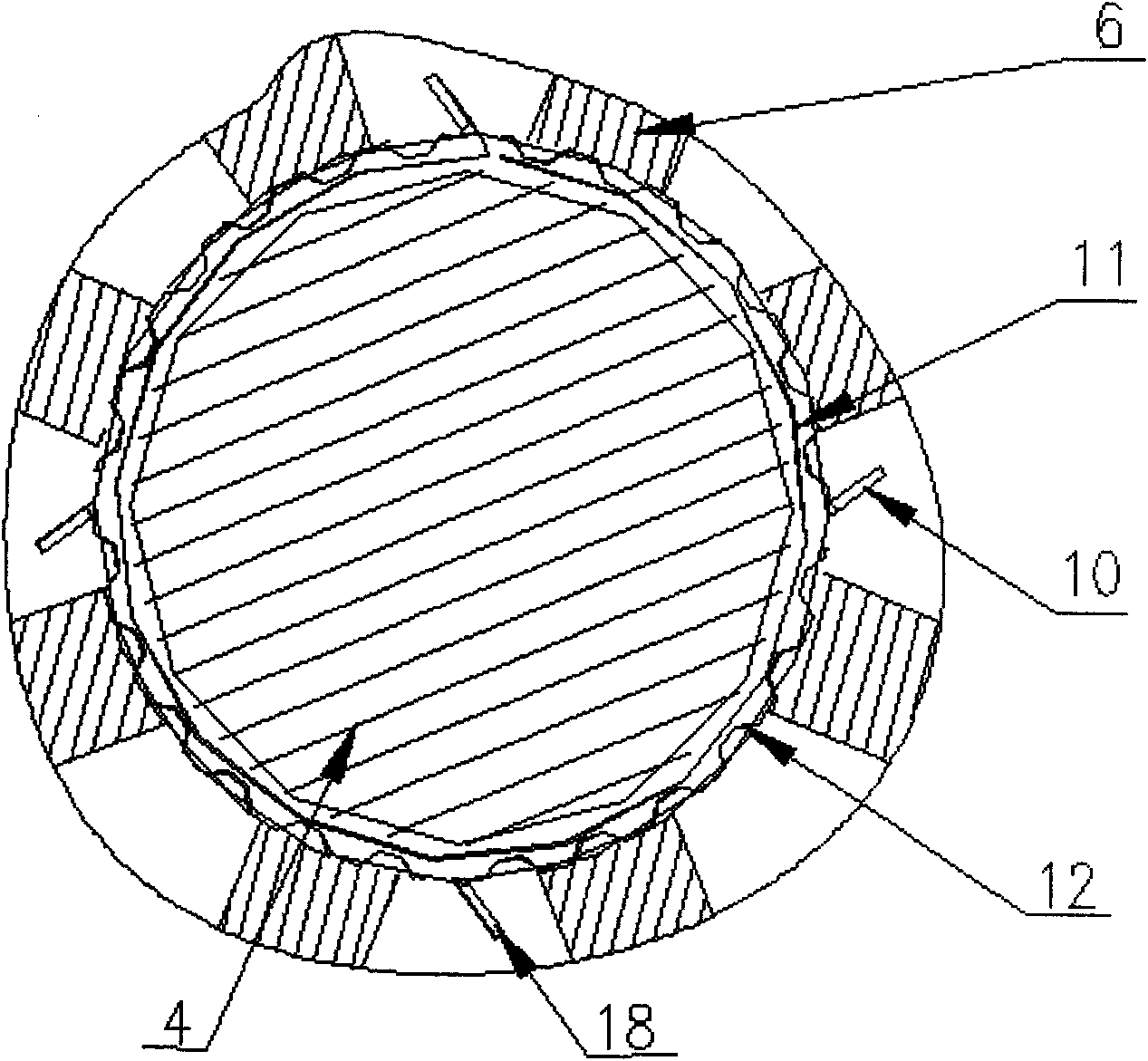

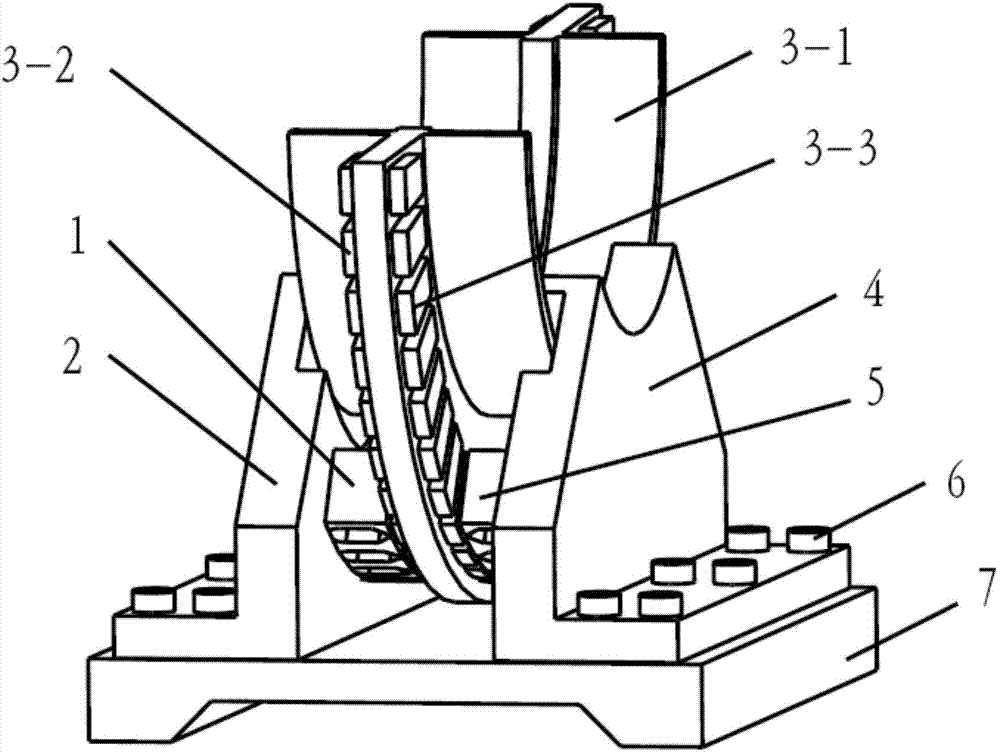

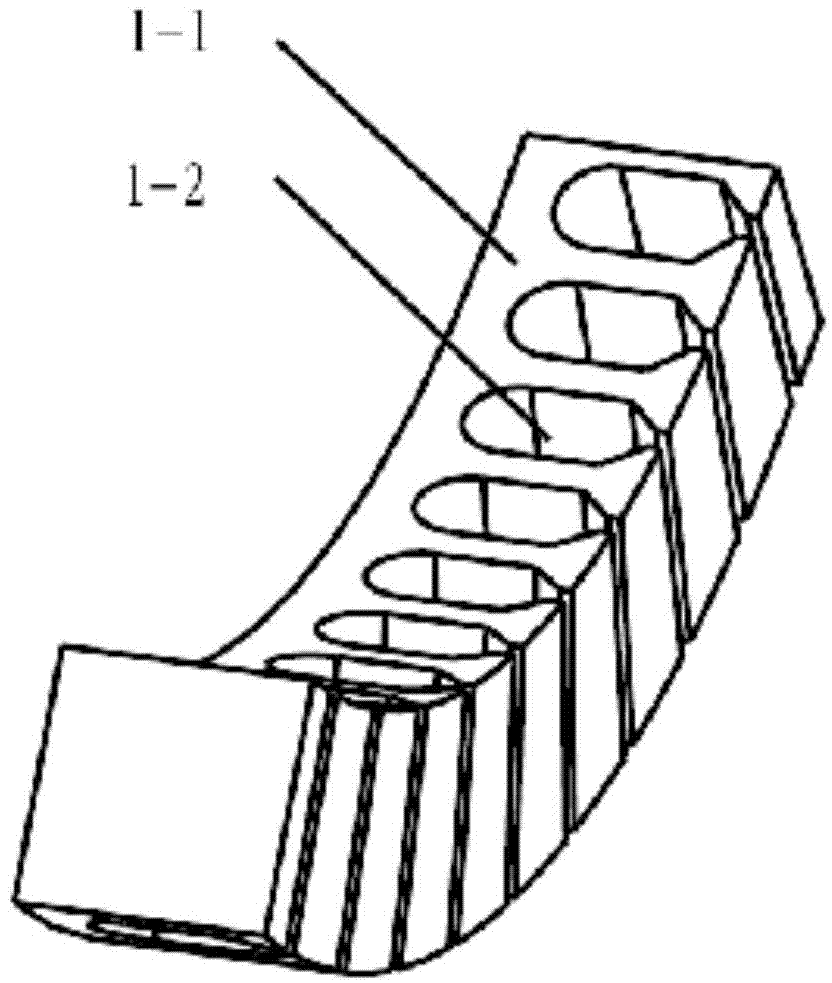

Embedded electromagnetic-elastic foil gas mixing bearing

The invention discloses an embedded electromagnetic-elastic foil gas mixing bearing, which comprises an electromagnetic bearing arranged in a bearing base, wherein the electromagnetic bearing is provided with a left end cover and a right end cover in an axial direction, an elastic foil bearing is embedded and sleeved between the left and right end covers and a rotor journal, the electromagnetic bearing is provided with a magnetic pole which has a coil, the left and right end covers are arranged in a branch opening at the root of the magnetic pole to form a bearing base of a foil bearing; and the bearing base of the oil bearing is provided with a groove, a top elastic foil and a bottom elastic foil are inserted into the groove, and when the coil is switched on, an electromagnetic field is formed between a pole shoe of the magnetic pole and the rotor journal, so that the pole shoe attracts the rotor journal. At a low speed, a rotor is supported by the electromagnetic bearing; when the rotating speed reaches a certain value, a gas film between the top foil and the journal generates a dynamic pressure; and at a high speed, the rotor is individually supported. The embedded electromagnetic-elastic foil gas mixing bearing has the characteristics of low power consumption, high precision, high bearing capability and compact structure.

