Forming method for improving structure property of QAl10-4-4 aluminum bronze alloy cast ingot

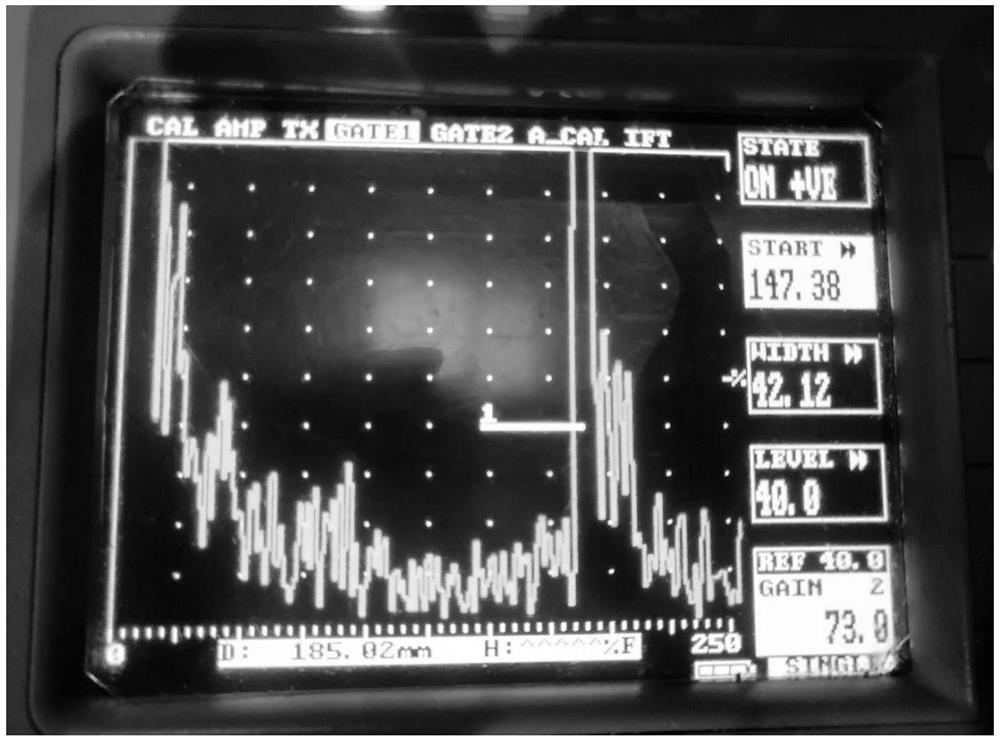

A technology for alloy ingots and microstructure properties, applied in furnace types, metal processing equipment, furnaces, etc., can solve the problems of limited forging deformation, coarse grains of ingots, and difficult to improve the structure, and achieve compact processing steps and flaw detection High level, fine grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In this embodiment, the specification of QAl10-4-4 aluminum bronze alloy bar is Ф360mm×750mm:

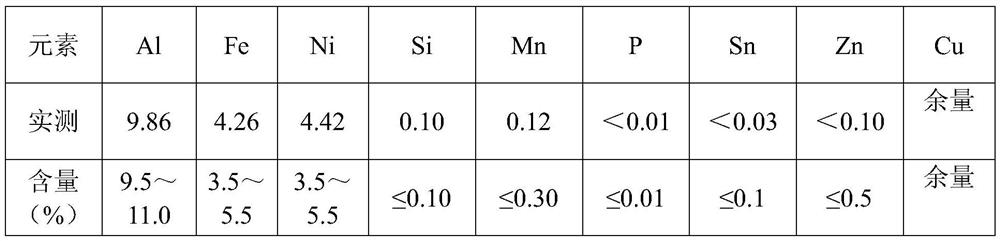

[0038] The main chemical element content of QAl10-4-4 alloy is shown in Table 1:

[0039] Table 1

[0040]

[0041] To implement the present invention, it is necessary to provide a band sawing machine, a forging furnace, a press, a manipulator, a heat treatment furnace, and testing equipment.

[0042] In this embodiment, the forming method for improving the microstructure and properties of a QAl10-4-4 aluminum bronze alloy ingot includes the following steps: billet forging of the ingot, intermediate process forging, final forging molding, and annealing treatment.

[0043]Ingot billet forging: The QAl10-4-4 aluminum bronze ingot with a size of Ф360mm×750mm is heated before forging by an electric furnace. Set the heating temperature to 890°C, cast the ingot to the warm charging furnace, select the heating coefficient at the set temperature to be 0.6min / mm, and the holding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com