Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Good stability and reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing high purity 2-hydroxy-3-naphthoic acid

ActiveCN102816063AEasy to handleImprove stabilityCarboxylic compound separation/purificationDistillationCarbonization

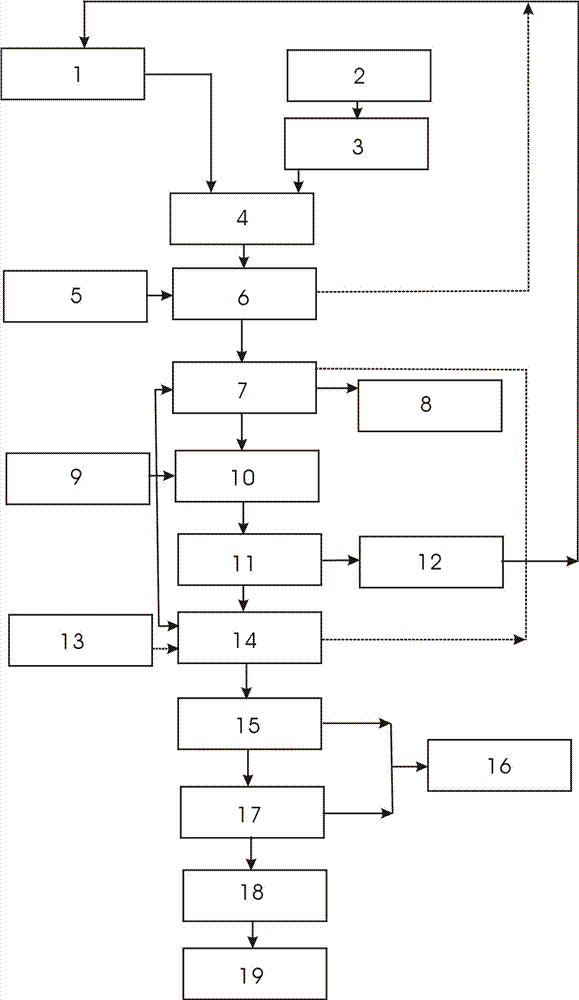

Disclosed is a method for producing a high purity 2-hydroxy-3-naphthoic acid. The method includes a 2-naphthol measuring tank, a caustic soda liquid storage tank, a caustic soda liquid measuring tank, a salt forming reaction vessel, carbon dioxide, a carbonization kettle, a resin separation, a resin solid waste, a dilute sulfuric acid, a neutralization, a filter pressing, a filter cake distillation, a 8% sodium hydroxide, a resin adsorption, an acid eduction, a sewage treatment workshop, a centrifugal dewatering, a pneumatic drying and finishing of a high purity 2-hydroxy-3-naphthoic acid product. The caustic soda liquid storage tank is downwards connected to the caustic soda liquid measuring tank, the caustic soda liquid measuring tank is connected to the salt forming reaction vessel, the salt forming reaction vessel is downwards connected to the carbonization kettle, simultaneously the carbon dioxide is connected to the carbonization kettle, 2-naphthol generated by reaction in the carbonization kettle and 2-naphthol obtained by the filter cake distillation are connected to the 2-naphthol measuring tank, the carbonization kettle is downwards connected to the resin separation, and simultaneously the resin separation is upwards connected to an ethyl naphthol feed liquid and the dilute sulfuric acid and downwards connected to the neutralization and the resin solid waste. According to the method, the whole process is simple, the operation and the usage are convenient, the stability is good, and the reliability is high.

Owner:山东世纪阳光科技有限公司

Detection circuit and method of temperature sensor

InactiveCN102207413AGood stability and reliabilityEasy to implementThermometer testing/calibrationOnline testProgrammable logic controller

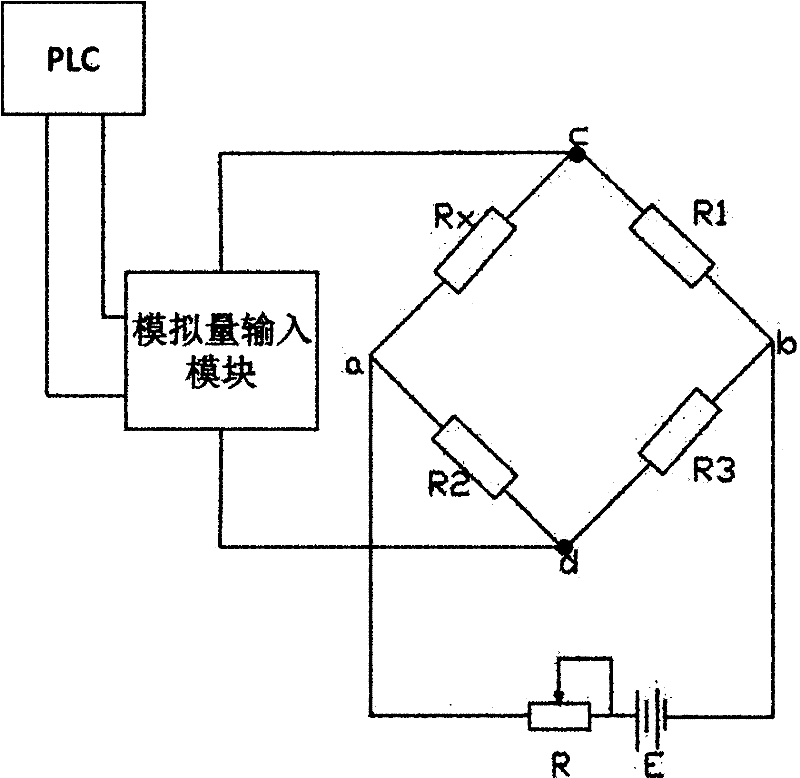

The invention discloses a detection circuit and method of a temperature sensor, wherein the detection circuit comprises or relates to a temperature sensor Rx to be detected, an analog quantity input module, a programmable logic controller PLC (programmable logical controller) and a power supply E, and further comprises a Wheatstone bridge consisting of a sample temperature sensor R1, a second resistor R2, a third resistor R3 and the detected temperature sensor Rx. The detection circuit and method of the temperature sensor in the invention overcome the influence of the change of ambient temperature on the test result. According to the invention, the judgment range for detection can be reduced from the range of the detected temperature sensor Rx from 770Omega to 3378Omega, to the range froma resistance difference value plus 200Omega to the resistance difference value minus 200 (corresponding to 0.5V output voltage of the Wheatstone bridge and below), wherein the resistance difference value is between the detected temperature sensor and the sample temperature sensor R1, thereby sufficiently implementing efficient test on the stability and reliability of the detected temperature sensor. The detection circuit and method of the temperature sensor are convenient in implementation, low in implementation cost and very suitable for workshop online test.

Owner:SHANGHAI BEHR THERMAL SYST

High-speed parallel D/A clock synchronization apparatus

ActiveCN105094014AStable and synchronous workGood stability and reliabilityProgramme controlComputer controlRadio frequency circuitsSignal production

The invention discloses a high-speed parallel D / A clock synchronization apparatus. The high-speed parallel D / A clock synchronization apparatus comprises a signal conditioning unit for adjusting the amplitude size of clock signals, increasing the amplitude of the clock signals to a saturation degree of an amplification unit before a switch unit is energized and then reducing the amplitude after a state is stable so as to enable the amplification unit to work at a linear interval, and the switch unit and the amplification unit. The invention further discloses a high-speed parallel D / A clock synchronization method. According to the apparatus and method provided by the invention, synchronization of a multichannel signal generation system can only be concentrated on on-off of a radio frequency switch, the transition time at the moment when the switch is turned on and turned off is substantially compressed, the influences of errors caused by clock jittering at D / A conversion initial time, and the stability and the reliability are good. On the other hand, by use of the feature of small noise of a radio frequency circuit, low-noise conversion of high-speed clock signals from a single end to a differential is finished, and the application requirement of circuit difference signals can be met.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

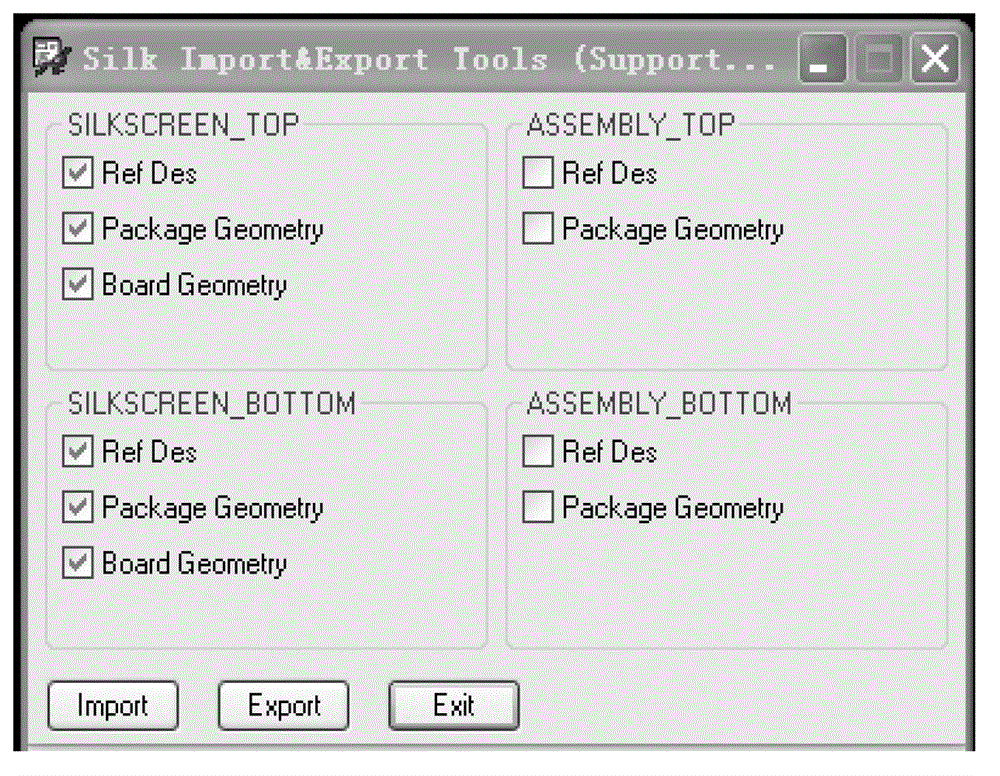

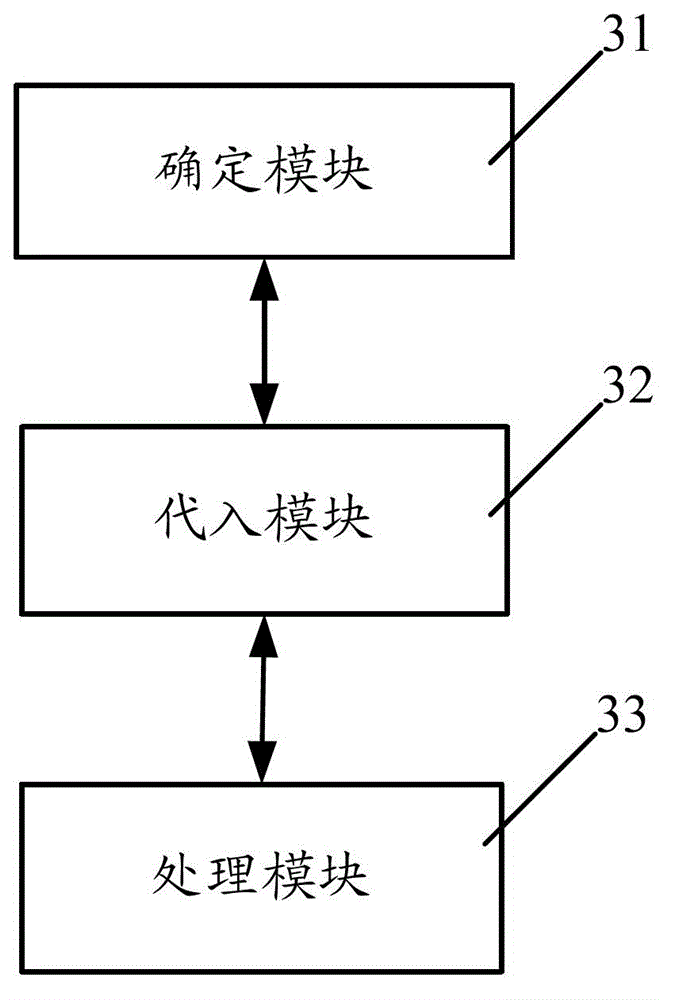

Processing method and device of screen print

ActiveCN102982217AReduce occupancyGood stability and reliabilitySpecial data processing applicationsEmbedded systemUser input

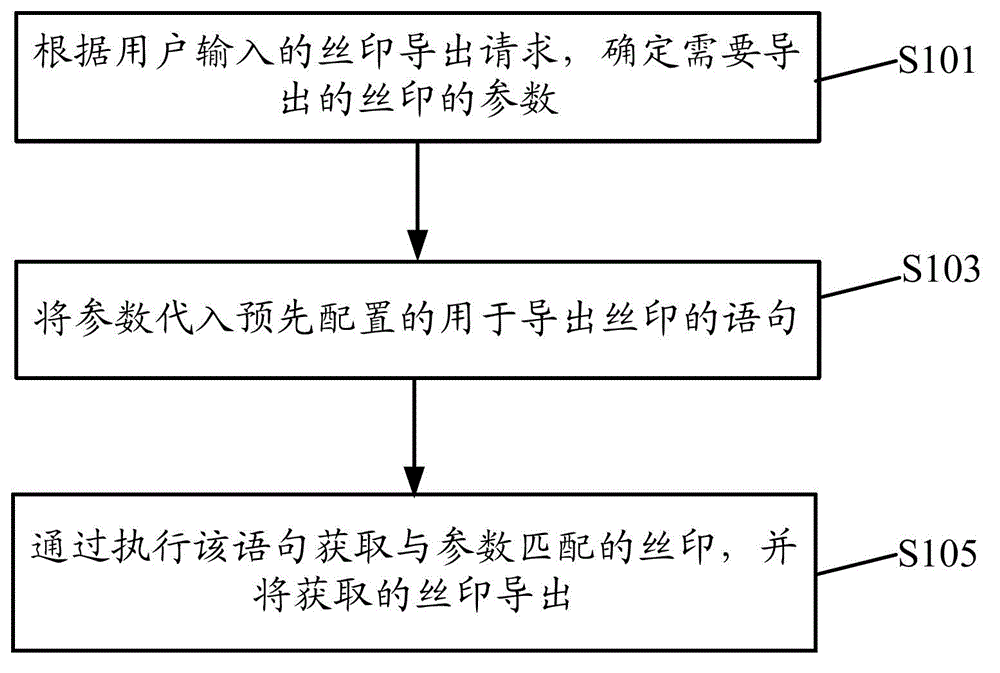

The invention discloses a processing method and a processing device of screen print. The method comprises the steps of: determining parameters of the screen print needed to be led out according to a screen print leading-out request input by a user; introducing the parameters into a statement predetermined for leading out the screen print; and obtaining the screen print matched with the parameters by executing the statement and leading out the obtained screen print. According to the processing method and the processing device of the screen print, provided by the invention, the memory footprint by screen print operation is reduced by receiving the request of the user and leading out the screen print require according to the stored statement for leading out the screen print, and as the statement is preconfigured, the accuracy of the screen print operation is improved. In addition, the users can share the design result, and the user experience is improved.

Owner:宁畅信息产业(北京)有限公司

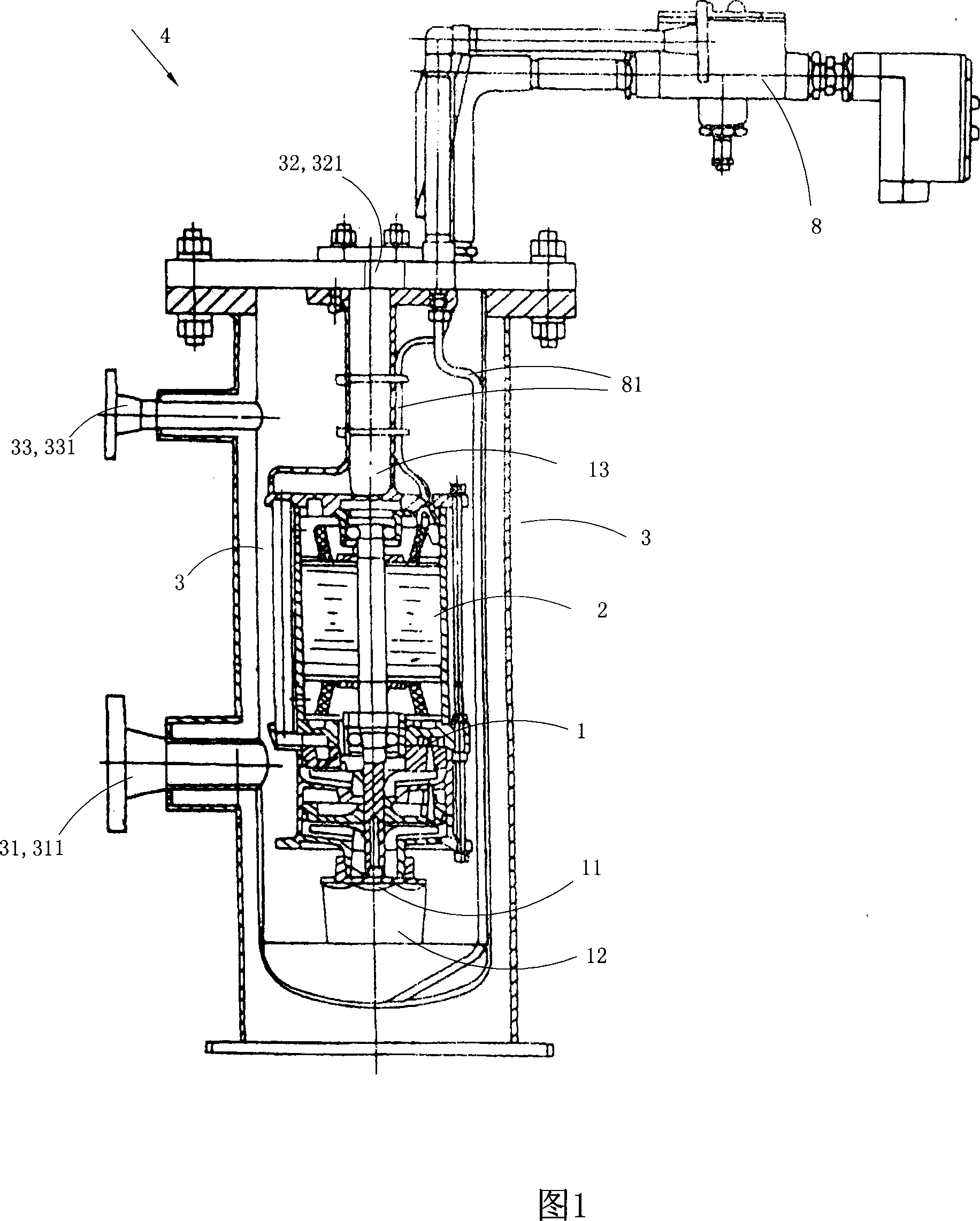

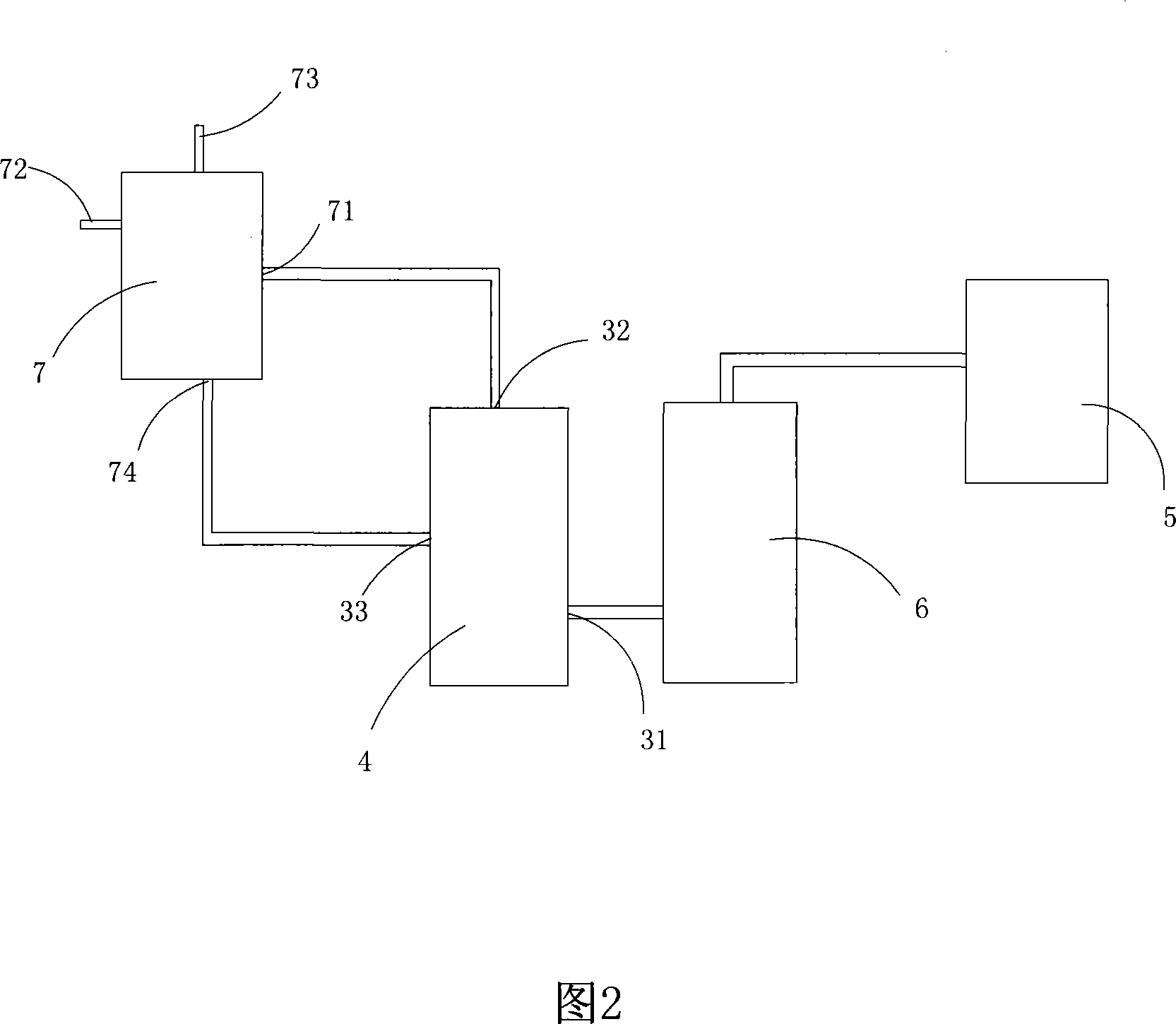

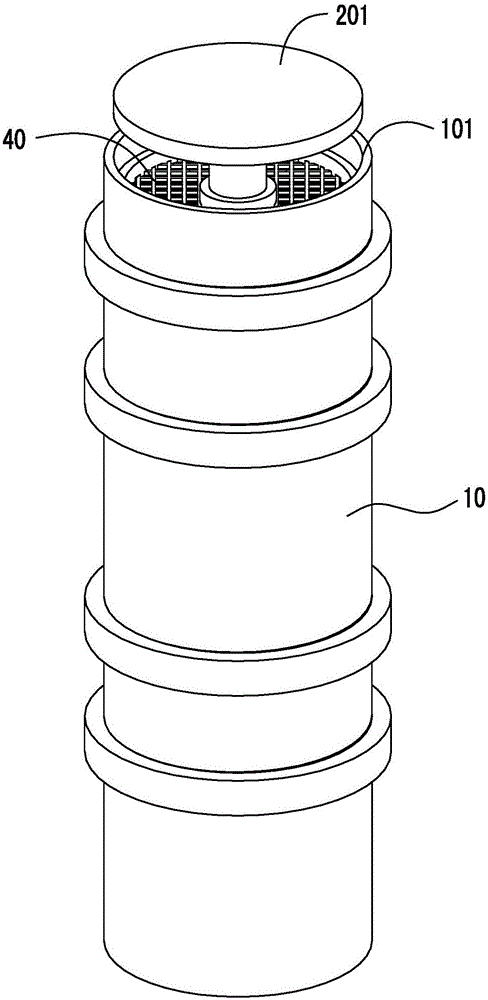

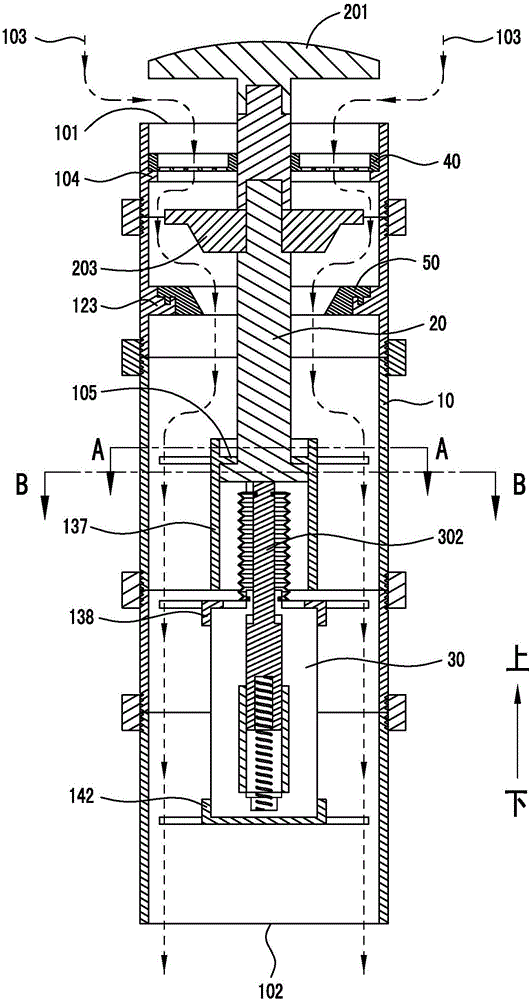

Natural gas liquid charging-up pump and natural gas liquid charging-up station

InactiveCN101131158AGood stability and reliabilitySimple manufacturing processPump componentsPump installationsImpellerLiquefied natural gas

The present invention discloses one kind of liquefied natural gas filling pump and corresponding liquefied natural gas filling station. The filling pump has one pump body with one sucking port and one pressing out port and one motor to drive the vane wheel inside the pump body to rotate, and features its shell for housing the pump body and the motor and with one liquid inlet, one liquid outlet communicated through pipeline to the pressing out port in the pump body, and one gas returning port. The liquefied natural gas filling station includes one unloading unit, one liquefied natural gas storage tank, one liquefied natural gas filling pump and one liquefied natural gas filling machine connected serially. The present invention has the advantages of operation stability and high reliability.