Owner:XI AN JIAOTONG UNIV

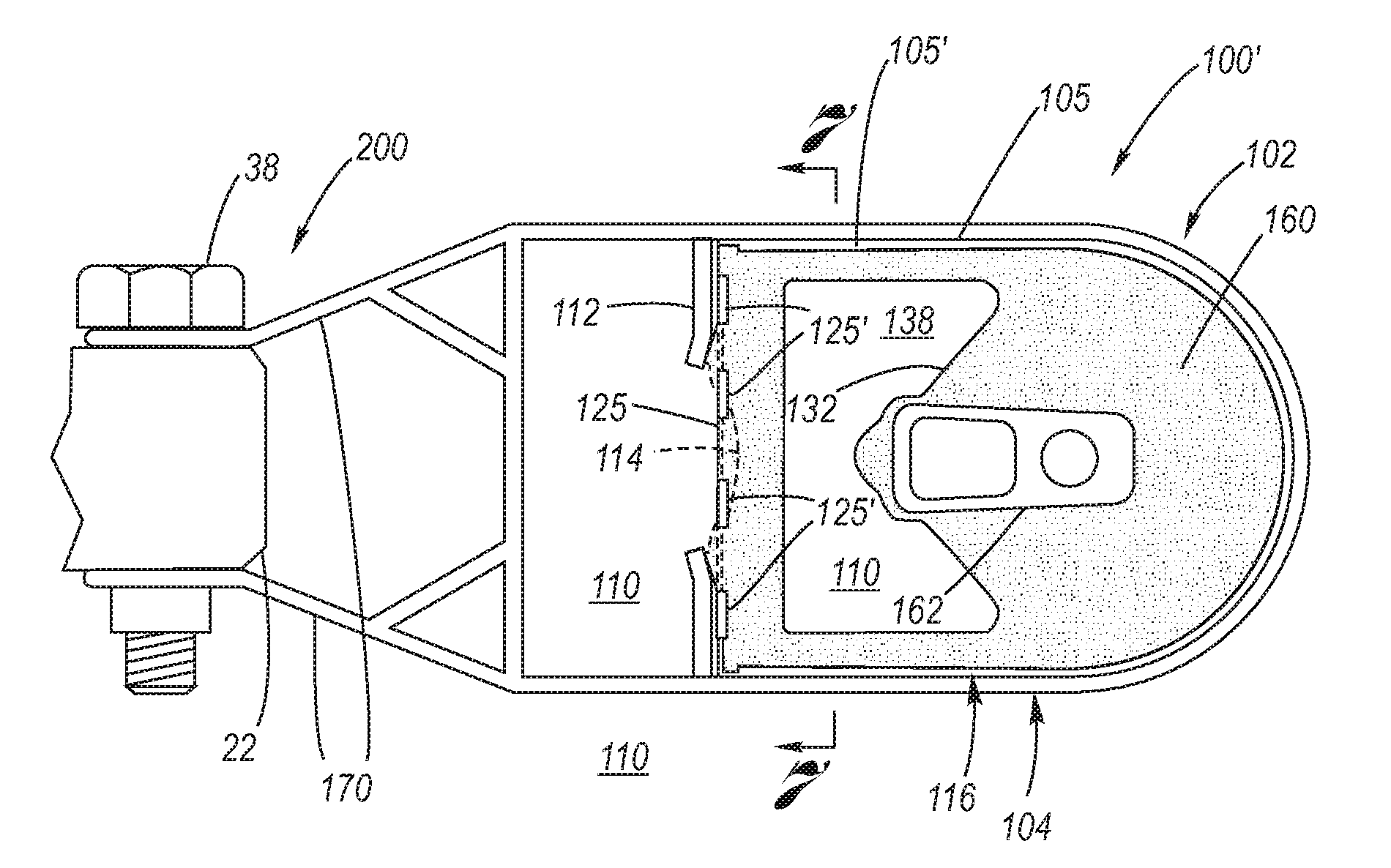

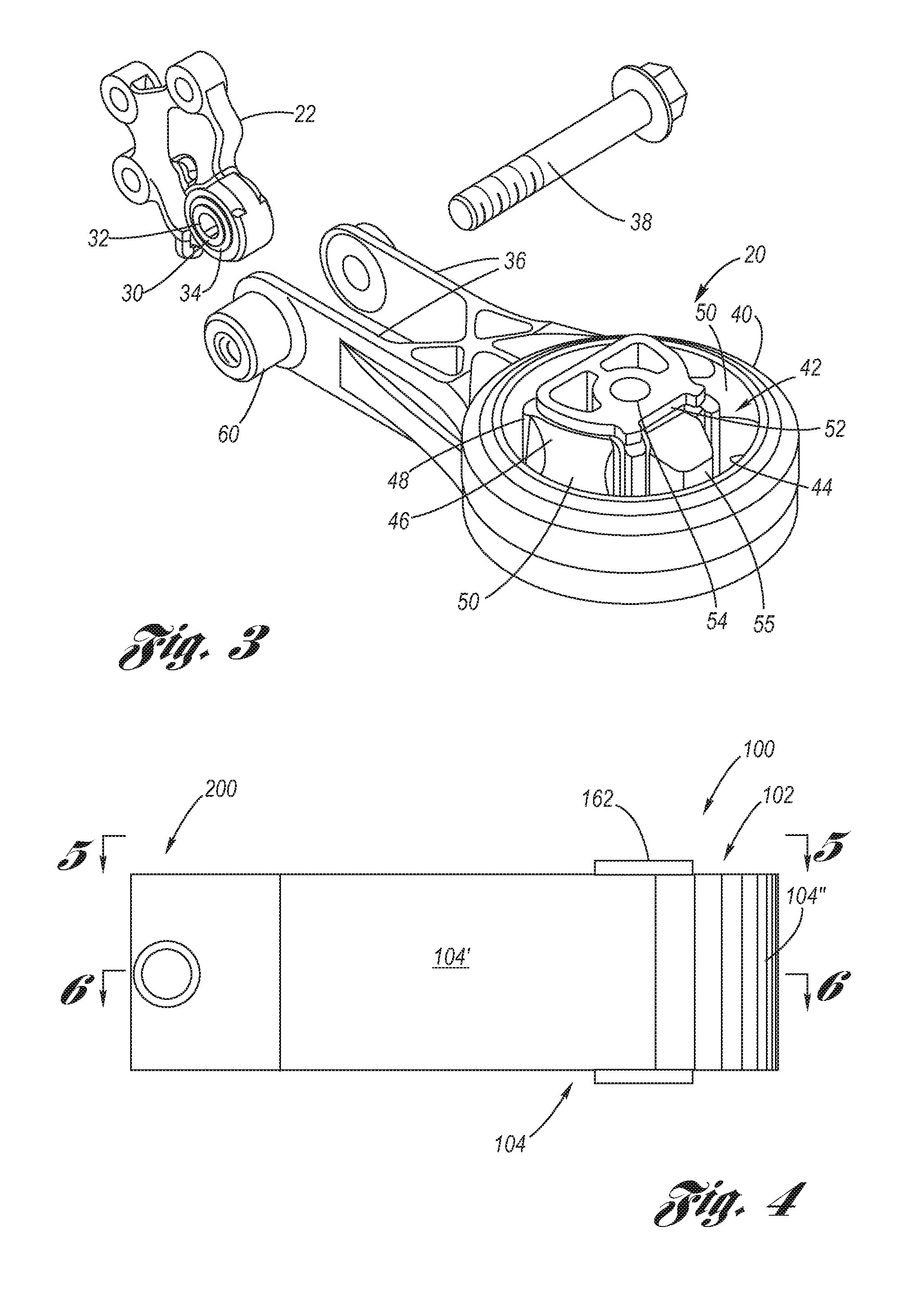

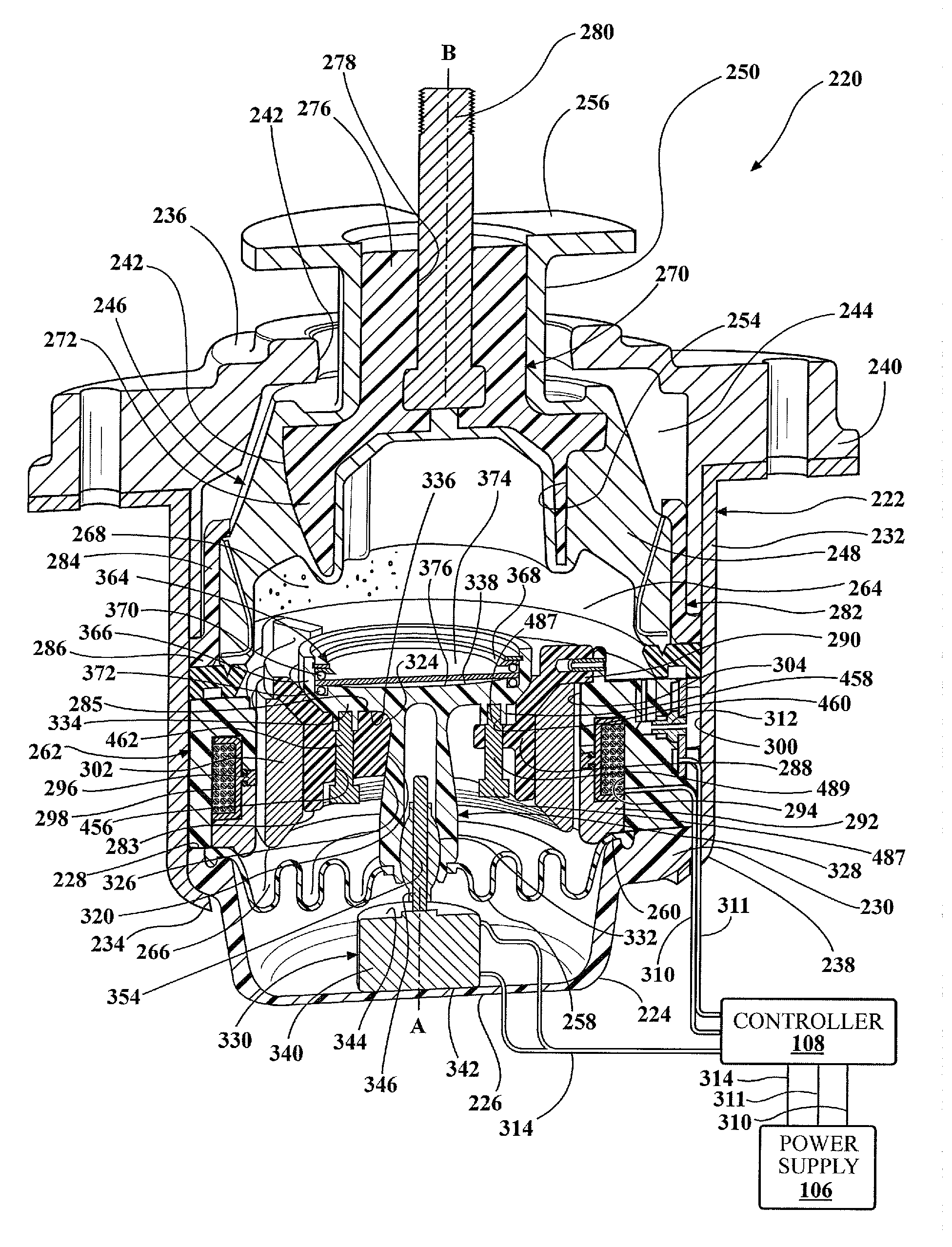

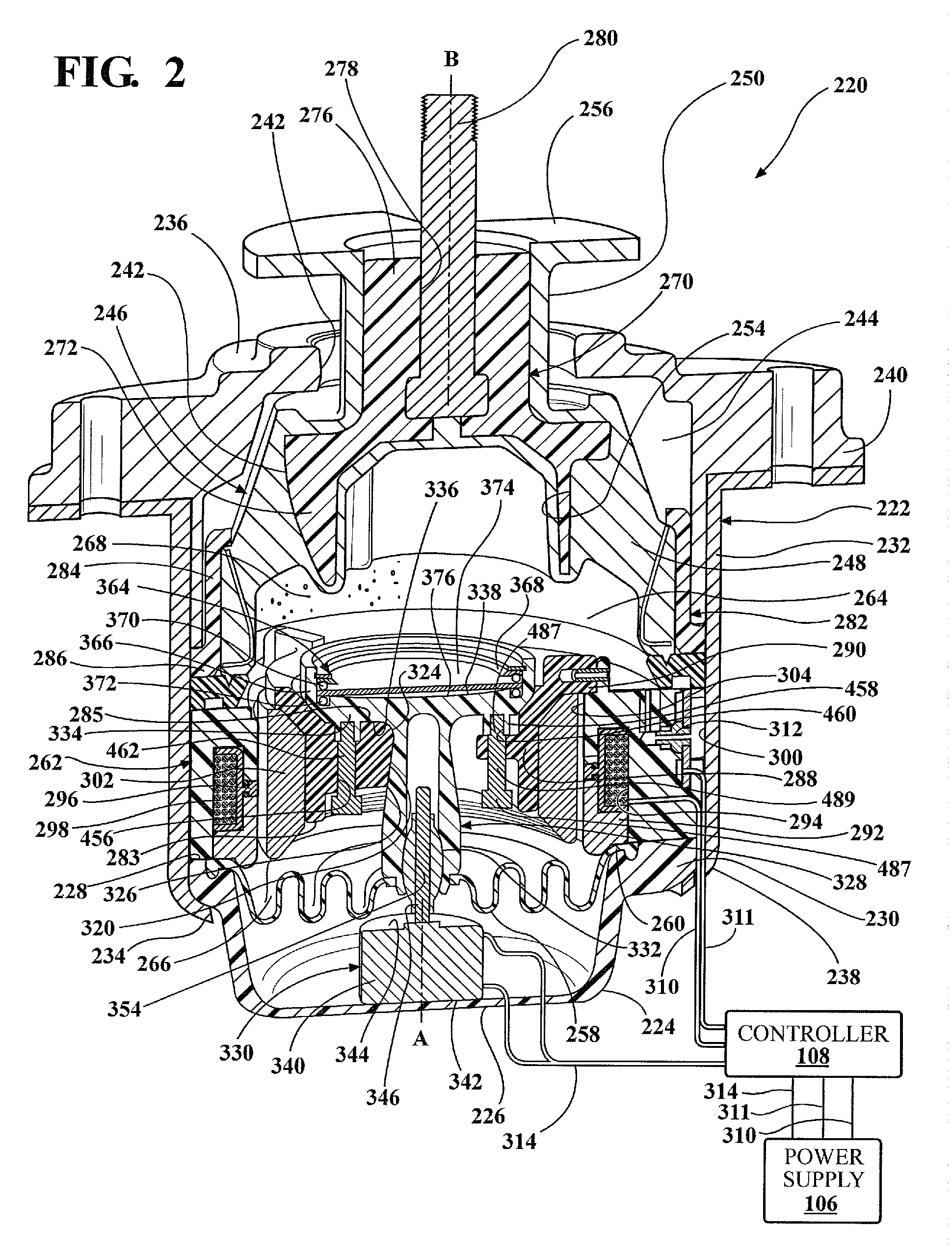

Fully Decoupled Hydraulic Torque Strut

InactiveUS20120091639A1High hydraulic dampingHigh stiffnessMachine framesUnderstructuresVibration amplitudePump chamber

A hydraulic device disposed in a torque strut so as to provide a fully decoupled hydraulic torque strut. A main rubber element vibrates in response to powertrain pitch torque. At high vibration amplitude, high hydraulic damping is provided via a pumping chamber, an inertia track and a bellowed compensation chamber, wherein a decoupler system hydraulically connected to the pumping chamber is passively disabled. At low vibration amplitude, minimal hydraulic damping is provided via the decoupler system which is connected by a decoupler track to the compensation chamber.

Owner:GM GLOBAL TECH OPERATIONS LLC

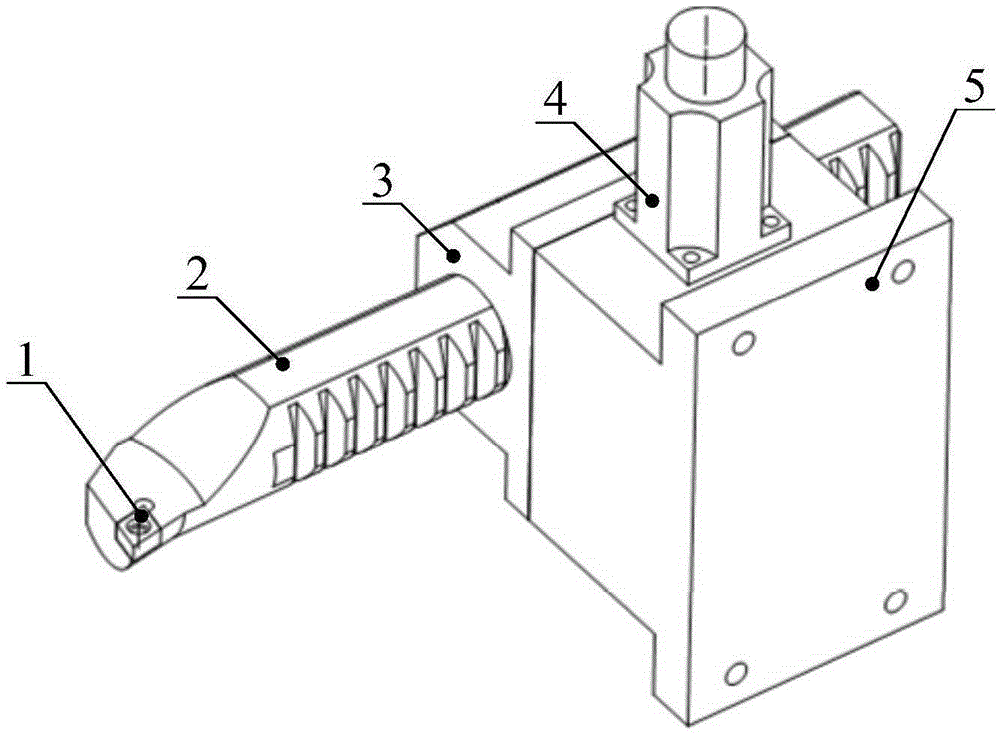

Anti-vibration tool rest with adjustable cutter bar extended length for deep hole turning

The invention discloses an anti-vibration tool rest with adjustable cutter bar extended length for deep hole turning, belongs to the technical field of mechanical processing, and aims to solve the problems that in the prior art, cutter bar extended length cannot be automatically regulated, a cutting chattering phenomenon is severe, efficiency is affected by tool changing and tool setting errors are easily caused. The anti-vibration tool rest with adjustable cutter bar extended length for deep hole turning comprises a combined type blade, a cutter bar, a cutter bar supporting base and a power drive unit, wherein the blade is arranged at one end part of the cutter bar; the other end of the cutter bar penetrates through a cutter bar slot of the cutter bar supporting base; and the cutter bar realizes stretching out and drawing back by virtue of the power drive unit. According to the anti-vibration tool rest with adjustable cutter bar extended length for deep hole turning disclosed by the invention, the principle of restraining cutting chattering is mainly realized by regulating extended length of the cutter bar, and improving dynamic rigidity of the cutter bar under the same cutting condition. For a hole with greater depth, a mode of gradually increasing extended length distribution of the cutter bar to process to the final depth is adopted, so that the cutting chattering phenomenon generated when directly adopting cutter bar extended length bigger than or equal to hole depth can be avoided.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

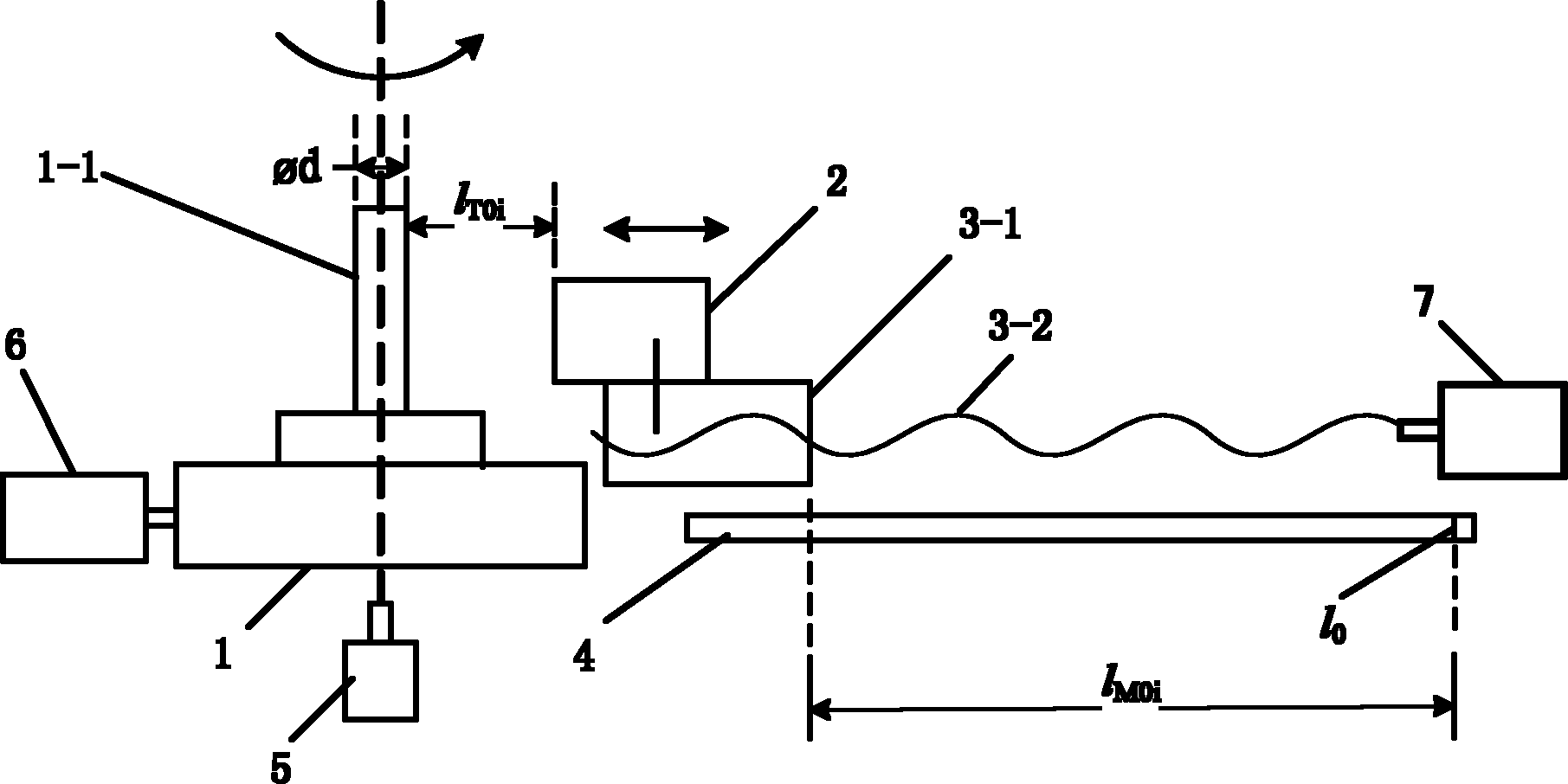

Device for detecting cam profile

InactiveCN102147238BThere is no transmission gapHigh dynamic stiffnessUsing optical meansNumerical controlActive cell

The invention provides a device for detecting cam profiles, which has the advantages of simple structure, high detection precision and higher efficiency. The device comprises a numerical control turntable, a linear motor, a laser measuring head, a grating scale displacement sensor, an encoder and an industrial personal computer, wherein the numerical control turntable is used for driving the cam to horizontally and coaxially rotate around a vertical mandrel; the linear motor is horizontally arranged on one side of the numerical control turntable; the laser measuring head is arranged on the active cell of the linear motor and at one side of the cam; the grating scale displacement sensor is used for measuring the horizontal displacement of the active cell; the encoder is used for detecting the rotation angle of the cam; and the industrial personal computer controls the numerical control turntable and the linear motor to act and obtains the outer profile data of the cam according to datameasured by the laser measuring head, the grating scale displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

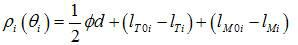

Detection method for cam outline detection system

The invention provides a detection method for a cam outline detection system which has a simple structure and high detection precision and efficiency. The adopted cam outline detection system comprises a numerically controlled rotary table, a screw rod and nut pair, a laser measurement head, a grating bar displacement sensor, an encoder and an industrial control computer; the numerically controlled rotary table is used for driving a cam to horizontally and coaxially rotate around a vertical mandrel; the screw rod and nut pair is horizontally arranged on one side of the numerically controlled rotary table; the laser measurement head is arranged on a movable nut of the screw rod and nut pair and positioned on one side of the cam; the grating bar displacement sensor is used for measuring the horizontal displacement value of the movable nut; the encoder is used for detecting a rotary angle of the cam; and the industrial control computer controls the operation of the numerically controlled rotary table and the screw rod and nut pair, and obtains data of the outer outline of the cam according to data measured by the laser measurement head, the grating bar displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

