Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Excellent physical durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus for asymmetric dual-screen digital radiography

ActiveUS20080011960A1High detective quantum efficiencyClear imagingSolid-state devicesMaterial analysis by optical meansSoft x rayFluorescence

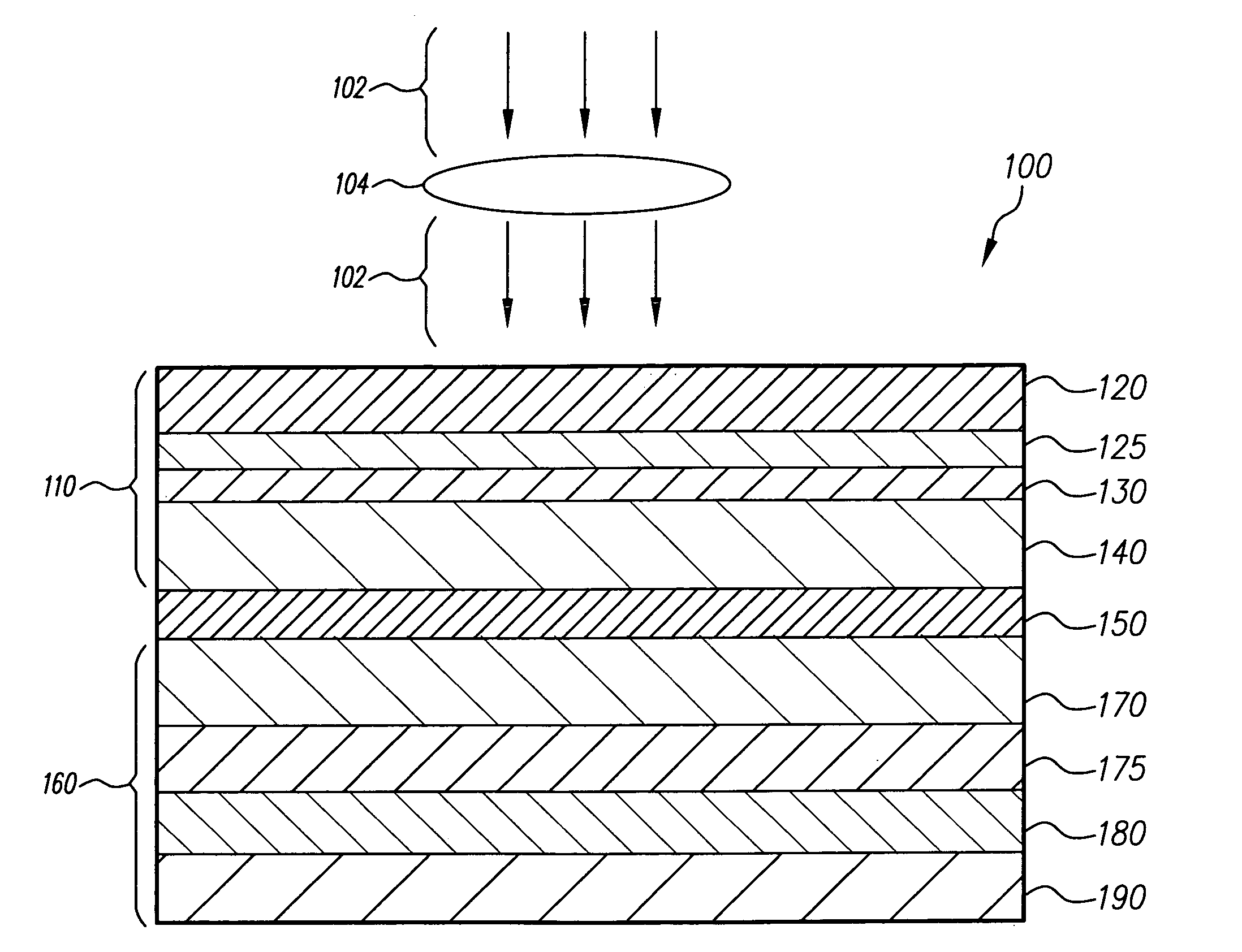

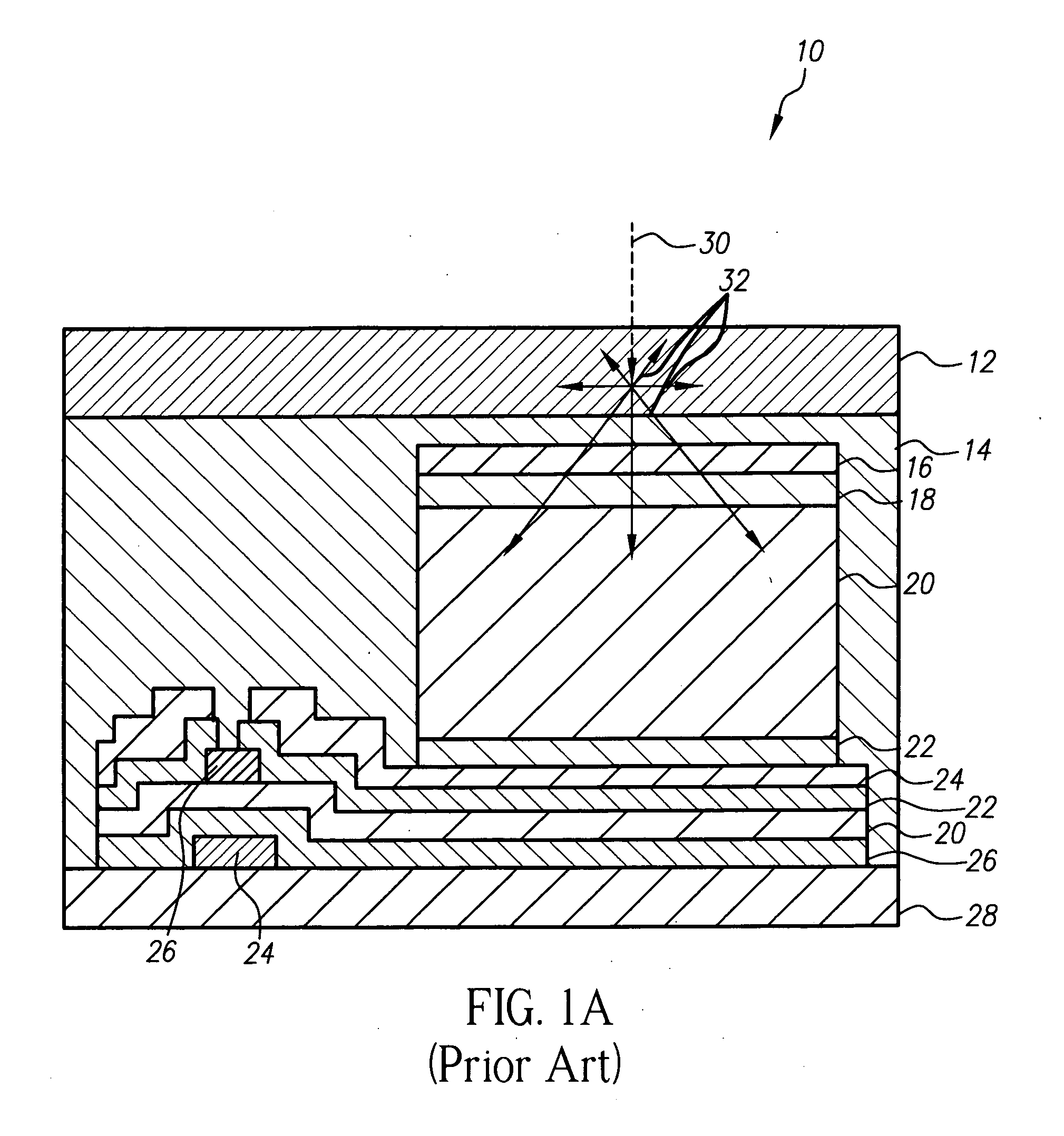

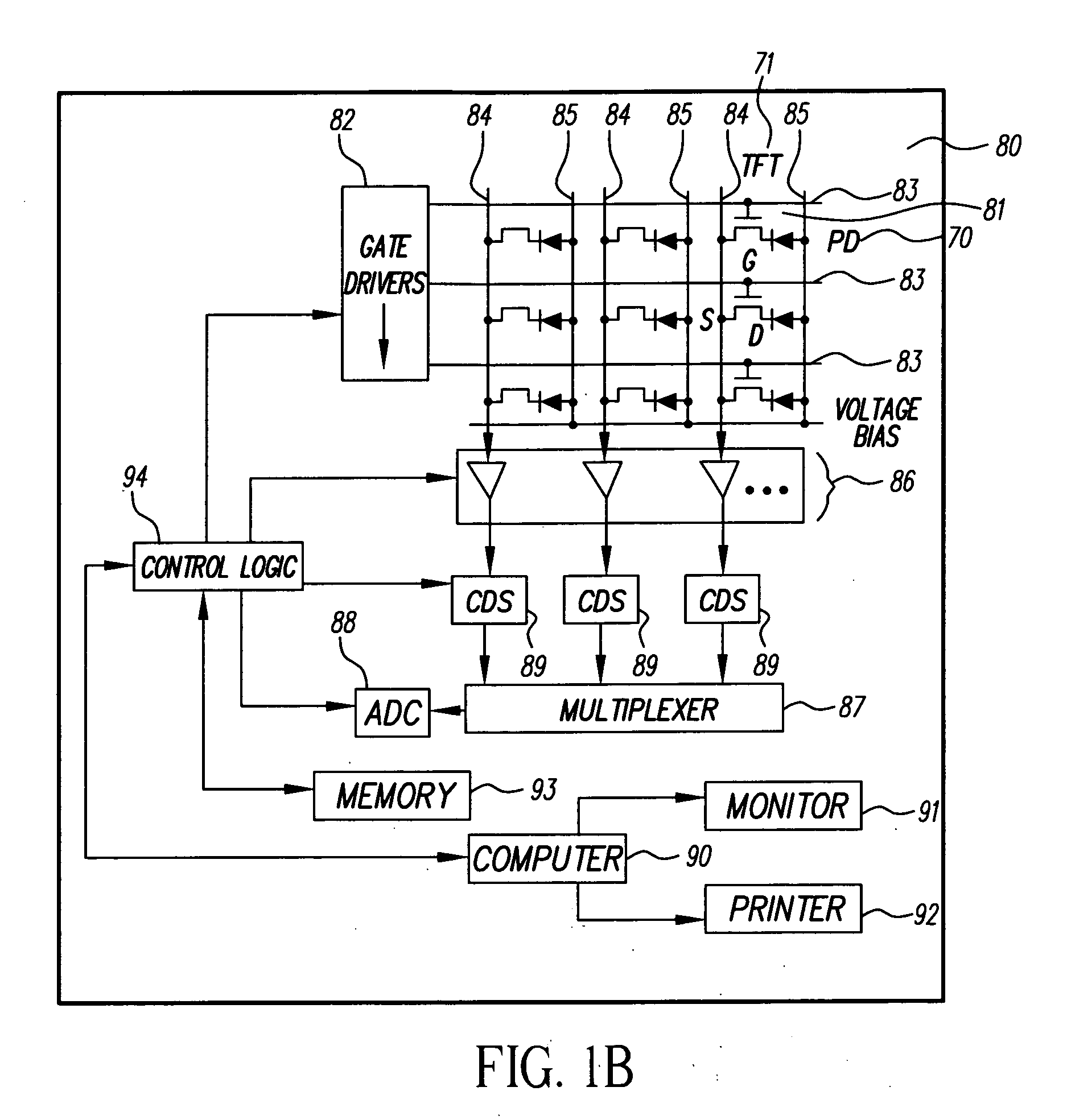

The present invention relates to radiographic imaging apparatus for taking X-ray images of an object. In various two-panel radiographic imaging apparatus configurations, a front panel and back panel have substrates, arrays of signal sensing elements and readout devices, and passivation layers. The front and back panels have scintillating phosphor layers responsive to X-rays passing through an object produce light which illuminates the signal sensing elements to provide signals representing X-ray images. The X-ray apparatus has means for combining the signals of the X-ray images to produce a composite X-ray image. Furthermore, the composition and thickness of the scintillating phosphor layers are selected, relative to each other, to improve the diagnostic efficacy of the composite X-ray image. Alternatively, a radiographic imaging apparatus has a single panel having arrays of signal sensing elements and readout devices and scintillating phosphor layers that are disposed on both sides of a single substrate. The present invention further relates to various embodiments of indirect dual-screen DR flat-panel imager apparatus that provide single-exposure dual energy imaging.

Owner:CARESTREAM HEALTH INC

Inkjet ink set for high image quality on photoglossy paper and plain paper

InactiveUS20080207805A1Excellent image stabilityExcellent physical durabilityMeasurement apparatus componentsInksWater basedImaging quality

A water based inkjet ink set with excellent image stability, durability and quality, comprising at least one cyan ink, at least one magenta ink, at least one yellow ink, at least one black ink, and at least one colorless protective ink, wherein:(a) the cyan, magenta, yellow, and black inks each comprise a pigment colorant;(b) the cyan, magenta, yellow, black, and colorless protective inks each comprise a polymeric binder additive; and(c) the surface tensions of the inks have the following relationships:(i) the dynamic surface tension at 10 milliseconds surface age for all inks of the ink set is greater than or equal to 35 mN / m,(ii) the static surface tensions of the yellow ink and of the colorless protective ink are at least 2.0 mN / m lower than the static surface tensions of the cyan, magenta and black inks of the ink set and(iii) the static surface tension of the colorless protective ink is at least 1.0 mN / m lower than the static surface tension of the yellow ink.

Owner:EASTMAN KODAK CO

Inkjet recording medium and methods therefor