Owner:林寿贵

Distributed cooperative transmission method in embedded environment

InactiveCN102075576AAvoid service overloadGood stability and reliabilityTransmissionData transmissionDistributed computing

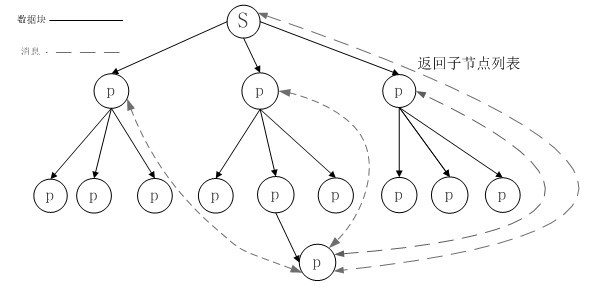

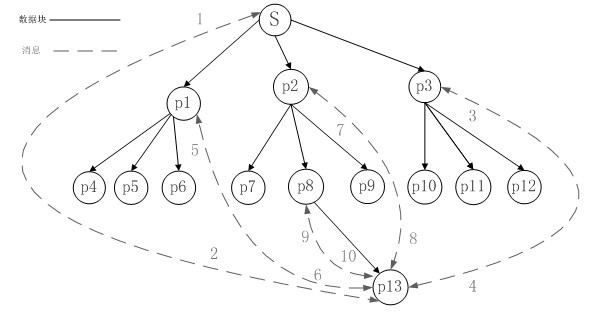

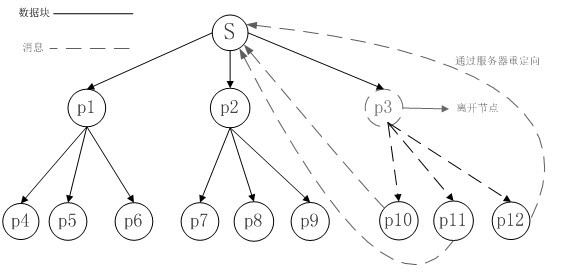

The invention discloses a distributed cooperative transmission method in an embedded environment, which is mainly applied to real-time media data transmission. In the method, based on tree hierarchical topology, a session initiator is used as a root node, and a session participant is used as a child node. When the participant joins in a session, the participant sends a connection request to the initiator, and the initiator determines to accept or reject the connection based on a personal connecting threshold value and sends a child node list at the same time. The participant initiates the connection request to the child node in the child node list according to the acquired child node list and a double linked list mechanism, and if the request is successful, the child node becomes a parent node of the current participant, otherwise, the participant continuously requests the child node for the child node list. The participant continuously repeats the processes and exits till the connection is established successfully or a maximum request number is achieved. The method makes full use of finite calculation resource, storage resource and network bandwidth of the embedded environment, and can effectively support medium and big-scale real-time media data distribution.

Owner:HUAZHONG UNIV OF SCI & TECH

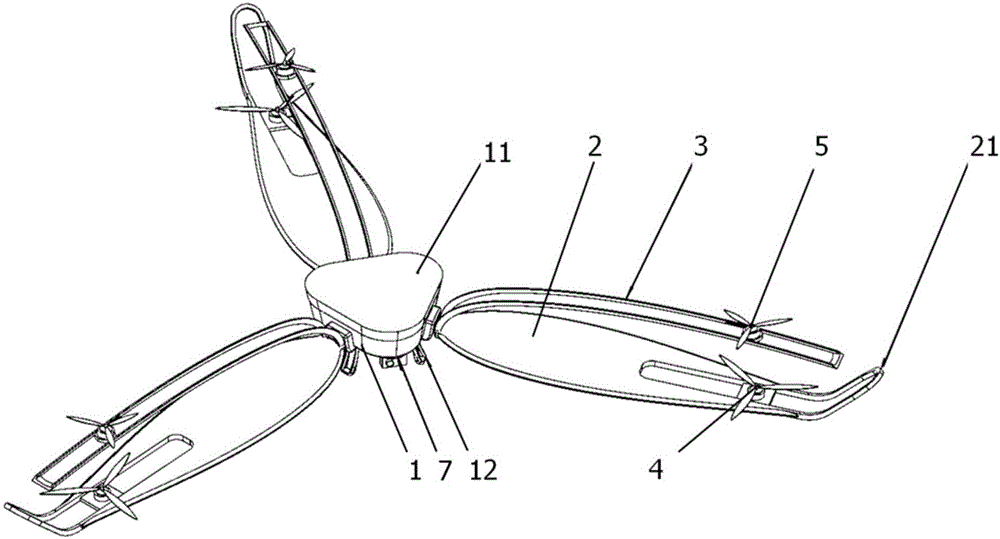

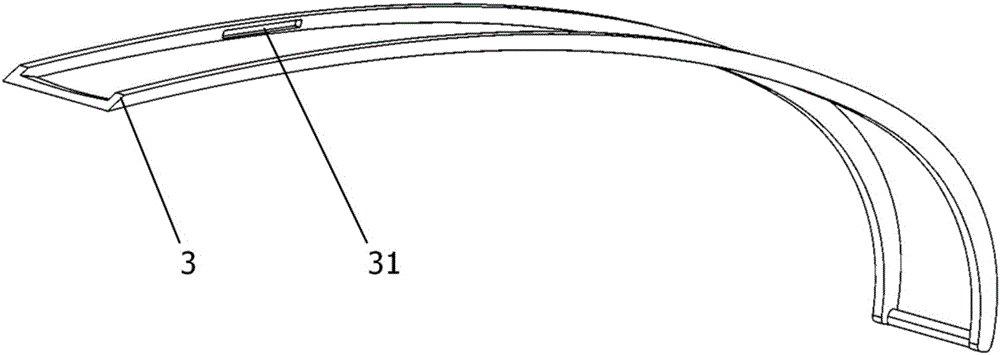

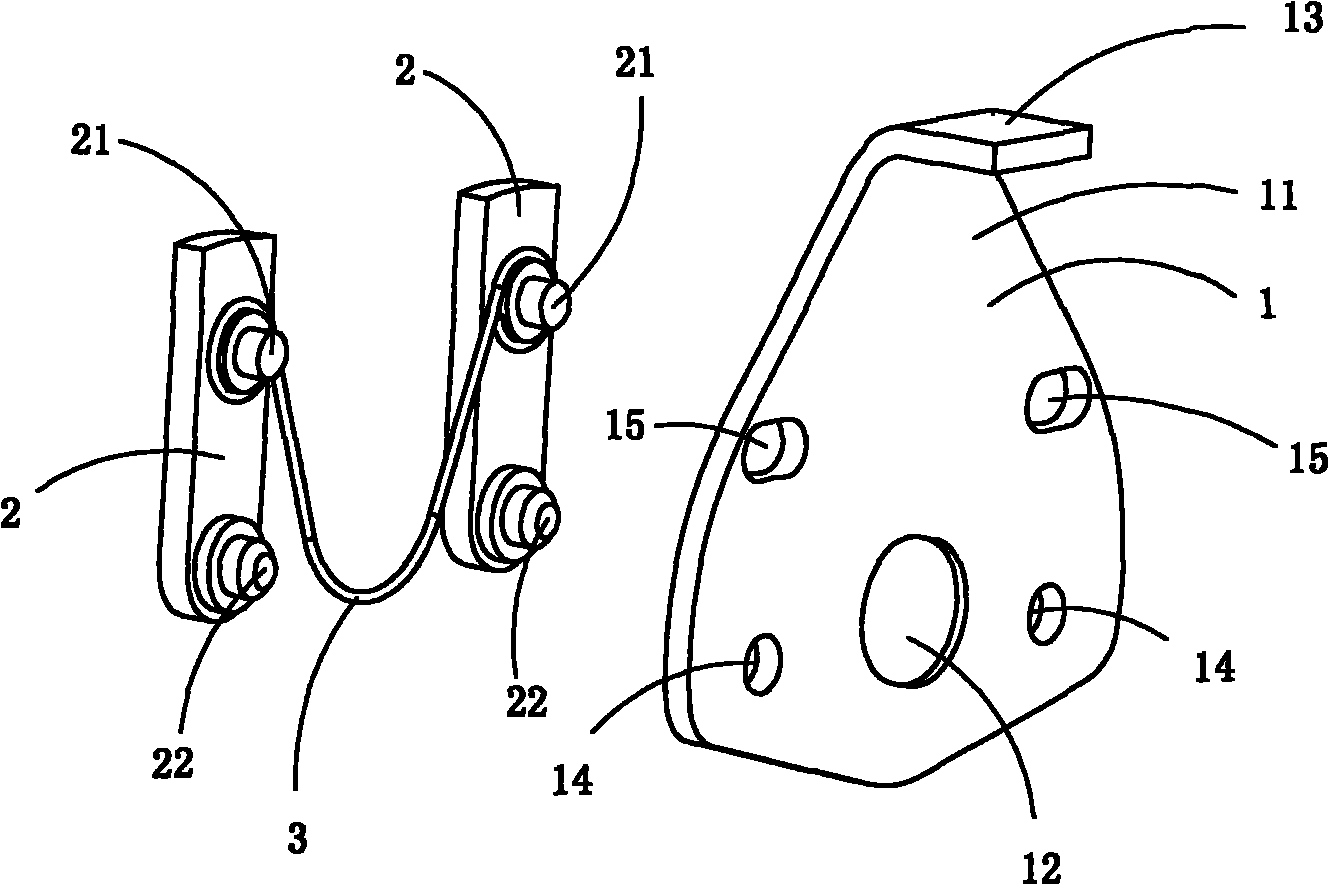

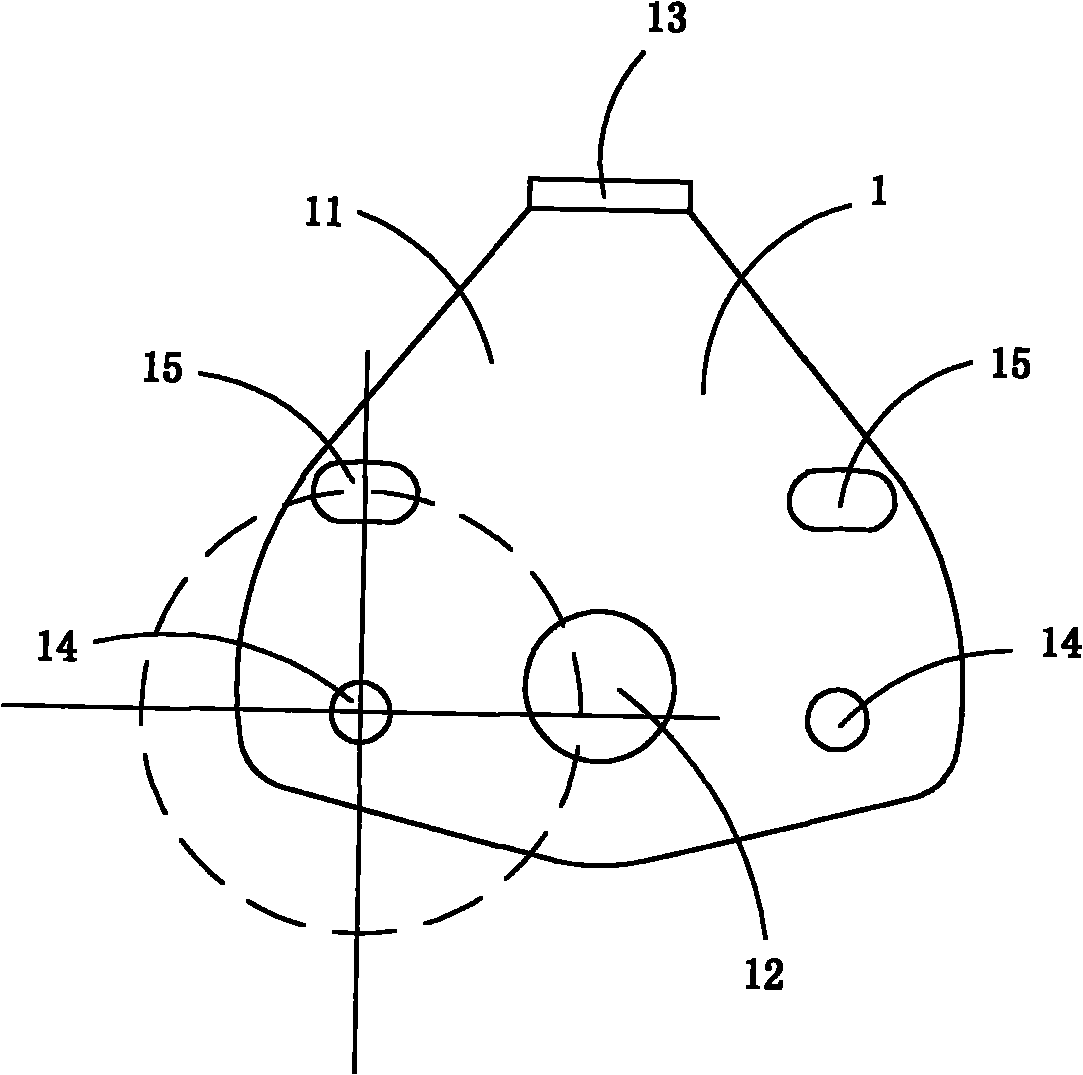

Three-axis aircraft

ActiveCN105730687AGood stability and reliabilityGuaranteed Stability and ReliabilityAircraft controlRotocraftFlight vehicleDrive motor

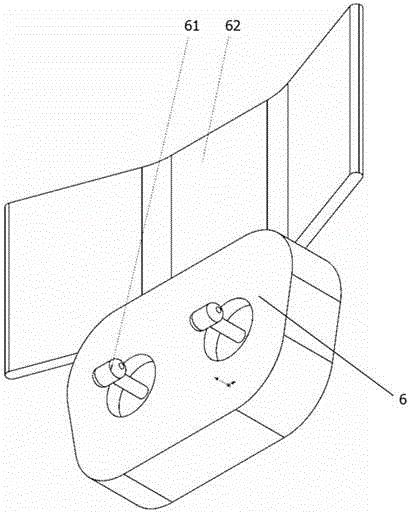

The invention discloses a three-axis aircraft.The three-axis aircraft comprises an aircraft body, main wings, auxiliary wings, power rotor wings, balance rotor wings, a drive motor and a remote control unit.Control equipment is arranged in the aircraft body, the three sets of main wings and the three sets of auxiliary wings are evenly distributed around the aircraft body, and the main wings vertically correspond to the corresponding auxiliary wings.The main wings are located under the auxiliary wings, and the ends, close to the aircraft body, of the main wings and the auxiliary wings are fixedly connected.The other ends of the main wings and the other ends of the auxiliary wings are provided with the power rotor wings and the balance rotor wings respectively.The lower portions of the power rotor wings and the lower portions of the balance rotor wings are connected with the drive motor, and the drive motor is connected with the control equipment inside the aircraft body through a wire.The remote control unit is wirelessly connected with the control equipment inside the aircraft body.According to the three-axis aircraft, through the three sets of main wings and the three sets of auxiliary wings, all of which are arranged in a staggered mode, the power rotor wings on the main wings provide main flight power, the balance rotor wings on the auxiliary wings can adjust the posture of the aircraft more precisely, and therefore the aircraft can fly stably and reliably.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