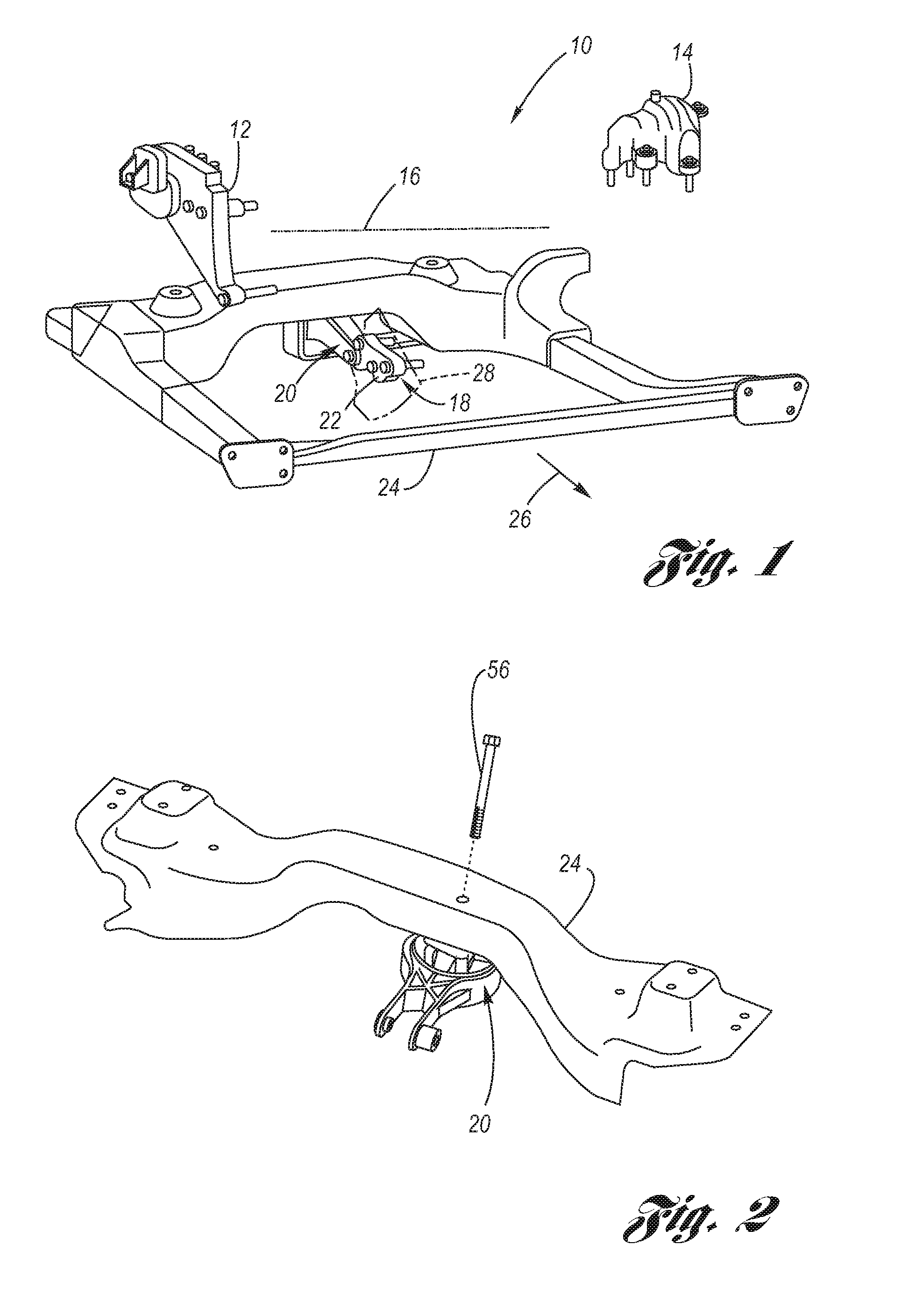

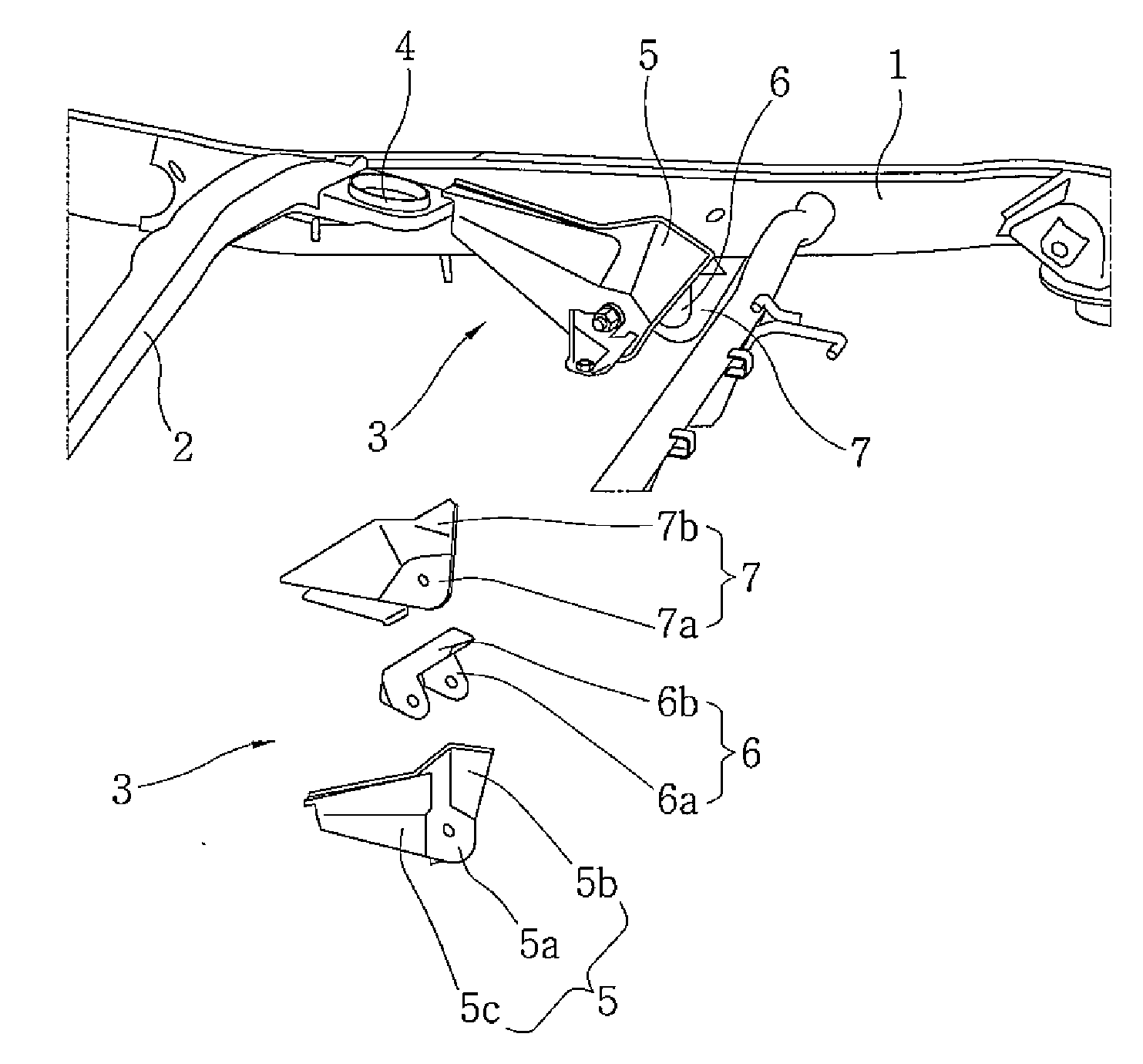

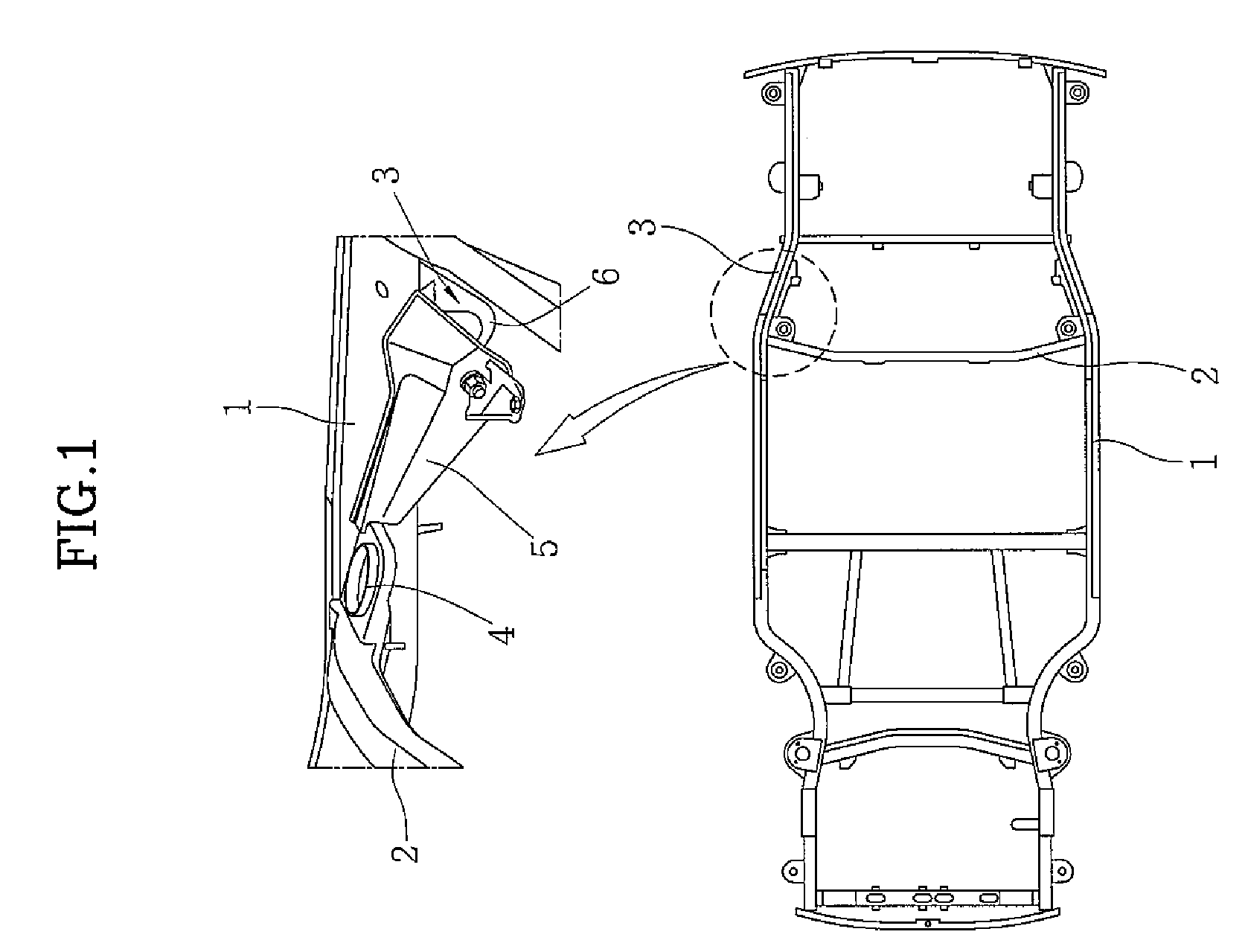

Trailing arm mounting device for vehicle with small-sized frame

InactiveUS20090121106A1High dynamic stiffnessFirmly connectedVehicle body-frame connectionsUnderstructuresDynamic stiffnessTrailing arm

The present invention relates to a trailing arm mounting device for a vehicle with a small-sized frame, in which mounting assembly that connects small-sized frame and the trailing arm and has a limit on the weight and cross-section by reducing the size of frame expands the fixing portion for small-sized frame, such that the fastening force to the mounting assembly is increased and the dynamic stiffness of the trailing arm used for small-sized frame is also increased.

Owner:HYUNDAI MOTOR CO LTD +1

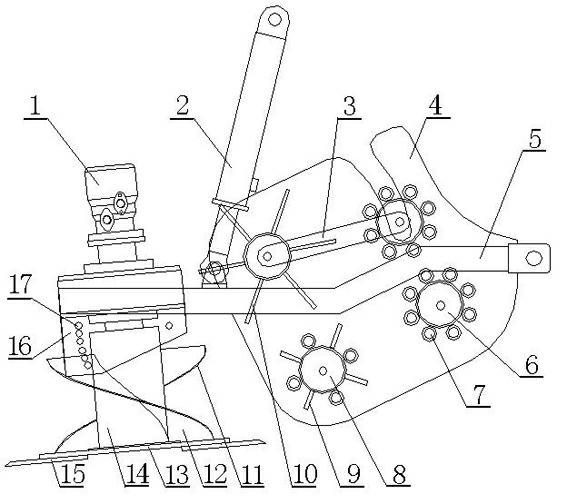

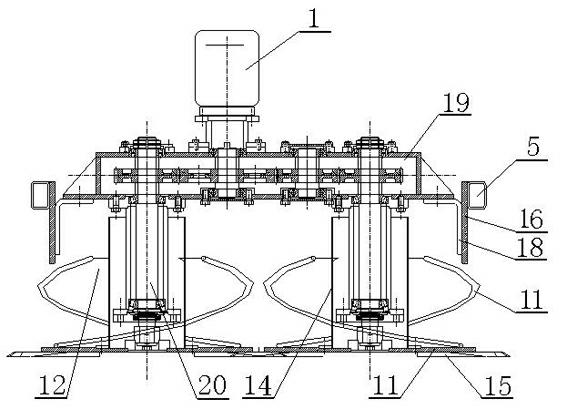

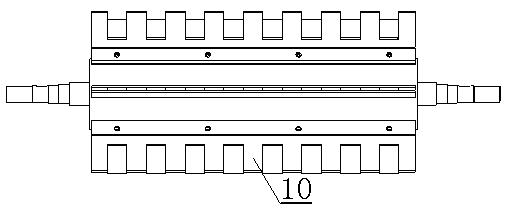

High-rigidity cutting and feeding conveyor system for sugarcane

InactiveCN102630430AHigh dynamic stiffnessReduce the rate of broken headsHarvestersTurning framesEngineering

The invention discloses a high-rigidity cutting and feeding conveyor system for sugarcane, which comprises a cutter, a feeding conveyor roller assembly and a lifting mechanism, wherein the lifting mechanism comprises a lifting cylinder (2) and a lifting frame (5). The high-rigidity cutting and feeding conveyor system is characterized in that a lateral plate III (18) and a lateral plate II (16) are respectively arranged at the front end of the cutter and the lifting frame (5); a lateral plate I (14) is arranged on the feeding conveyor roller assembly; the lateral plate III (18) and the lateral plate II (16) are connected through a bolt; the feeding conveyor roller assembly is fixedly connected with the lifting frame through the lateral plate I (14); hinges are arranged on the front part and the rear part of the lifting frame (5); the front hinge is connected with the lifting cylinder (2), and the rear hinge is hinged with a frame of a sugarcane harvester. The cutting system adopts a sectional lifting mode, is light in weight, larger in natural frequency and better in rigidity compared with an overall lifting cutting system, and is not affected by low frequency.

Owner:GUANGXI UNIV +2

Satellite-remote sensor flexible heat sinking joint

InactiveCN102588716AImprove cooling effectEffective protectionStands/trestlesImaging qualitySystem stability

The invention discloses a satellite-remote sensor flexible heat sinking joint, which belongs to the field of spatial remote sensor optical instruments using a satellite as a carrier. The satellite-remote sensor flexible heat sinking joint comprises a first supporting rod, a second supporting rod and a plurality of unloading grooves such as an unloading groove a, an unloading groove b and the like. The unloading groove a and an unloading groove d are positioned on the first supporting rod and are mutually parallel; the unloading groove b and an unloading groove c are positioned on the first supporting rod, are mutually parallel, and are mutually perpendicular to the unloading groove a and the unloading groove d; an unloading groove e and an unloading groove h are positioned on the first supporting rod and are mutually parallel; an unloading groove f and an unloading groove g are positioned on the first supporting rod, are mutually parallel, and are mutually perpendicular to the unloading groove e and the unloading groove h; the first supporting rod and the second supporting rod are arranged triangularly; and the unloading grooves on the second supporting rod are fully symmetrical with the unloading grooves on the first supporting rod. When a large spatial remote sensor is assembled and positioned, the system stability is optimal, and the satellite-remote sensor flexible heat sinking joint has higher vibration resistance. A stress environment in a working process is improved, so that the remote sensor is in a favorable working condition, and the imaging quality is guaranteed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method for improving stability of high temperature superconducting magnetic suspension system

InactiveCN101314329AEasy to operateWide range of applicationsElectric propulsionMagnetic suspension systemSystem stability

A method for increasing the stability of a high-temperature superconductor magnetic suspension system comprises the following: (A) a step of field cooling, during which, a suspension body of the high-temperature superconductor magnetic suspension system is supported at a preset position through a support system, and then refrigeration equipment is started to ensure that a superconducting block enters superconducting state; (B) a step of support release, during which, the support system releases the support on the suspension body so as to ensure that the suspension body is in an idling stable state; (C) a step of loading, during which, external force is applied on the suspension body so as to ensure that the suspension body is in a stable suspension state under external force loading; and (D) a step of loading and the external force release, during which, the suspension body is in the stable suspension state again, and the state is taken as an initial state for the operation of the high-temperature superconductor magnetic suspension system. The method does not need to change the construction of the high-temperature superconductor magnetic suspension system, and ensures simple structure and operation and cost reduction; moreover, the method can obviously improve the stability of the high-temperature superconductor magnetic suspension system, and is suitable for any high-temperature superconductor magnetic suspension systems based on the high-temperature superconducting block type magnetic suspension principle.

Owner:SOUTHWEST JIAOTONG UNIV

Detection method of cam contour detection device

InactiveCN102175181BNo mechanical wearThere is no transmission gapUsing optical meansComputer hardwareElectric machine

The invention provides a detection method of a cam contour detection device which has the advantages of simple structure and high detection accuracy and efficiency. The cam contour detection device which is adopted by the detection method provided by the invention comprises a digital control rotary table, a linear motor, a laser measuring head, a grating ruler displacement sensor, an encoder and an industrial personal computer, wherein the digital control rotary table is used for driving a cam to be horizontally and coaxially rotated around a vertical mandrel; the linear motor is horizontallyarranged at one side of the digital control rotary table; the laser measuring head is arranged on the rotor of the linear motor and at one side of the cam; the grating ruler displacement sensor is used for measuring the horizontal displacement of the rotor; the encoder is used for detecting the rotation angle of the cam; and the industrial personal computer controls the motion of the digital control rotary table and the linear motor and obtains the outer contour data of the cam according to the data which is obtained by the laser measuring head, the grating ruler displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

Numerical control system for detecting cam contours

InactiveCN102122144BReduce loadSmall precision retentionUsing optical meansNumerical controlEngineeringPersonal computer

The invention provides a numerical control system for detecting cam contours, which has a simple structure, high precision and high efficiency. The numerical control system comprises a numerical control turntable, a screw rod nut pair, a laser measuring head, a grating scale displacement sensor, an encoder and an industrial personal computer, wherein the numerical control turntable is used for driving a cam to horizontally and coaxially rotate around a vertical mandrel; the screw rod nut pair is horizontally arranged on one side of the numerical control turntable; the laser measuring head is arranged on a movable nut of the screw rod nut pair and is positioned on one side of the cam; the grating scale displacement sensor is used for measuring the horizontal displacement of the movable nut; the encoder is used for detecting the rotation angle of the cam; and the industrial personal computer is used for controlling the numerical control turntable and the screw rod nut pair to act and acquiring external contour data of the cam according to data acquired by the measurement of the laser measuring head, the grating scale displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

Engine mount and method of manufacturing the same

ActiveUS20180162211A1Reduce level differenceIncreased durabilitySpringsSprings/dampers functional characteristicsEngineeringEngine mount

An engine mount may include: a support device; a bracket device; and a vibration proof device which connects the support device and the bracket device, and, in which the vibration proof device may include a nozzle device fastened to the support device, and has a nozzle plate dividing an internal space of the vibration proof device into a first liquid chamber and a second liquid chamber, and a flow path penetrating the nozzle plate; a first insulator defining the first liquid chamber together with the nozzle plate; a first core protruding from the first insulator toward one side, and fastened to the bracket device; a second insulator defining the second liquid chamber together with the nozzle plate; and a second core protruding from the second insulator and fastened to the bracket device.

