Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Excellent in term" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Person-To-Person Lending Program Product, System, And Associated Computer-Implemented Methods

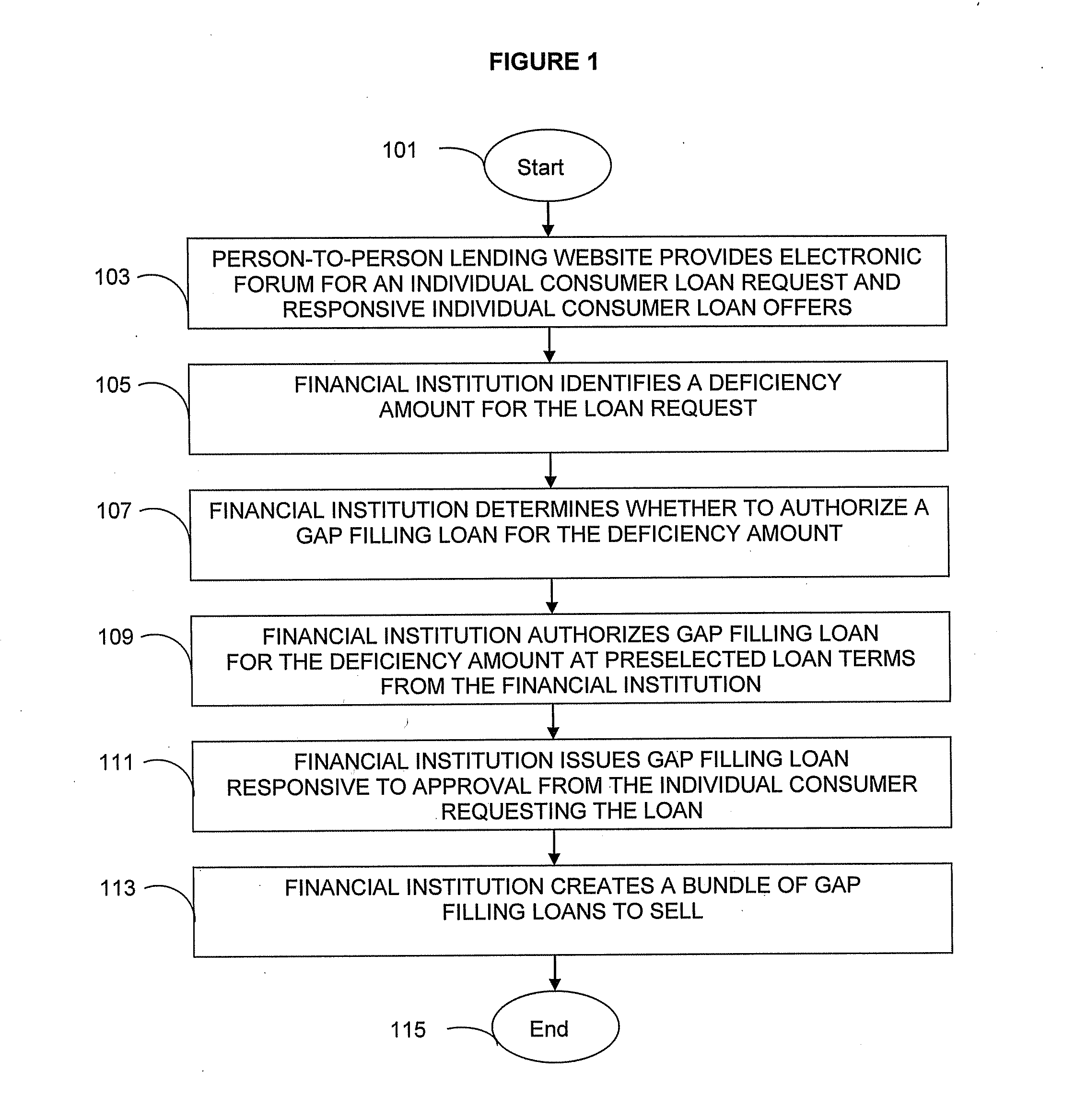

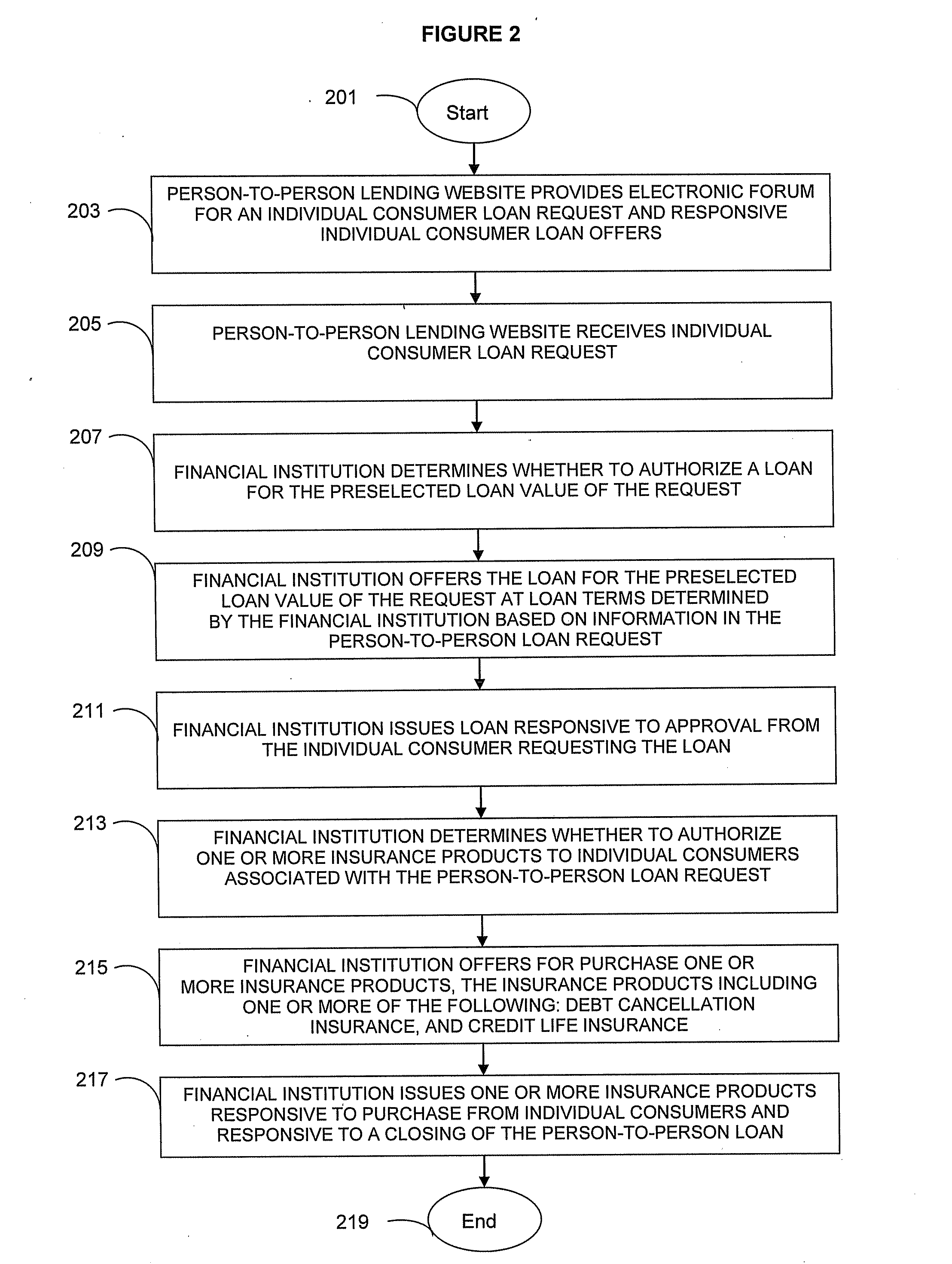

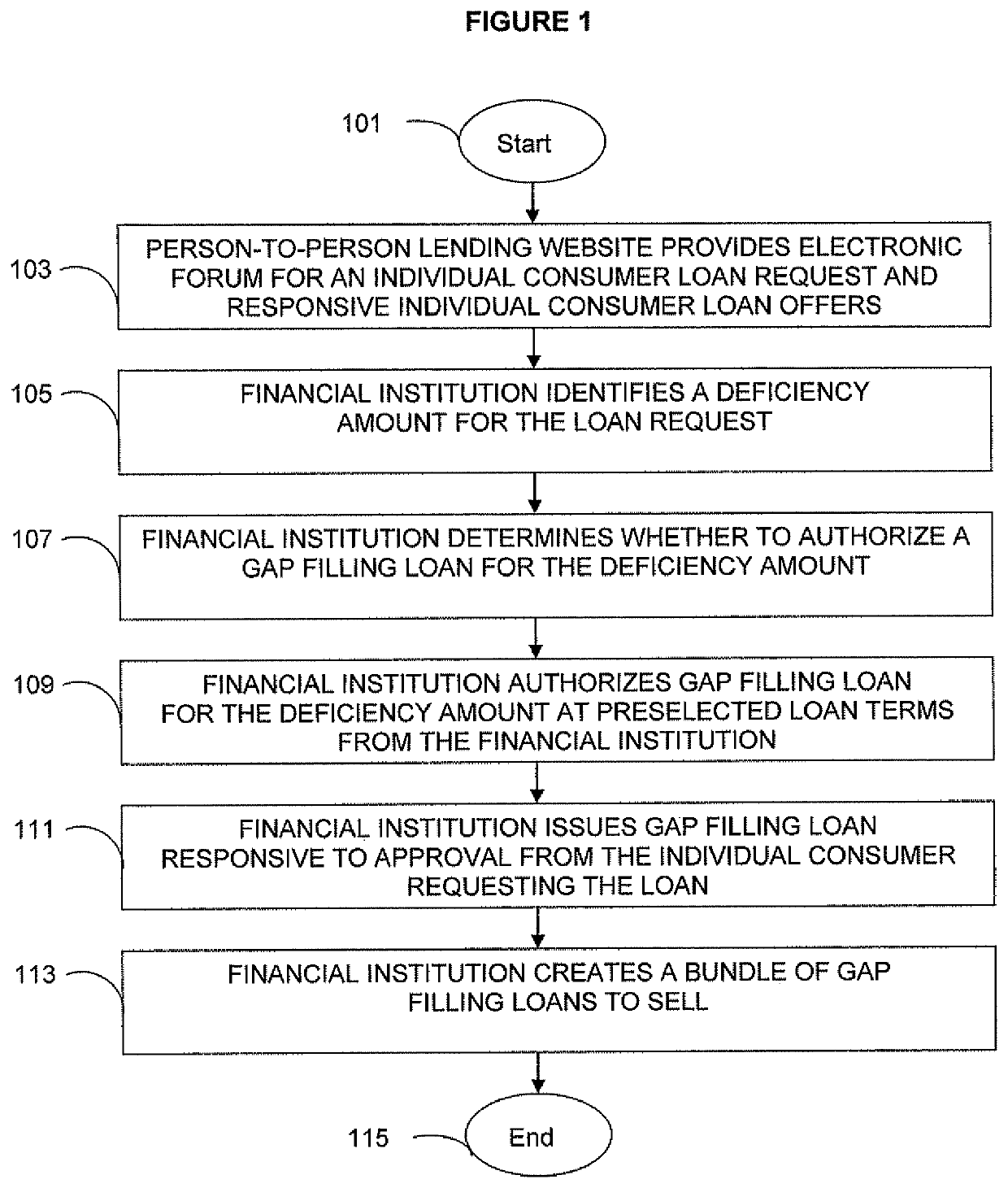

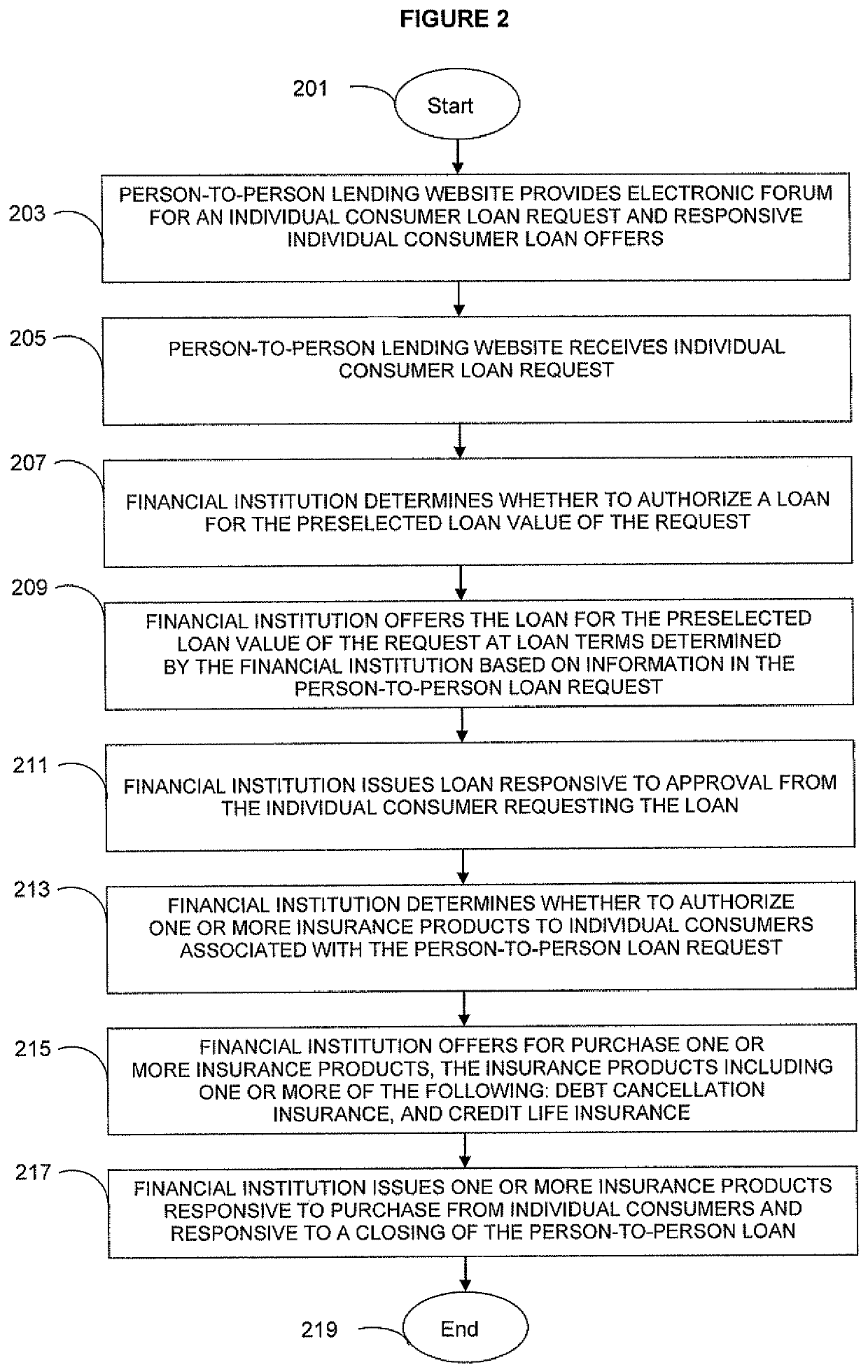

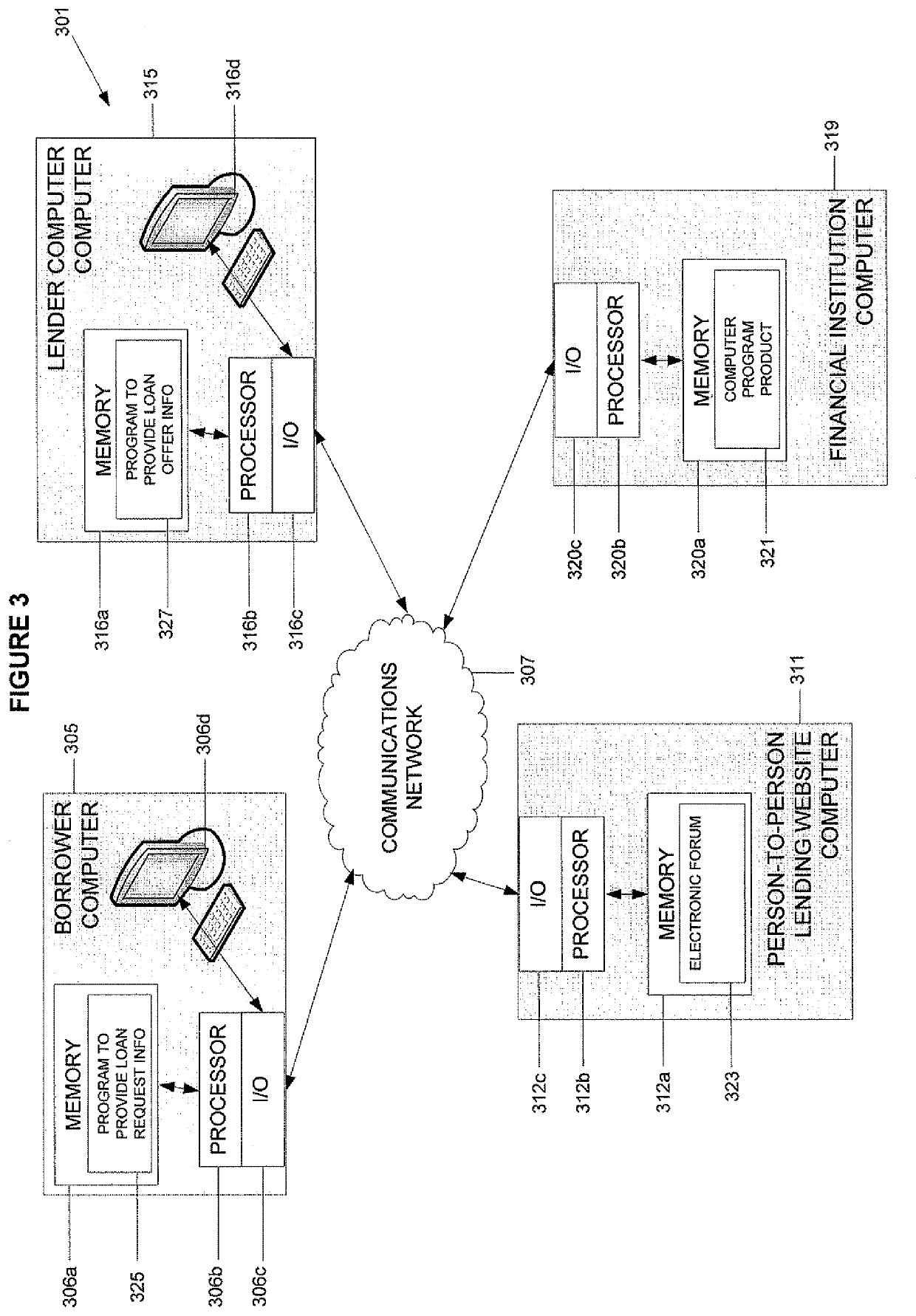

An individual consumer borrower accessing a person-to-person lending website is provided an opportunity to have a loan request wholly or partially satisfied by a financial institution at loan terms from the financial institution. The financial institution, for example, can receive information about a person-to-person loan request, determine whether to authorize a financial institutional loan, offer a loan to the individual on terms determined by the financial institution, and issue the loan to an individual consumer borrower responsive to approval of the terms. Prior to an auction, the individual consumer can choose an immediate loan offer having financial institution terms or choose to solicit individual consumer loan offers with more favorable terms through the person-to-person lending website. The financial institution can also offer a gap filling loan for a deficiency amount so that the loan request can be partially satisfied by individual consumer loan offers.

