Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Guarantee forging quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

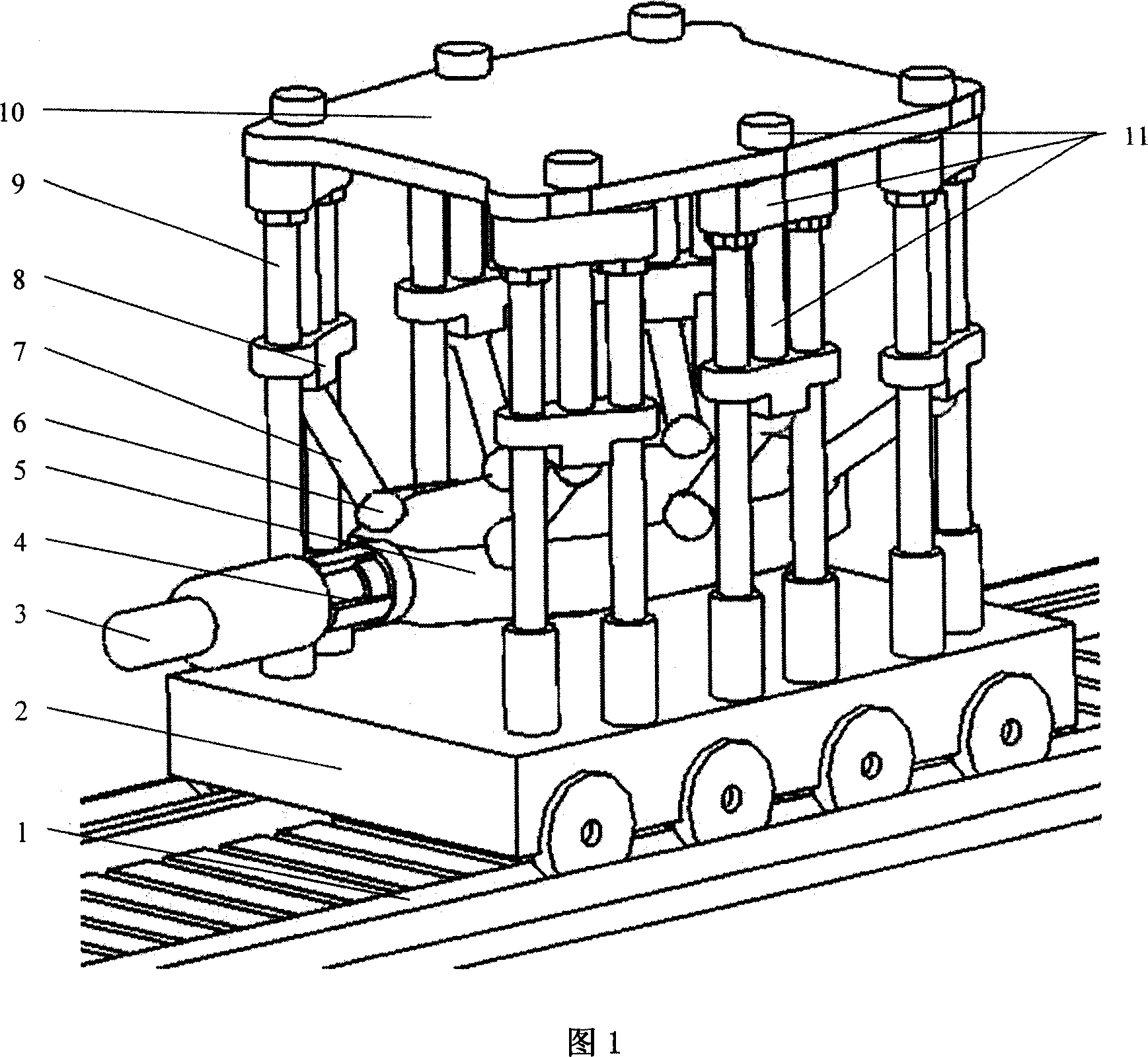

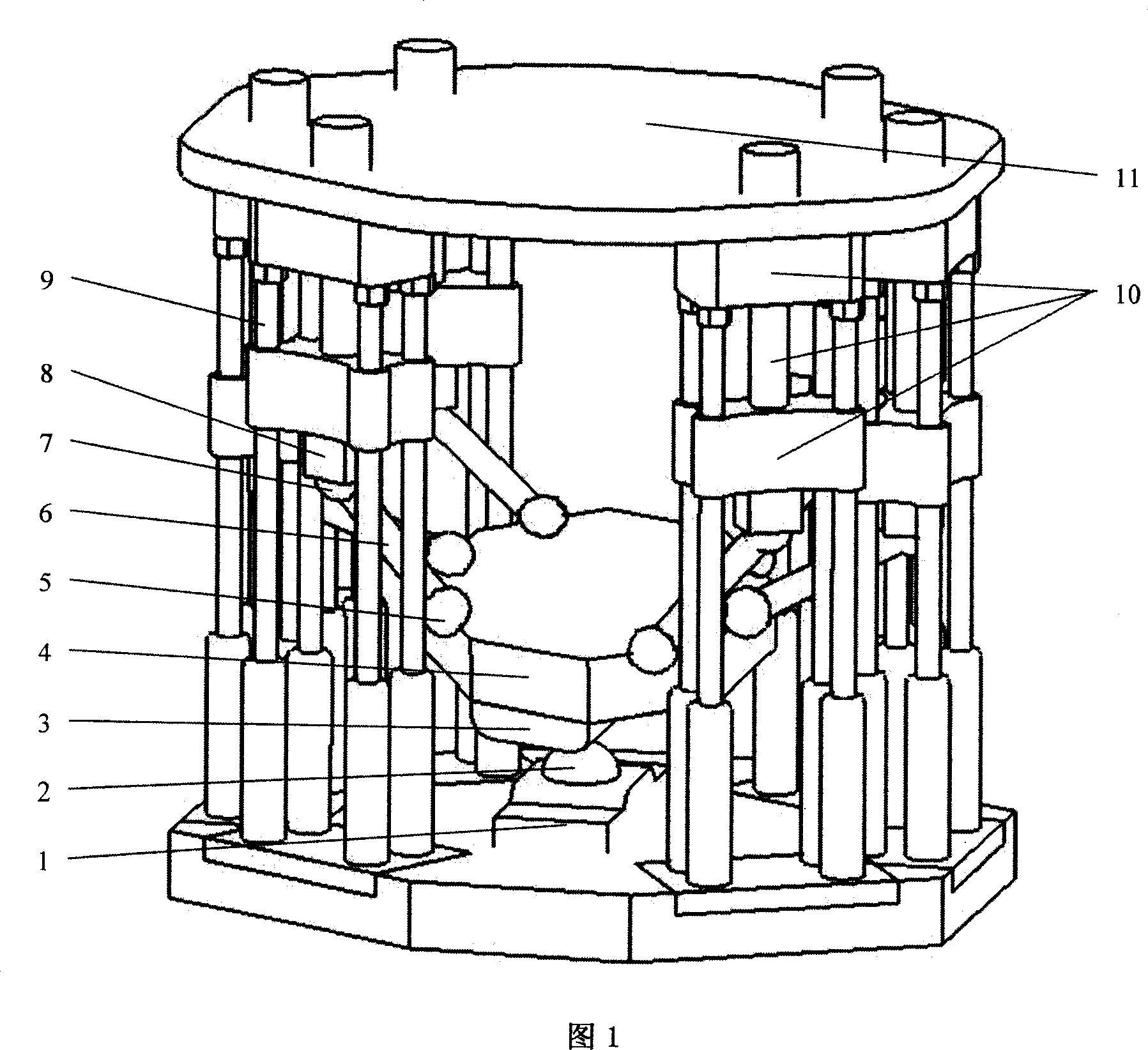

Six-dimensional parallel forging operator

InactiveCN1745937AGuarantee forging qualitySimple structureForging/hammering/pressing machinesForging press detailsEngineeringForge

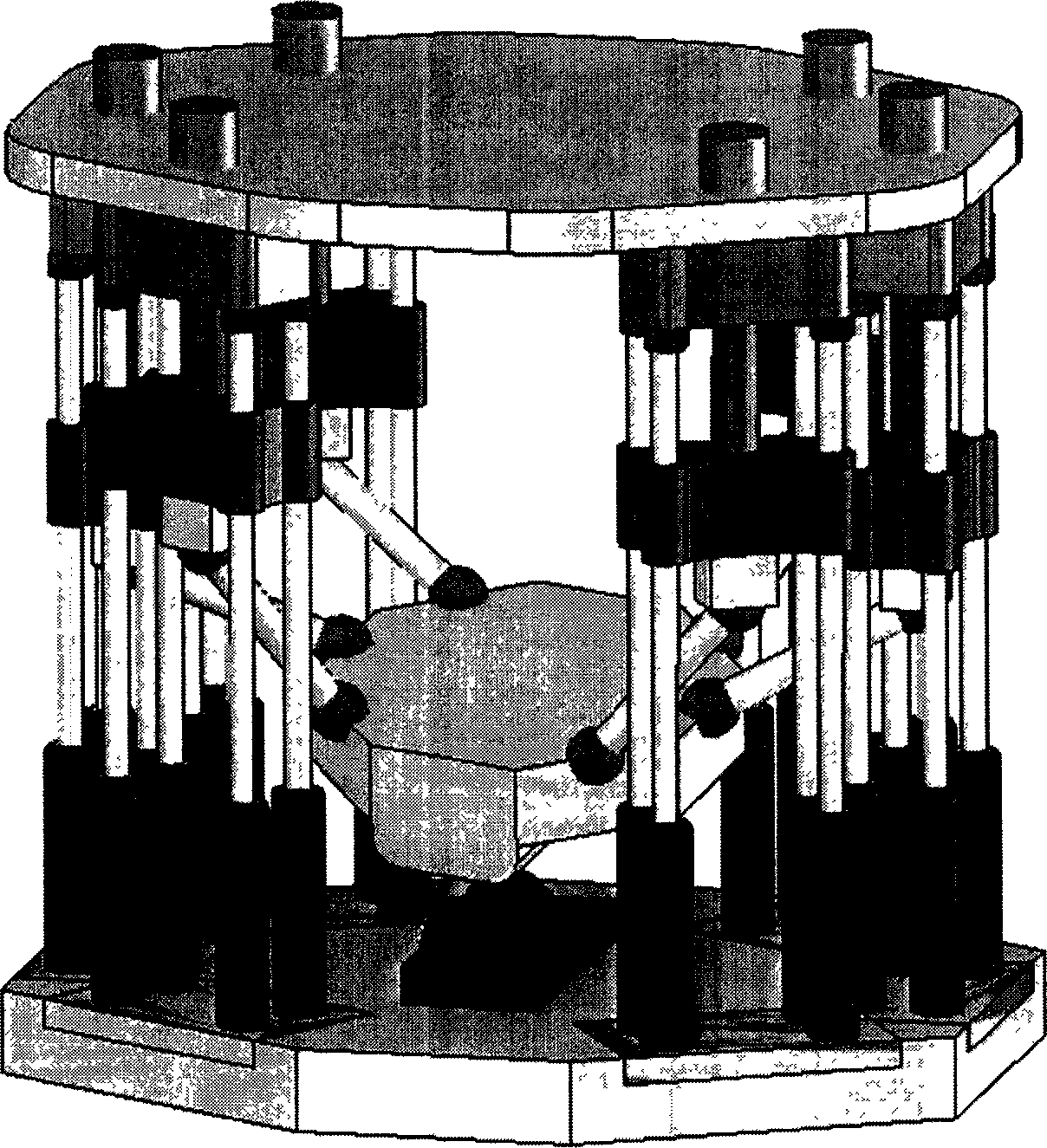

A 6D parallelly connected forge machine is composed of 6 linear drive systems fixed to upper platform, and the join mechanism between linear drive systems and platform. Each linear drive system has a vertical column as its guide track and can drive a jointer connected to one end of a connecting rod via a primary spherical hinge. Another end of said connecting rod is connected to the platform via primary spherical hinge. A gripper for grasping the work-piece to be forged is installed to the platform.