Owner:HYUNDAI MOTOR CO LTD +1

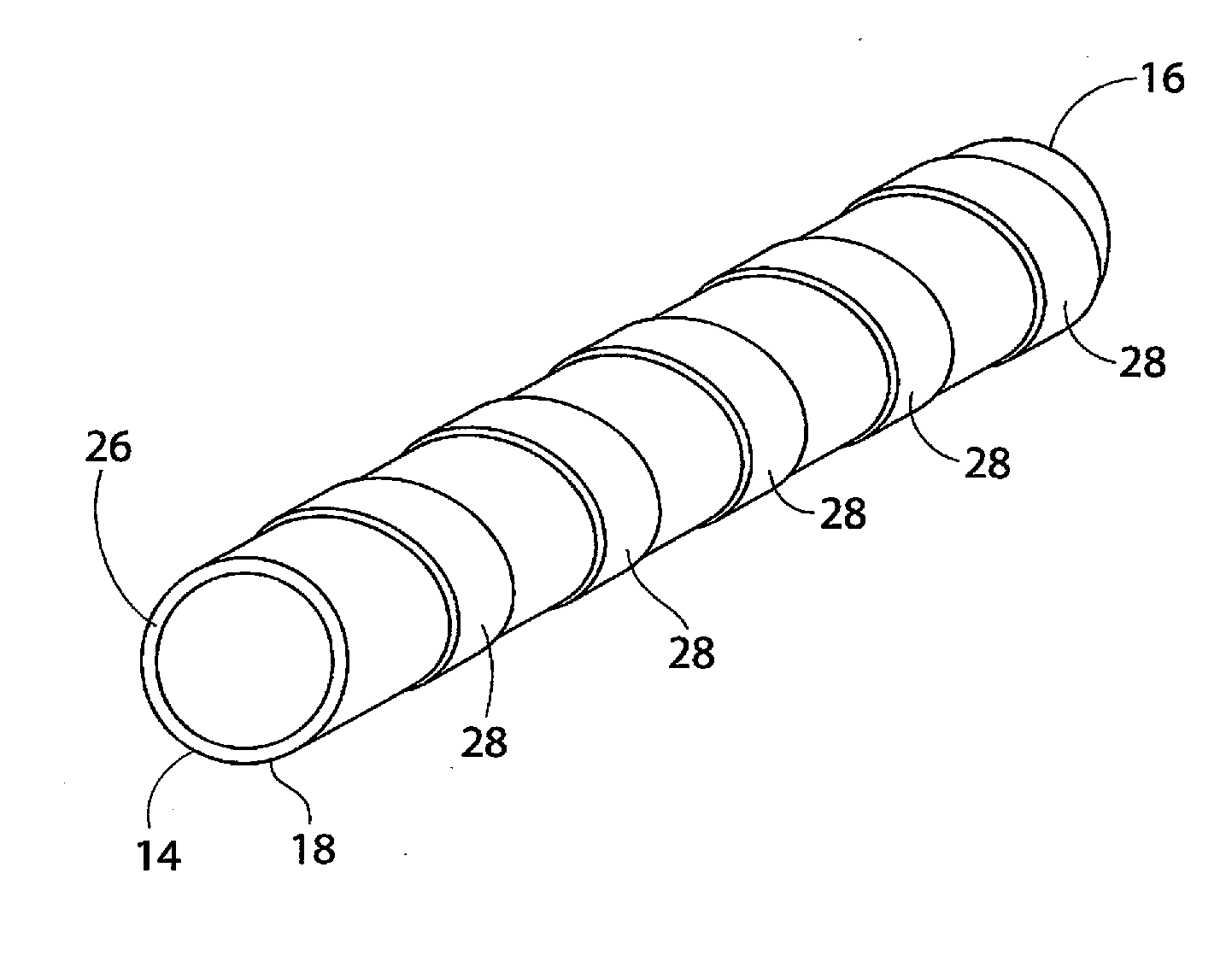

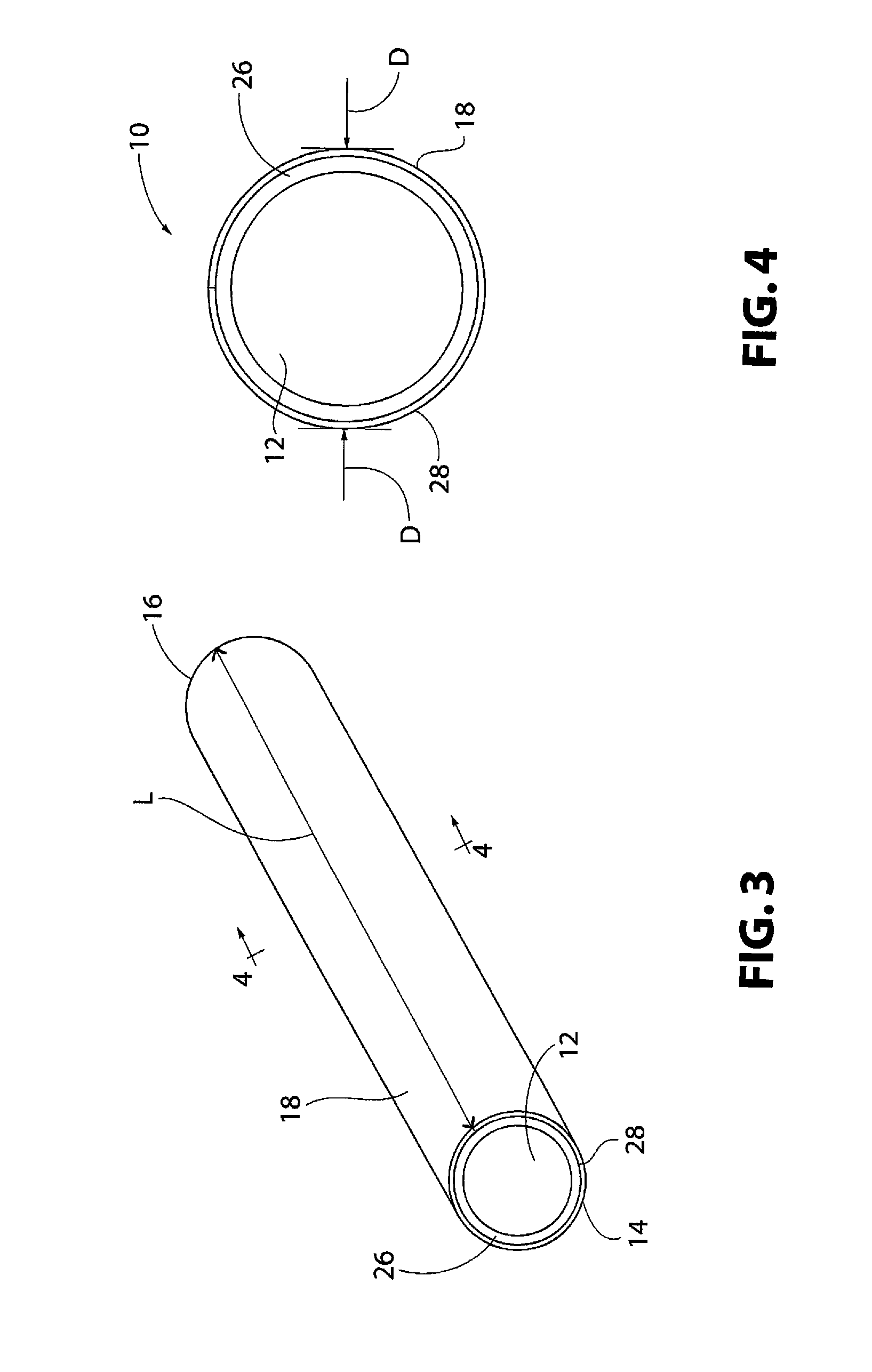

"Boring Bar with Improved Stiffness"

ActiveUS20150258612A1High dynamic stiffnessImprove dynamic stiffnessTransportation and packagingWorkpiecesDistal portionPlasma diffusion

A tunable or tuned boring bar having increased stiffness is provided. Increasing the stiffness of the bar increases the natural frequency, thereby reducing directional deformation of the bar during use. The tunable boring bar includes a distal portion configured to support a tool, a proximal portion configured for attachment to a support structure of a metalworking machine, and a body, which is at least partially tubular, extending between the proximal portion and the distal portion. The tubular portion of the body has an elongated cylindrical cavity. The body of the boring bar includes a core layer formed from a first material and a coating layer formed from a second material. The second material has a higher modulus of elasticity than the first material. In certain configurations, the coating layer is bonded to the core layer by cladding, welding, chemical adhesives, chemical vapor deposition, pulsated plasma diffusion, or combinations thereof.

Owner:KENNAMETAL INC

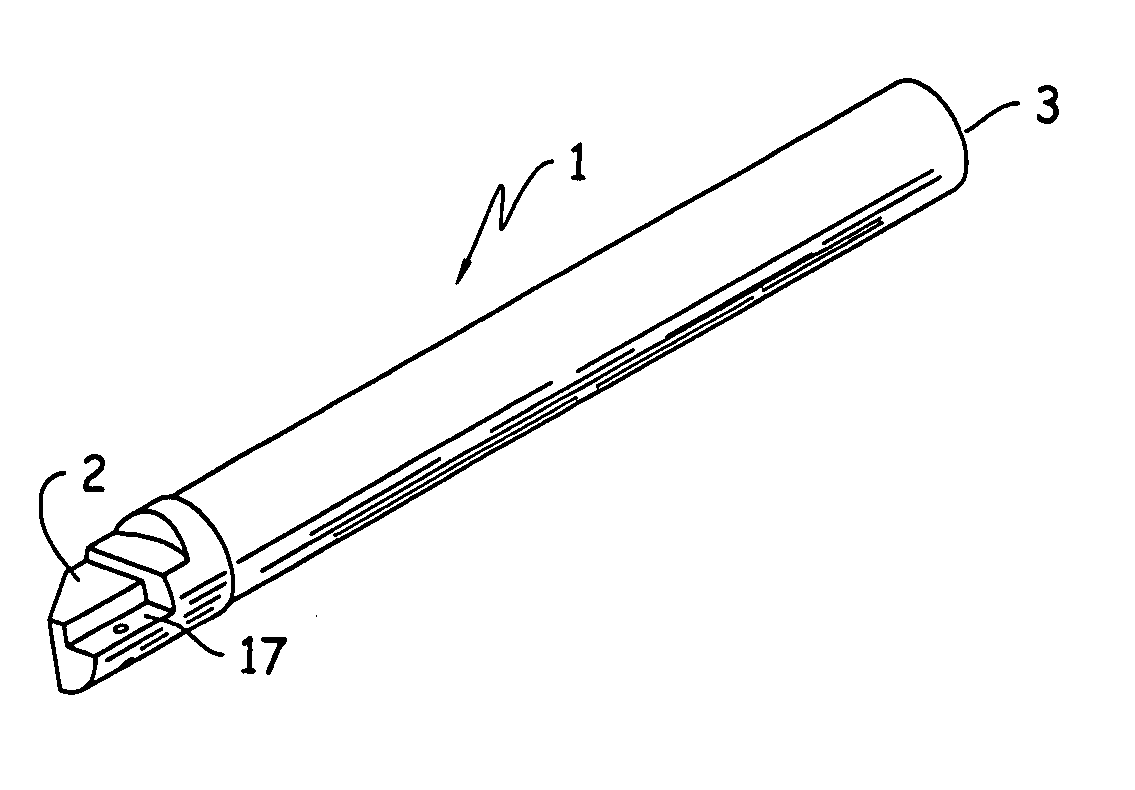

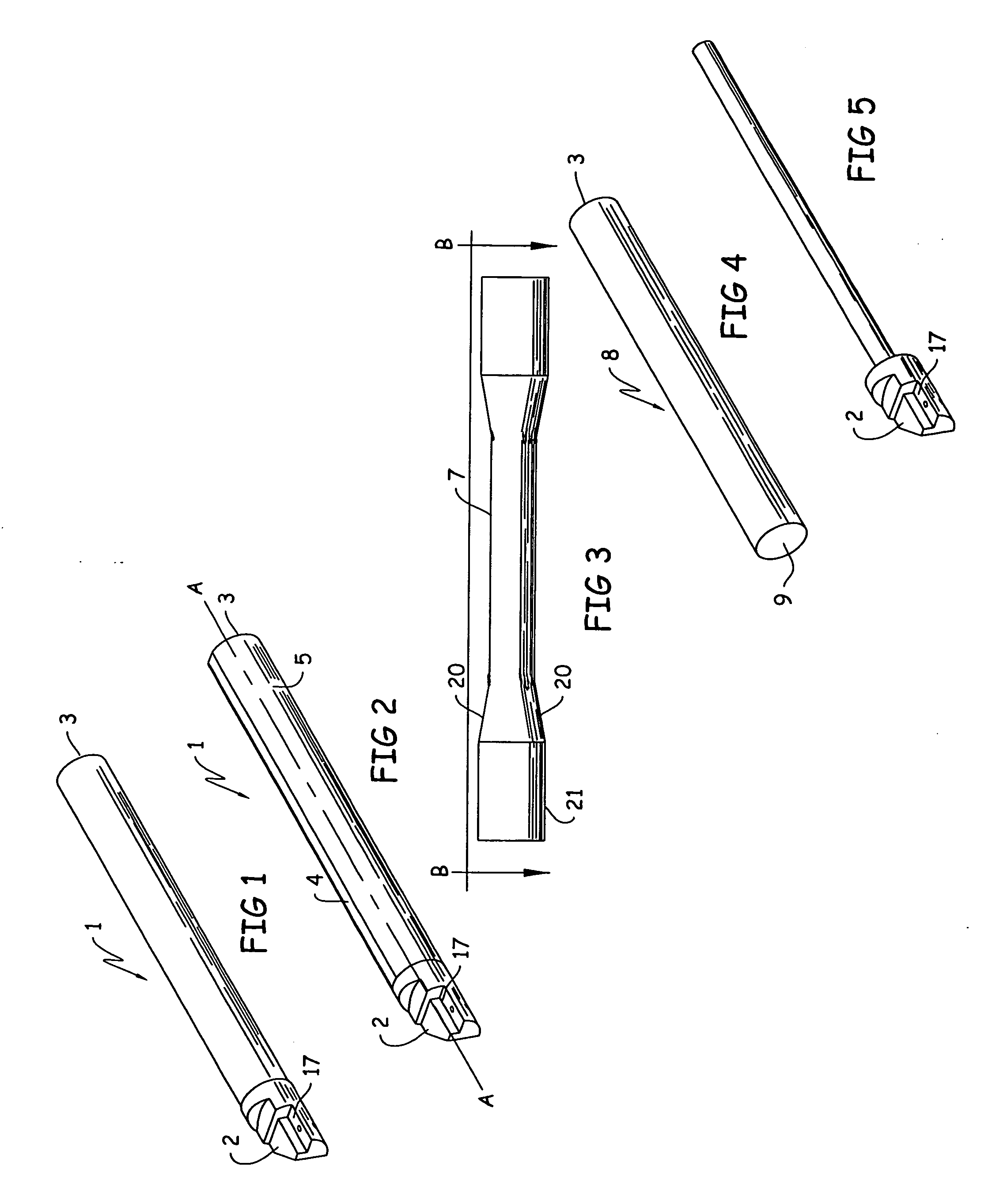

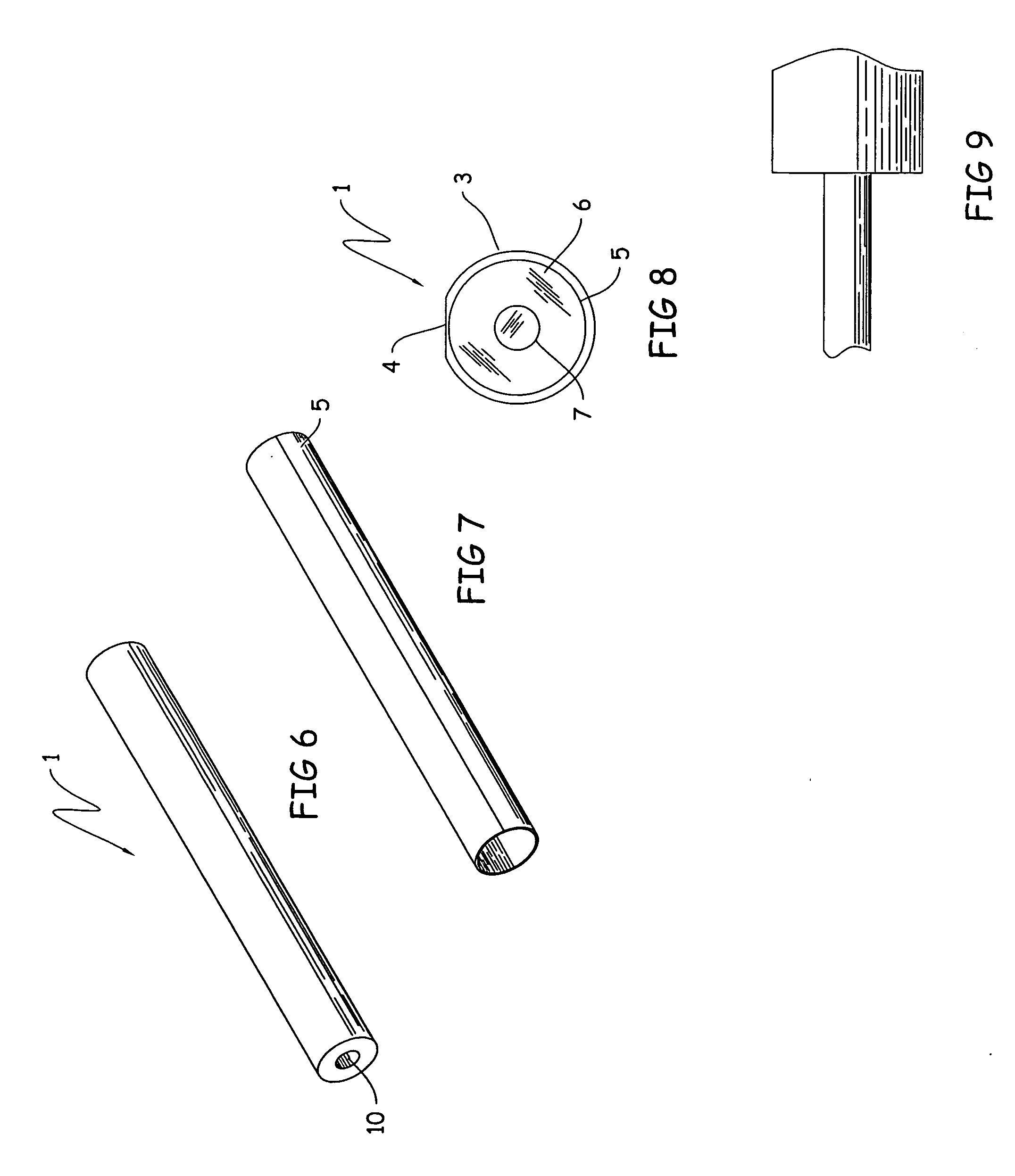

Novel composite tool holders and boring tools

InactiveUS20080292418A1Eliminate the effects ofIncrease the angleThread cutting machinesSynthetic resin layered productsSurface finishHigh density

Tool bars that are manufactured as a composite, that is, layered devices. The tool bars can have a solid core, covered with a wrapped composite material, and then optionally covered with a metal sleeve. The tool bars are provided with high strength, improved stiffness over prior art tool bars, high density, low coefficient of thermal expansion, high damping capacity, improved rigidity, improved damping, less chatter and vibration, improved work piece tolerance, improved surface finish, increased speed / fee rates, and low production cost.