Owner:PATHWARD NAT ASSOC

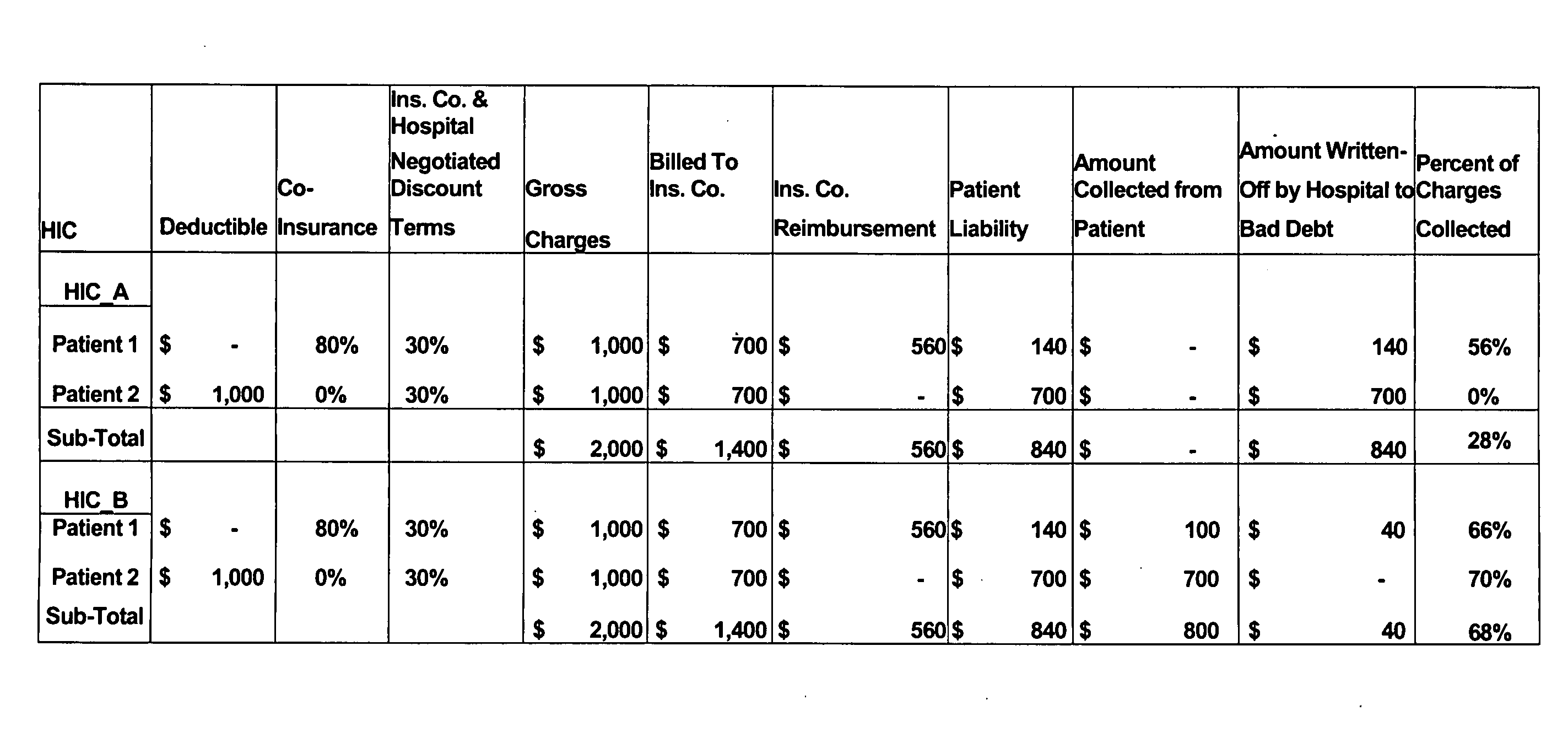

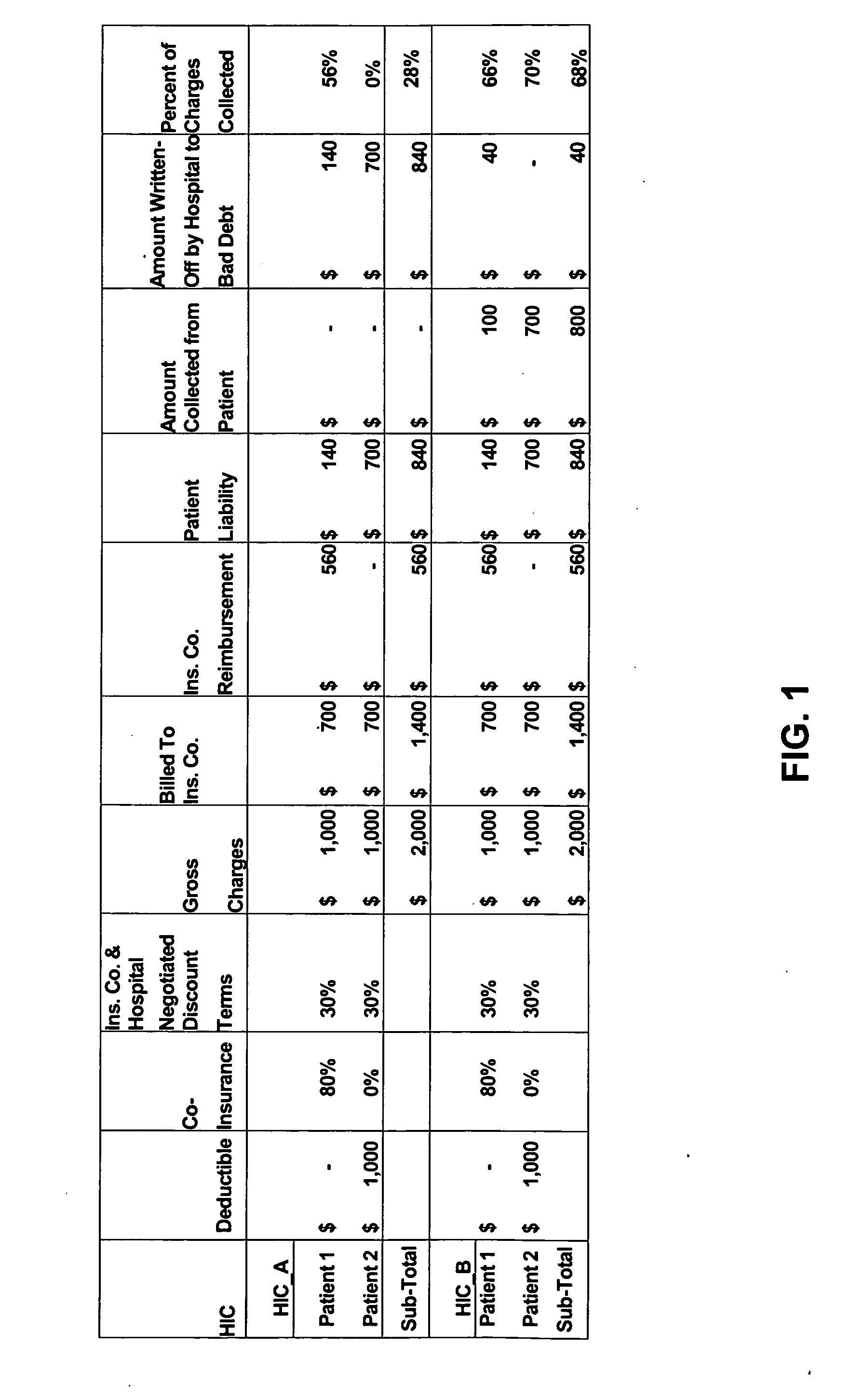

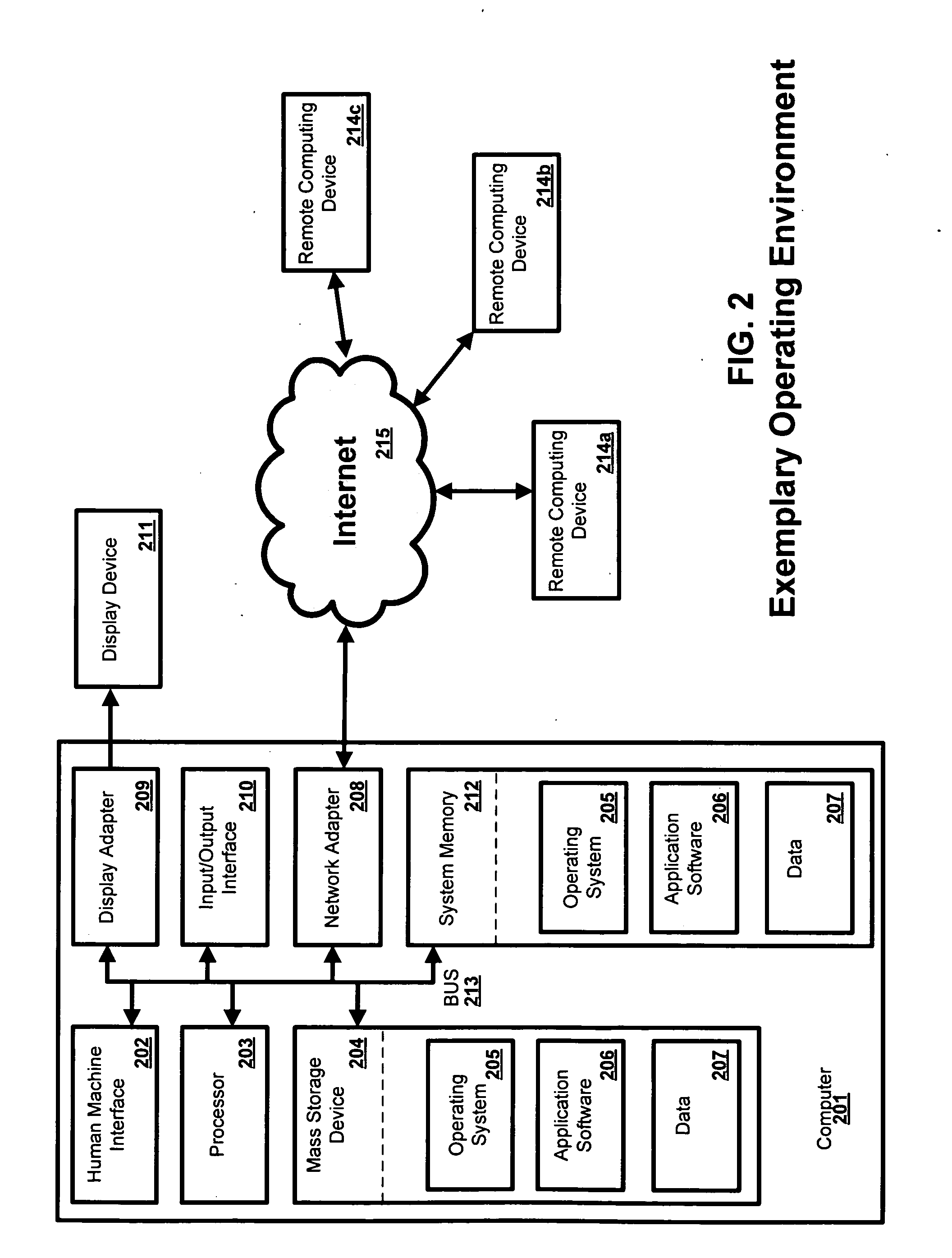

Method for predicting the payment of medical debt

InactiveUS20080120133A1Excellent in termBetter reimbursementOffice automationCommercePaymentMedical treatment

The present invention provides methods, systems, and computer program products that are useful for establishing contractual terms and agreements between health care providers and health care payors. For example, one embodiment of the present invention provides a method for predicting a person's payment of a medical debt. Another embodiment of the present invention provides a method for predicting a propensity of a group of one or more health care participants to pay an actual or potential medical debt.