Owner:SHANGHAI JIAO TONG UNIV

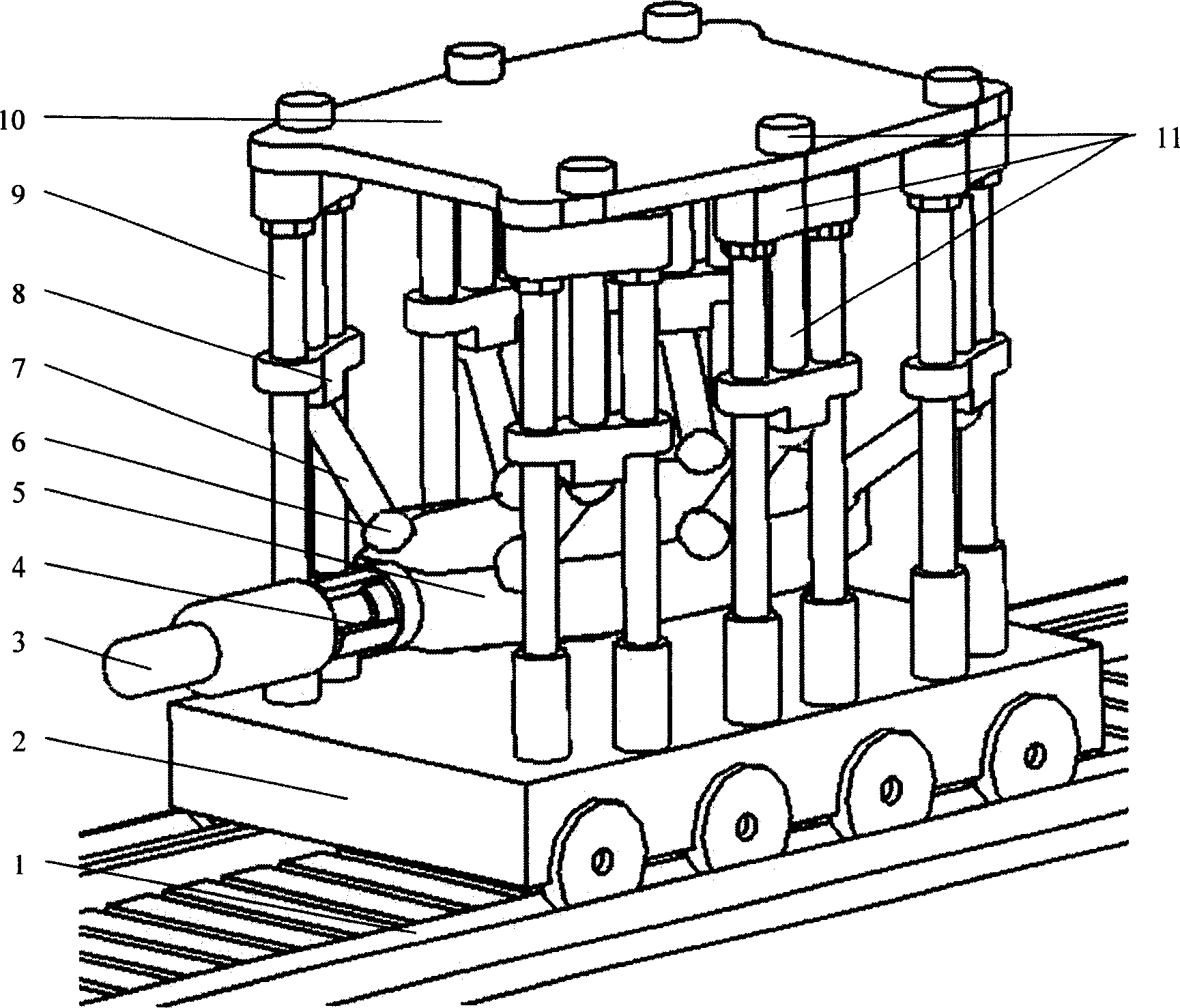

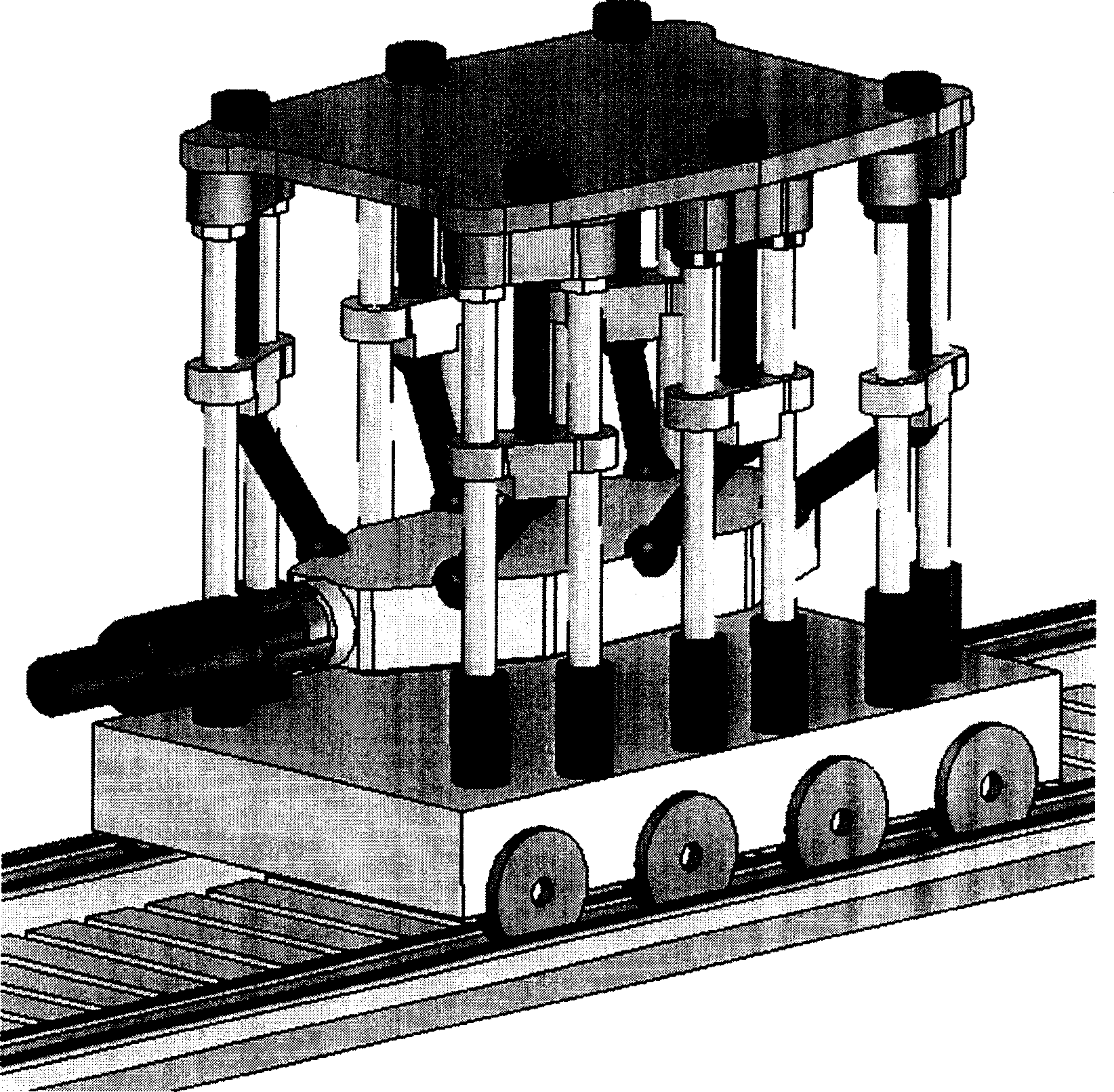

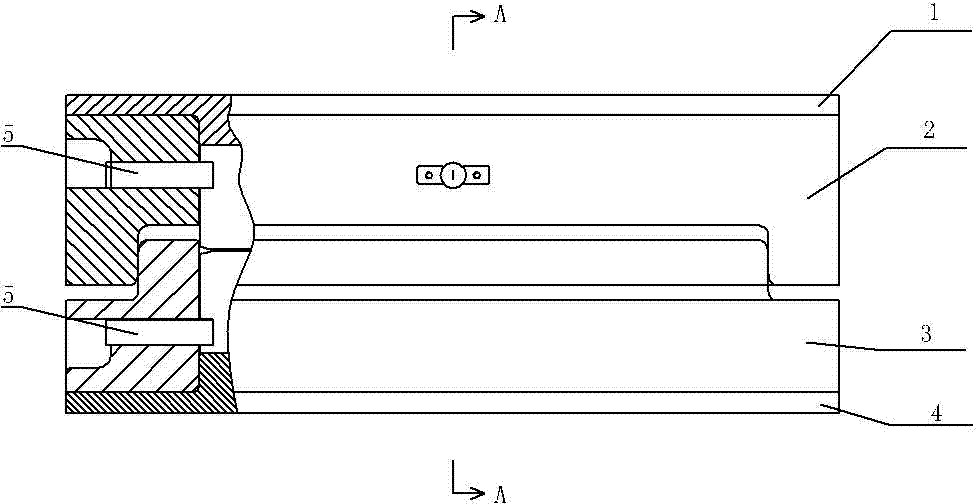

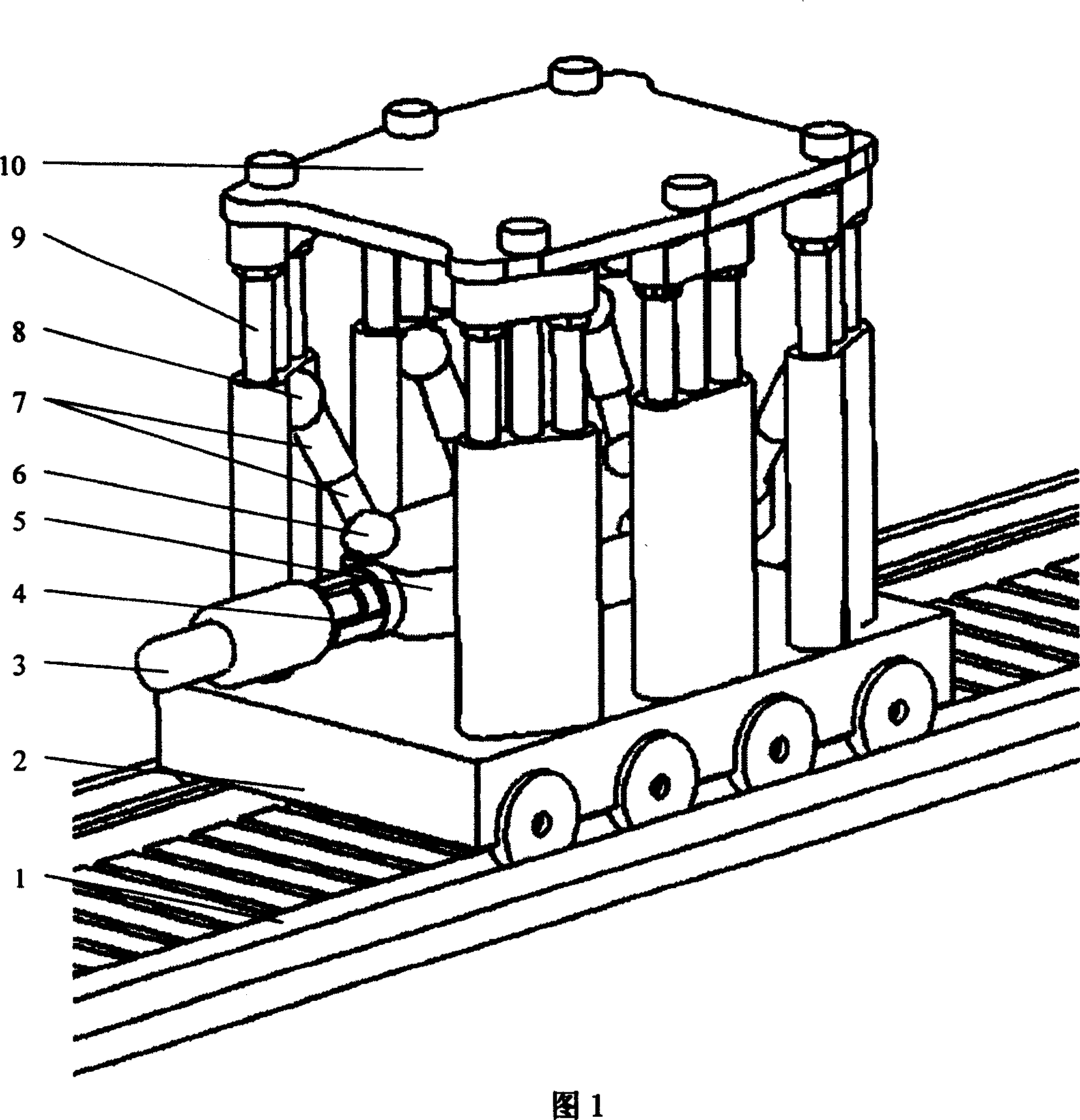

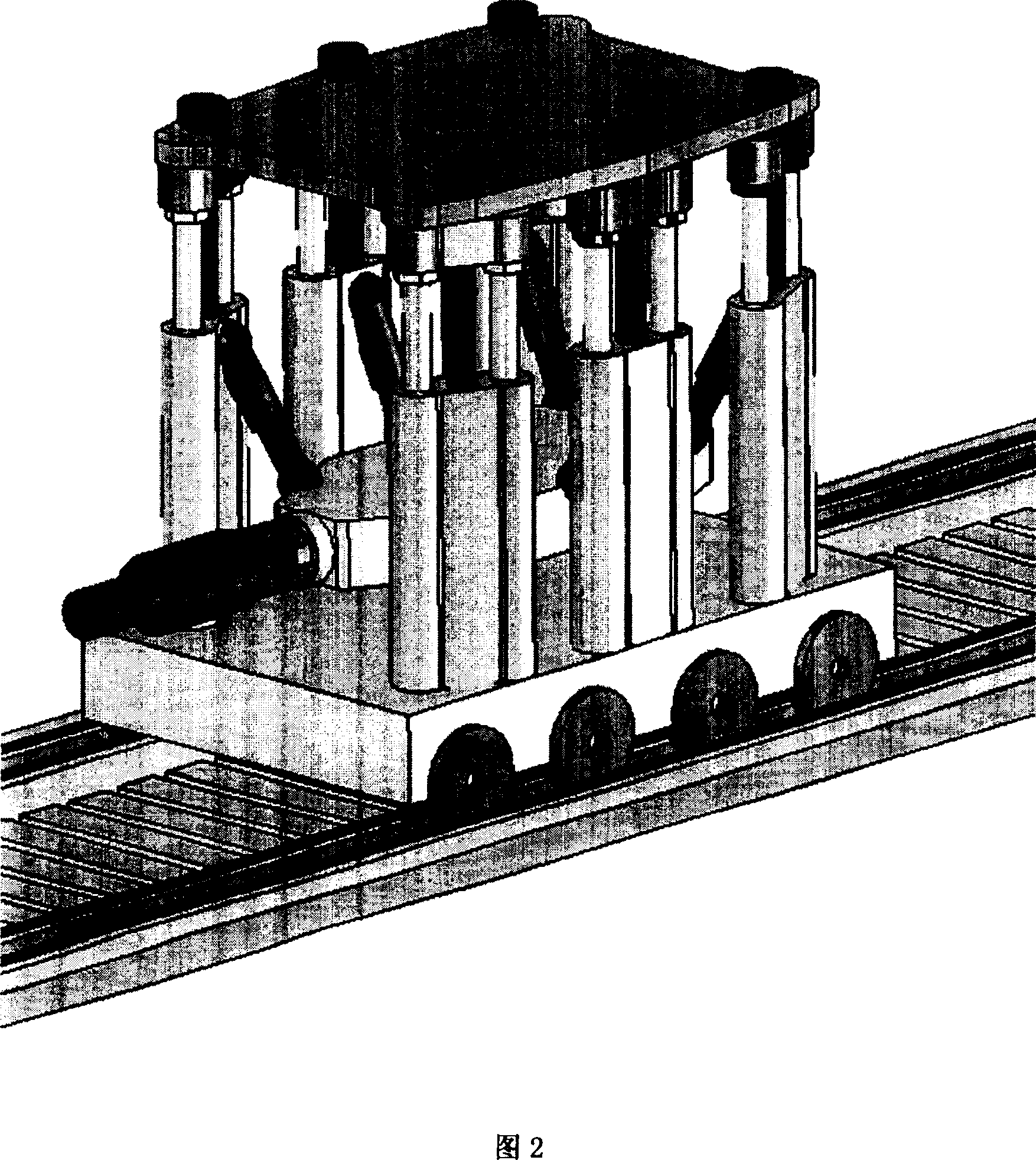

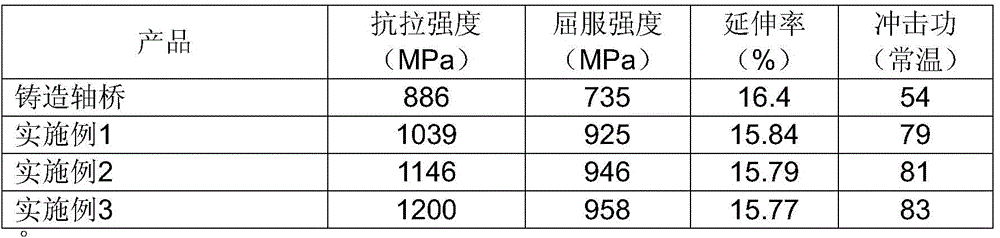

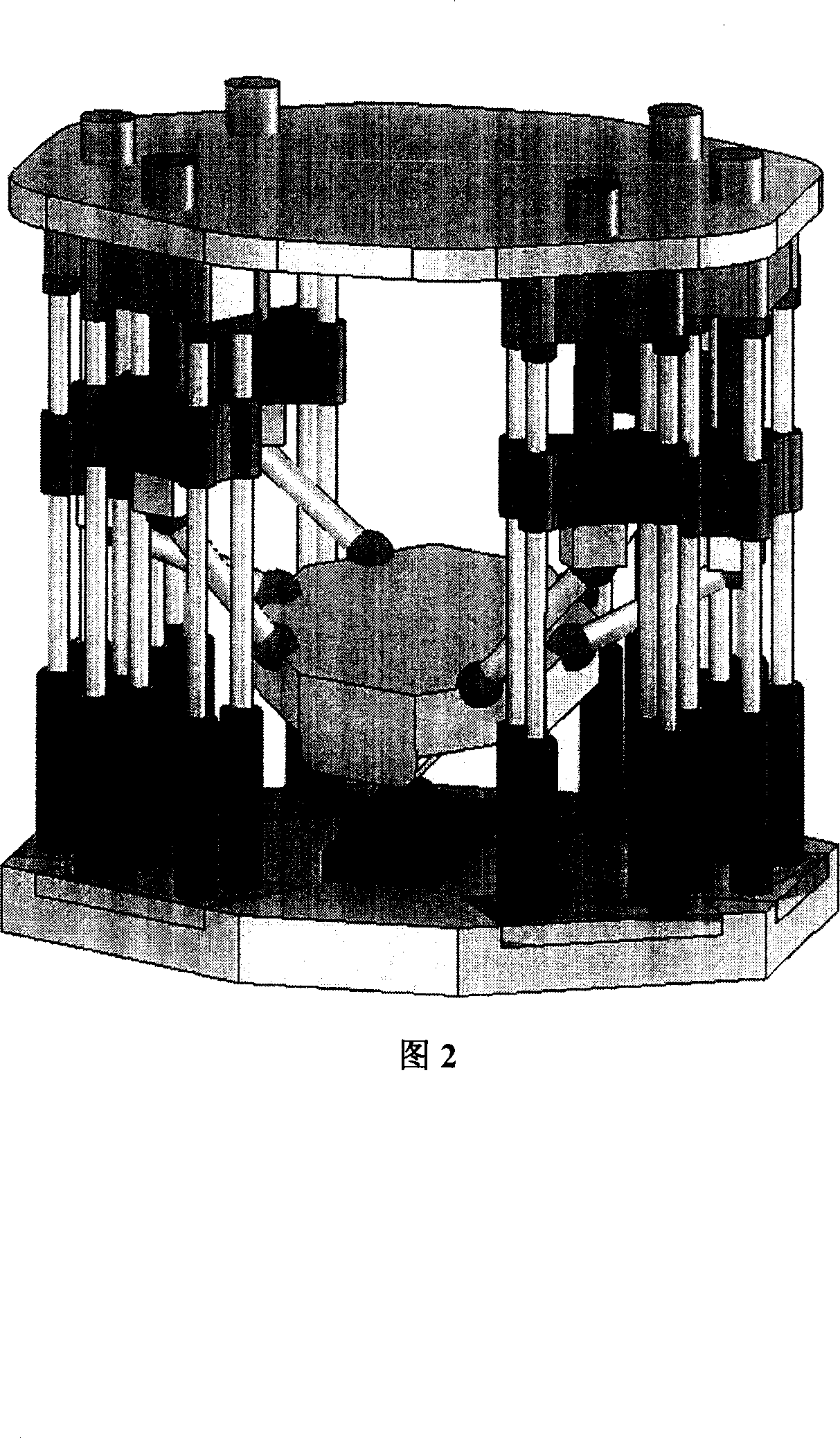

Double-ball joint telescopic six-dimensional parallel forging operation machine

InactiveCN1772411AGuarantee forging qualitySimple structureForging/hammering/pressing machinesHydraulic cylinderEngineering

The double-ball joint telescopic six-dimensional parallel forging operation machine consists of six identical fixed ball joints, six identical hydraulic cylinders, six identical dynamic ball joints, one claw beam platform, one clamp, one upper platform, and six sets of identical uprights. The six sets of identical uprights are configured symmetrically on the large walking chassis, and each of the upright set is connected to one hydraulic cylinder via one fixed ball joint, the hydraulic cylinder is then connected via one dynamic ball joint to the claw beam platform, these six dynamic ball joints are configured symmetrically on the large walking chassis in the mode corresponding to that of the six upright sets, and the clamp for grasping forging is mounted onto the claw beam platform. The present invention utilizes six hydraulic cylinders for great tonnage operation force and six operation motion, and realizes the multiple bearing operation of large forging at low cost.

