Electric spindle structure suitable for longhole inner circle processing

An electric spindle and deep hole technology, which is applied in metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, manufacturing tools, etc., can solve the problem that the spindle is difficult to achieve sufficient accuracy requirements, reduce the service life of the spindle bearing, and replace the intermediate position bearing. Difficulties and other problems, to achieve the effect of improving cutting quality, improving machining accuracy, and reducing alternating stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

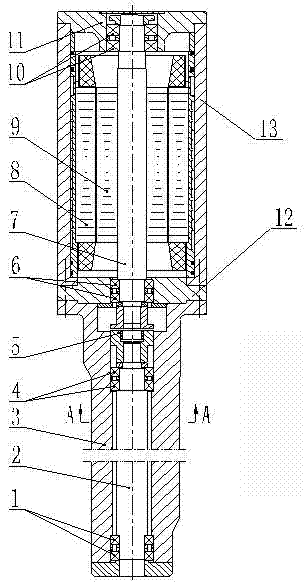

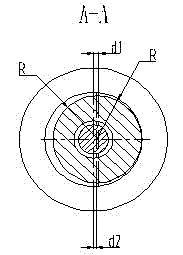

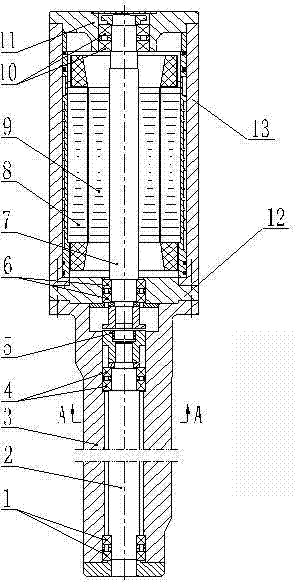

[0017] see figure 1 , figure 2 , the present invention relates to an electric spindle structure suitable for deep hole inner circle machining, including a motor casing 13, a motor rotor 9, a motor stator 8, a motor spindle 7, and a motor front bearing 6 and a motor front for supporting the motor spindle 7. Bearing housing 12, motor rear bearing 10 and motor rear bearing housing 11, grinding wheel shaft housing 3, grinding wheel shaft 2, grinding wheel front bearing 1 supporting grinding wheel shaft 2, grinding wheel rear bearing 4, coupling shaft connecting grinding wheel shaft 2 and motor main shaft 7 device 5.

[0018] Motor stator 8 is housed in motor shell 13, and motor main shaft 7 is housed on the inner axis position of motor shell 3, and motor rotor 9 is housed in the middle part of motor main shaft 7, and motor main shaft 7 passes motor front bearing 6 and motor rear bearing that are installed at its two ends. 10 supports, the motor front bearing 6 is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com