ActiveUS20110279554A1Increase speedImprove image qualityNon-fibrous pulp additionCoatings with pigmentsCross-linkWater soluble

An inkjet receiving medium including a substrate and having a topmost layer coated thereon at solid content of from 0.1 to 25 g / m2, wherein the topmost layer comprises from 30-70 wt % of one or more aqueous soluble salts of multivalent metal cations and at least 0.05 g / m2 of a cross-linked hydrophilic polymer binder. Improved optical density, reduced mottle and improved wet abrasion resistance are provided when the receiver is printed with an aqueous pigment-based ink. In further embodiments, the topmost layer may further comprise a latex dispersion for improved image durability.

Owner:EASTMAN KODAK CO

Flexible display device

ActiveUS20180097197A1Excellent physical durabilityStress minimizationDigital data processing detailsCasings with display/control unitsEngineeringFlexible display

A flexible display device is disclosed. The flexible display device includes a flexible display panel and a back cover disposed on a back surface of the flexible display panel and having a plurality of opening patterns provided in the third region. The plurality of opening patterns include opening patterns arranged in odd-numbered columns along the first direction and opening patterns arranged in even-numbered columns along the first direction. Each of the opening patterns includes a first portion having a width becoming smaller in a second direction intersecting with the first direction as the first portion progresses along the first direction and a second portion extending from the first portion and having a width becoming greater in the second direction as the second portion progresses along the first direction.

Owner:LG DISPLAY CO LTD

Flexible display device

ActiveUS10074824B2Excellent physical durabilityStress minimizationDigital data processing detailsCasings with display/control unitsEngineeringFlexible display

A flexible display device is disclosed. The flexible display device includes a flexible display panel and a back cover disposed on a back surface of the flexible display panel and having a plurality of opening patterns provided in the third region. The plurality of opening patterns include opening patterns arranged in odd-numbered columns along the first direction and opening patterns arranged in even-numbered columns along the first direction. Each of the opening patterns includes a first portion having a width becoming smaller in a second direction intersecting with the first direction as the first portion progresses along the first direction and a second portion extending from the first portion and having a width becoming greater in the second direction as the second portion progresses along the first direction.

Owner:LG DISPLAY CO LTD

Pre-treatment composition for inkjet printing

InactiveUS8562126B1Increase speedImprove image qualityDuplicating/marking methodsPolyurea/polyurethane coatingsWater dispersibleCationic polyelectrolytes

