Forging device

A technology of equipment and support mechanism, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of high labor intensity and low efficiency of operators, reduce labor intensity, and ensure forging efficiency and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

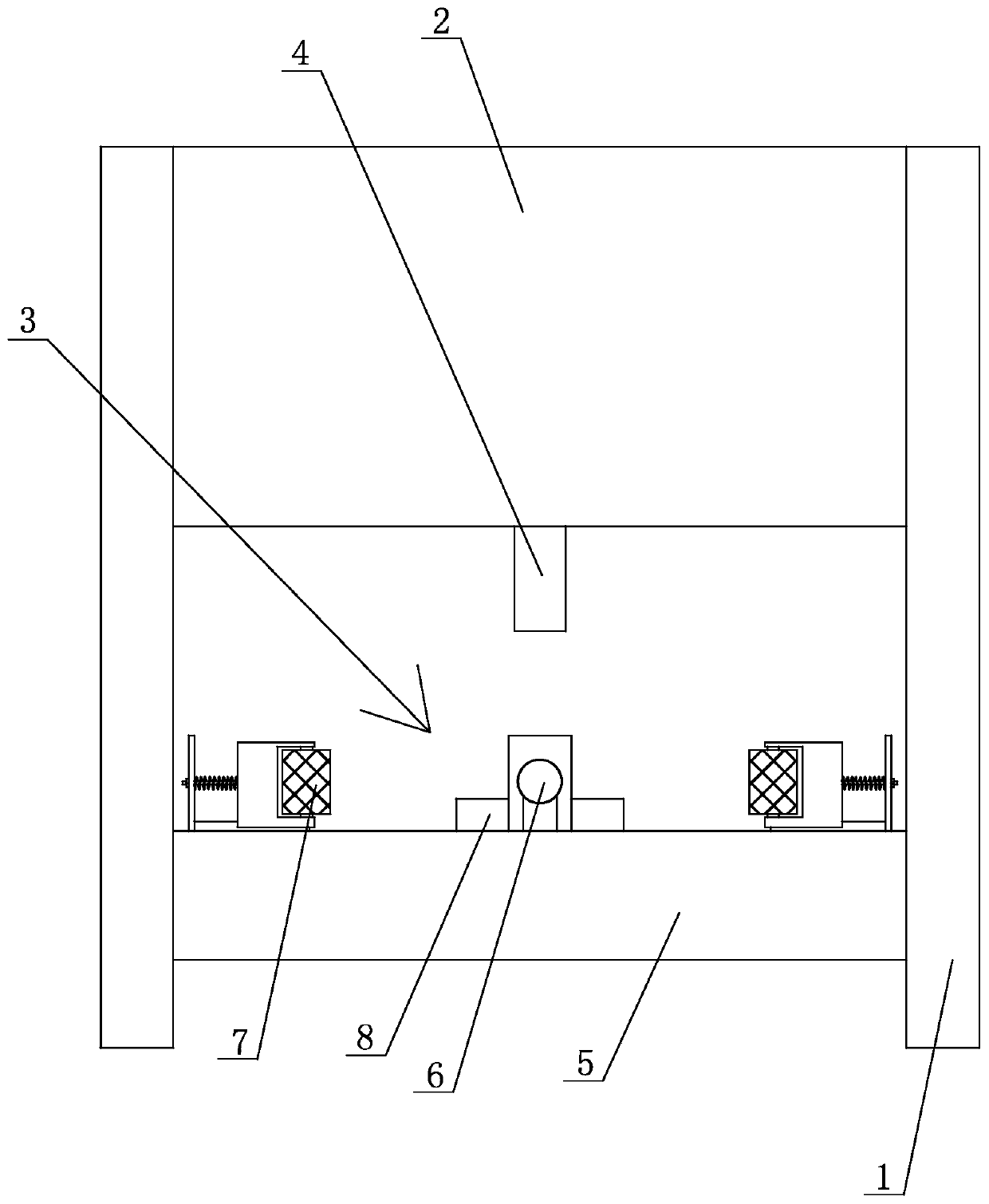

[0024] Embodiment one: see Figure 1~5 As shown, a kind of forging equipment comprises a frame 1, a forging mechanism 2 arranged on the top of the frame 1 and a support mechanism 3 arranged below the forging mechanism 2, and a forging head 4 is arranged on the forging mechanism 2, and the forging mechanism 2 The head 4 is set facing the support mechanism,

