Electromagnetic suspension ball system with acceleration detection function, and control method thereof

An electromagnetic levitation and levitation controller technology, which is applied to controllers with specific characteristics, speed/acceleration/shock measurement, acceleration measurement using inertial force, etc., can solve the vibration, instability, and excessive interference of the electromagnetic levitation ball system To achieve the effect of improving the anti-interference ability, improving the suspension stability and increasing the stability range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

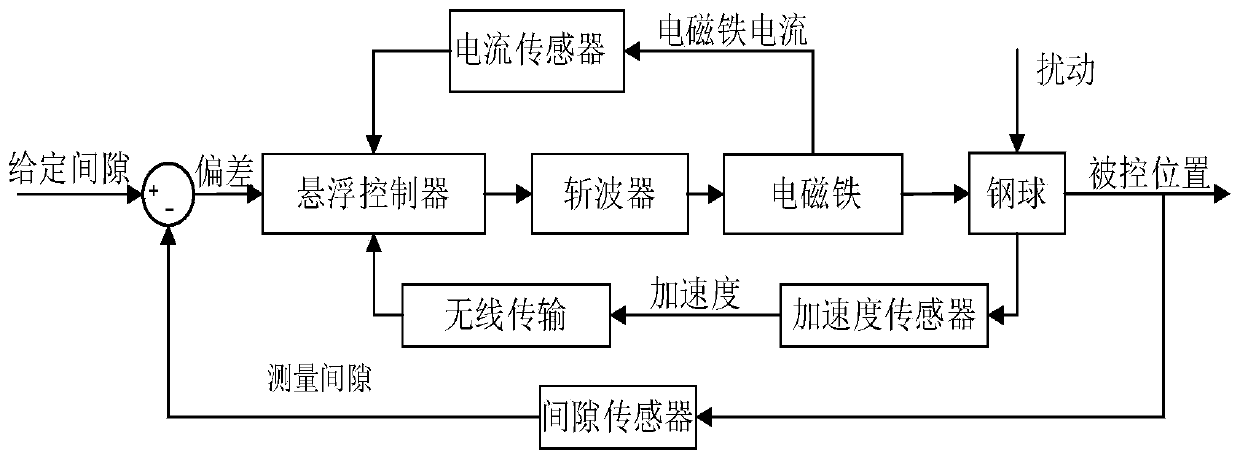

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The invention designs an electromagnetic levitation ball system with the functions of acceleration detection and wireless transmission, and optimizes the levitation control method in combination with the feedback of acceleration signals. Since the steel ball itself is in a suspended state and has no electrical connection with the outside world in the magnetic levitation ball system, the transmission of the acceleration signal of the steel ball is realized by means of wireless communication. The working principle diagram of the electromagnetic levitation ball system is as follows: figure 2 shown.

[0039] Such as image 3 As shown, the electromagnetic levitation ball system of the present invention includes an eddy current gap sensor, an acceleration sensor, a levitation controller, a chopper and a current sensor; the eddy current gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com