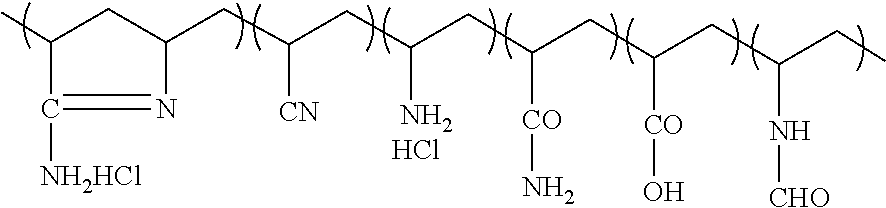

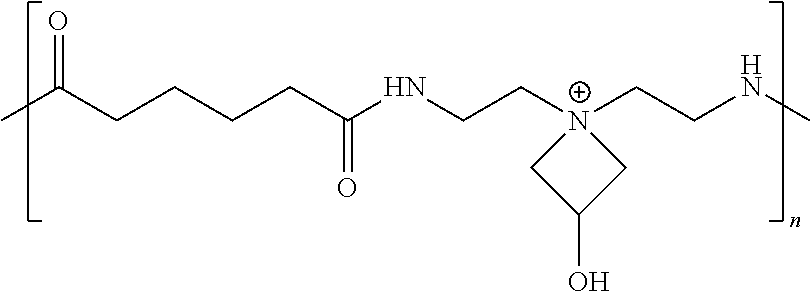

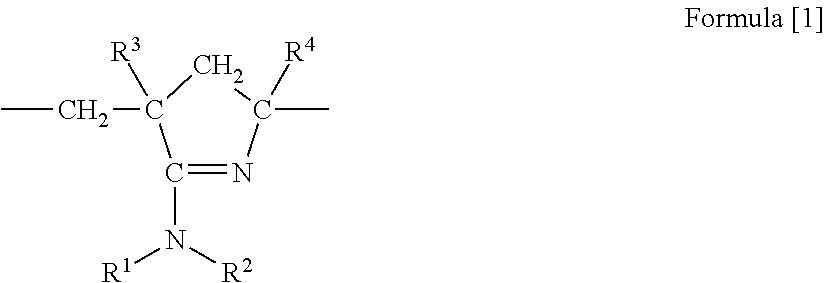

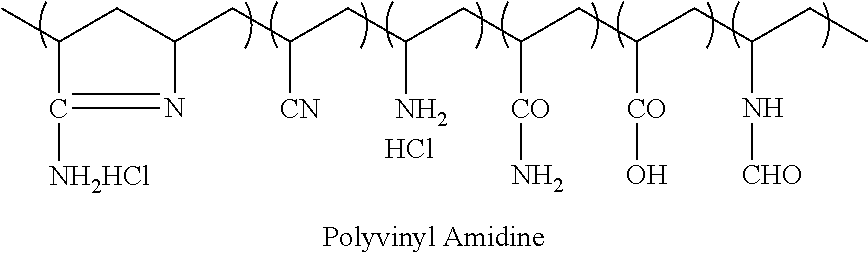

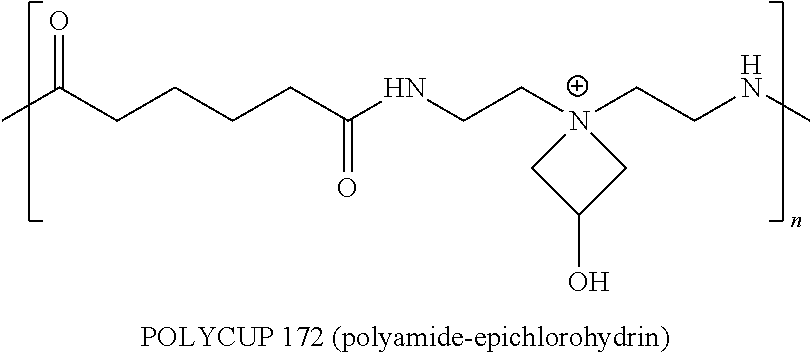

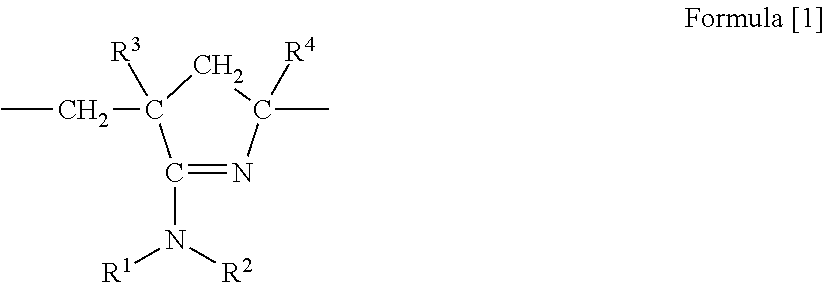

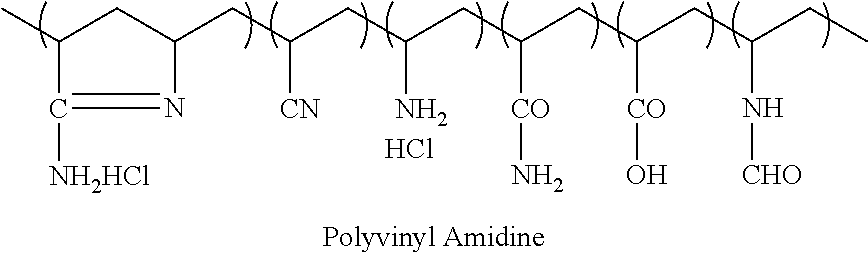

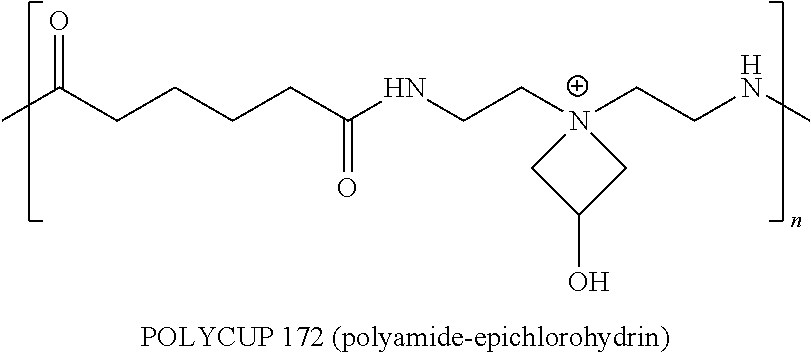

A coating composition for pre-treating a substrate prior to inkjet printing thereon, and an inkjet receiving medium comprising a substrate and having a topmost layer coated thereon, where the coating composition and topmost layer comprise one or more aqueous-soluble salts of multivalent metal cations, a cationic polyelectrolyte comprising amidine moieties, and one or more second polymer which is distinct from the cationic polyelectrolyte and which is selected from the group consisting of a polyamide-epichlorohydrin, a polyamine solution polymer, and a waterborne or water-dispersible polyurethane. The topmost layer is advantageously at a solid content of from 0.1 to 5 g / m2, and comprises from 30-90 wt % of the one or more aqueous soluble salts of multivalent metal cations, at least 0.01 g / m2 of the cationic polyelectrolyte comprising amidine moieties, and at least 0.005 g / m2 of the second polymer which is distinct from the cationic polyelectrolyte comprising amidine moieties.

Owner:EASTMAN KODAK CO

Pre-treatment composition for inkjet printing

ActiveUS20130293647A1Increase speedImprove image qualityCoatingsThermographyAqueous solubilitySolid content

A coating composition for pre-treating a substrate prior to inkjet printing thereon, and an inkjet receiving medium comprising a substrate and having a topmost layer coated thereon, where the coating composition has a solids content which comprises at least 30 wt % of one or more aqueous soluble salts of multivalent metal cations, and particles comprised primarily of polymer having a Rockwell Hardness of less than R90 and having a mode equivalent spherical diameter of at least about 2 micrometers. When coated, the composition provides at least 0.01 g / m2 of particles comprised primarily of polymer having a Rockwell Hardness of less than R90 and which have an equivalent spherical diameter of i) at least about 2 micrometers and ii) at least 0.1 micrometer greater than the minimum coated thickness of the topmost layer.

Owner:EASTMAN KODAK CO

Pre-treatment composition for inkjet printing

ActiveUS9067448B2Increase speedImprove image qualityCoatingsThermographyAqueous solubilitySolid content

A coating composition for pre-treating a substrate prior to inkjet printing thereon, and an inkjet receiving medium including a substrate and having a topmost layer coated thereon, where the coating composition has a solids content which includes at least 30 wt % of one or more aqueous soluble salts of multivalent metal cations, and particles had primarily of polymer having a Rockwell Hardness of less than R90 and having a mode equivalent spherical diameter of at least about 2 micrometers. When coated, the composition provides at least 0.01 g / m2 of particles included primarily of polymer having a Rockwell Hardness of less than R90 and which have an equivalent spherical diameter of i) at least about 2 micrometers and ii) at least 0.1 micrometer greater than the minimum coated thickness of the topmost layer.

