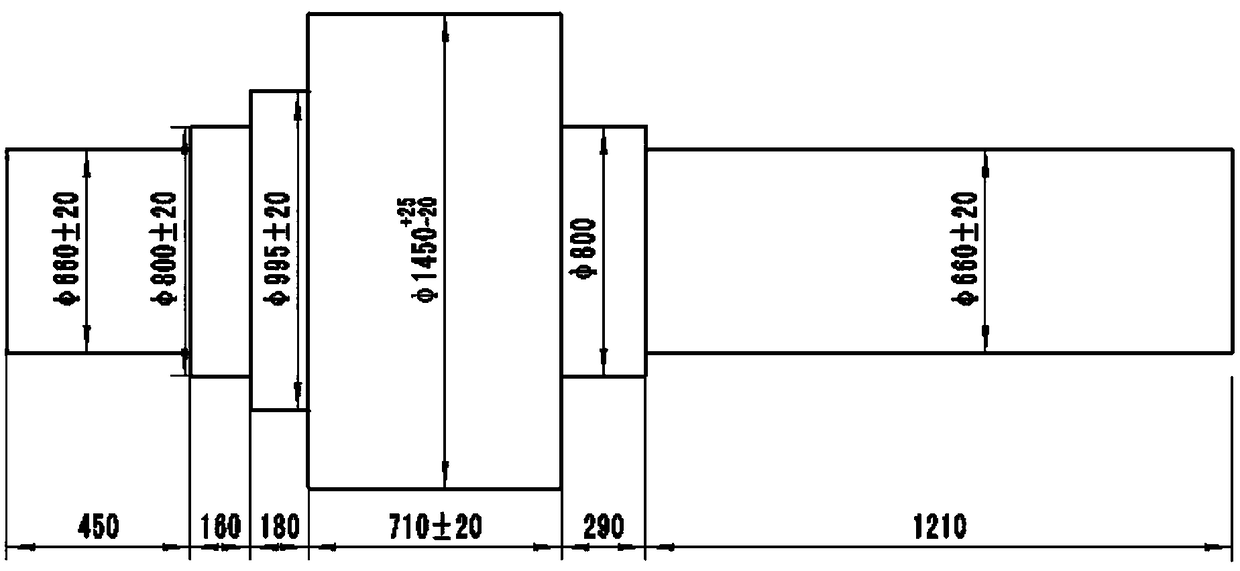

A low-cost free forging method for large vertical roll forgings

A low-cost, vertical roll technology, applied in the forging field of roll forgings, can solve the problems of not less than 1/3 of the diameter, the increase of the weight of the steel ingot, and the increase of production costs, so as to avoid process surplus, benefit the surface quality, and ensure forging quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

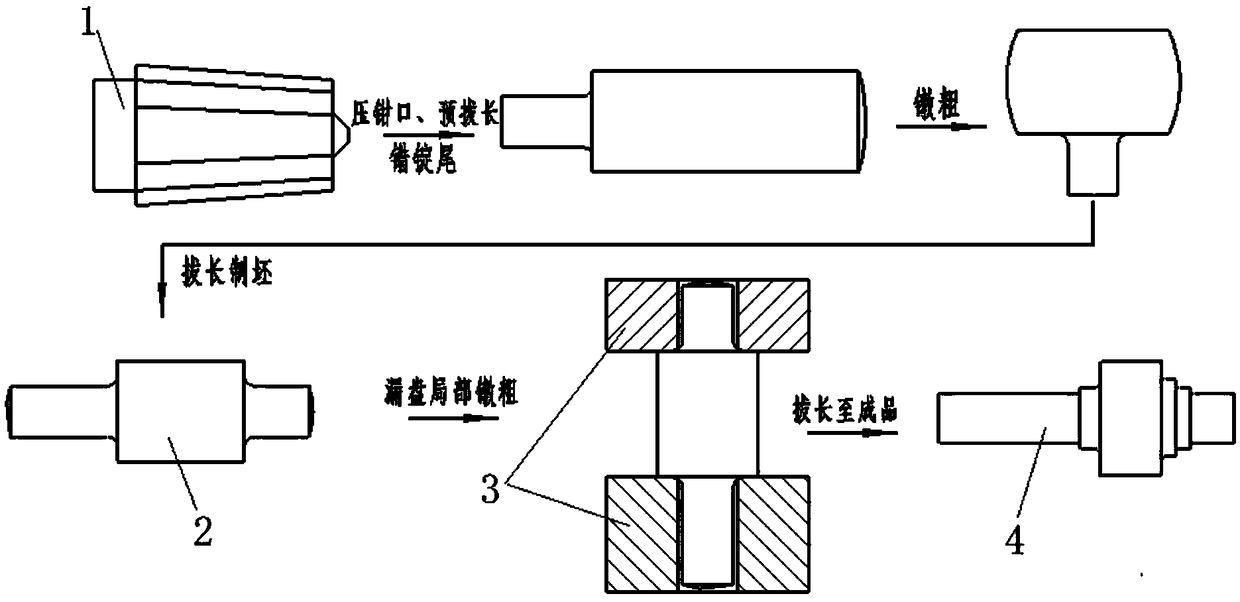

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] Such as figure 2 Shown, the low-cost free forging method of a kind of large-scale vertical roll forging described in the present invention comprises the following steps:

[0021] 1) Preheating the forging tool;

[0022] 2) making steel ingot 1 for vertical roll forging;

[0023] 3) For the first fire, press the jaws, pre-draw the length, and stagger the ingot tail; steel ingot 1 presses the jaws at the riser, and after pre-drawing the long steel ingot 1, gas cut the ingot tail and chamfer;

[0024] 4) The second fire, upsetting;

[0025] 5) The third fire, drawing and lengthening to make forging billet 2;

[0026] 6) For the fourth firing, put the two ends of the forging billet 2 into the leakage plate 3, and upset the middle;

[0027] 7) In the fifth fire, the upsetting forging billet 2 is elongated to the finished forging 4 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com