Double-ball joint telescopic six-dimensional parallel forging operation machine

A forging manipulator and telescopic technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve problems such as large number of parts, large moment of inertia, and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

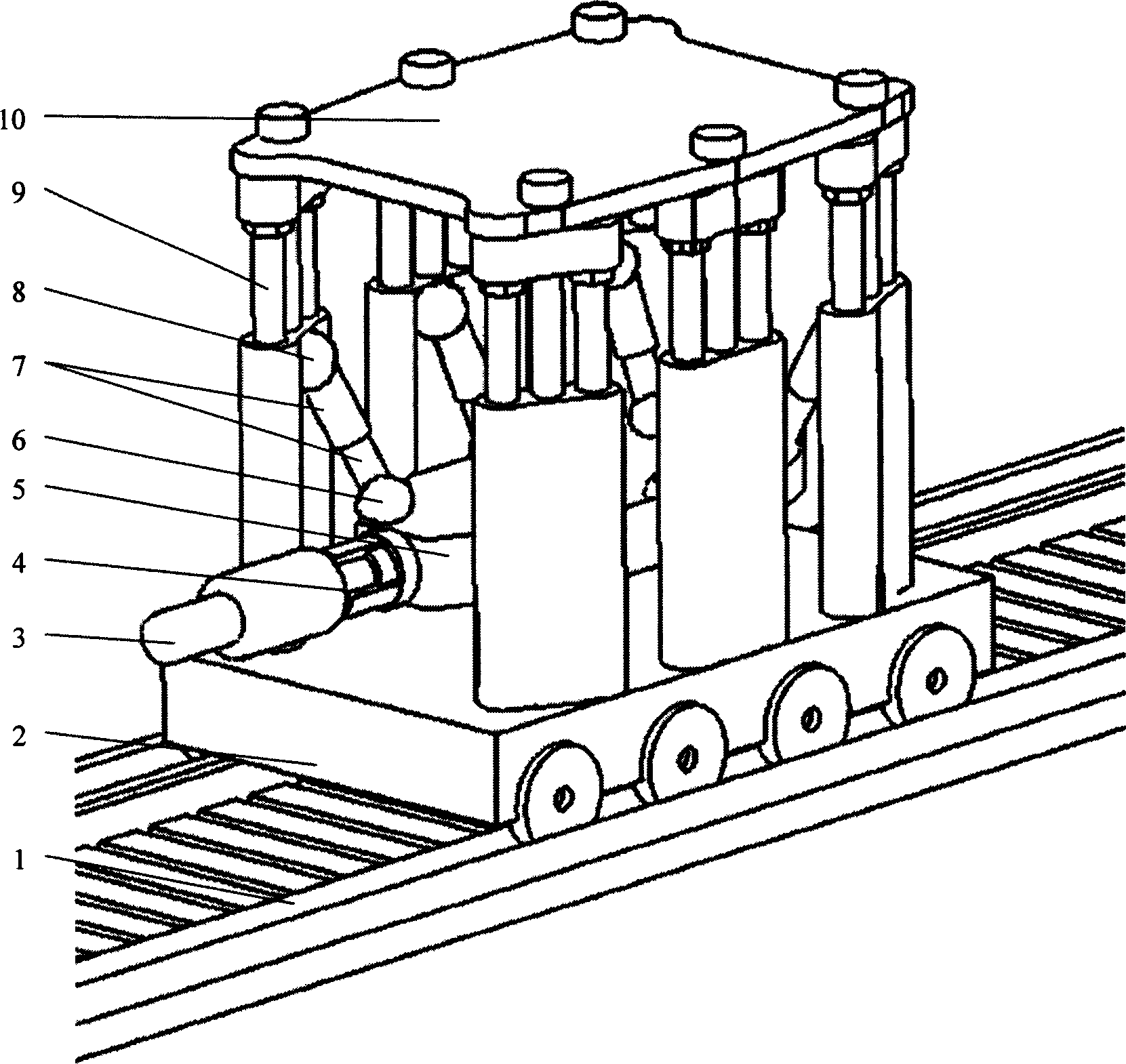

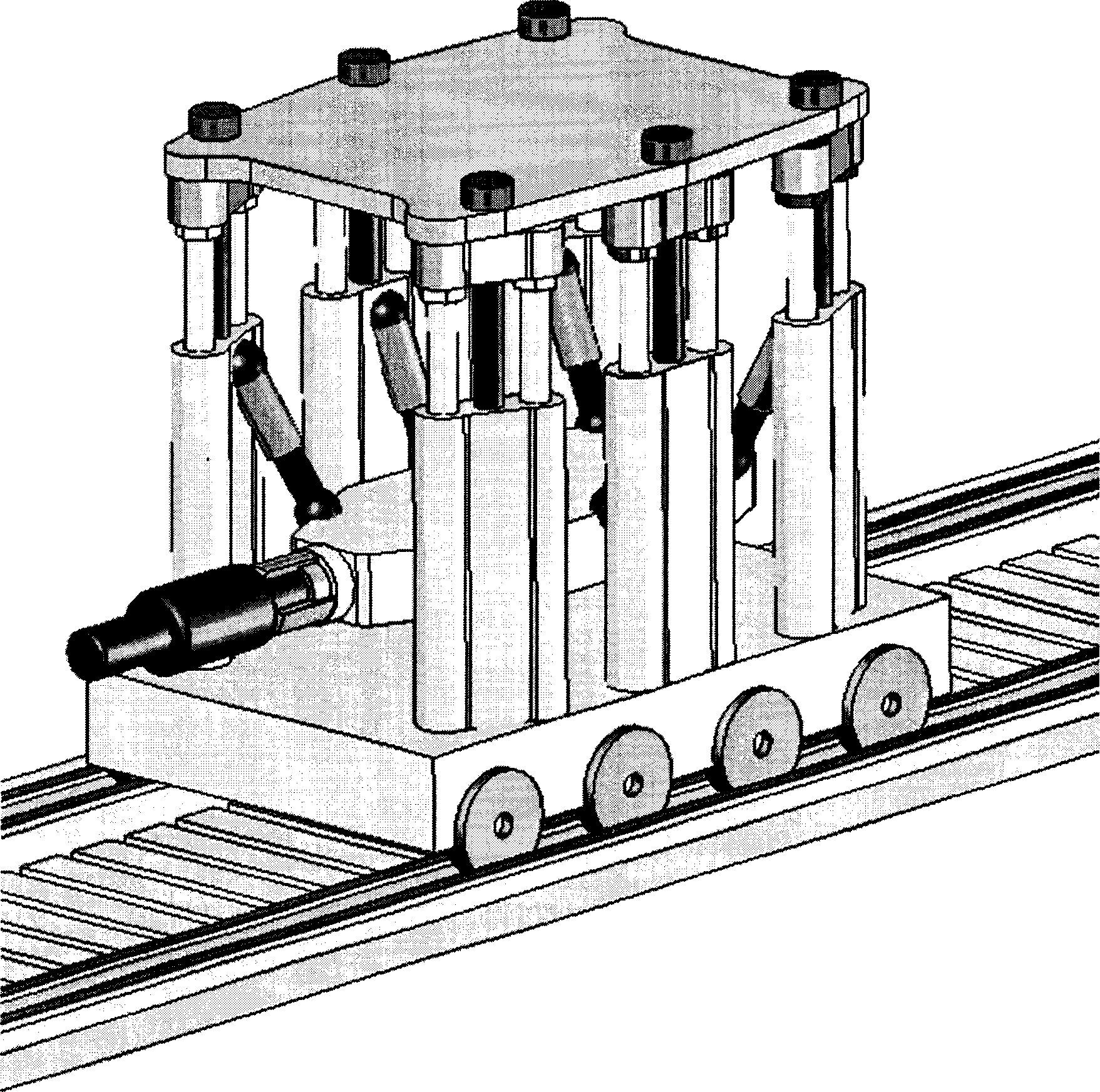

[0011] figure 1 It is a schematic diagram of the structure of the present invention. like figure 1 As shown, the double ball hinge telescopic six-dimensional parallel forging manipulator of the present invention mainly includes: six identical fixed ball hinges 8, six sets of identical hydraulic cylinders 7, six identical moving ball hinges 6, and a clamp rod Platform 5, a clamp 4, an upper platform 10, and six groups of identical columns 9. Six groups of columns 9 are symmetrically arranged on the chassis of the walking cart 2, and the upper ends of the six groups of columns 9 are fixedly connected to the upper platform 10. Each group of columns 9 is connected to a set of hydraulic cylinders 7 through a fixed spherical hinge 8, and the hydraulic cylinders 7 pass through a set of hydraulic cylinders. Only the movable ball hinge 6 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com