Owner:EASTMAN KODAK CO

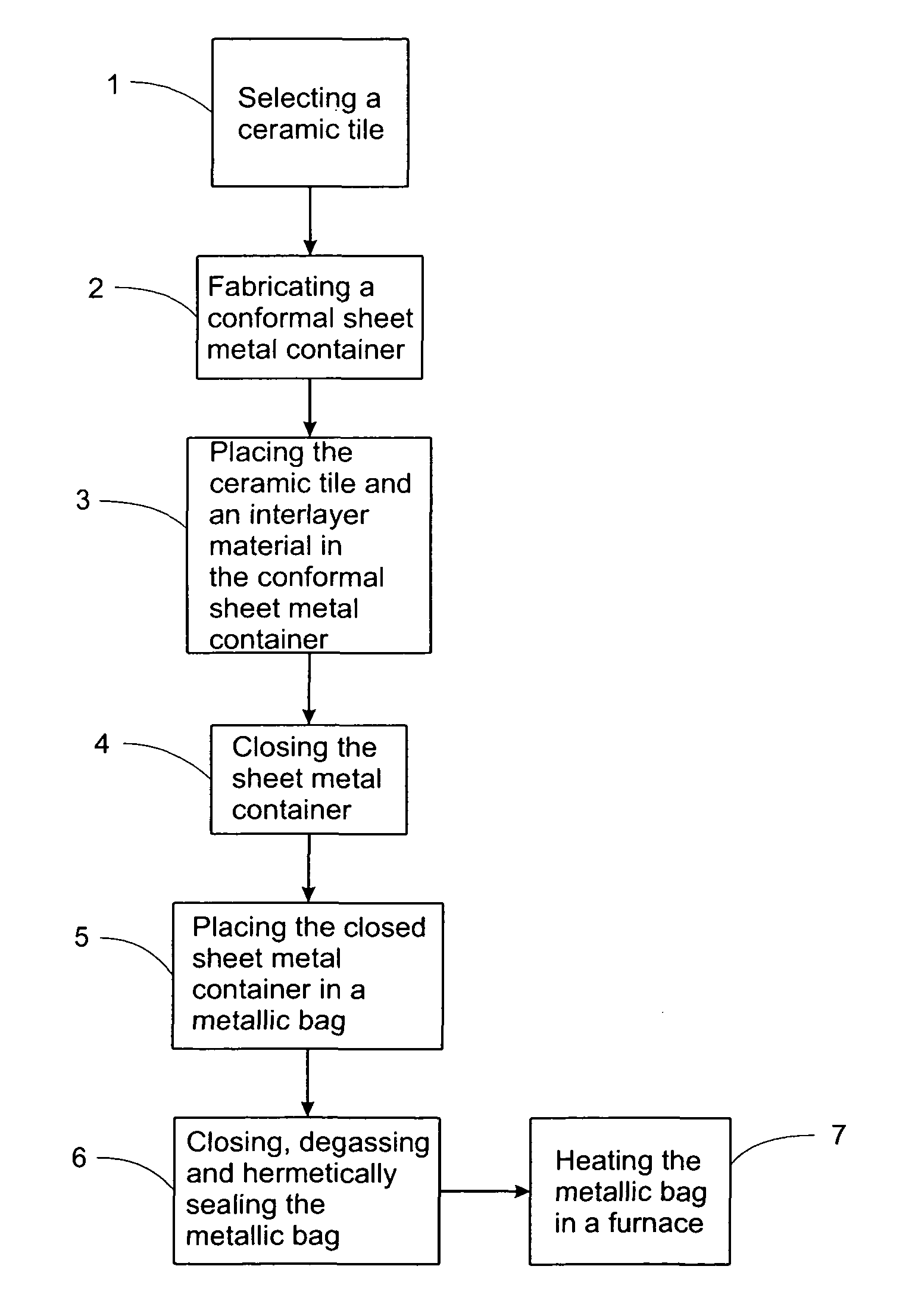

Method for producing armor through metallic encapsulation of a ceramic core

ActiveUS8087143B2Little and no loss in ballistic efficiencyImprove cutting effectDoor/window protective devicesMetal rolling stand detailsDiffusion bonding

Owner:EXOTHERMICS

Inkjet recording medium and methods therefor

ActiveUS9434201B2Increase speedImprove image qualityNon-fibrous pulp additionCoatings with pigmentsCross-linkOptical density

An inkjet receiving medium including a substrate and having a topmost layer coated thereon at solid content of from 0.1 to 25 g / m2, wherein the topmost layer comprises from 30-70 wt % of one or more aqueous soluble salts of multivalent metal cations and at least 0.05 g / m2 of a cross-linked hydrophilic polymer binder. Improved optical density, reduced mottle and improved wet abrasion resistance are provided when the receiver is printed with an aqueous pigment-based ink. In further embodiments, the topmost layer may further comprise a latex dispersion for improved image durability.

Owner:EASTMAN KODAK CO

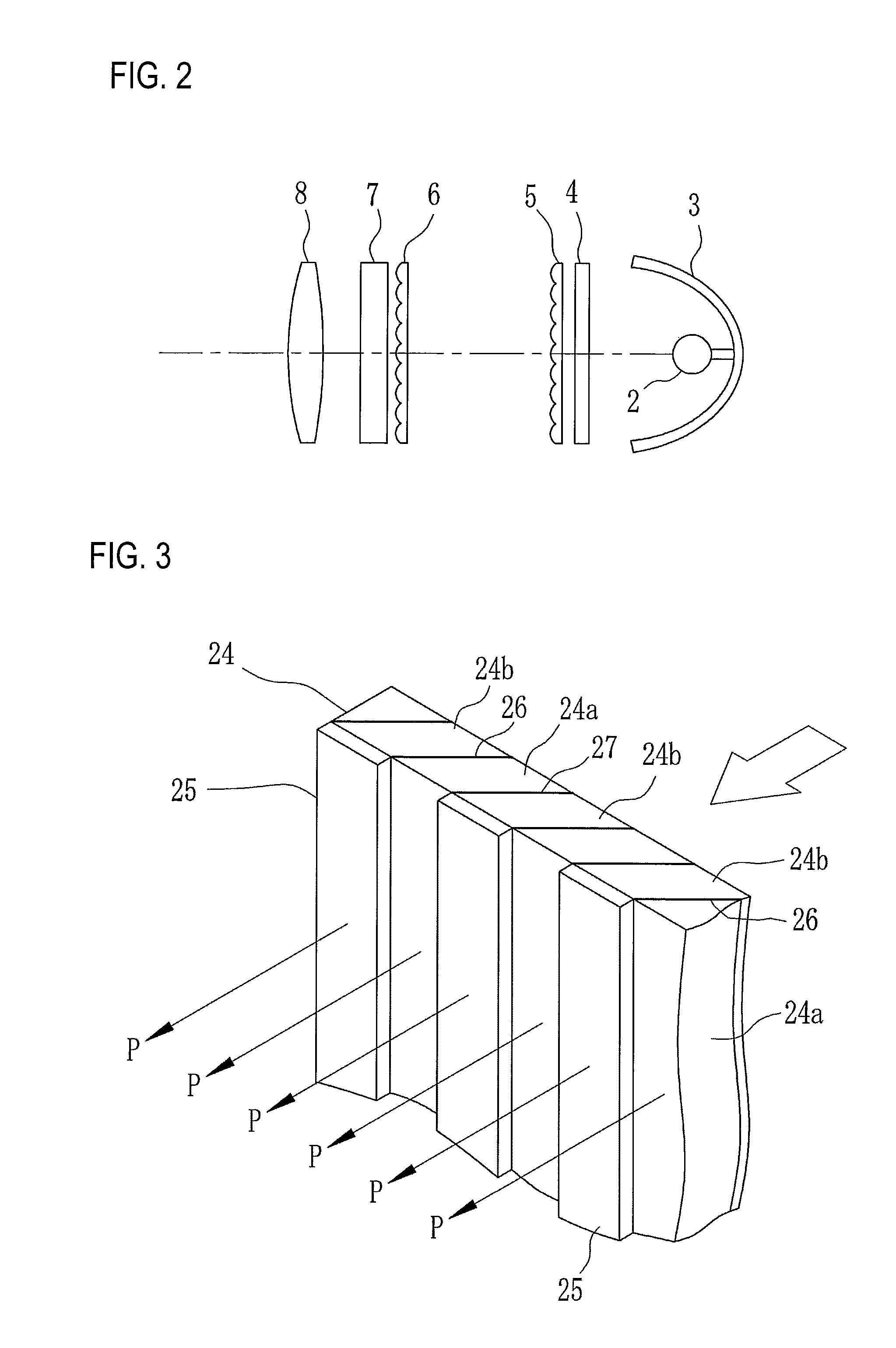

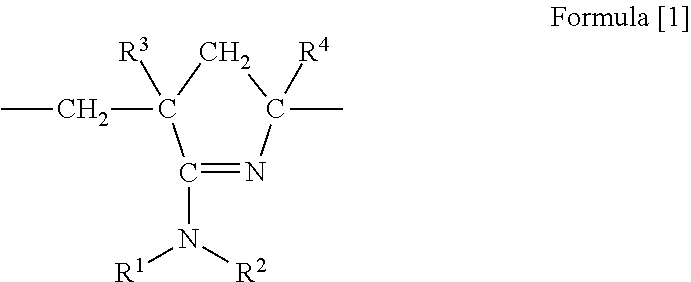

Polarization conversion device, polarized illumination optical device, and liquid crystal projector

InactiveUS20100245691A1Improve heat resistanceReduce manufacturing costProjectorsColor photographyBeam splitterPhase difference

A polarizing split layer 26 and a reflection layer 27 are alternately provided on bonding surfaces between prism rods 24a and 24b which constitute a polarized beam splitter array 24. Polarization conversion devices 25 are bonded to emission surfaces of the prism rods 24b from which linearly polarized light being reflected by the polarizing split layers 26 and being reflected by the reflection layer 27 are emitted. In the polarization conversion device 25, each edge line 30b of a rectangular prism element 30a is inclined by 45° with respect to a polarization direction of linearly polarized light being incident. On each inclined surface of the rectangular prism element 30a, a retardation film 32 whose optical axis matches the normal line of the inclined surface is formed. The retardation film 32 serves as a uniaxial negative C plate which gives a phase difference of a ½ wavelength to incident light.