Owner:KAY DONALD ELWOOD

Cam profile detection system

The invention provides a cam profile detection system based on a direct driving motor, and the system is simple in structure and high in detection precision and efficiency. The system comprises the direct driving motor, a mandrel, a feed screw nut pair, a laser measurement head, a grating ruler displacement sensor, a circular grating and an industrial personal computer, wherein the mandrel is coaxially fixedly arranged on the rotor of the direct driving motor and is used for driving a cam to coaxially rotate synchronously; the feed screw nut pair is horizontally arranged at one side of the cam; the laser measurement head is arranged on the movable nut of the feed screw nut pair; the grating ruler displacement sensor is used for measuring the horizontal displacement amount of the movable nut; the circular grating is arranged in the fixed seat of the direct driving motor and is used for detecting the rotation angle of the rotor; and the industrial personal computer is used for controlling the actions of the direct driving motor and the feed screw nut pair, and obtaining outer profile data of the cam according to data obtained by the laser measurement head, the grating ruler displacement sensor and the circular grating.

Owner:CHANGZHOU INST OF TECH

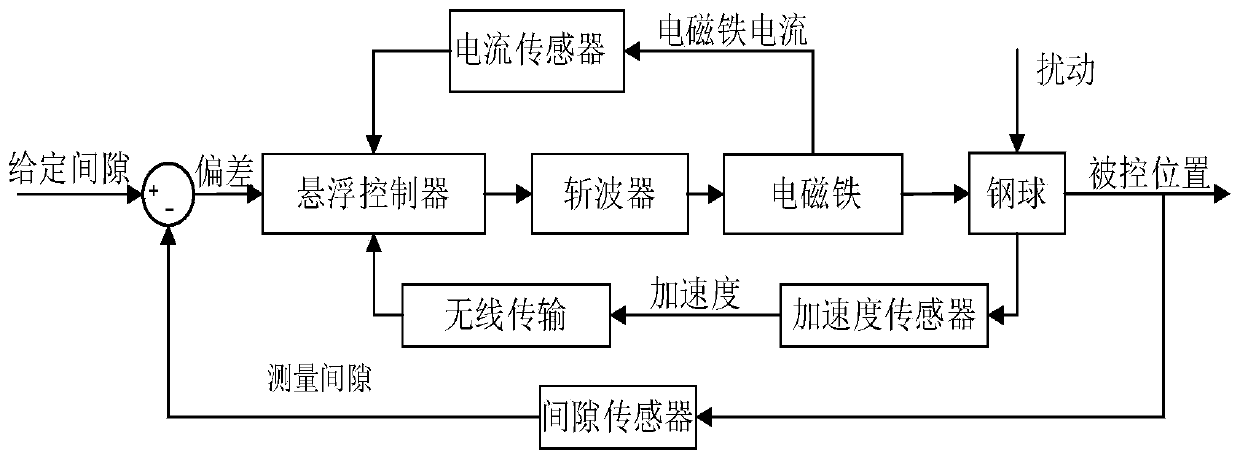

Electromagnetic suspension ball system with acceleration detection function, and control method thereof

InactiveCN110320385AImprove suspension performanceHigh dynamic stiffnessAcceleration measurement using interia forcesControllers with particular characteristicsElectricityEngineering

The invention discloses an electromagnetic suspension ball system with an acceleration detection function, and a control method thereof. In the system, an eddy current gap sensor collects a suspensiongap signal value and sends the same to a suspension controller; an acceleration sensor and a wireless transmitting unit are arranged in a steel ball, the acceleration sensor collects an accelerationvalue of the steel ball and sends the same to a suspension controller through the wireless transmitting unit and a wireless receiving unit; a current sensor detects a current signal of an electromagnet and sends the same to the suspension controller; and the suspension controller determines the magnitude of the current to be output according to the received suspension gap signal value, the acceleration data and real-time of the current signal, and then adjusts the winding current of the electromagnet through a chopper to change the magnitude of an electromagnetic force, so that the steel ballis suspended at a given suspension gap. The electromagnetic suspension ball system disclosed by the invention improves the suspension performance of the suspension system, increases the dynamic stiffness of the system, changes the damping and the vibration frequency of the system, and improves the anti-interference ability and the suspension stability of the system.

Owner:SOUTHWEST JIAOTONG UNIV

Antivibration Support

InactiveUS20080169592A1Mitigate such drawbackHigh dynamic stiffnessMachine framesMultiple spring combinationsEngineeringElastomer

An antivibration support disposed for supporting and dampening loads between external elements, comprising a first and a second rigid member for securing to the external elements, and an elastomer body, connecting respectively the first and second rigid members.The support also comprises a second body, having dissimilar material properties from the elastomer body, acting in parallel with the elastomer body to support and dampen the loads.

Owner:PAULSTRA CRC

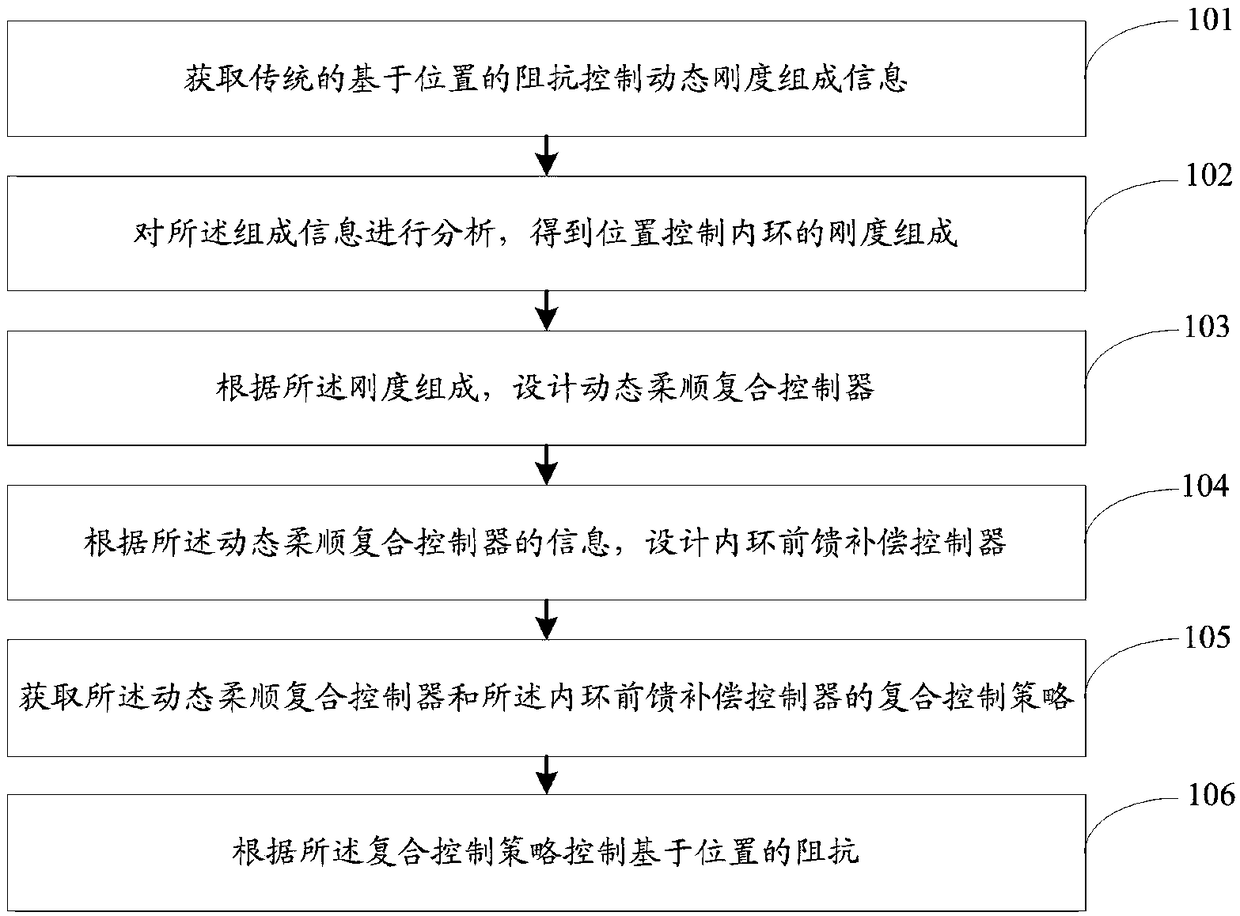

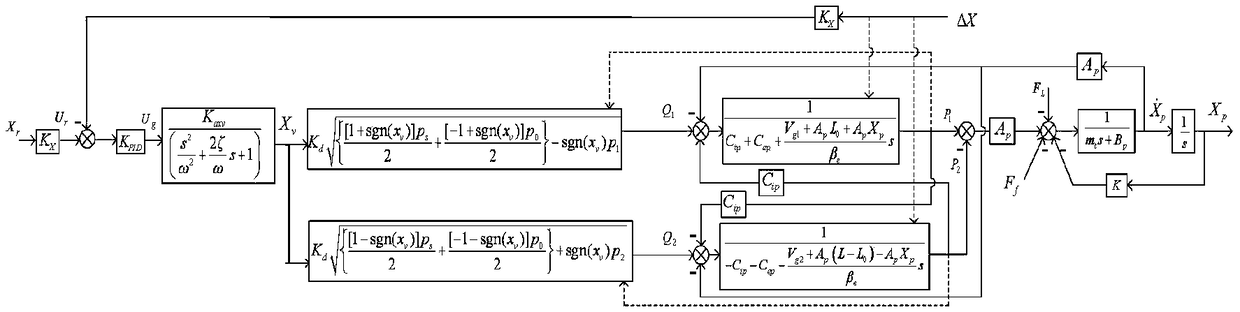

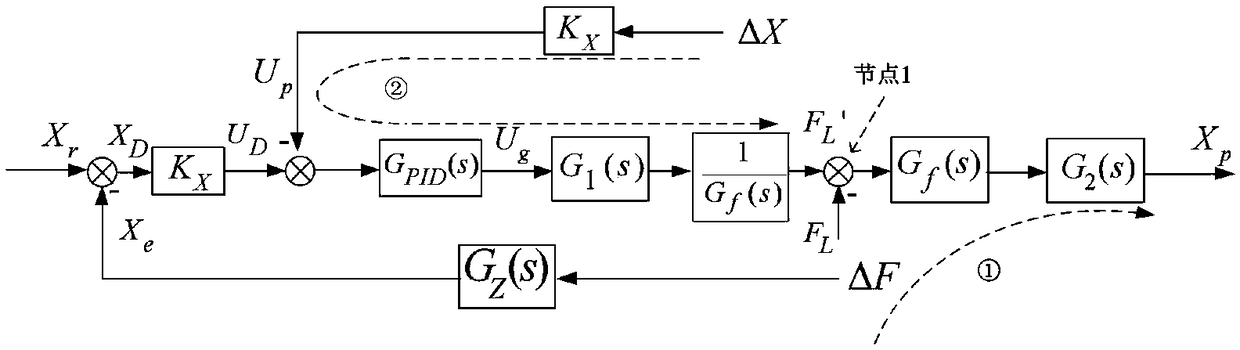

Position based impedance control method and system for hydraulic driving unit

ActiveCN109210037AImprove anti-interference abilityHigh dynamic stiffnessFluid-pressure actuator componentsVehiclesPosition controlComposite controller

The invention discloses a position based impedance control method and system for a hydraulic driving unit. The method comprises that dynamic rigidity composition information of traditional position based impedance control is obtained; the composition information is analyzed to obtain inner-ring rigidity composition of position control; a dynamic submissive composite controller is designed according to the rigidity composition; according to information of the dynamic submissive composite controller, an inner-ring feedforward compensation controller is designed; a composite control strategy of the dynamic submissive composite controller and the inner-ring feedforward compensation controller are obtained; and the position based impedance is controlled according to the composite control strategy. The method and system of the invention can be used to improve the position based impedance control precision substantially.

Owner:YANSHAN UNIV

Cam profile detection system based on direct driving motor

The invention provides a cam profile detection system based on a direct driving motor, and the cam profile detection system is simple in structure and high in detection precision and efficiency. The system comprises the direct driving motor, a mandrel, a feed screw nut pair, a laser measurement head, a grating ruler displacement sensor, a circular grating and an industrial personal computer, wherein the mandrel is coaxially and fixedly arranged on the rotor of the direct driving motor and is used for driving a cam to coaxially rotate synchronously; the feed screw nut pair is horizontally arranged at one side of the cam; the laser measurement head is arranged on the movable nut of the feed screw nut pair; the grating ruler displacement sensor is used for measuring the horizontal displacement amount of the movable nut; the circular grating is arranged in the fixed seat of the direct driving motor and is used for detecting the rotation angle of the rotor; and the industrial personal computer controls actions of the direct driving motor and the feed screw nut pair, and obtains outer profile data of the cam according to data obtained by the laser measurement head, the grating ruler displacement sensor and the circular grating.

