Series-parallel forging manipulator

A forging manipulator and mixed-type technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of inconsistency between the structure setting of the forging manipulator and the target function, etc. Achieve the effects of reducing energy consumption, ensuring forging quality, and making it easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

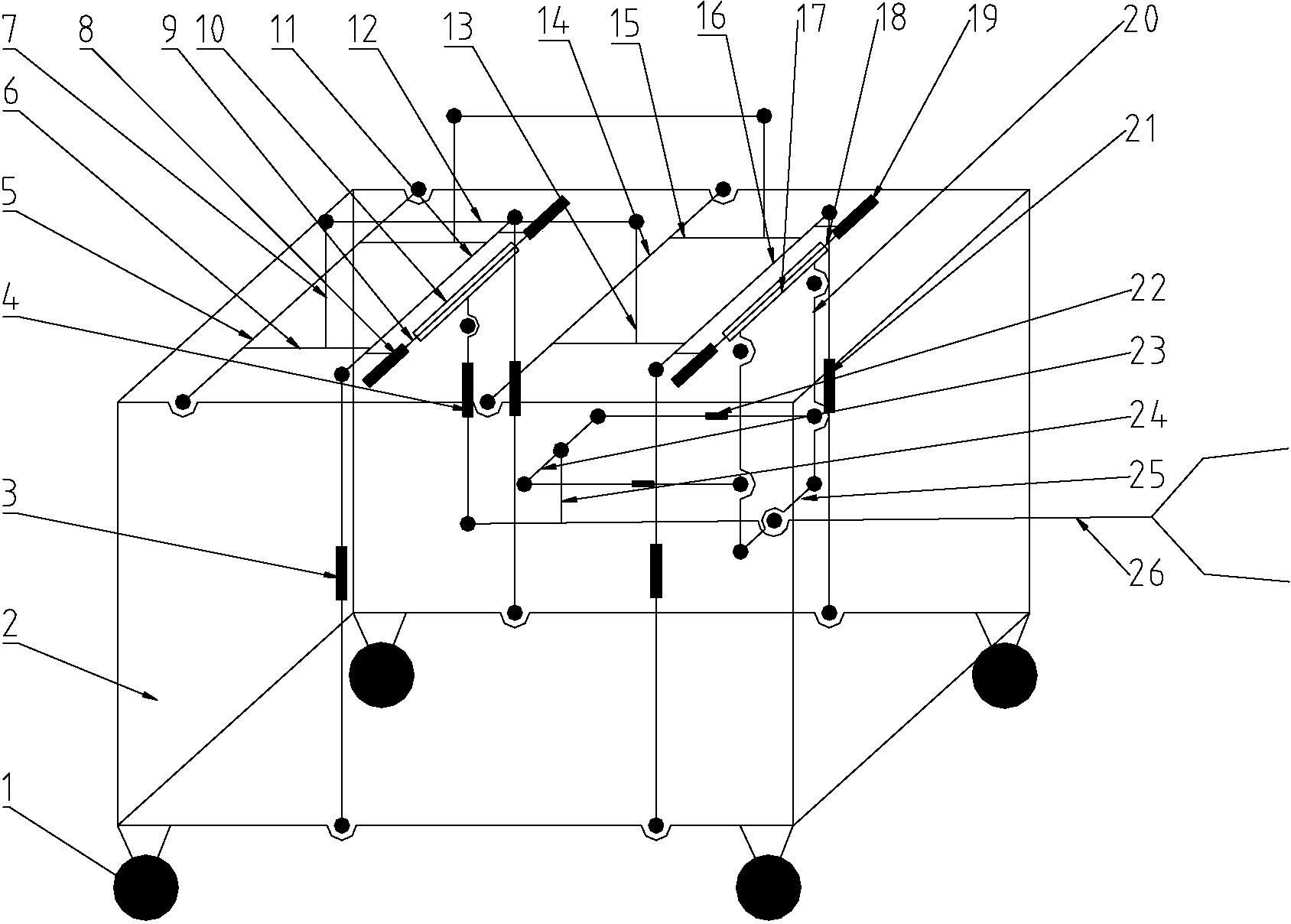

[0023] The hybrid forging manipulator of the present invention includes a lifting mechanism for realizing lifting and pitching movement of the tongs, a swing mechanism for realizing the lateral translation and swinging movement of the tongs, a buffer mechanism for realizing the buffering movement of the tongs, tongs and connecting devices and Walk the cart.

[0024] see now figure 1 , figure 1 It is a structural schematic diagram of the hybrid six-degree-of-freedom forging manipulator of the present invention. As shown in the figure, the lifting mechanism consists of a front lifting arm, a pair of front suspension rods 20, a clamp support shaft 25, a pair of front lifting linear drives 21, a rear lifting arm, a pitching linear drive 4, and a pair of rear lifting linear drives. 3 and a pair of upper connecting rods 12 form. The front and rear lifting arms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com