Movable scaffold device for belt gallery

A technology of scaffolding and belt corridor, which is applied in the direction of scaffolding supported by house structure, house structure support, house structure support, etc. It can solve the problem that the comprehensive performance of scaffolding cannot meet the needs of engineering construction, the maintenance, reinforcement, repair, and replacement of belt corridors are inconvenient, and the increase in Problems such as installation and disassembly workload of workers, to achieve the effect of increasing the reuse rate, light structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

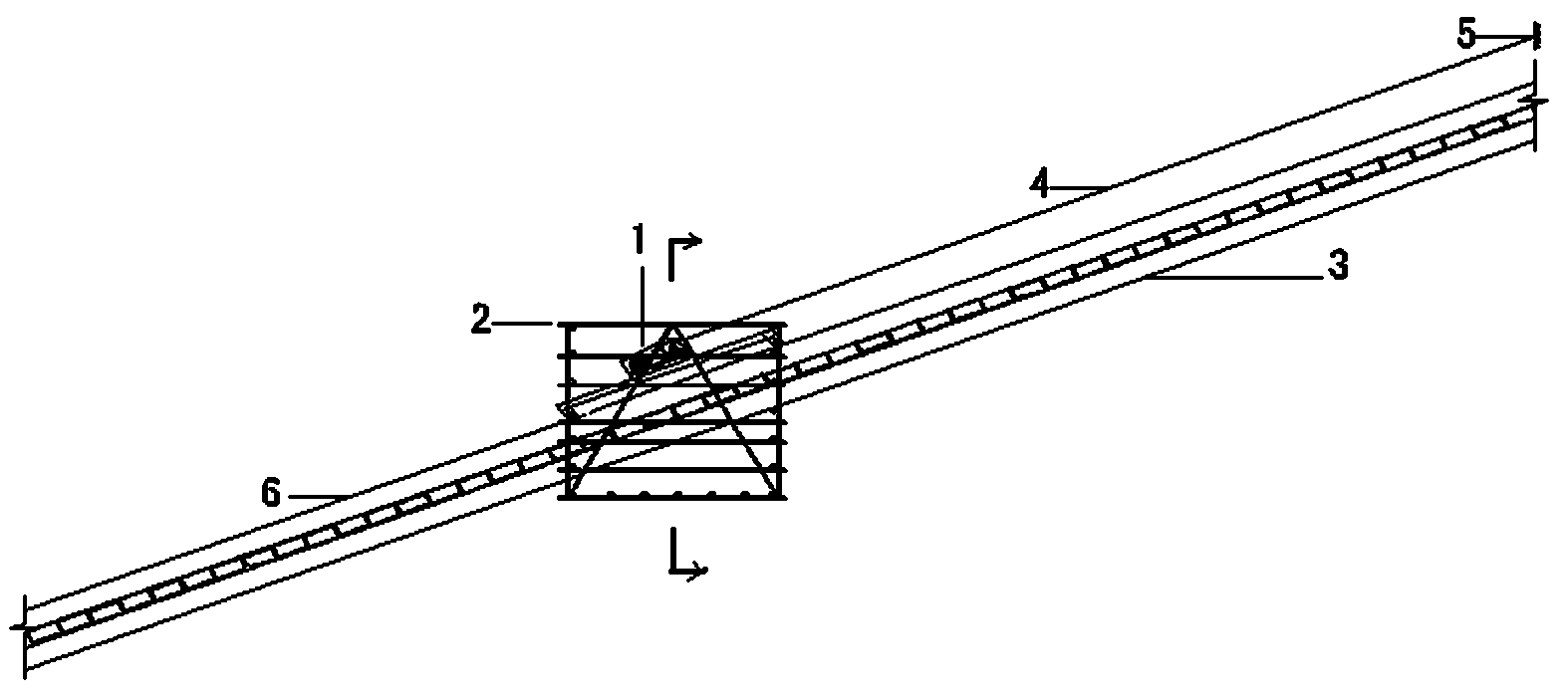

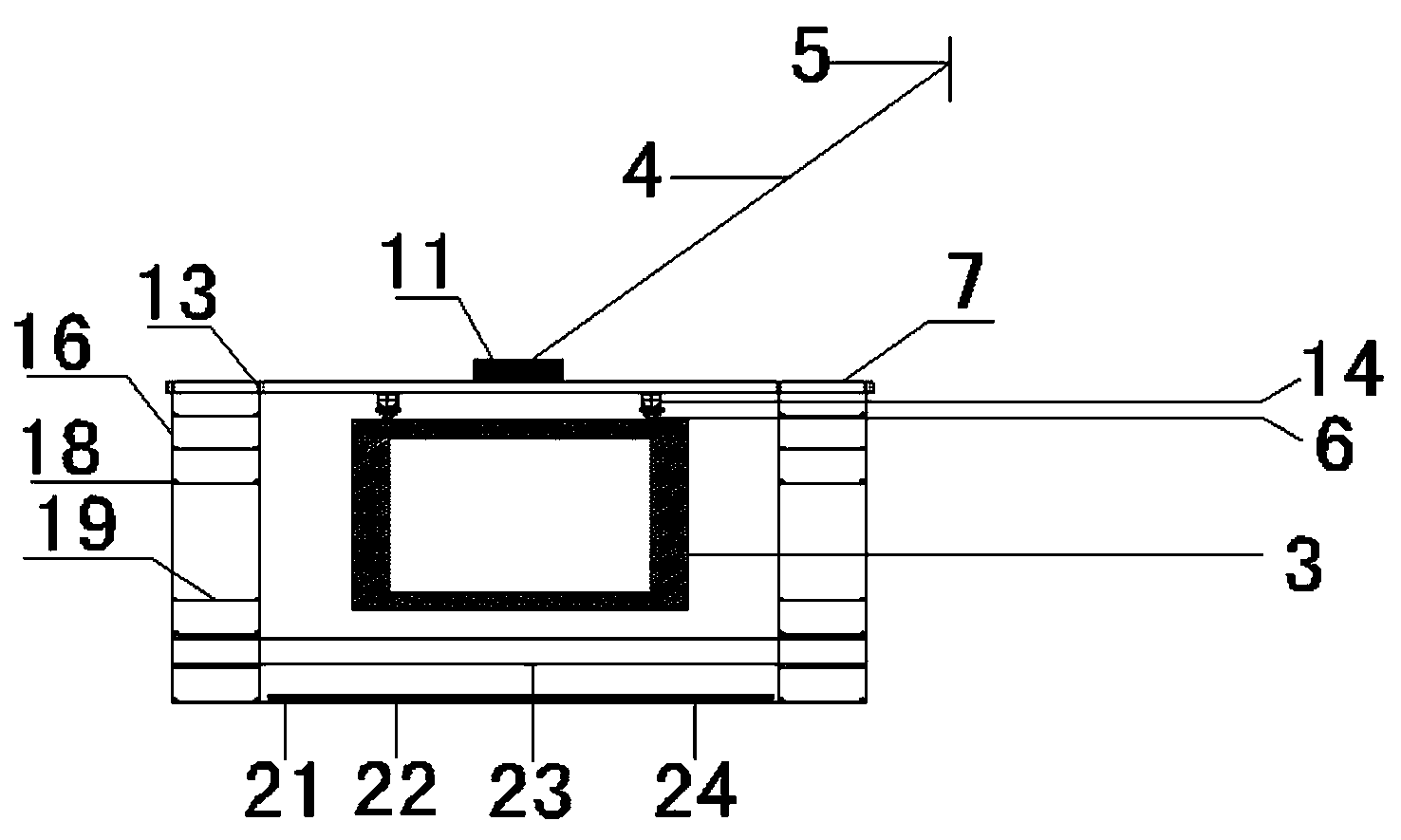

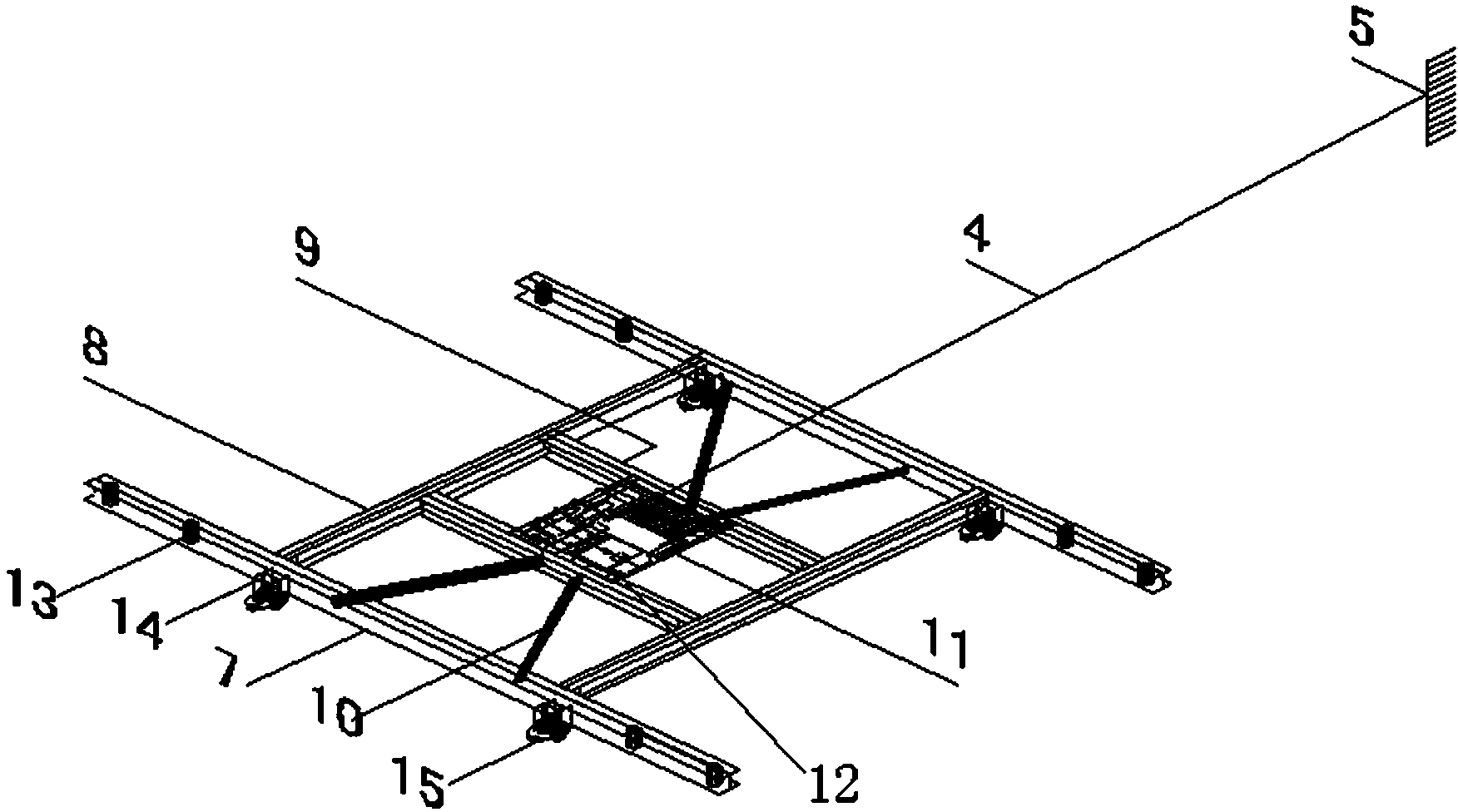

[0035] Such as Figure 1 to Figure 9 As shown, the mobile scaffolding device for the belt gallery includes a power system 1, a mobile support, a construction scaffold 2, a lifting belt gallery 3, and a steel wire rope 4. The mobile support is connected to the construction scaffold 2, and the lower part of the mobile support is provided with Pulley 14, the power system 2 includes an electric hoist 11, the electric hoist 11 is installed on the base of the electric hoist, the base of the electric hoist is connected with the mobile support, and the lifting belt corridor is from low to high along the top of the lifting belt corridor inclined to the ground Two parallel rails 6 are laid, the pulley 14 cooperates with the rails 6, the electric winch 11 is connected with one end of the wire rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com