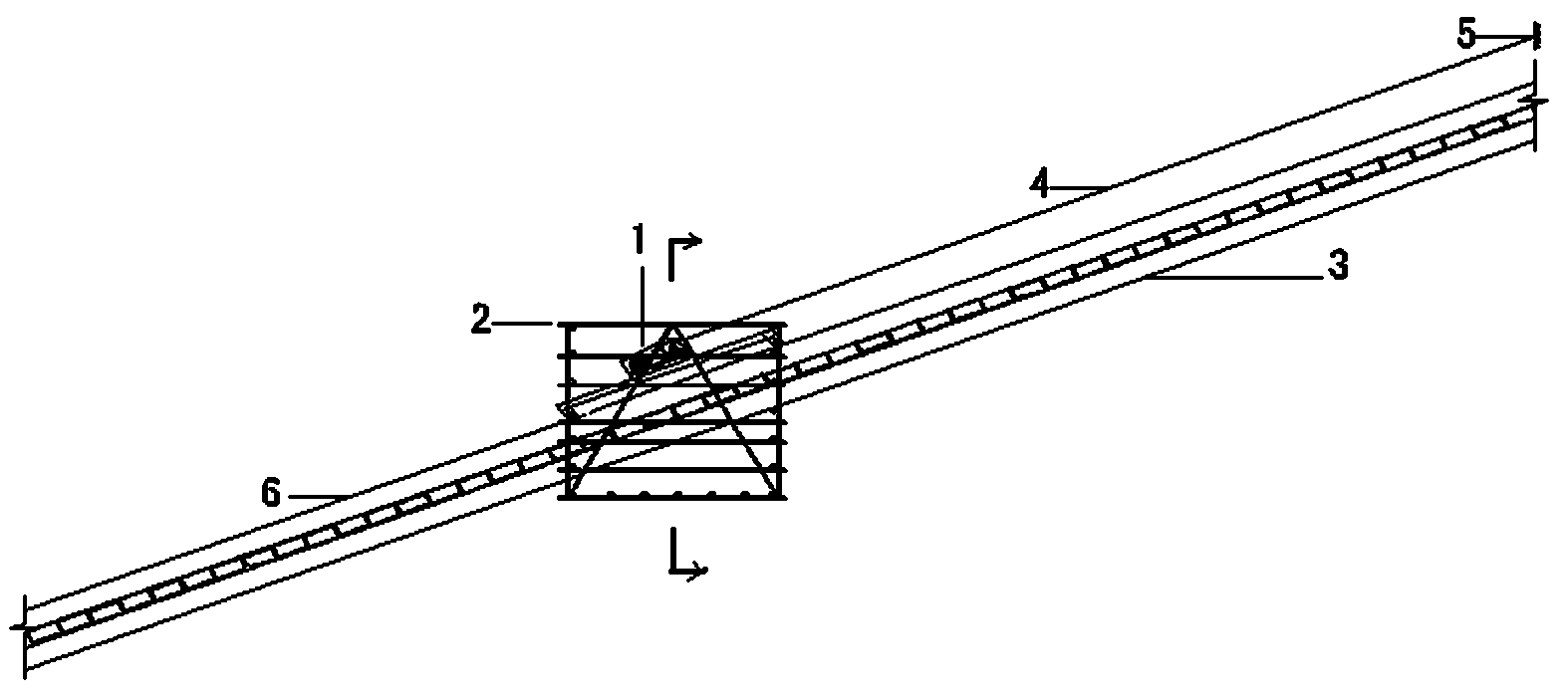

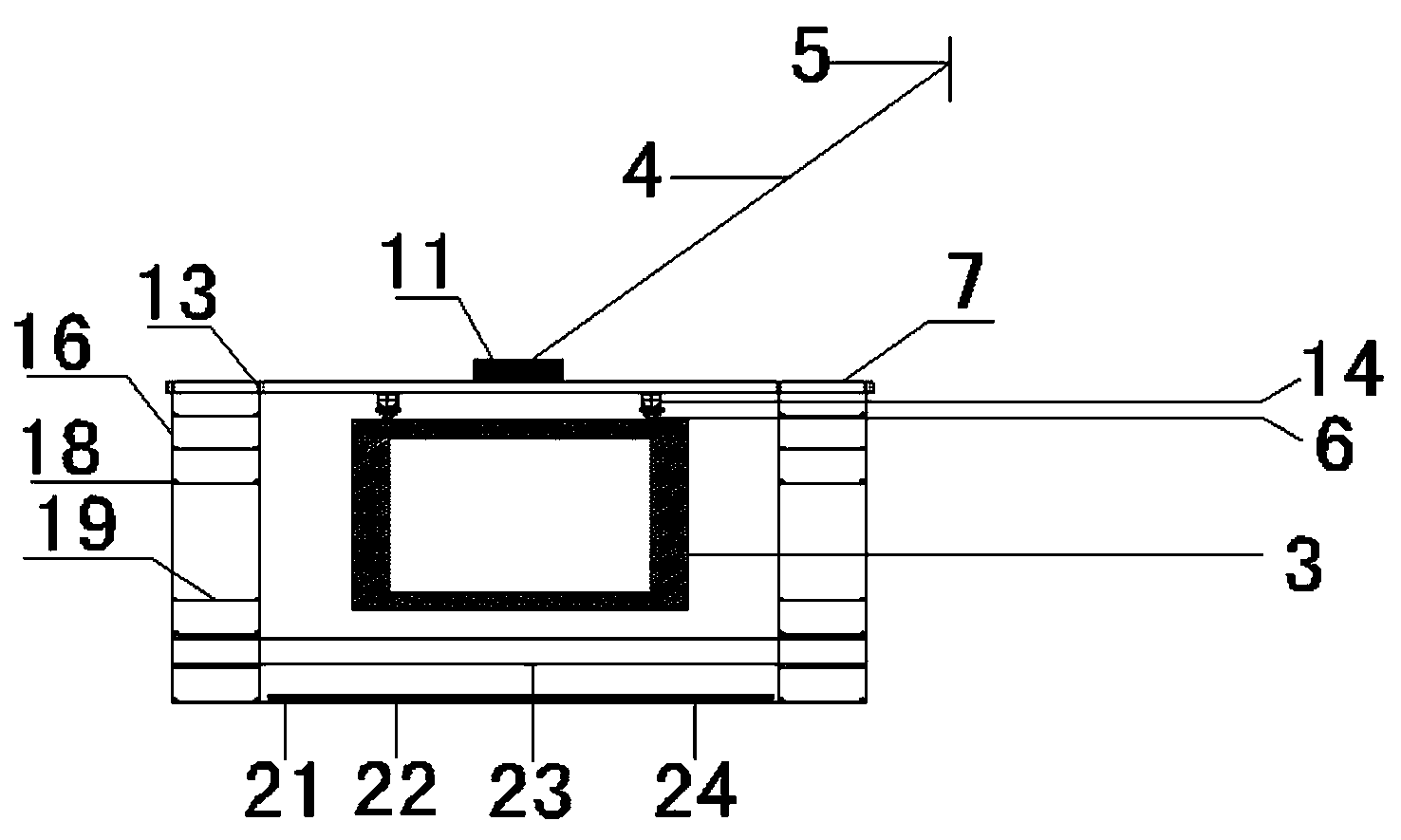

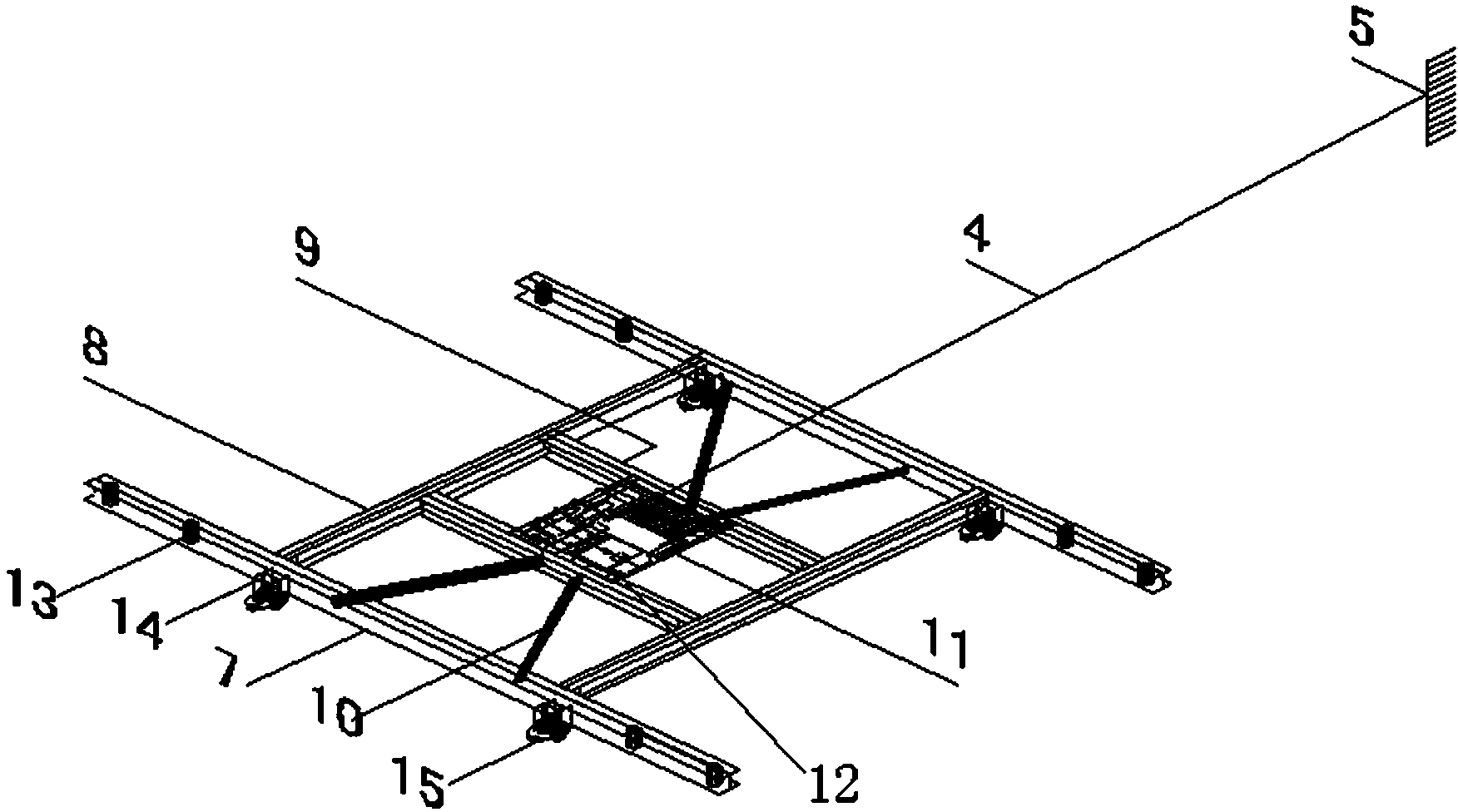

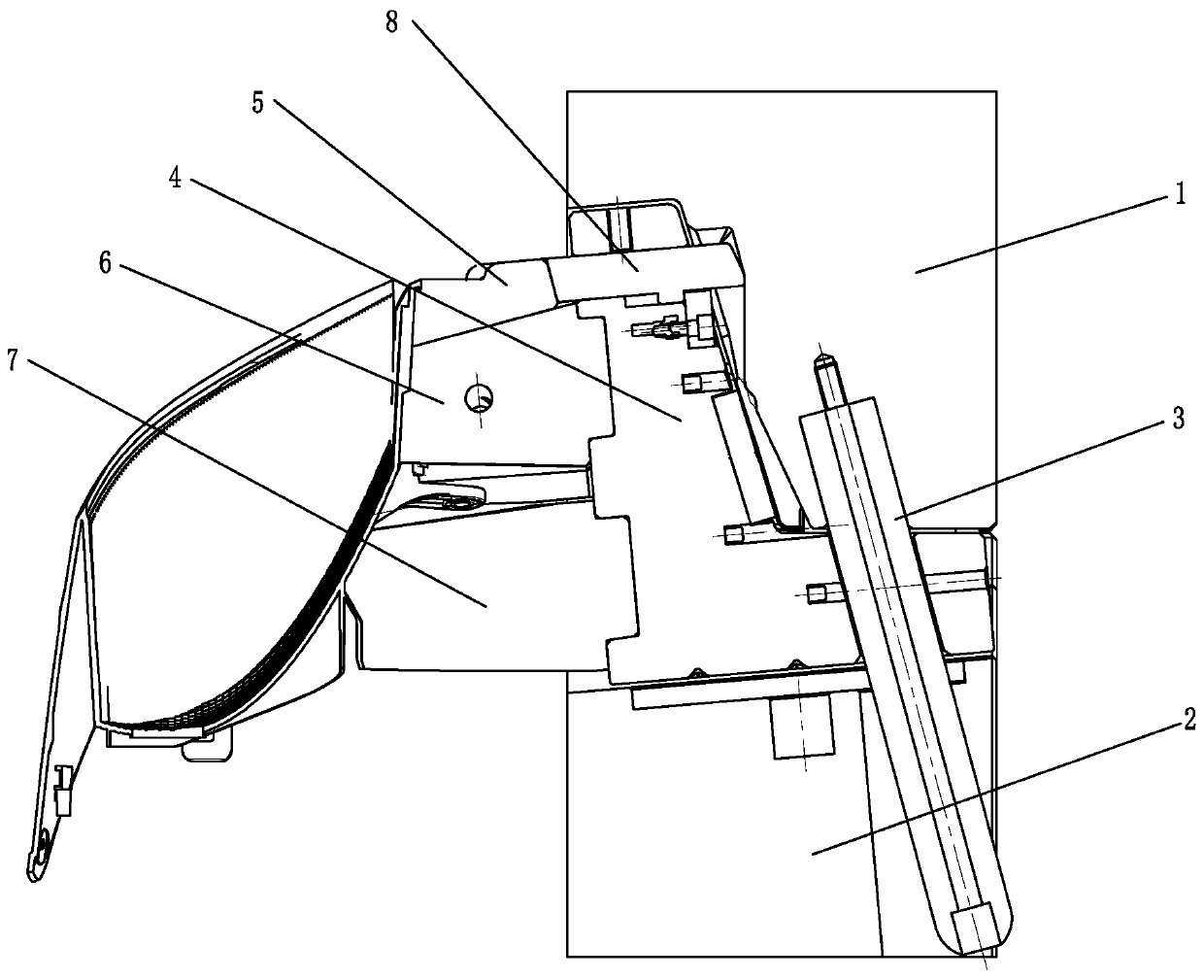

Movable scaffold device for belt gallery

ActiveCN103643791ALight in massGood stability and reliabilityBuilding support scaffoldsPulleyArchitectural engineering

The invention discloses a movable scaffold device for a belt gallery. The movable scaffold device comprises a power system, a movable bracket, a construction scaffold, a lifting belt gallery and a steel wire rope, wherein the movable bracket is connected with the construction scaffold; pulleys are arranged at the lower part of the movable bracket; the power system comprises an electric hoist which is mounted on an electric hoist base; the electric hoist base is connected with the movable bracket; two parallel tracks are paved on the lifting belt gallery from low to high along the top of the lifting belt gallery oblique to the ground; the pulleys are matched with the tracks; the electric hoist is connected with one end of the steel wire rope through a speed reducer; the other end of the steel wire rope is connected with a steel wire rope fixing point; the steel wire rope fixing point is arranged at the uppermost end of the top of the lifting belt gallery; an electric control structure for controlling positive and negative rotation of the electric hoist is arranged on the construction scaffold. The movable scaffold device is light in weight, good in stability and reliability, convenient to mount and dismount, and low in labor intensity and project and construction costs.

Owner:SHANDONG SHUANGDELI CONSTR TECH

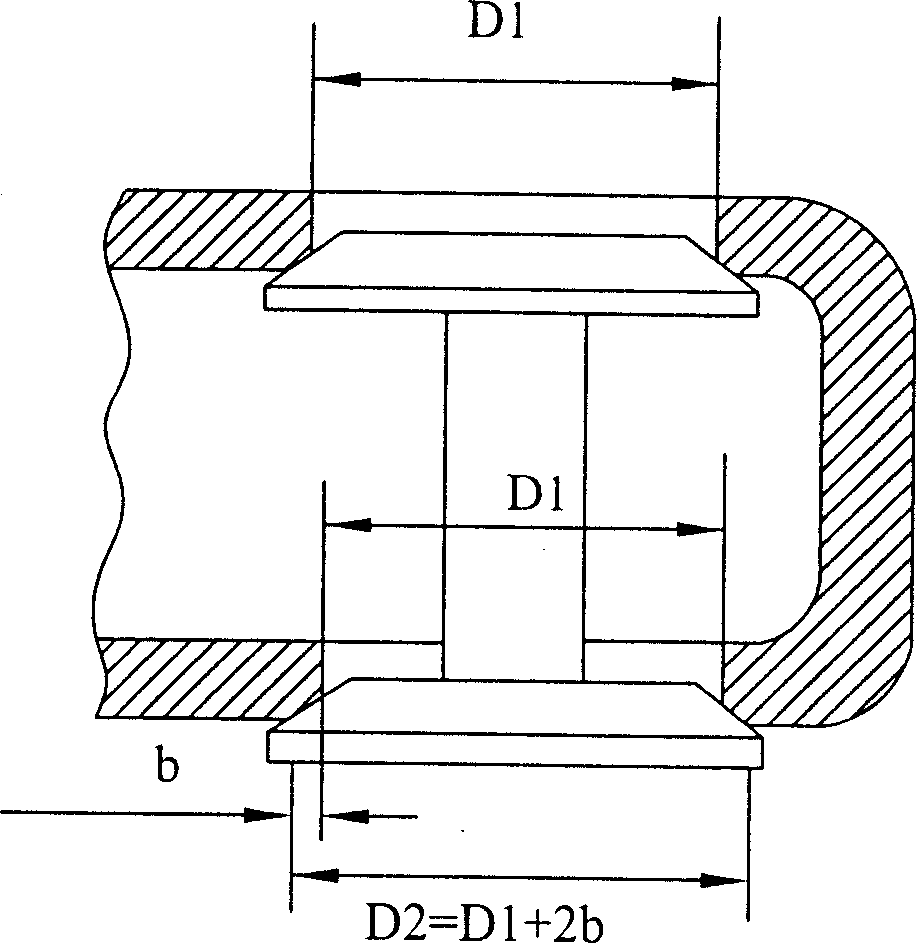

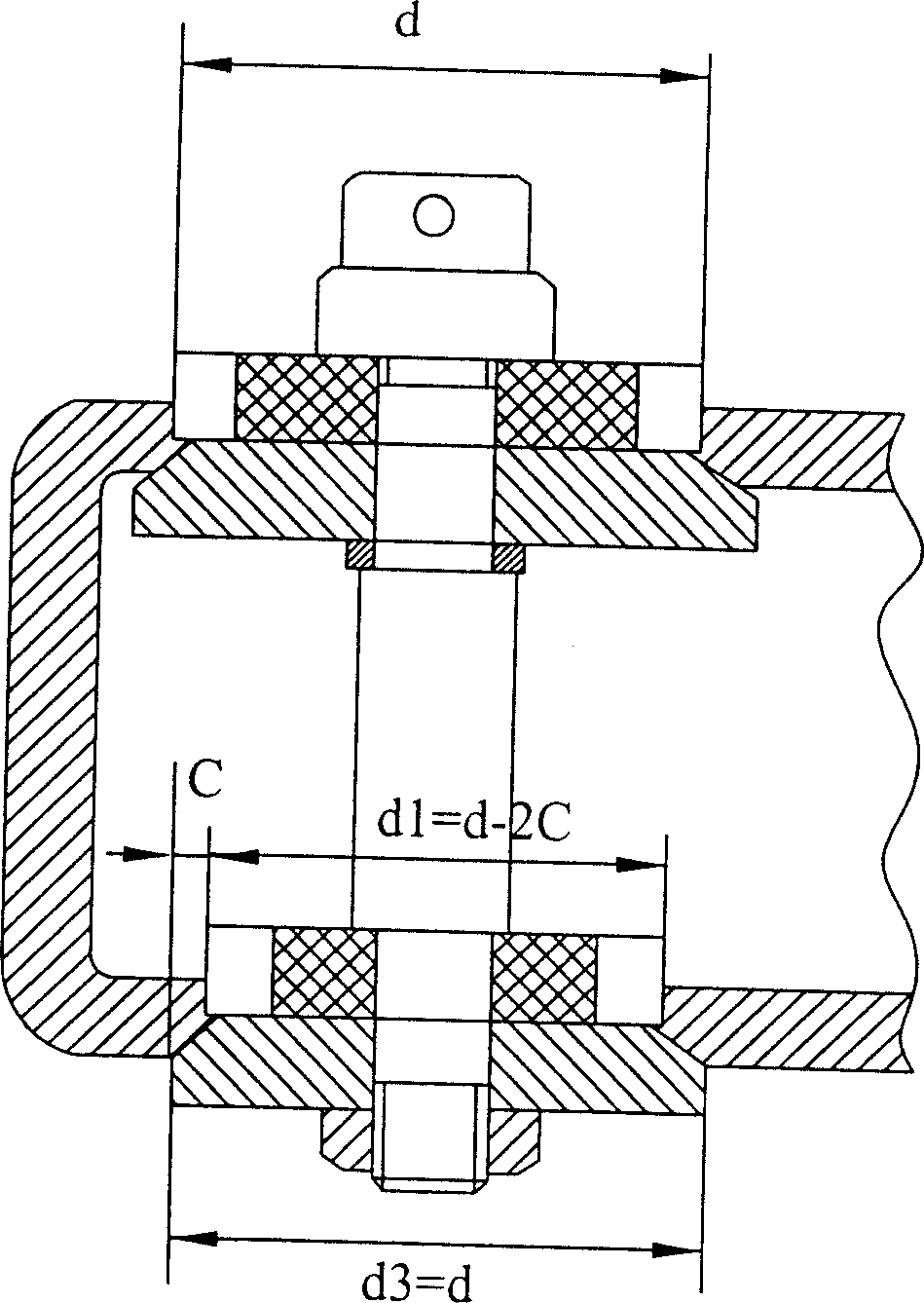

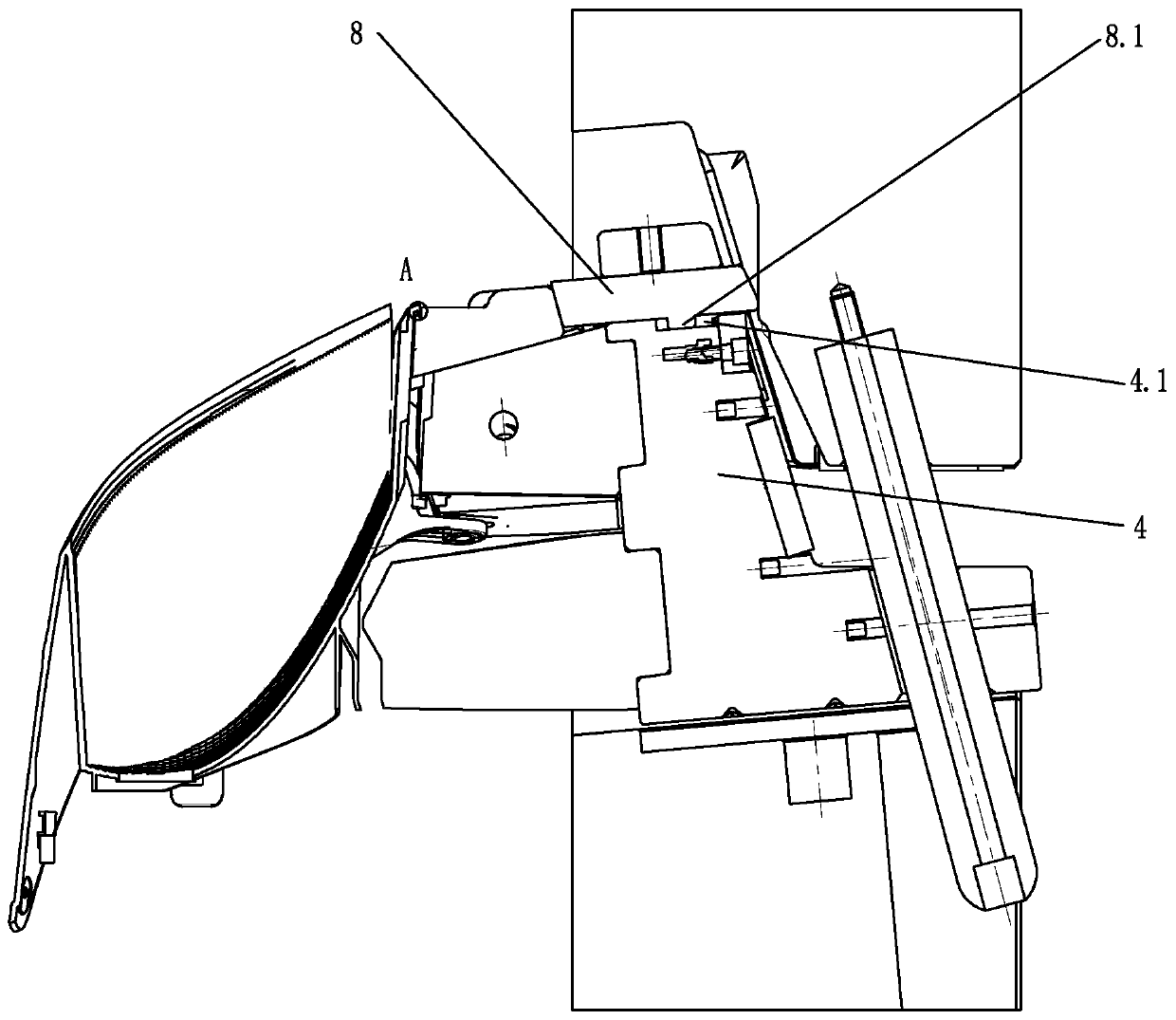

Lever and floating steam trap of balanced and two-valve seat

This invention relates to a kind of bivalve seat stop type level float steam trap. It includes float ball, level, pin shaft, pin, connecting bar, valve stem, upper and lower spools, upper and lower spool locating blocks, upper and lower valve seats, shim, nut, connecting head, connecting pin and level support. One end of level connects to float ball, the other end connects to the upper end of pin and connecting bar. Level and pin shaft are connected and are supported on the level support. The level support is arranged above the upper level seat. The lower end of connecting rod is connected to connecting head through connecting pin. The shim, upper spool and upper spool-locating block are all capped on the upside of valve stem. The upper spool is in the upper valve seat and connects to the nut and lower conical surface of the upper valve seat. The connecting head connects to the top of valve stem. The adjustable underside of valve stem inserts into lower spool and lower spool locating block. The lower spool is in the lower valve seat and connects to the lower conical surface of the lower valve seat.

Owner:洪有福

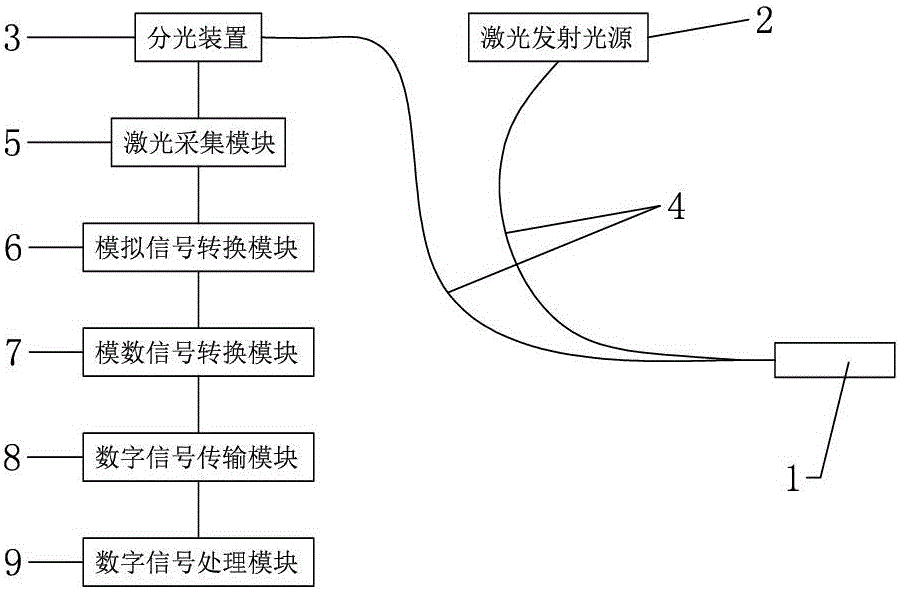

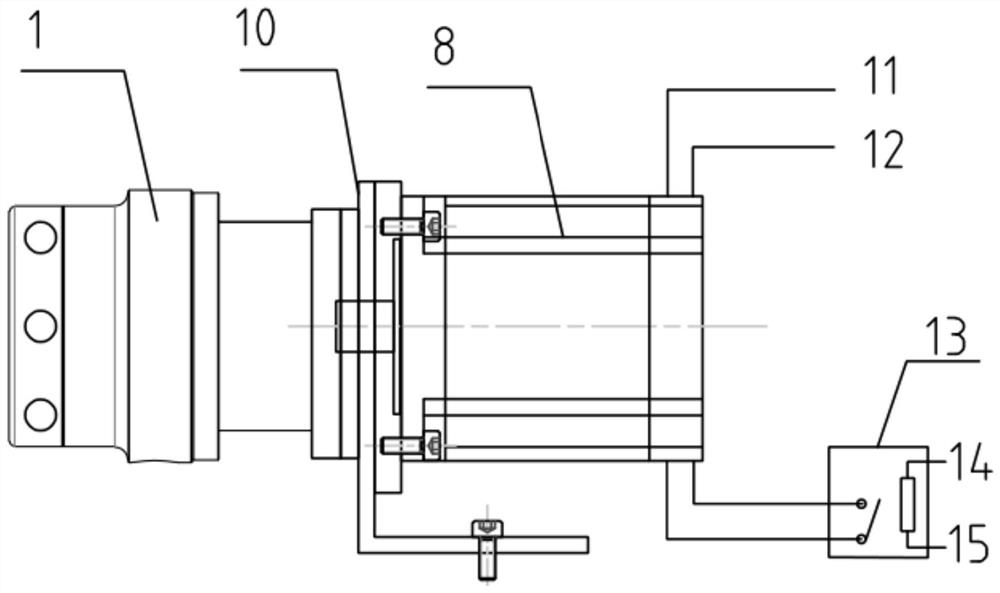

Dispersive confocal detection device and dispersive confocal detection system

InactiveCN104990496ASimple structureGood stability and reliabilityUsing optical meansDigital signal processingLight source

The invention discloses a dispersive confocal detection device and a dispersive confocal detection system. The dispersive confocal detection device comprises a laser sampling pen, a laser emission light source, a light splitting device, and a digital signal processing module. The light output position of the laser emission light source is connected with the optical sampling pen through a transmission optical fiber. The light input position of the light splitting device is connected with the optical sampling pen through a transmission optical fiber. The light splitting device is equipped with a laser acquisition module at the light output position. The laser acquisition module is equipped with an analog signal conversion module. An analog / digital signal conversion module and a digital signal transmission module are arranged between the digital signal processing module and the analog signal conversion module. The dispersive confocal detection system comprises the detection device, a fixed installation frame, and a motion platform, wherein the detection device is installed on the fixed installation frame. The dispersive confocal detection device and the dispersive confocal detection system can be used to effectively measure the shape size, height and other physical dimensions of electronic parts and hardware and plastic parts, and have the advantages of simple structure, high stability and reliability, and high detection accuracy.