Owner:SHANGHAI JIAO TONG UNIV +1

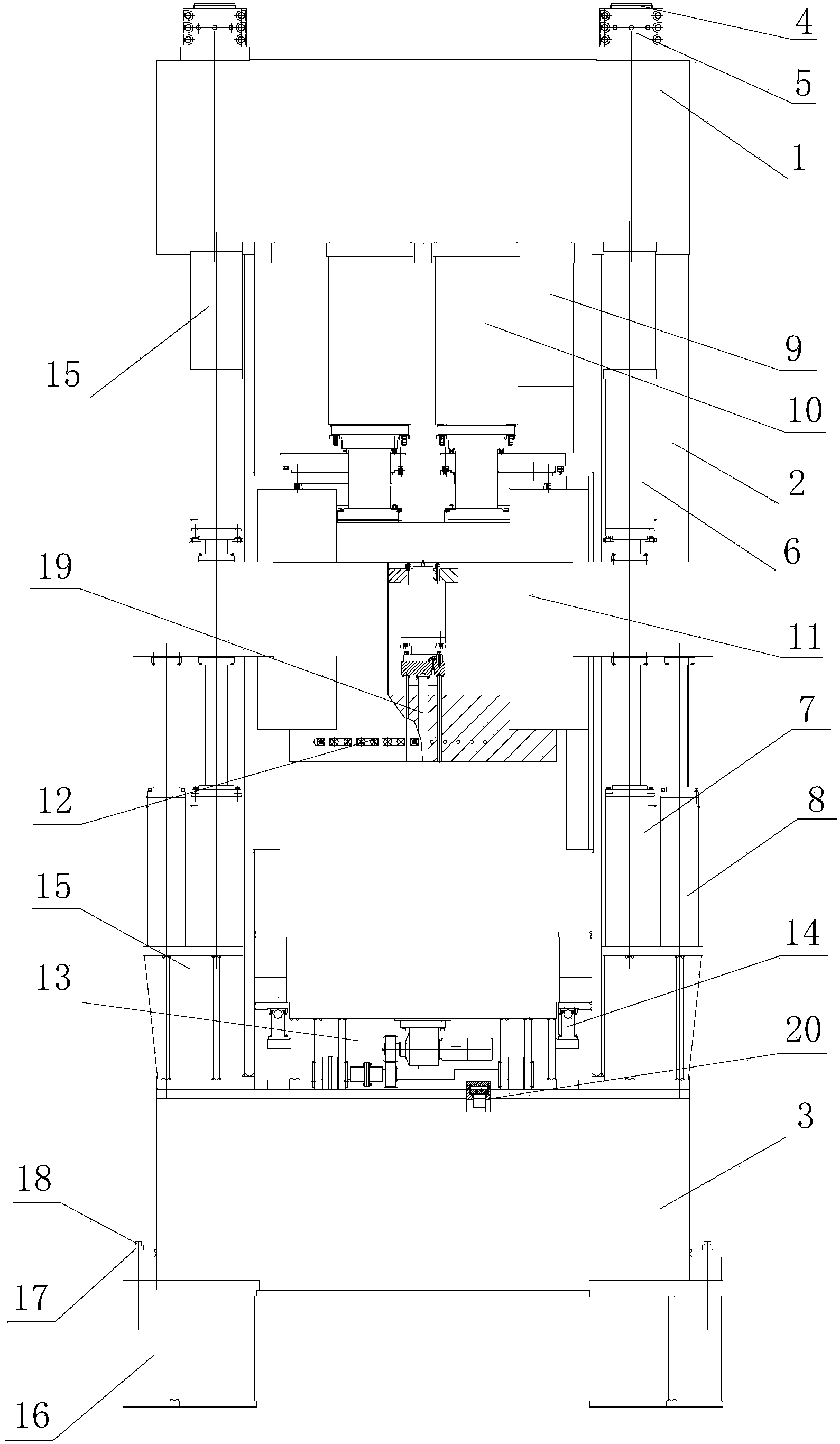

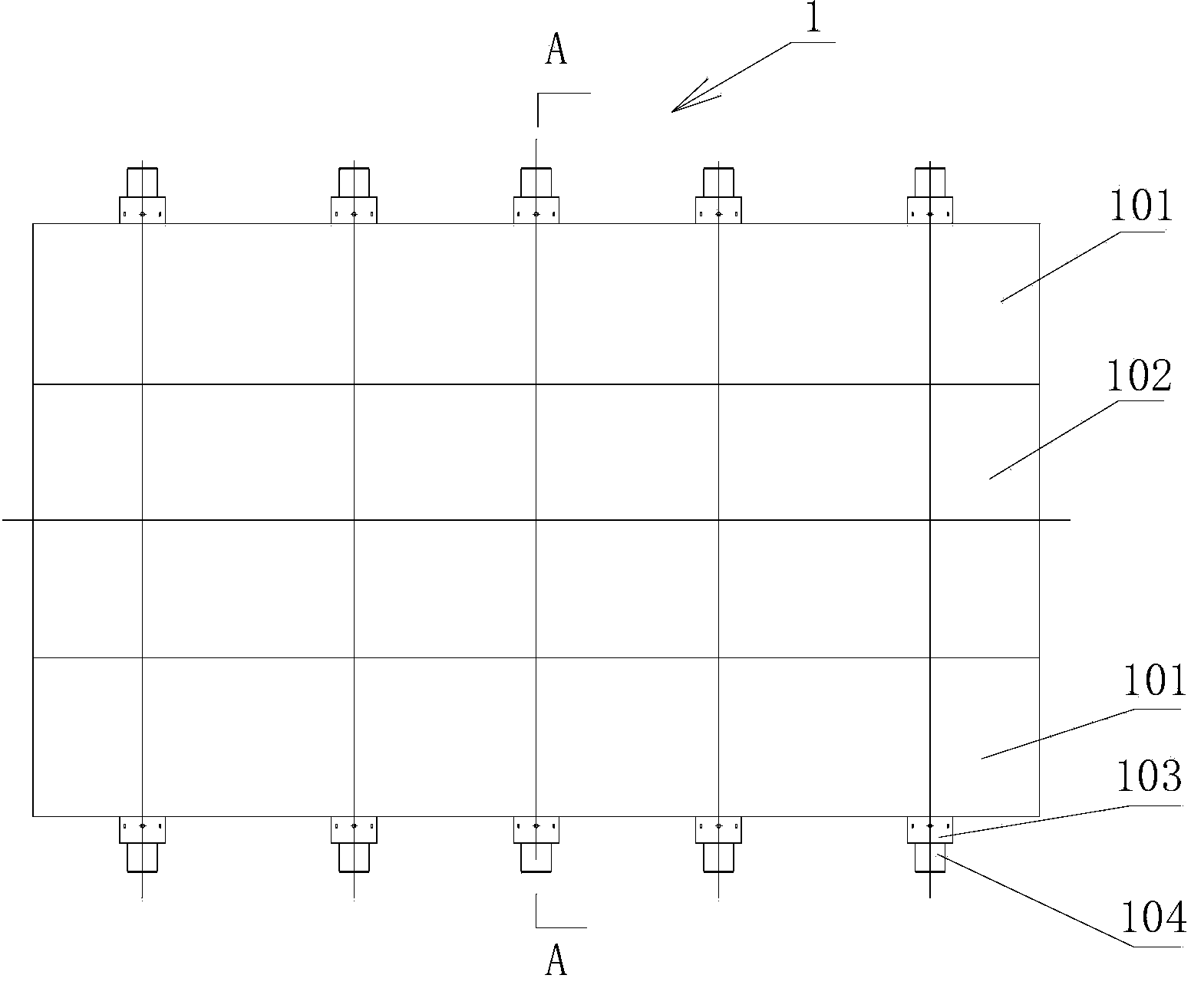

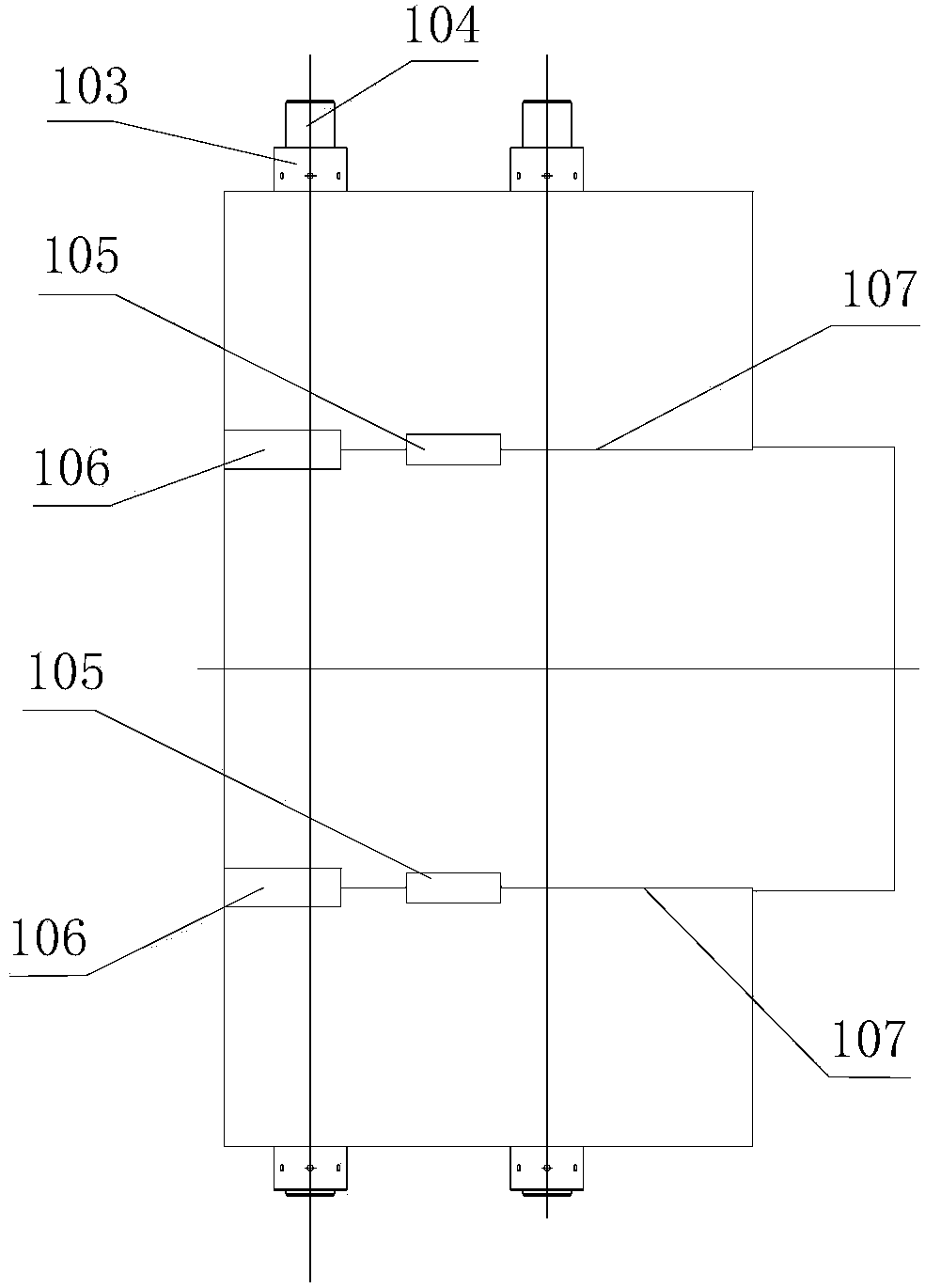

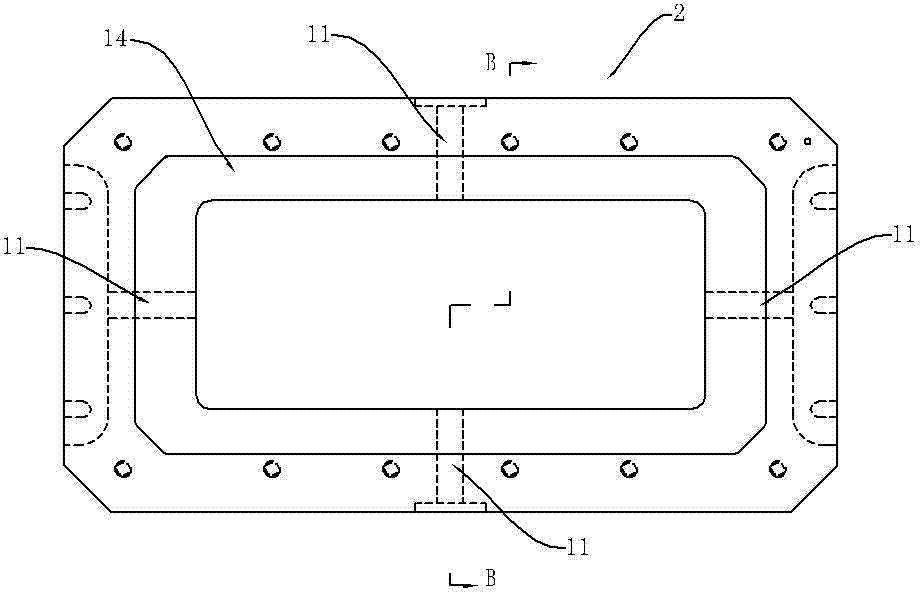

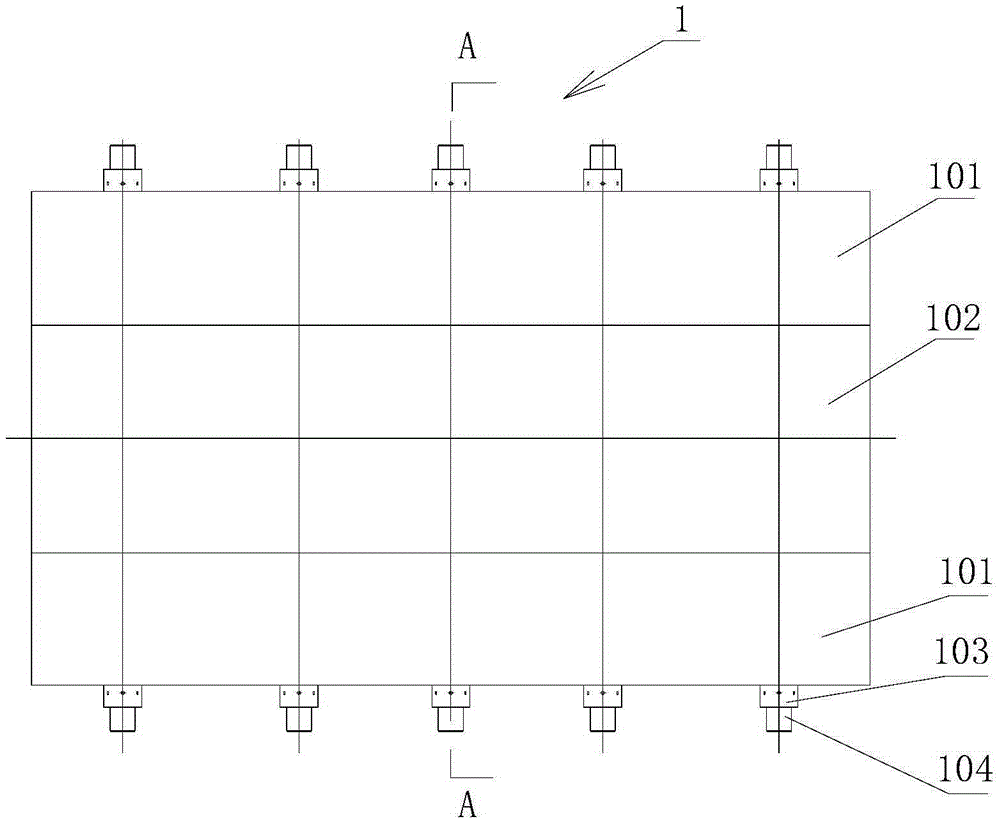

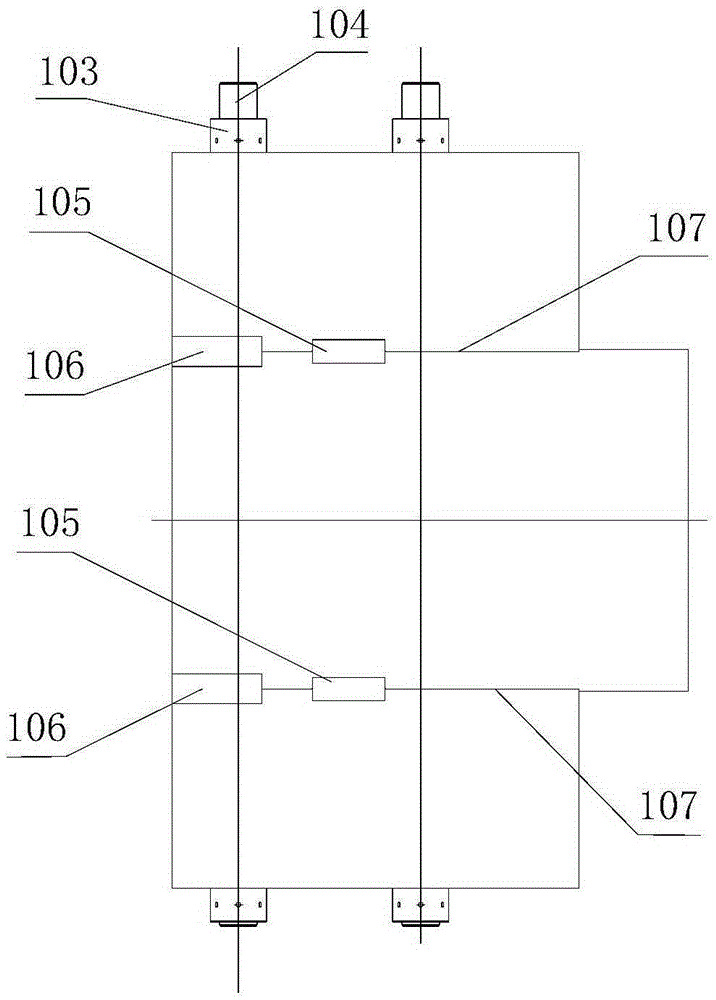

Heavy-duty isothermal forging hydraulic press

ActiveCN103447434AReduce manufacturing costHigh leveling accuracyForging/hammering/pressing machinesForging press detailsAviationLeveling effect

The invention relates to a heavy-duty isothermal forging hydraulic press, which comprises an upper transverse beam, a lower transverse beam, upright posts, a main cylinder, side cylinders and a slide block, wherein an upper baseplate is fixed on the lower plane of the slide block; and a movable workbench is arranged on the lower transverse beam. The heavy-duty isothermal forging hydraulic press is characterized in that the upper transverse beam and the lower transverse beam form a combined beam body structure; leveling cylinders are fixed on the four corners of the upper end of the upper transverse beam and the upper end of the lower transverse beam; each leveling cylinder is provided with an independent leveling control system; an upper knock-out device is arranged on the slide block; movable workbench positioning mechanisms are arranged on the lower part of the movable workbench body and in the lower transverse beam; and the movable workbench body is further provided with a movable workbench clamping device. The heavy-duty isothermal forging hydraulic press is characterized in that a combined transverse beam is light in weight and is convenient to transport and produce, and the manufacturing cost can be reduced; a leveling effect is achieved via the leveling cylinders, the leveling response time is shortened, and energy is saved greatly; through the upper knock-out device, successful demolding of workpieces can be realized, and the workpiece forging and pressing quality is ensured; and accurate positioning and stable running of a press workbench can be realized, and the production requirement of forging equipment for heavy-duty aviation forgings is met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

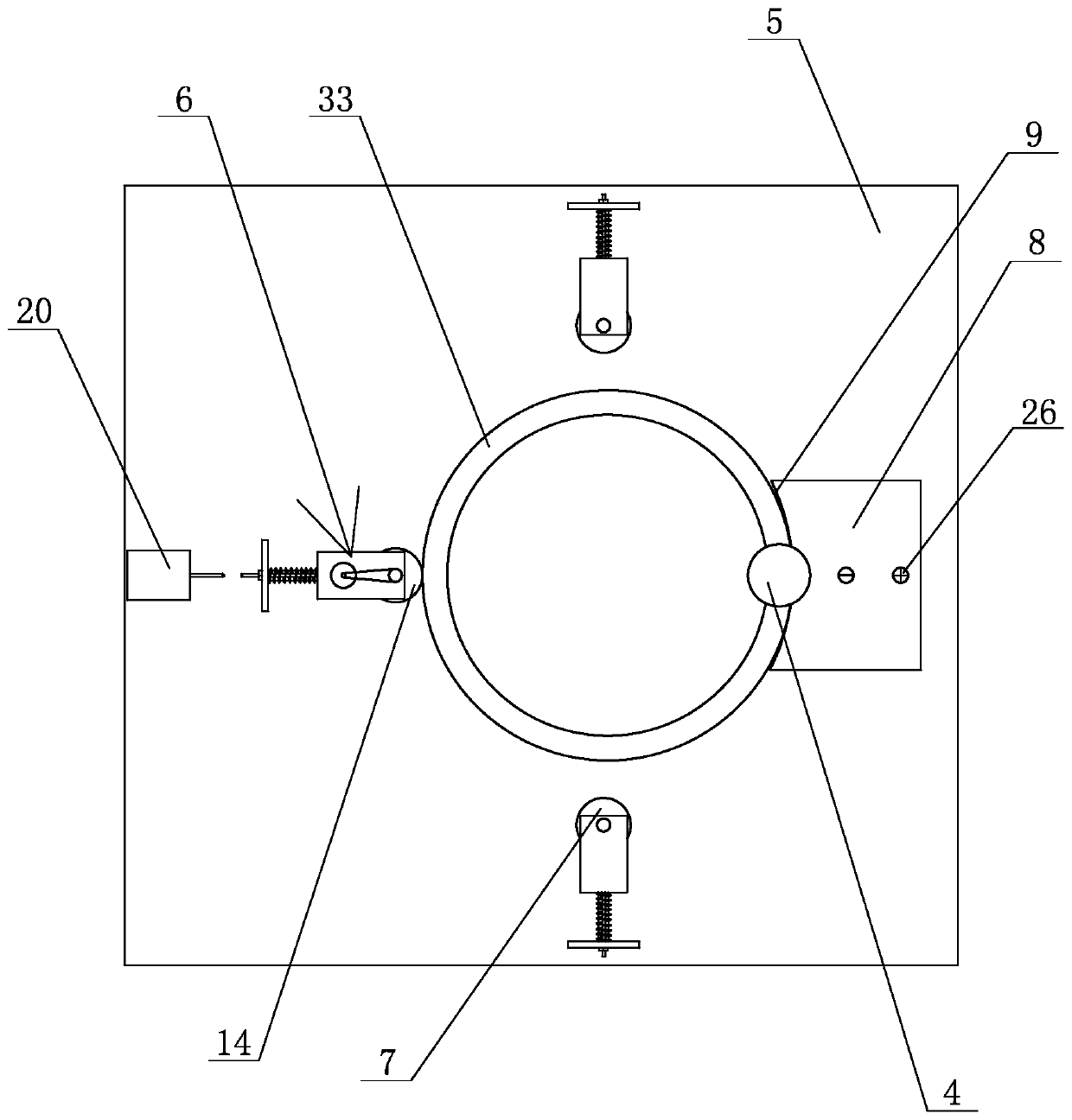

Six-dimensional parallel forging press

InactiveCN1745934ARealize multi-directional forgingGuarantee forging qualityForging press detailsForging press drivesEngineeringForge

A 6D parallelly connected high-power forge press is composed of 6 linear drive systems, one movable platform and the join mechanism between said linear drive systems and movable platform. Said linear drive systems are jointed to upper platform. Each drive system has a vertical column as its guide track and can drive a jointer connected to one end of a connecting rod via an upper spherical hinge. Another end of said connecting rod is connected to movable platform via a lower spherical hinge. A punch head is installed to the movable platform.

Owner:SHANGHAI JIAO TONG UNIV

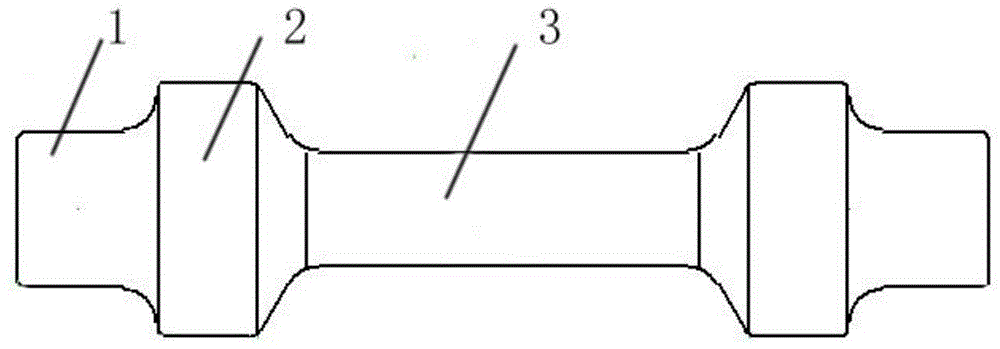

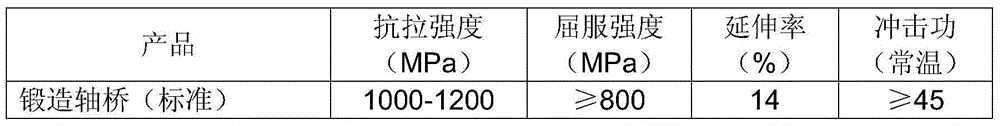

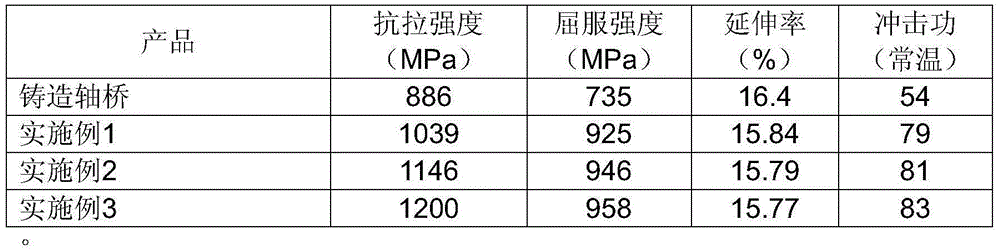

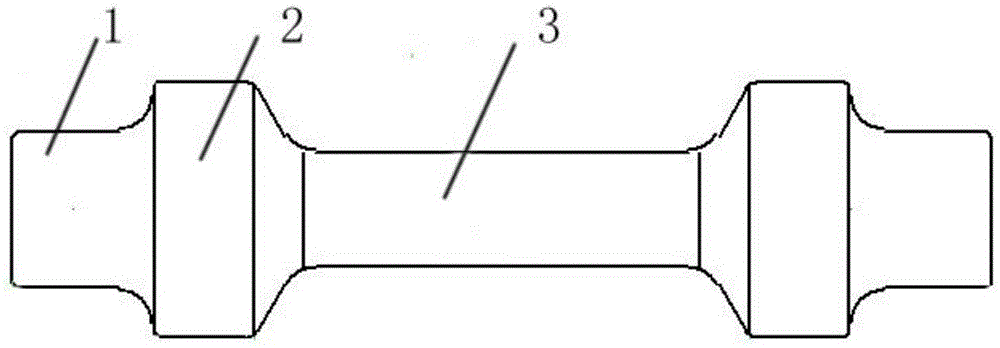

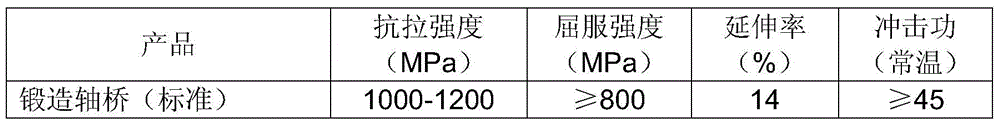

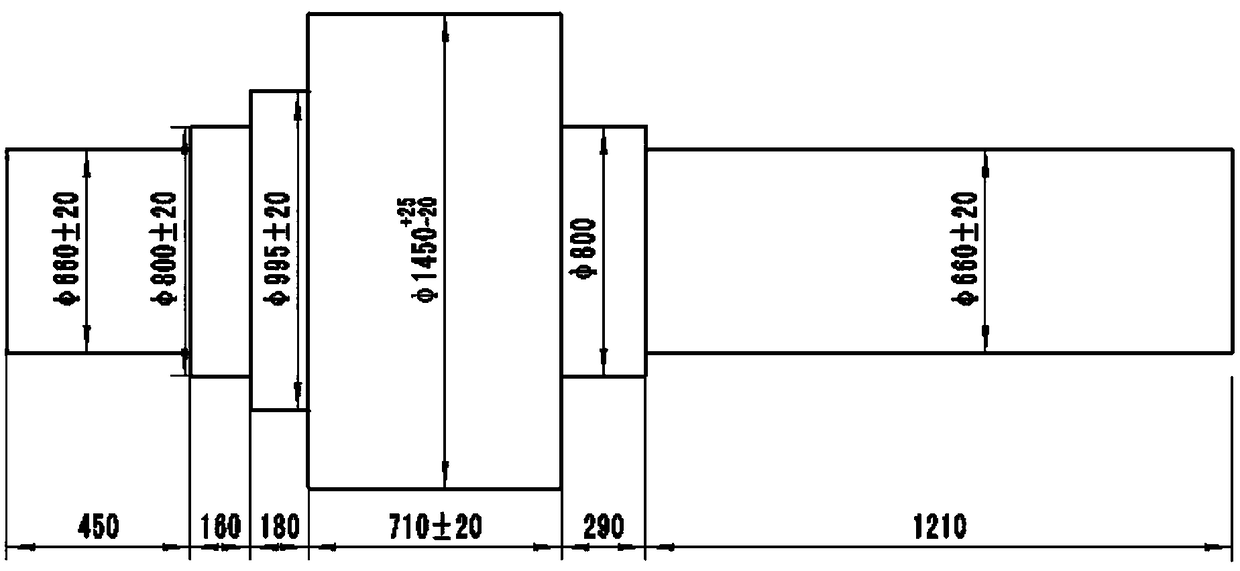

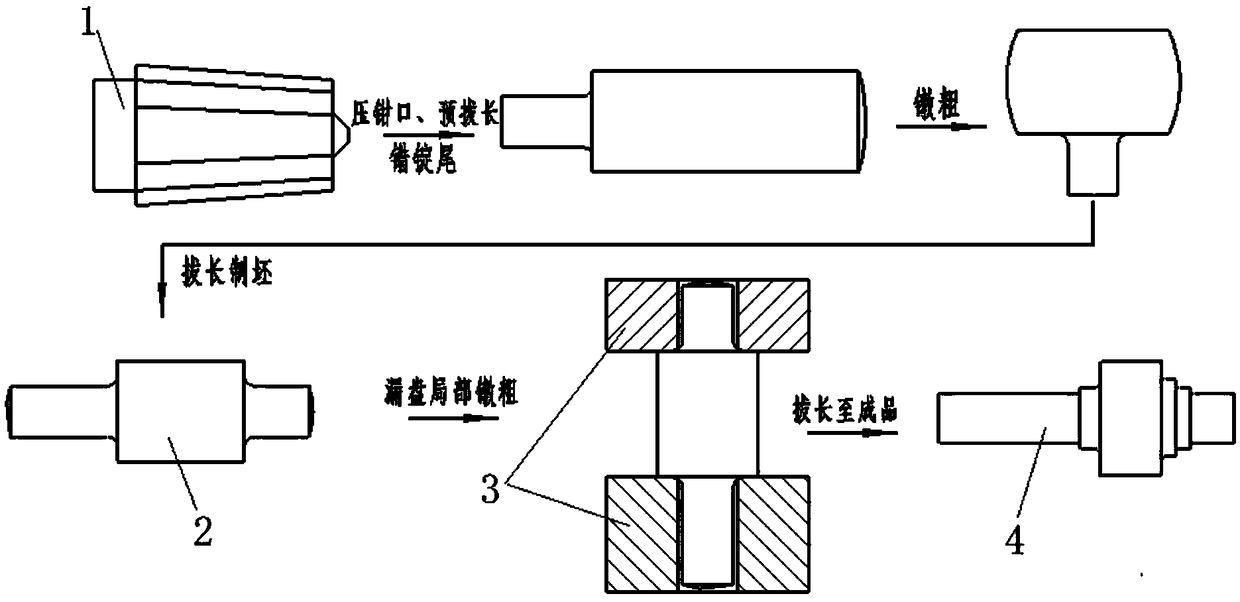

Preparation process of modern track low-floor motor train large-scale integral forging axle

ActiveCN104959503AImprove mechanical propertiesMeet the mechanical performance indexRailway componentsMetal-working apparatusElectric arc furnaceIngot

Provided is a preparation process of a modern track low-floor motor train large-scale integral forging axle. The preparation process includes that 34CrNiMo6 is taken as the raw material and is subjected to arc furnace melting and vacuum smelting to obtain steel ingot, and a blank material is obtained through electroslag re-dissolving; after the two ends of the blank material are drawn to be pre-forging blank materials by a free forging hammer, the pre-forging blank materials are preheated by an electrothermal far-infrared heating furnace and then is heated and insulated by a natural gas furnace; an axel head and axel shoulders are forged on the heated pre-forging blank materials, leftover material edges are removed, the heated pre-forging blank materials with the axel head and axel shoulders are returned to the furnace to be heated, the waist part is drawn out by the free forging hammer, and then the heated pre-forging blank materials with the drawn-out waist part are returned to the furnace to be heated, the heated pre-forging blank materials with the axel head, the axel shoulders, and the drawn-out waist part are put into an axel forging forming die to be integrally forged and formed to obtain a product. The preparation process is advantageous in that the raw material components are strictly controlled to meet the mechanical performance indexes of the product; and the integral forging forming is carried out after the local pre-forging, the forging quality is guaranteed, the waste can be reduced, the yield is improved, and the product performance meets the national standard.