Owner:KRISHNASWAMI ARVIND +1

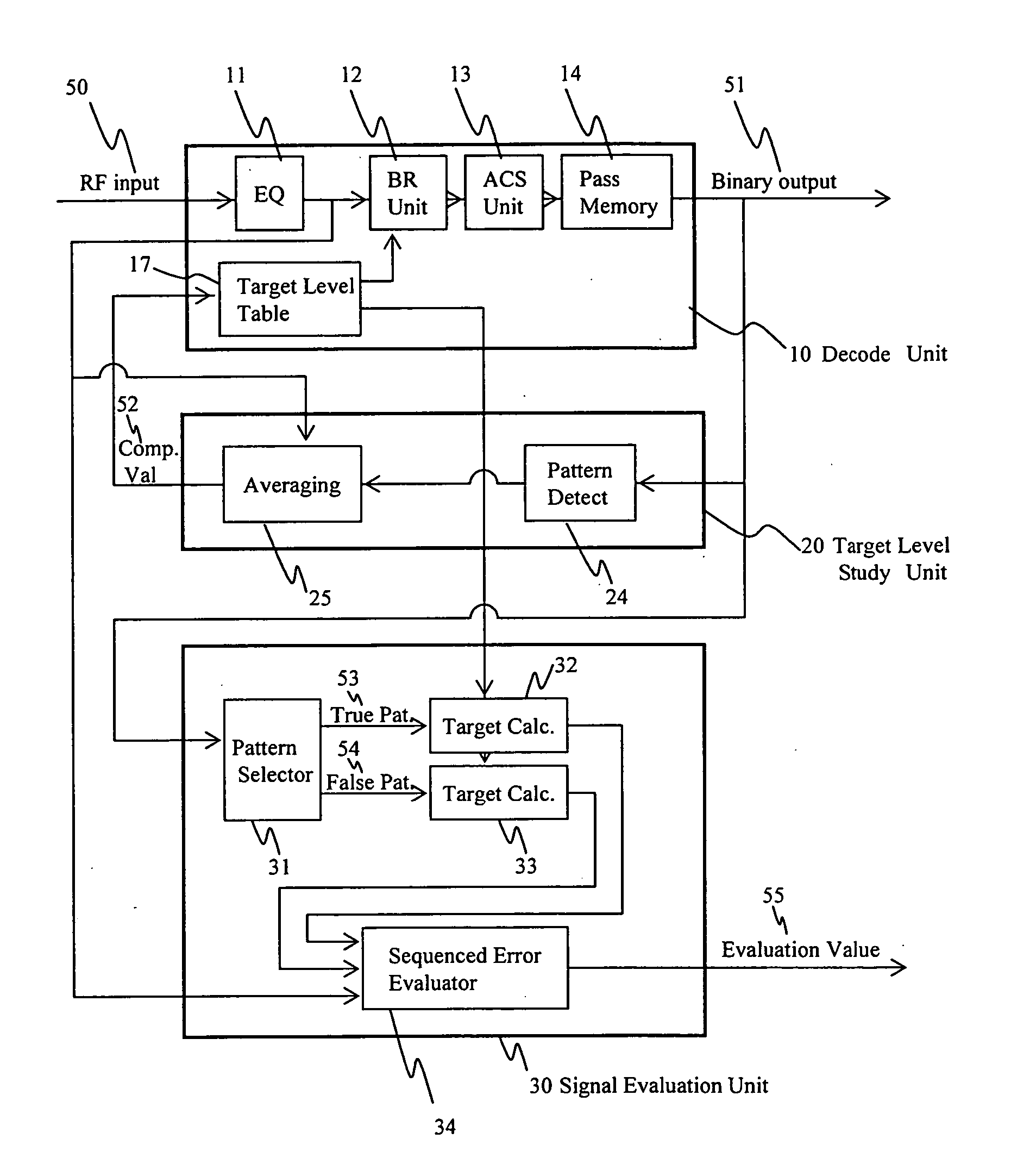

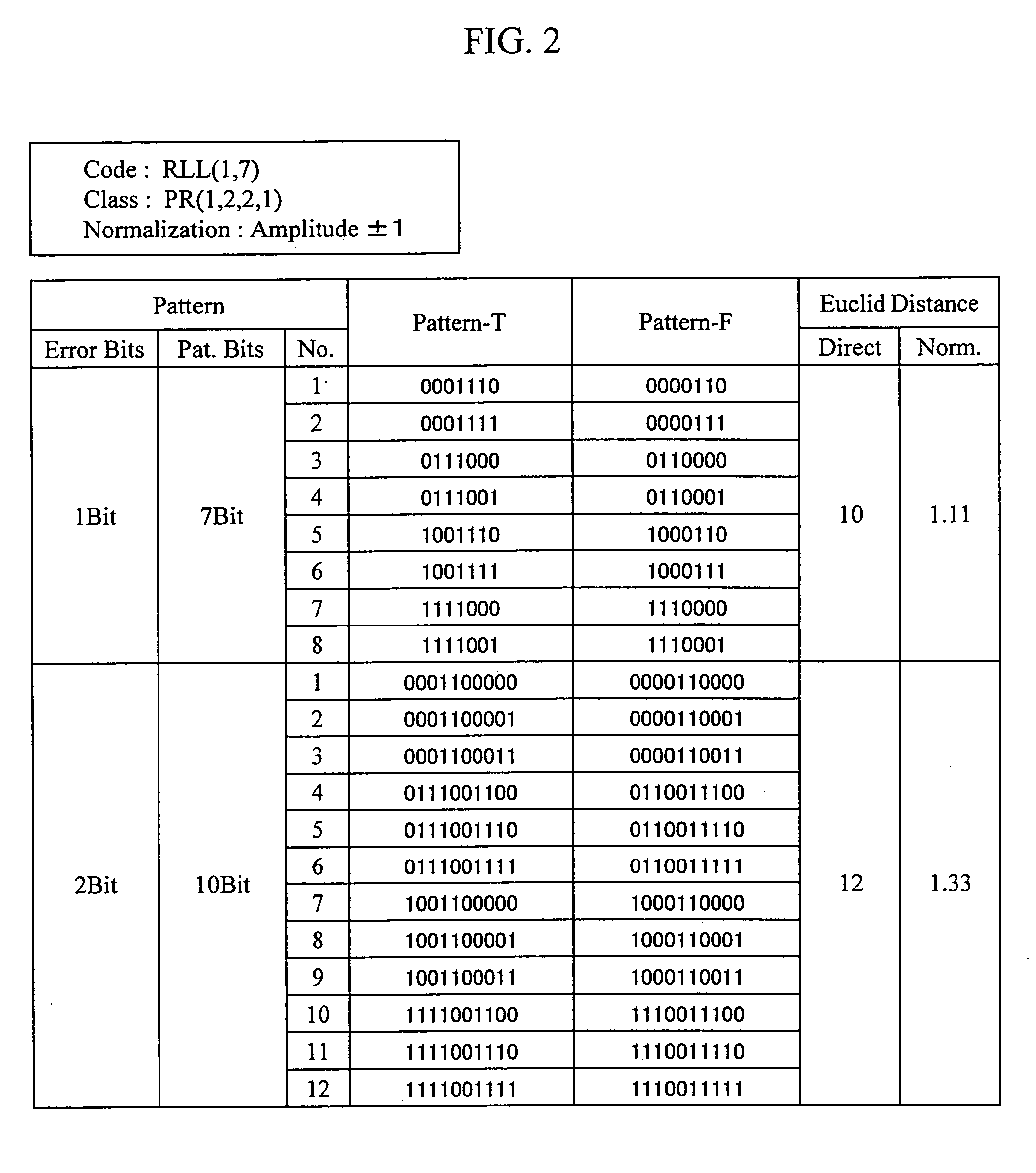

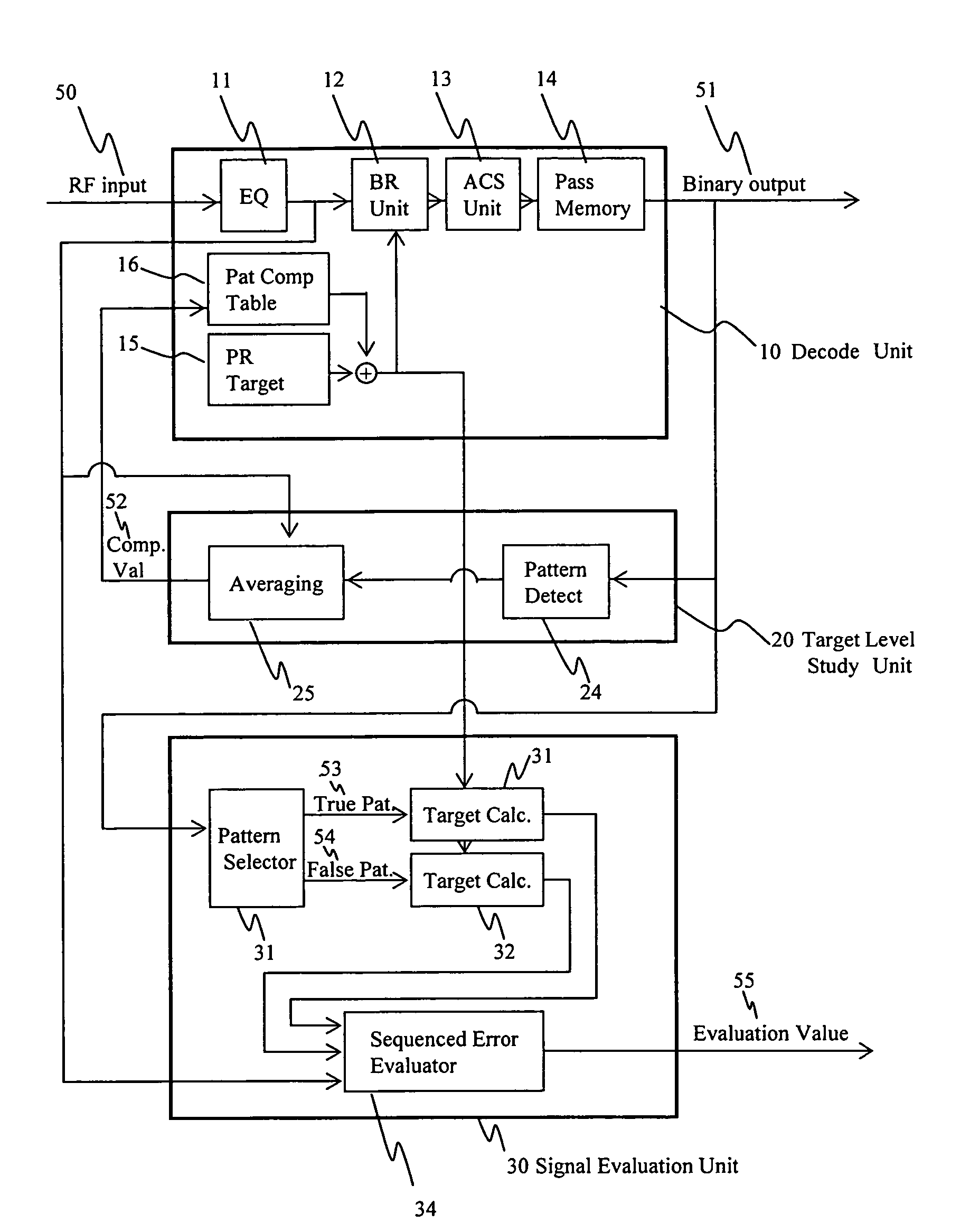

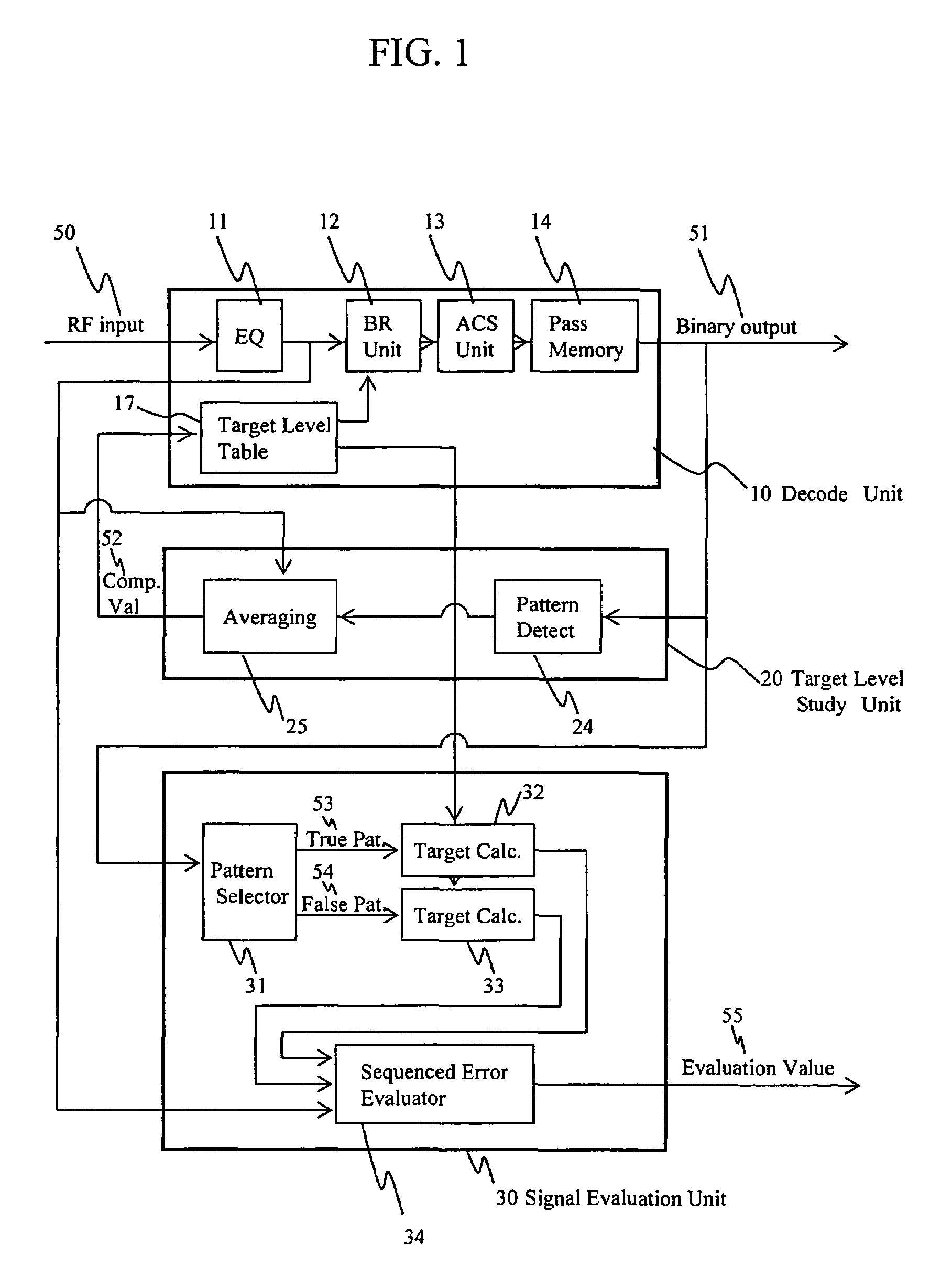

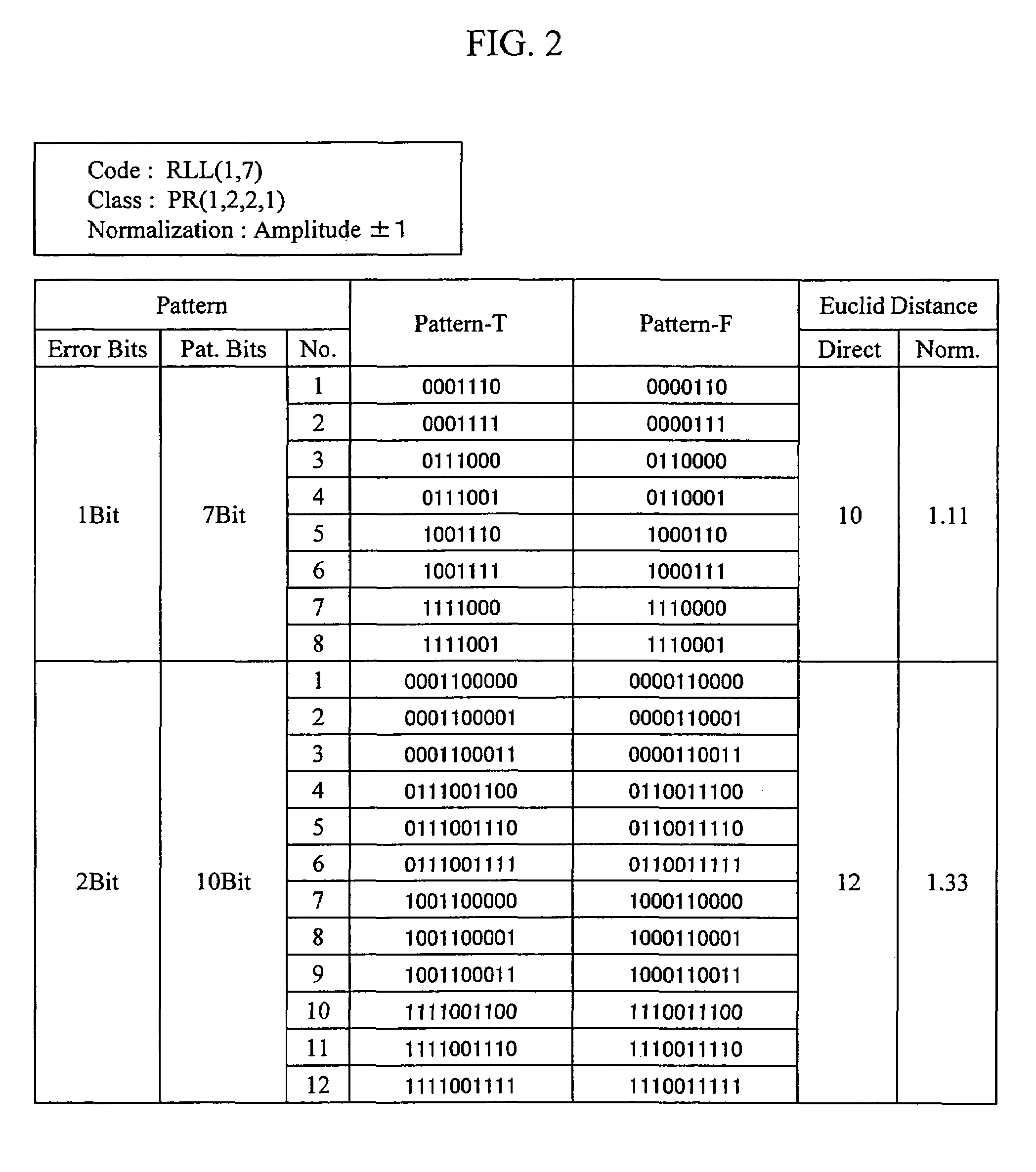

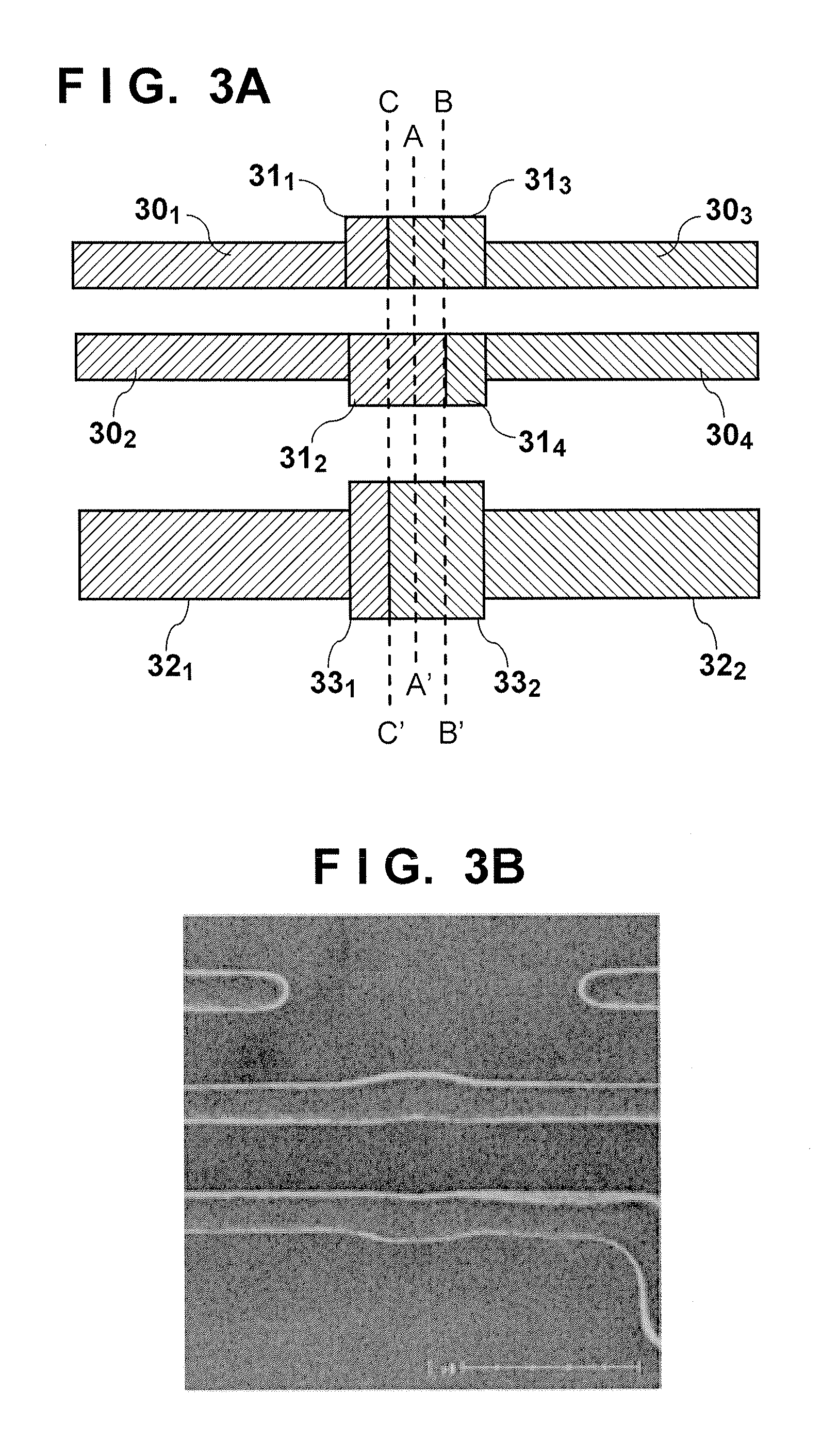

Method of evaluating a readout signal, and optical disc apparatus

InactiveUS20050249318A1Precise positioningAccurate assessmentModification of read/write signalsOptical beam sourcesViterbi decoderSignal quality

A method of evaluating the quality of a read signal from the viewpoint of the detection margin of a Viterbi decoder in the PRML method in which a target signal level varies depending on the read signal, and an optical disc apparatus implementing the method. A method of evaluating the quality of a signal pattern comprising a combination of minimum run lengths from the viewpoint of edge shift, and an optical disc apparatus implementing the method. From the target signal level that varies depending on the read signal, a target signal is generated based on a decoding result, and an error target signal is generated in which the decoding result is edge-shifted. The signal quality is evaluated by calculating a Euclidean distance between these signals and the read signal. A virtual state that is not included in the Viterbi decoder and that is less than the minimum run length is defined, and a target signal level for the virtual state is generated using a target signal level table inside the Viterbi decoder, based on the concept of convolution. In this way, the signal quality can be evaluated by the same method as mentioned above even in cases where the pattern of a combination of the minimum run lengths has edge-shifted.

Owner:HITACHI-LG DATA STORAGE +1

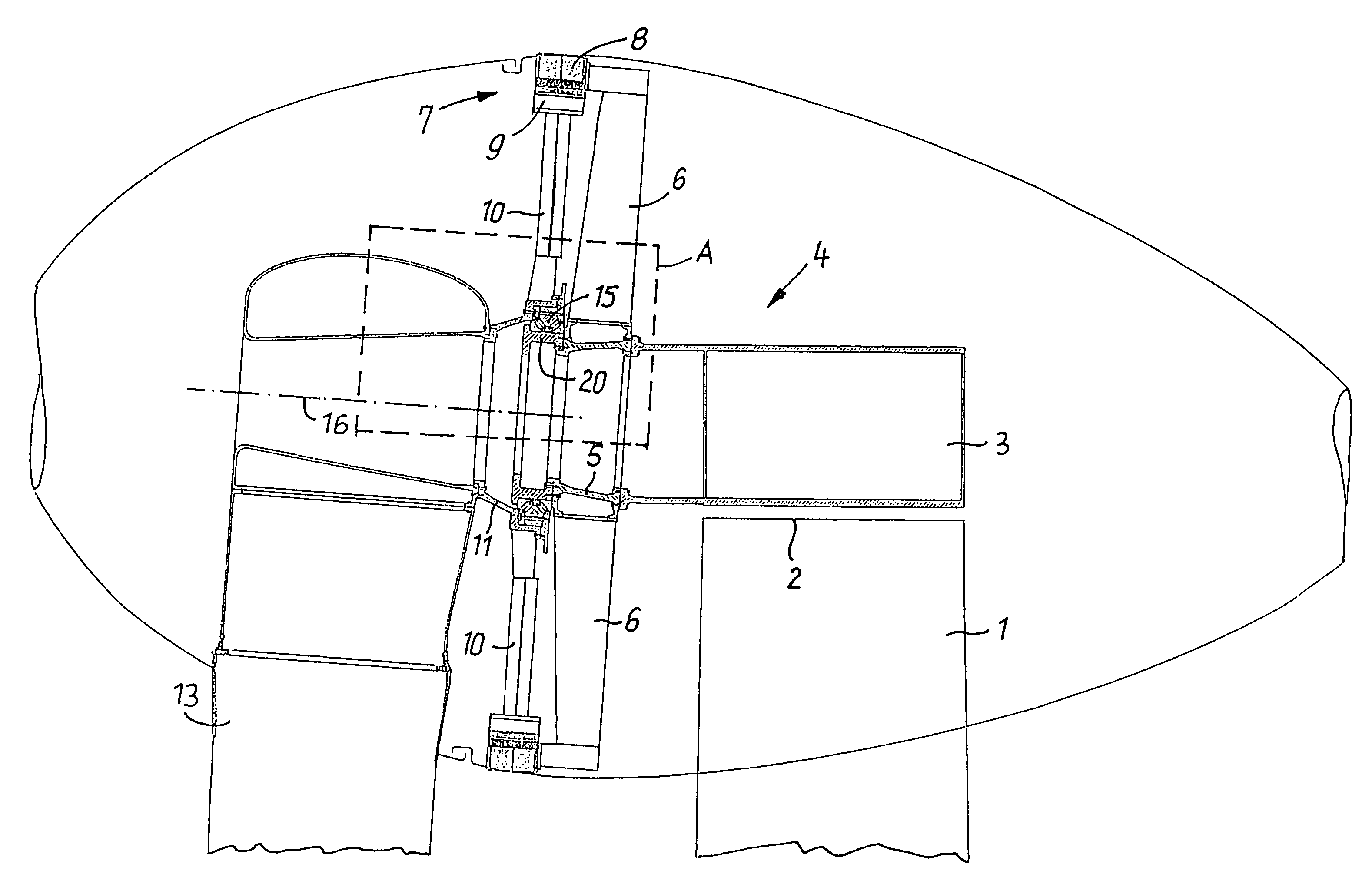

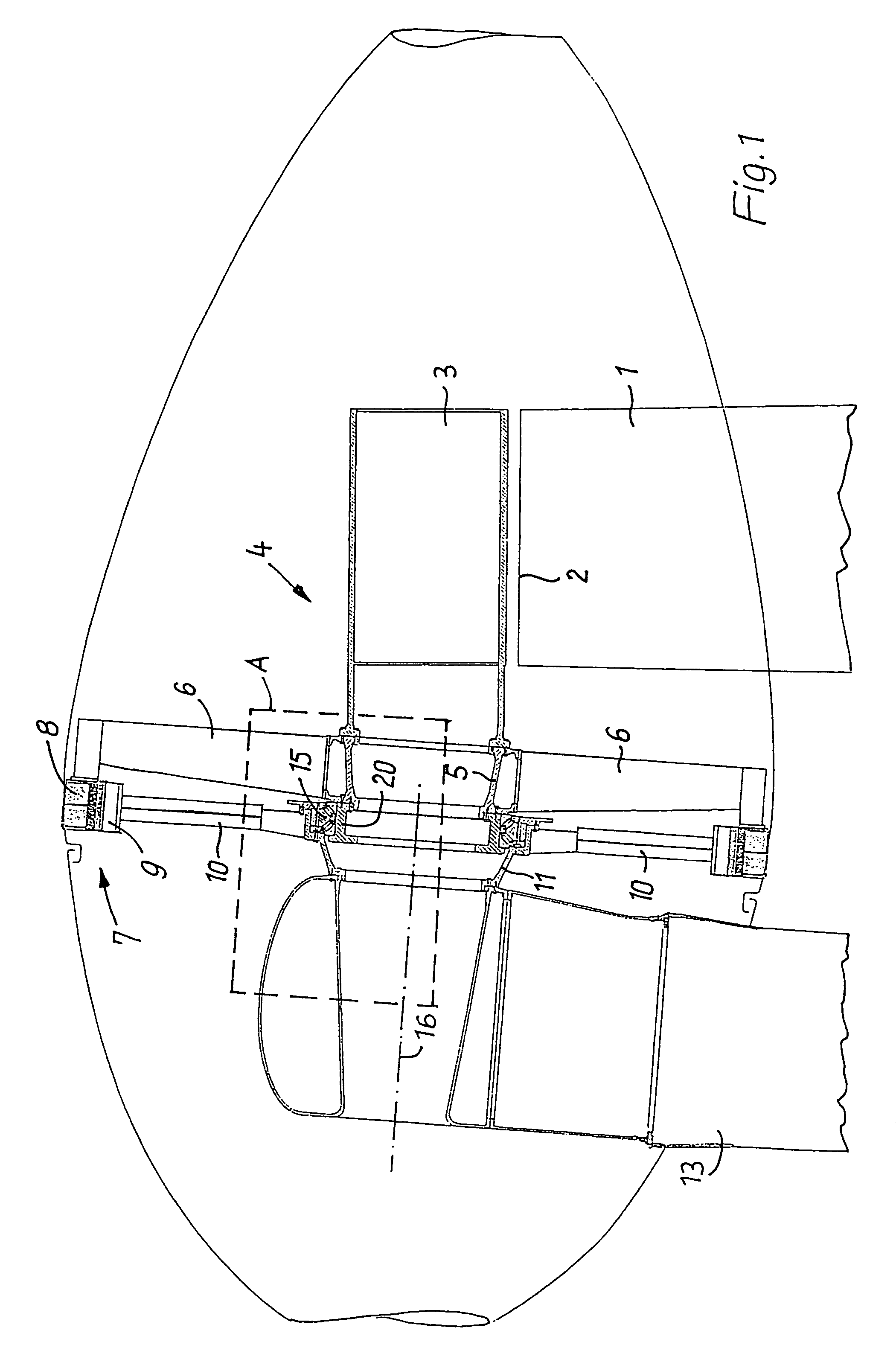

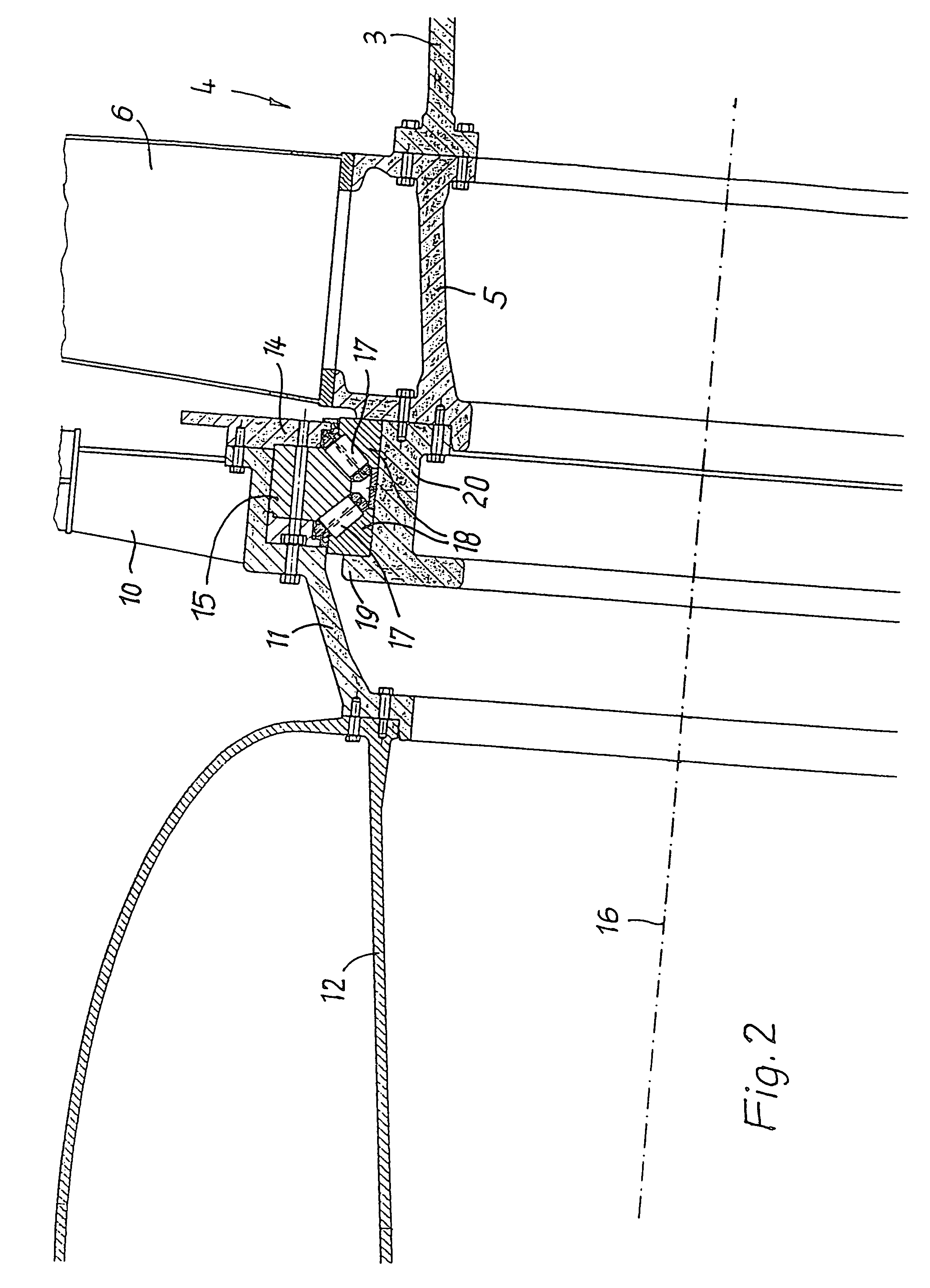

Wind energy unit comprising a hollow shaft for rotor hub and generator

InactiveUS7084522B2Reduce weightReduced moment loadInfluencers using Magnus effectRoller bearingsWind forceWind power

In a wind power installation with a (hollow) axis tube member and a hollow shaft mounted thereon for the rotor there is provided only a single bearing which also carries moments, between the axis tube member and the hollow shaft, whereby the parts of the machine which are to be fixed to the machine carrier and thus on the top of the pylon are of a markedly lower weight without the required orientation between the rotating and stationary parts of the electrical generator being adversely affected. In that arrangement the rotating part of the generator is radially aligned substantially with the bearing. The bearing to be used is in particular a twin-row inclined roller bearing with rows of rollers arranged at an angle of about 45° relative to each other.

