Oxygen lance Spray nozzle

An oxygen lance nozzle and oxygen lance technology, applied in furnaces, manufacturing converters, lighting and heating equipment, etc., can solve problems such as water leakage, easy generation of pores, shrinkage holes, etc., and achieve high product qualification rate, dense internal organization, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

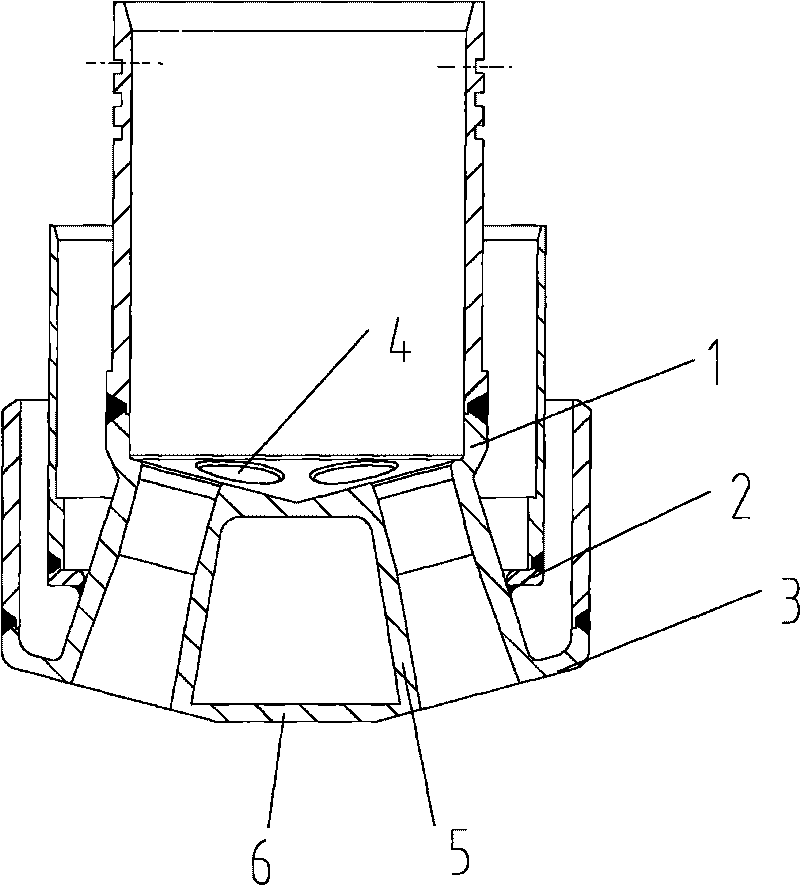

[0021] A kind of oxygen lance nozzle of the present invention as shown in accompanying drawing 1, comprises oxygen lance top 1, oxygen lance middle part 2, oxygen lance bottom 3; The end of described oxygen lance top 1 is provided with a plurality of oxygen channels Hole 4; a plurality of Laval hole copper pillars 5 are evenly arranged on the end of the upper part 1 of the oxygen lance, and the Laval hole forms an air flow channel with the oxygen through hole 4; the middle part of the oxygen lance 2 is arranged on the Laval hole The middle part of the copper column 5; the lower part 3 of the oxygen lance is arranged on the outside of the lower end of the Laval hole copper column 5; the inner side of the lower end of the Laval hole copper column 5 is provided with a bottom plate 6; the parts are integrally arranged , made by precision casting.