Owner:锦州捷通铁路机械股份有限公司

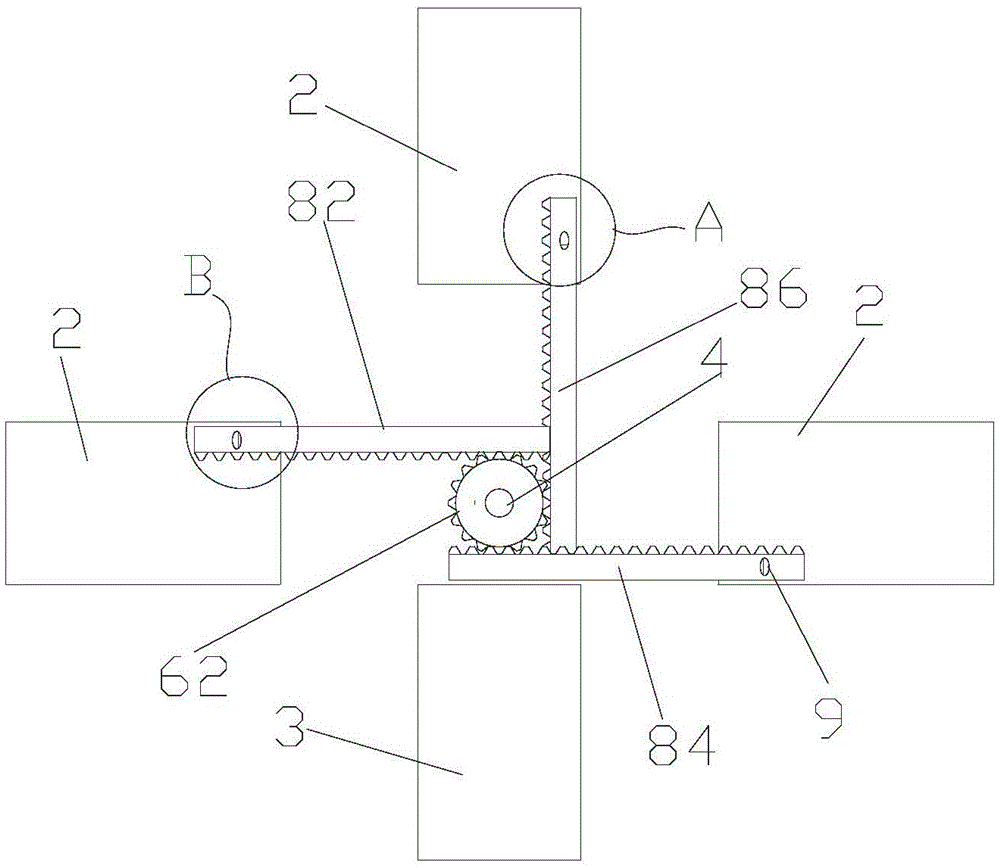

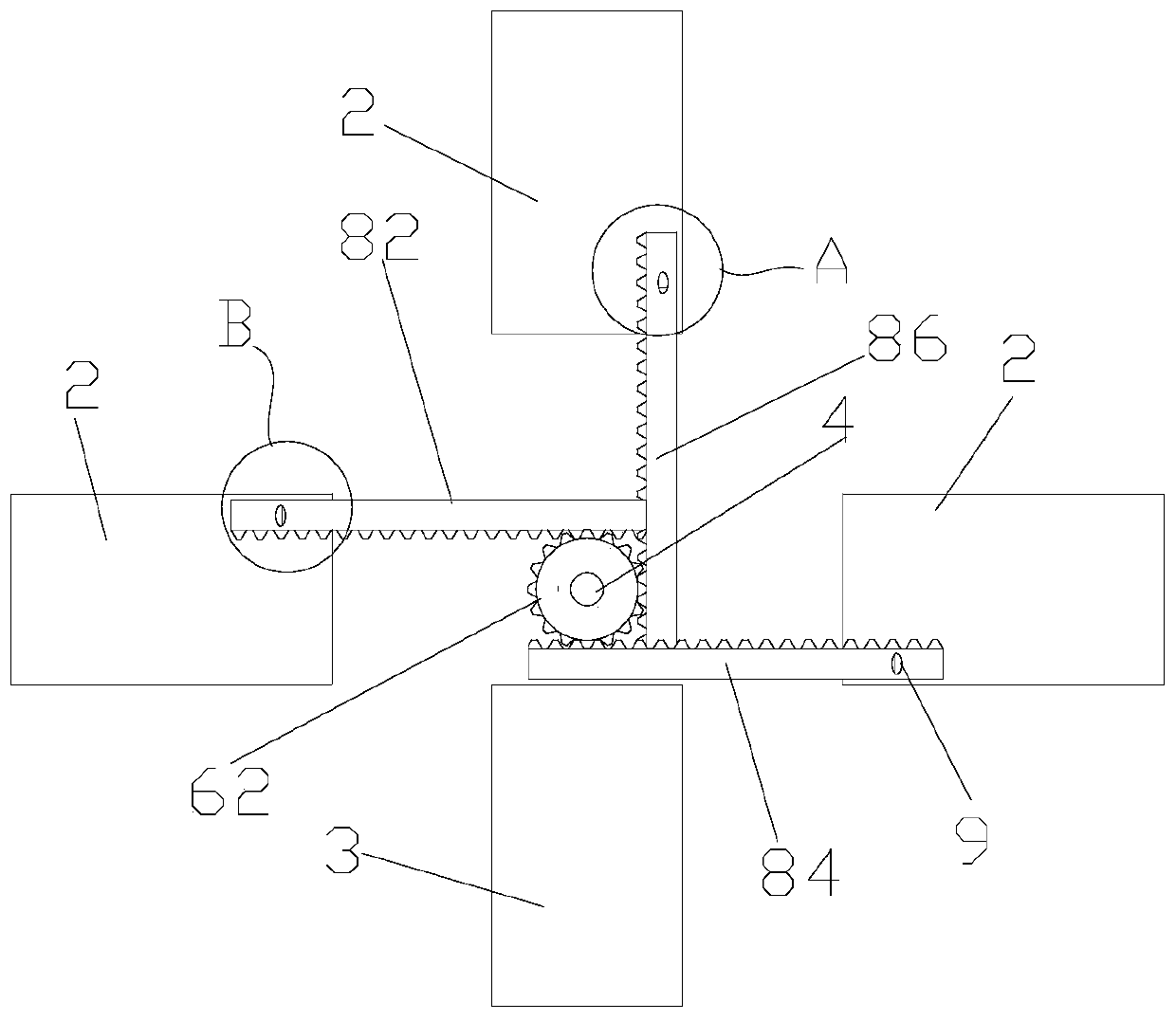

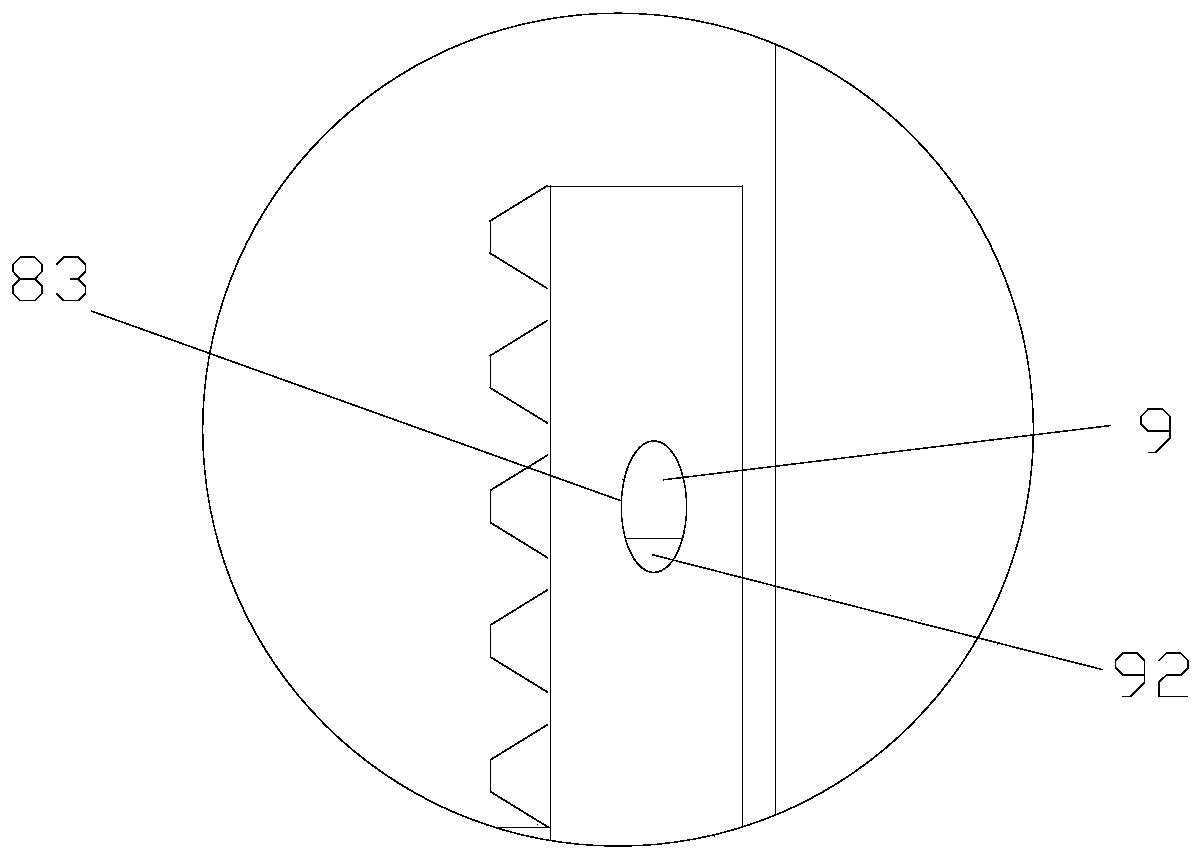

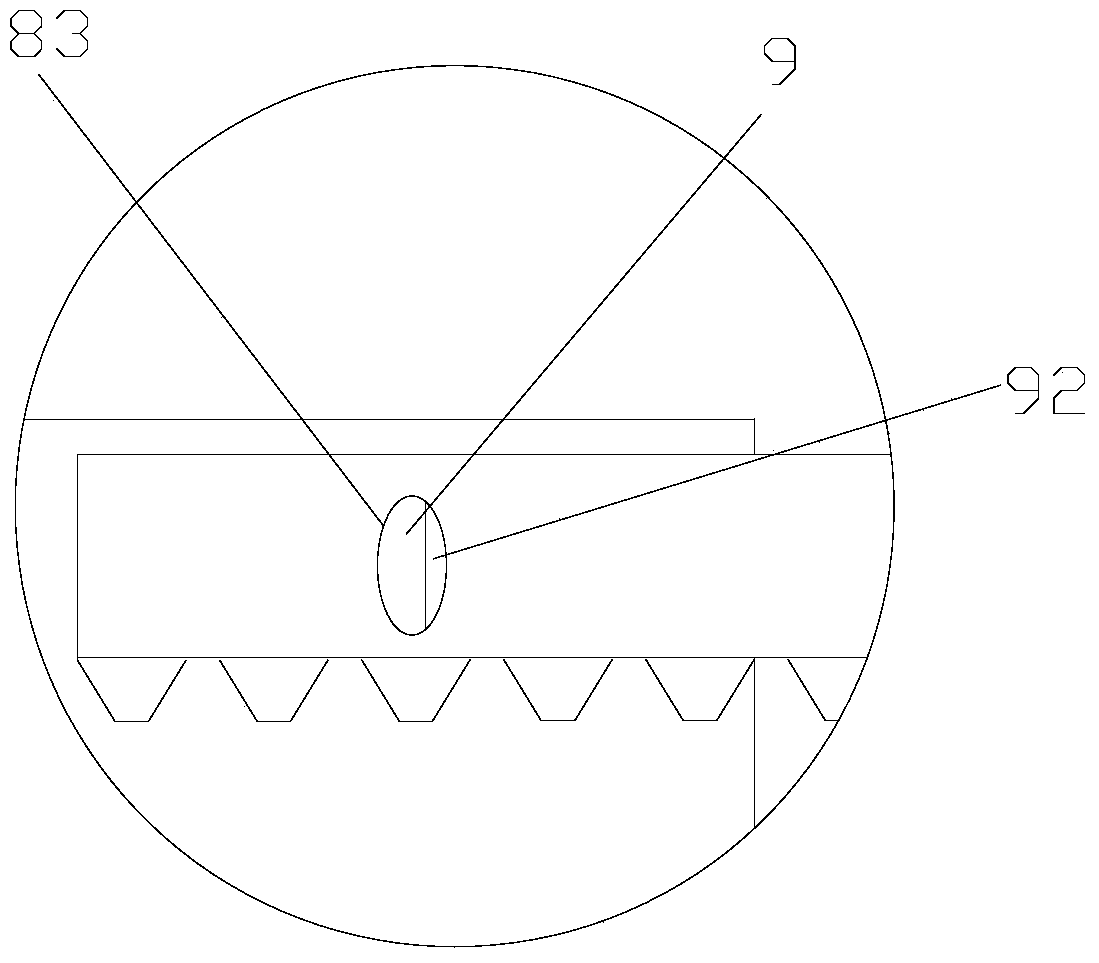

High-synchronicity forging equipment

The invention relates to high-synchronicity forging equipment. The equipment comprises three hammer units which are distributed in a T shape and arranged in a manner that the heads of the hammer units face the center and a driving device which drives the hammer units to move towards the center or the outer portion. The equipment is characterized by further comprising a transmission device for connecting the driving device with the hammer units; the transmission device comprises two gears which are coaxially integrated; and one of the two gears is at least in transmission fit with a rack, and the other one of the two gears is at least in transmission fit with two racks; and the racks are correspondingly connected with the hammer units. According to the forging equipment, the three hammer units which are distributed in the T shape can be matched with a fixed hammer unit for beating forging, and the gears and the racks are transmitted in a matched manner; and due to the fact that the two gears are coaxially integrated, the racks can be driven to synchronously move, and it is guaranteed that the hammer units synchronously carry out hammering and retreating; and the equipment is simple in structure and high in synchronicity.

Owner:忻州市质量技术监督检验测试所

Forging machining process of parking gear

PendingCN112404914AReduce material wasteIncrease productivityMetal-working apparatusMachining processManufacturing engineering

The invention discloses a forging machining process of a parking gear, and relates to the technical field of gear machining. The problems that parking gear machining production efficiency is low, andmaterial waste is serious in the prior art are solved. The machining process comprises the following steps of blanking, outer circle turning, heating, blank making, center hole punching, hot precisionforging, connected skin turning, isothermal normalizing, shot blasting, scale saponification and cold extrusion. The forging process is adopted for parking gear machining, material waste is reduced,a cavity is machined through preforming, and a cake-shaped structure is formed through common preforming. An annular structure with a taper step is adopted and adapts to a product, and when a blank ismachined into the cavity, the peripheral wall of the opening end of the cavity is expanded outwards and inclines to form an opening face, the opening face horizontally extends towards the end face ofa cylindrical body to penetrate through the end face of the cylindrical body, and accordingly, a positioning boss is formed, axial positioning of a die and the blank is facilitated, and the subsequent forging quality is guaranteed. Through the design of the cavity, the forging force requirement of precision forging forming can be reduced.

Owner:SICHUAN ZHONGYOU MACHINERY

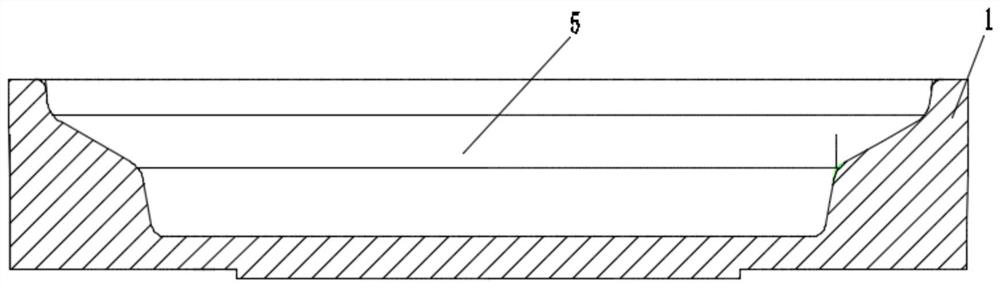

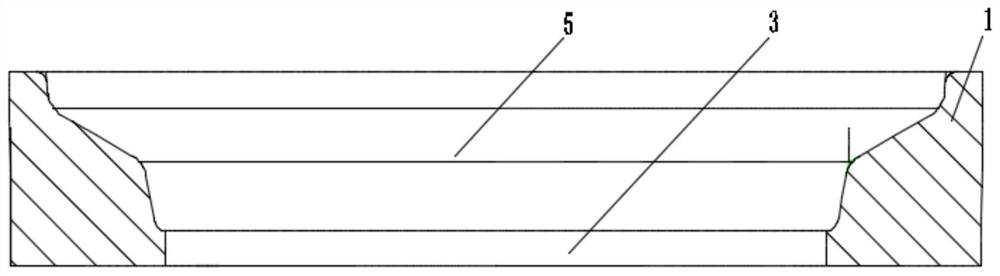

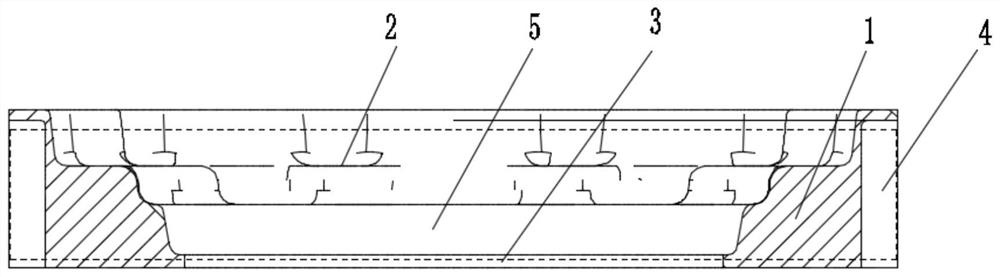

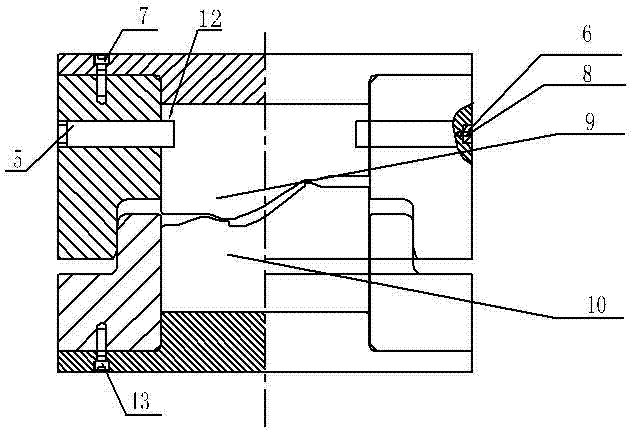

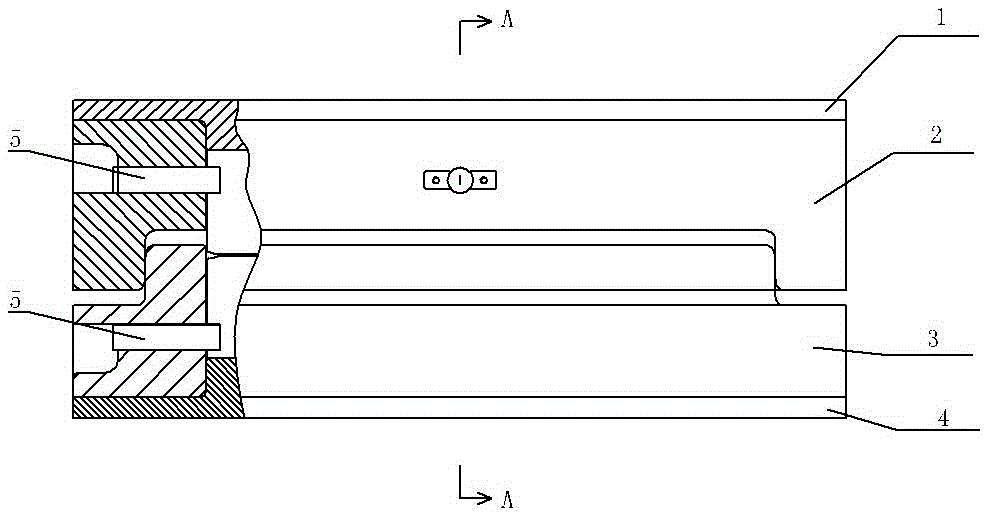

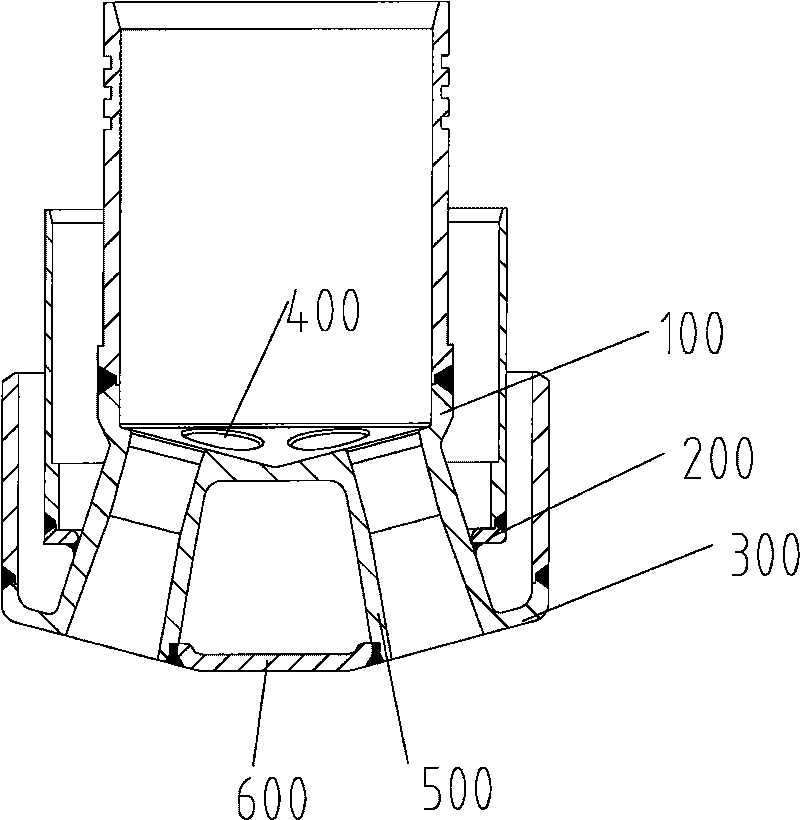

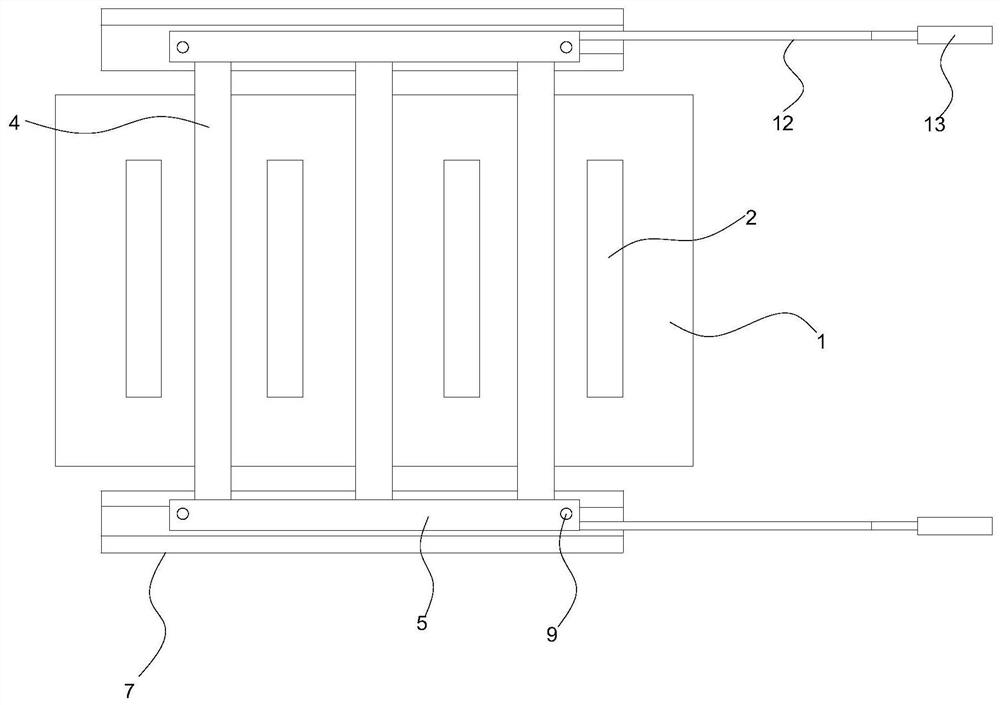

Mounting structure for forging die

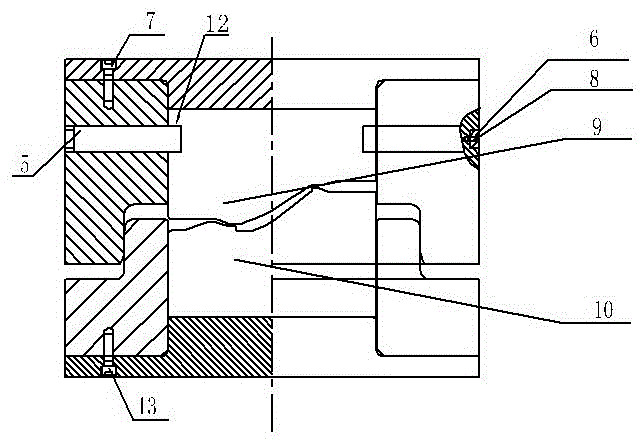

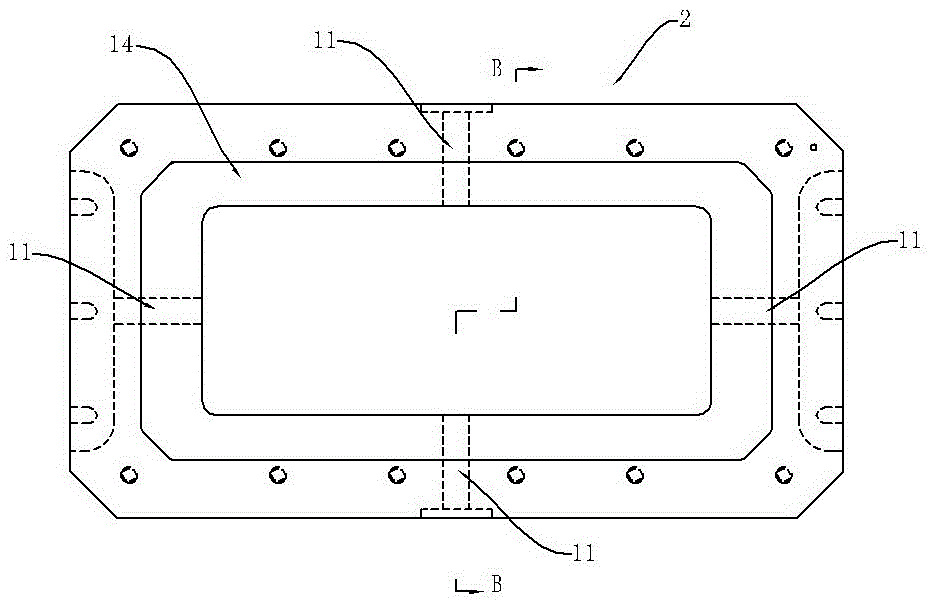

ActiveCN104493047AEliminate lateral forceReliable lockingForging/hammering/pressing machinesLocking mechanismForging

The invention provides a mounting structure for a forging die, and aims to solve the problem that the forging die cannot be mounted and locked reliably as the forging die is directly mounted on a conventional die seat serving as a mounting structure through a wedge iron locking mechanism. The mounting structure comprises a die seat and the forging die, wherein the die seat comprises an upper die seat and a lower die seat; the forging die comprises an upper die and a lower die; the mounting structure is characterized in that the upper die and the lower die are mounted in the upper die seat and the lower die seat respectively through an upper die sleeve and a lower die sleeve; the upper die and the upper die sleeve as well as the lower die and the lower die sleeve are respectively in clearance fit; locking of the upper die and the lower die is realized between the upper die and the upper die sleeve as well as between the lower die and the lower die sleeve respectively through hanging pin structures.

