Automatic multi-station forging production line for sector gear shaft

A sector-shaped gear shaft and multi-station technology, applied in the direction of manufacturing tools, engine components, metal processing equipment, etc., to achieve the effect of ensuring forging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0057] In describing the present invention, it should be understood that the terms "center", "longitudinal", "transverse", "length", "width", "thickness", "upper", "lower", "front", " Back", "Left", "Right", "Vertical", "Horizontal", "Top", "Bottom", "Inner", "Outer", "Clockwise", "Counterclockwise", "Axial", The orientation or positional relationship indicated by "radial", "circumferential", etc. is based on the orientation or positional relationship shown in the drawings, and is only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying the referred device or element Must be in a particular orientation, be constructed in a particular orientation, and operate in a particular orientation, and therefore should not be construed as limiting the invention.

[0058] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in d...

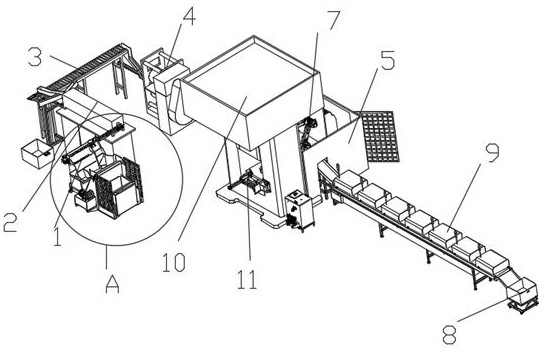

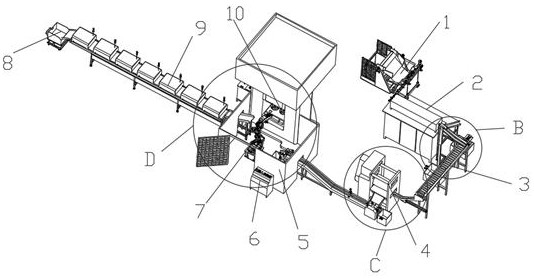

specific Embodiment 1

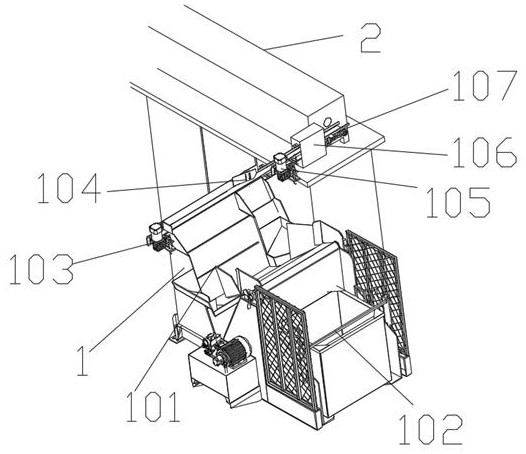

[0061] An automatic multi-station forging production line for a sector gear shaft, the starting end is provided with a feeder 1, the feeder 1 is provided with a material basket 102, and a push plate 101 is provided inside the material basket 102, the thickness of the push plate 101 is the same as that of the billet bar The diameter is the same, and there are three push plates 101, which are respectively low push plate, middle push plate and high push plate. If the push plate is high, the axial direction of the billet rod is not the same as the thickness direction of the push plate 101 during this process, and it cannot stay on the push plate, and falls back to the material basket 101 under the action of its own gravity for the next push cycle, which can Staying on the push plate 101 and being pushed to the high push plate includes two situations: lying horizontally and standing upright, and the high push plate pushes the blank bars of these two postures into the first plate cha...

specific Embodiment 2

[0078] On the basis of Embodiment 1, an automatic rotating device is installed in the heating furnace, and the billet is held by the automatic rotating device to rotate 90-180° clockwise or counterclockwise and move along the feeding direction of the conveying line.

[0079] Specifically, plate chains are used for conveying in the heating furnace, each plate chain is provided with a V-shaped supporting plate, and the bottom of the V-shaped supporting plate is provided with rollers, and the top of the rollers is exposed above the bottom of the V-shaped supporting plate, and is in contact with the billet bar. At the joint, the rollers form an angle of 45 degrees with the conveying direction of the plate chain. During the forward conveying process of the plate chain, the rollers are driven to rotate on the bottom pallet, and the rollers drive the billet rods to rotate in the V-shaped pallet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com