Method for heating large sheet arc-shaped forge piece before forging

A heating method and forging technology, which are applied in metal processing equipment, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve problems such as uncontrollable deformation, mismatched sheet shapes, and reduced initial forging temperature. , to avoid the low initial forging temperature, ensure the forging quality and improve the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

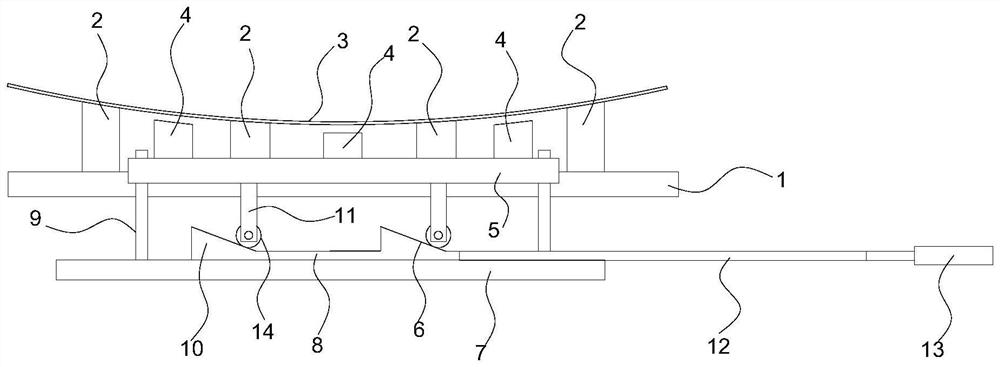

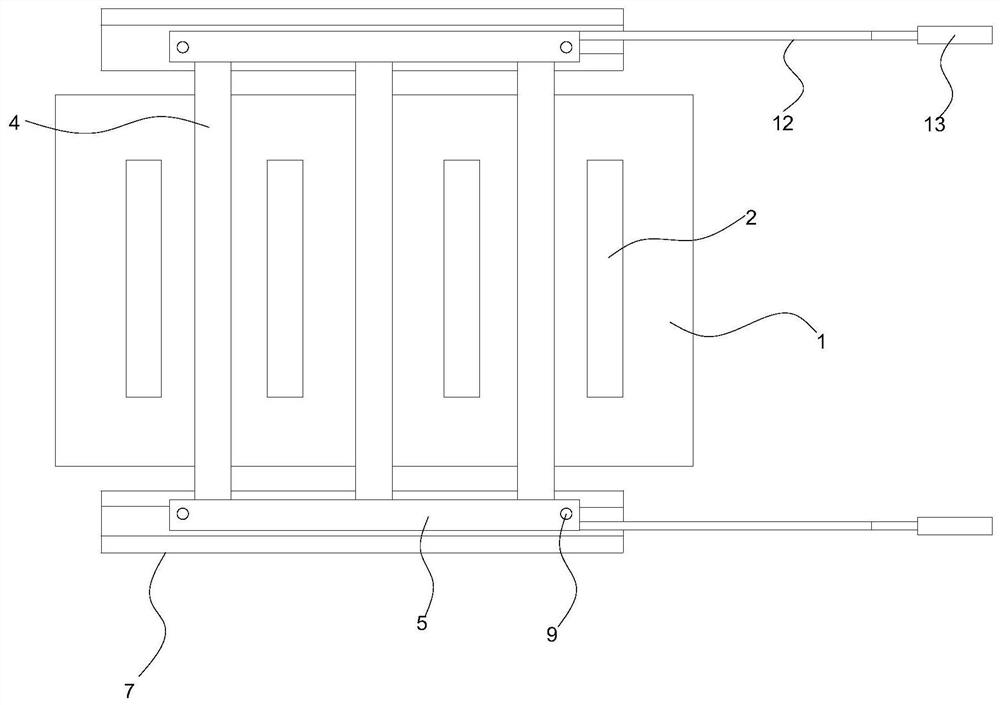

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] The heating method before forging of large thin plate arc forgings of the present invention comprises

[0023] A. If figure 1 with figure 2 As shown, a plurality of shim irons 2 parallel to each other are arranged on the universal tray 1, and the height of the shim irons 2 decreases gradually from both ends to the middle. The forging 3 is a straight plate before heating, and the heating deformation is generally a downward depression in the middle position. Therefore, in the parallel iron group composed of multiple parallel irons 2, the parallel iron 2 at both ends has the largest height, and the horizontal parallel iron 2 in the middle The height is small, so that the height distribution of the parallel iron 2 is adapted to the deformation of the forging 3 , and the uniformity of the deformation of the forging 3 can be ensured while supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com