Owner:WOBBEN ALOYS

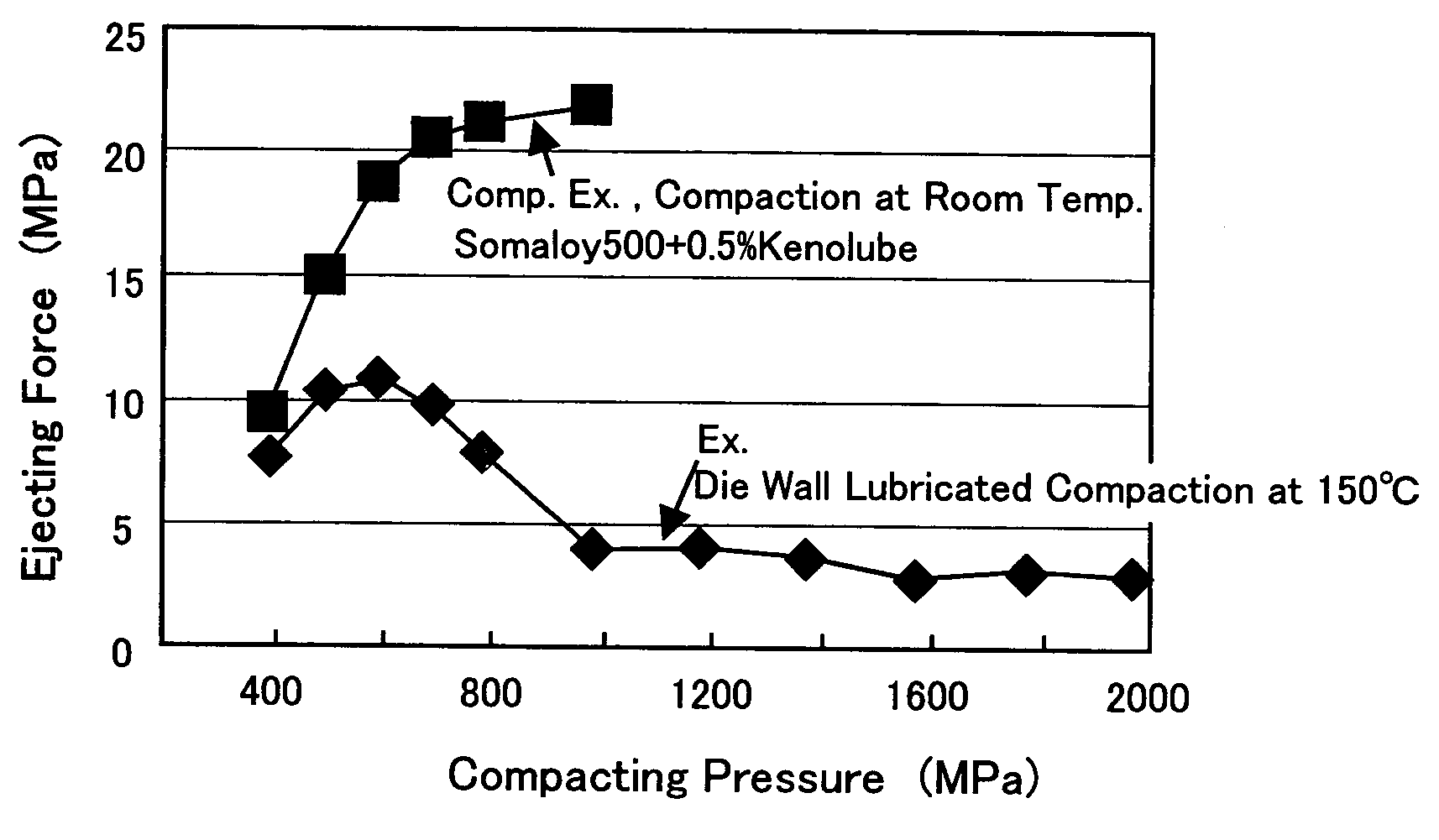

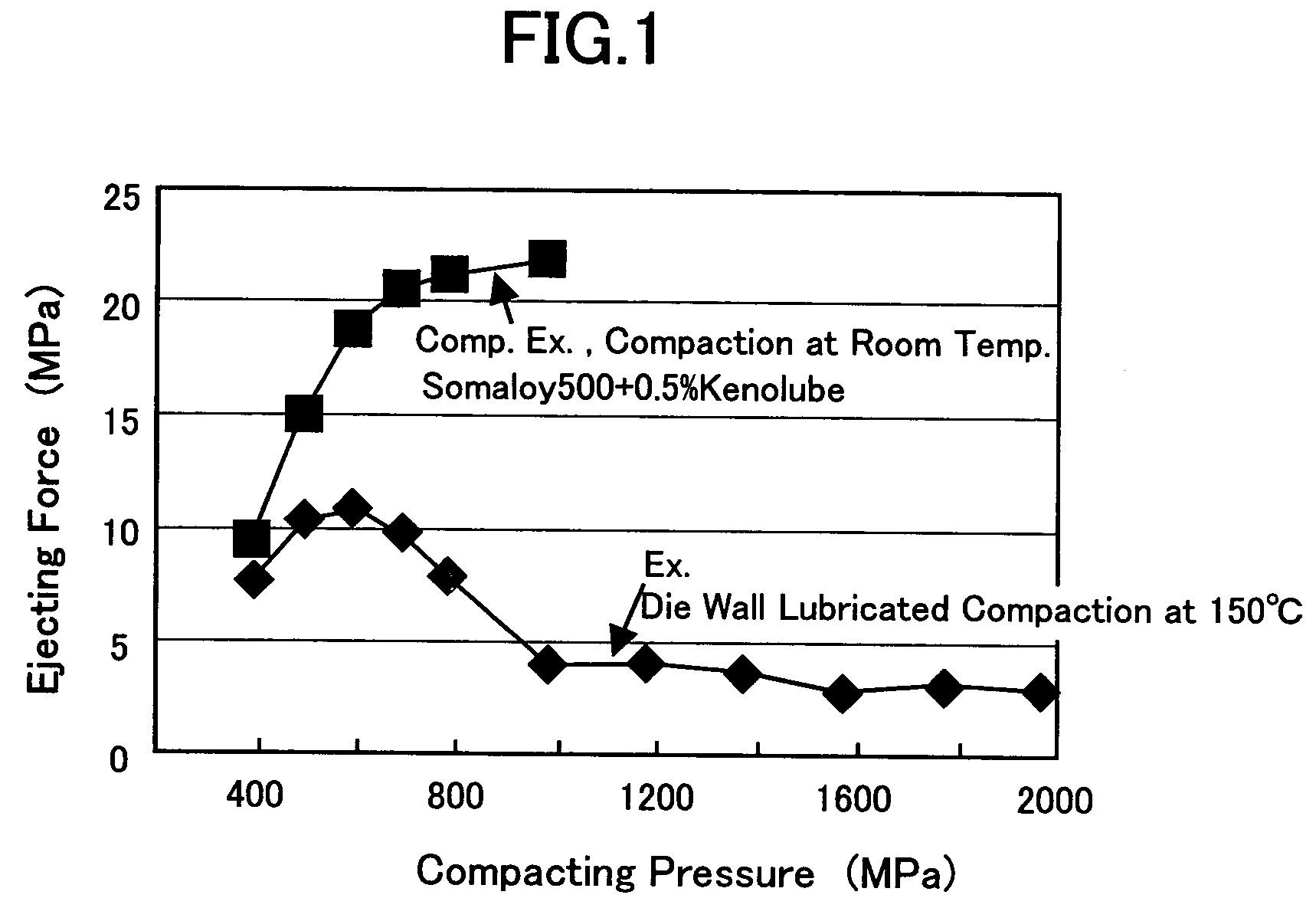

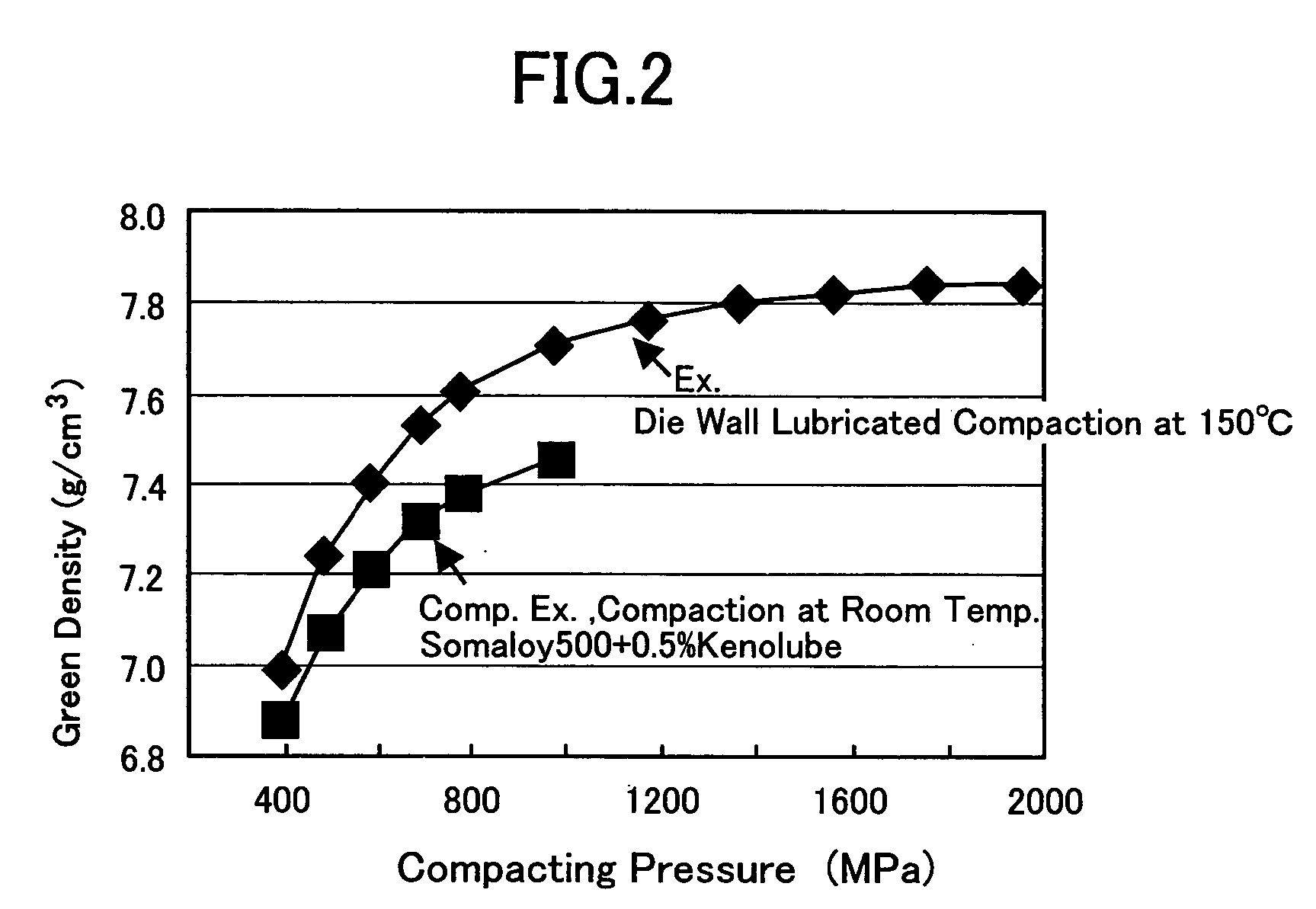

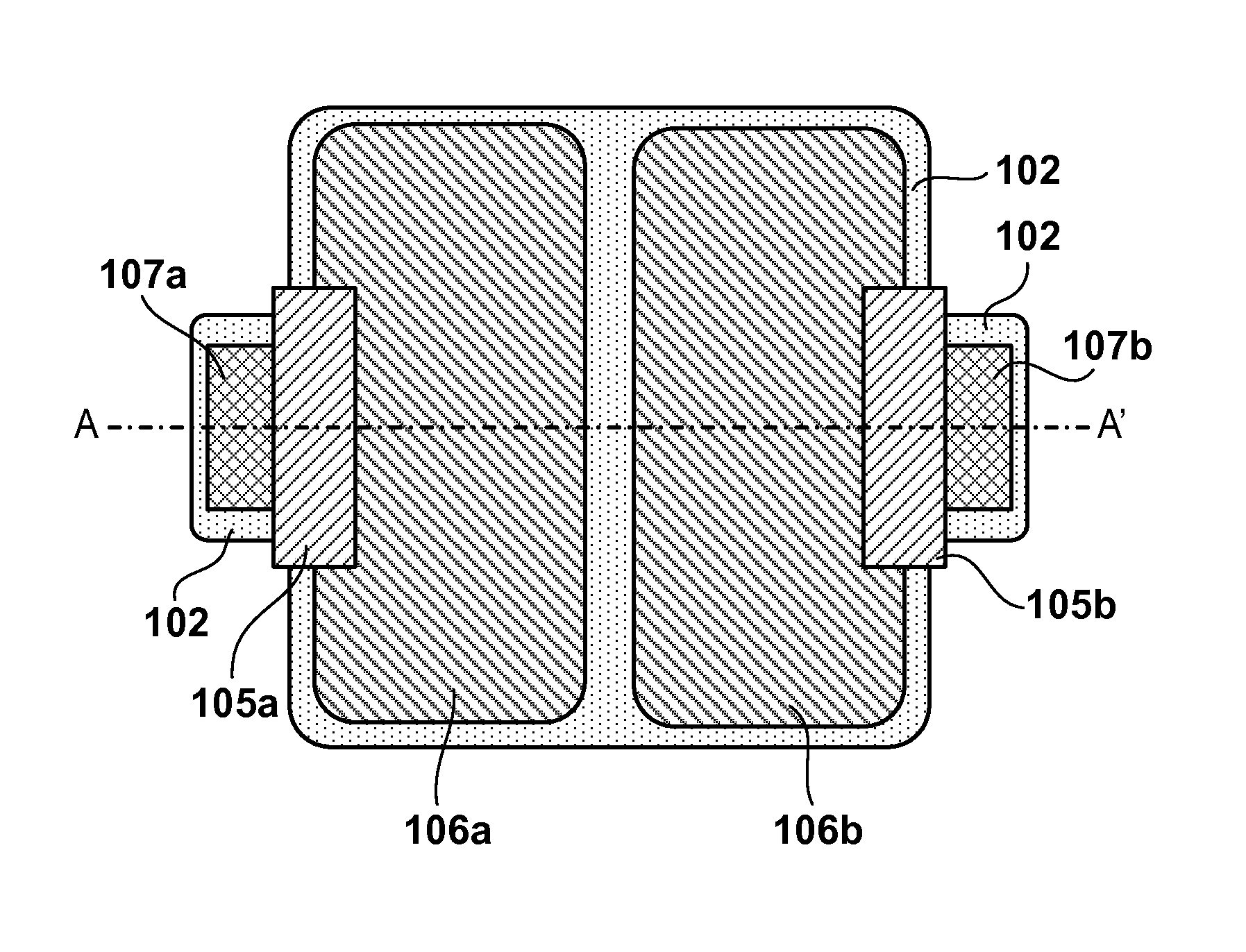

Dust core and method for producing the same

InactiveUS20040061582A1Improve performanceDownsizeTransformers/inductances casingsTransportation and packagingHigh densityMagnetization

Owner:TOYOTA CENT RES & DEV LAB INC +1

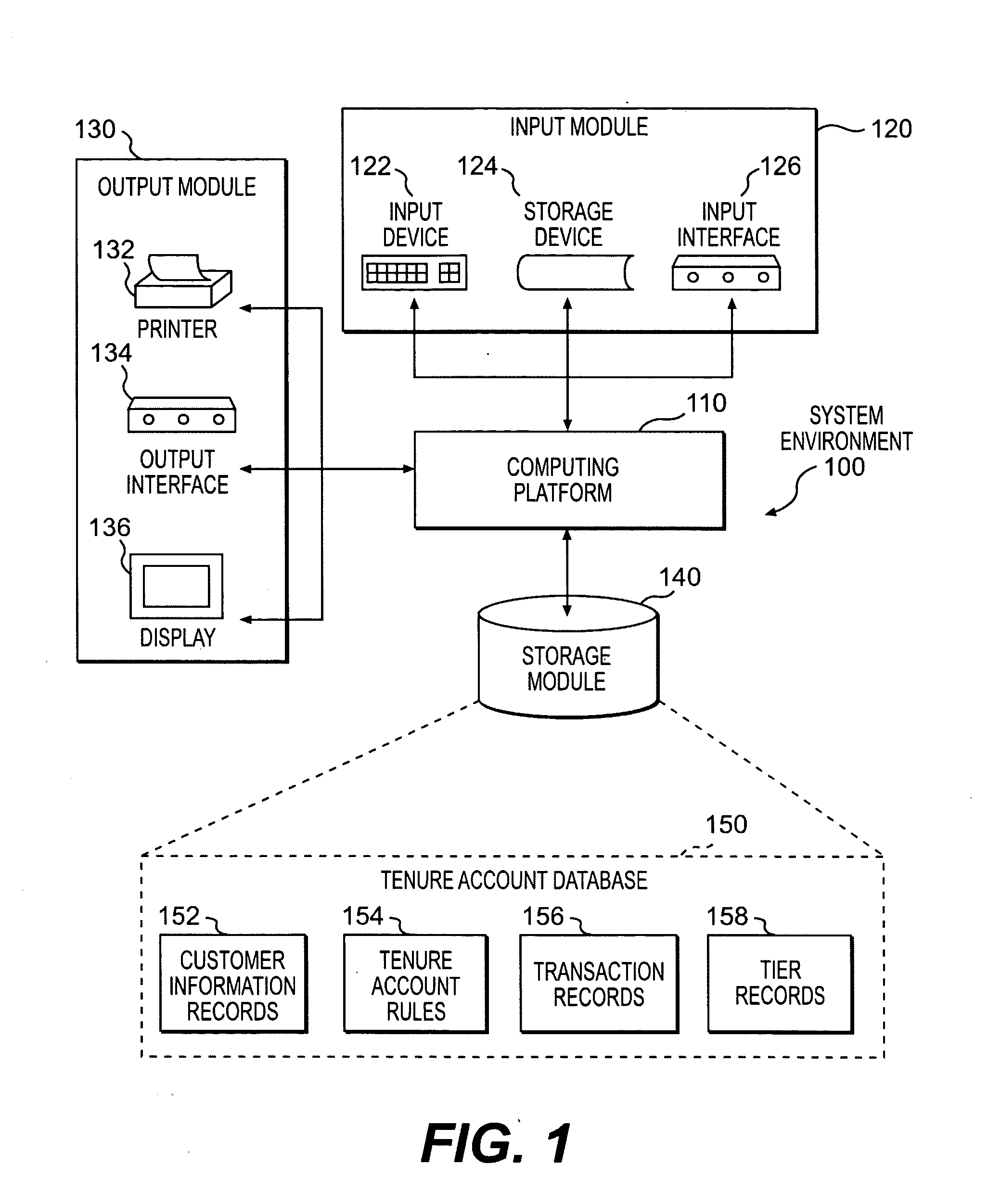

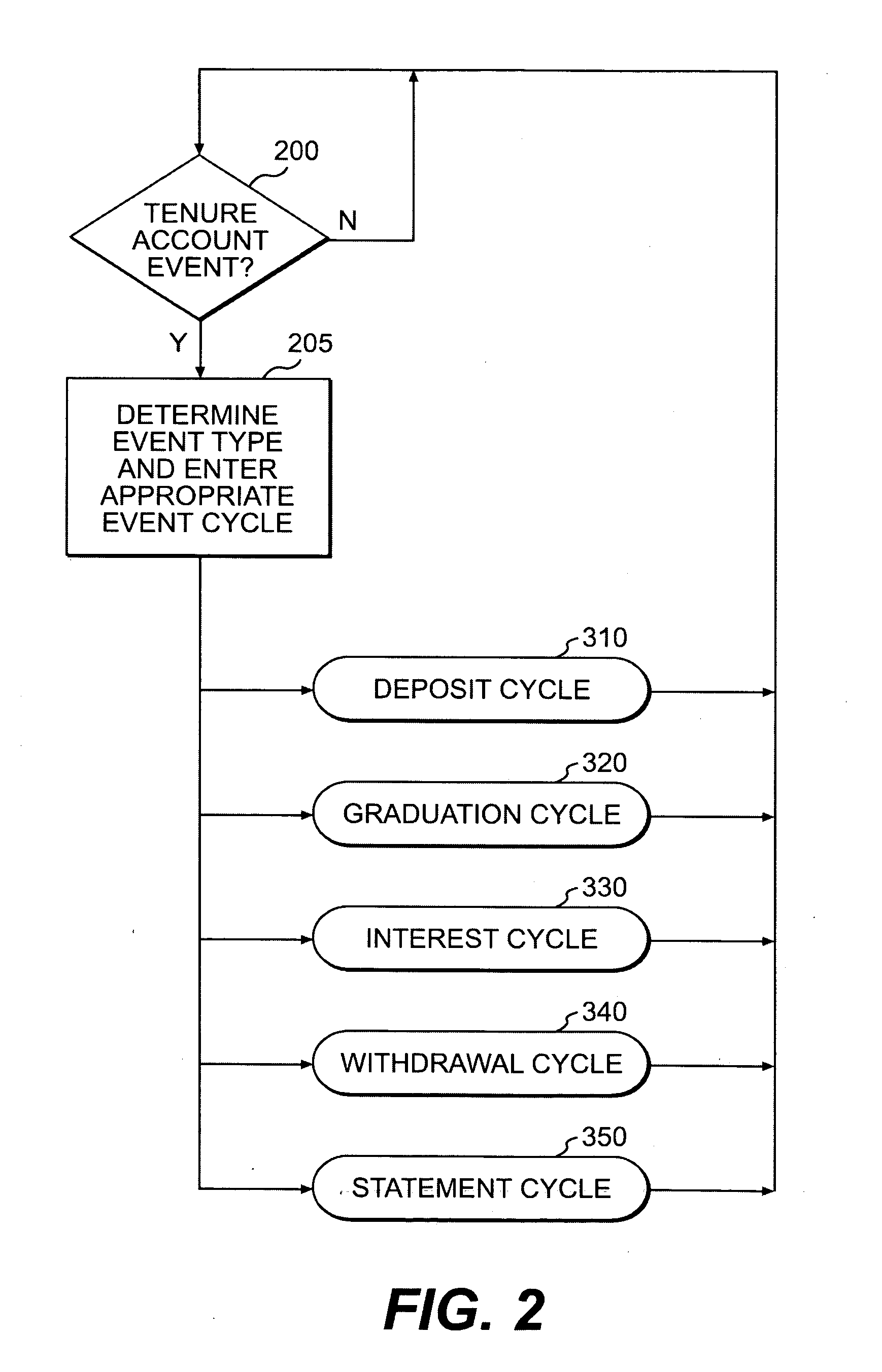

Systems, methods, and computer readable media for managing interest-bearing financial accounts

Owner:CAPITAL ONE FINANCIAL

Electrode material, electrode and lithium ion battery

ActiveUS20140287310A1Improve electronic conductivityImprove diffusivityNon-metal conductorsElectrode thermal treatmentNitrogenThin layer

An electrode material which can improve the mobility of electrons and the mobility of ions at the same time, and, furthermore, does not have a problem of the impairment of the diffusion of lithium ions in a thin layer containing a carbonaceous electron-conductive substance so as to be excellent in terms of load characteristics and energy density, and an electrode and a lithium ion battery are provided.The electrode material of the invention is produced by forming a thin layer made of a carbonaceous electron-conductive substance on surfaces of primary particles made of an electrode active material, in which the carbonaceous electron-conductive substance contains nitrogen atoms.