Owner:FUJIFILM CORP

Preparation of articles with conductive micro-wire pattern

ActiveUS20150156886A1Improve propertiesReduce distortion problemsCircuit optical detailsPhotomechanical apparatusNanoparticleViscosity

Conductive articles and devices have conductive micro-wires formed by curing a photocurable layer on a transparent flexible substrate that has a distortion temperature of less than 150° C. The photocurable layer has a viscosity <5,000 Pascal-seconds at the temperature micro-channels formation and the micro-channels having an average width of less than or equal to 4 μm and an average depth to average width ratio that is greater than or equal to 1. The photocurable layer is exposed to curing ultraviolet radiation to form a pattern of photocured micro-channels and a conductive composition comprising metal nano-particles is formed in the photocured micro-channels. The conductive composition is cured in the pattern of photocured micro-channels to provide a pattern of conductive micro-wires in the pattern of photocured micro-channels on the transparent flexible substrate. Each of at least 50% of the conductive micro-wires has a sheet resistance of less than 0.025 ohms / sq.

Owner:EASTMAN KODAK CO

Pre-treatment composition for inkjet printing

InactiveUS20130257988A1Increase speedImprove image qualityDuplicating/marking methodsPolyurea/polyurethane coatingsWater dispersibleCationic polyelectrolytes

A coating composition for pre-treating a substrate prior to inkjet printing thereon, and an inkjet receiving medium comprising a substrate and having a topmost layer coated thereon, where the coating composition and topmost layer comprise one or more aqueous-soluble salts of multivalent metal cations, a cationic polyelectrolyte comprising amidine moieties, and one or more second polymer which is distinct from the cationic polyelectrolyte and which is selected from the group consisting of a polyamide-epichlorohydrin, a polyamine solution polymer, and a waterborne or water-dispersible polyurethane. The topmost layer is advantageously at a solid content of from 0.1 to 5 g / m2, and comprises from 30-90 wt % of the one or more aqueous soluble salts of multivalent metal cations, at least 0.01 g / m2 of the cationic polyelectrolyte comprising amidine moieties, and at least 0.005 g / m2 of the second polymer which is distinct from the cationic polyelectrolyte comprising amidine moieties.

Owner:EASTMAN KODAK CO

Sulfonic acid group-containing polymer, sulfonic acid group-containing aromatic compound and method of making same, as well as polymer electrolyte material, polymer electrolyte molded product and solid polymer fuel cell using same

ActiveCN103814062AImprove proton conductivityHigh mechanical strengthNon-metal conductorsFinal product manufacturePolymer electrolytesFuel cells

It is an object of the present invention to provide a sulfonic acid group- containing polymer and a sulfonic acid group-containing aromatic compound, which have excellent proton conductivity even under the low humidification condition, are excellent in mechanical strength and chemical stability and, moreover, can attain high output and excellent physical durability when processed into a solid polymer fuel cell, as well as a polymer electrolyte material, a polymer electrolyte molded product and a solid polymer fuel cell respectively using the same. The sulfonic acid group-containing polymer of the present invention is a sulfonic acid group-containing polymer comprising a constituent unit containing a sulfonic acid group (A1), and a constituent unit not containing a sulfonic acid group (A2), wherein the polymer contains a constituent unit having a specified structure as at least one constituent unit containing a sulfonic acid group (A1) at 25 mol% or more based on a sum of the constituent unit containing a sulfonic acid group (A1). Further, the polymer electrolyte material, polymer electrolyte molded product and solid polymer fuel cell of the present invention are constituted using such a sulfonic acid group-containing polymer.

Owner:TORAY IND INC

Method for producing armor through metallic encapsulation of a ceramic core

ActiveUS20110220280A1Little and no loss in ballistic efficiencyImprove cutting effectArmourDoor/window protective devicesDiffusion bondingMetal

Owner:EXOTHERMICS

Heat radiation printed circuit board, method of manufacturing the same, backlight unit including the same, and liquid crystal display device

InactiveUS20150289358A1Excellent physical durabilityImprove reliabilityMechanical apparatusPrinted circuit aspectsResistLiquid-crystal display

Provided are a heat radiation printed circuit board and a method of manufacturing the same, the heat radiation printed circuit board being produced by the method including: forming a circuit layer having an insulating layer, a circuit pattern and a solder resist on a first area of one surface of a metal substrate; and forming a bending part in a second area, in which the insulating layer is not formed, by bending the metal substrate, whereby a crack can be prevented in advance from being generated in the insulating layer, and durability and reliability of the heat radiation printed circuit board and a backlight unit applying the same can be improved.

Owner:LG INNOTEK CO LTD

Molded article of polymer electrolyte composition and solid polymer type fuel cell using same

InactiveUS20140335440A1Excellent physical durabilityIncrease productionSolid electrolytesFinal product manufacturePolymer scienceHigh energy

[Summary]To provide a formed article of polymer electrolyte composition which exhibits excellent proton conductivity even under low-humidification conditions and under low-temperature conditions, which is excellent in chemical stability, mechanical strength, fuel shutoff properties, and which can achieve high output, high energy density, and excellent long-term durability when used in a polymer electrolyte fuel cell; and also to provide a polymer electrolyte fuel cell using thereof. The formed article of polymer electrolyte composition includes: a block copolymer having one or more of each of a hydrophilic segment (A1) containing an ionic group and a hydrophobic segment (A2) not containing an ionic group; and an additive, wherein the formed article forms co-continuous or lamellar phase separation structure, and the additive is hydrophilic.

Owner:TORAY IND INC

Polarization conversion device, polarized illumination optical device, and liquid crystal projector

InactiveUS20100245690A1Improve heat resistanceReduce manufacturing costProjectorsPolarising elementsPhase differenceOptical axis

Polarizing split layers 26 and reflection layers 27 are provided on bonding surfaces between prism rods 24a and 24b. Polarization conversion devices 25 are bonded to an emission surface from which linearly polarized light being reflected by the polarizing split layers 26 and reflected by the reflection layer 27 are emitted. The polarization conversion devices 25 are formed by bonding plural prism rods 30 with side surfaces being inclined by 45° with respect to an incidence surface. Retardation films formed of dielectric multilayers are provided between the bonding surfaces to give a phase difference of a ½ wavelength to transmitted light. The retardation films and bonding borderlines 31 are inclined by 45° within a plane perpendicular to an optical axis of linearly polarized light so that an optical axis of the retardation film has an angle of 45° with respect to a polarization direction of the linearly polarized light.

Owner:FUJIFILM CORP

Method for producing metallically encapsulated ceramic armor

ActiveUS8091204B2Improve cutting effectImprove corrosion resistanceDoor/window protective devicesWallsMetallurgy

A method for the manufacture of metallically encapsulated ceramic armor through the use of low pressure processing methods in autoclave furnaces or brazing furnaces.

Owner:EXOTHERMICS

Method for producing metallically encapsulated ceramic armor

ActiveUS20110220281A1Improve cutting effectImprove corrosion resistanceArmourDoor/window protective devicesMetalMaterials science

A method for the manufacture of metallically encapsulated ceramic armor through the use of low pressure processing methods in autoclave furnaces or brazing furnaces.