Owner:CHANGZHOU INST OF TECH

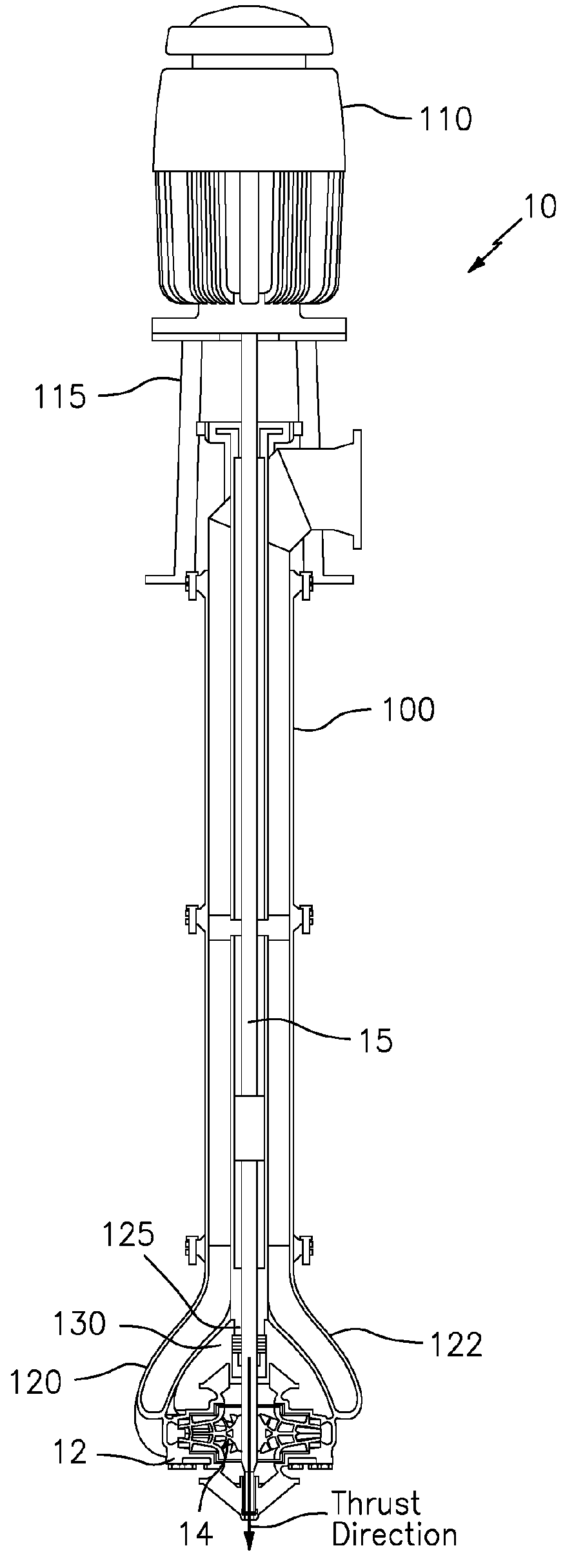

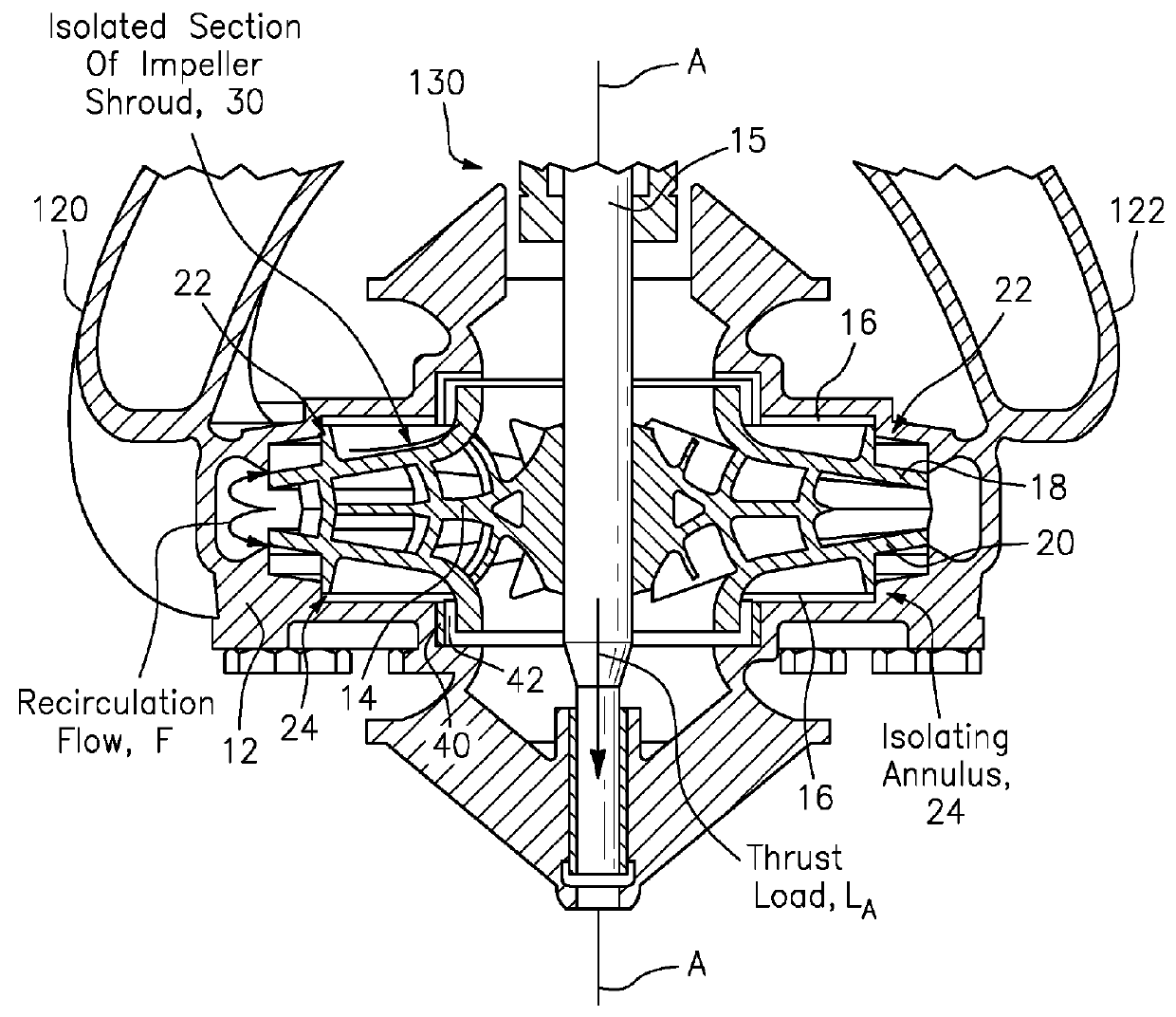

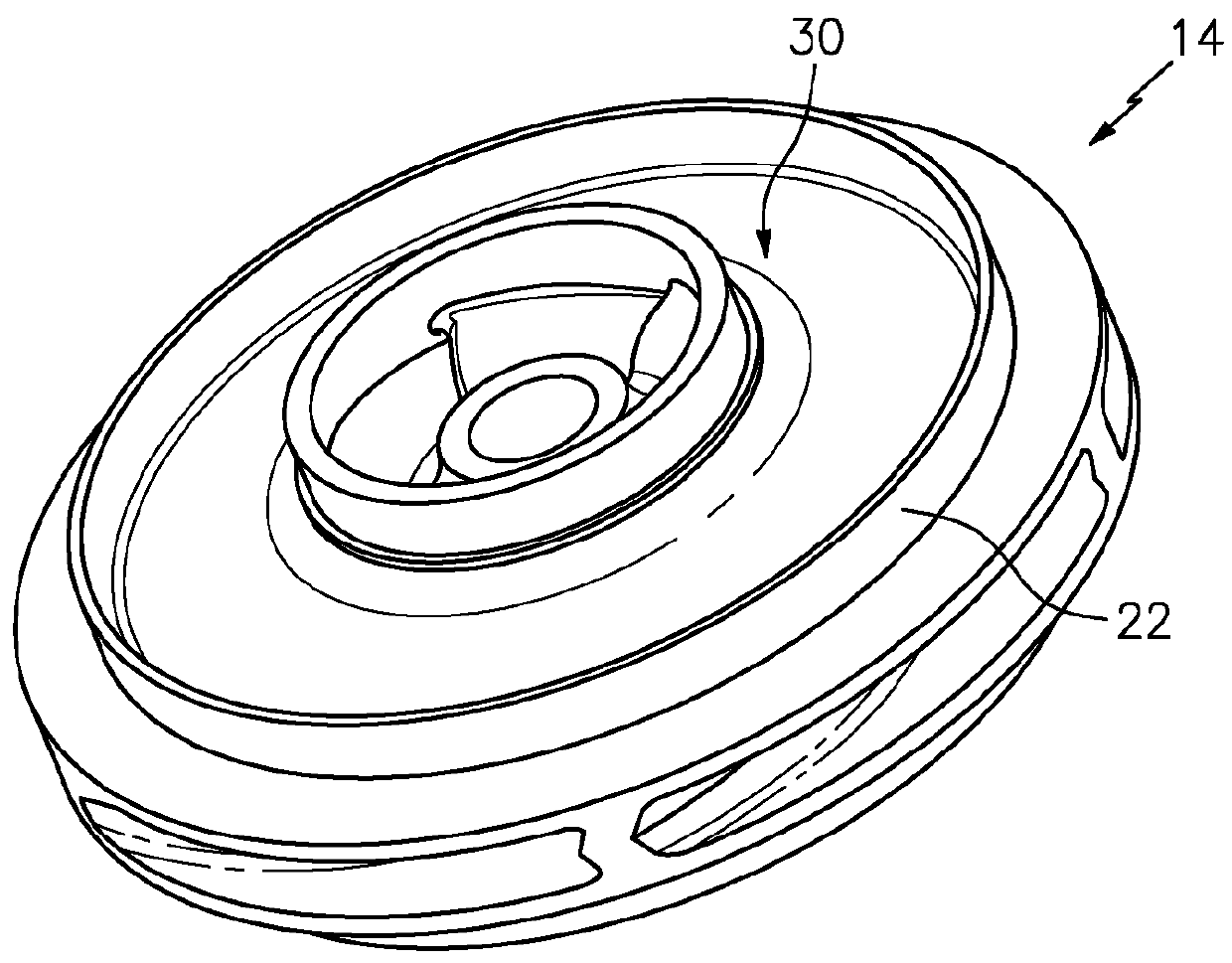

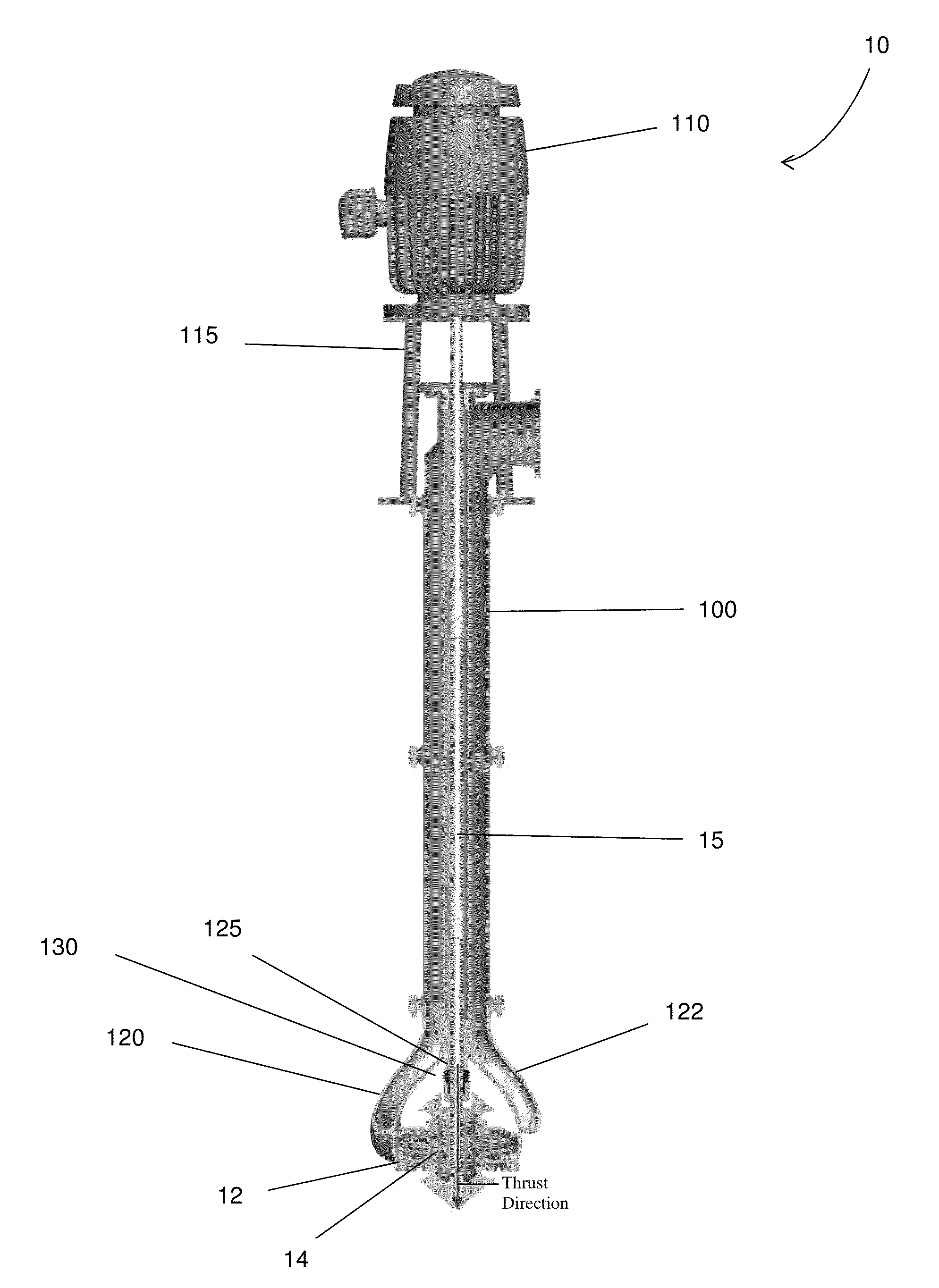

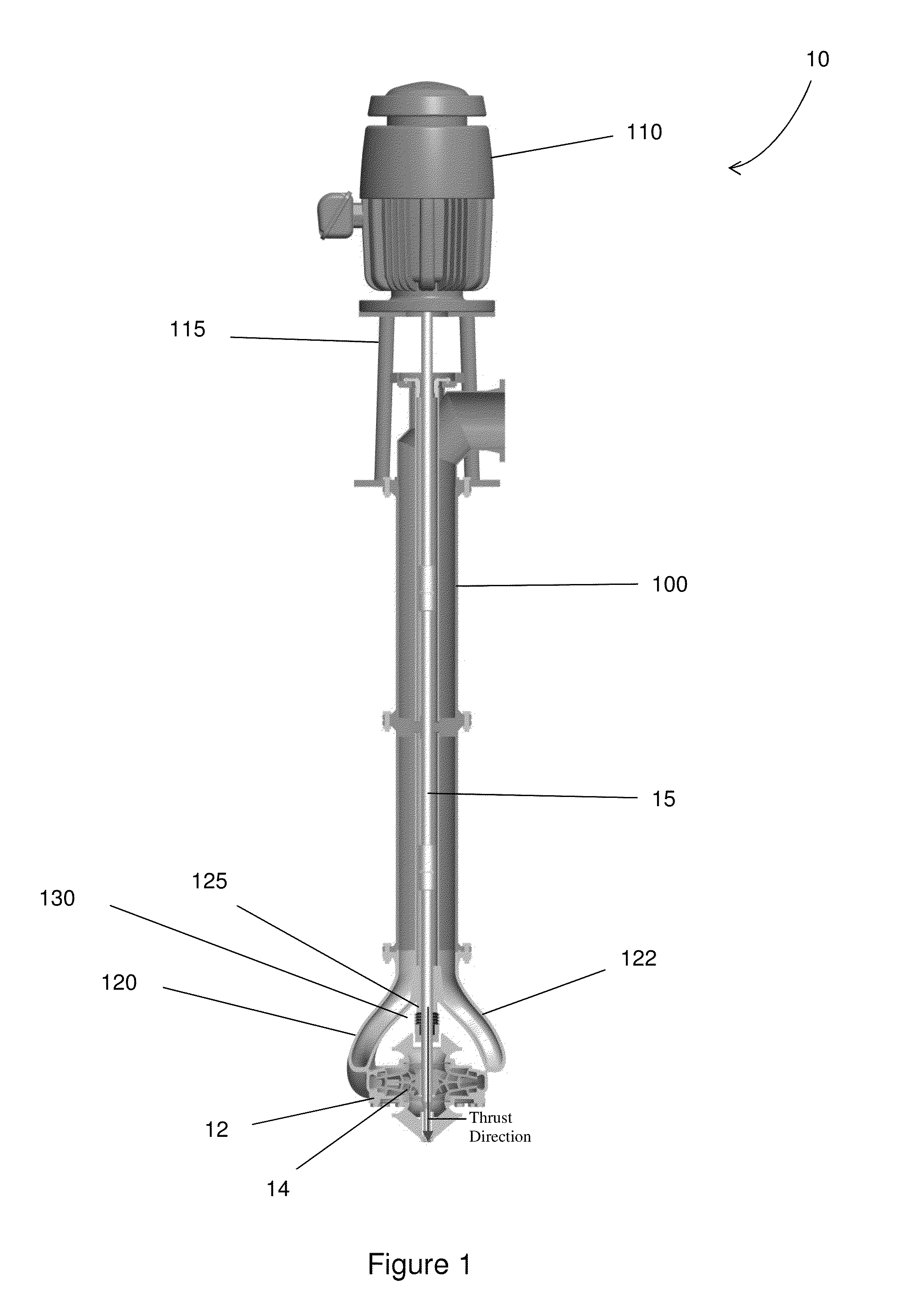

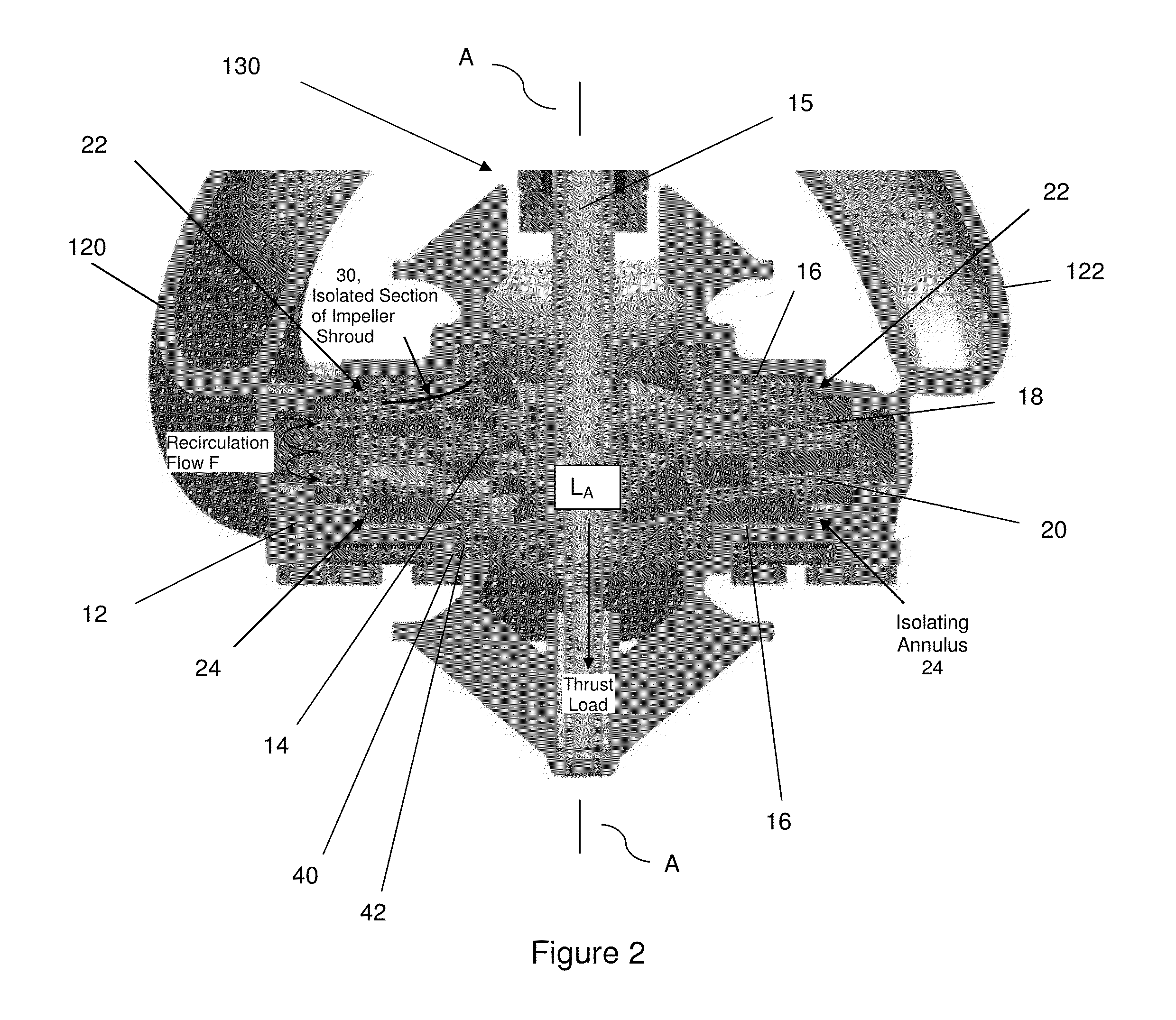

Vertical double-suction pump having beneficial axial thrust

ActiveUS9377027B2High dynamic stiffnessImprove reliabilityPump componentsWorking fluid for enginesImpellerAxial thrust