Owner:WUXI TURBINE BLADE

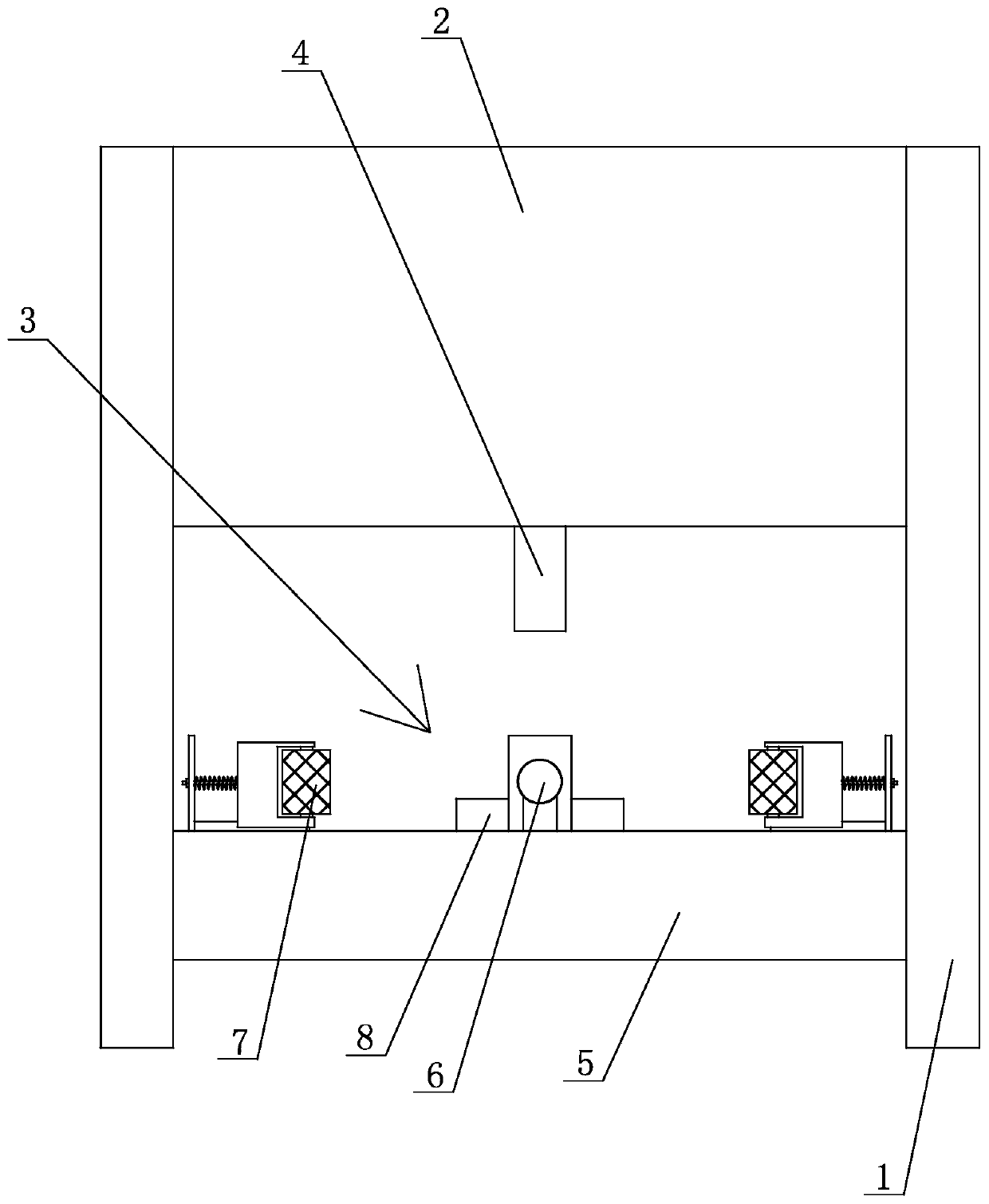

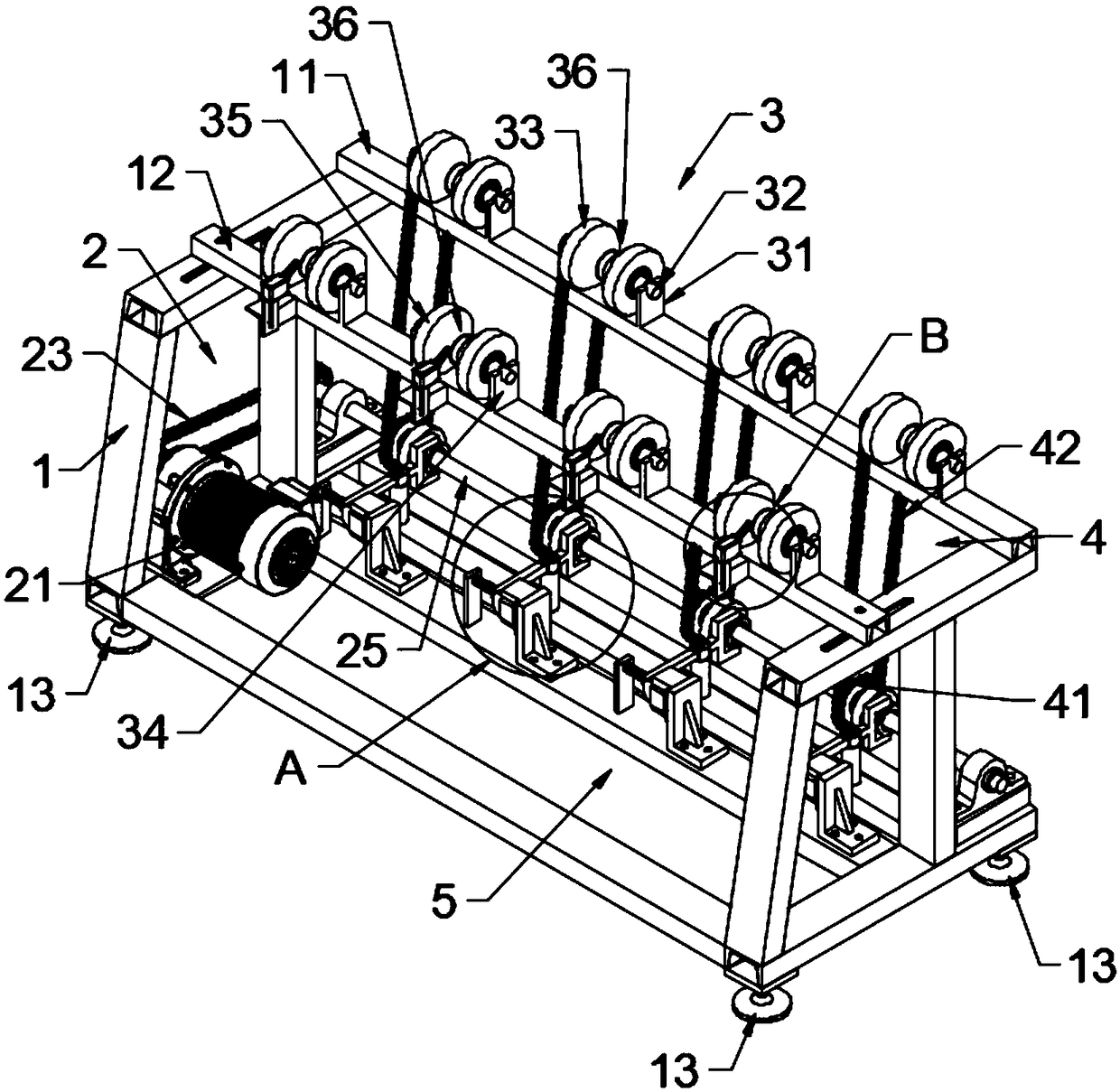

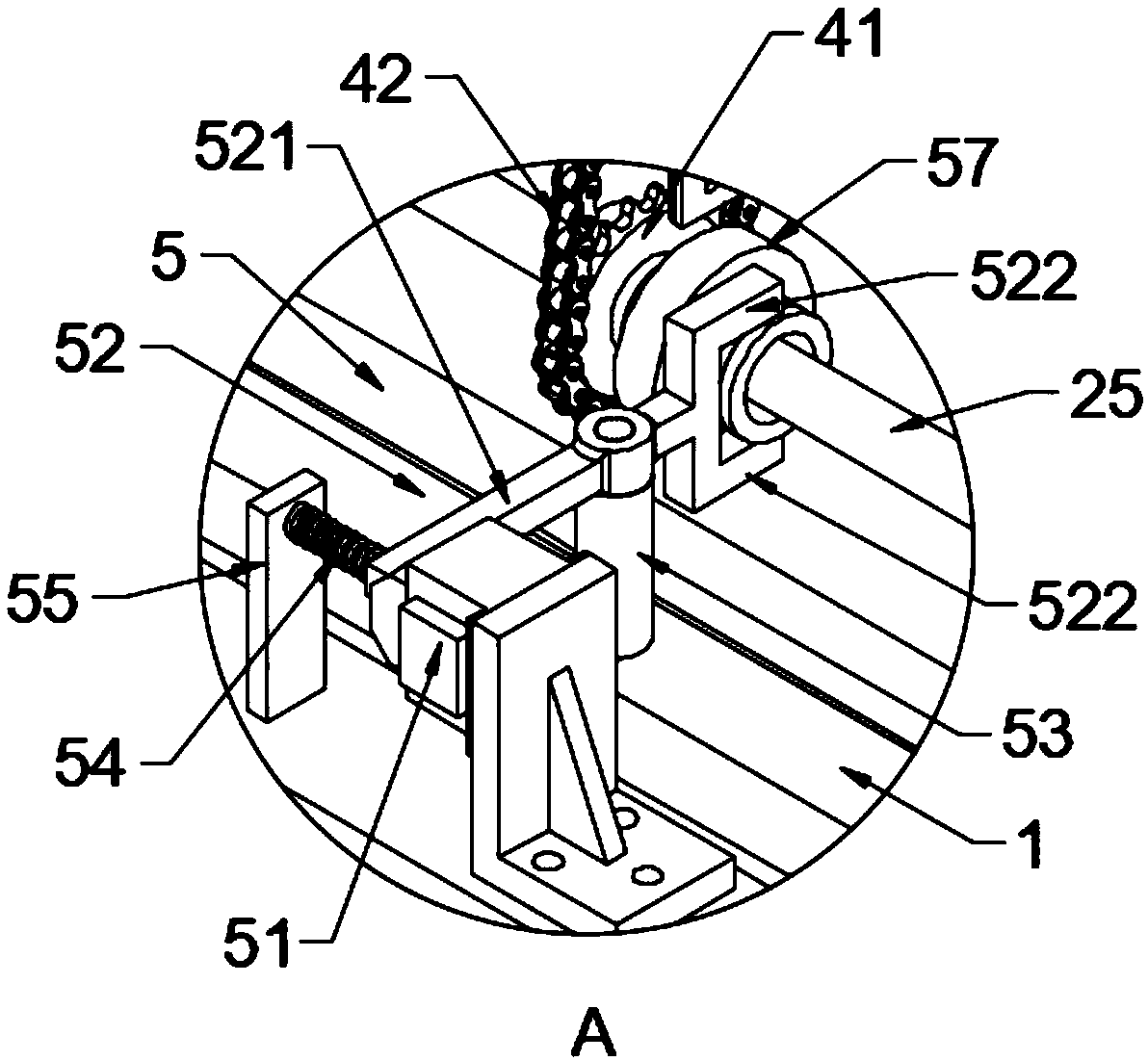

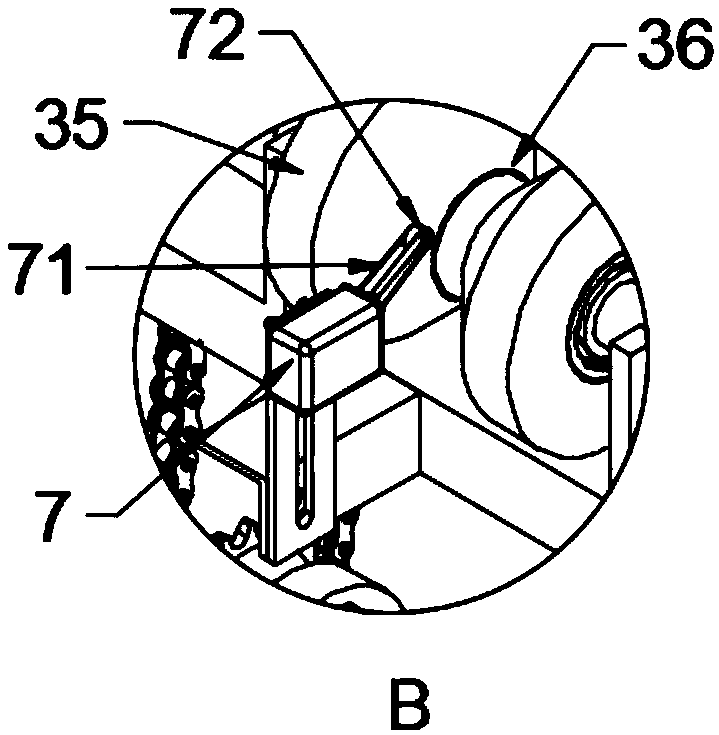

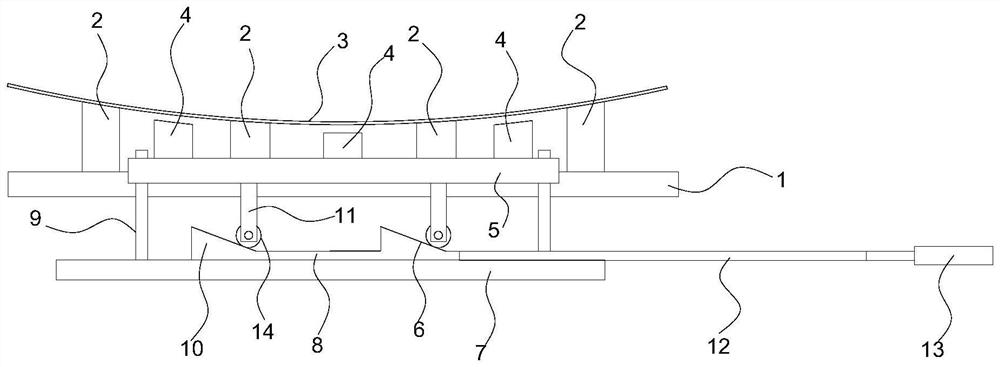

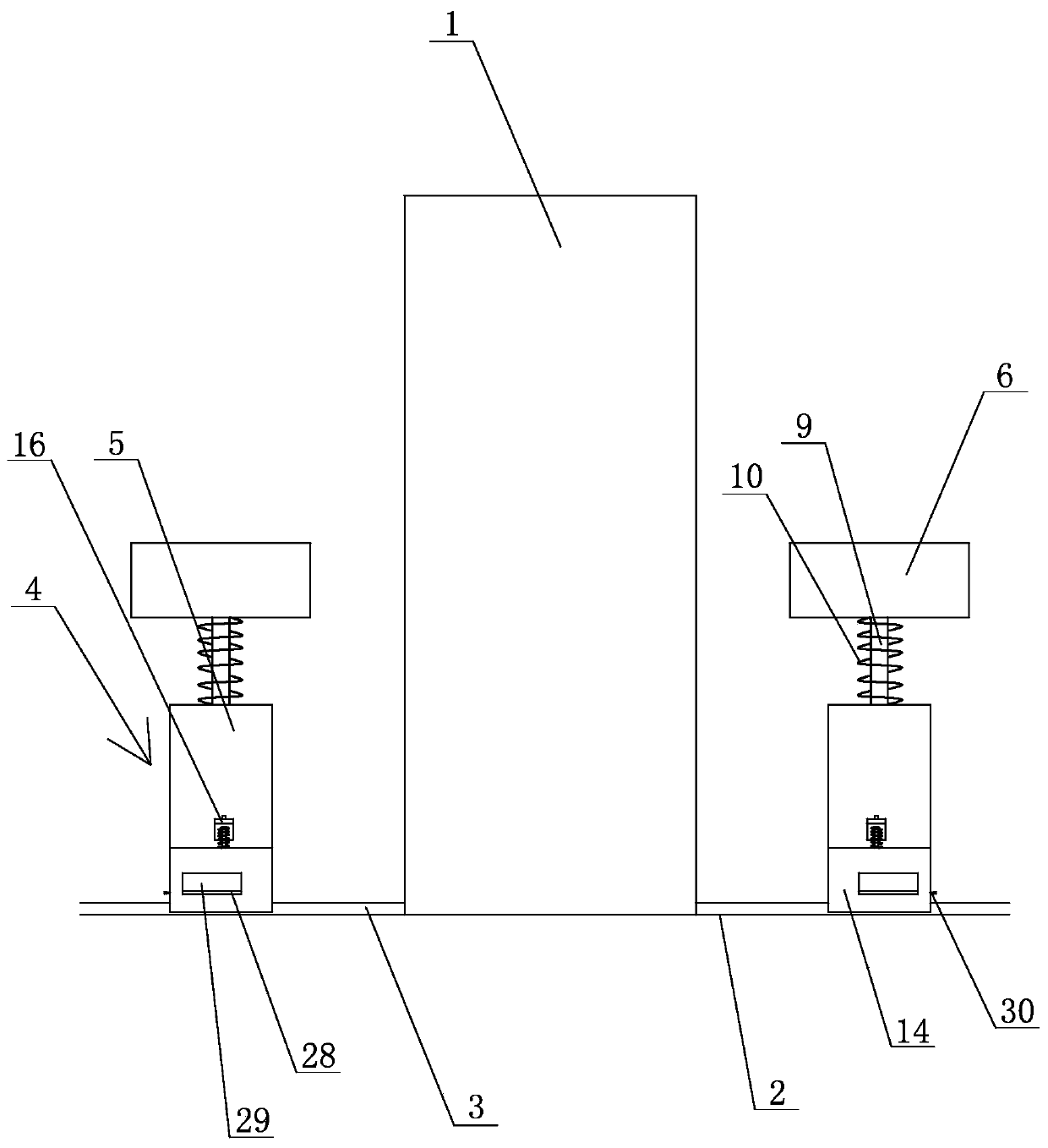

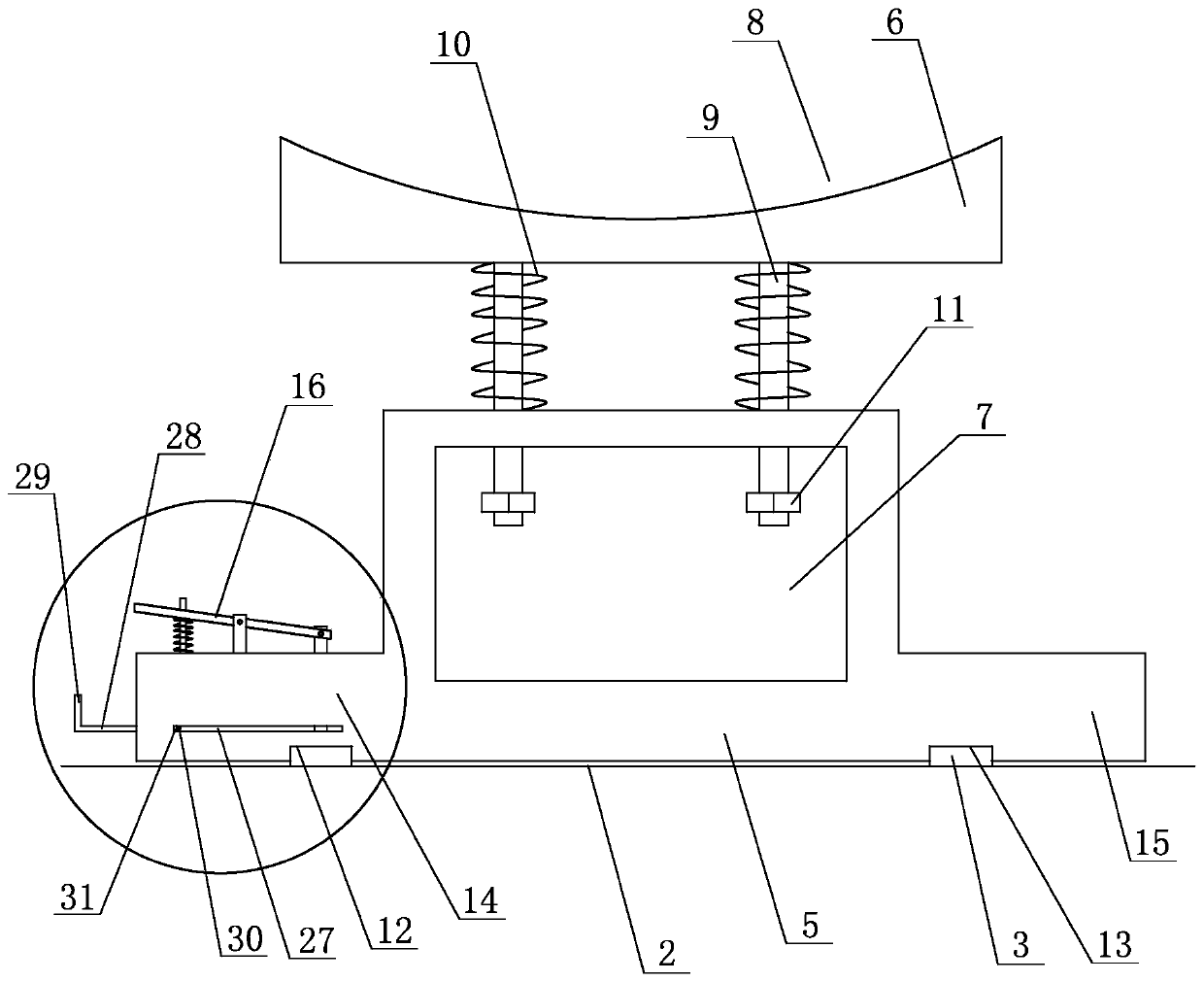

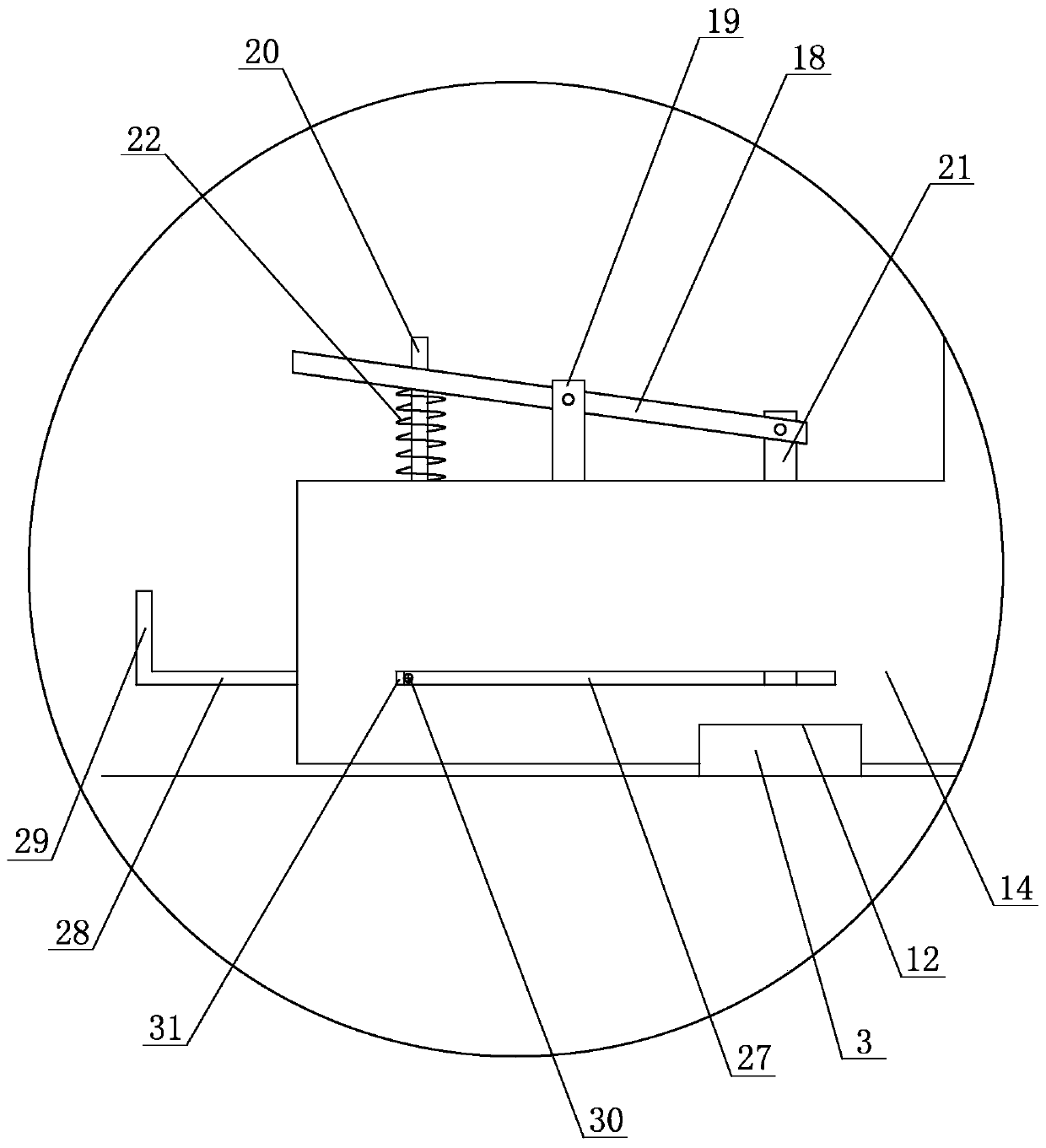

Forging device

PendingCN109967681AReduce labor intensityGuarantee forging qualityForging/hammering/pressing machinesEngineeringUltimate tensile strength

The invention discloses a forging device comprising a frame, a forging mechanism and a supporting mechanism. The forging mechanism is provided with a forging head, and the forging head is opposite tothe supporting mechanism; the forging device is characterized in that the supporting mechanism comprises a base, a limiting mechanism and two sets of support limiting rollers, wherein the limiting mechanism is arranged on the left side of the top surface of the base, a limiting block is arranged on the right side of the top surface of the base, the left side face of the limiting block is an arc-shaped surface, the limiting mechanism is opposite to the arc-shaped surface, and the forging head is arranged over the middle portion of the arc-shaped surface; and the two sets of the support limitingrollers are arranged between the limiting mechanism and the limiting block, each set of support limiting rollers are mounted on the base through a connecting mechanism, one set of the support limiting rollers are arranged to be adjacent to the front side face of the base, and the other set of support limiting rollers are arranged to be adjacent to the rear side face of the base. The forging device improves the forging efficiency and quality of products and reduces the labor intensity of operators.