Owner:EXOTHERMICS

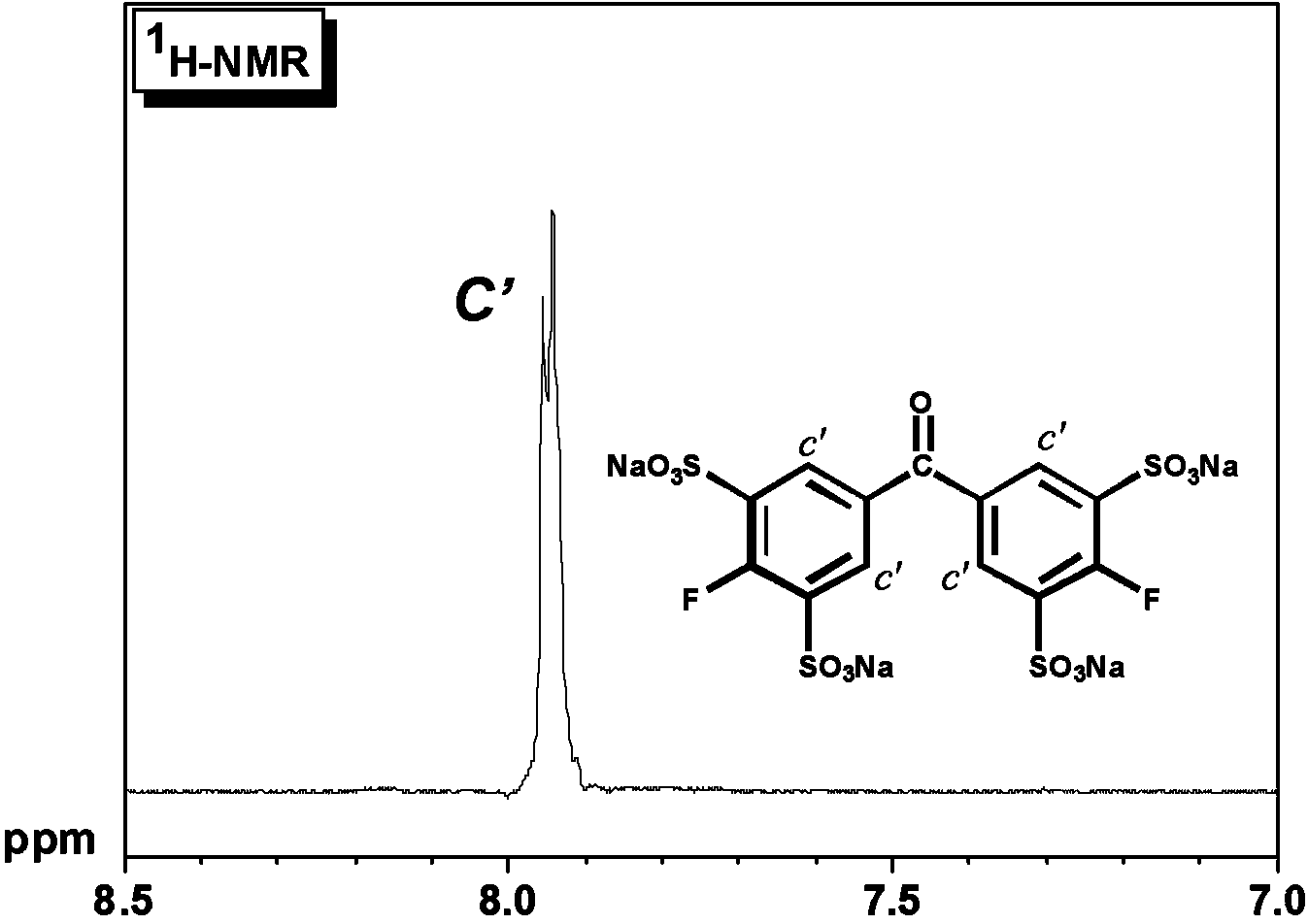

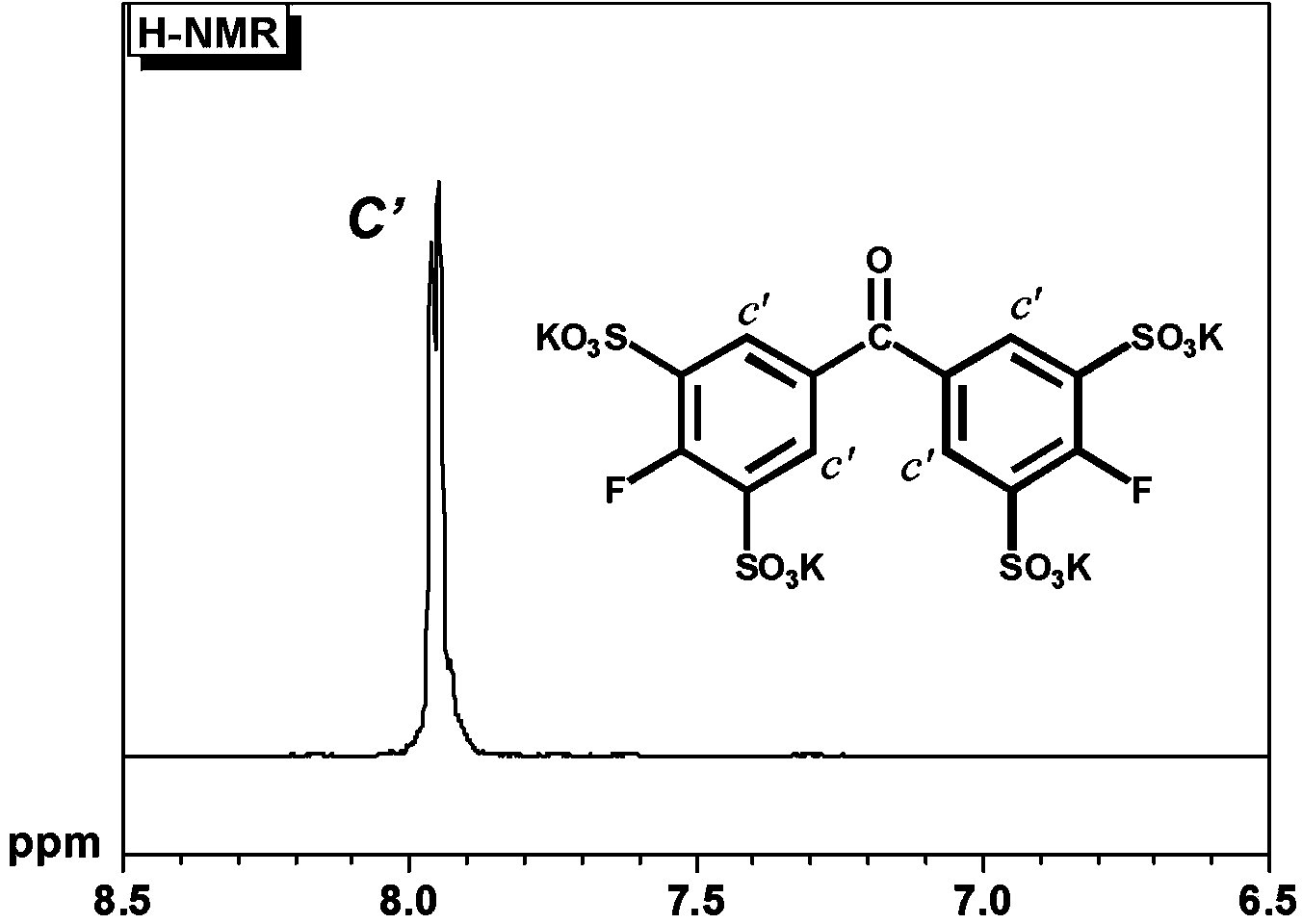

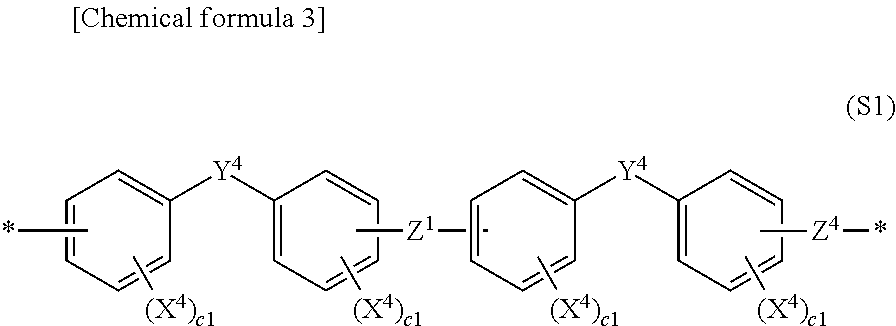

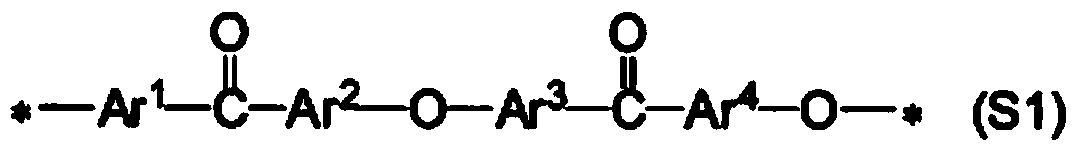

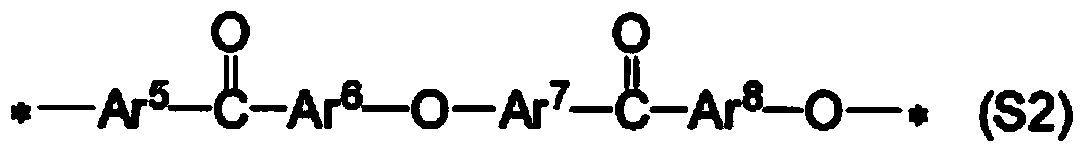

Aromatic sulfonic acid derivative, sulfonic acid group-containing polymer, block copolymer, polymer electrolyte material, polymer electrolyte form article, and polymer electrolyte fuel cell

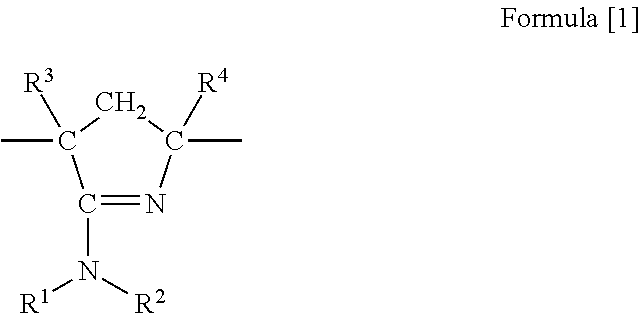

ActiveUS9126908B2Improve proton conductivityExcellent physical durabilitySolid electrolytesOrganic chemistryPolymer electrolytesFuel cells

Provided are an aromatic sulfonic acid derivative and a sulfonic acid group-containing polymer, each of which has excellent proton conductivity even under low humidification conditions, while having excellent mechanical strength and chemical stability, and enables a solid polymer fuel cell to achieve high output and excellent physical durability when used therein. This aromatic sulfonic acid derivative has a specific structure and is characterized in that a sulfonic acid group is introduced into more than 50% of all the phenyl groups. This sulfonic acid group-containing polymer is characterized by being obtained by polymerization using the aromatic sulfonic acid derivative, and is also characterized by having a specific structure.