Owner:ITT MFG ENTERPRISES LLC

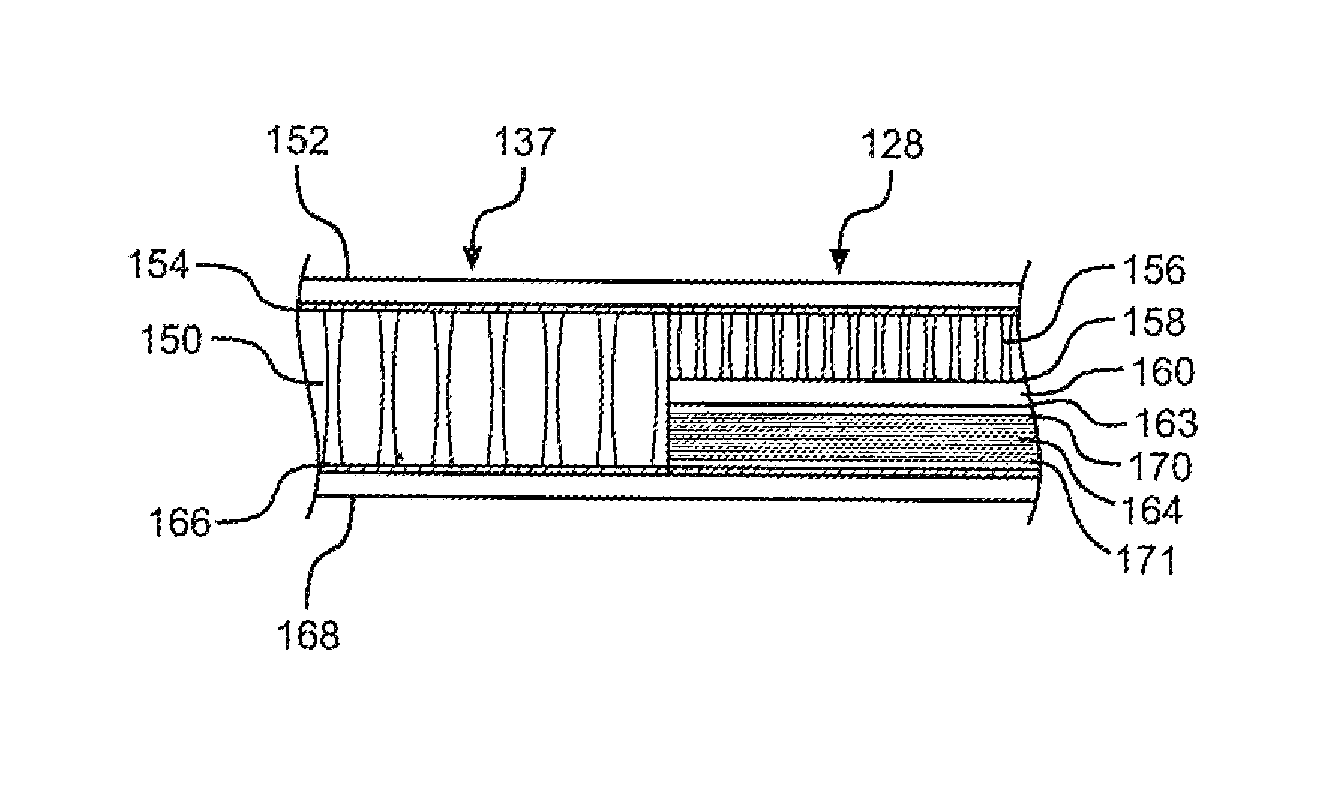

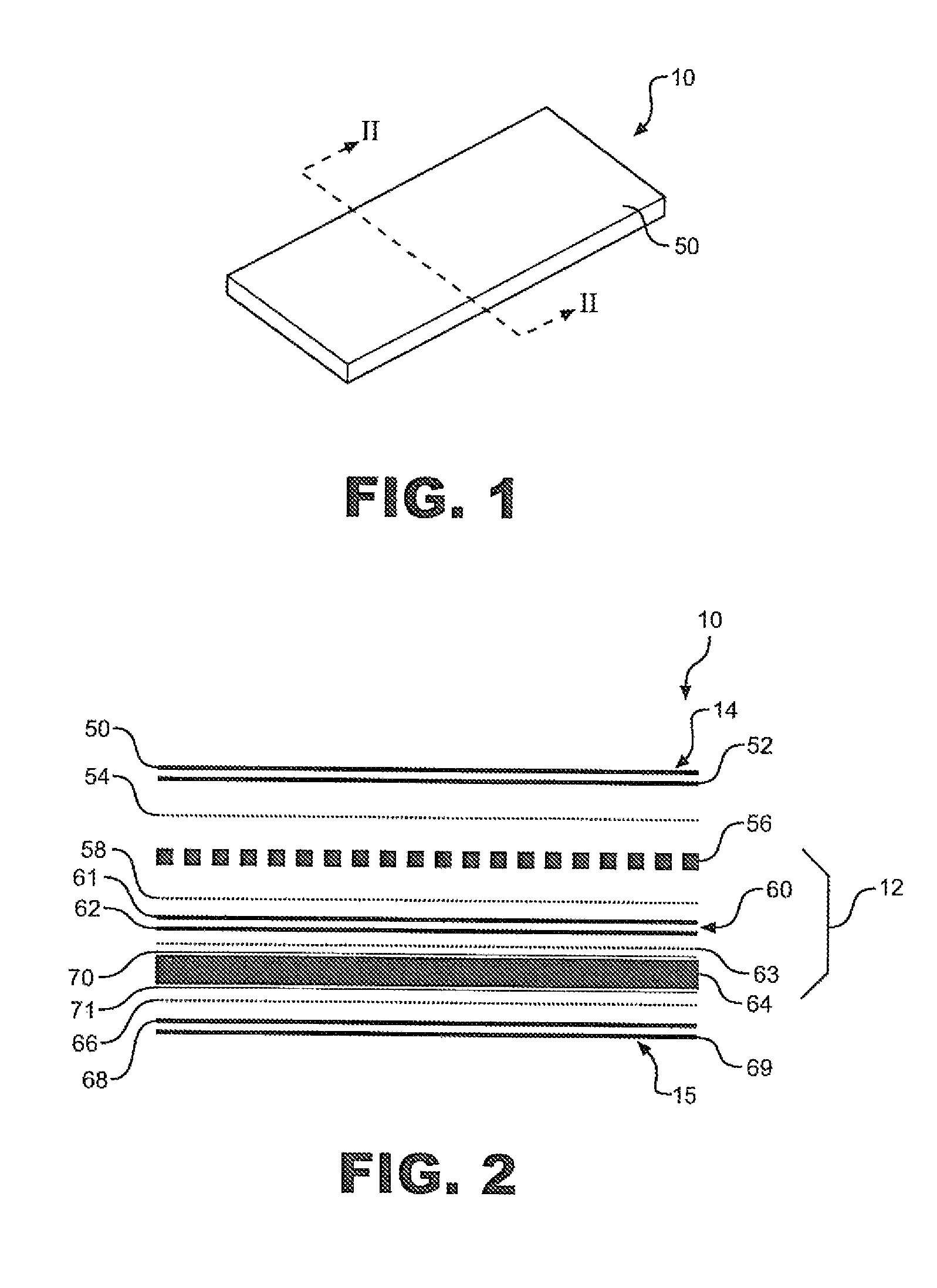

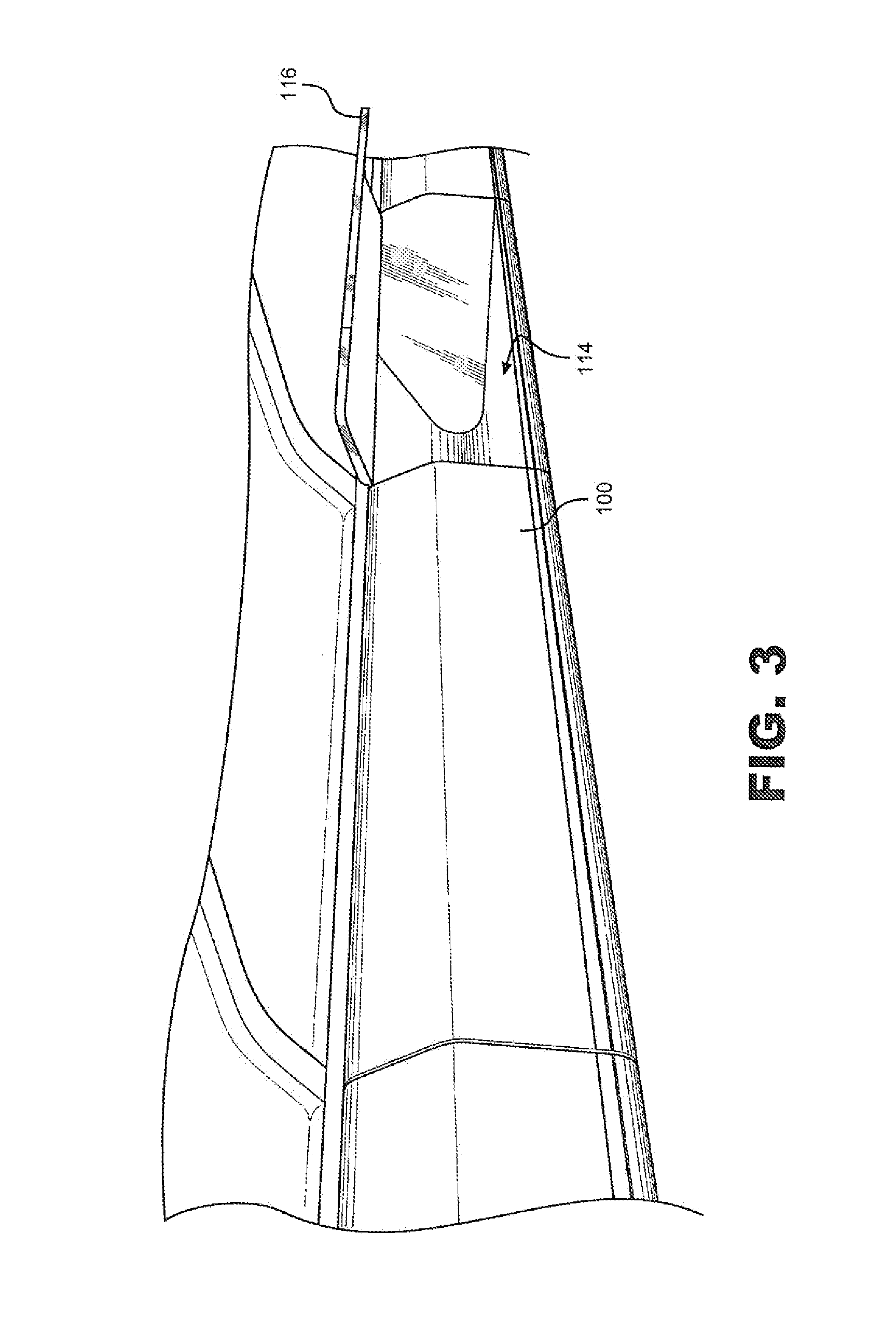

Lightweight blast mitigating composite panel

ActiveUS8777161B2High dynamic stiffnessAbility to disperse/distribute localized blast loadSynthetic resin layered productsMilitary adjustmentGlass compositesFiber

Lightweight blast mitigating composite panels (10) include a first glass composite shell (14; 152), an intermediate, preferably honeycomb layer (56; 156), a reinforcing layer (60; 160), an ultra high molecular weight polyethylene fiber (UHMWPE) layer (64; 164) and a second glass composite shell (15; 168) adhered together with fire resistant adhesive layers (54; 58, 63, 66; 154, 158, 163, 166). The UHMWPE layer (64; 164) includes top and bottom coatings (70, 71) of fire resistant thermoset plastic preferably in the form of a paste. The panels (10) have use in a wide range of applications including in a blast mitigating overhead storage bin (100). The storage bin (100) includes a main body portion (133) defining a storage area formed from composite unarmored and armored panel segments (137, 138; 128-132). The unarmored and armored panel segments (137, 138; 128-132) share first and second shells (14, 15) to form an integral main body portion, with the armored panel segments (128-132) providing blast protection between the storage area and a wall (125) of an airplane cabin (120).

Owner:BATTELLE MEMORIAL INST

Double-stator axial magnetic flow arc-shaped permanent magnet motor

ActiveCN103580412AImprove power densityIncreased torque densityMagnetic circuit rotating partsDynamic stiffnessElectric machine

The invention relates to a double-stator axial magnetic flow arc-shaped permanent magnet motor, and belongs to the technical field of limited angle permanent magnet motors. A rotor is composed of an arc-shaped rotor iron core and permanent magnets, wherein the permanent magnets are installed on the left side and the right side of the arc-shaped rotor iron core. A double-stator assembly is composed of a left-side arc-shaped stator located at the left side of the arc-shaped rotor and a right-side stator located on the right side of the rotor. The left-side arc-shaped stator, the arc-shaped rotor iron core and the permanent magnet on the left side form a left-side axial magnetic flow arc-shaped permanent magnet motor body, the right-side arc-shaped stator, the arc-shaped rotor iron core and the permanent magnet on the right side form a right-side axial magnetic flow arc-shaped permanent magnet motor body, the torque of the two arc-shaped permanent magnet motor bodies is overlaid to serve as the output torque of the whole motor, the power density and the torque density of the motor are improved, the direct drive mode is adopted for a scanning structure, and the problems that the indirect drive mode formed by a high-speed servo motor, a gear set, a gear ring and the like in an existing scanning mechanism causes system vibration, slow motion response, poor dynamic stiffness and the like are solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Magnetorheological fluid-based mount apparatus including rate dip track passage

ActiveUS9051989B2Low dynamic stiffnessHigh dynamic stiffnessSpringsNon-rotating vibration suppressionDynamic stiffnessPump chamber

Owner:BEIJING WEST IND CO LTD

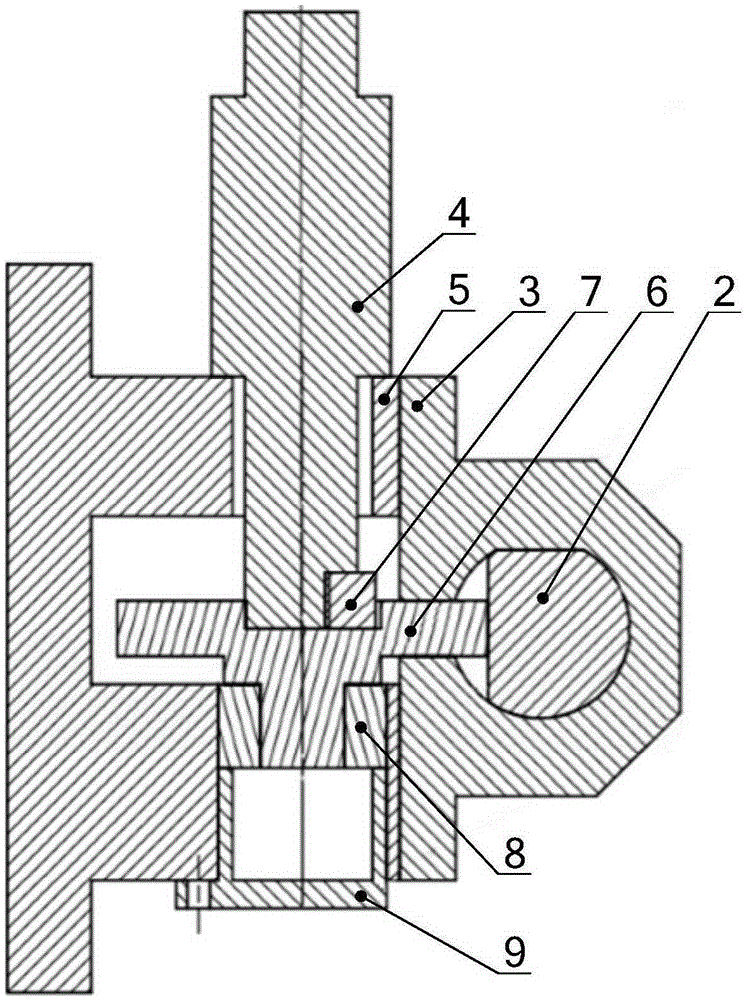

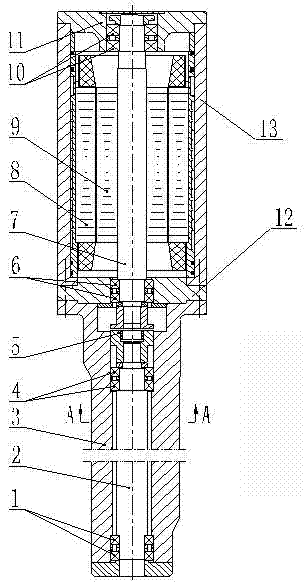

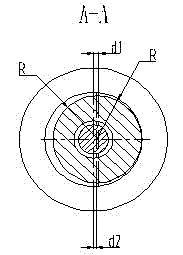

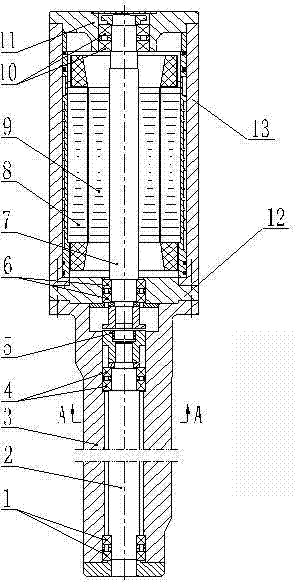

Electric spindle structure suitable for longhole inner circle processing

InactiveCN102240969AShorten the lengthReduce wearGrinding carriagesRevolution surface grinding machinesElectric machineControl theory

The invention relates to an electric spindle structure suitable for longhole inner circle processing. The electric spindle structure comprises a motor shell (13), a motor rotor (9), a motor stator (8), a motor spindle (7), and a motor front bearing (6) and a motor front bearing seat (12) which are used for supporting the motor spindle (7), a motor rear bearing (10) and a motor rear bearing seat (11), a grinding spindle shell (3), a grinding spindle (2), a grinding wheel front bearing (1) and a grinding wheel rear bearing (2) which are used for supporting the grinding spindle (2), and a coupler (5) which is connected with the grinding spindle (2) and the motor spindle (7); and the electric spindle structure is characterized in that: the motor stator (8) is arranged in the motor shell (13);and the motor spindle (7) is arranged at the axial line position in the motor shell (3). The processing accuracy and assembly accuracy of the spindle structure can be guaranteed.