Owner:SUMITOMO METAL MINING CO LTD

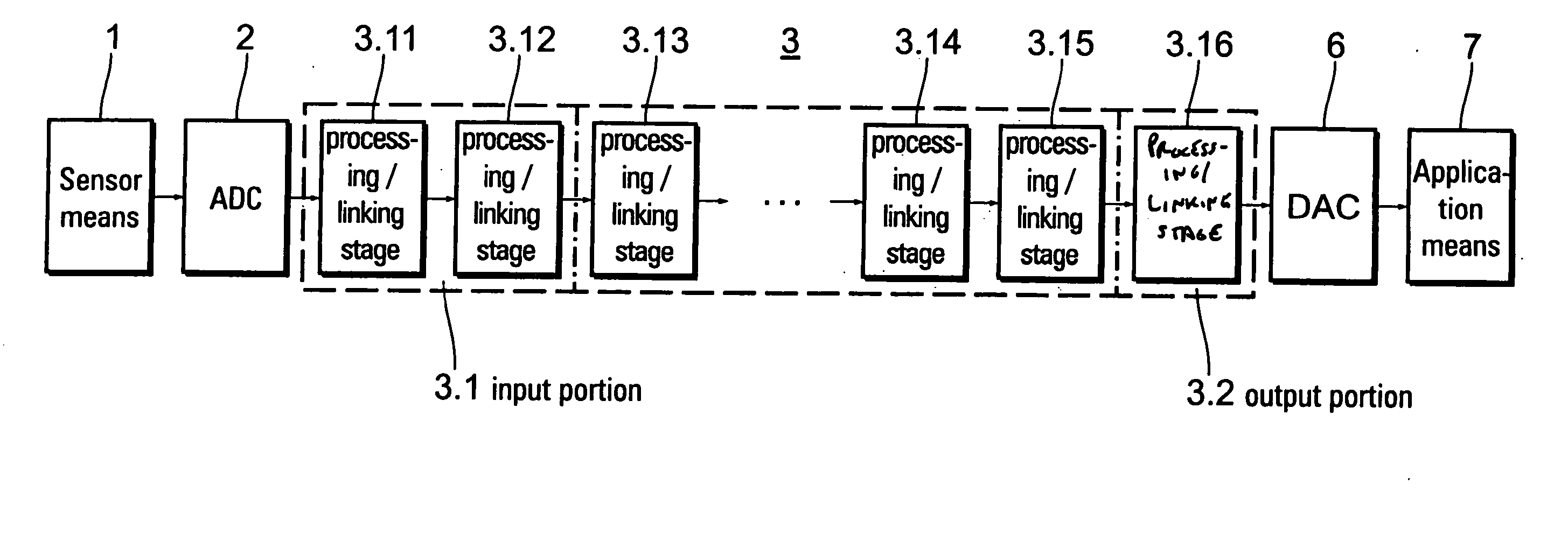

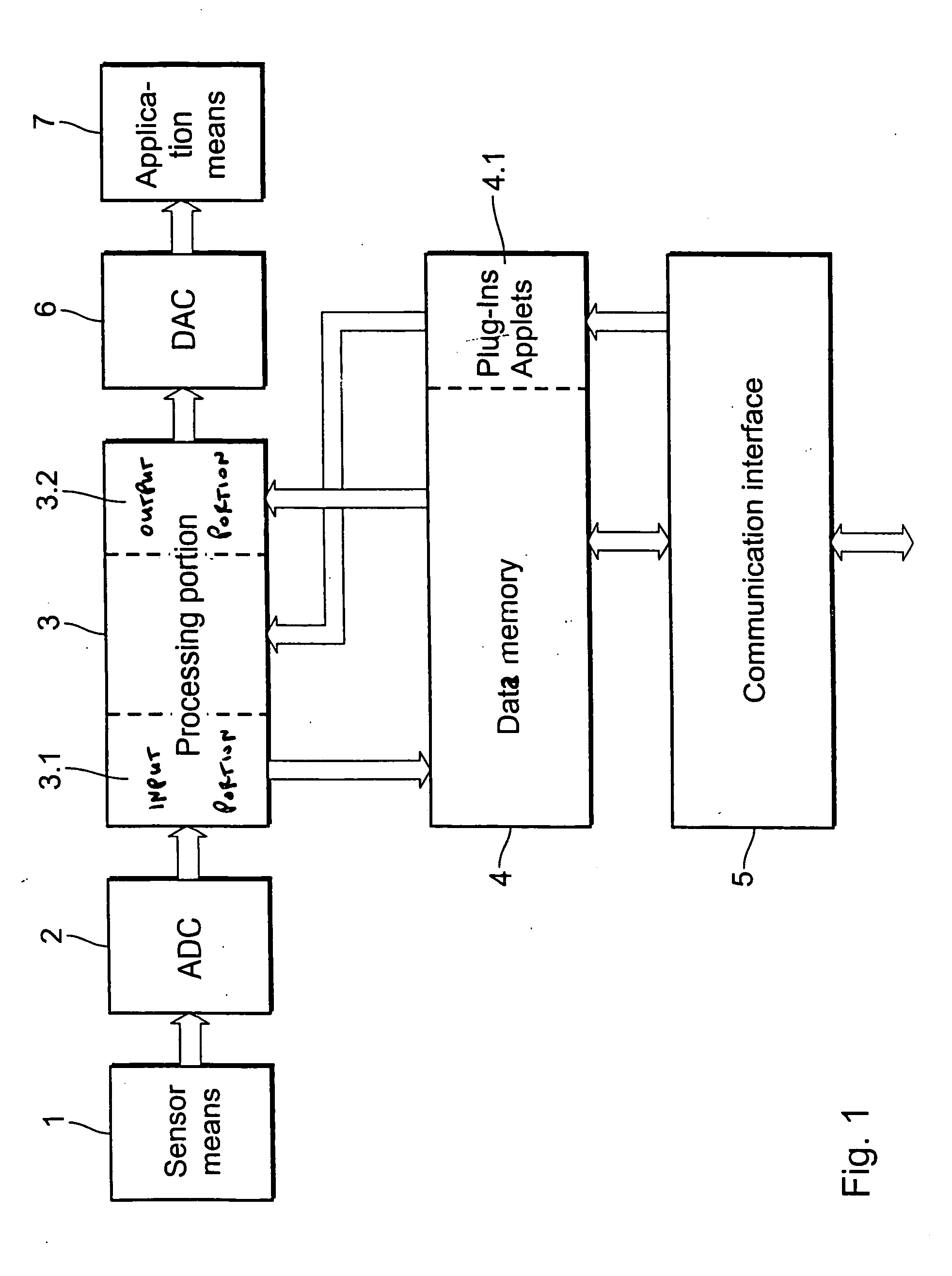

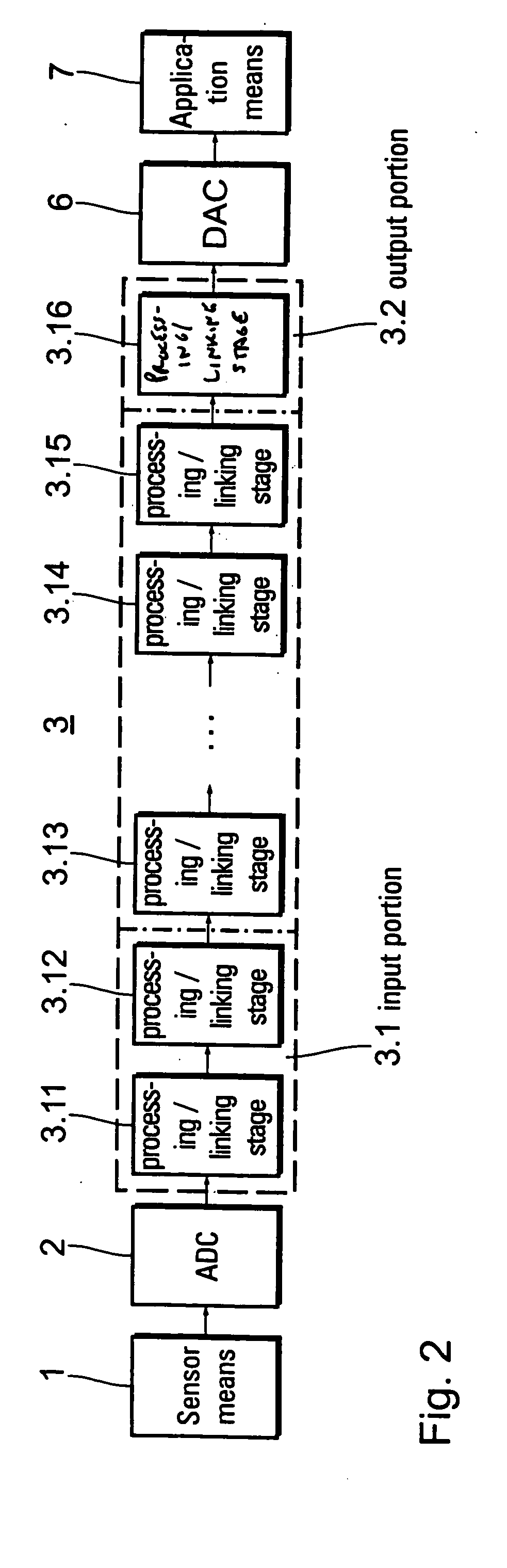

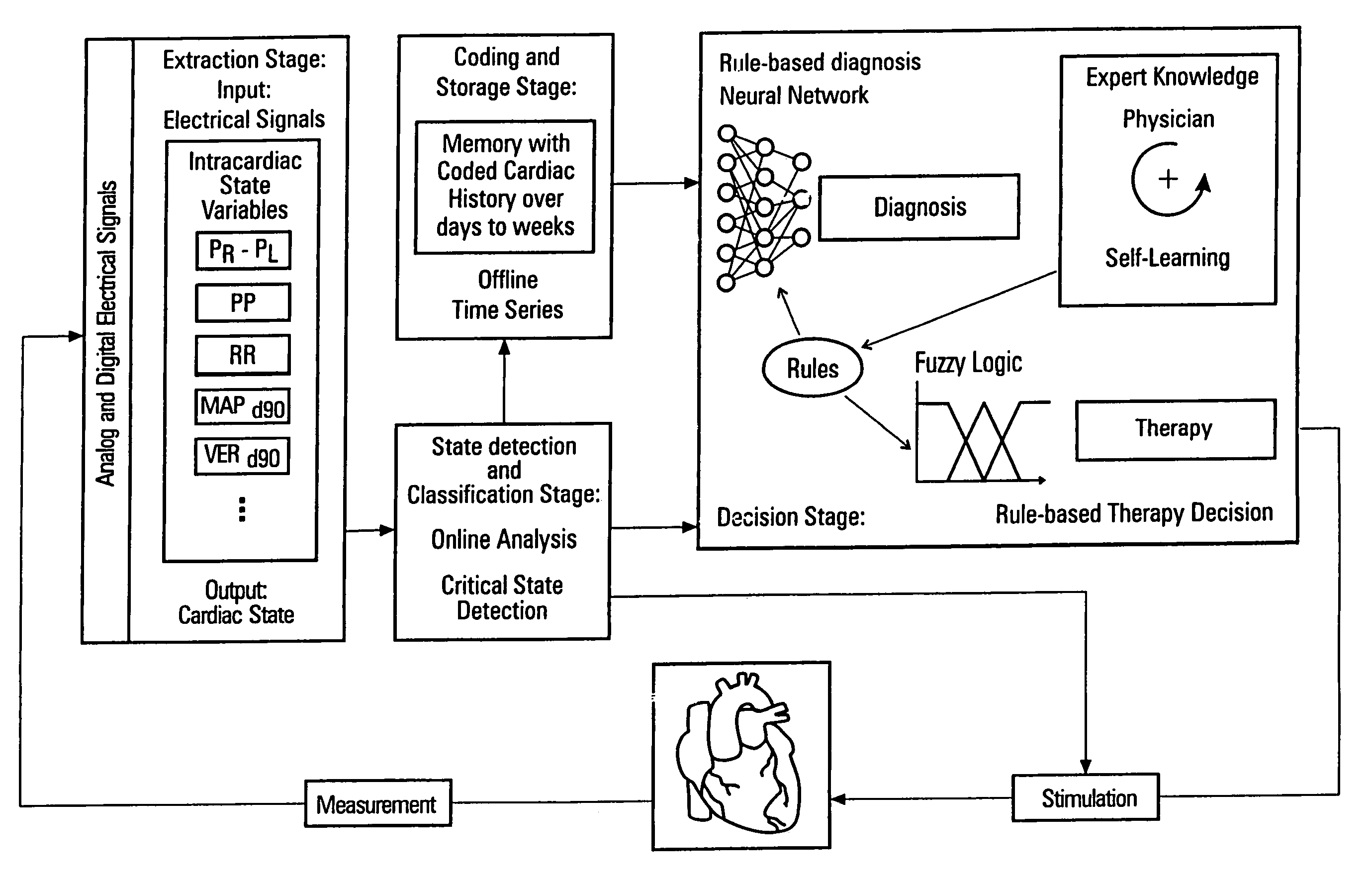

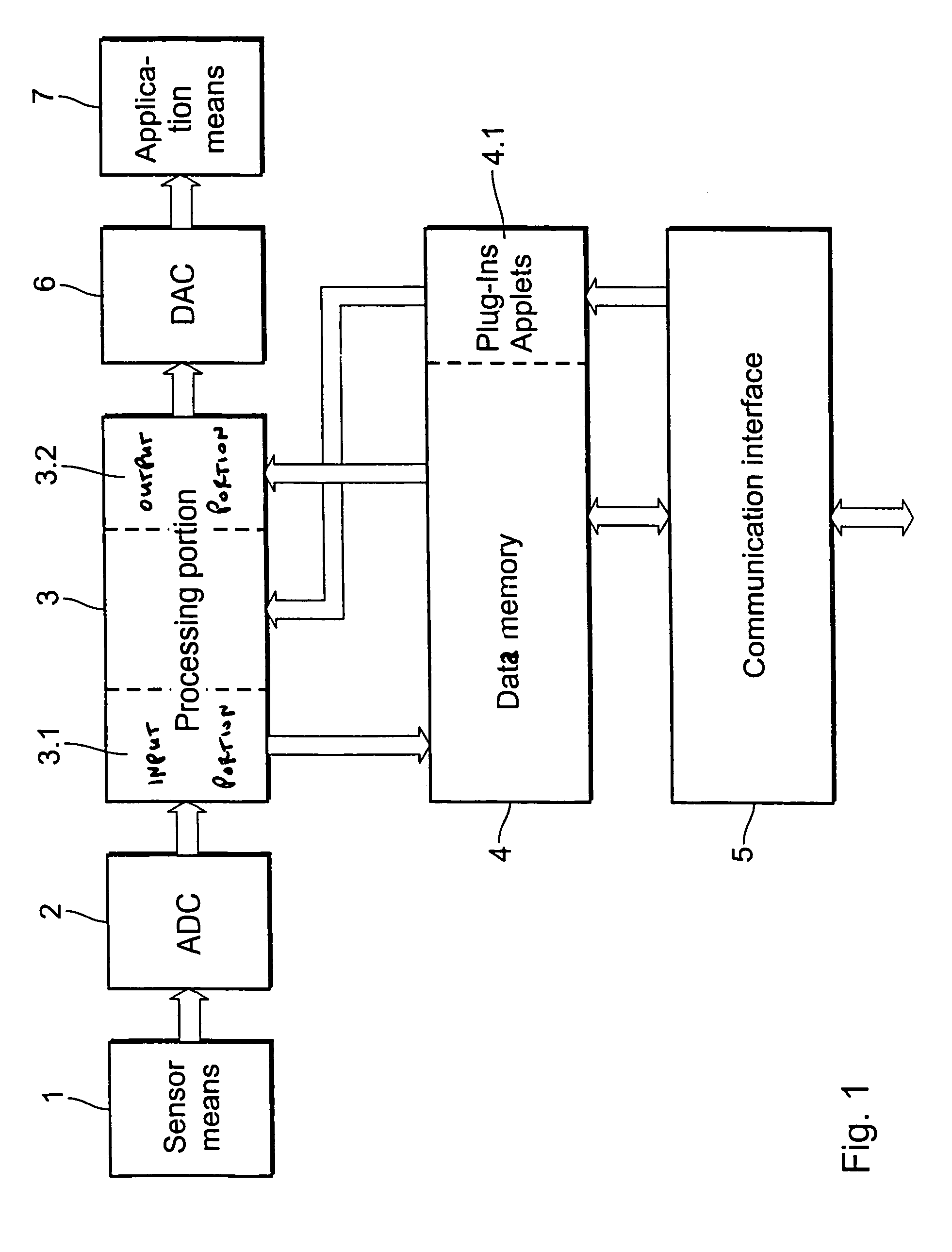

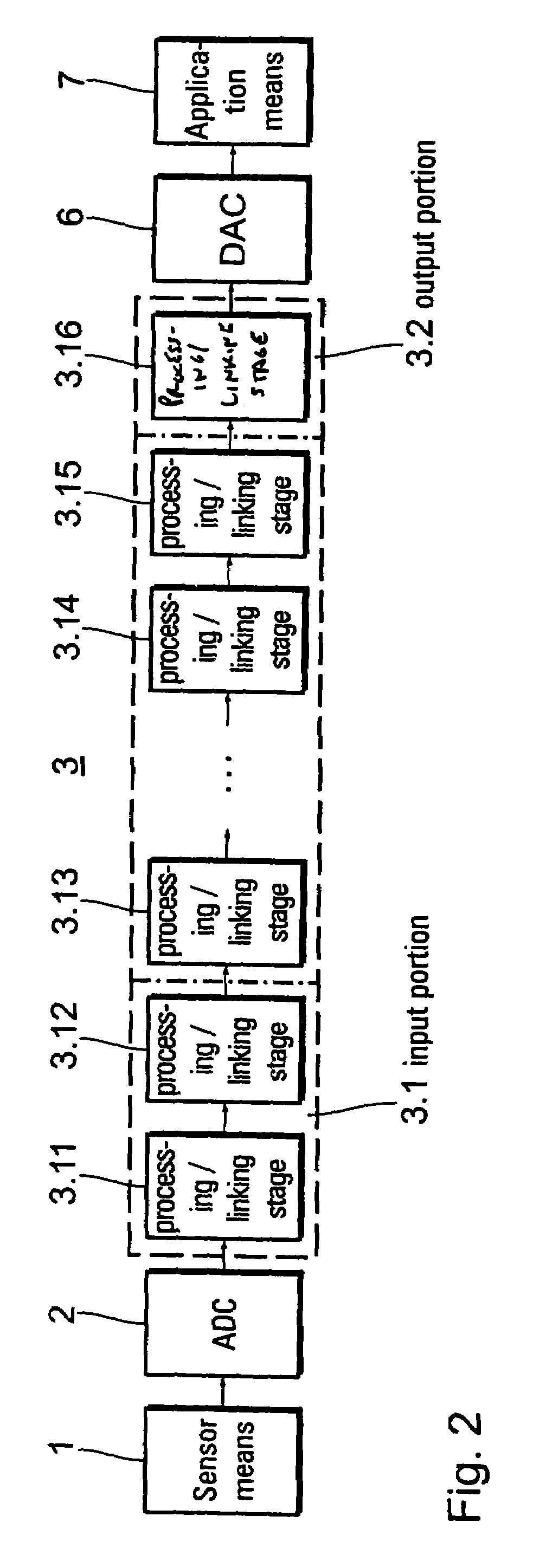

Therapy system

InactiveUS20050027324A1High safety and reliabilitySpeed upHeart stimulatorsEngineeringMedical therapy

A medical therapy system has logic and / or signal processing stages between sensors on the input side and therapy applicators on the output side. A signal parameter is determined from the input signals using the logic / processing stages, and / or an indicator signal is determined from the input signals using a logic / processing module consisting of several logic / processing stages. The indicator signal is a measure of the probability of a future event requiring therapy, or a measure of the success of the therapy.