Owner:TORAY IND INC

Molded article of polymer electrolyte composition and solid polymer type fuel cell using same

ActiveCN103814413AExcellent physical durabilityHigh outputNon-metal conductorsSolid electrolytesPolymer electrolytesPolymer science

Provided are a molded article of a polymer electrolyte composition, which has an excellent proton conductivity even under low humidity and low temperature conditions, yet shows a high chemical stability, a good mechanical strength and a good fuel shutoff ability, and, when used in a solid polymer type fuel cell, can achieve a high output, a high energy density and a long-term durability, and a solid polymer type fuel cell using the same. The molded article of the polymer electrolyte composition, which comprises a block copolymer having one or more ionic group-containing hydrophilic segments (A1) and one or more ionic group-free hydrophobic segments (A2) together with an additive, is characterized in that the molded article forms a co-continuous or lamellar phase separation structure and the additive has a hydrophilic nature.

Owner:TORAY IND INC

Polymer electrolyte membrane, membrane electrode assembly using same, and solid polymer fuel cell

ActiveCN103782434AIncrease output powerImprove proton conductivityNon-metal conductorsConductive materialX-rayCrystallinity

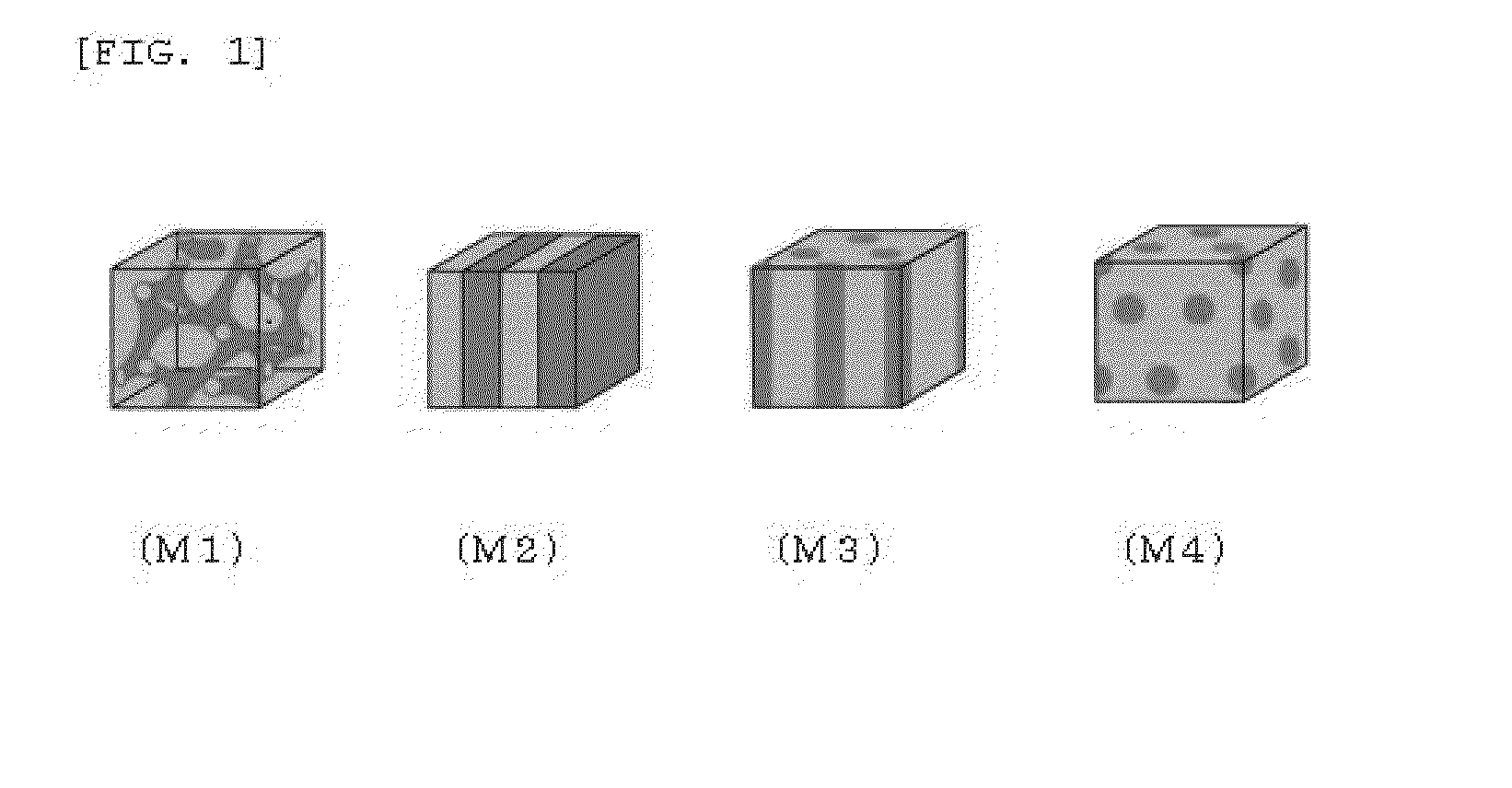

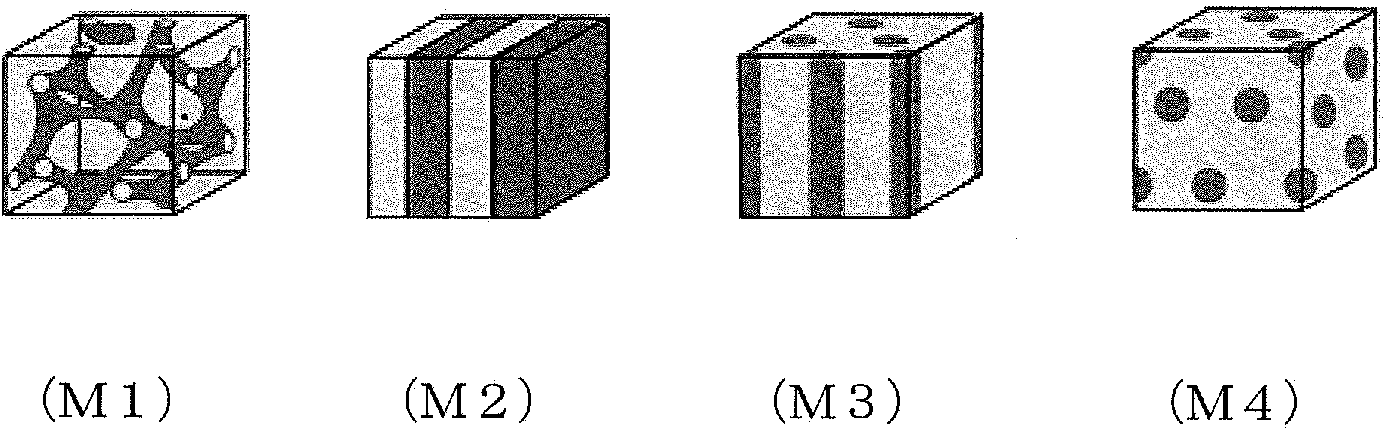

Provided is a polymer electrolyte membrane that has excellent proton conductivity even under low humidification conditions, has excellent mechanical strength and chemical stability, and can achieve high output and excellent physical durability when made into a solid polymer fuel cell. This polymer electrolyte membrane comprises a block copolymer including at least one each of a segment (A1) that contains an ionic group and a segment (A2) that does not contain an ionic group, the polymer electrolyte membrane being characterized by: forming a co-continuous (M1) or lamellar (M2) phase-separated structure; and having a crystallization heat quantity of 0.1 J / g or greater as measured by differential scanning calorimetry, or a degree of crystallinity of 0.5% or greater as measured by wide-angle X-ray diffraction.

