Novel forging equipment

A new type of equipment and technology, applied in the field of forging, can solve the problems of high maintenance rate of forging manipulators, damage of forging manipulators, short service life, etc., and achieve the effect of preventing rigid contact, ensuring forging quality, and preventing movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

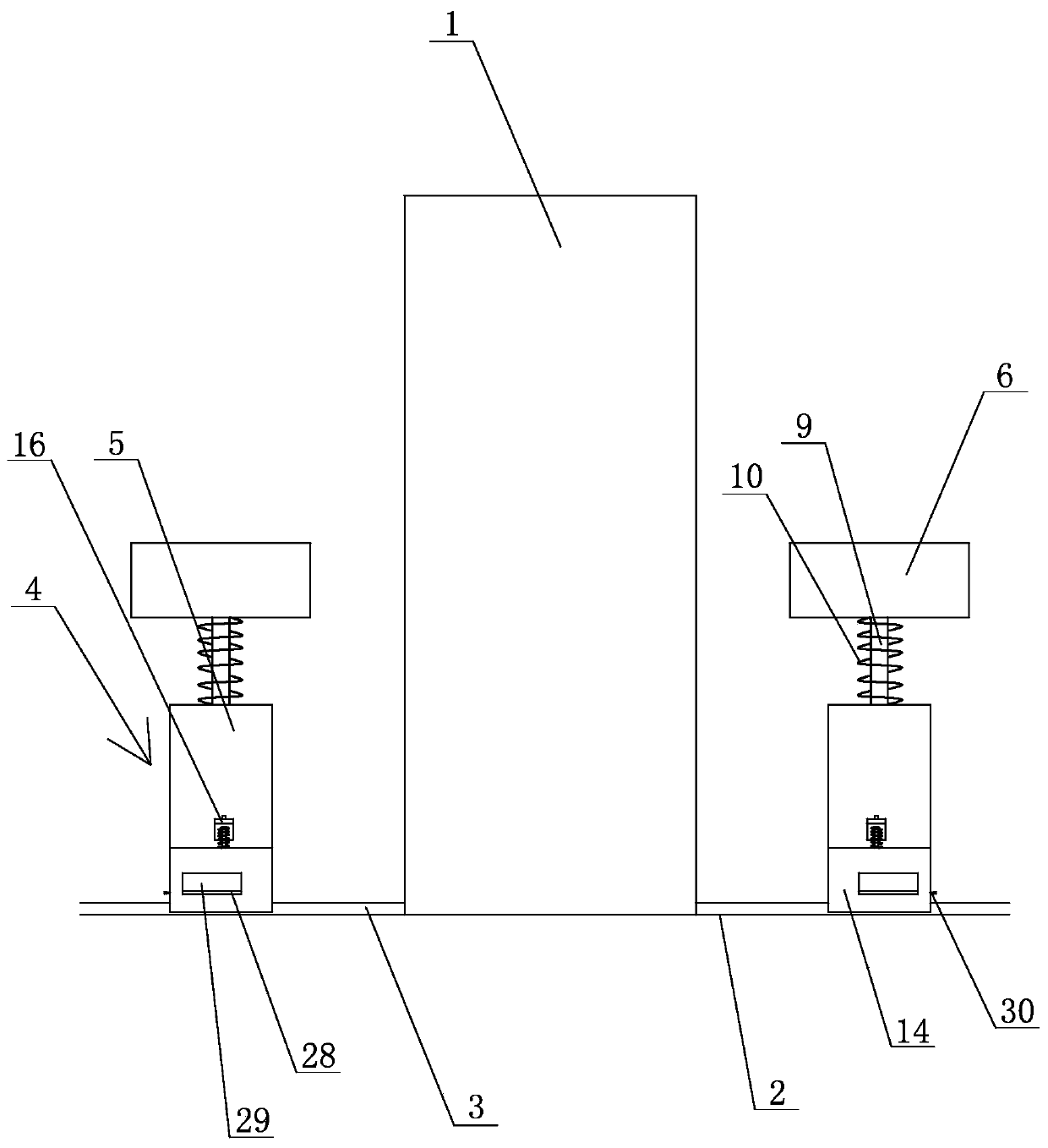

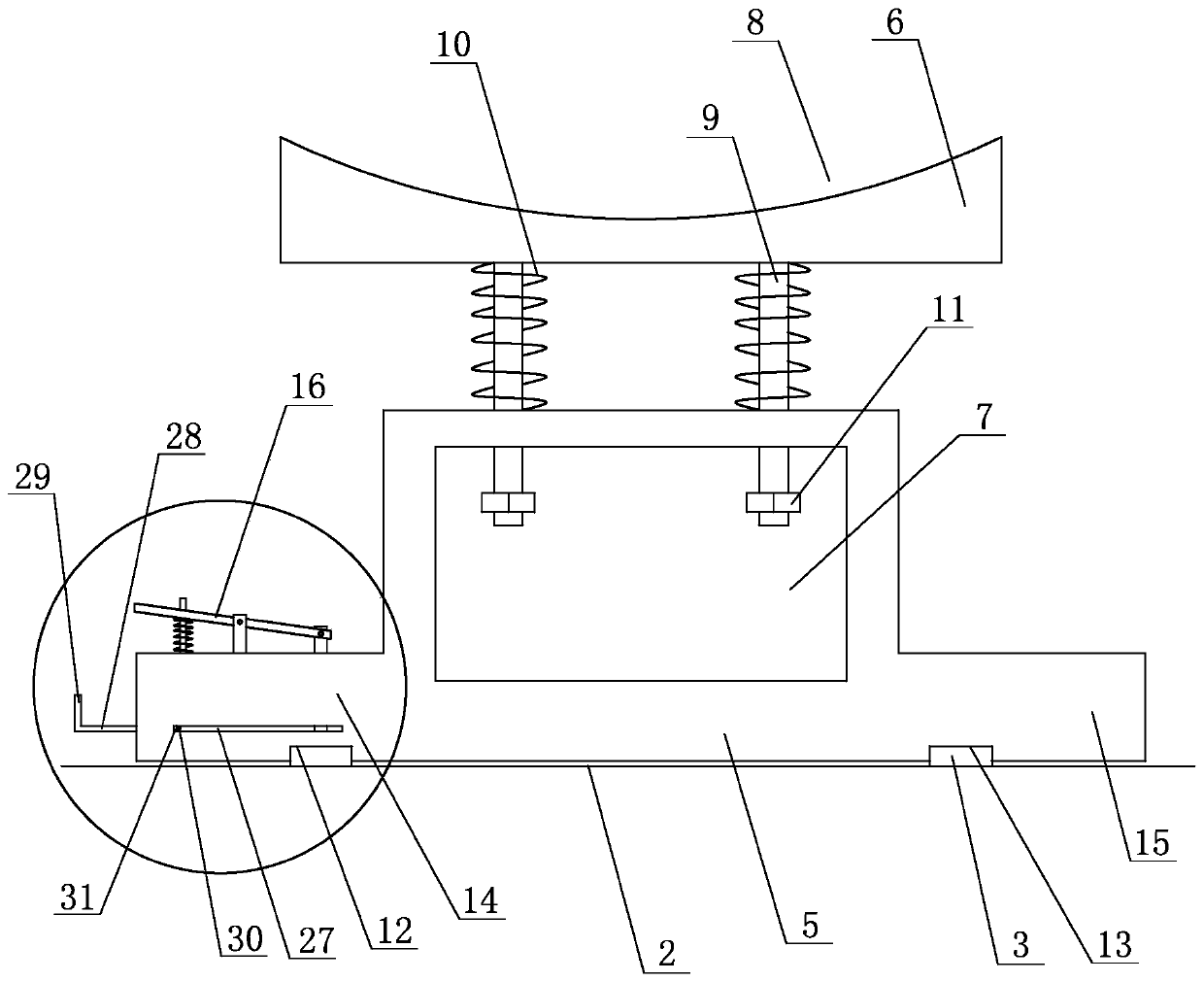

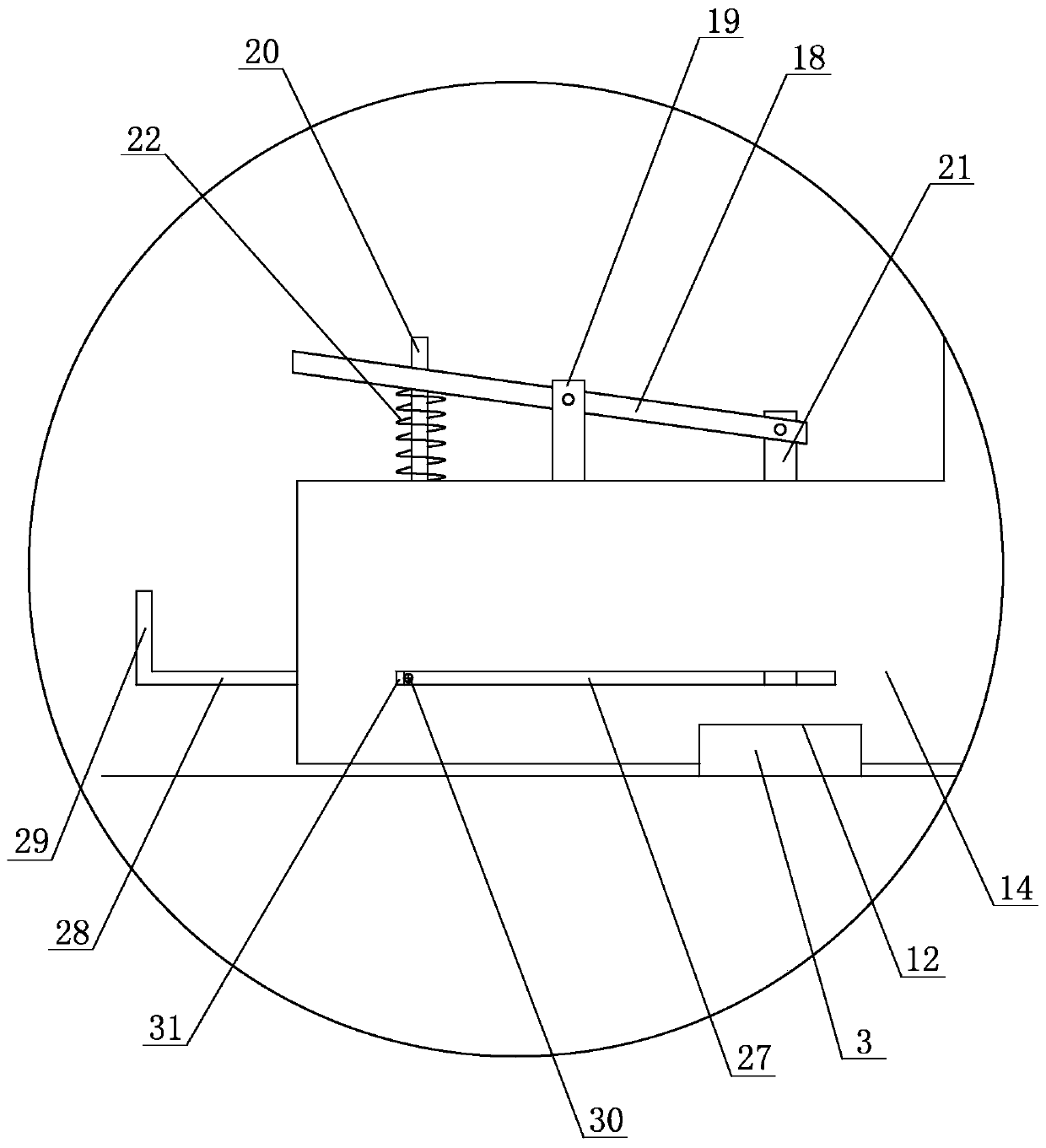

[0024] Embodiment one: see Figure 1~5 As shown, a new type of forging equipment includes a forging machine 1, the forging machine 1 is installed on the ground 2, slide rails 3 are respectively provided on the ground on both sides of the forging machine 1, and the slide rails 3 on both sides A support mechanism 4 is respectively slidably provided, and the support mechanism 4 includes a base 5 and a support block 6 arranged on the top of the base 5. The bottom surface of the base 5 is provided with two mutually parallel slide grooves, and the base 5 Slidingly arranged on the slide rail 3 through the chute; a cavity 7 is provided in the middle of the base 5, and two first through holes are provided on the top surface of the base 5, and the two first through holes The hole communicates with the cavity 7, the top of the support block 6 is provided with an arc-shaped opening 8, and the bottom of the support block 6 is provided with two guide rods 9, and the bottoms of the two guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com