Owner:GUANGDONG SAMSUN TECH CO LTD

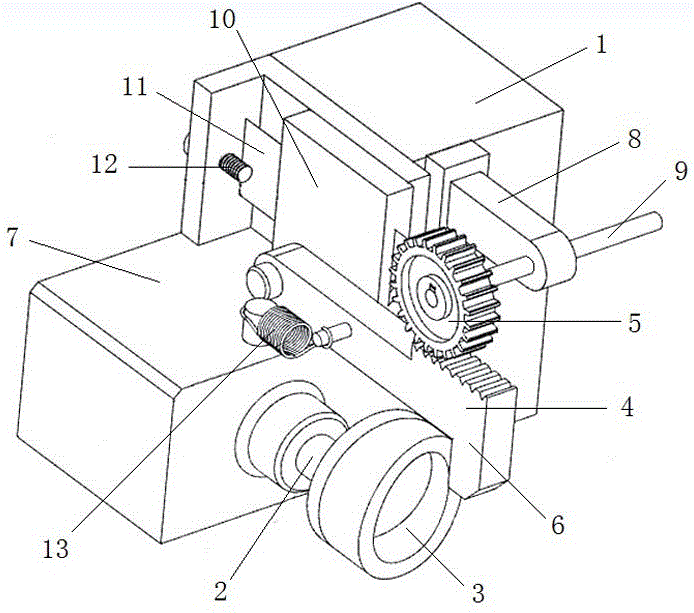

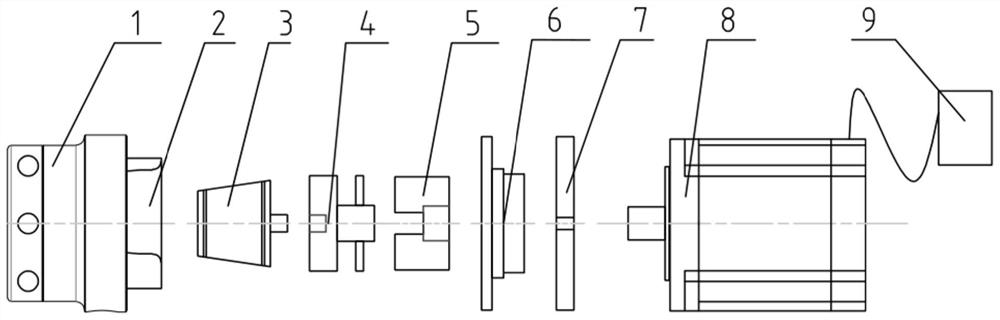

Low-speed intermittent rotating mechanism and working method thereof

The invention relates to a low-speed intermittent rotating mechanism and a working method thereof. The low-speed intermittent rotating mechanism comprises a seat body; the seat body is provided with a cam shaft driven by a driving device to rotate, and the end of the cam shaft is provided with an eccentric end cam which is eccentrically arranged; a rack capable of vertically swinging and moving back and forth is arranged above the eccentric end cam, and a gear meshed with the rack when the rack upwards swings is arranged above the rack; and the front end of the rack is provided with a hook part which is downwards bent and is fitted with the end of the eccentric end cam, when the side, far away from an axis, of the eccentric end cam rotates to the upsides, the eccentric end cam drags the rack to upwards swing, and a raised profile on the end of the eccentric end cam pushes the rack to forwards move to drive the gear to rotate. The low-speed intermittent rotating mechanism disclosed by the invention is good in stability and reliability, high in efficiency, adjustable in rotation angle and convenient to use.

Owner:FUZHOU UNIVERSITY

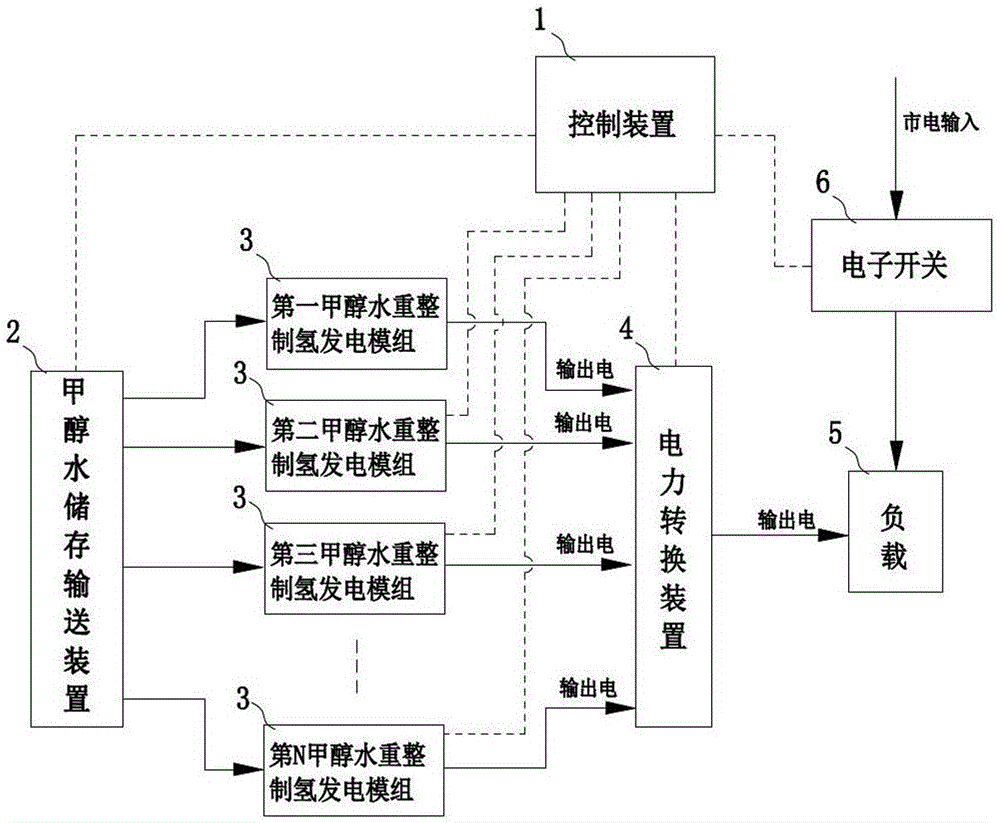

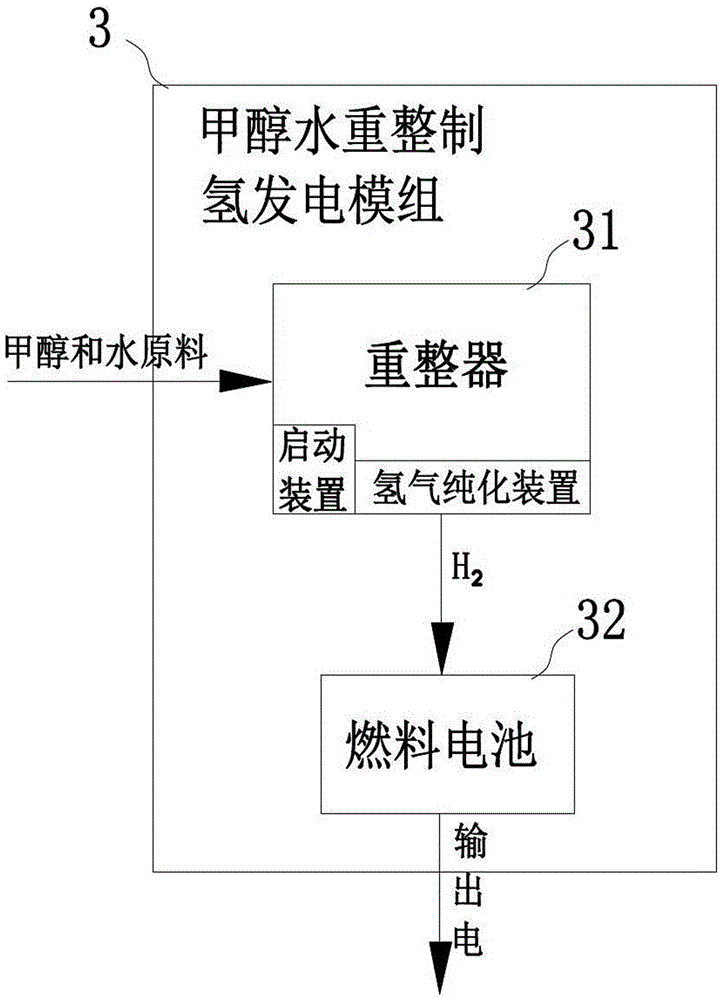

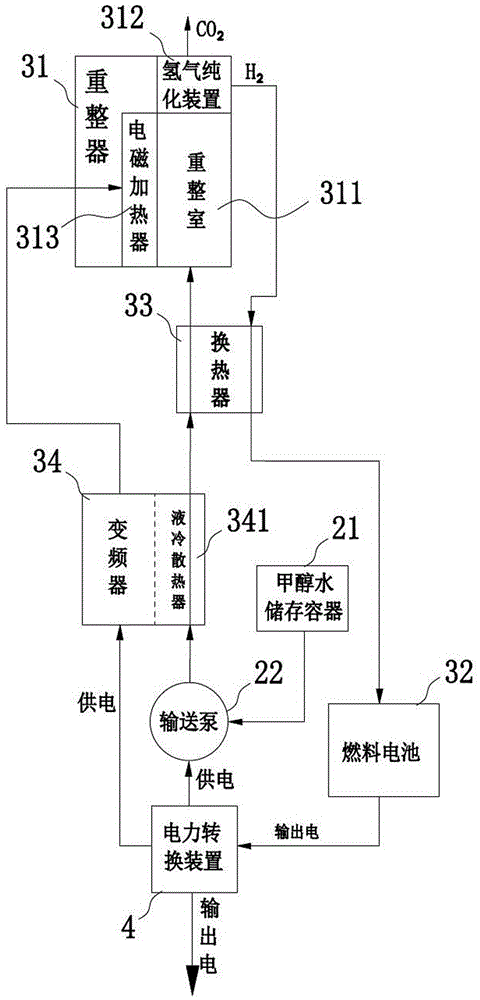

Peak shaving and load shifting power supply system and method based on methanol water reforming hydrogen generation power generation system

InactiveCN105811443AReduce consumptionReduce peak loadEnergy storageAc network load balancingMethanol waterHydrogen

The invention discloses a peak shaving and load shifting power supply system based on a methanol water reforming hydrogen generation power generation system. The system comprises a control device, a methanol water storage and transmission device, at least two methanol water reforming hydrogen generation power generation modules, a power conversion device, a load and an electronic switch, wherein the control device is electrically connected with the methanol water storage and transmission device, the methanol water reforming hydrogen generation power generation modules, the power conversion device and the electronic switch and controls the working conditions of the methanol water storage and transmission device, the methanol water reforming hydrogen generation power generation modules, the power conversion device and the electronic switch, and the electronic switch is used for connecting or disconnecting a mains supply; when the mains supply is in a power utilization peak, the control device controls the electronic switch to cut off the mains supply and controls an appropriate amount of methanol water to be reformed to generate hydrogen and the power generation modules to run according to the electricity utilization power of the load so as to supply power to the load; and when the mains supply is in a power utilization valley, the control device controls the methanol water to generate hydrogen and the power generation modules to rotate and also controls the electronic switch to connect the mains supply so as to supply power to the load. The system has the advantages of high power supply continuity, peak shaving and load shifting, energy saving, emission reduction and high power supply safety, and is easy to control.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

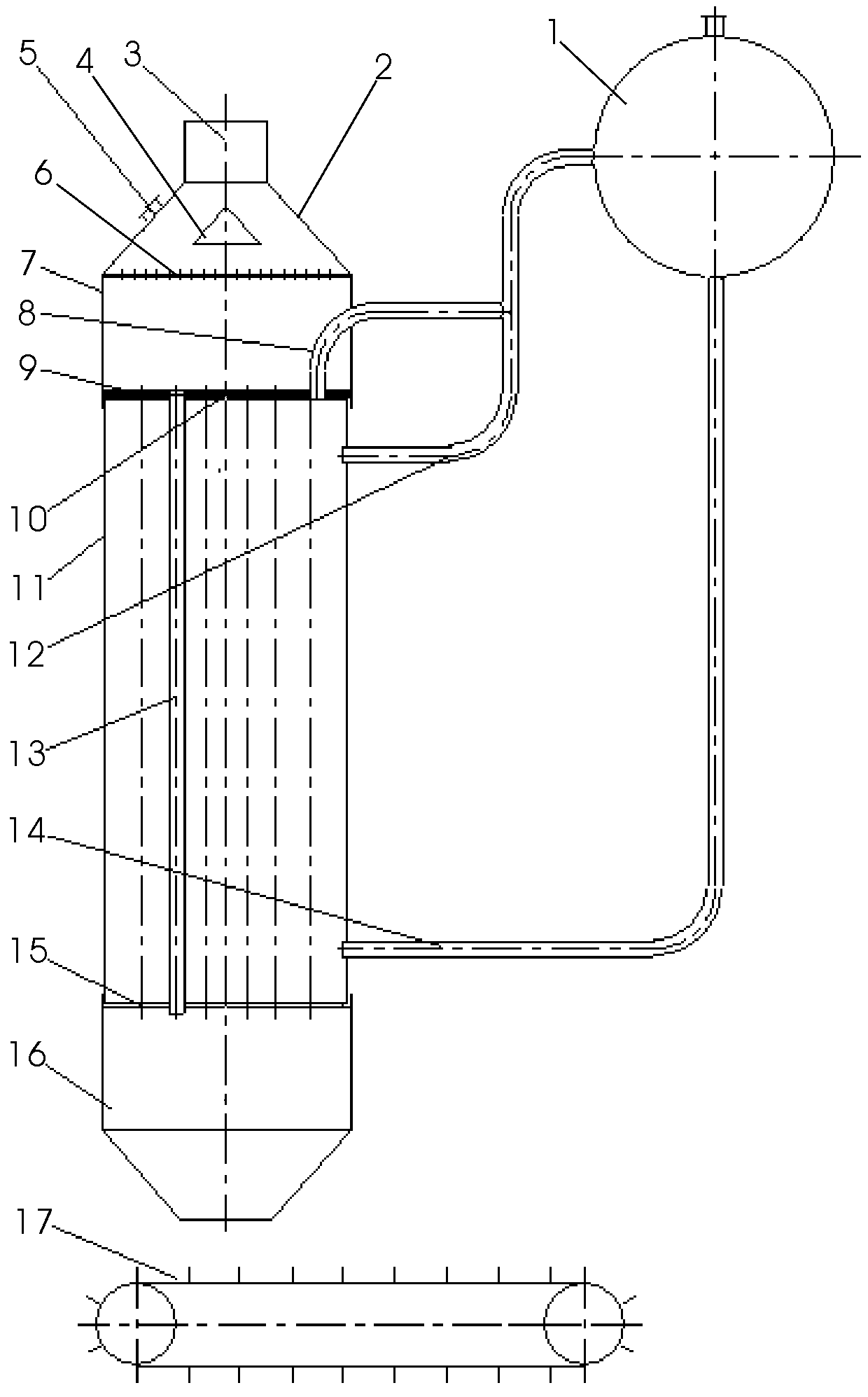

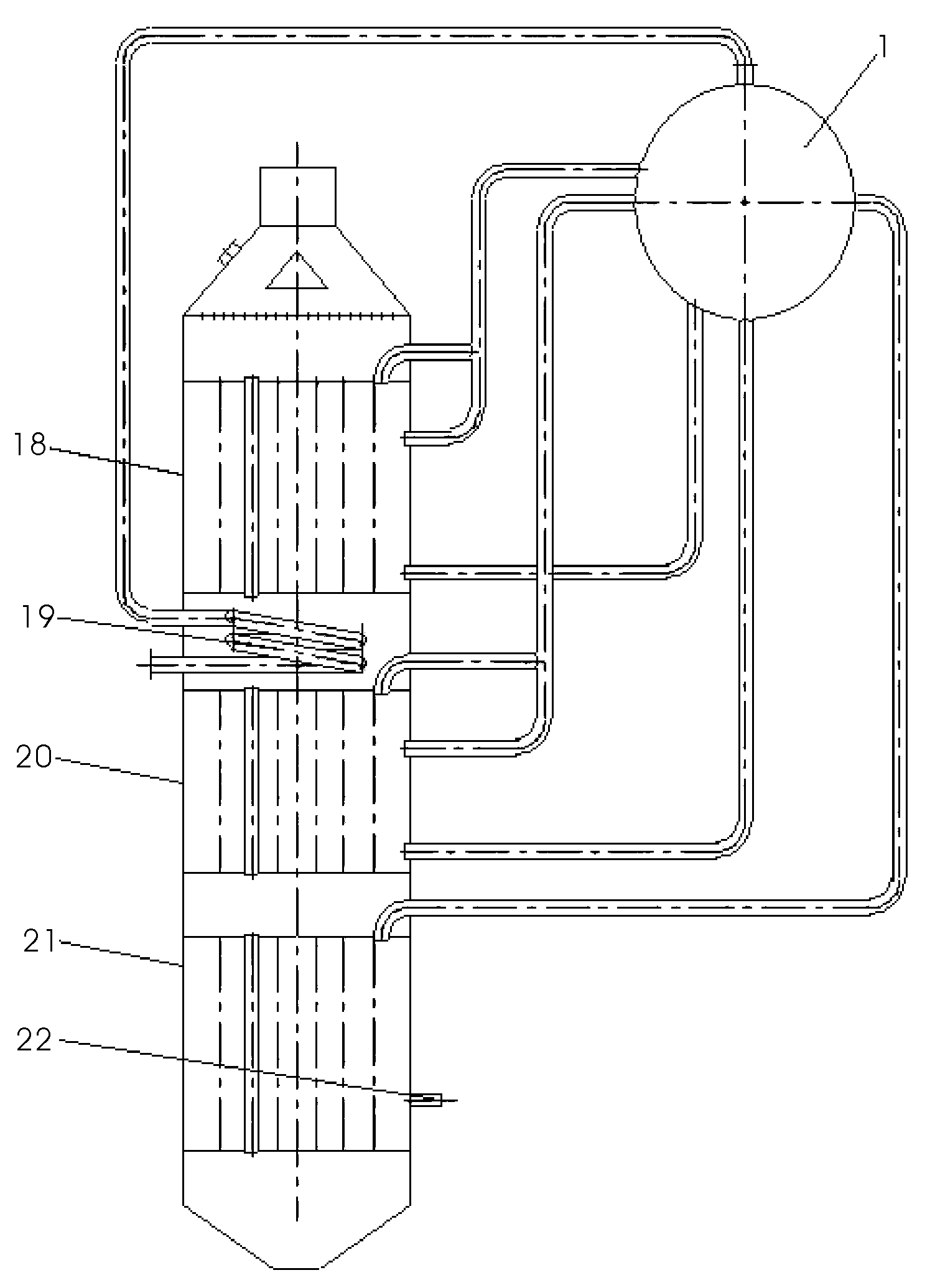

Slag cooler for calcinator

InactiveCN103644745ASimple structureEasy to installIncreasing energy efficiencySteam generation using hot heat carriersSingle stageSlag

A slag cooler for a calcinator includes a steam dome, an upper end cover, a slag inlet, a flow division and equalization device, an inspection door, a flat-layer flow equalization device, a seal cover plate, an upper steam water connecting pipe, fireproof materials, an upper pipe plate, an outer cylinder body, a lower steam water connecting pipe, a fire pipe, a down pipe, a lower pipe plate, a slag outlet, a slag remover, an upper-stage evaporator, a superheater, a lower-stage evaporator, a coal economizer and a water supply pipe seat, wherein a single-stage evaporator is the basic structural form, and the two-stage evaporators or multi-stage evaporators can also be arranged on the basis of the single-stage evaporator; the upper pipe plate is arranged at the upper end of the outer cylinder body in a connected manner, the seal cover plate is arranged above the upper pipe plate in a connected manner, the upper end cover is arranged at the upper end of the seal cover plate in a connected manner, the flat-layer flow equalization device is arranged at the joint of the upper end cover and the seal cover plate, the flow division and equalization device is arranged in the center of the inside of the upper end cover, and the slag inlet is arranged in the center of the upper end of the upper end cover. The slag cooler for the calcinator has the advantages of simple overall structure, and convenience in mounting, operation and use, as well as high stability and reliability.