Owner:BIOTRONIK

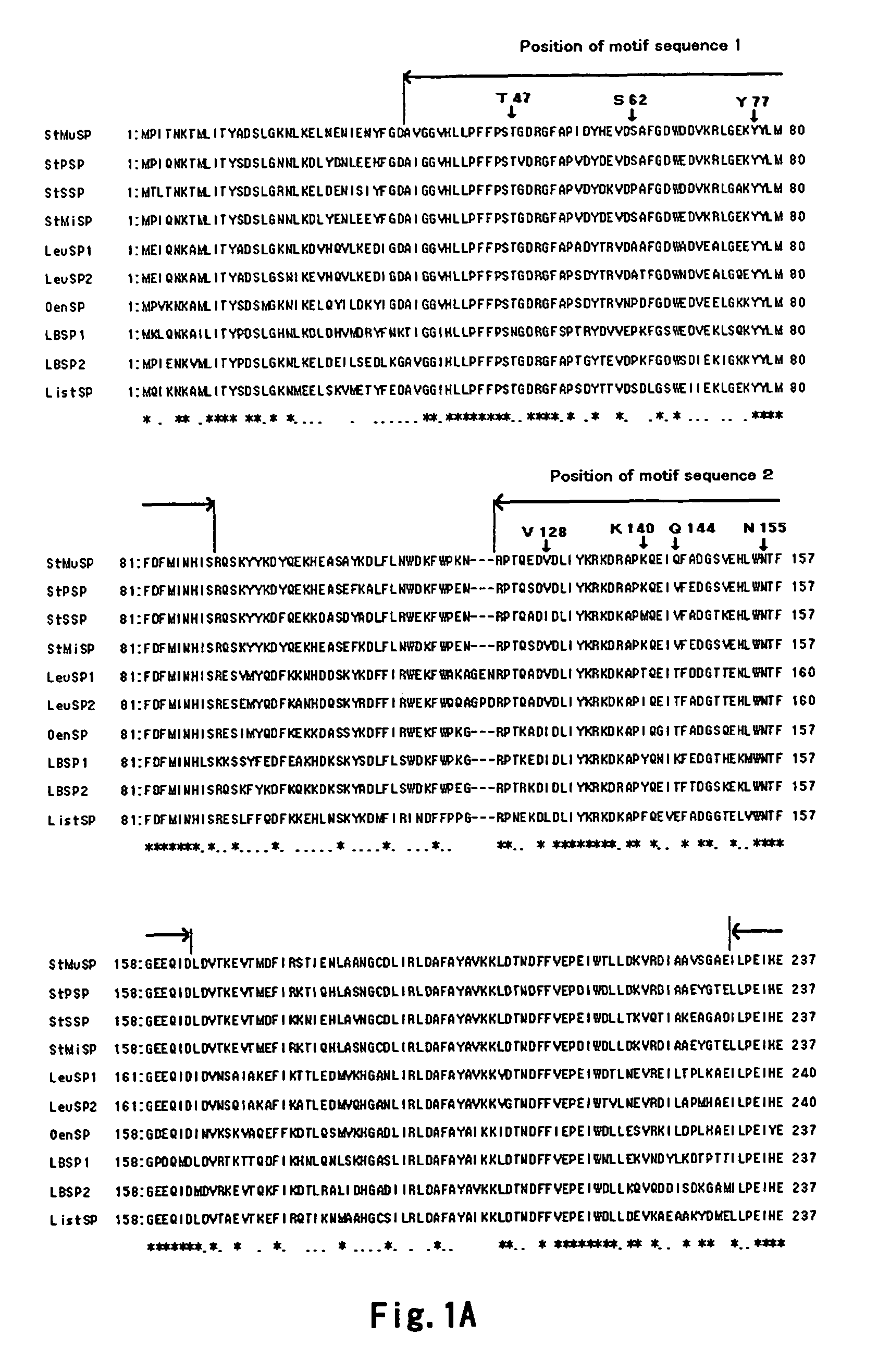

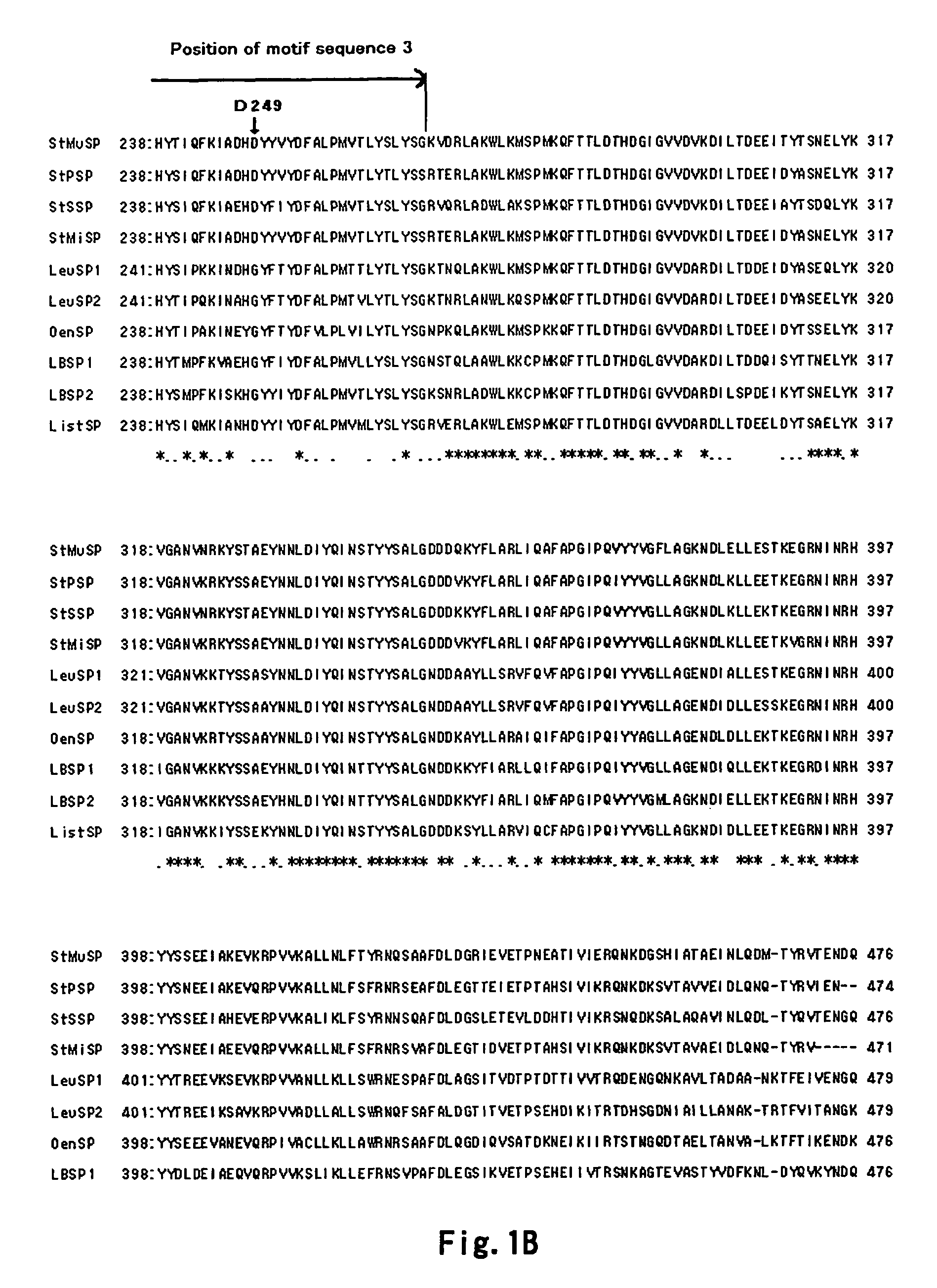

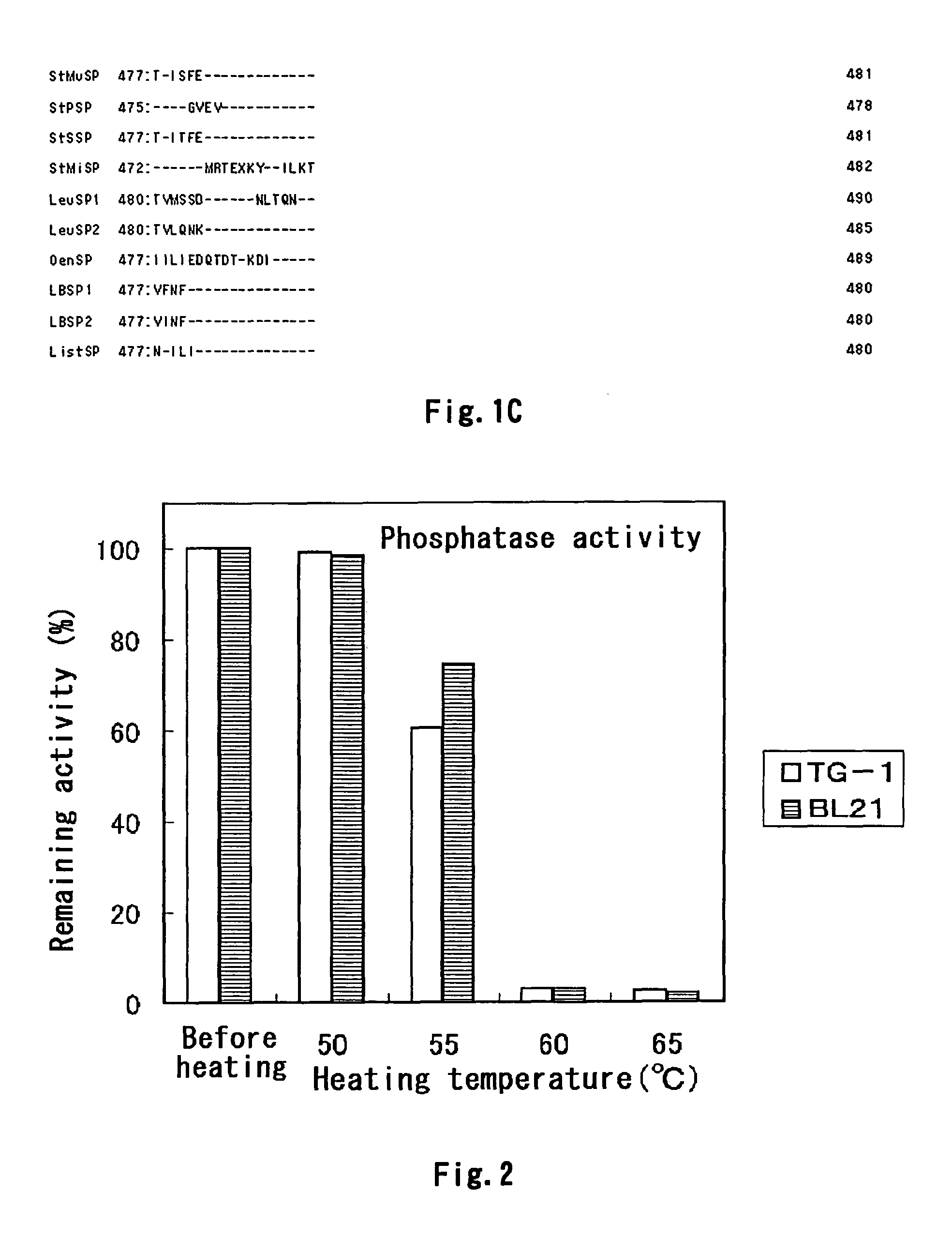

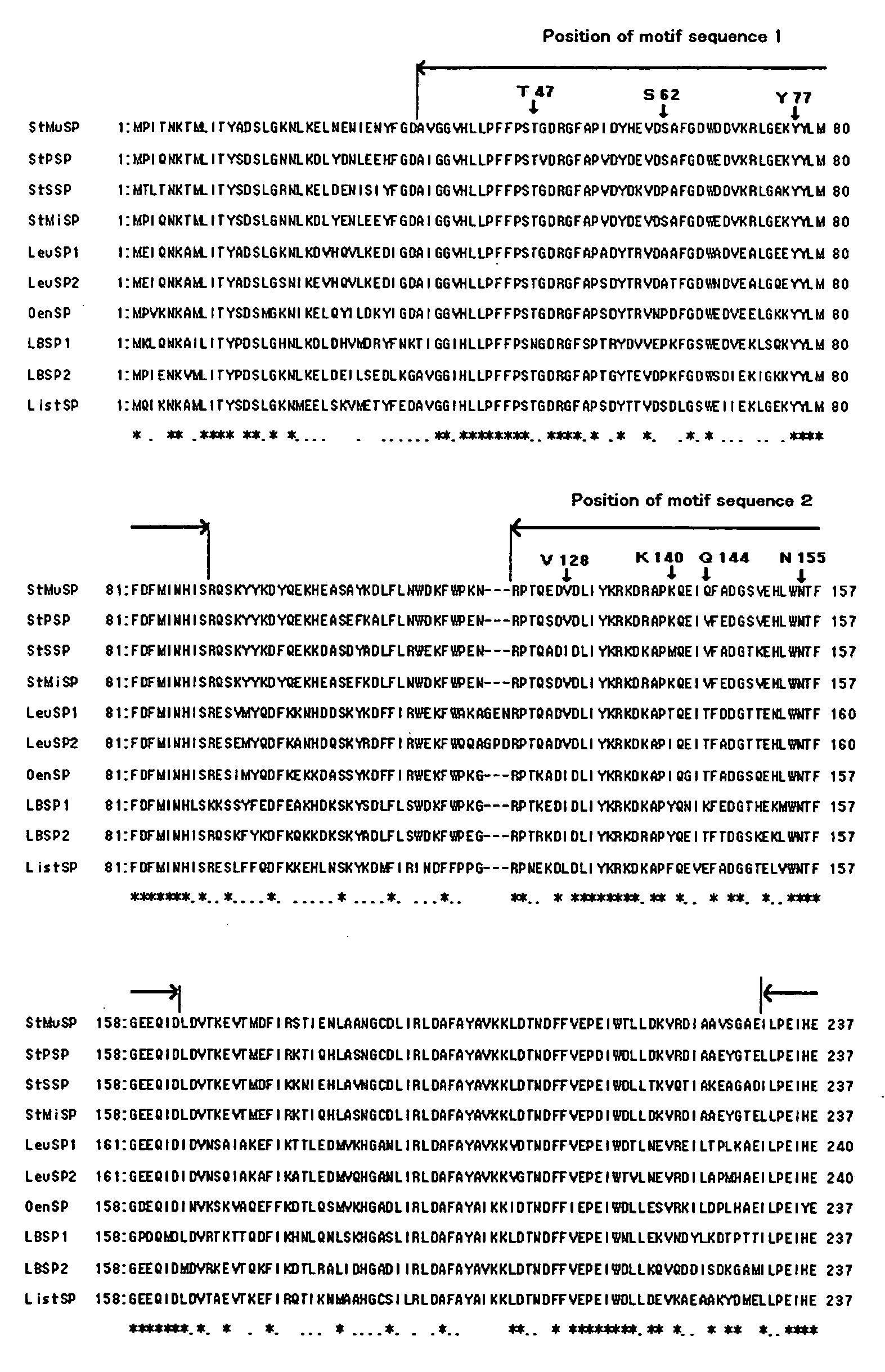

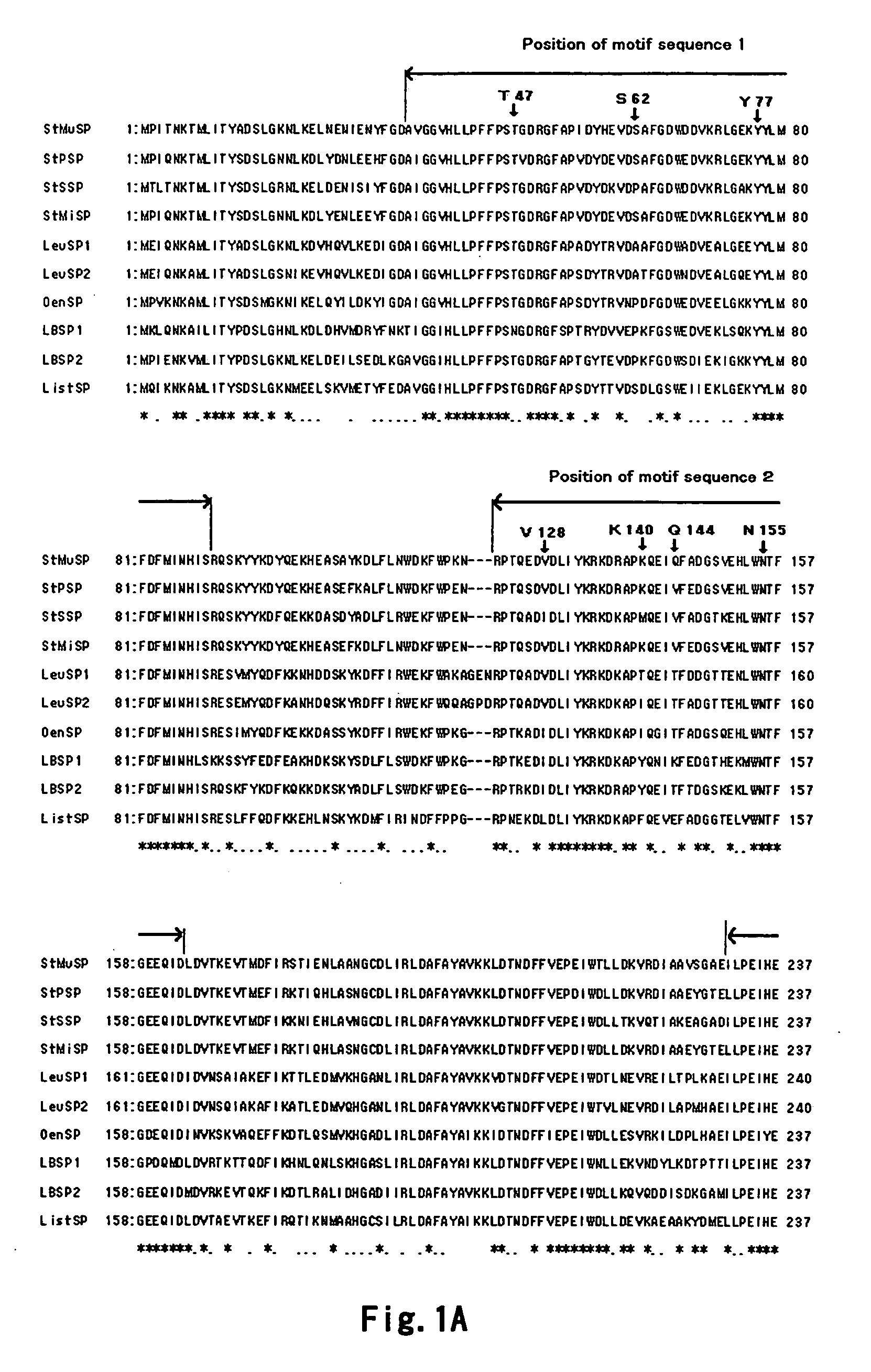

Method for improving the thermostability of sucrose phosphorylase (SP)

ActiveUS7968309B2High activityImprove thermal stabilitySugar derivativesMicrobiological testing/measurementSucrose phosphorylaseChemistry

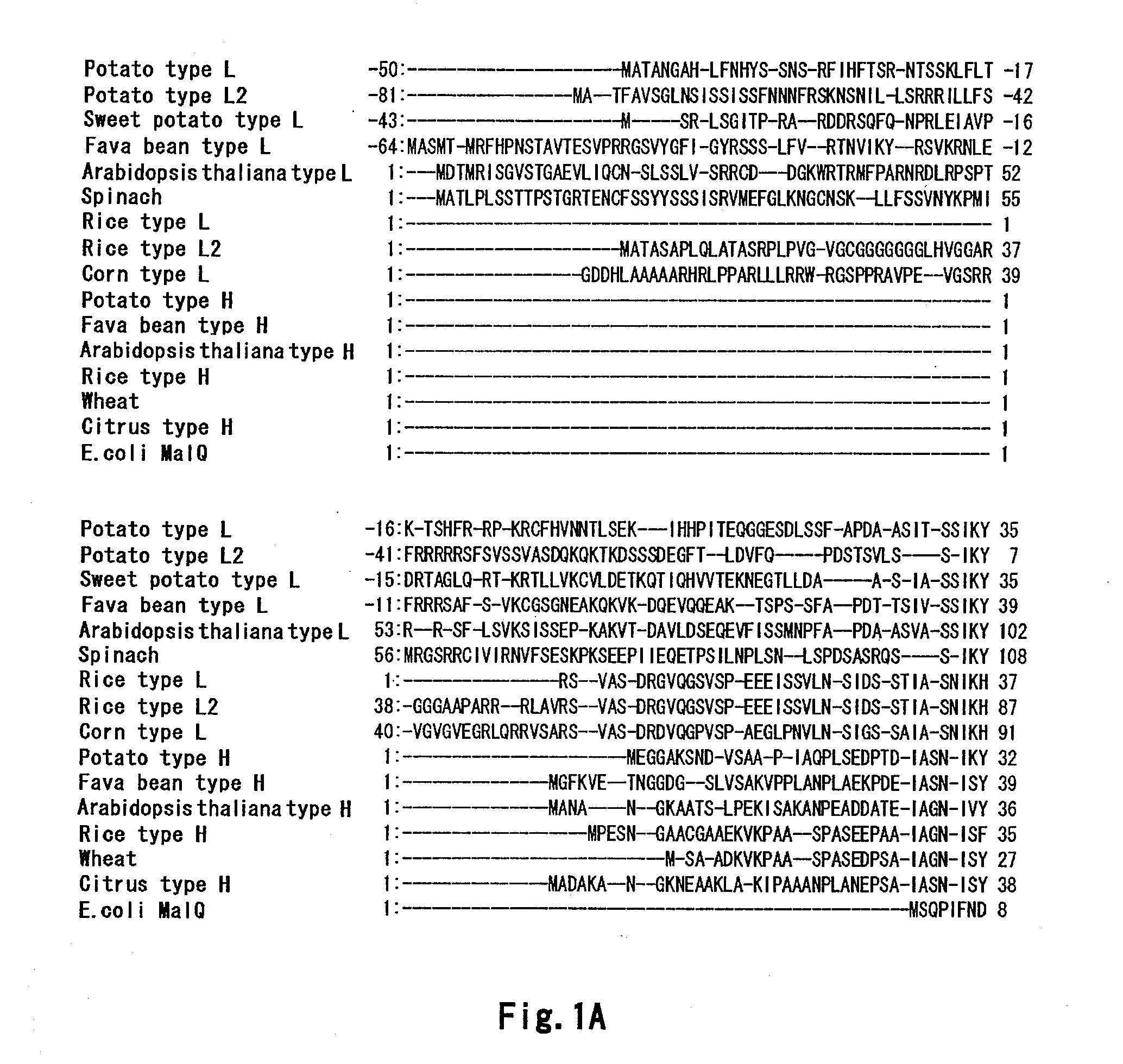

A sucrose phosphorylase (SP) having improved thermostability obtained by modifying a natural SP and a method for producing the SP having improved thermostability is provided. This SP having improved thermostability has an amino acid residue which is different from that of the natural sucrose phosphorylase, in at least one position selected from the group consisting of a position corresponding to position 14, a position corresponding to position 29 and a position corresponding to position 44 in motif sequence 1; a position corresponding to position 7, a position corresponding to position 19, a position corresponding to position 23 and a position corresponding to position 34 in motif sequence 2; and a position corresponding to position 19 in motif sequence 3, and wherein the enzyme activity of the SP having improved thermostability at 37° C., after heating the SP having improved thermostability in 20 mM Tris buffer (pH 7.0) at 55° C. for 20 minutes, is 20% or more of enzyme activity of the SP having improved thermostability at 37° C. before heating.