Owner:江阴市劲松科技有限公司

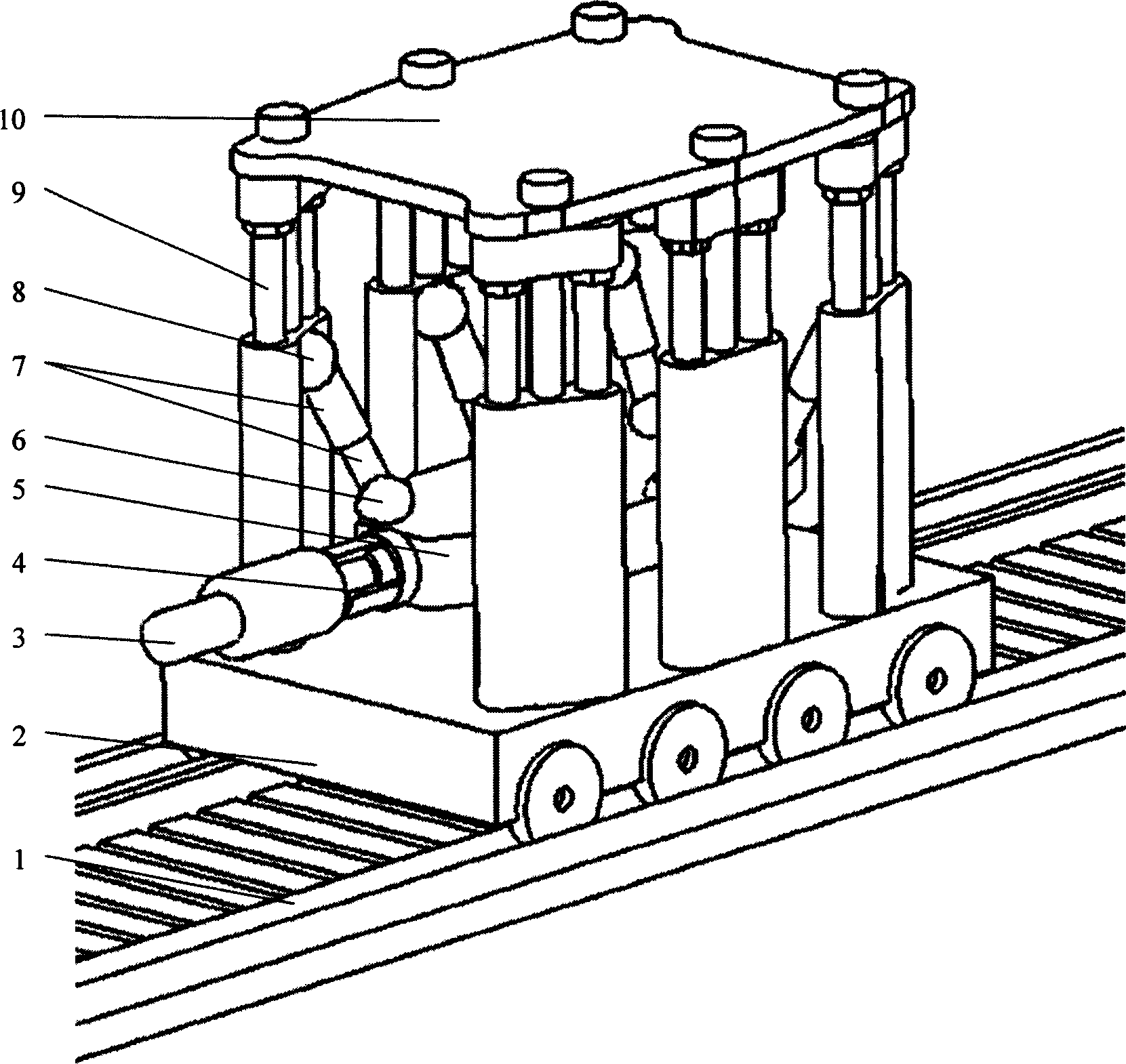

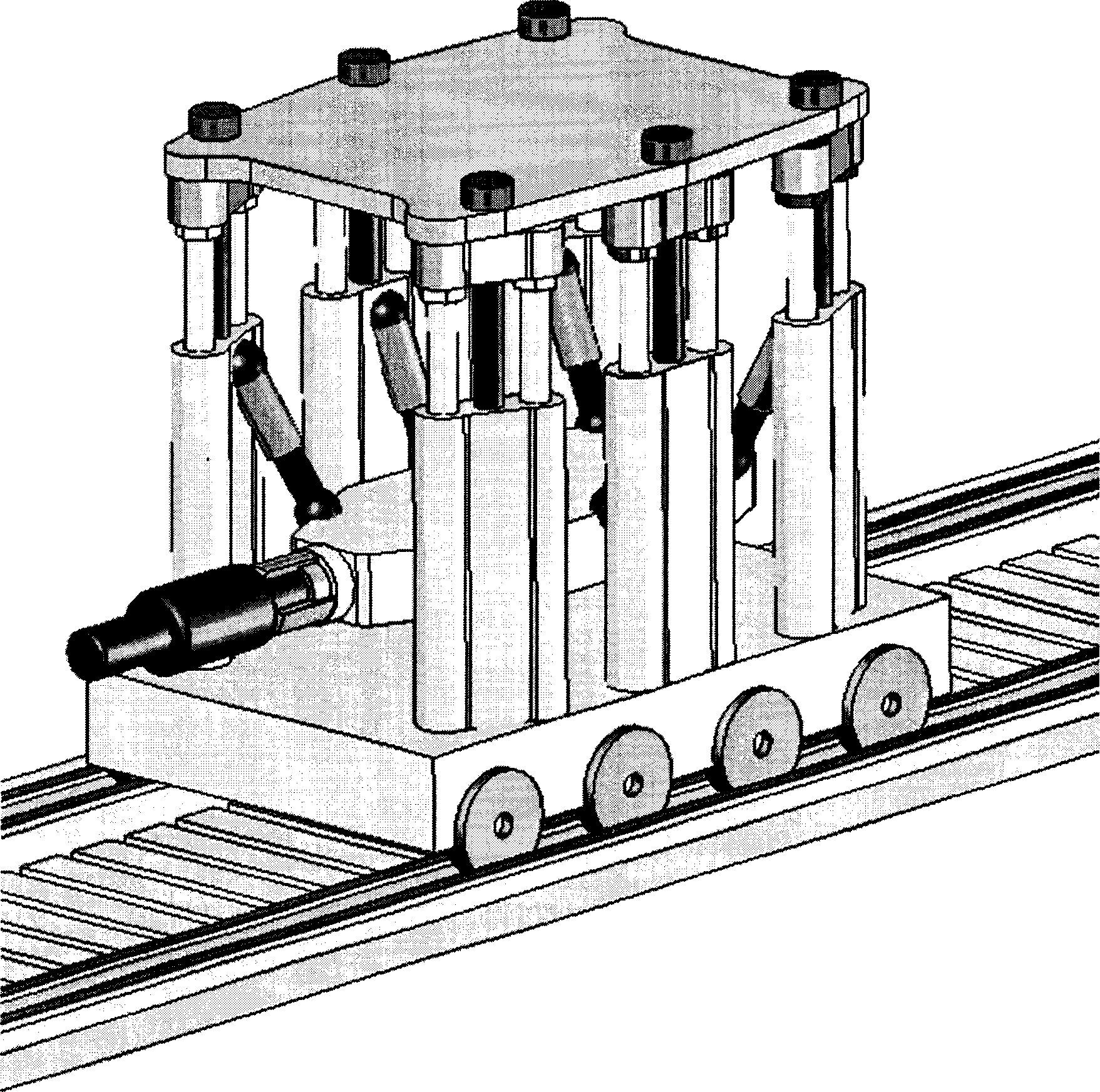

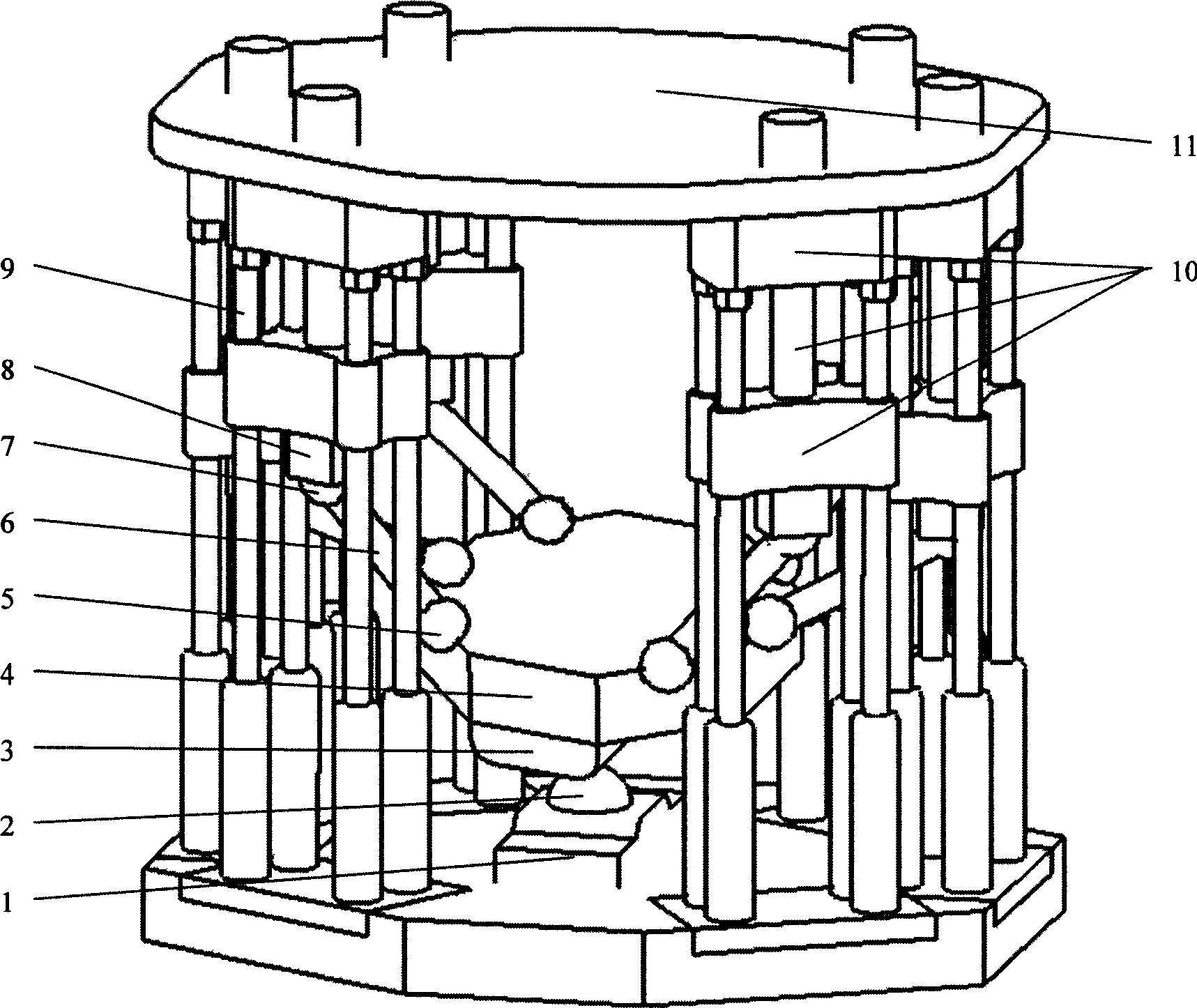

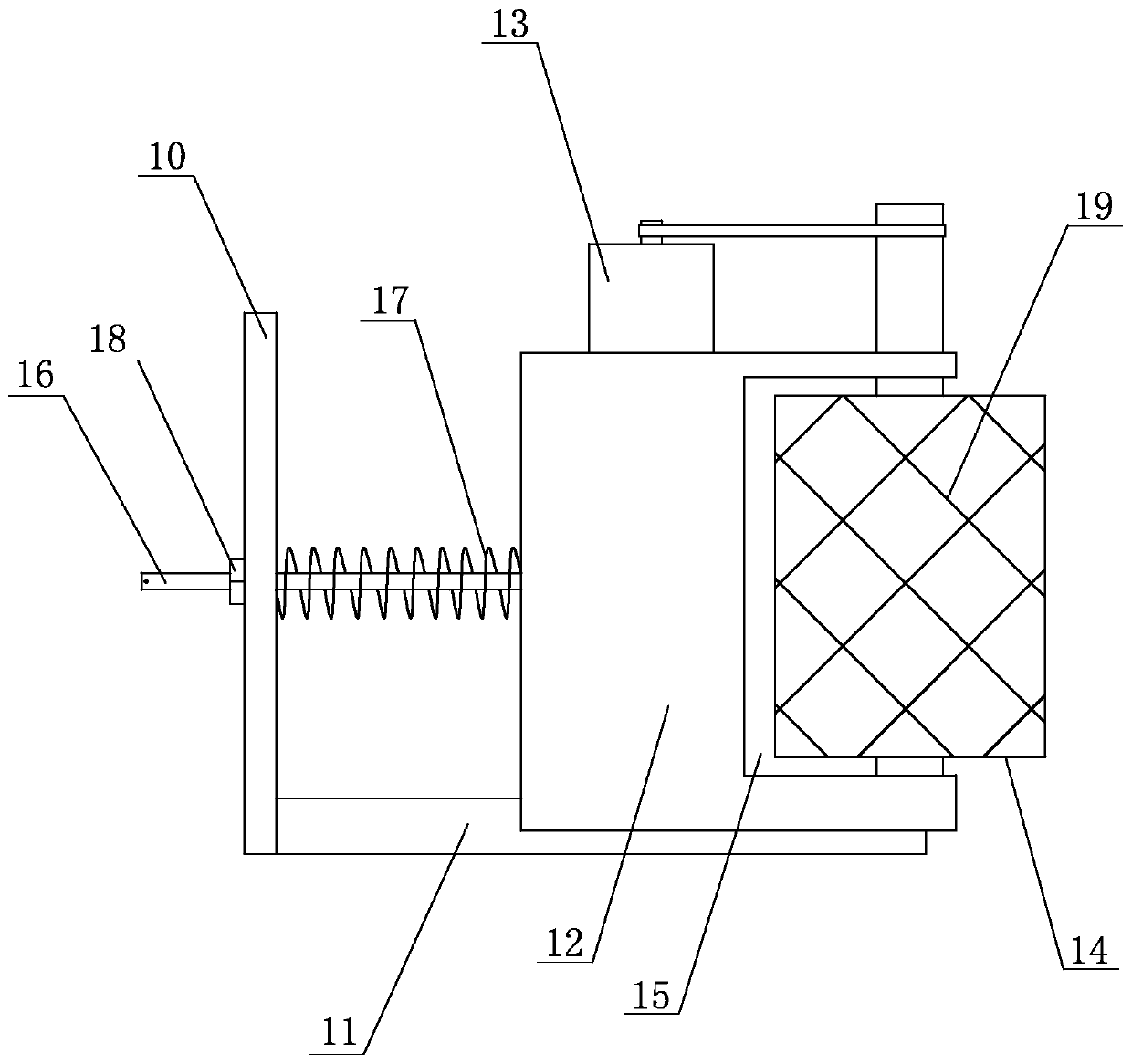

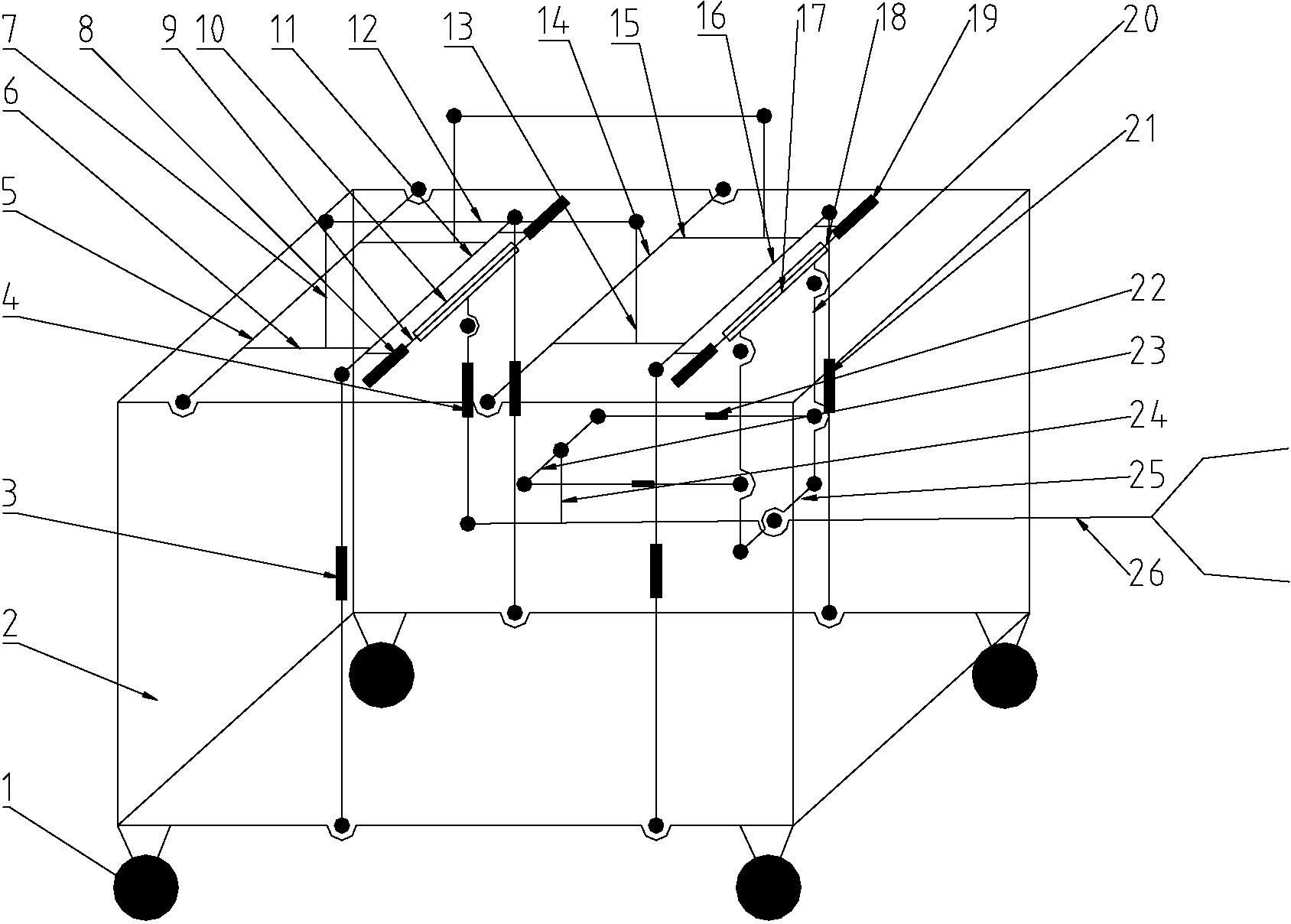

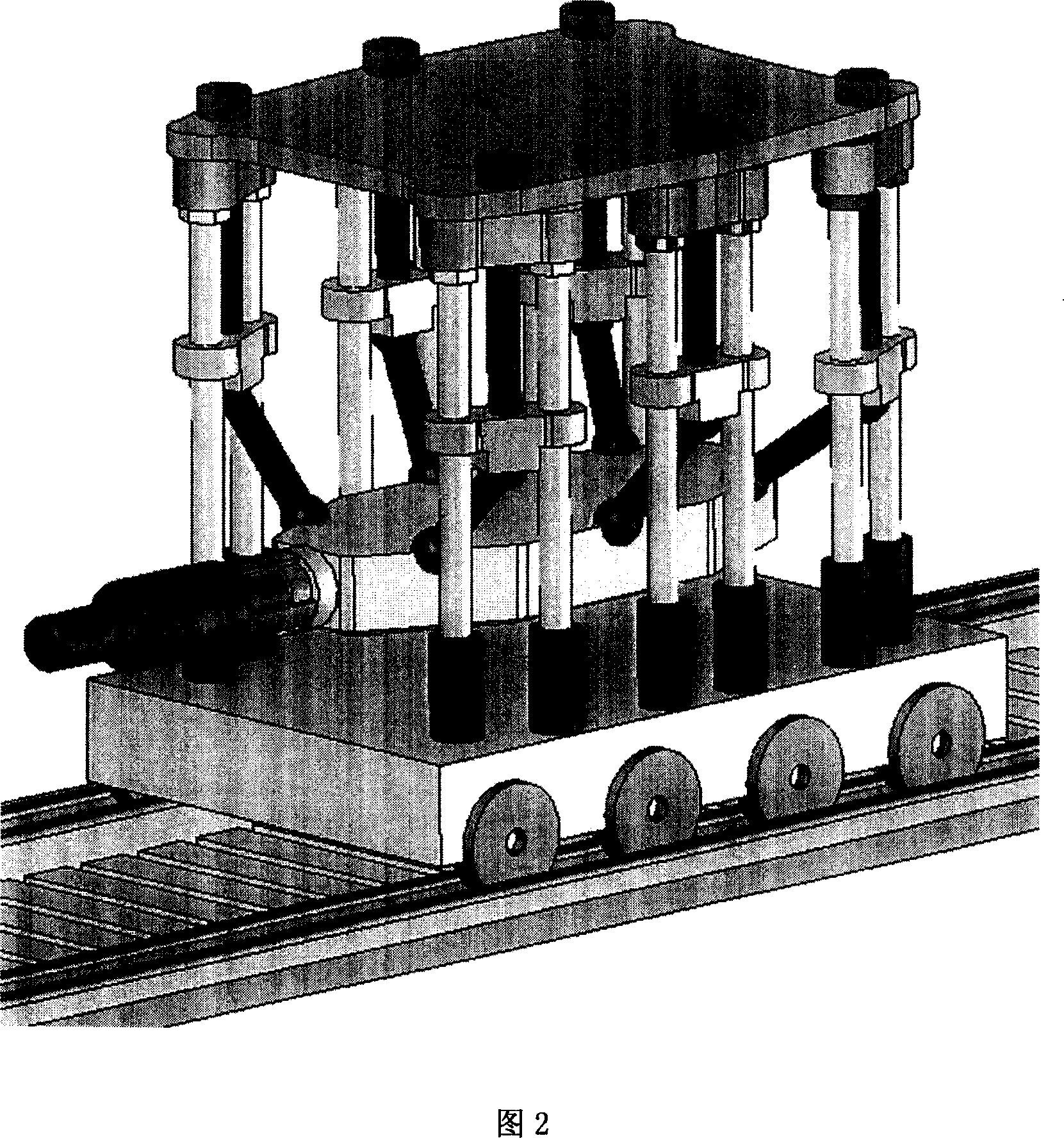

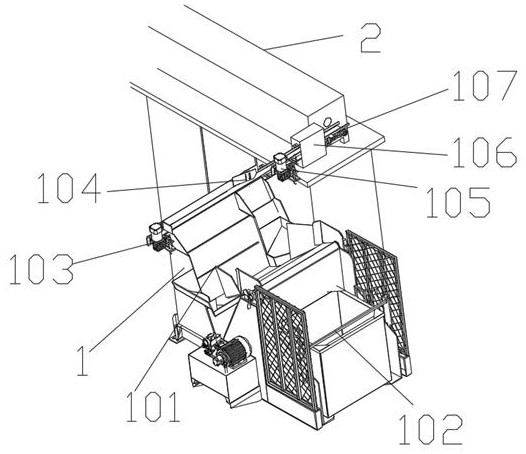

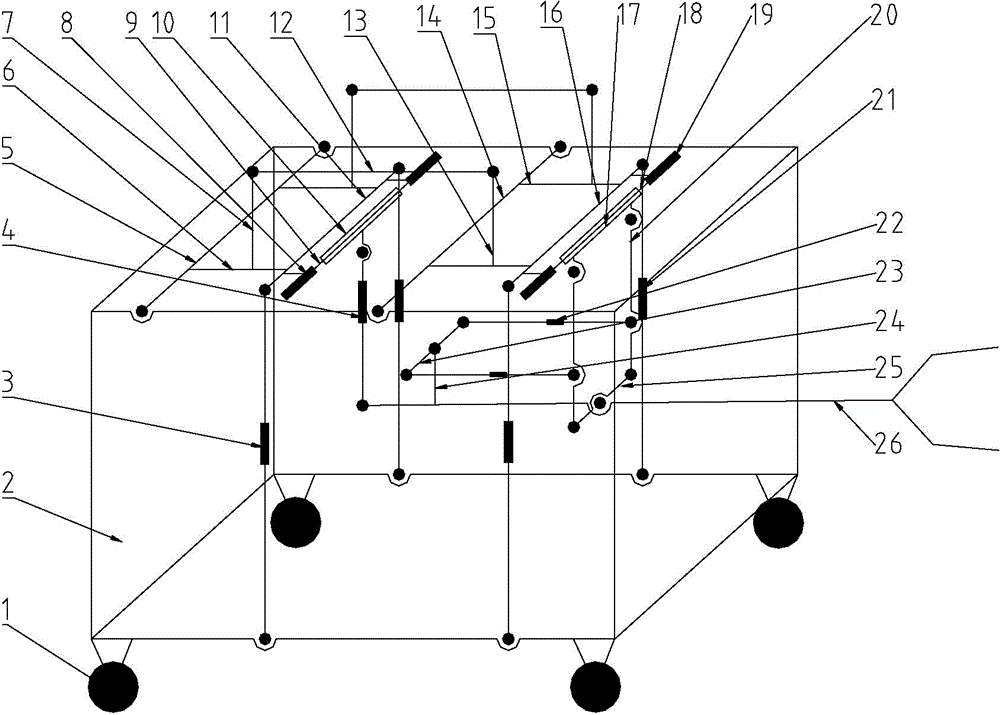

Series-parallel forging manipulator

ActiveCN103406484AEasy to manufactureGuarantee forging qualityForging/hammering/pressing machinesVehicle frameEngineering

The invention relates to a series-parallel forging manipulator which comprises a lifting mechanism, an oscillating mechanism, a buffering mechanism, a clamp, a connecting device and a walking big trolley. The series-parallel forging manipulator is characterized in that the lifting mechanism comprises a front lifting arm, a pair of front suspension rods, a clamp supporting shaft, a pair of front lifting linear drivers, a rear lifting arm, a pitching linear driver, a pair of rear lifting linear drivers and a pair of upper connection rods. The oscillating mechanism comprises a pair of rear side moving linear drivers, a rear sliding rod, a rear sliding sleeve, a front sliding sleeve, a front sliding rod and a pair of front side moving linear drivers. The buffering mechanism comprises a pair of front and rear buffering linear drivers. The clamp and the connecting device comprise a clamp body and a clamp body supporting shaft. The walking big trolley comprises a big trolley frame and four big trolley wheels which are installed and fixed at the bottom of the big trolley frame. The series-parallel forging manipulator has the advantages that the modular design of the series-parallel forging manipulator is achieved, the series-parallel forging manipulator is easy to manufacture, the forging quality of a forge piece is easy to ensure, energy consumption is reduced and the production efficiency is improved.

Owner:CHINA FIRST HEAVY IND

Technology for forging heavy steel ingots into plates

The invention discloses a technology for forging heavy steel ingots into plates. The technology includes the steps of heating the ton-grade steel ingots in a heating furnace for 14-16 hours with the temperature preserved; carrying out rough forging and returning the steel ingots in the heating furnace for heating after rough forging is completed; forging and drawing plate blanks and returning the steel ingots in the heating furnace for heating; forging and drawing the plate blanks again to meet the requirements of technological sizes and flattening surfaces, wherein the finish forging temperature is 840 DEG C; and placing forged plates into a thermal treatment furnace, heating the plates to 980 DEG C, carrying out normalization after the temperature is preserved for a period of appropriate time, cooling the plates in air, then placing work-pieces into the furnace, heating the work-pieces to 740 DEG C and carrying out air cooling after heat preserving and tempering. The technology has the beneficial effects that deformation of the steel ingots is easy, metal flowing is fast, high temperature diffusion is added in the heating process for removing intragranular segregation and intragranular micro-cracks, the forging quality of the steel ingots is guaranteed, and the grain sizes of the forged plates are uniform.

Owner:YUANFANG HIGH TECH EQUIP PARTS CO LTD

Heavy Isothermal Forging Hydraulic Press

ActiveCN103447434BGuaranteed accuracyGuaranteed stiffnessForging/hammering/pressing machinesForging press detailsAviationLeveling effect

The invention relates to a heavy-duty isothermal forging hydraulic press, which comprises an upper transverse beam, a lower transverse beam, upright posts, a main cylinder, side cylinders and a slide block, wherein an upper baseplate is fixed on the lower plane of the slide block; and a movable workbench is arranged on the lower transverse beam. The heavy-duty isothermal forging hydraulic press is characterized in that the upper transverse beam and the lower transverse beam form a combined beam body structure; leveling cylinders are fixed on the four corners of the upper end of the upper transverse beam and the upper end of the lower transverse beam; each leveling cylinder is provided with an independent leveling control system; an upper knock-out device is arranged on the slide block; movable workbench positioning mechanisms are arranged on the lower part of the movable workbench body and in the lower transverse beam; and the movable workbench body is further provided with a movable workbench clamping device. The heavy-duty isothermal forging hydraulic press is characterized in that a combined transverse beam is light in weight and is convenient to transport and produce, and the manufacturing cost can be reduced; a leveling effect is achieved via the leveling cylinders, the leveling response time is shortened, and energy is saved greatly; through the upper knock-out device, successful demolding of workpieces can be realized, and the workpiece forging and pressing quality is ensured; and accurate positioning and stable running of a press workbench can be realized, and the production requirement of forging equipment for heavy-duty aviation forgings is met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Six-dimensional parallel forging operator

InactiveCN100342995CGuarantee forging qualitySimple structureForging/hammering/pressing machinesForging press detailsEngineeringForge

A 6D parallelly connected forge machine is composed of 6 linear drive systems fixed to upper platform, and the join mechanism between linear drive systems and platform. Each linear drive system has a vertical column as its guide track and can drive a jointer connected to one end of a connecting rod via a primary spherical hinge. Another end of said connecting rod is connected to the platform via primary spherical hinge. A gripper for grasping the work-piece to be forged is installed to the platform.

Owner:SHANGHAI JIAO TONG UNIV

Installation structure of forging die

ActiveCN104493047BEliminate lateral forceReliable lockingForging/hammering/pressing machinesEngineeringForging