Owner:JINING HOWARD ENVIRONMENTAL

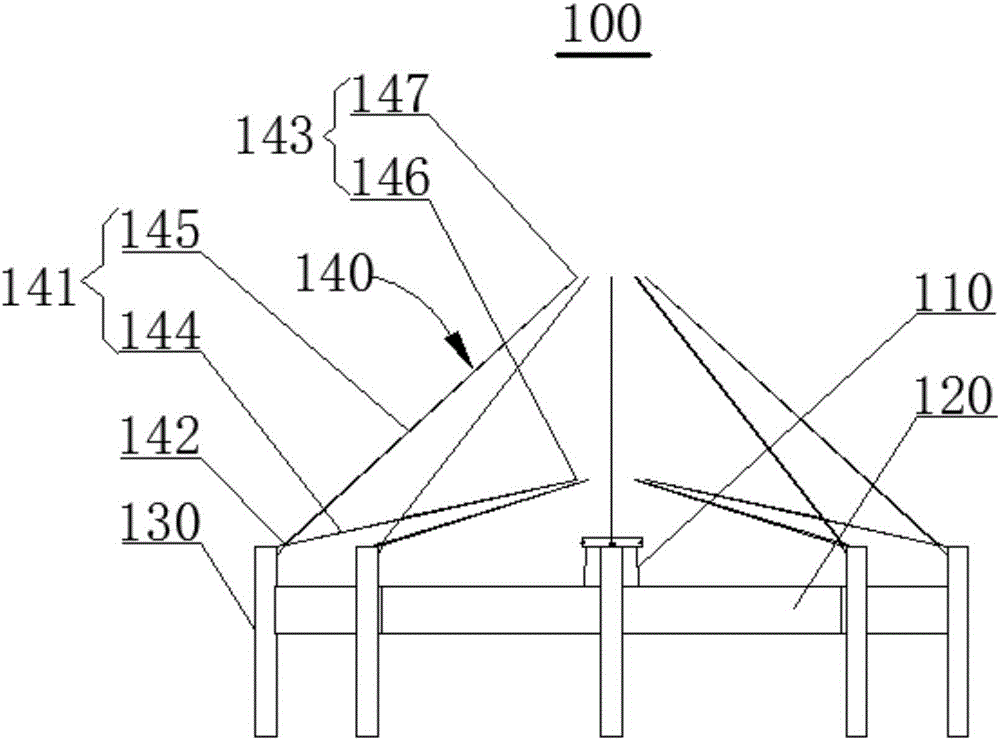

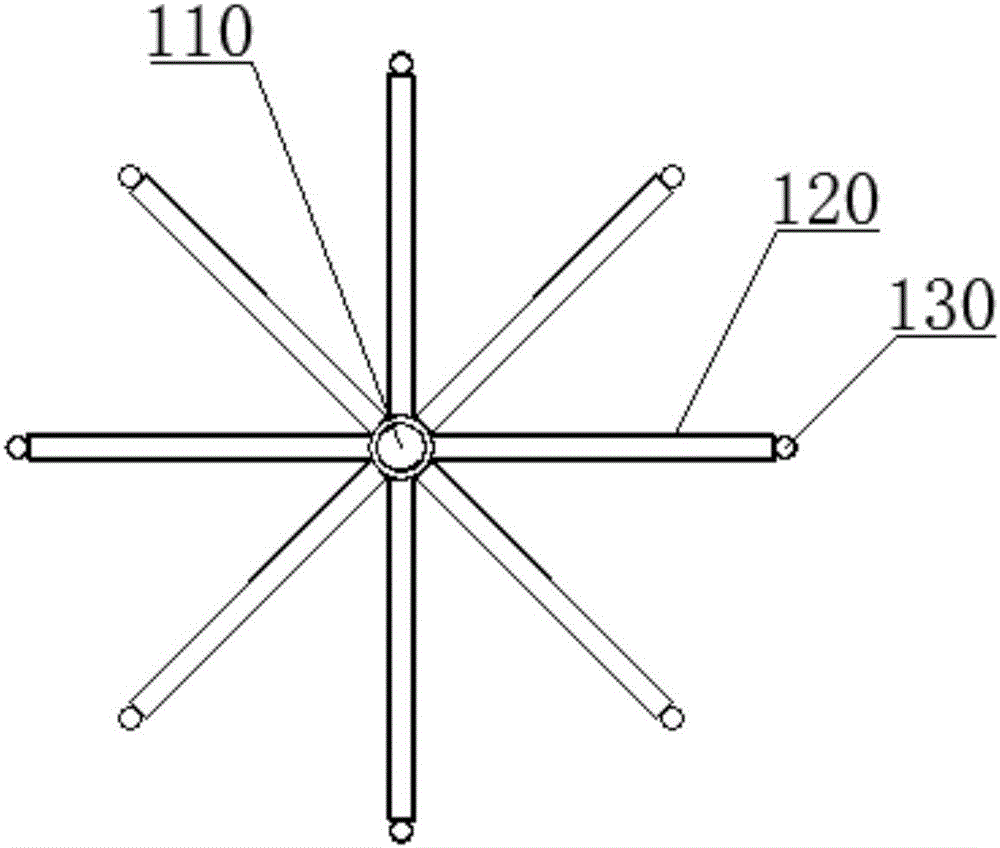

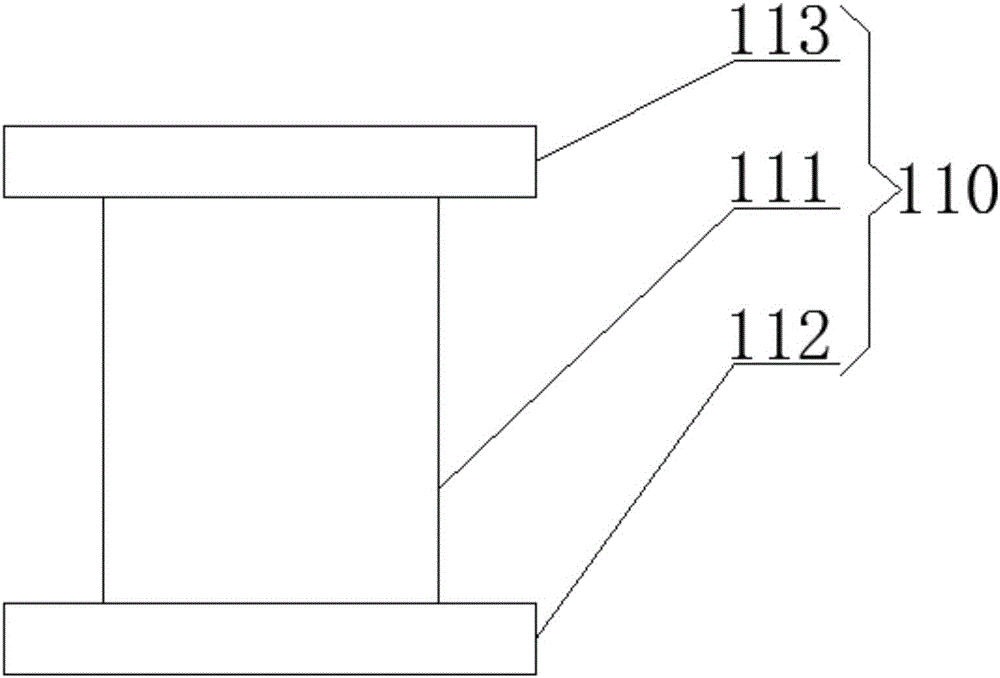

Overland fan foundation, foundation construction method and fan

ActiveCN106049523AGood stability and reliabilityReduce steel consumptionWind motor supports/mountsFoundation engineeringWind drivenTerrain

The invention provides an overland fan foundation, a foundation construction method and a fan and belongs to the technical field of wind-driven power generation. The overland fan foundation comprises a foundation ring, a plurality of ground beams and a plurality of ground piles, wherein the ground beams are in one-to-one correspondence with the ground piles, one end of each ground beam is connected with the foundation ring, and the other end of each ground beam is connected with the corresponding ground pile. The foundation construction method comprises the step of building the overland fan foundation. The fan comprises a fan main body and the overland fan foundation, wherein the fan main body comprises a tower tube, and the bottom of the tower tube is connected with the foundation ring of the overland fan foundation. The overland fan foundation combines the advantages of a gravity type foundation and a pile foundation, has excellent reliability and stability, can adapt to various work terrains, can reduce steel material usage and reduce cost and can also improve the deformation resistance of the tower tube. The fan adopting the overland fan foundation has the characteristics of high reliability, wide work terrain adapting range, low construction cost and strong tower tube deformation resistance.

Owner:SANY ELECTRIC CO LTD

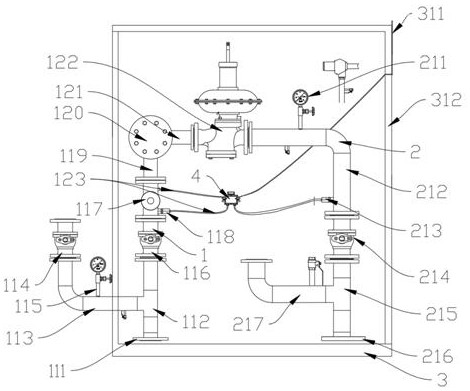

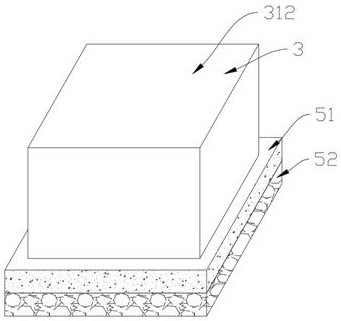

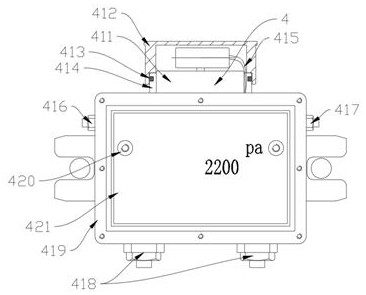

Gas pressure regulating cabinet intelligent system and method

PendingCN112013281ARealize acquisitionRealize analysisPipeline systemsElectrical batteryControl engineering

The invention belongs to the technical field of gas pressure regulation, and particularly relates to a gas pressure regulating cabinet intelligent system and a method. The system comprises a control module box, an air inlet assembly, an air outlet assembly and a box body assembly, the air inlet assembly is connected with the air outlet assembly through a pipeline, the air inlet assembly and the air outlet assembly are fixedly connected to the lower surface of the interior of the box body assembly, and the control module box is connected with the air inlet assembly and the air outlet assembly through cables. The control module box comprises a battery valve line connector, an antenna connector, two avionics plugs and a shell. Two sides of the shell are fixedly connected with the battery valve line connector and the antenna connector respectively. The invention further discloses a use method of the gas pressure regulating cabinet intelligent system. The use method comprises the steps of equipment installation, software installation, software operation and the like. According to the system and method, the problems that real-time data acquisition and analysis cannot be realized in the prior art, real-time control of equipment cannot be realized, and accidents such as air leakage and abnormal air pressure cannot be warned and handled in time are solved.

Owner:襄阳山城燃气设备科技有限公司

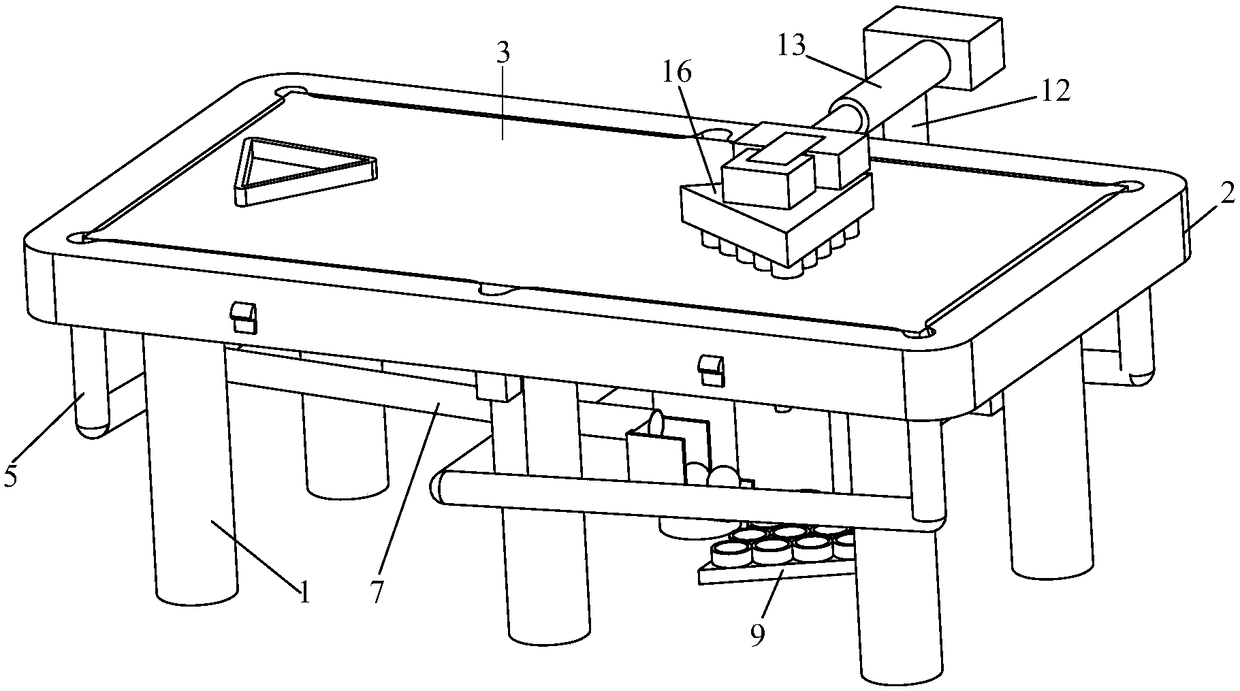

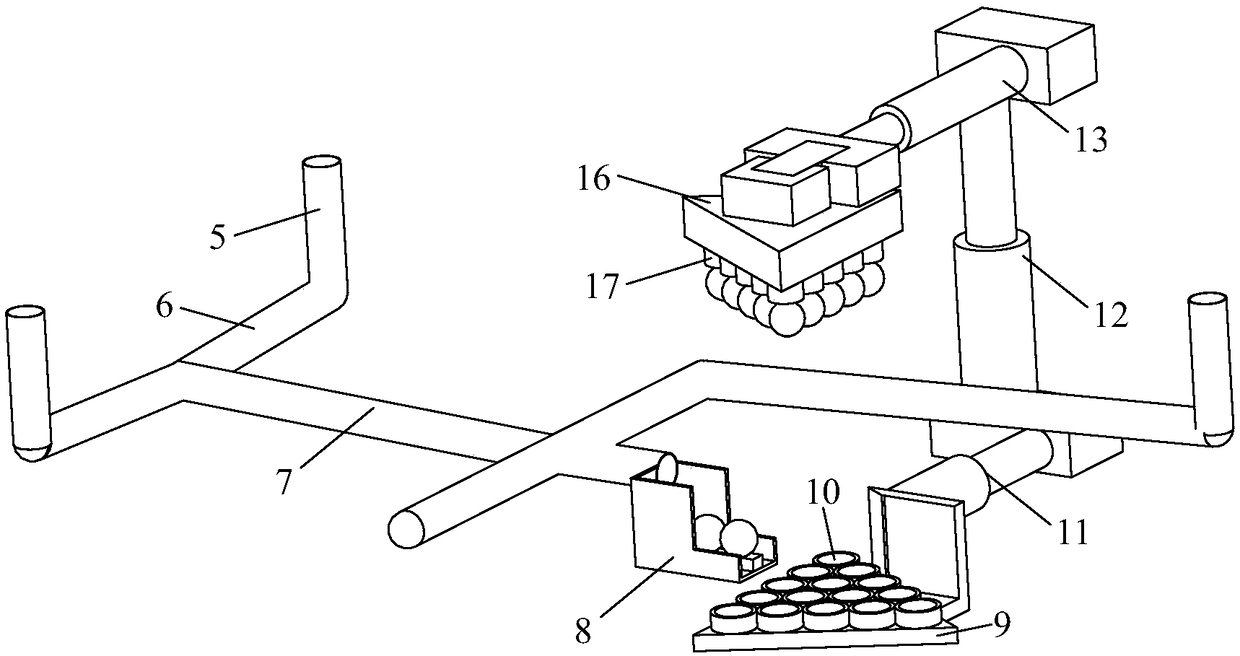

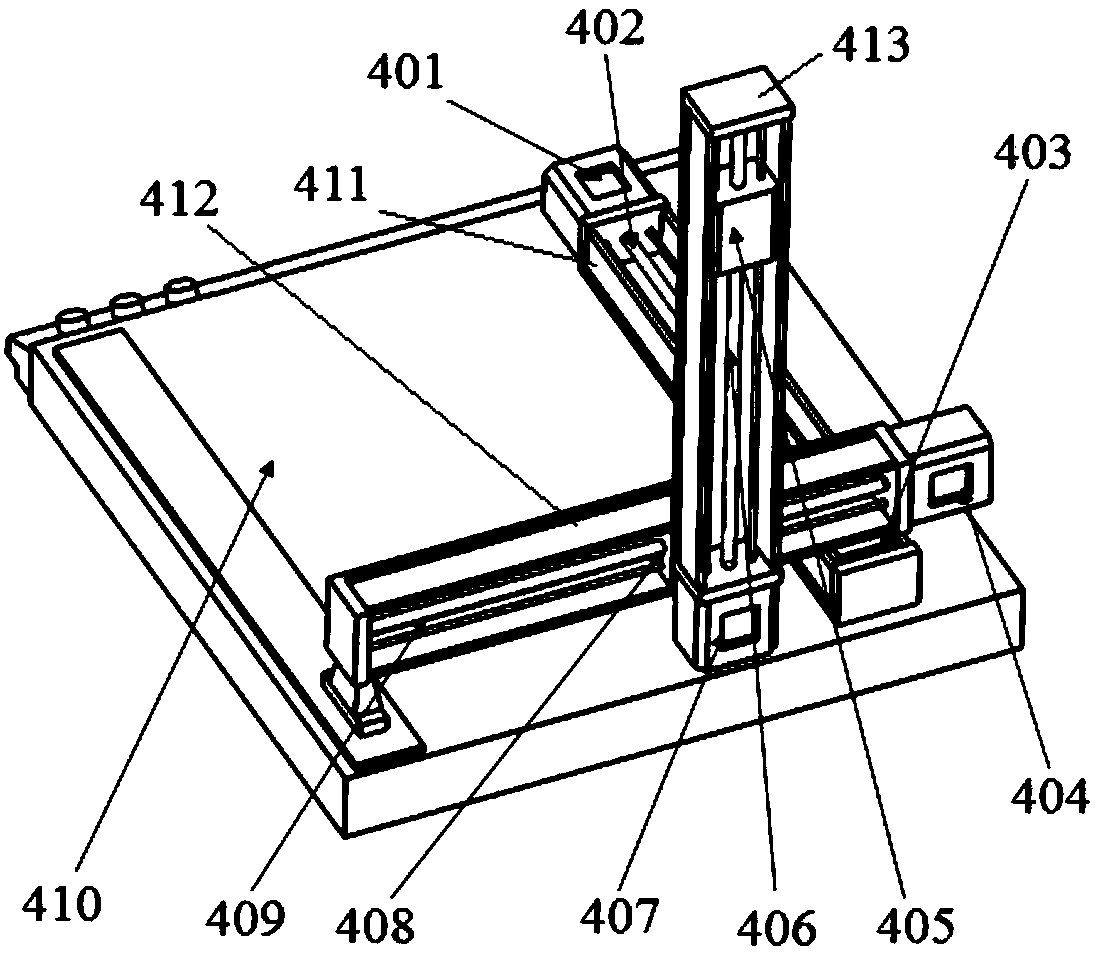

Billiard table with automatic ball placement device

ActiveCN108465231AGood for scrollingPrecise positioningCard tablesTable tennis tablesEngineeringBilliard ball

The invention discloses a billiard table with an automatic ball placement device. The billiard table comprises a ball table unit, a ball falling device for receiving billiard balls which fall down from ball holes and guiding the billiard balls to the designated positions, a billiard ball collection device for making the billiard balls placed regularly, a billiard ball pickup device for picking upthe billiard balls located on the ball falling device and making the billiard balls move to the billiard ball collection device and a billiard ball placement device for picking up the billiard balls located on the billiard ball collection device and making the billiard balls move to the ball table unit. According to the billiard table with the automatic ball placement device, the billiard balls can be effectively and automatically collected and placed, the time and labor are saved, and the workload of workers can be greatly reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Telescopic mechanism

ActiveCN106369215ASimple structureGood stability and reliabilityOperating means/releasing devices for valvesDomestic plumbingArchitectural engineering

Owner:海宁家纺产业基地投资开发有限公司

Injection mold with step-by-step demolding structure

Owner:NINGBO BOCHAO MOLD

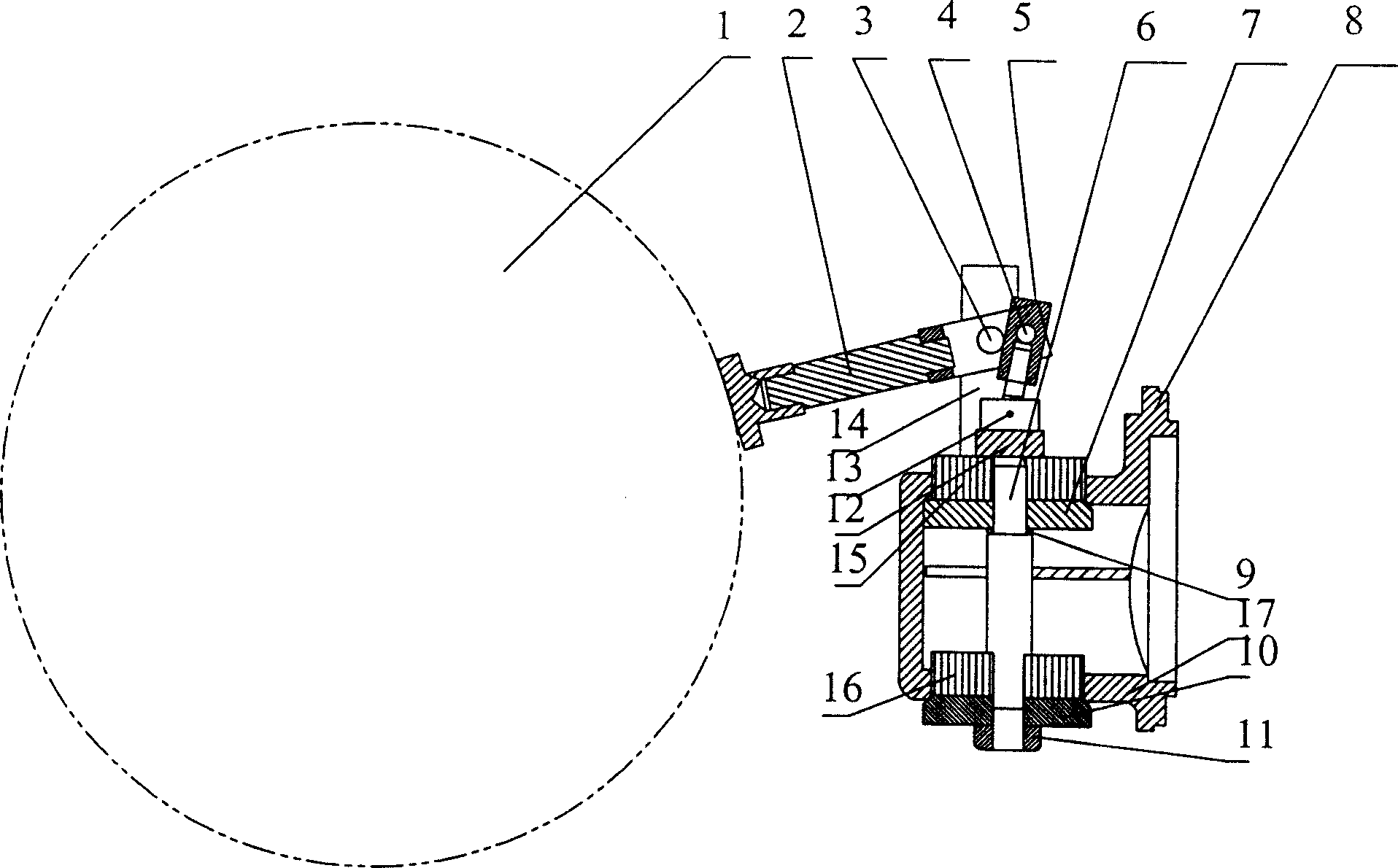

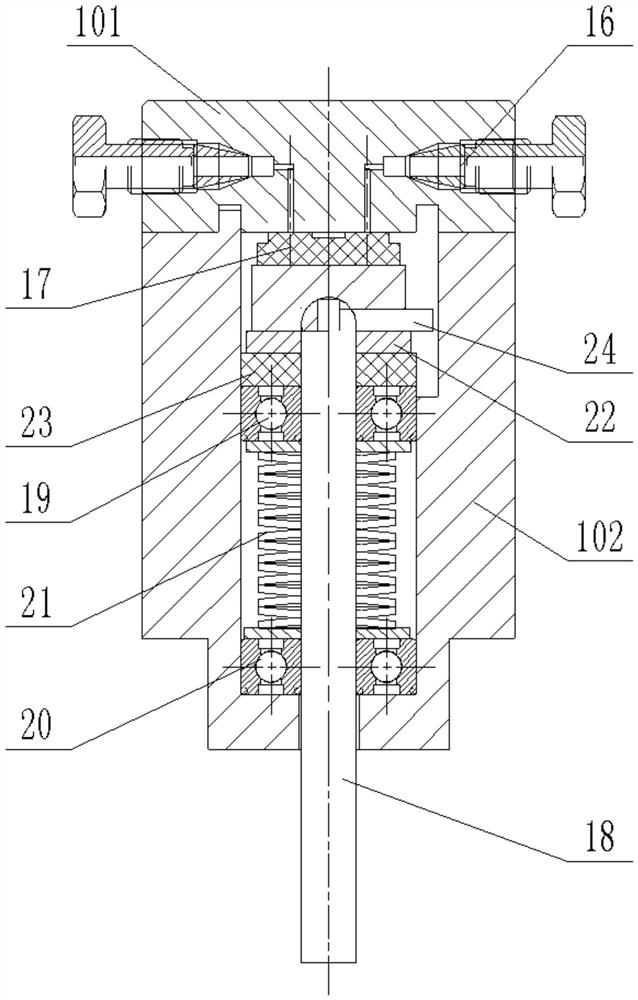

Program control valve electrically driven by zero dead volume and sample injection gas path system