Owner:EZAKI GLICO CO LTD

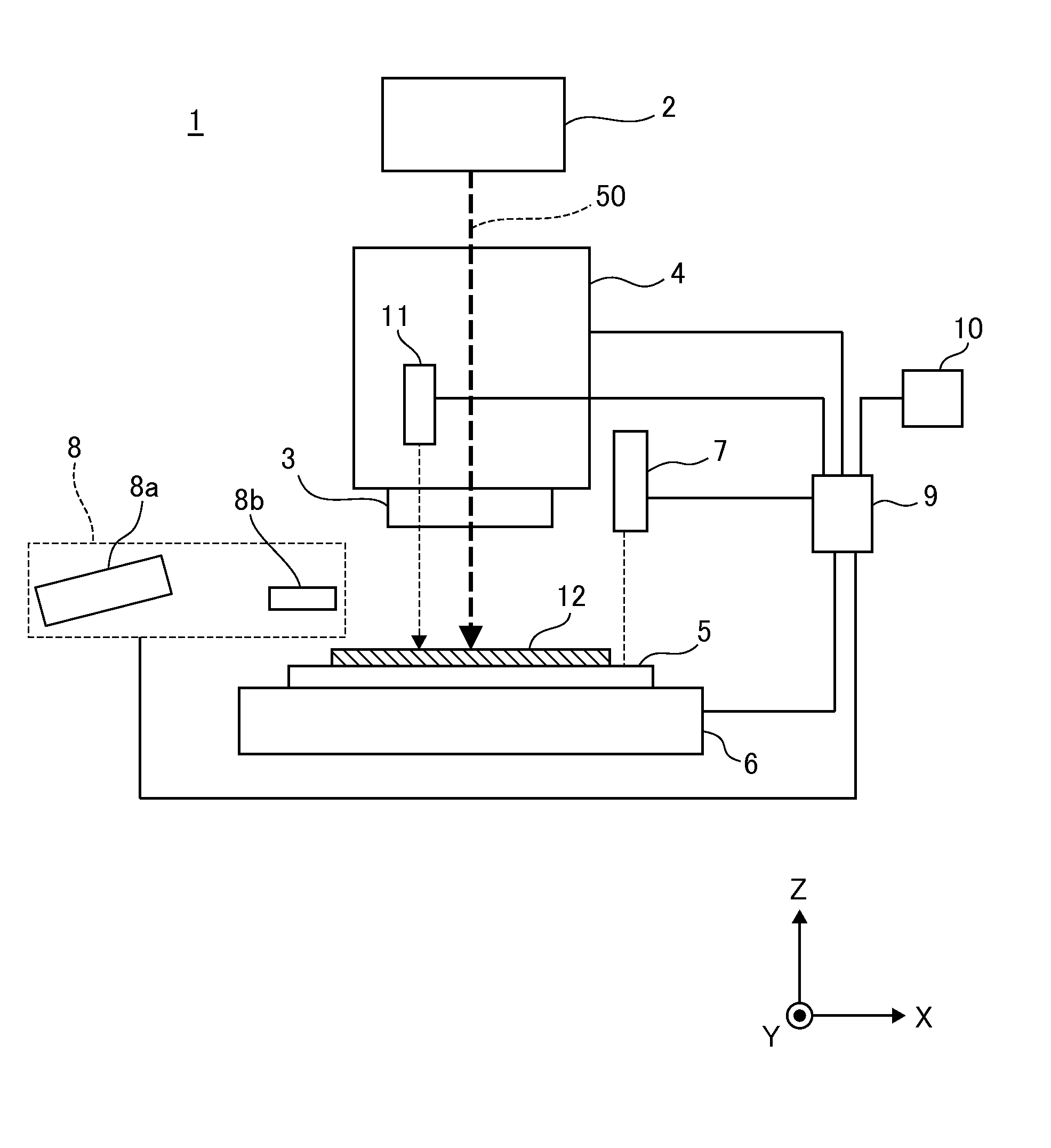

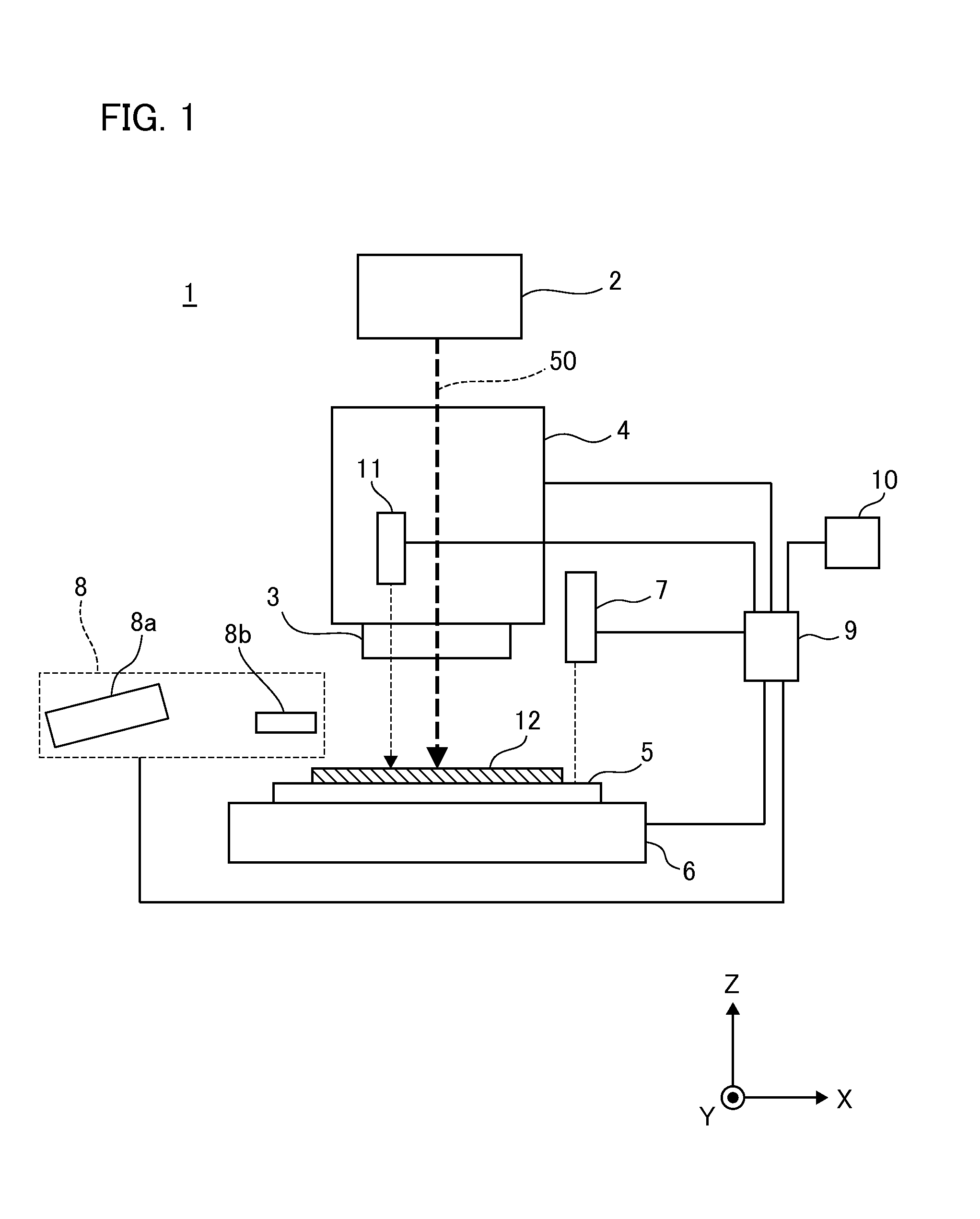

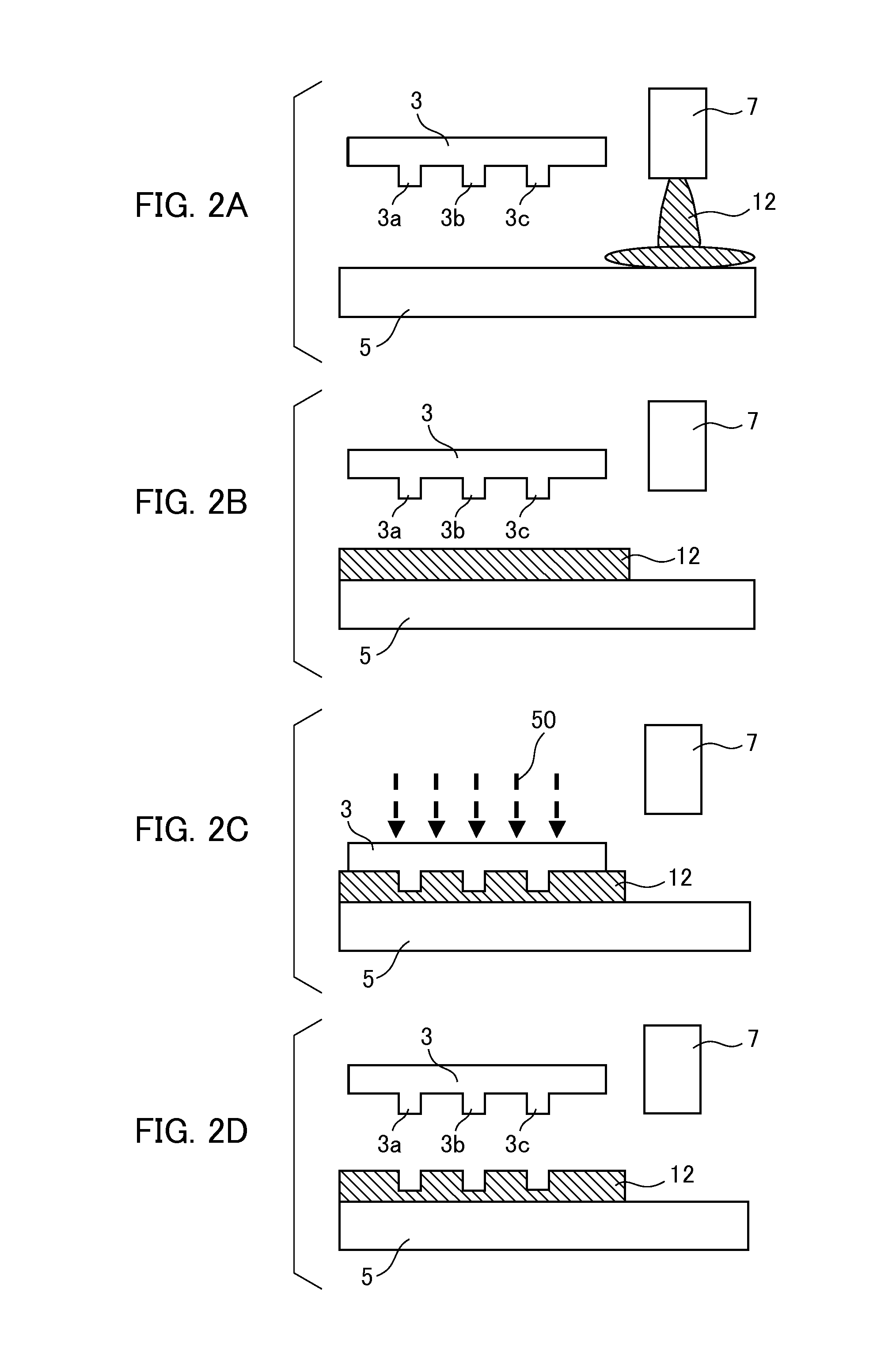

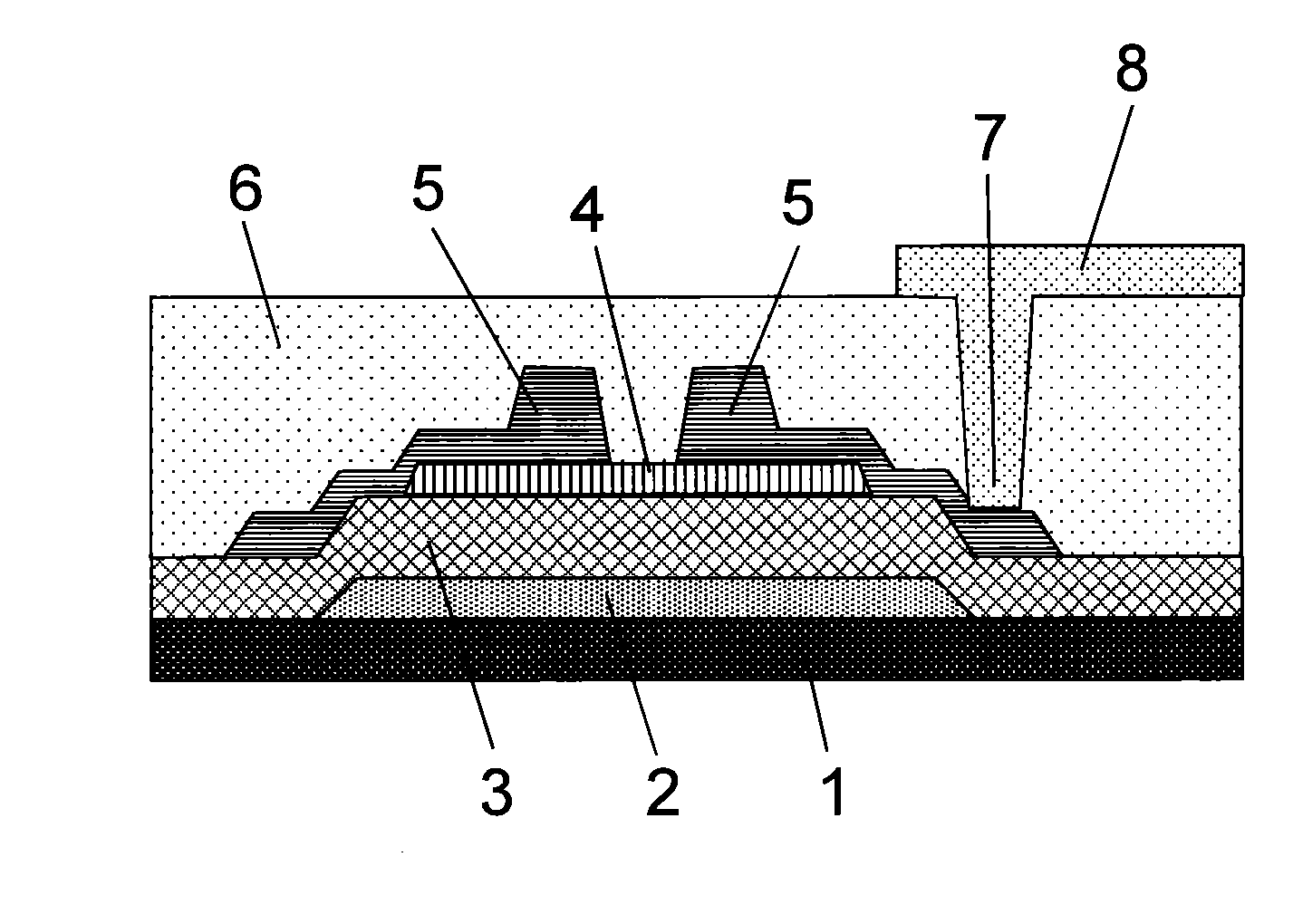

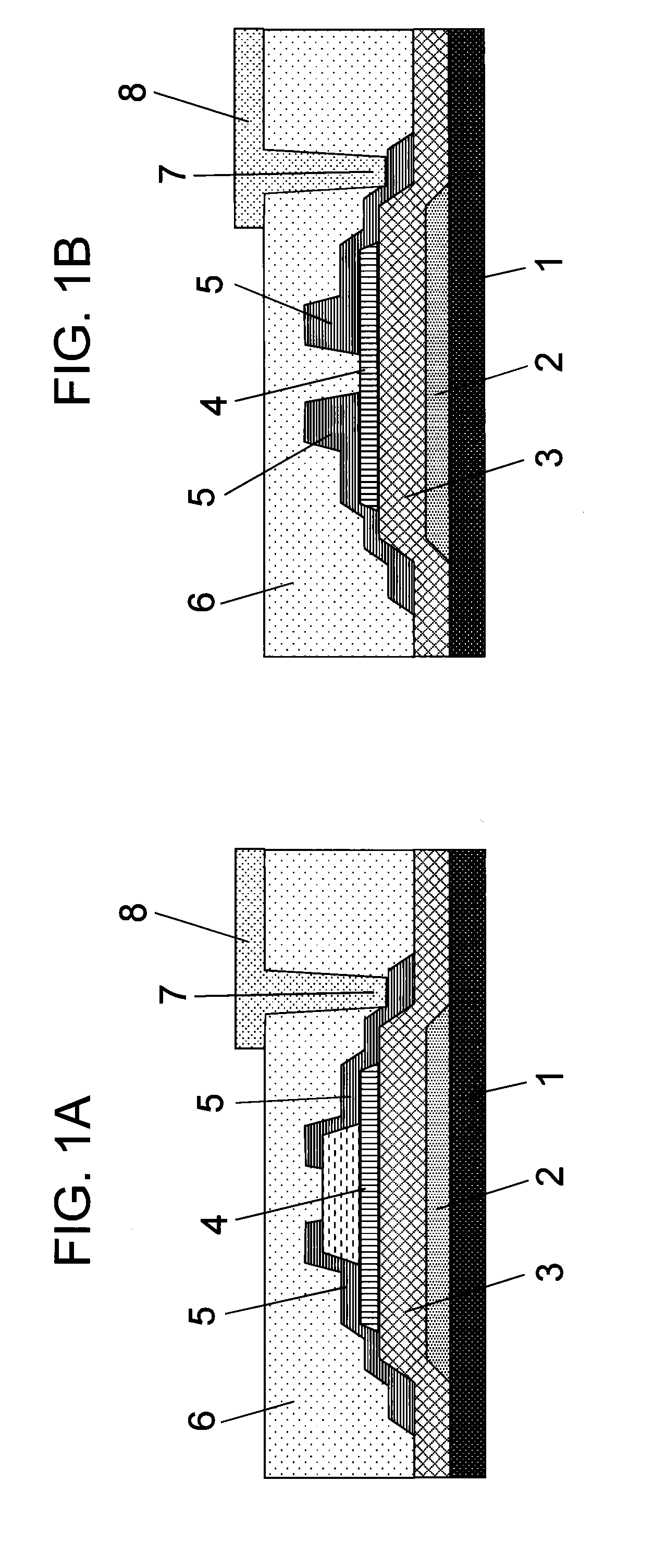

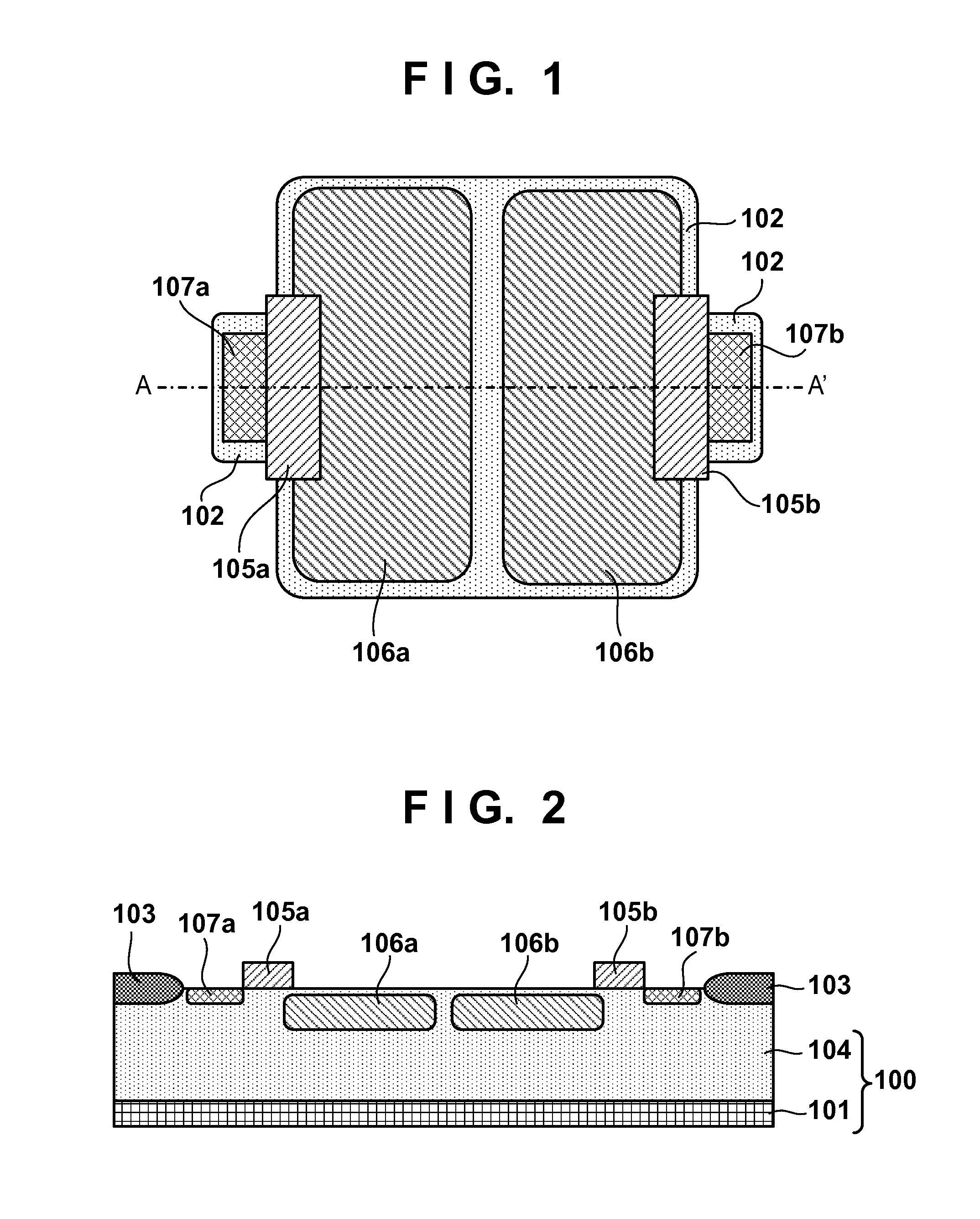

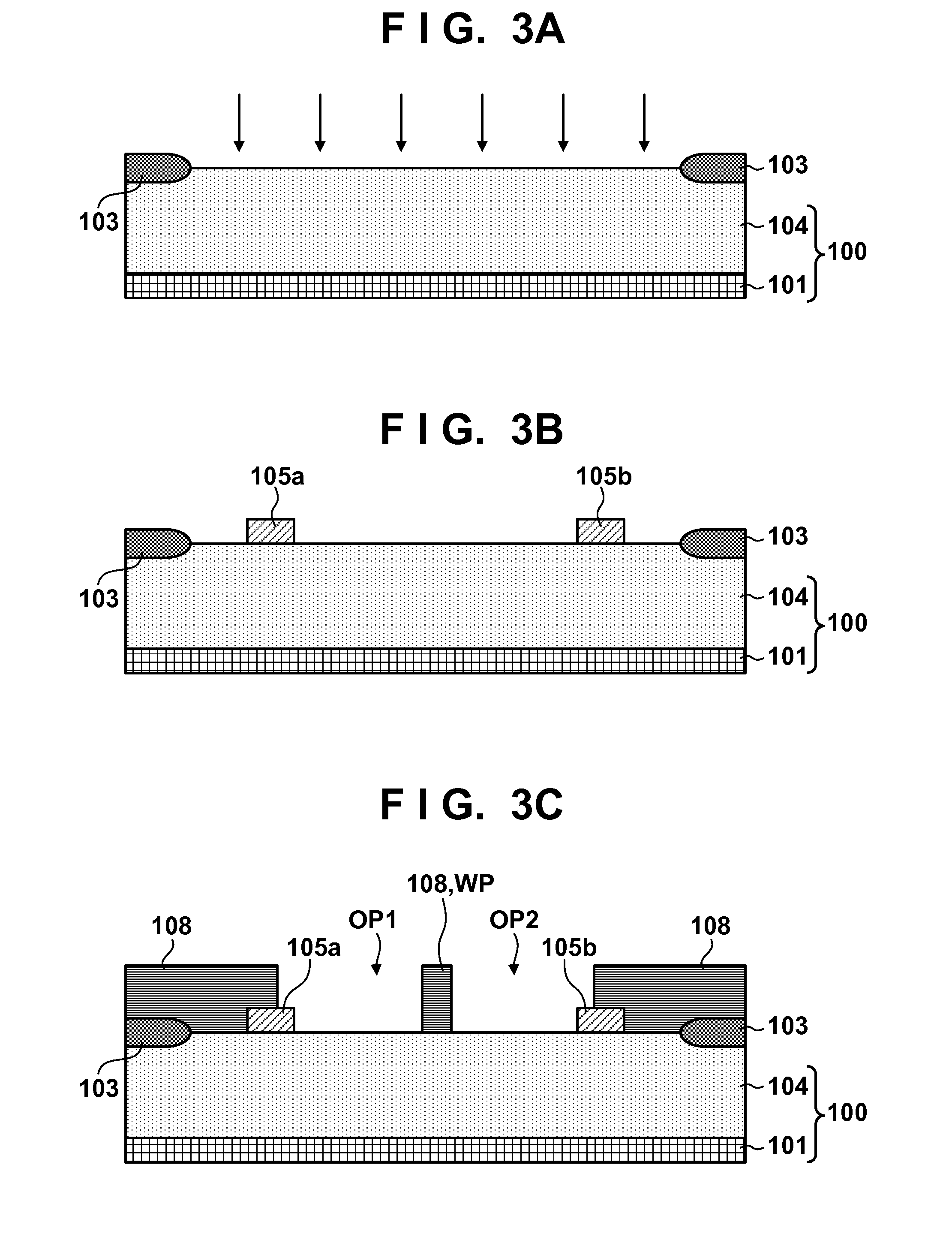

Imprint apparatus and article manufacturing method

ActiveUS20110198769A1Convenient inspectionExcellent in termNanoinformaticsPhotomechanical apparatusMeasurement deviceEngineering

The imprint apparatus of the present invention molds an uncured resin on a substrate using a mold to form a resin pattern on the substrate. The apparatus includes a measuring device configured to project a light onto the mold, to receive a light scattered by the mold, and to measure the scattered light; and a controller. The controller is configured to store a reference signal, to cause the measuring device to measure the mold to obtain a measurement signal, and to obtain an index indicating a discrepancy between the measurement signal and the reference signal.

Owner:CANON KK

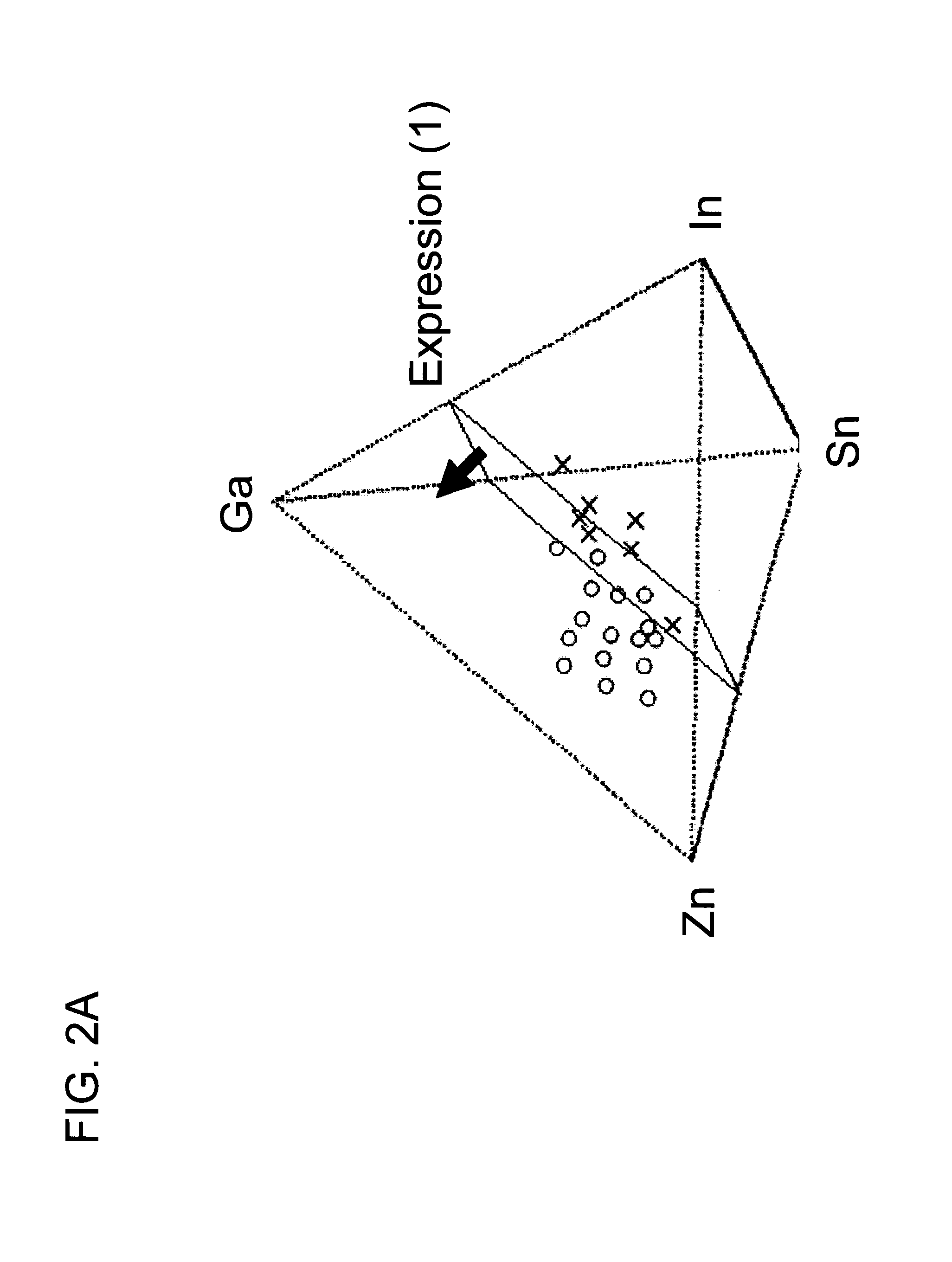

Oxide for semiconductor layer in thin film transistor, thin film transistor, display device, and sputtering target

Provided is an oxide semiconductor configured to be used in a thin film transistor having high field-effect mobility; a small shift in threshold voltages against light and bias stress; excellent stress resistance. The oxide semiconductor has also excellent resistance to a wet-etchant for patterning of a source-drain electrode. The oxide semiconductor comprises In, Zn, Ga, Sn and O, and satisfies the requirements represented by expressions (1) to (4) shown below, wherein [In], [Zn], [Ga], and [Sn] represent content (in atomic %) of each of the elements relative to the total content of all the metal elements other than oxygen in the oxide.(1.67×[Zn]+1.67×[Ga])≧100 (1){([Zn] / 0.95)+([Sn] / 0.40)+([In] / 0.4)}≧100 (2)[In]≦40 (3)[Sn]≧5 (4)