The invention provides a mounting structure for a forging die, and aims to solve the problem that the forging die cannot be mounted and locked reliably as the forging die is directly mounted on a conventional die seat serving as a mounting structure through a wedge iron locking mechanism. The mounting structure comprises a die seat and the forging die, wherein the die seat comprises an upper die seat and a lower die seat; the forging die comprises an upper die and a lower die; the mounting structure is characterized in that the upper die and the lower die are mounted in the upper die seat and the lower die seat respectively through an upper die sleeve and a lower die sleeve; the upper die and the upper die sleeve as well as the lower die and the lower die sleeve are respectively in clearance fit; locking of the upper die and the lower die is realized between the upper die and the upper die sleeve as well as between the lower die and the lower die sleeve respectively through hanging pin structures.

Owner:WUXI TURBINE BLADE

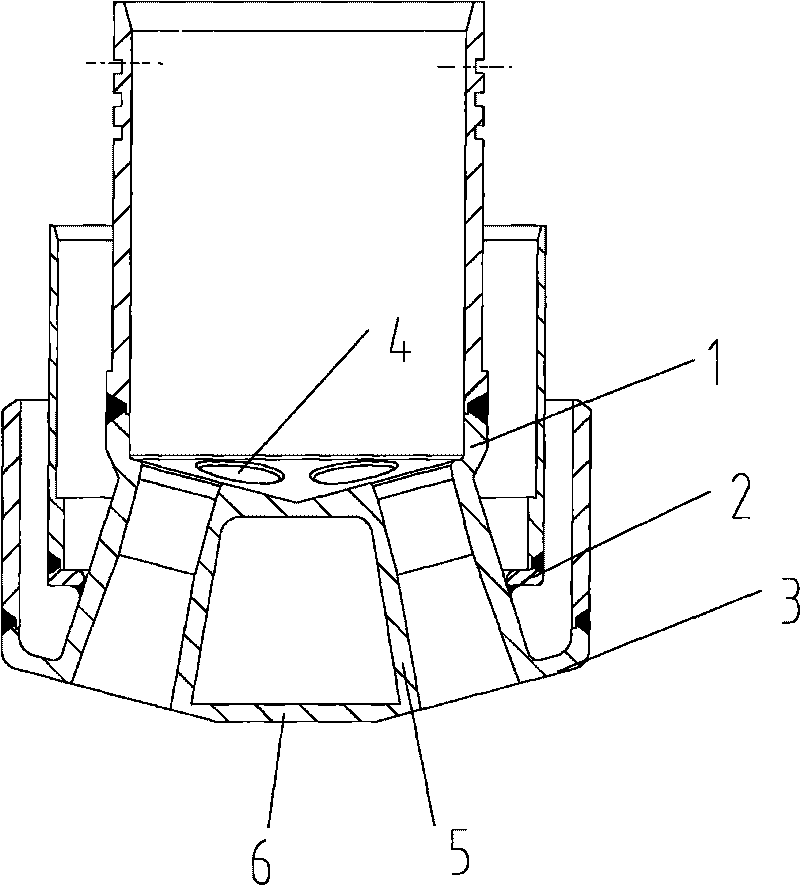

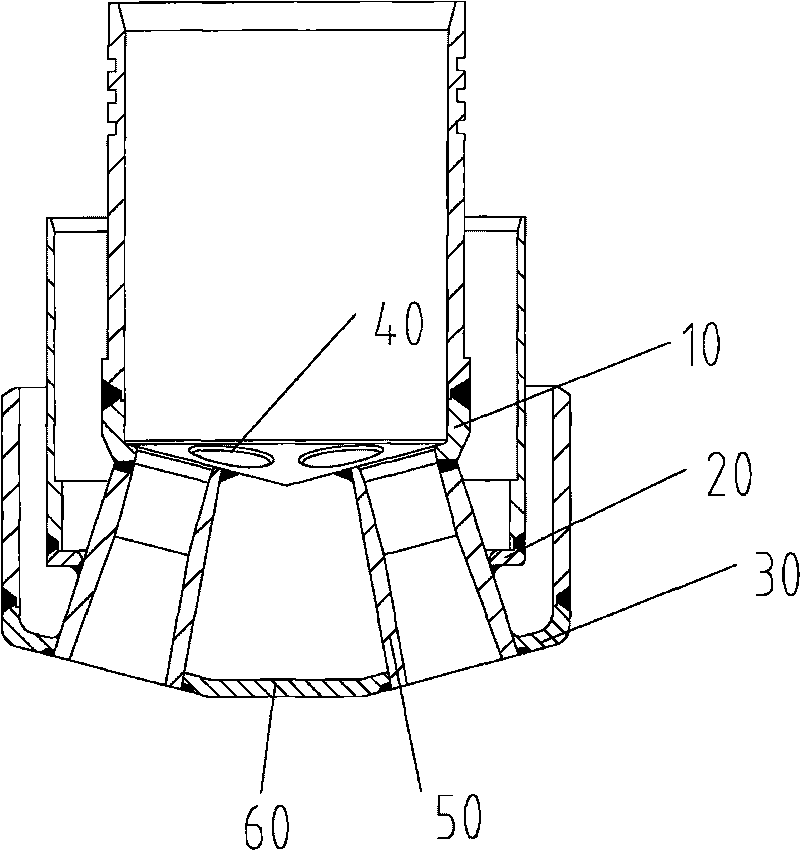

Oxygen lance Spray nozzle

InactiveCN101701774ALow manufacturing costImprove product qualification rateCharge manipulationManufacturing convertersAirflowEngineering

The invention relates to an oxygen lance spay nozzle which comprises an oxygen lance upper part, an oxygen lance middle part and an oxygen lance lower part; wherein a plurality of oxygen through holes area arranged at the end part of the oxygen lance upper part; a plurality of laval hole copper pillars are uniformly arranged on the end part of the oxygen lance upper part and form an air current channel with the oxygen through holes; the oxygen lance middle part is arranged in the middle part of the laval hole copper pillars; the oxygen lance lower part is arranged on the external side of the lower end part of the laval hole copper pillars; all parts are not integrally arranged; the centre line of the six laval hole copper pillars and the centre line of the oxygen lance upper part are arranged in 15-45 degree way; the laval hole copper pillars and the oxygen lance lower part are integrally arranged; the inner side of the lower end part of the laval hole copper pillars is provided with a bottom plate; all parts of the invention are mainly guaranteed by forging quality, have compact internal organization, and then form the product by the welding; the product is obviously superior to a casting piece in the collision performance and is reliable in use, and has high production percent of pass.

Owner:SUZHOU BAOLIAN HEAVY IND

Material returning device for forging and heating of automobile half shafts

The invention discloses a material returning device for forging and heating of automobile half shafts, and belongs to the field of automobile half shaft machining equipment. The material returning device includes a machine frame, a driving mechanism, a transmitting mechanism, a connecting mechanism, and a clutch mechanism; a fixed beam and a mounting beam are arranged at the upper end of the machine frame, and the mounting beam is located on the front side of the fixed beam and parallel to the fixed beam; and the driving mechanism, the transmitting mechanism, the connecting mechanism, and theclutch mechanism are arranged on the machine frame, and a switching device and a time control device are further arranged on the machine frame. The material returning device controls each automobile half shaft individually, avoids the phenomenon of burnout or overheating, and ensures the forging quality; and meanwhile, the switching device and the time control device can ensure the fact that the heating time of the automobile half shafts is the same, the same heating temperature is achieved, and the product quality is further ensured.

Owner:荆江半轴(湖北)有限公司

Method for heating large sheet arc-shaped forge piece before forging

ActiveCN112439854AAvoid deformationFast transferForging/hammering/pressing machinesHandling devicesEngineeringSizing

The invention provides a method for heating a large sheet arc-shaped forge piece before forging. The method comprises the following steps that A, a plurality of parallel sizing blocks are arranged ona universal charging tray, and the heights of the sizing blocks are gradually reduced from two ends to the middle; B, the forge piece is placed on sizing blocks, the forge piece makes contact with thesizing blocks located at the two ends, and gaps exist between other sizing blocks and the forge piece; C, the forge piece is heated to initial forging temperature. The plurality of sizing blocks withdifferent heights are arranged on the charging tray. When a plate is heated to be softened and deformed under the action of gravity, the sizing blocks can support the plate. The deformation amount can be controlled within a certain range, and the plate is prevented from generating large deformation. The shape of the heated plate can be matched with a mold, and therefore the plate can be quickly transferred into the mold and positioned. Thus, the efficiency is improved, the initial forging temperature is prevented from being too low, and the forging quality is guaranteed.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

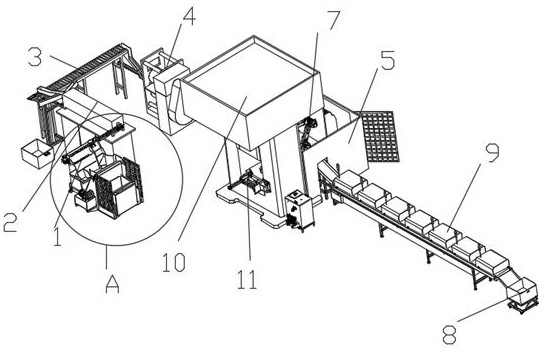

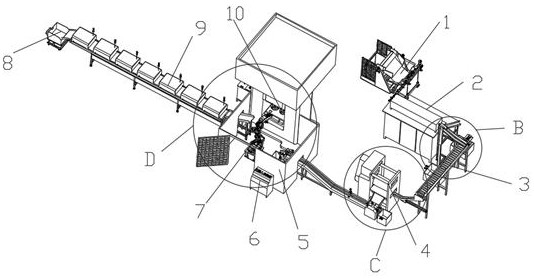

Automatic multi-station forging production line for sector gear shaft

PendingCN114367624AFully automatedGuarantee forging qualityRailway componentsForging/hammering/pressing machinesProduction lineLogistics management

The invention discloses an automatic multi-station forging production line for sector gear shafts, which comprises a feeding machine, a heating furnace, a dephosphorization device, a forging press and a cooling conveyor which are connected in sequence according to a processing flow, after the feeding machine sorts blank bars, the blank bars are conveyed to a first plate chain conveyor connected behind the feeding machine, and the first plate chain conveyor is connected with a second plate chain conveyor; a derusting and deburring device and a saponification device are sequentially arranged on the plate chain conveyor; the heating furnace and the forging press are connected through a second plate chain conveyor, the dephosphorization device is fixed to the second plate chain conveyor, and the dephosphorization device is provided with a steel wire wheel brush channel and a water mist channel; the forging press and the second plate chain conveyor carry materials through a six-axis mechanical arm, and a double-station forging and pressing die is fixed in the forging press and comprises a forming station and an edge cutting station. The sector gear shaft forging system has the beneficial effects that automation of sector gear shaft forging is achieved, logistics delivery is completed through the mechanical arm or the conveyor, full-station and full-process automation is achieved, and the dephosphorization, the double-station forging and pressing die and the controllable isothermal slow-cooling cooling conveyor guarantee the forging and pressing quality of forged parts.