ActiveCN111650321AGood stability and reliabilityEfficient samplingComponent separationPhysicsDrive motor

The invention discloses a program control valve electrically driven by zero dead volume. The program control valve mainly comprises a valve body, a transmission device and a driving motor, wherein thevalve body is provided with a gas inlet / outlet arranged in the valve body; the hardness of the metal material of the gas inlet / outlet is smaller than the hardness of the material of the valve body, and after the matching surface between the gas inlet / outlet and the valve body reaches a certain degree of finish, a conical sealing surface is formed between the gas inlet / outlet and the valve body ina press fit mode. The invention also provides a sample injection gas path system. Sample injection is realized through match between the program control valve and the gas path. The valve body is connected with the gas circuit through a zero dead volume sealing joint, the gas circuit is designed to have a small drift diameter ranging from 0.5 mm to 1 mm, and the tolerance of the outer diameter ofa pipeline used for gas circuit connection is within + / -0.002 mm. The external power supply drives the motor to rotate, and the driving motor drives the transmission device to drive the valve elementof the valve body to rotate so as to achieve the purpose of valve switching. According to the program control valve and the sample injection gas path system, the dead volume can be controlled to be 0.15 muL or below.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

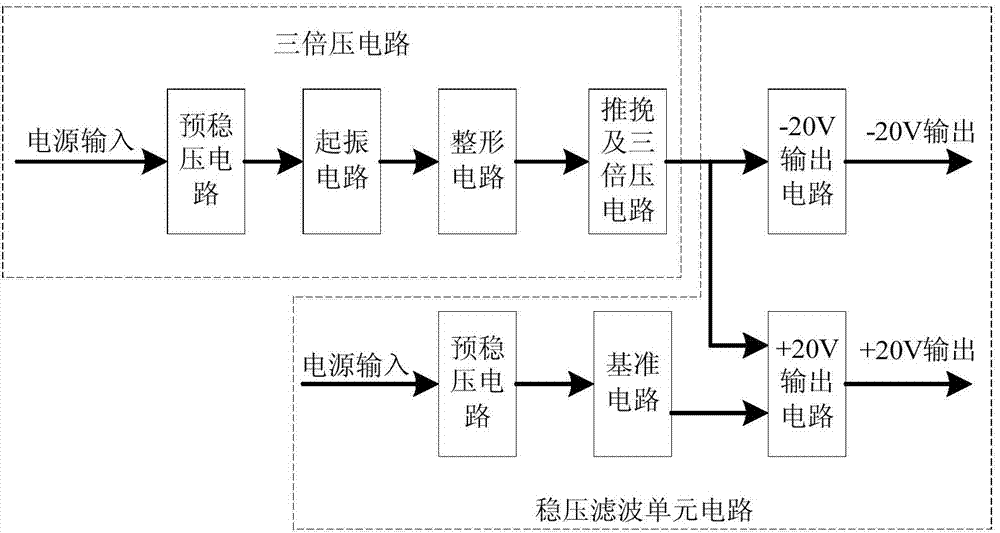

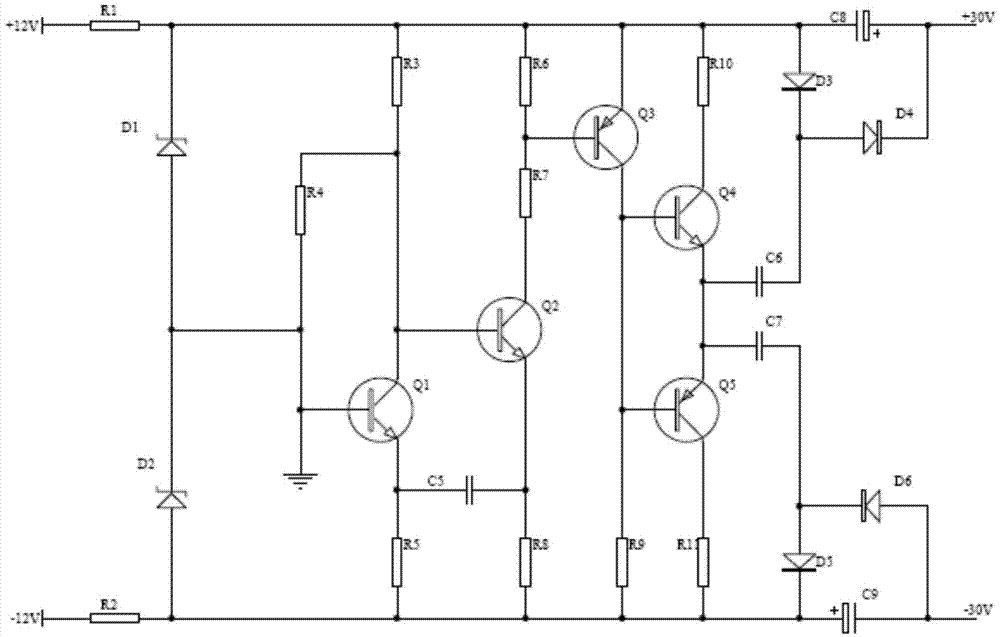

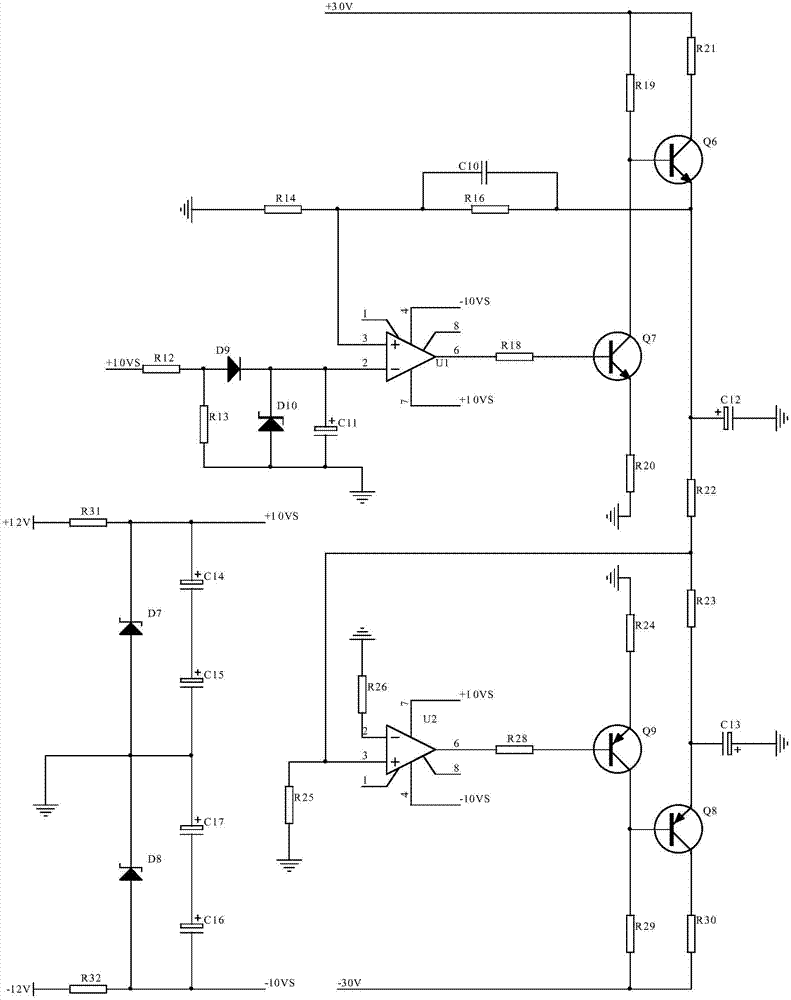

Low-noise and high-stability infrared bias power supply

ActiveCN103501111AGood stability and reliabilityGood manufacturabilityDc-dc conversionElectric variable regulationPush pullFixed frequency

The invention relates to a low-noise and high-stability infrared bias power supply which consists of two parts including a triple voltage circuit and a voltage stabilization filter unit circuit, wherein the triple voltage circuit comprises a pre-voltage stabilizing circuit, an oscillation circuit, a shaping circuit and a push-pull and triple voltage circuit; after power is input into the pre-voltage stabilizing circuit, the power voltage with stable amplitude is output and is stably provided for other circuits in the triple voltage circuit; the oscillation circuit is used for generating signals with fixed frequency and outputting the signals into the shaping circuit; the shaping circuit is used for shaping the signals, and the signals are changed into regular square signals; the push-pull and triple voltage circuit is used for carrying out push-pull output and triple boosting on the square signals; the voltage stabilization filter unit circuit is used for generating a stable reference source and converting the voltage which is output by the push-pull and triple voltage circuit and boosted by three times into the voltage needed by an infrared detector by utilizing the generated reference source.

Owner:BEIJING INST OF CONTROL ENG

Liver protection tea paste prepared from golden camellia leaves

InactiveCN106070859AGood for liver protectionGood stability and reliabilityTea extractionFunctional foodChinese licorice

The invention belongs to the field of food processing, and particularly relates to liver protection tea paste prepared from golden camellia leaves. The liver protection tea paste is prepared from the following ingredients in percentage by weight: 90 percent to 93 percent of extract instant powder, 2 percent to 4 percent of Pu'er tea instant powder, 0.01 percent to 0.1 percent of golden camellia self extraction saponin powder and 1 percent to 2 percent of beta cyclodextrine; the extract instant powder is prepared from the following preparation raw materials in parts by weight: 8 to 12 parts of cassia seeds, 8 to 12 parts of lotus leaves, 8 to 12 parts of oolong, 18 to 22 parts of golden camellia, 3 to 5 parts of rhizoma polygonati, 10 to 15 parts of fruit of Chinese wolfberry, 8 to 12 parts of poria cocos and 3 to 5 parts of liquorice roots. The liver protection tea paste achieves a good liver protection effect, and fills the blanks of the development and the production of golden camellia leave liver protection functional food.

Owner:GUANGXI FUXIN SCI & TECH

Method for removing accumulated snow on high-altitude power transmission lines

InactiveCN104201633AGood stability and reliabilityIncrease heating powerOverhead installationPower transmissionElectrical wiring

The invention provides a method for removing accumulated snow on high-altitude power transmission lines. The method includes measures of connecting various sections of power transmission lines with one another by load tap switches; enabling controllers of the load tap switches to control the load tap switches to act in a certain mode when ice and the snow cover the power transmission lines, to be more specific, sorting a plurality of groups of power lines in the ice and snow covered sections of power transmission lines, and sequentially and alternately concentrating total currents in the sections of power transmission lines into one of the groups of power lines until the ice and the snow which cover the various groups of power lines are melted. The method has the advantage that normal power supply of the power transmission lines to users can be unaffected in snow melting procedures.

Owner:马根昌

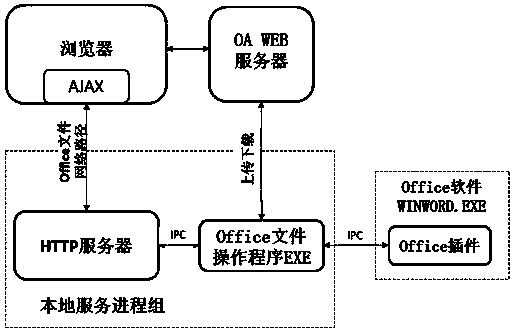

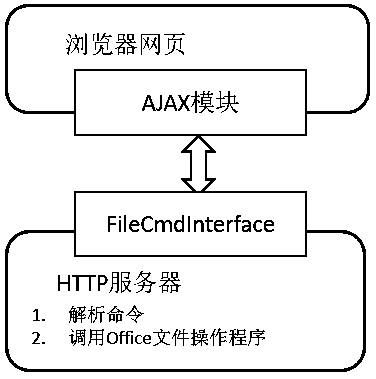

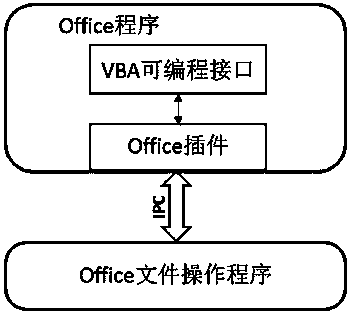

Method for using Office in OA system in non-embedded mode

InactiveCN110471716AGood stability and reliabilityReduce the possibility of errorInterprogram communicationProgram loading/initiatingSoftwareFunctional module

The invention discloses a method for using Office in an OA system in a non-embedded mode. A background HTTP server program is started, a webpage JS script is used for communicating with the backgroundHTTP server program through the AJAX technology, AJAX accesses a file operation interface of a local HTTP server, and then Office file operation is completed through an Office operation function module. According to the invention, the possibility that various errors exist in links such as file downloading, uploading, opening, storing and the like due to factors of a browser is eliminated.All fileoperations are the same as local Office program operation files. And the stability and the reliability are greatly superior to those of free browser software.

Owner:江西金格科技有限公司

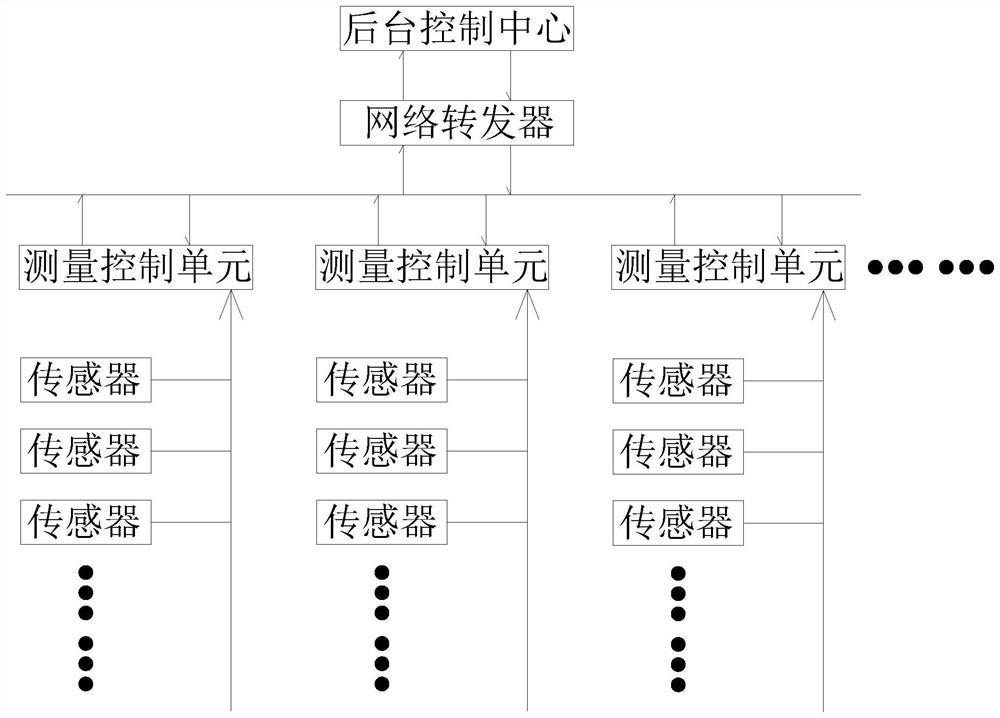

Safety monitoring system for water conservancy and hydropower engineering

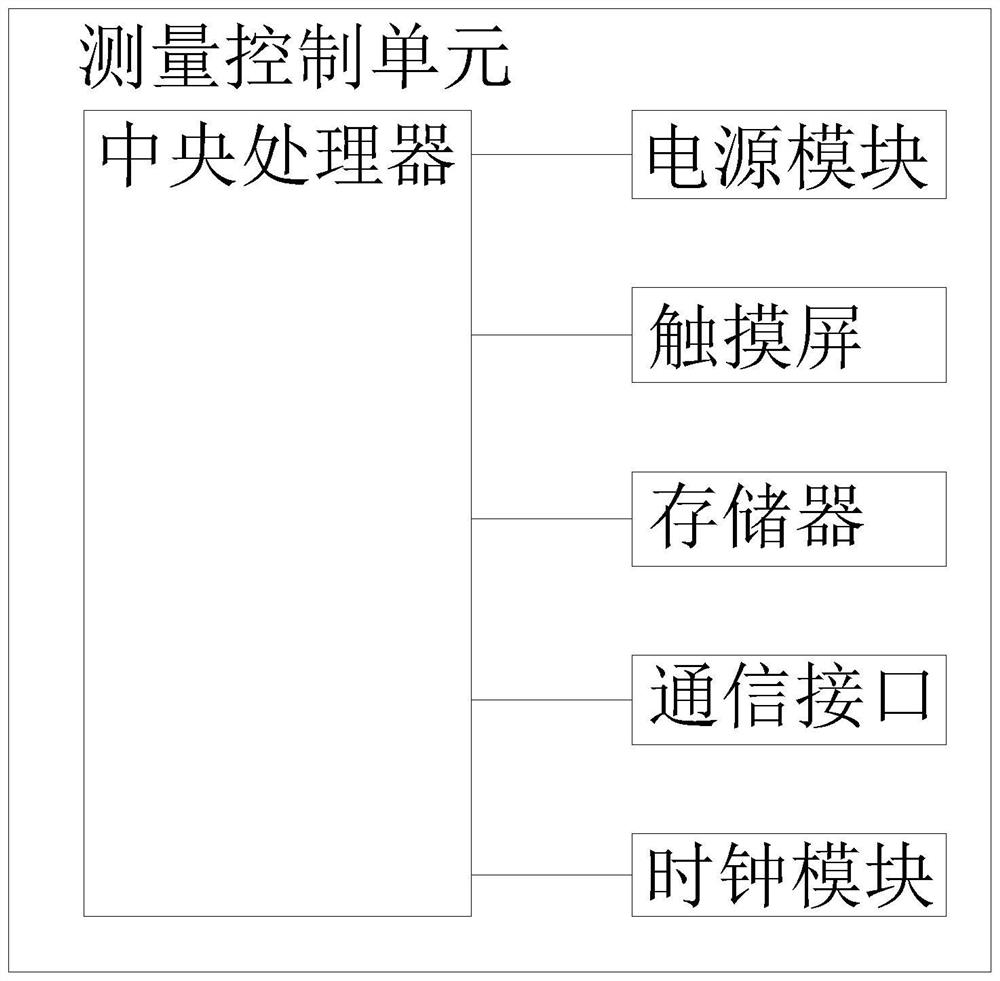

PendingCN114152294AHigh precisionGood stability and reliabilityMeasurement devicesInternet communicationHydropower engineering

The invention discloses a water conservancy and hydropower engineering safety monitoring system which comprises a background control center which is connected with a network transponder through an internet communication technology and is used for exchanging and circulating data, programs and instruction information with the background control center. The network transponder is connected with distributed measurement control units through an internet communication technology and used for exchanging and circulating data, programs and instruction information with the measurement control units, and the measurement control units are connected with various distributed sensors used for safety monitoring. The invention relates to the technical field of water conservancy and hydropower engineering. According to the invention, the problems that the working environment of the safety monitoring equipment for water conservancy and hydropower engineering is abnormally severe, the equipment is easily influenced by various interference factors, the reliability, stability, accuracy and the like of the equipment are difficult to guarantee, and real-time monitoring cannot be realized are solved.