Owner:SOUTHEAST UNIV

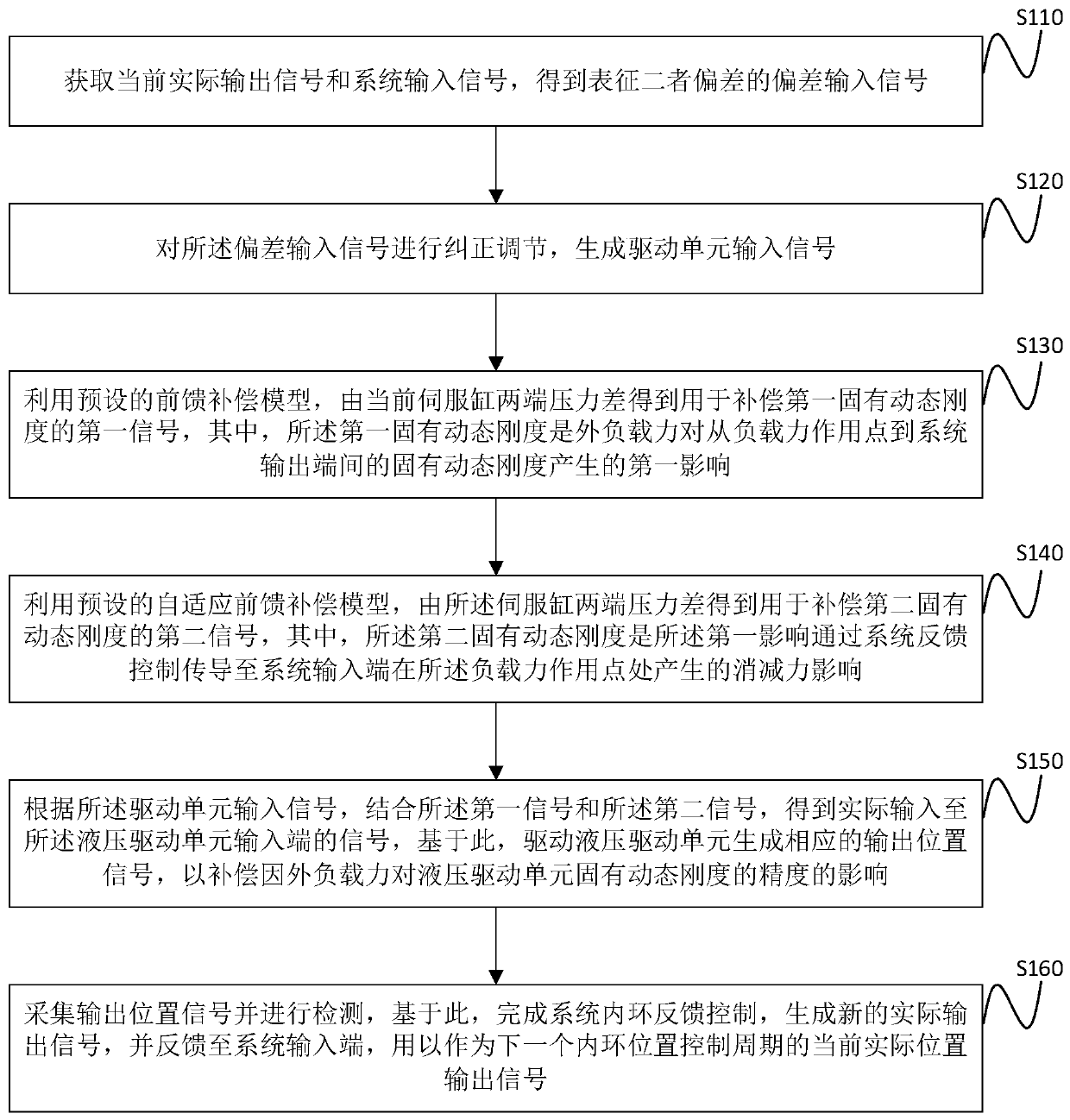

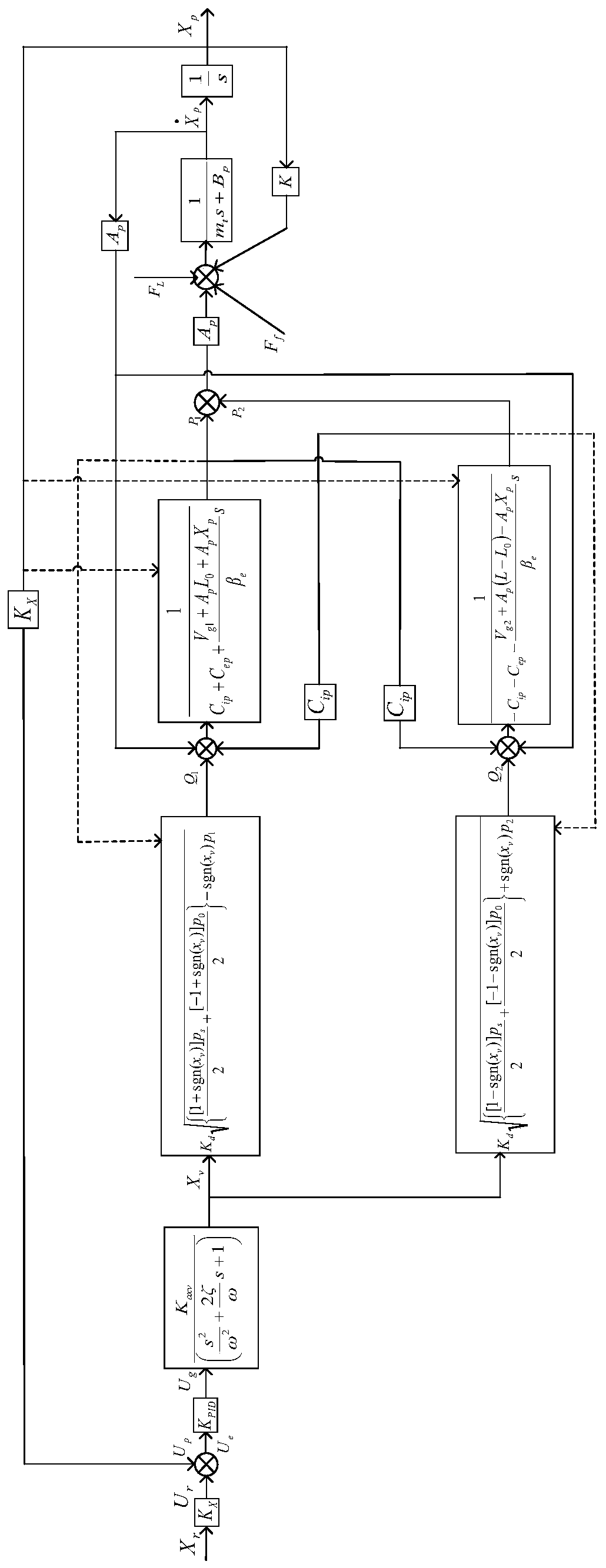

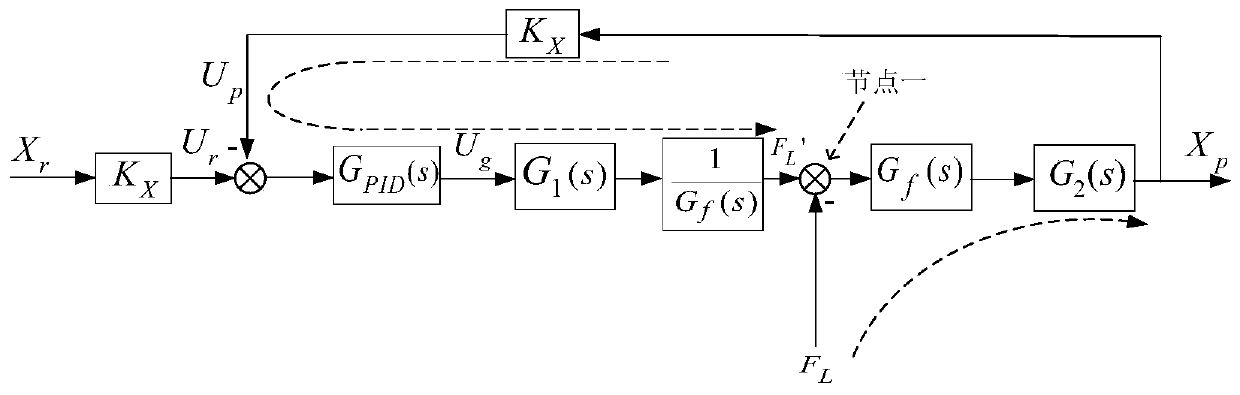

Compound control method and system for hydraulic drive unit position control system

ActiveCN110030233AHigh dynamic stiffnessHigh precisionProgramme-controlled manipulatorServometer circuitsDynamic stiffnessSelf adaptive

The invention discloses a compound control method and system for a hydraulic drive unit position control system. The method comprises the steps that feedforward compensation control is adopted for forming a stiffness model opposite to first inherent dynamic stiffness in the system for compensating the influence of external load force on the inherent dynamic stiffness from the load force application point to the system output end. Further, self-adaptive feedforward compensation control is added for further compensating the deviation of input voltage and output voltage, and thus variations in system load pressure are compensated. In addition, through self-adjusting position control, the robustness of the two feedforward compensation control modes is improved. Finally, the three compensationcontrol modes are integrated, and the position compound control method is formed, so that the system dynamic stiffness tends to infinite. The dynamic stiffness of the position control system is improved, and the precision and robustness of outer loop compliant control are improved. Besides, the algorithm of the method is simpler and easier to implement in engineering.

Owner:江苏亚力亚气动液压成套设备有限公司

Vertical double-suction pump having beneficial axial thrust

ActiveUS20130039754A1High dynamic stiffnessImprove reliabilityPump componentsWorking fluid for enginesAxial thrustPressure difference

Apparatus, including a vertical double-suction pump, is provided featuring a pump casing and a double suction impeller arranged therein on a shaft. The pump casing has a pump casing wall. The double suction impeller has upper and lower shrouds with metal rims configured to form upper and lower isolating annuli between the double suction impeller and the wall of the pump casing in order to impede a recirculation flow from an impeller discharge to be able to act of the upper and lower shrouds and create a controlled axial thrust load from differentiated hydraulic pressure on the upper and lower shrouds. The upper and lower isolating annuli may also be geometrically varied between the upper and lower shrouds of the double suction impeller to create a pressure differential in a direction parallel to an axis of rotation of the double suction impeller.

Owner:ITT MFG ENTERPRISES LLC

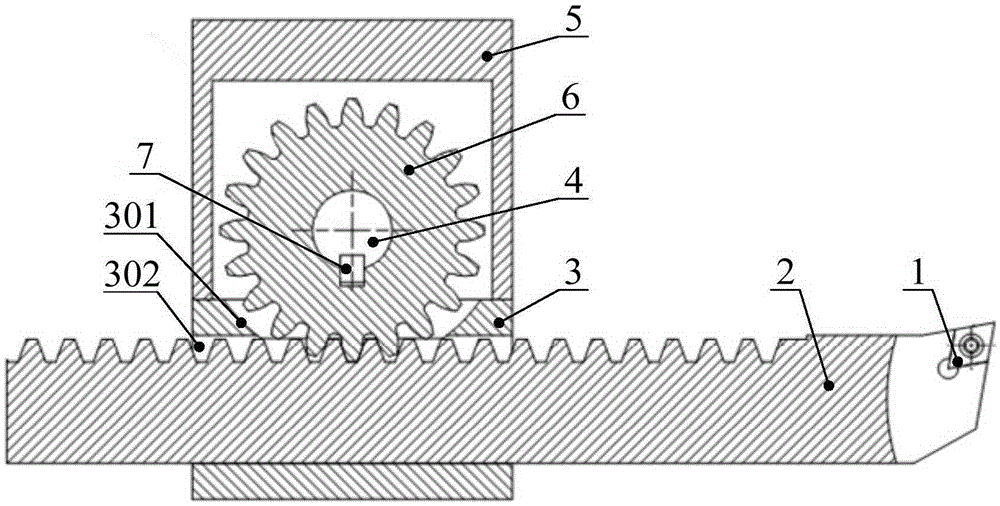

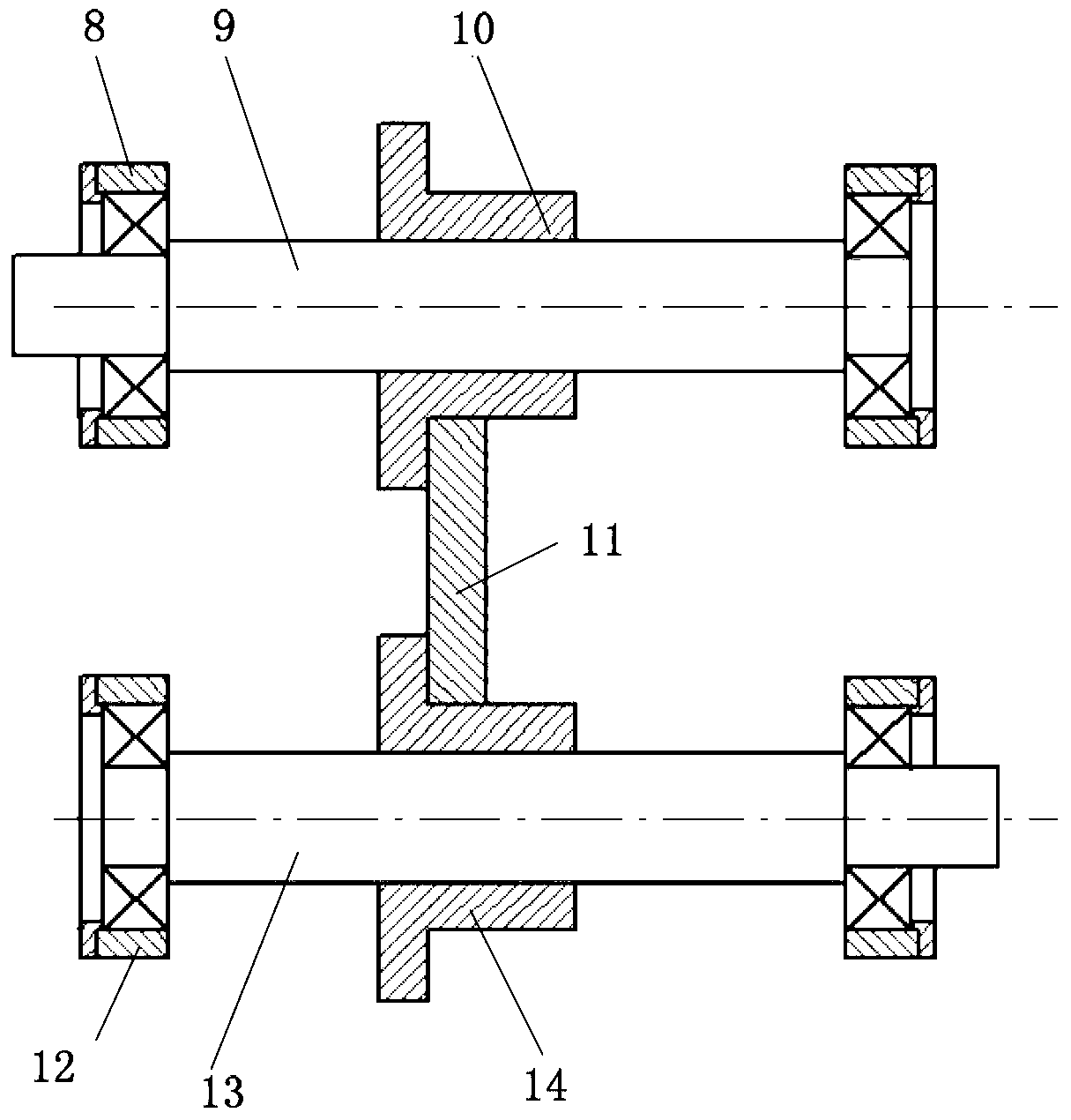

High-precision constant-transmission-ratio transmission mechanism based on ball screws

InactiveCN103277475AHigh transmission precisionHigh dynamic stiffnessGearingOptical instrumentationBall screw

The invention provides a high-precision constant-transmission-ratio transmission mechanism based on ball screws, and belongs to the field of precision transmission. The mechanism is used for achieving constant-transmission-ratio transmission of parallel shafts (including coaxial shafts). Nuts of the ball screws of the two parallel shafts are connected, leads, precision grades and turning directions of the two ball screws are selected, and accordingly constant-transmission-ratio high-precision transmission in different turning directions is achieved. The mechanism has high transmission precision, high dynamic rigidity and long-term position stability, and is free of backlash, suitable for being use in a space in an optical instrument where the constant-transmission-ratio transmission is needed and meanwhile suitable for the precise transmission field with the same requirement.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com