Six-dimensional parallel forging operator

A forging manipulator and parallel technology, which is applied to forging presses, forging presses, driving devices of forging presses, etc., can solve the problems of large motion inertia, complex structure, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

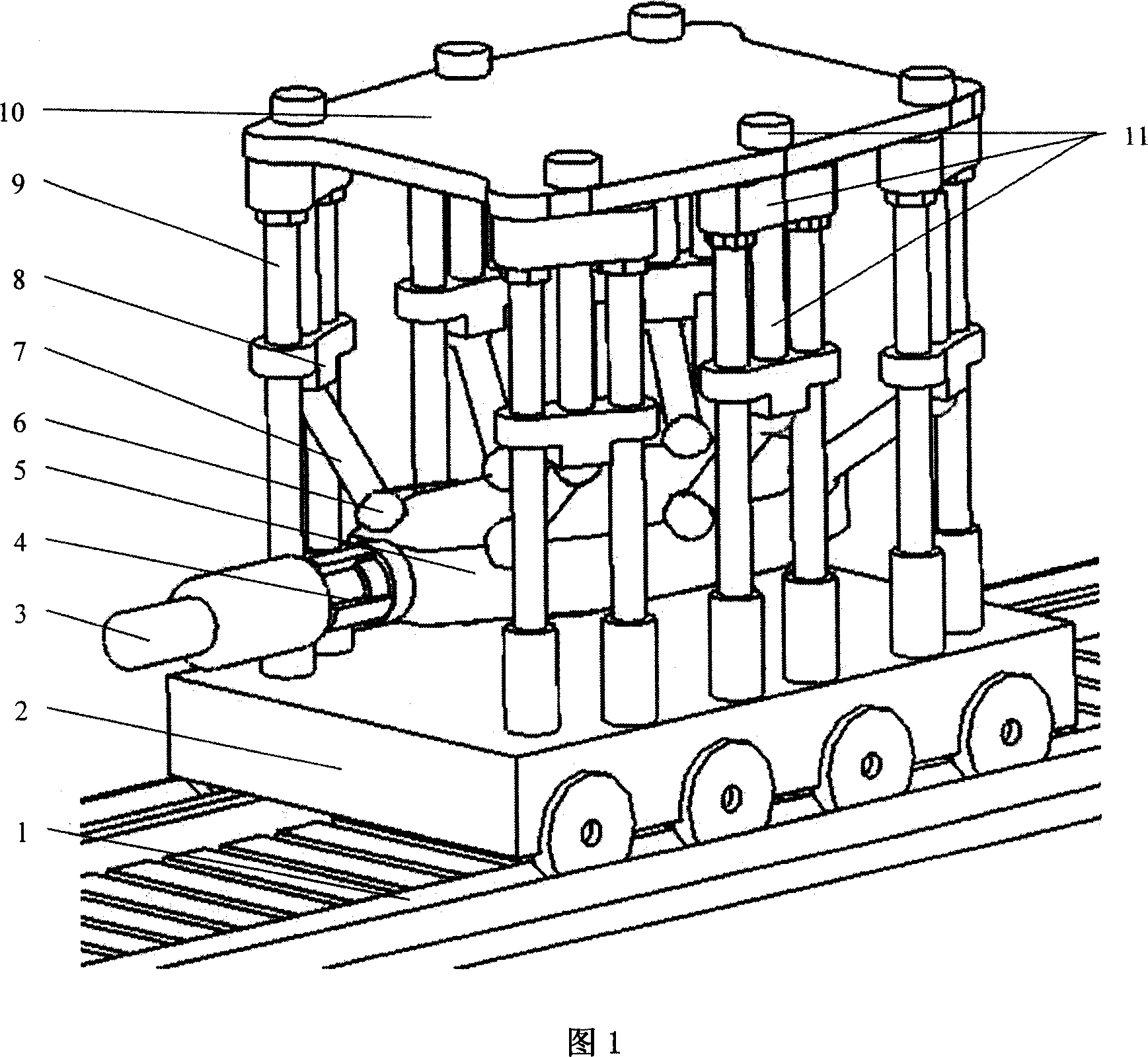

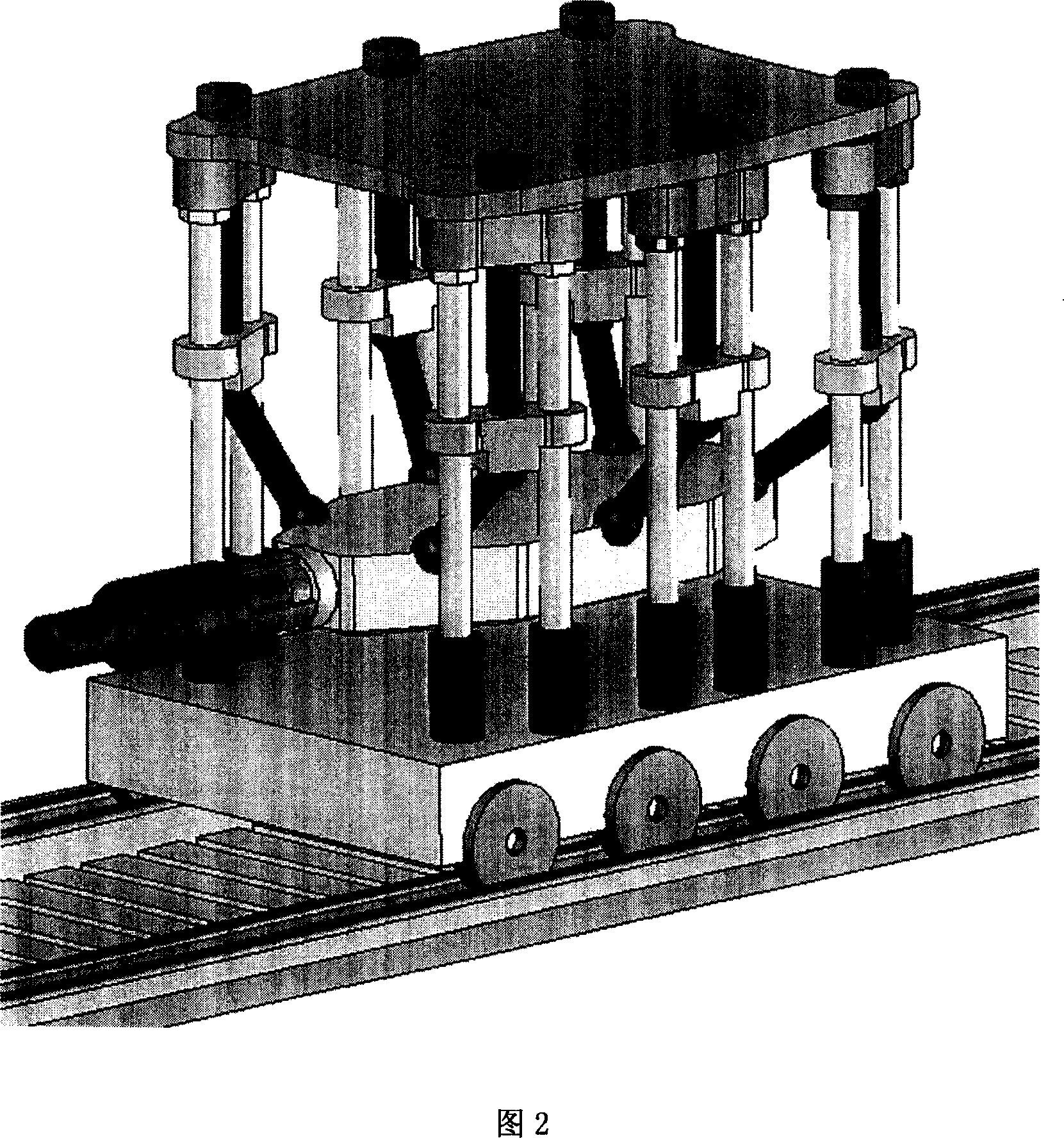

[0012] Fig. 1 is a schematic diagram of the structure of the present invention. As shown in Figure 1, the six-dimensional parallel forging manipulator of the present invention is composed of six sets of linear drive systems and a connecting mechanism connecting the linear drive systems with the clamp bar platform, mainly including: six identical connecting parts 8, twelve The same main ball joint 6, six equal-length connecting rods 7, one clamp rod platform 5, one clamp 4, one upper platform 10, six sets of identical column slide rails 9, and six sets of identical straight lines drive system 11. Six sets of linear drive systems 11 are fixedly connected to the upper platform 10 along the circumferential direction of the upper platform 10, and are each guided by a set of column slide rails 9 fixed on the traveling cart 2. Each set of linear dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com