Owner:安徽省维宁建设集团有限公司

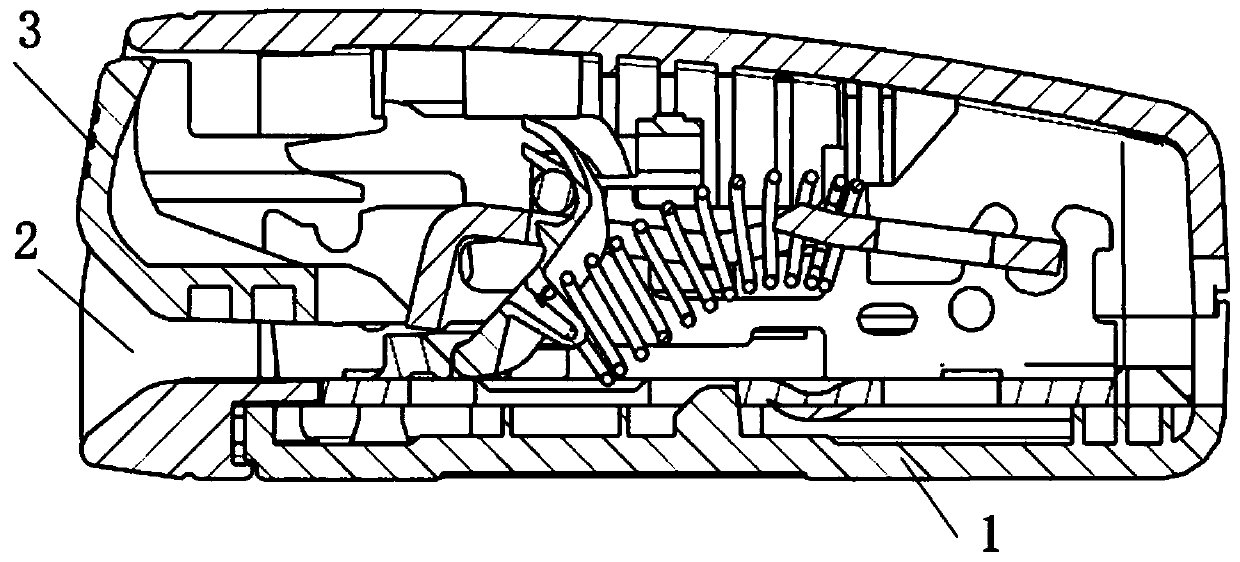

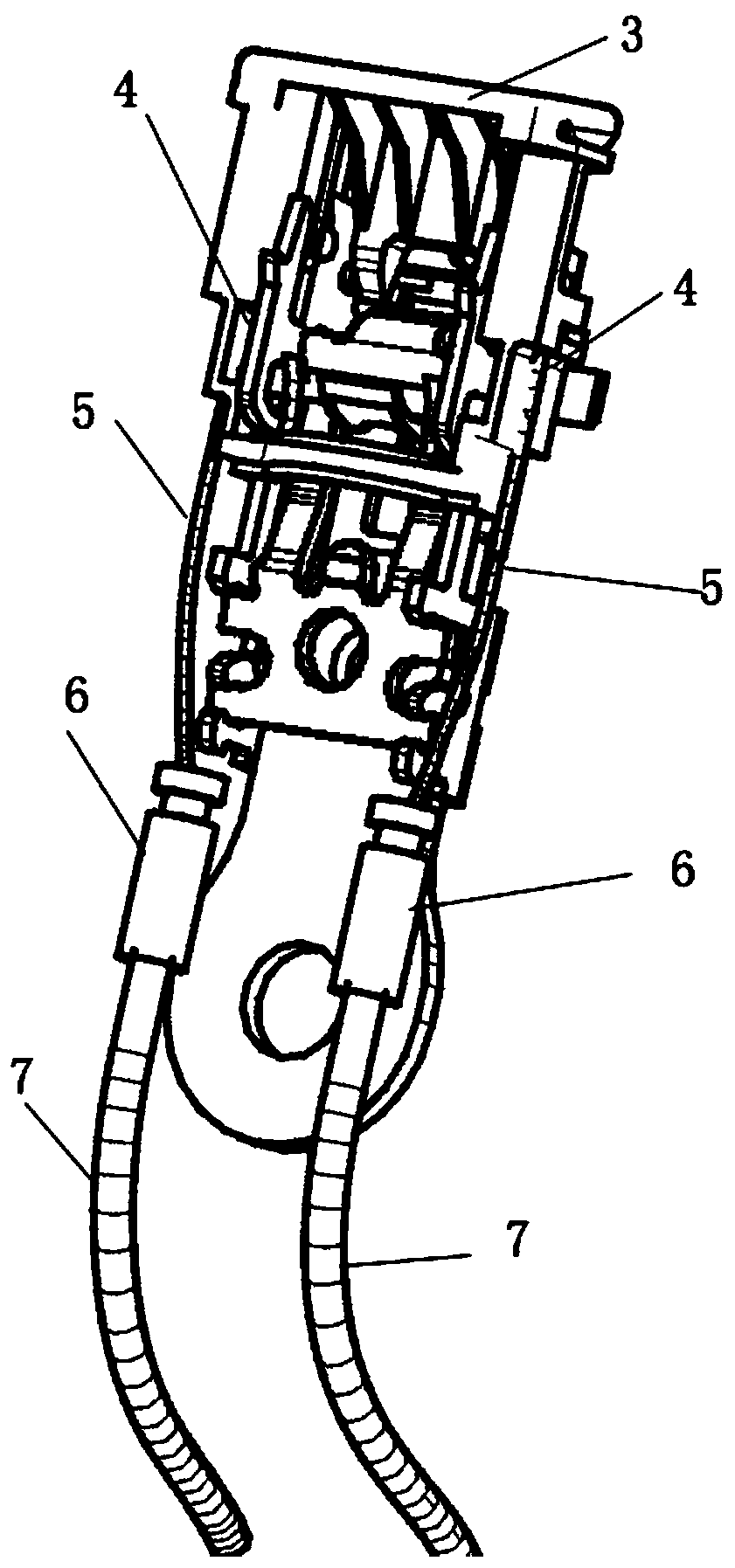

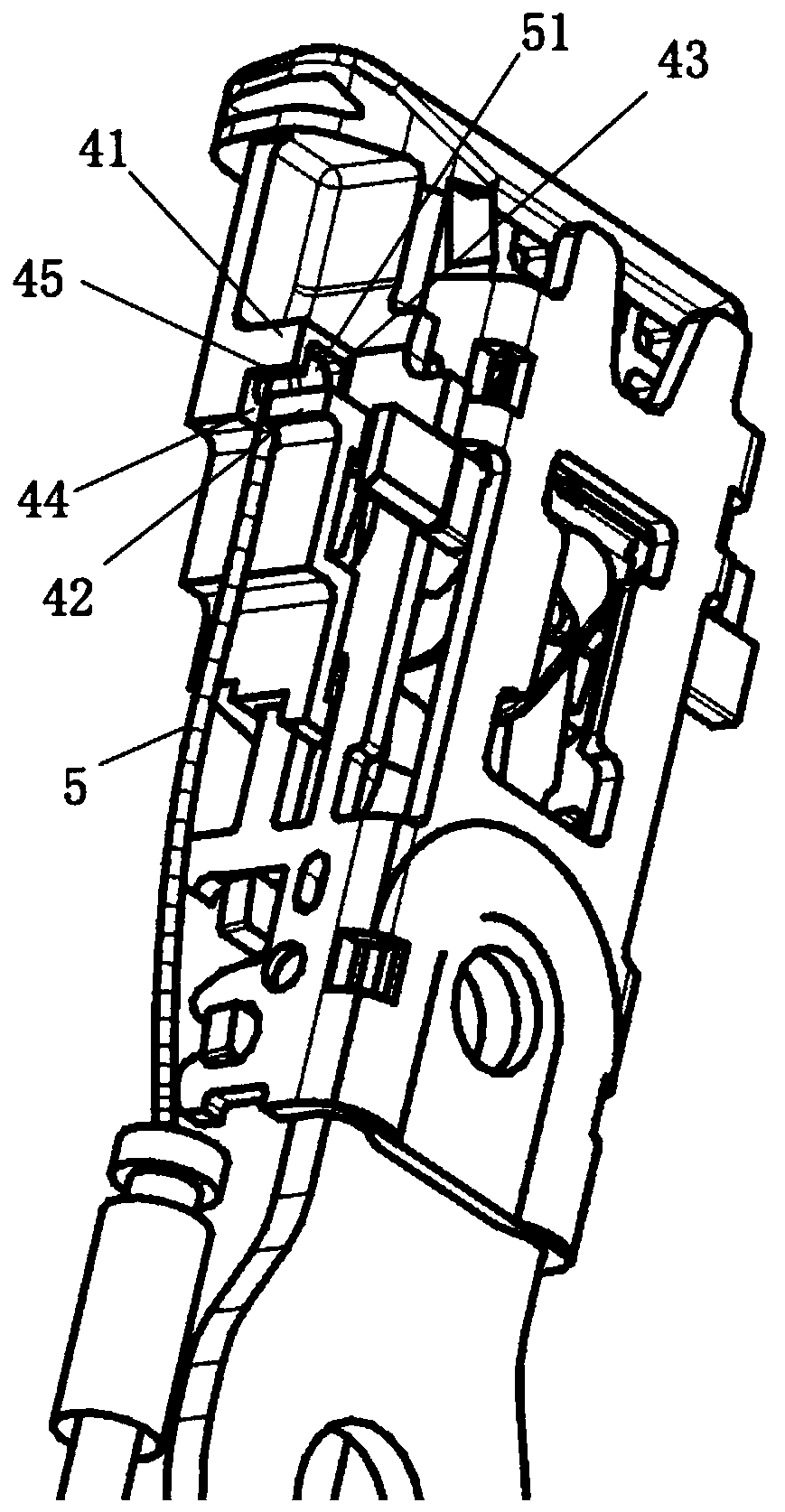

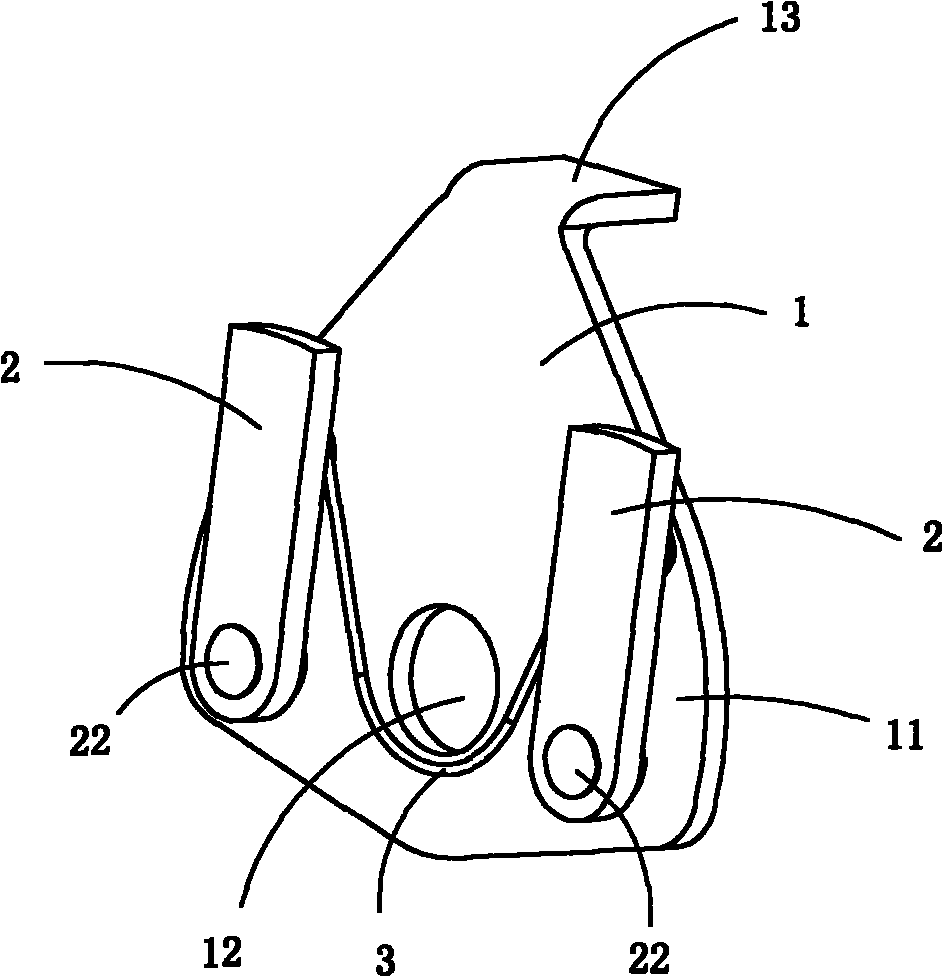

Stable and reliable one-key unlocking type lock catch assembly for safety belt

InactiveCN110316142AAvoid loose noiseGood stability and reliabilityBelt anchoring devicesEngineeringBelt safety

The invention relates to a stable and reliable one-key unlocking type lock catch assembly for a safety belt. The lock catch assembly for the safety belt comprises a lock catch body, wherein a button is arranged at the upper end of the lock catch body; two clamping groove mechanisms are arranged on the lower edge of the button; the two clamping groove mechanisms are arranged on two sides of the button; a rope head is connected into each clamping groove mechanism in a clamping mode; each rope head is connected with a pulling rope; the other end of each pulling rope is connected with a pull rod;the lower edge of each pull rod is connected to a pulling rope system; each pulling rope system is matched with a car body seat electric motor and a control button, when each control button is started, the corresponding car body seat electric motor is used for controlling the corresponding pulling rope system to move towards a direction keeping away from the control button, and the corresponding pulling rope system is used for pulling the button through the corresponding pulling rope, so that the button is pressed downwards relative to the lock catch body so as to realize unlocking of the safety belt inside the lock catch body. The lock catch assembly has the advantages that automatic one-key unlocking can be realized, loosening abnormal sound is avoided, and the stability and reliabilityare high.

Owner:CHONGQING GUANGDA IND

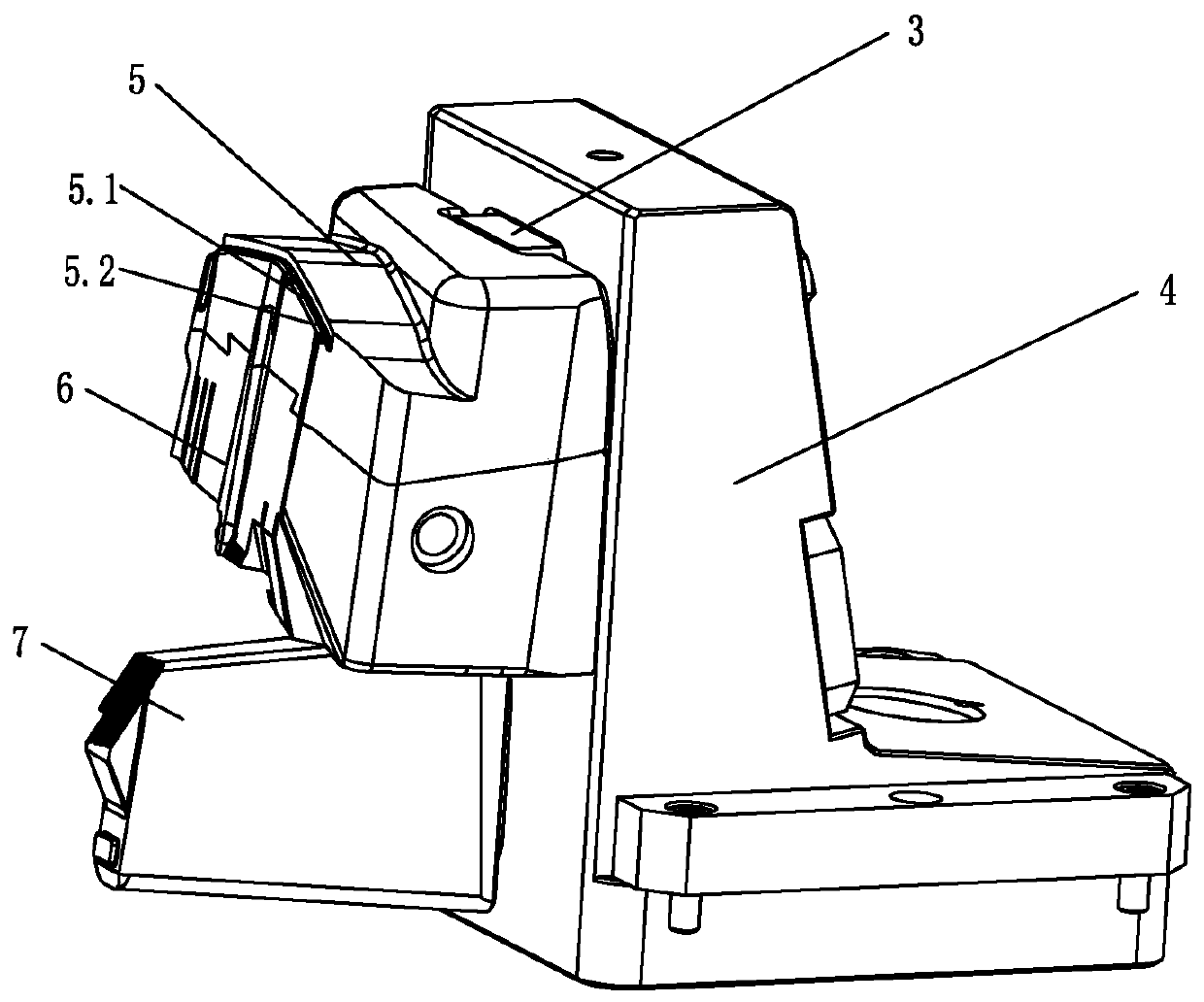

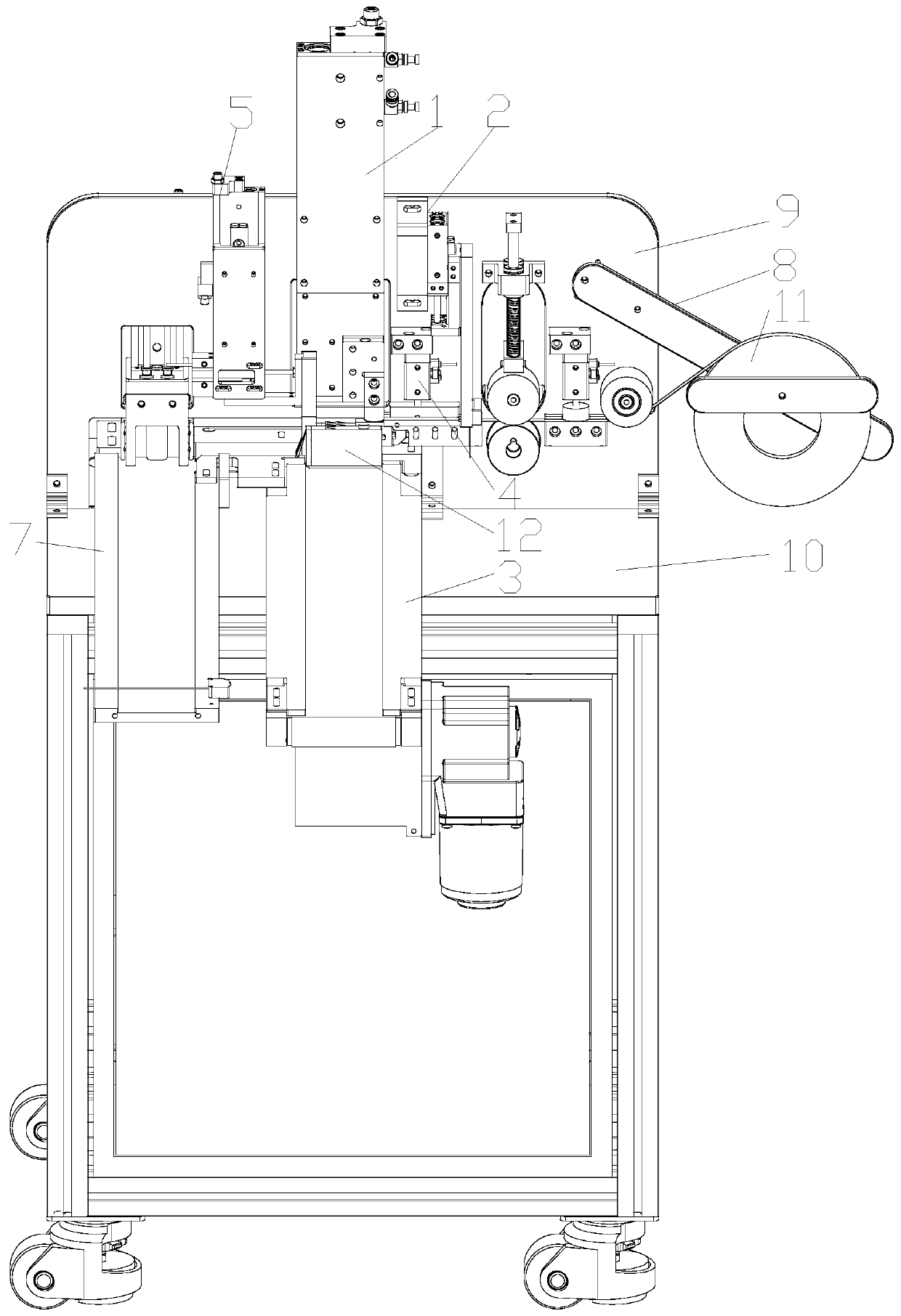

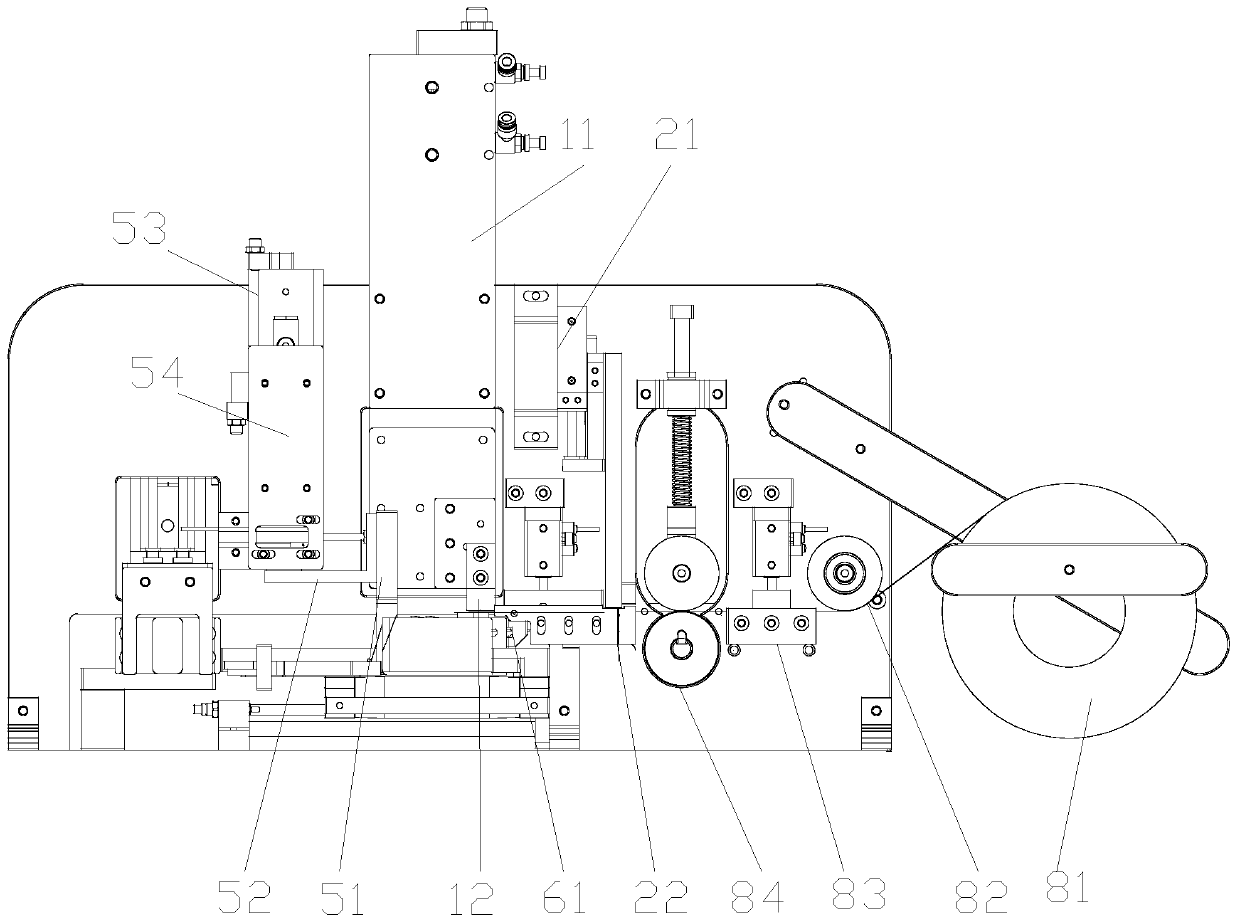

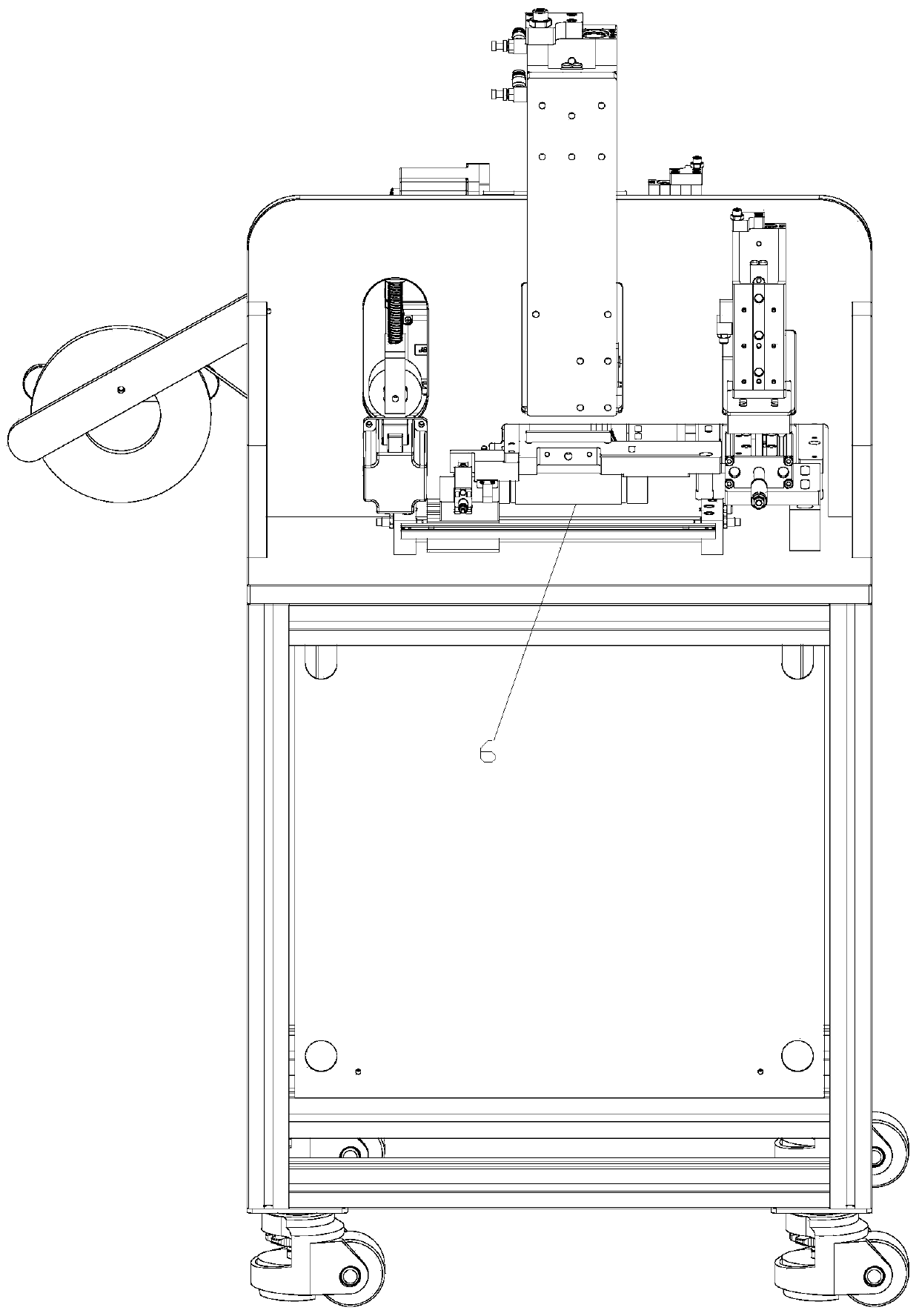

Automatic ink box sealing device

PendingCN110092021AGood stability and reliabilityThe conveying process is stableWrapper twisting/gatheringEngineeringMaterial resources

The invention relates to an automatic ink box sealing device. The automatic ink box sealing device comprises a rack, a machine table, a first guide mechanism, a second guide mechanism, an ironing mechanism, an unrolling mechanism, a pressing mechanism and a first conveying mechanism, wherein the first guide mechanism comprises a first pushing plate and a first guide part; the first guide part is used for pushing the first pushing plate to move in a length direction of the machine table; the second guide mechanism comprises a second pushing plate and a second guide part; the second guide part is used for pushing the second pushing plate to move in a width direction of the machine table; the ironing mechanism is positioned between the first pushing plate and the second pushing plate; the cutting mechanism comprises a cutting part and a cutting guide part; the cutting guide part is used for pushing the cutting part to move in the horizontal direction; and the unrolling mechanism is used for mounting an aluminum film roll; and the unrolling mechanism, the pressing mechanism, the cutting part and the ironing mechanism are sequentially arranged. The automatic ink box sealing device is high in working efficiency, is good in sealing effect, can save a great seal of manpower and material resources, and is high in popularization value.