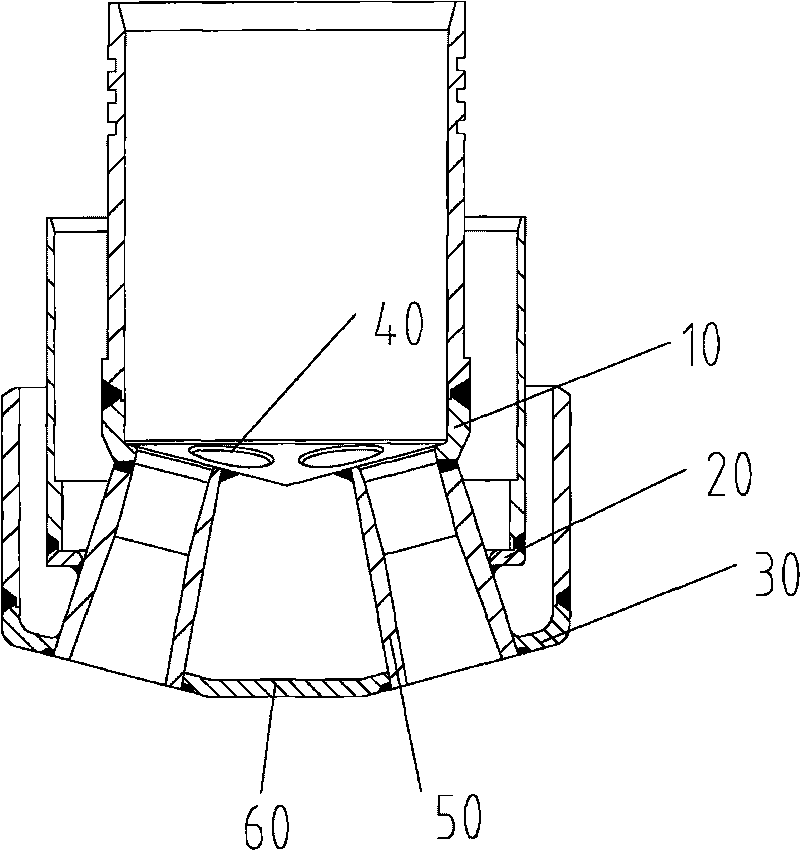

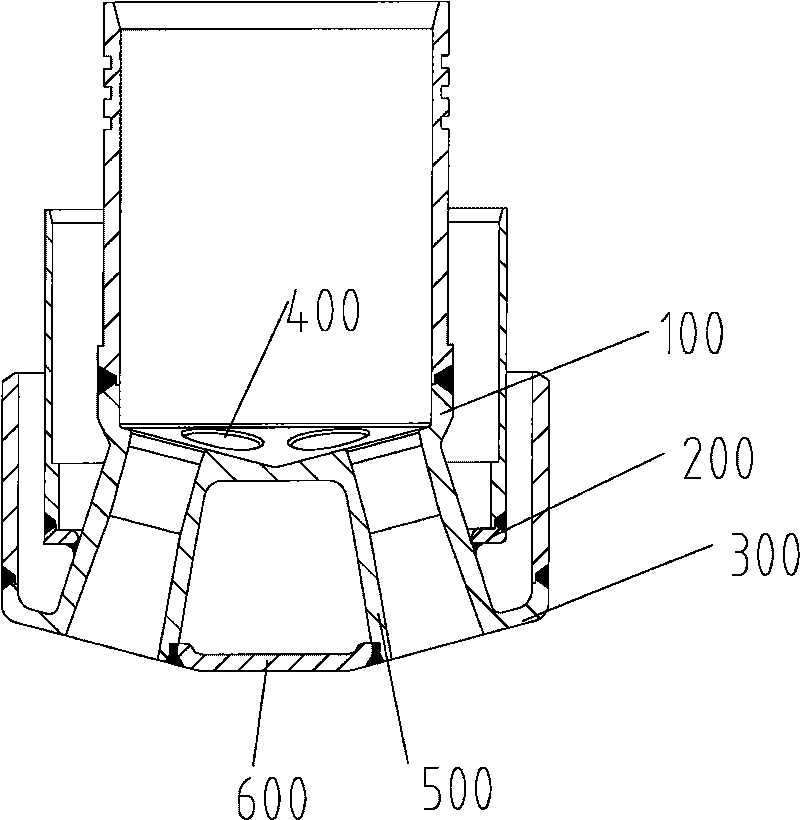

[0022] A kind of oxygen lance nozzle of the first embodiment of the present invention as shown in accompanying drawing 2, comprises ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com