Owner:TORAY IND INC

Block copolymer, manufacturing method therefor, and polymer electrolyte material, molded polymer electrolyte, and solid-polymer fuel cell using said block copolymer

ActiveUS20140193742A1Excellent physical durabilityIncrease productionElectrolyte holding meansSolid electrolytesPolymer electrolytesFuel cells

To provide: a block copolymer that exhibits excellent proton conductivity even under low-humidification conditions, exhibits excellent mechanical strength and chemical stability, and when used in a polymer electrolyte fuel cell, allows high output and excellent physical durability; a polymer electrolyte material; and a polymer electrolyte form article and a polymer electrolyte fuel cell, using the same.The block copolymer of the present invention includes each one or more of: a segment (A1) containing an ionic group; a segment (A2) not containing an ionic group; and a linker moiety connecting the segments. The segment (A1) containing an ionic group comprises a constituent unit represented by a specific structure. The polymer electrolyte material, the polymer electrolyte form article, and the polymer electrolyte fuel cell according to the present invention are manufactured by using the above block copolymer.

Owner:TORAY IND INC

Aromatic sulfonic acid derivative, sulfonic acid group-containing polymer, block co-polymer, polymer electrolyte material, polymer electrolyte molded body, and solid polymer fuel cell

ActiveUS20140213671A1Improve proton conductivityExcellent physical durabilitySolid electrolytesOrganic chemistryPolymer electrolytesFuel cells

Provided are an aromatic sulfonic acid derivative and a sulfonic acid group-containing polymer, each of which has excellent proton conductivity even under low humidification conditions, while having excellent mechanical strength and chemical stability, and enables a solid polymer fuel cell to achieve high output and excellent physical durability when used therein. This aromatic sulfonic acid derivative has a specific structure and is characterized in that a sulfonic acid group is introduced into more than 50% of all the phenyl groups. This sulfonic acid group-containing polymer is characterized by being obtained by polymerization using the aromatic sulfonic acid derivative, and is also characterized by having a specific structure.

Owner:TORAY IND INC

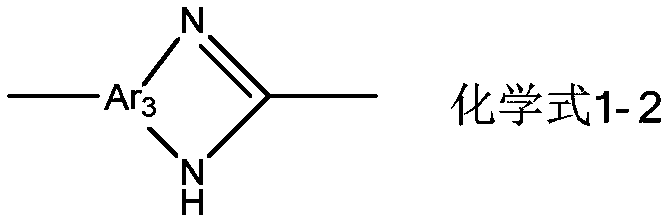

COMPOSITE POLYMER ELECTROLYTIC MEMBRANE, AND MEMBRANE ELECTRODE COMPOSITE AND SOLID POLYMER FUEL CELL USING the SAME

ActiveCN108701847AHigh outputImprove proton conductivityFinal product manufactureConductive materialFiberPolymer electrolytes

Provided are a composite polymer electrolytic membrane that has excellent proton conductivity even under low-humidification and low-temperature conditions, a small dimensional change rate, and excellent mechanical strength and chemical stability, and that is capable of achieving a high output and excellent physical durability when being used in a solid polymer fuel cell; and a membrane electrode composite and a solid polymer fuel cell using the composite polymer electrolytic membrane. This composite polymer electrolytic membrane has a composite layer formed by combining a polyazole-containingnanofiber unwoven fabric (A) and an ionic-group-containing polymer electrolyte (B), and is characterized in that the polyazole-containing nanofiber unwoven fabric (A) is basic.

Owner:TORAY IND INC +1

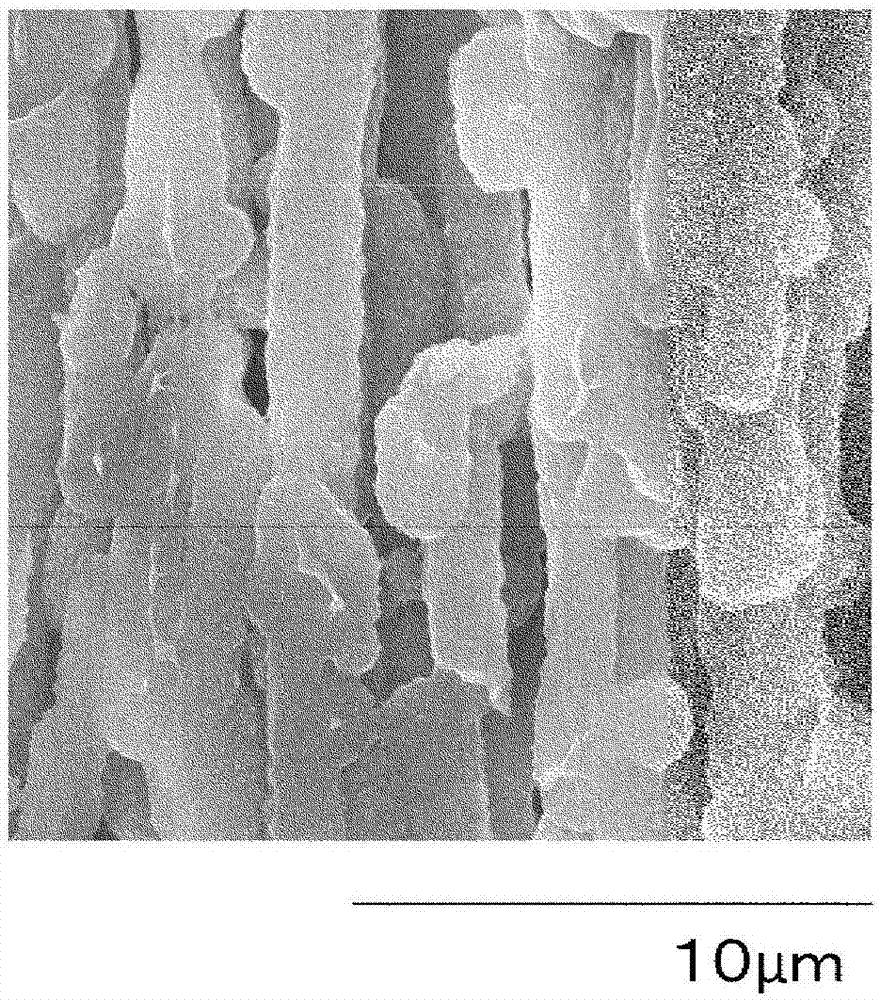

Porous hollow fiber membrane

ActiveCN107106998AHigh purity water permeabilityExcellent chemical durabilitySemi-permeable membranesMembranesHollow fibre membraneHigh intensity

The purpose of the present invention is to provide a porous hollow fiber membrane that has high strength while maintaining high purified water permeability. This porous hollow fiber membrane is formed from a fluororesin polymer, wherein there is a columnar structure oriented in the longitudinal direction of the porous hollow fiber membrane, and the molecular chain of the fluororesin polymer is oriented in the longitudinal direction of the porous hollow fiber membrane.

Owner:TORAY IND INC

High transmittance, low emissivity coatings for substrates

InactiveUS20050202256A1Low emissivityAchieve neutralityMirrorsOptical filtersAngle of incidenceInter layer

The present invention provides a coating for a transparent substrate which exhibits a “neutral” color through a wide range of angles of incidence of light. The coating employs a base coat adjacent the transparent substrate having a thickness of no more than about 275 Å and may include two reflective metal layers having an intermediate layer of an anti-reflective metal oxide therebetween and an outer anti-reflective layer of metal oxide over the second reflective metal layer. If so desired, the coating of the invention may include an abrasive-resistant overcoat as its outermost layer. This overcoat is desirably formed of an abrasive-resistant metal oxide, such as zinc oxide applied at a thickness which does not significantly affect the optical properties of said coated substrate.

Owner:CARDINAL CG

Polarization conversion device, polarized illumination optical device, and liquid crystal projector

InactiveUS8035759B2Improve heat resistanceReduce manufacturing costProjectorsNon-linear opticsOptical axisLCD projector

Owner:FUJIFILM CORP

Polymer electrolyte membrane, membrane electrode assembly using same and polymer electrolyte fuel cell

InactiveUS20140322628A1Excellent physical durabilityGood chemical stabilityIon-exchanger regenerationConductive materialIonCrystallinity

To provide a polymer electrolyte membrane that has excellent proton conductivity even under low-humidification conditions, has excellent mechanical strength and chemical stability, and can achieve high output and excellent physical durability when made into a polymer electrolyte fuel cell.The polymer electrolyte membrane includes a block copolymer containing each one or more of: a segment (A1) containing anionic group; and a segment (A2) not containing an ionic group. The polymer electrolyte membrane forms a co-continuous (M1) or lamellar phase-separated (M2) structure, and gives a crystallization heat quantity of 0.1 J / g or larger determined by differential scanning calorimetry, or a degree of crystallinity of 0.5% or larger determined by wide-angle X-ray diffractometry.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com