Owner:北海绩迅科技股份有限公司

Brake mechanism for coil spring-type operation device

InactiveCN101777442ASimple structureGood stability and reliabilitySwitch power arrangementsEngineeringCoil spring

The invention discloses a brake mechanism for a coil spring-type operation device, which comprises an output board, two brake engines and a support spring for providing reset elastic force for the engines; the output board comprises a board body, and the board body comprises a shaft hole, a baffle, two installation holes for installing the engines and two limit holes for limiting the rotating angles of the engines; all the limit holes are arranged above the installation holes; the two engines are symmetrically arranged on both sides of the shaft hole, the front side end of each engine is provided with two cylinders which protrude forwards, an upper cylinder serves as a limit column and is arranged in a corresponding limit hole on the output board, and a lower cylinder serves as an installation column and is arranged in an installation holed of the output board; and both ends of the support spring form a V shape, and are respectively propped against the limit columns of the two engines. The brake mechanism for the coil spring-type operation device has the advantages of more simplified structure, fewer parts, and better reliability and stability.

Owner:南通贺禧机械设备贸易有限公司

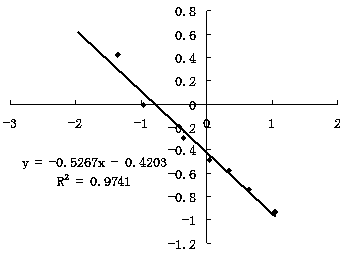

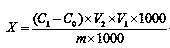

Method for rapidly determining content of ractopamine in animal-originated product

InactiveCN103823056AGood stability and reliabilityImprove stabilityColor/spectral properties measurementsRactopamineAntibody

The invention provides a method for rapidly determining the content of ractopamine in an animal-originated product. the method comprises the following steps: preparing nine ractopamine standard solutions from a ractopamine standard stock solution, respectively mixing the nine ractopamine standard solutions with an antibody solution with the equal volume, drying and incubating, adding to an enzyme label plate, drying and incubating, washing the plate, beating dry, adding a secondary antibody solution into the enzyme label plate, washing the plate after the reaction, and beating dry; adding a color developer, drying and incubating, and fully developing; adding a sulfuric acid stopping solution, determining light absorption value of each pore with ELIASA wave, and drawing working curves of the series ractopamine standard solutions; preparing a sample preparation solution from pure lean meat to be determined, determining light absorption value of each pore after processing, and simultaneously carrying out a blank experiment; and calculating the content of ractopamine in the animal-originated product. By the rapid determination method, sensitivity can be raised and energy can be saved. The method has good stability and reproducibility and high recovery rate, and can meet detection requirement of a lab.

Owner:甘肃省商业科技研究所有限公司

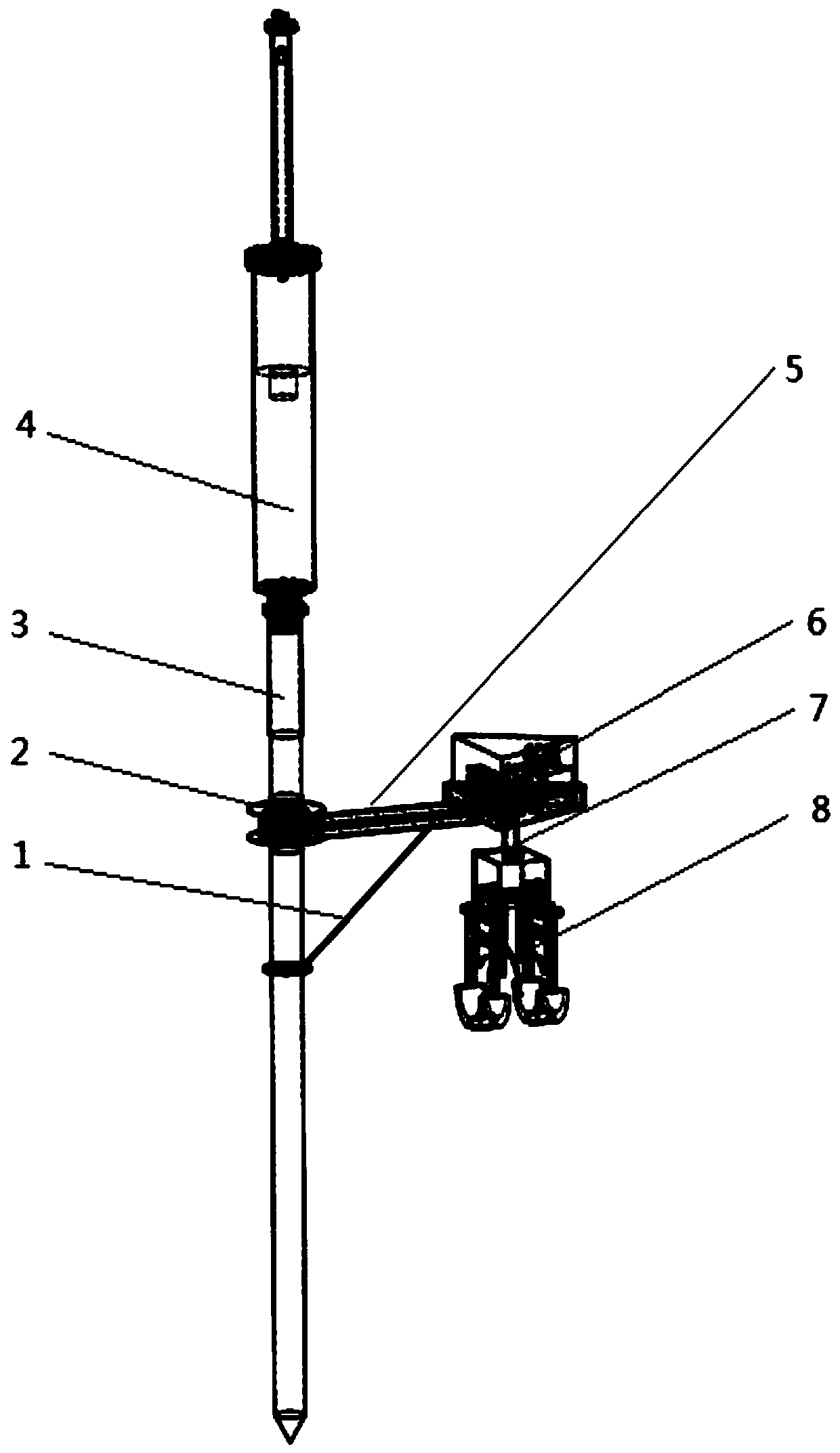

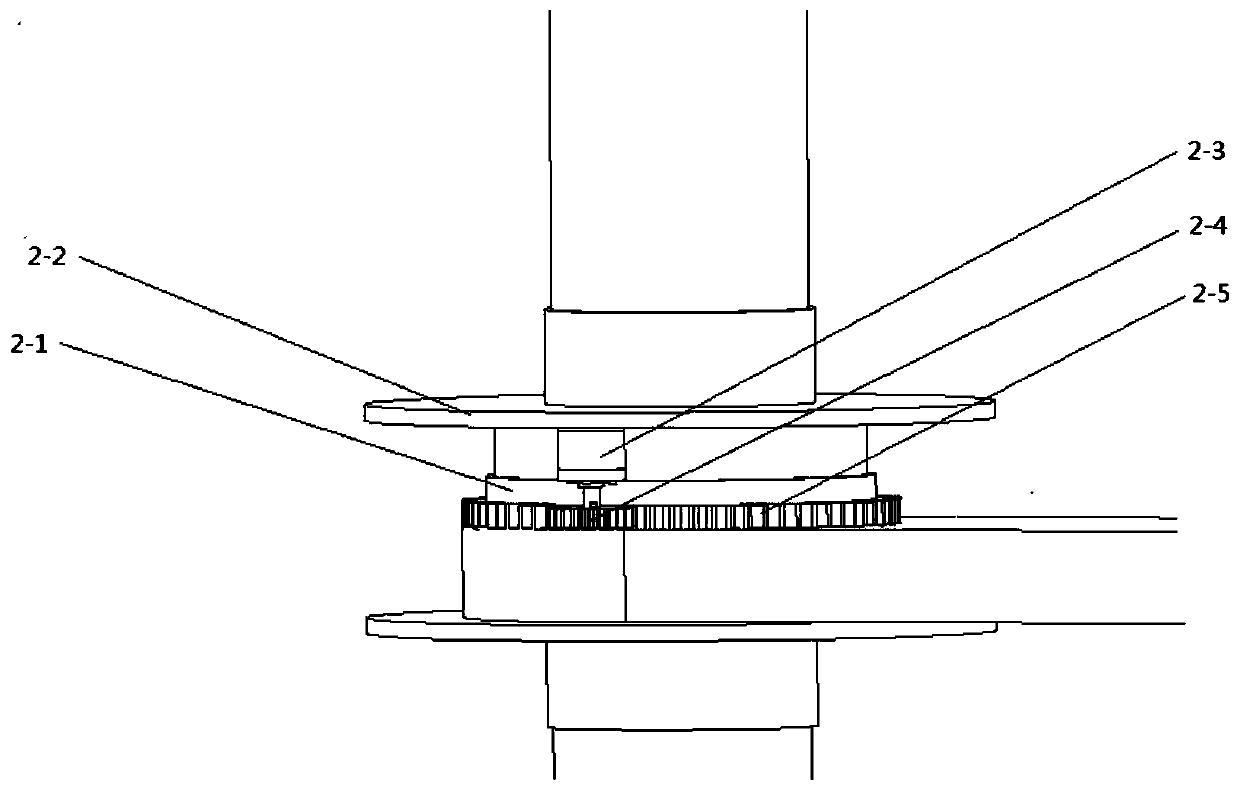

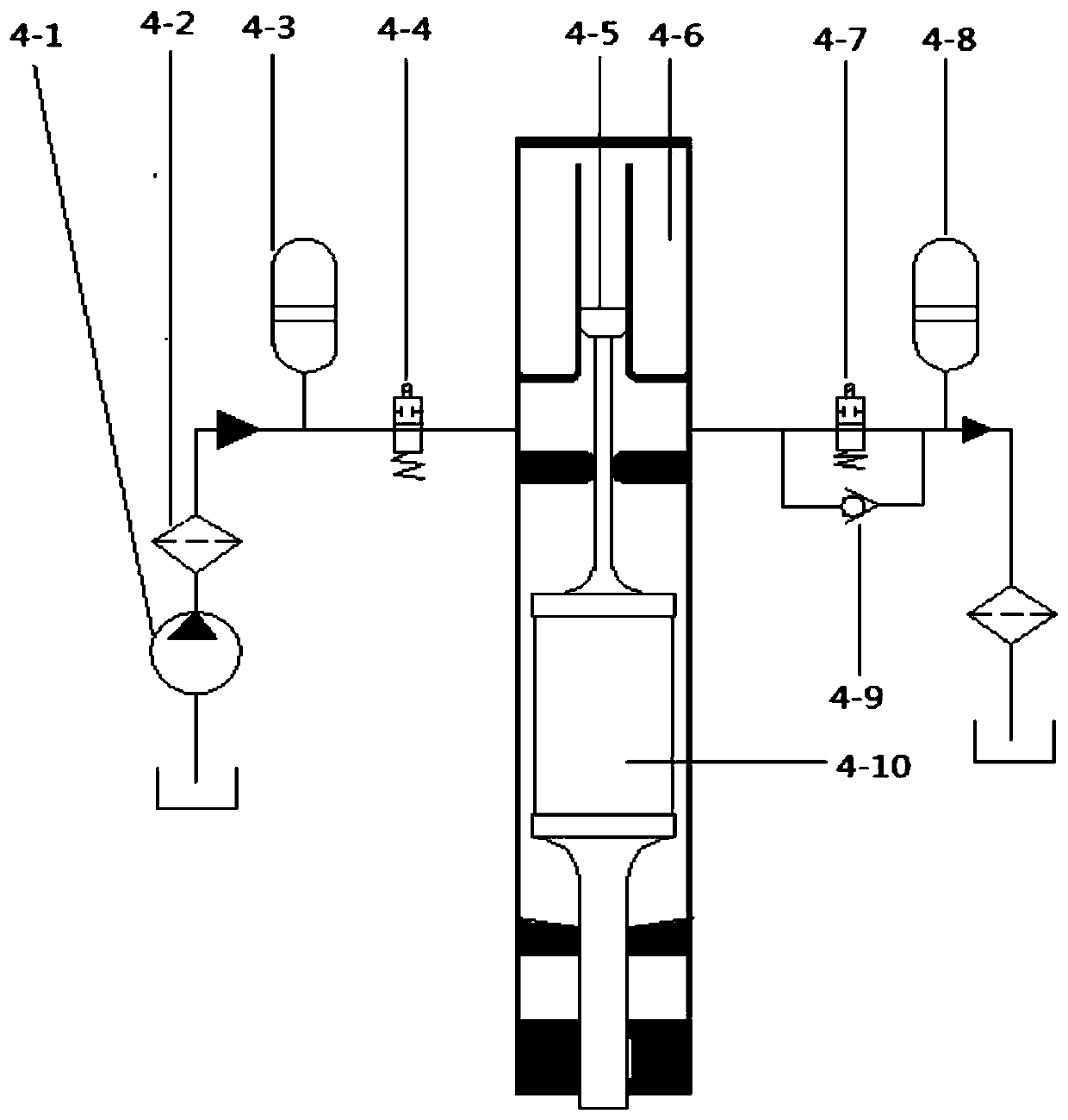

Vertical type pile support device used for processing seabed pipeline suspended span

InactiveCN110107740AGuaranteed reliabilityGood stability and reliabilityPipe supportsServomotorsDrive motorMaximum diameter

The invention provides a vertical type pile support device used for processing seabed pipeline suspended span, and the vertical type pile support device is suitable for a seabed pipeline suspended span processing condition while a pipeline maximum diameter ranges from 280 mm to 500 mm, water depth is smaller than or equal to 60 m, and pipeline suspended span height is lower than or equal to 2 m. The vertical type pile support deice comprises a head hydraulic system, a supporting rod, a telescopic arm hydraulic cylinder, a piling mechanism, a rotary mechanism drive motor, a grabbing mechanism,a grabbing drive cylinder, a positioning rod, a lifting-pulling cylinder, an oil conveying pipeline, a limiting block and the like. The vertical type pile support device is simple and convenient in mounting construction, is short in construction period, can be suitable for various complex seabed geographical environments, does not need manual underwater operation, and has the increasingly emergingadvantage.

Owner:HARBIN ENG UNIV

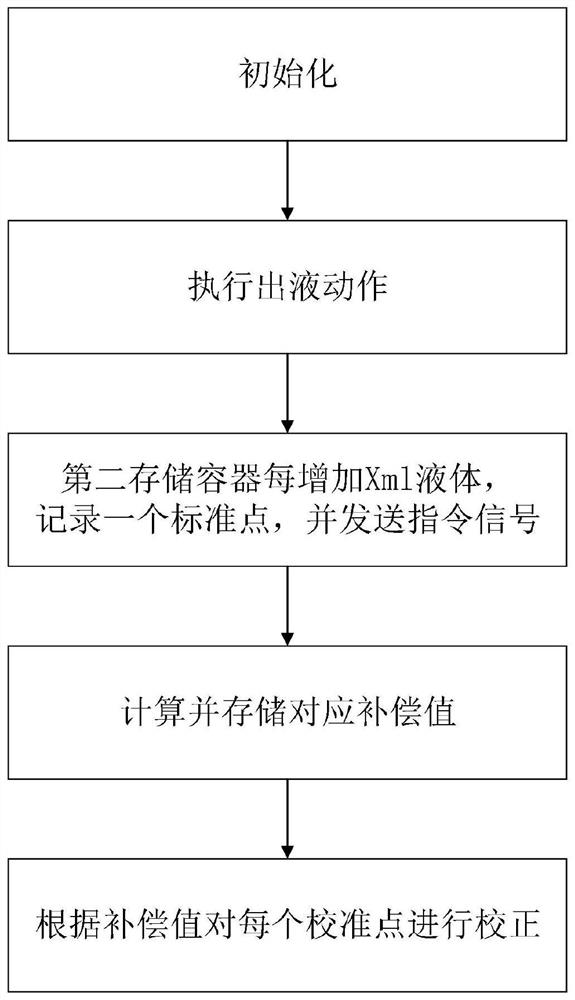

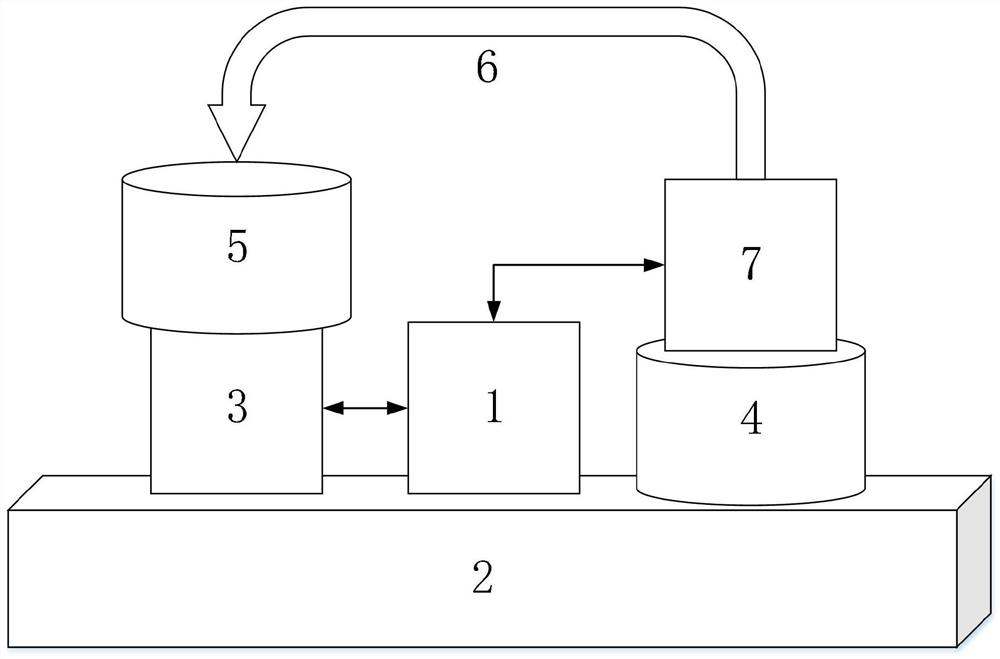

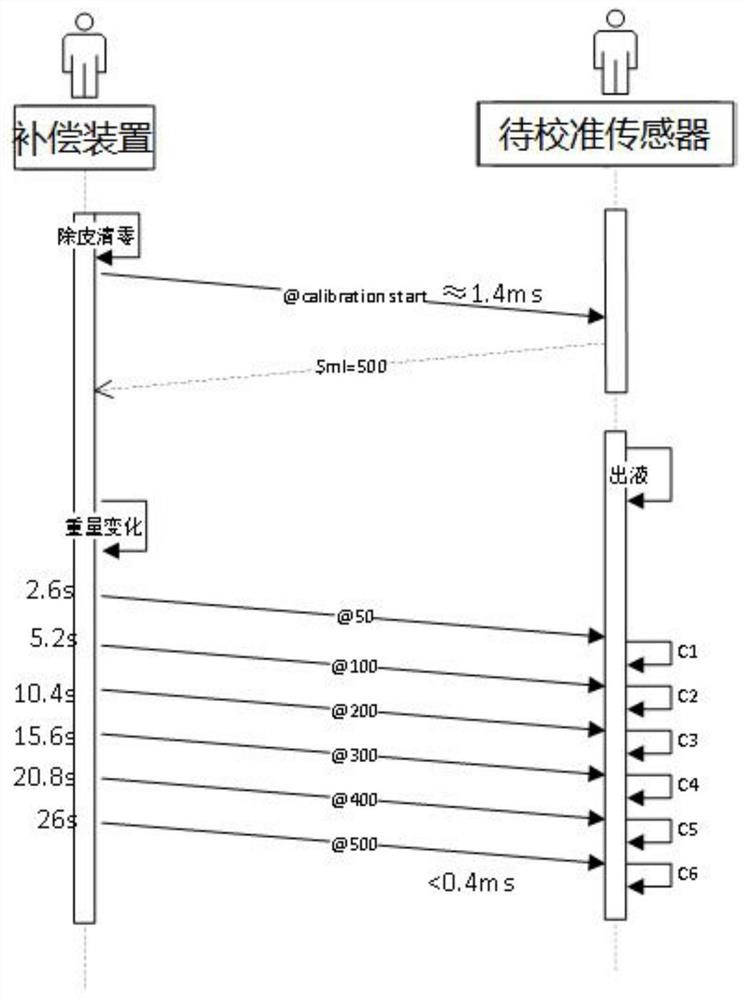

Automatic calibration compensation method and device for Hall flow sensor

ActiveCN113358169AEasy to measureGood stability and reliabilityTesting/calibration apparatusVolume/mass flow by electromagnetic flowmetersElectrical and Electronics engineeringControl engineering

The invention relates to the field of flowmeter calibration, in particular to an automatic calibration compensation method and device for a Hall flow sensor. Based on a weight measurement principle, accurate flow calibration is synchronously completed by weighing liquid weight and cooperating with Hall sensing. The deviation of the calibration points is searched, the compensation value of each calibration point is calculated, calculation is carried out by taking the volume obtained by weight conversion as the reference through the density conversion formula, and due to the fact that weight measurement is relatively easy and simple, and stability and reliability are excellent, on the premise that the calibration process is simplified and the density is variable, the calibration precision is greatly improved, and automatic machine operation can be adopted in the whole process, so that the sensors to be calibrated can be automatically calibrated in batches.

Owner:CHENGDU LONGRAISE TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com