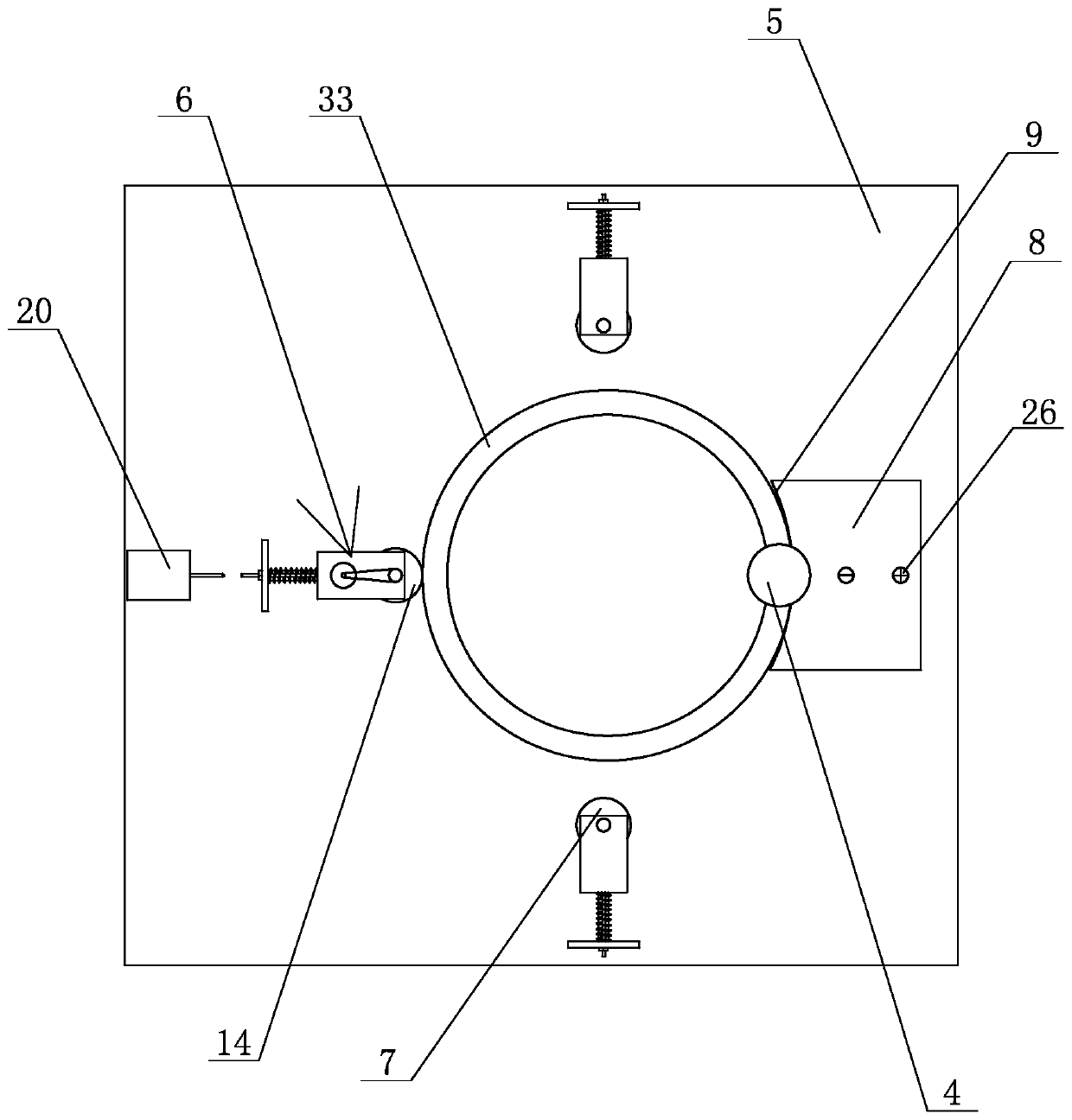

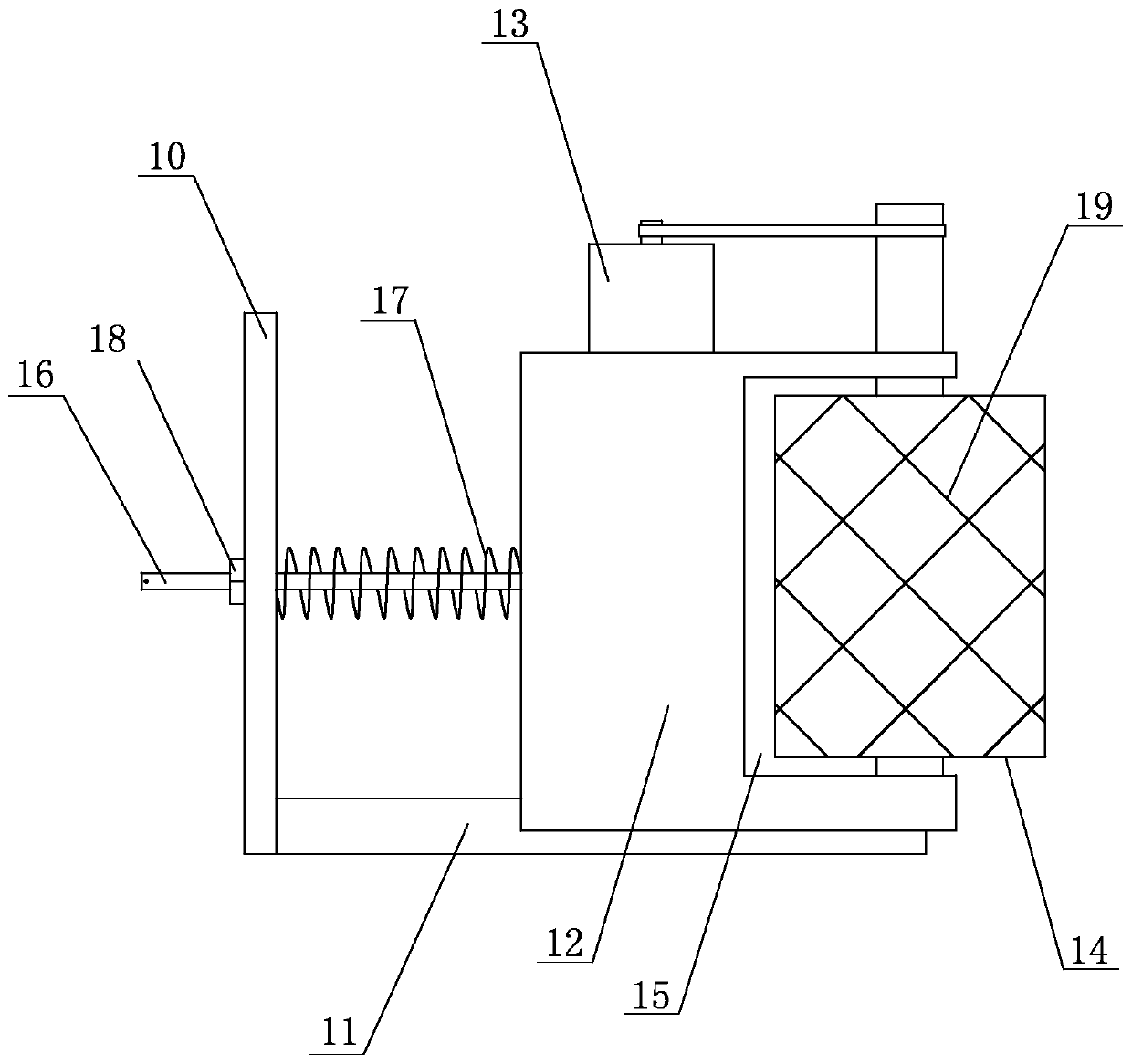

[0025] The support mechanism 2 includes a base 5, a position-limiting mechanism 6 arranged on the base 5 and two groups of support position-limiting rollers 7, the position-limiting mechanism 6 is arranged on the left side of the top surface of the base 5, and the base 5 The right side of the top surface of the top surface is provided with a limit block 8, the left side of the limit block 8 is an arc-shaped surface 9, the limit mechanism 6 is set up against the arc-shaped surface 9, and the forging head 4 It is arranged directly above the middle part of the arc-shaped surface 9; two sets of support limit rollers 7 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com