Owner:SHANDONG JINMA INDAL GROUP

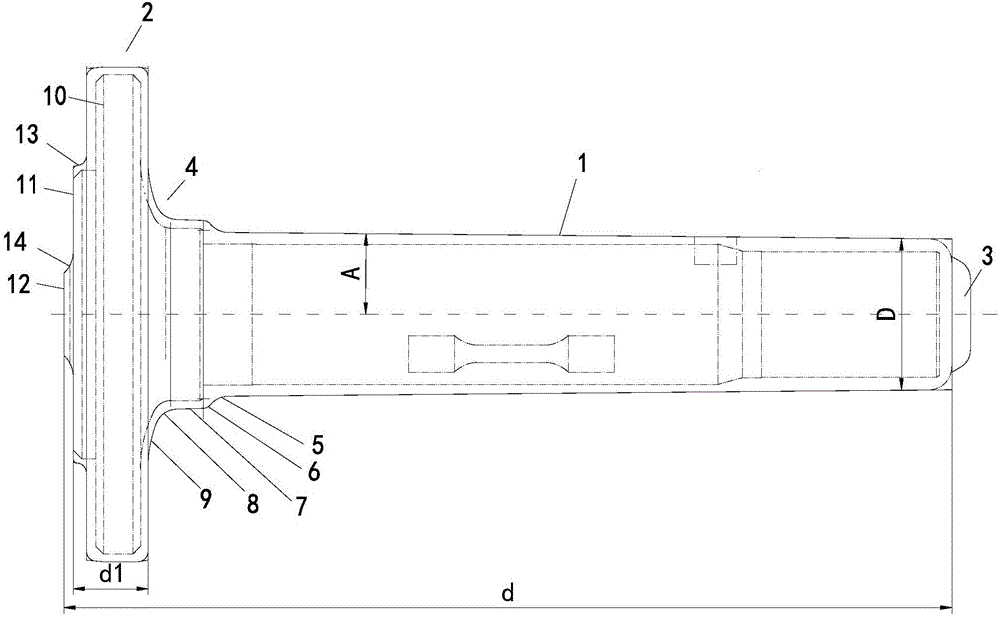

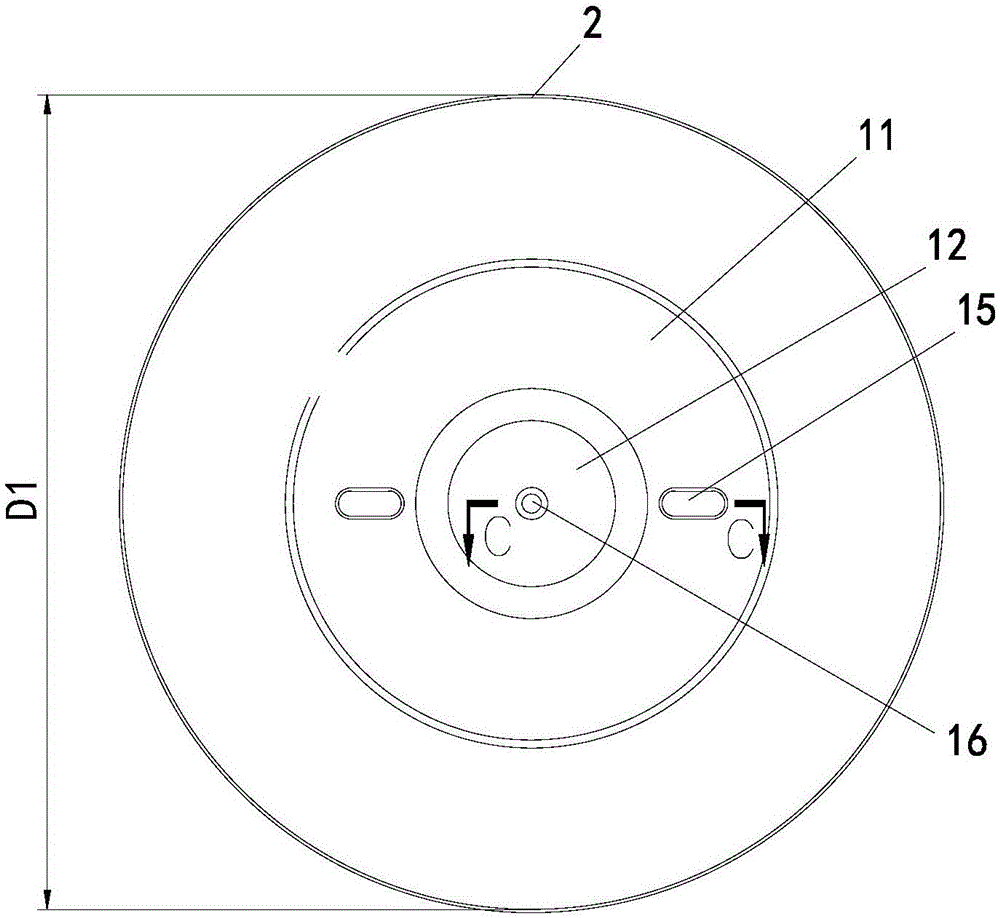

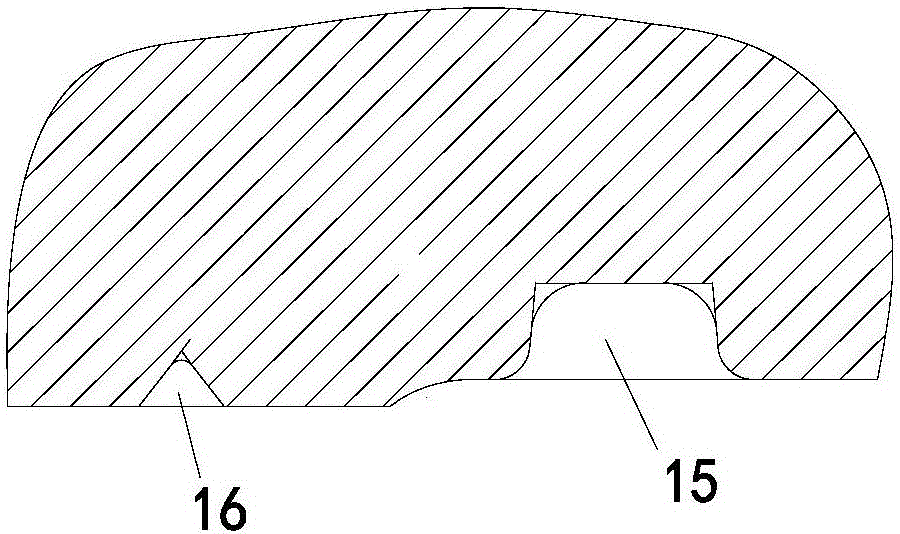

Farm mechanical shaft forge piece

InactiveCN106438661ALarge connecting surfaceImprove connection strengthShaftsRotary machine partsDrive shaftEngineering

The invention relates to a farm mechanical shaft forge piece which comprises a transmission shaft and a flange, wherein the flange is located at the left end, and the flange and the transmission shaft are integrally forged. The outer diameter of the transmission shaft is increased from the right end to the left end, and the total length d of the transmission shaft and the flange is 460-470 mm; the thickness d1 of the flange is 35-40 mm, and the outer diameter D of the right end of the transmission shaft is 75-80 mm; the outer diameter D1 of the flange is 250-255 mm, and the right end face of the transmission shaft is provided with a boss with the diameter smaller than that of the transmission shaft and the thickness being 9-11 mm; and the peripheral wall of the left end of the transmission shaft is connected with the middle of the flange through a curve face with the size being gradually increased. The farm mechanical shaft forge piece is reasonable in structural design, by adoption of one-time forge-forming and structure optimization of the joint, the mechanical performance of the overall mechanical shaft is improved, and the service lift is prolonged.

Owner:CHANGZHOU JINGLING CASTING & FORGING

A kind of high synchronous forging equipment

The invention relates to a high-synchronization forging equipment, comprising three T-shaped hammering units with heads facing the center, and a driving device for driving each hammering unit to move to the center or to the outside, and is characterized in that it also includes: The transmission device connecting the driving device and the hammer unit, the transmission device includes two coaxial and integrated gears, one of the two gears is at least matched with one rack, and the other is at least connected with two racks. fit, and each rack is correspondingly connected to one of the hammering units. In the forging equipment of the present invention, three T-shaped hammering units can cooperate with a fixed hammering unit to carry out hammering forging, which is driven by gears and racks. Since the two gears are coaxial and integrated, each The racks can be driven to move synchronously, thereby ensuring that each hammering unit also performs hammering and retreating synchronously, with a simple structure and high synchronization.

Owner:忻州市质量技术监督检验测试所

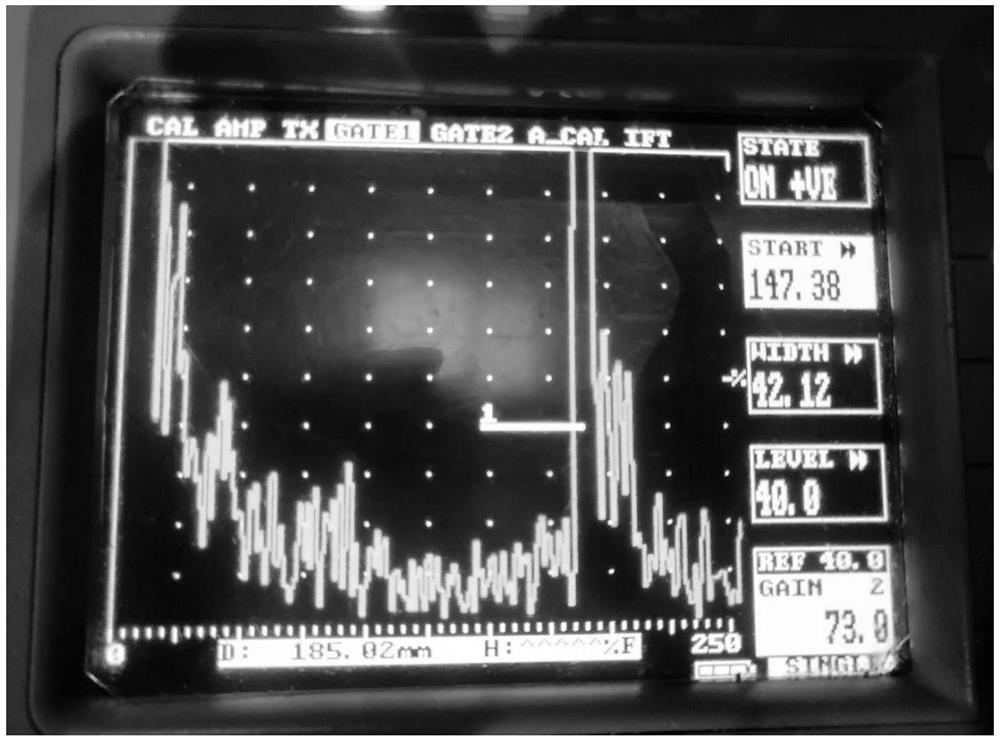

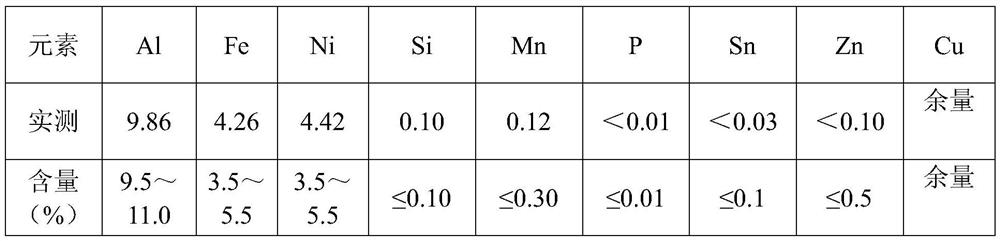

Forming method for improving structure property of QAl10-4-4 aluminum bronze alloy cast ingot

ActiveCN112427588AMeet plastic deformation requirementsFine grainMetal-working apparatusFurnace typesStructure propertyIngot casting

The invention discloses a forming method for improving the structure property of a QAl10-4-4 aluminum bronze alloy cast ingot. According to the technical scheme, a sawn QAl10-4-4 aluminum bronze alloybar is heated to a preset high-temperature interval, heat preservation is conducted, and then cast ingot cogging forging is conducted; a blank obtained after ingot casting cogging is heated to a preset medium-temperature interval, heat preservation is conducted, and then intermediate procedure forging is conducted; a blank obtained after intermediate procedure forging is heated to the preset medium-temperature interval, heat preservation is conducted, and then final forging forming is conducted; and a blank which is finally forged and formed is annealed according to a preset temperature, andafter discharging and air-cooling, a finished product forging is obtained. According to the method, a forging with fine grains, uniform structure, high flaw detection level and good comprehensive performance can be obtained.

Owner:SHAANXI HEYE SPECIAL STEEL TOOL

Double-ball joint telescopic six-dimensional parallel forging operation machine

InactiveCN100335197CGuarantee forging qualitySimple structureForging/hammering/pressing machinesHydraulic cylinderEngineering

The double-ball joint telescopic six-dimensional parallel forging operation machine consists of six identical fixed ball joints, six identical hydraulic cylinders, six identical dynamic ball joints, one claw beam platform, one clamp, one upper platform, and six sets of identical uprights. The six sets of identical uprights are configured symmetrically on the large walking chassis, and each of the upright set is connected to one hydraulic cylinder via one fixed ball joint, the hydraulic cylinder is then connected via one dynamic ball joint to the claw beam platform, these six dynamic ball joints are configured symmetrically on the large walking chassis in the mode corresponding to that of the six upright sets, and the clamp for grasping forging is mounted onto the claw beam platform. The present invention utilizes six hydraulic cylinders for great tonnage operation force and six operation motion, and realizes the multiple bearing operation of large forging at low cost.

Owner:SHANGHAI JIAO TONG UNIV +1

Preparation Technology of Large Integral Forged Axle Bridge of Modern Track Low-floor EMU

ActiveCN104959503BImprove mechanical propertiesMeet the mechanical performance indexRailway componentsMetal-working apparatusElectric arc furnaceNational standard

Provided is a preparation process of a modern track low-floor motor train large-scale integral forging axle. The preparation process includes that 34CrNiMo6 is taken as the raw material and is subjected to arc furnace melting and vacuum smelting to obtain steel ingot, and a blank material is obtained through electroslag re-dissolving; after the two ends of the blank material are drawn to be pre-forging blank materials by a free forging hammer, the pre-forging blank materials are preheated by an electrothermal far-infrared heating furnace and then is heated and insulated by a natural gas furnace; an axel head and axel shoulders are forged on the heated pre-forging blank materials, leftover material edges are removed, the heated pre-forging blank materials with the axel head and axel shoulders are returned to the furnace to be heated, the waist part is drawn out by the free forging hammer, and then the heated pre-forging blank materials with the drawn-out waist part are returned to the furnace to be heated, the heated pre-forging blank materials with the axel head, the axel shoulders, and the drawn-out waist part are put into an axel forging forming die to be integrally forged and formed to obtain a product. The preparation process is advantageous in that the raw material components are strictly controlled to meet the mechanical performance indexes of the product; and the integral forging forming is carried out after the local pre-forging, the forging quality is guaranteed, the waste can be reduced, the yield is improved, and the product performance meets the national standard.

Owner:锦州捷通铁路机械股份有限公司

Hybrid Forging Manipulator

ActiveCN103406484BEasy to manufactureGuarantee forging qualityForging/hammering/pressing machinesForging manipulatorModular design

The invention relates to a series-parallel forging manipulator which comprises a lifting mechanism, an oscillating mechanism, a buffering mechanism, a clamp, a connecting device and a walking big trolley. The series-parallel forging manipulator is characterized in that the lifting mechanism comprises a front lifting arm, a pair of front suspension rods, a clamp supporting shaft, a pair of front lifting linear drivers, a rear lifting arm, a pitching linear driver, a pair of rear lifting linear drivers and a pair of upper connection rods. The oscillating mechanism comprises a pair of rear side moving linear drivers, a rear sliding rod, a rear sliding sleeve, a front sliding sleeve, a front sliding rod and a pair of front side moving linear drivers. The buffering mechanism comprises a pair of front and rear buffering linear drivers. The clamp and the connecting device comprise a clamp body and a clamp body supporting shaft. The walking big trolley comprises a big trolley frame and four big trolley wheels which are installed and fixed at the bottom of the big trolley frame. The series-parallel forging manipulator has the advantages that the modular design of the series-parallel forging manipulator is achieved, the series-parallel forging manipulator is easy to manufacture, the forging quality of a forge piece is easy to ensure, energy consumption is reduced and the production efficiency is improved.

Owner:CHINA FIRST HEAVY IND

Novel forging equipment

PendingCN109967682APrevent rigid contactGuarantee forging qualityForging/hammering/pressing machinesForgingComputer engineering

The invention discloses novel forging equipment. The novel forging equipment comprises a forging machine, wherein the forging machine is installed on the ground; the novel forging equipment is characterized in that sliding rails are arranged on the ground and on the two sides of the forging machine correspondingly, and each of the sliding rails on the two sides is provided with a supporting mechanism in a sliding mode; each supporting mechanism comprises a base and a supporting block, a cavity is formed in the middle of each base, two first through holes are formed in the top surface of each base, and the two first through holes are in communication with the corresponding cavity; an arc-shaped opening is formed in the top of each supporting block, two guide rods are arranged at the bottomof each supporting block, and the bottoms of the two guide rods penetrate through the corresponding first through holes so as to be inserted into the corresponding cavity; and a spring is arranged oneach guide rod in a sleeving mode, the top of each spring abuts against the bottom surface of the corresponding supporting block, and the bottom of each spring abuts against the top surface of the corresponding base. According to the novel forging equipment, the forging efficiency is ensured, and the damage to a forging operation machine is prevented.

Owner:江阴市劲松科技有限公司

A low-cost free forging method for large vertical roll forgings

ActiveCN107008837BGuarantee forging qualityAvoid process wasteMetal-working apparatusEngine componentsForgingIngot

The invention relates to a low-cost free forging method for a large vertical roll forging. The low-cost free forging method comprises the steps that (1) a forging tool is preheated; (2) a steel ingot for the vertical roll forging is manufactured; (3) the first time of heating is conducted, and the steel ingot is subjected to tong holding, pre-drawing and ingot tail filing; (4) the second time of heating is conducted, and the steel ingot is subjected to upsetting; (5) the third time of heating is conducted, and the steel ingot is drawn to be prepared into a forging blank; (6) the fourth time of heating is conducted, the two ends of the forging blank are put into a leaking disc, and the middle of the forging blank is subjected to upsetting; and (7) the fifth time of heating is conducted, and the forging blank subjected to upsetting is drawn into the finished forging. According to the low-cost free forging method, by improving a forging process, residual process blocks are avoided from being additionally generated during forging, and therefore the weight of the steel ingot is lowered, and production cost is greatly reduced.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

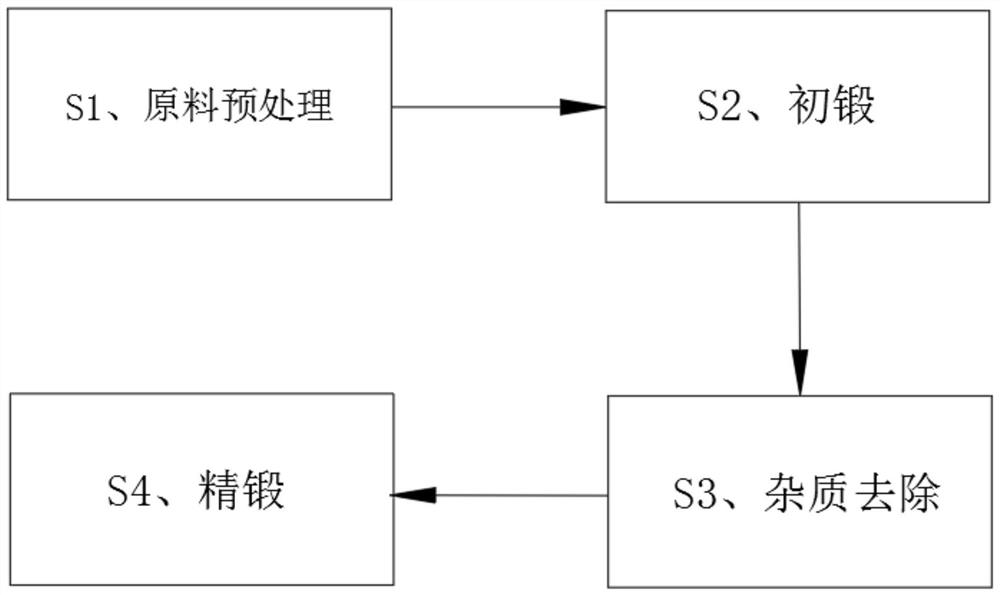

Four-step forging forming process for automobile hub axle tube

PendingCN114346155AGuarantee forging qualityImprove antioxidant capacityEngine componentsSpecial surfacesTemperature controlOxidation resistant

The invention discloses a four-step forging forming process for an automobile hub axle tube, and relates to the technical field of forging forming. The four-step forging forming process for the automobile hub axle tube comprises the following steps: S1, raw material pretreatment: selecting a bar with proper length, placing the bar in a heating furnace body for heating, controlling the heating temperature between 350 DEG C and 450 DEG C, and carrying out subsequent primary forging and precision forging; a bar can be cut and ground and then is heated through the heating furnace body, the heated bar is taken out of the heating furnace and placed in the pre-forging die through the transfer device, the bar is subjected to primary forging and forming through hydraulic forging equipment, and precision forging operation is carried out after impurities are removed. The anti-oxidation treatment is carried out on the hub axle tube after the hub axle tube is formed, the forging forming quality of a workpiece is guaranteed, and meanwhile through spraying of the anti-oxidation layer, the anti-oxidation performance of the hub axle tube is improved.

Owner:襄阳丰正汽车配件制造有限公司

A process for forging plates from heavy steel ingots

Owner:YUANFANG HIGH TECH EQUIP PARTS CO LTD

Anti-crack manufacturing method of duplex stainless steel F53 forging forming

InactiveCN111570690AImprove performanceImprove forging efficiencyHeating/cooling devicesCrazingIngot

The invention discloses an anti-crack manufacturing method for duplex stainless steel F53 forging forming. The anti-crack manufacturing method comprises the following steps of (1) putting a steel ingot into a heating furnace, charging the steel ingot into the furnace to avoid direct flame injection, heating the steel ingot along with the furnace to be less than 60 DEG C / h, and keeping the temperature for 4 hours when the temperature reaches 300-350 DEG C; (2) heating the steel ingot with the temperature of 300-350 DEG C to 1020-1050 DEG C at the speed of 100 DEG C / h, and keeping the temperature for 20 hours; (3) heating the steel ingot with the temperature of 1020-1050 DEG C to 1200 DEG C at the speed of 70-100 DEG C / h, and keeping the temperature for 20 hours; (4) taking out the steel ingot obtained in the step (3) and placing the steel ingot in a forging machine for forging; (5) if cracks appear on the outer surface in the forging and pressing process, immediately removing the cracksby gas cutting in a hot state; and (6) placing a blank forge piece forged to the size into the heating furnace to be continuously heated to 1070 DEG C, conducting solid solution after heat preservation is carried out for 3 h, and enabling the water temperature of solid solution to be larger than 40 DEG C. According to the anti-crack manufacturing method, the forging efficiency and quality are improved, product surface cracks are prevented, energy consumption is reduced, and the cost is reduced.

Owner:江阴市劲松科技有限公司

Six-dimensional parallel forging press

InactiveCN100342994CRealize multi-directional forgingGuarantee forging qualityForging press detailsForging press drivesEngineeringForge

A 6D parallelly connected high-power forge press is composed of 6 linear drive systems, one movable platform and the join mechanism between said linear drive systems and movable platform. Said linear drive systems are jointed to upper platform. Each drive system has a vertical column as its guide track and can drive a jointer connected to one end of a connecting rod via an upper spherical hinge. Another end of said connecting rod is connected to movable platform via a lower spherical hinge. A punch head is installed to the movable platform.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com