Owner:KOBE STEEL LTD

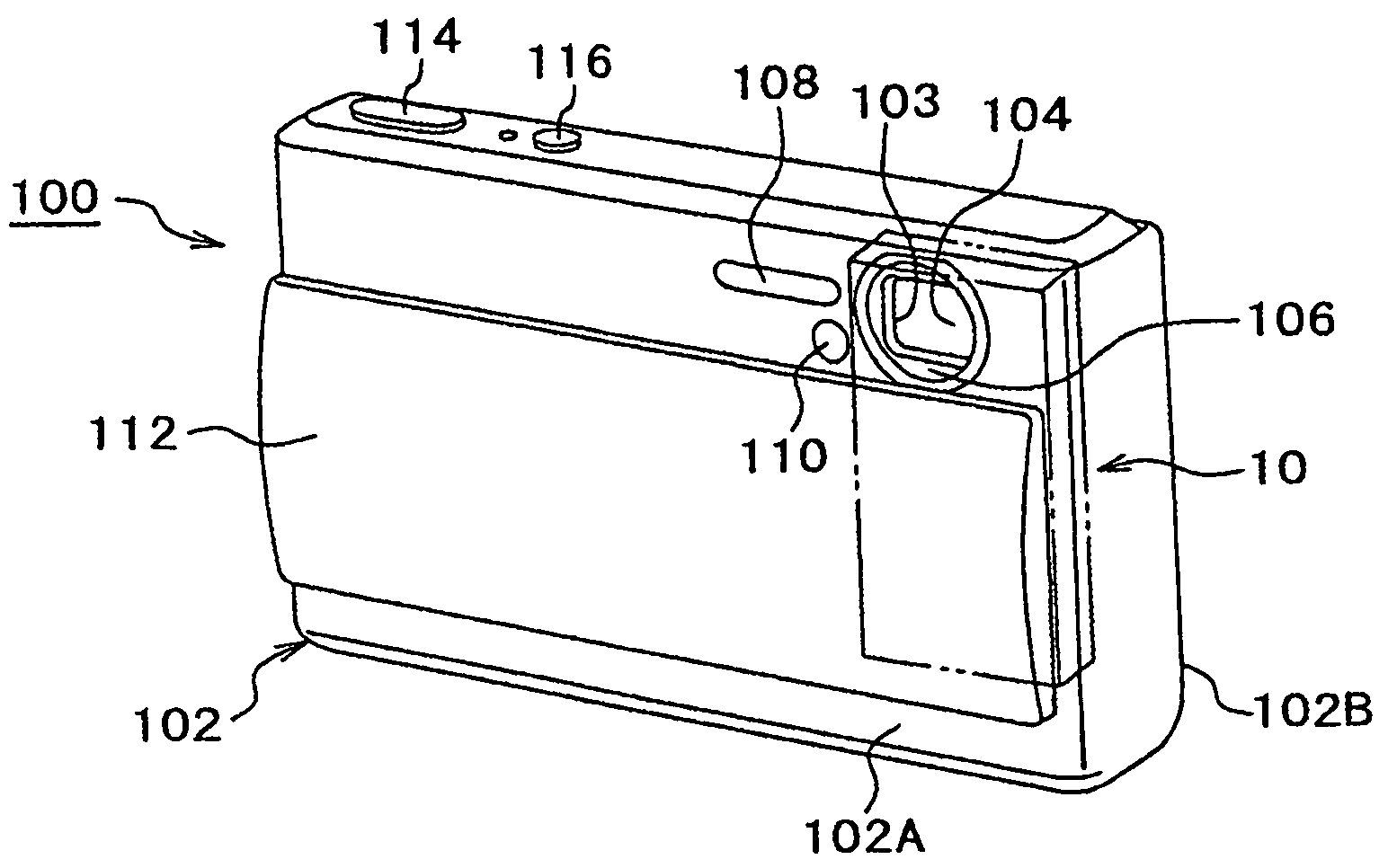

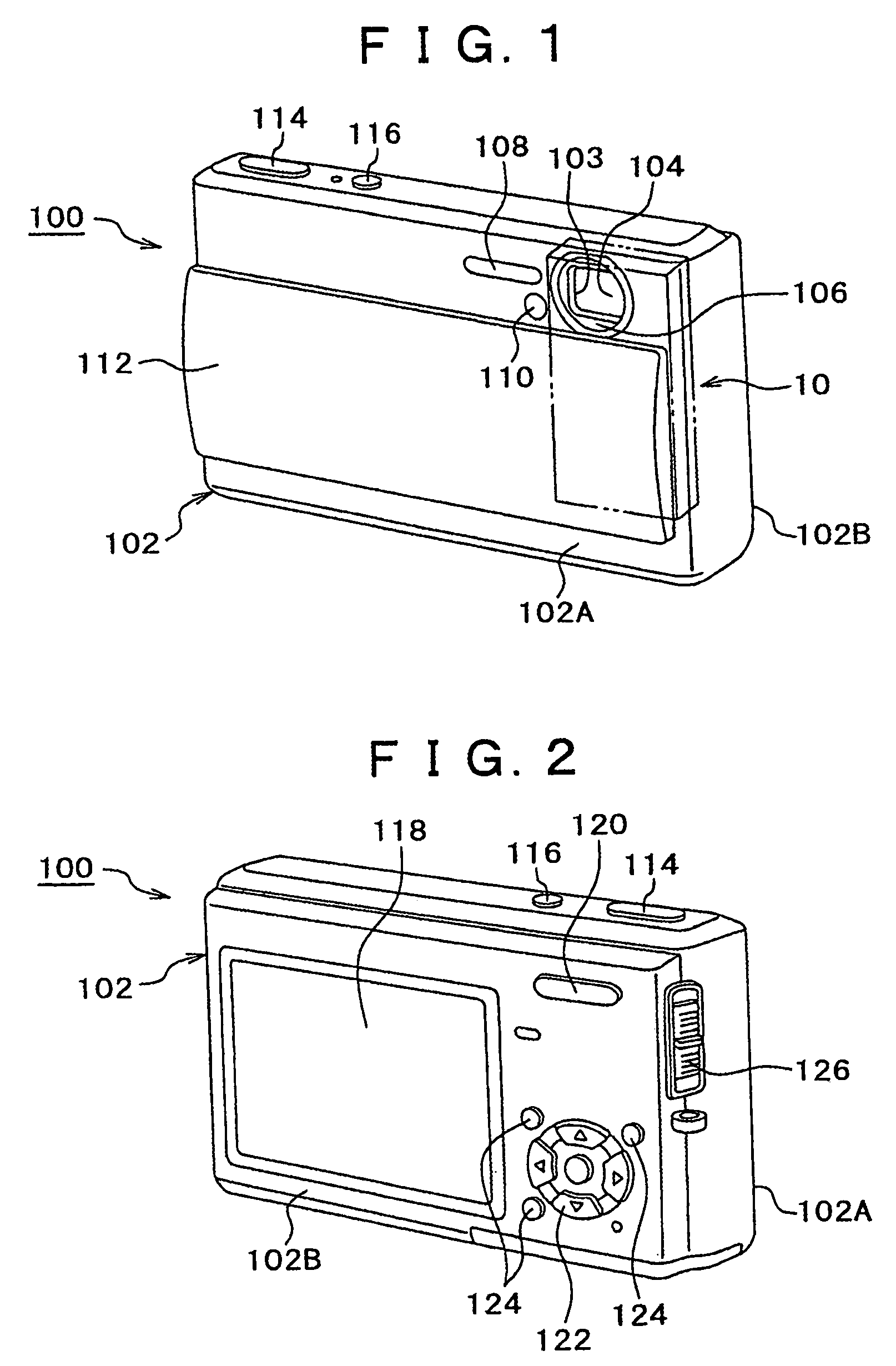

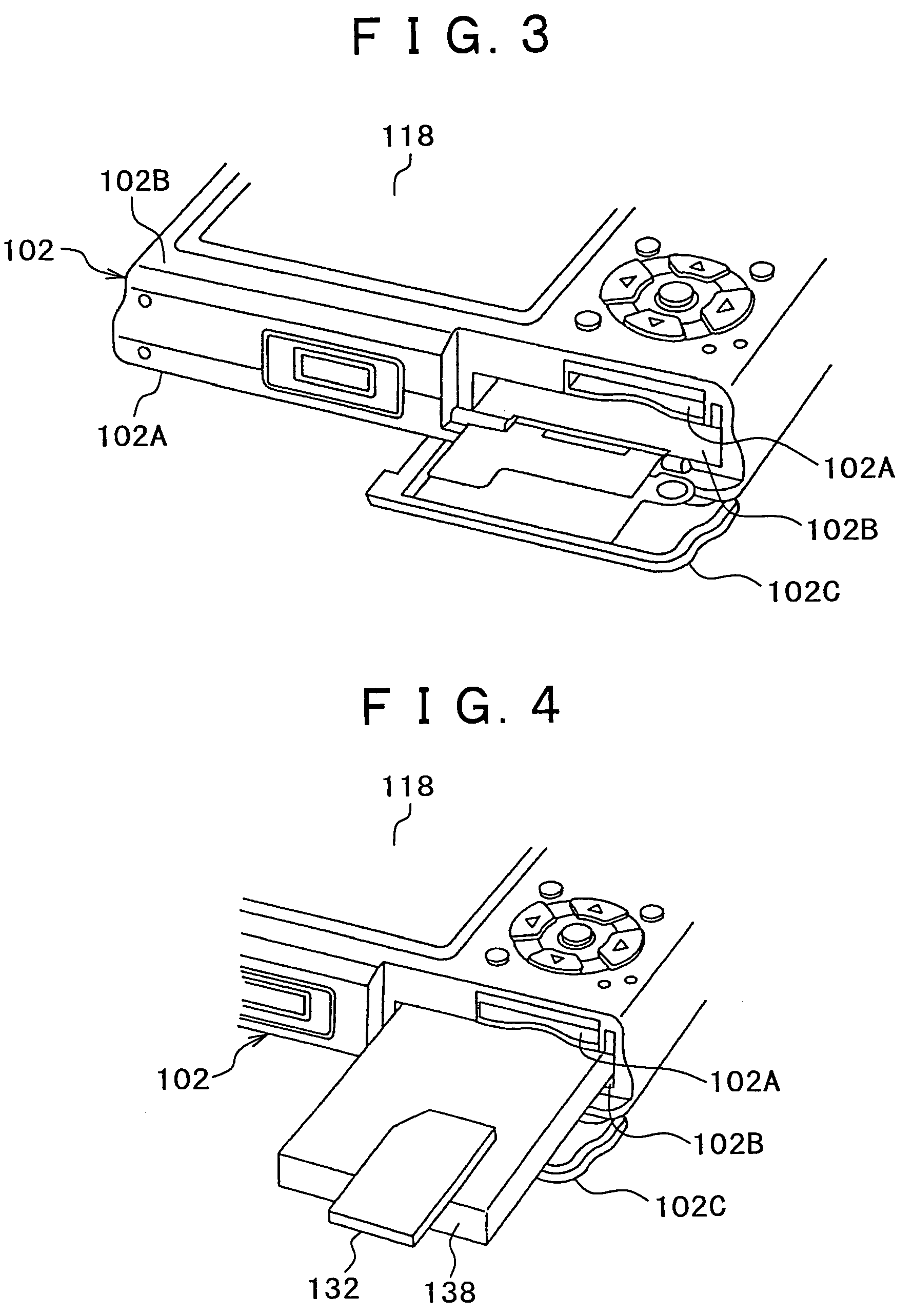

Lens barrel and imaging apparatus

InactiveUS7057829B2Reliable interconnectionExcellent in termTelevision system detailsPrinted circuit assemblingFlexible circuitsMiniaturization

A lens barrel and an imaging apparatus is provided for securely connecting an imaging element with an imaging circuit and advantageous in terms of downsizing of devices. A plurality of first connecting terminals is provided to a bottom face of an imaging element package. A flexible circuit board is constituted by an imaging element mounting section, an extending section and a connecting section. The imaging element mounting section includes a flexible circuit board and a plurality of second connecting terminals provided on a surface of the flexible circuit board so that each of the second connecting terminals match with a corresponding first connecting terminal. A metal plate is mounted at a position where the outline of the metal plate matches the outline of the package or the outline of the package is placed in the outline of the metal plate as viewed from the thicknesswise direction of the package, on the rear face of the imaging-element mounting section.

Owner:SONY CORP

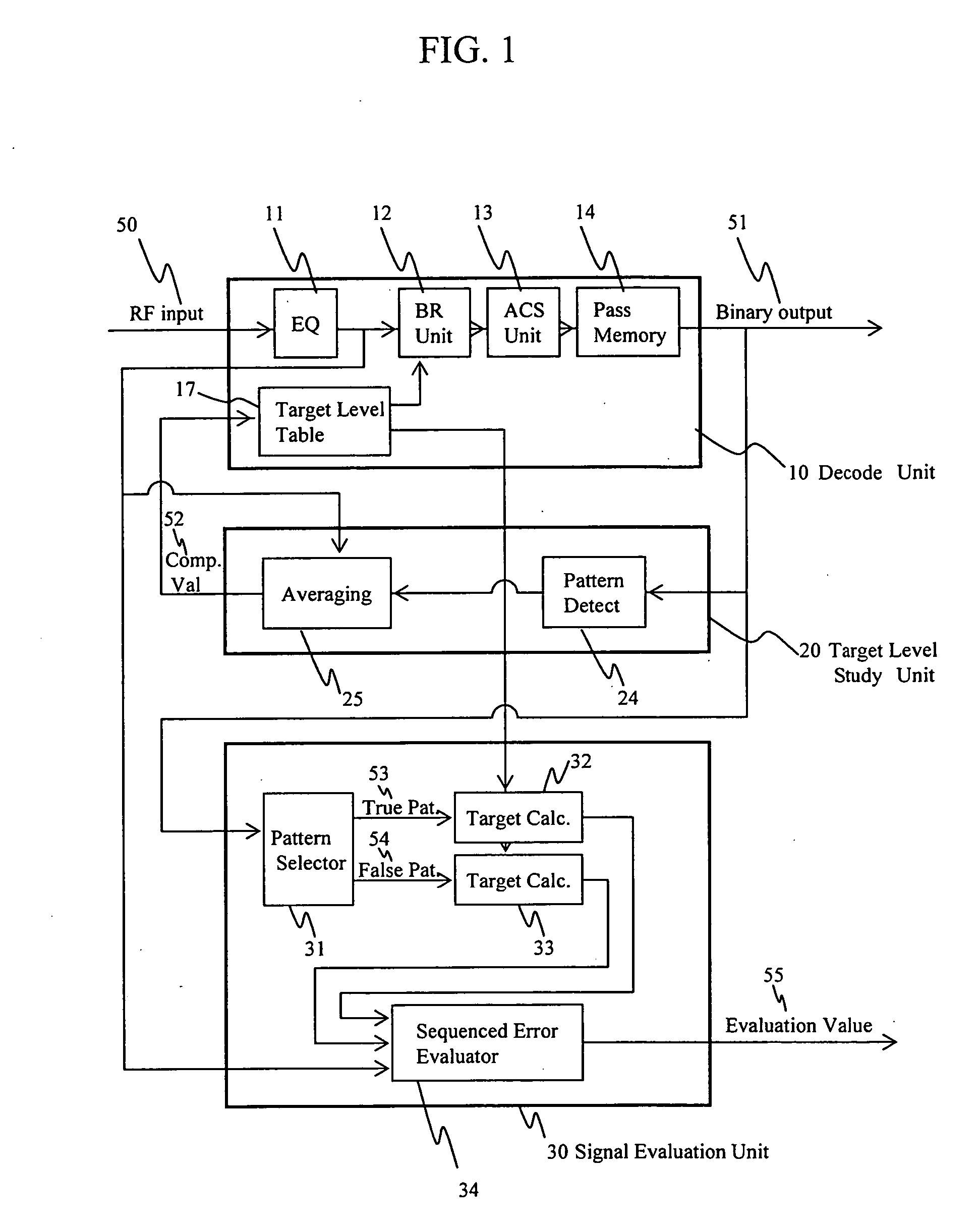

Method of evaluating a readout signal, and optical disc apparatus

InactiveUS7440522B2Improve performanceReduce the amount of calculationModification of read/write signalsOptical beam sourcesViterbi decoderSignal quality

A method of evaluating the quality of a read signal from the viewpoint of the detection margin of a Viterbi decoder in the PRML method in which a target signal level varies depending on the read signal, and an optical disc apparatus implementing the method. A method of evaluating the quality of a signal pattern comprising a combination of minimum run lengths from the viewpoint of edge shift, and an optical disc apparatus implementing the method. From the target signal level that varies depending on the read signal, a target signal is generated based on a decoding result, and an error target signal is generated in which the decoding result is edge-shifted. The signal quality is evaluated by calculating a Euclidean distance between these signals and the read signal. A virtual state that is not included in the Viterbi decoder and that is less than the minimum run length is defined, and a target signal level for the virtual state is generated using a target signal level table inside the Viterbi decoder, based on the concept of convolution. In this way, the signal quality can be evaluated by the same method as mentioned above even in cases where the pattern of a combination of the minimum run lengths has edge-shifted.

Owner:HITACHI-LG DATA STORAGE +1

Method for Improving the Thermostability of Sucrose Phosphorylase (Sp)

ActiveUS20080206822A1High activityImprove thermal stabilitySugar derivativesMicrobiological testing/measurementSucrose phosphorylaseChemistry

A sucrose phosphorylase (SP) having improved thermostability obtained by modifying a natural SP and a method for producing the SP having improved thermostability is provided. This SP having improved thermostability has an amino acid residue which is different from that of the natural sucrose phosphorylase, in at least one position selected from the group consisting of a position corresponding to position 14, a position corresponding to position 29 and a position corresponding to position 44 in motif sequence 1; a position corresponding to position 7, a position corresponding to position 19, a position corresponding to position 23 and a position corresponding to position 34 in motif sequence 2; and a position corresponding to position 19 in motif sequence 3, and wherein the enzyme activity of the SP having improved thermostability at 37° C., after heating the SP having improved thermostability in 20 mM Tris buffer (pH 7.0) at 55° C. for 20 minutes, is 20% or more of enzyme activity of the SP having improved thermostability at 37° C. before heating.

Owner:EZAKI GLICO CO LTD

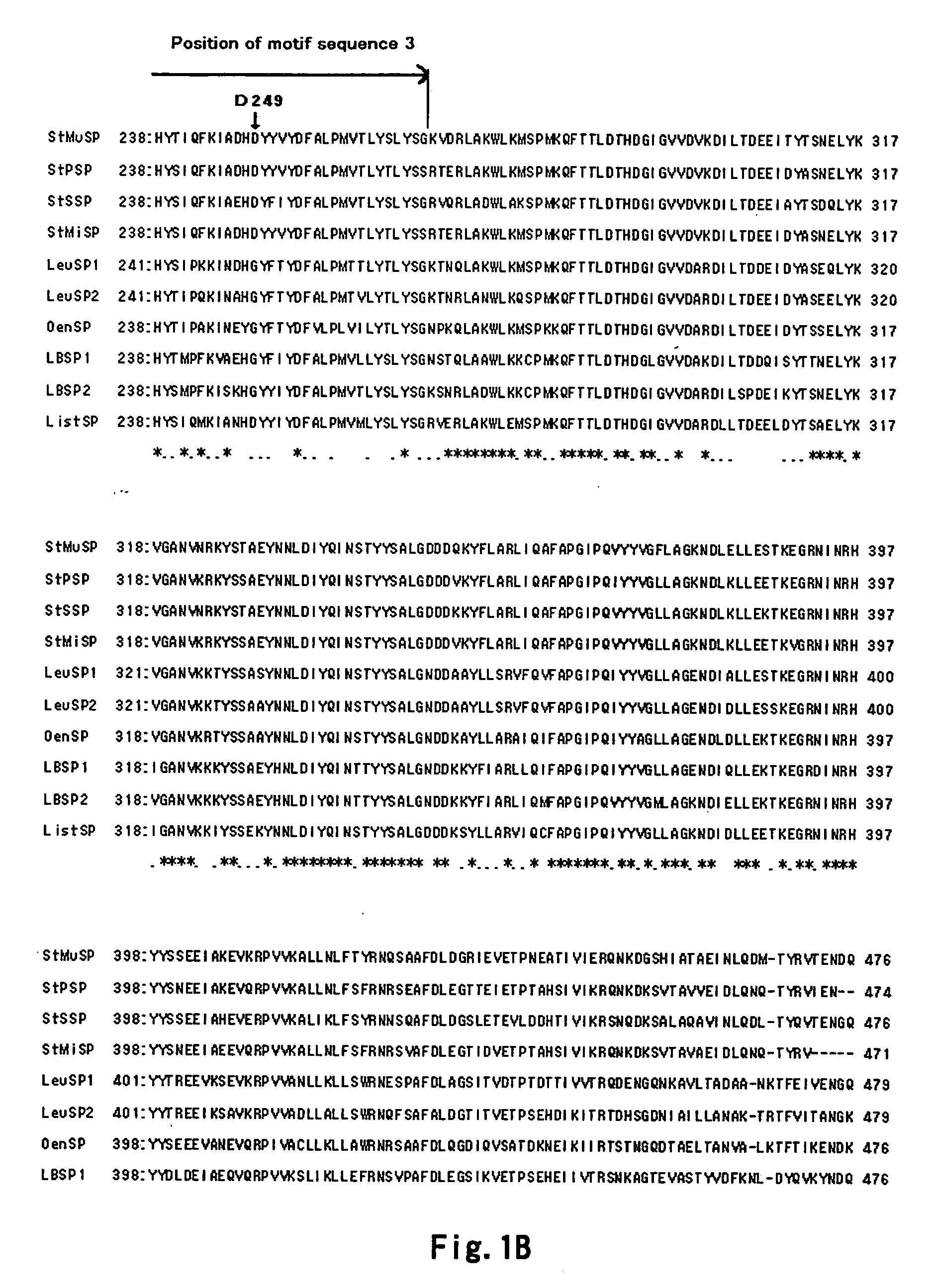

Method and system for mortgage exchange

InactiveUS20080120227A1Convenient transactionAccurate representationFinanceUser inputDecision matrix

A method and system for electronically facilitating real estate transactions by providing accurate representations of the loans a borrower is qualified to receive, which are based on actual data, rather than estimates. All actions required for completing the real estate transaction, from entry of the borrower information to the closing and funding of the loan, are seamlessly integrated. An automated underwriting engine is provided for generating a decision matrix based on user input and / or existing data. An appropriate loan is selected based on the decision matrix, and is communicated to a potential borrower. After a loan is selected, fulfillment processing is performed, and the loan is funded and closed.

Owner:LAUREL M LEE FLORIDA SEC OF STATE & SUCCESSORS THERETO +6

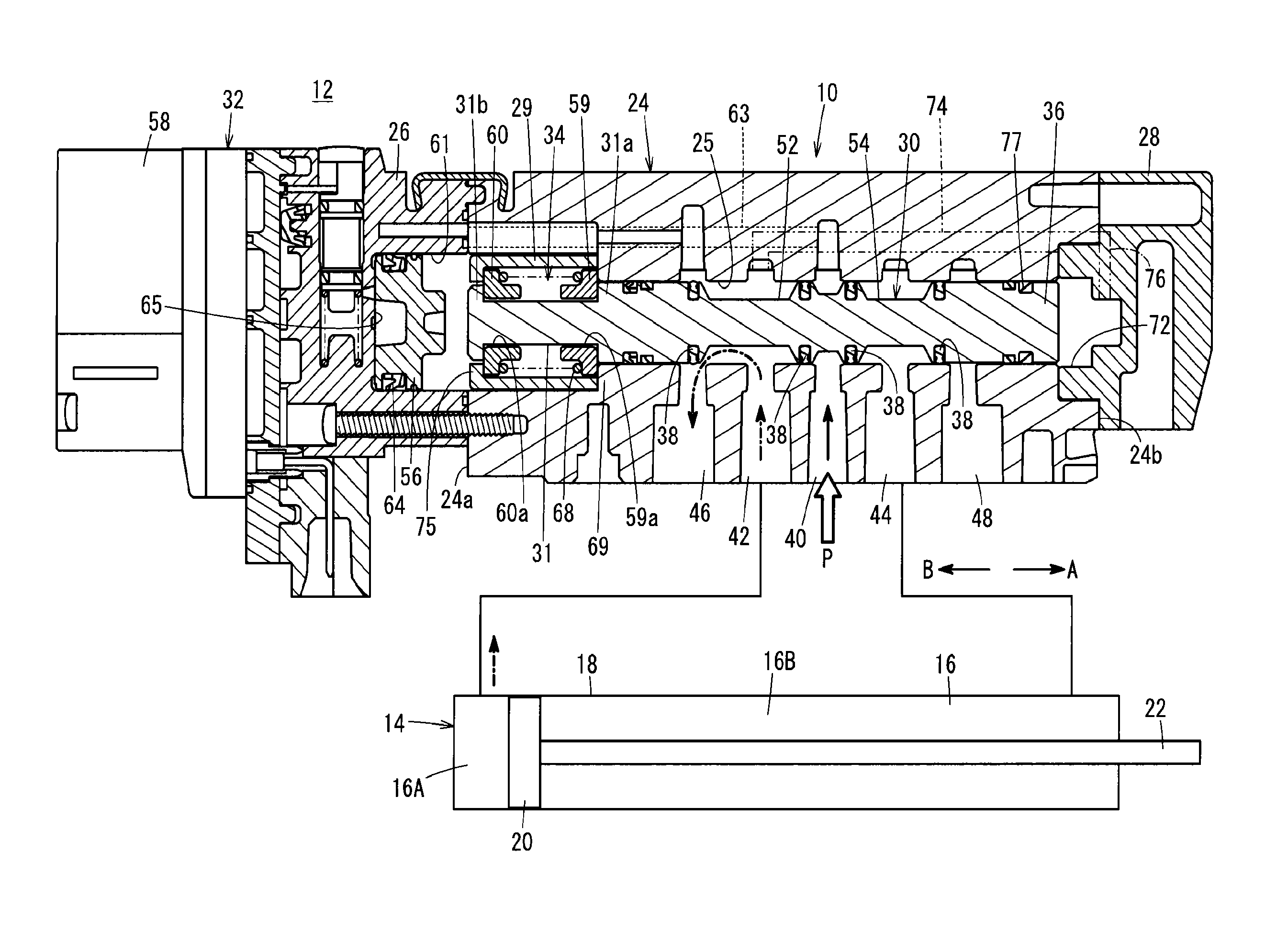

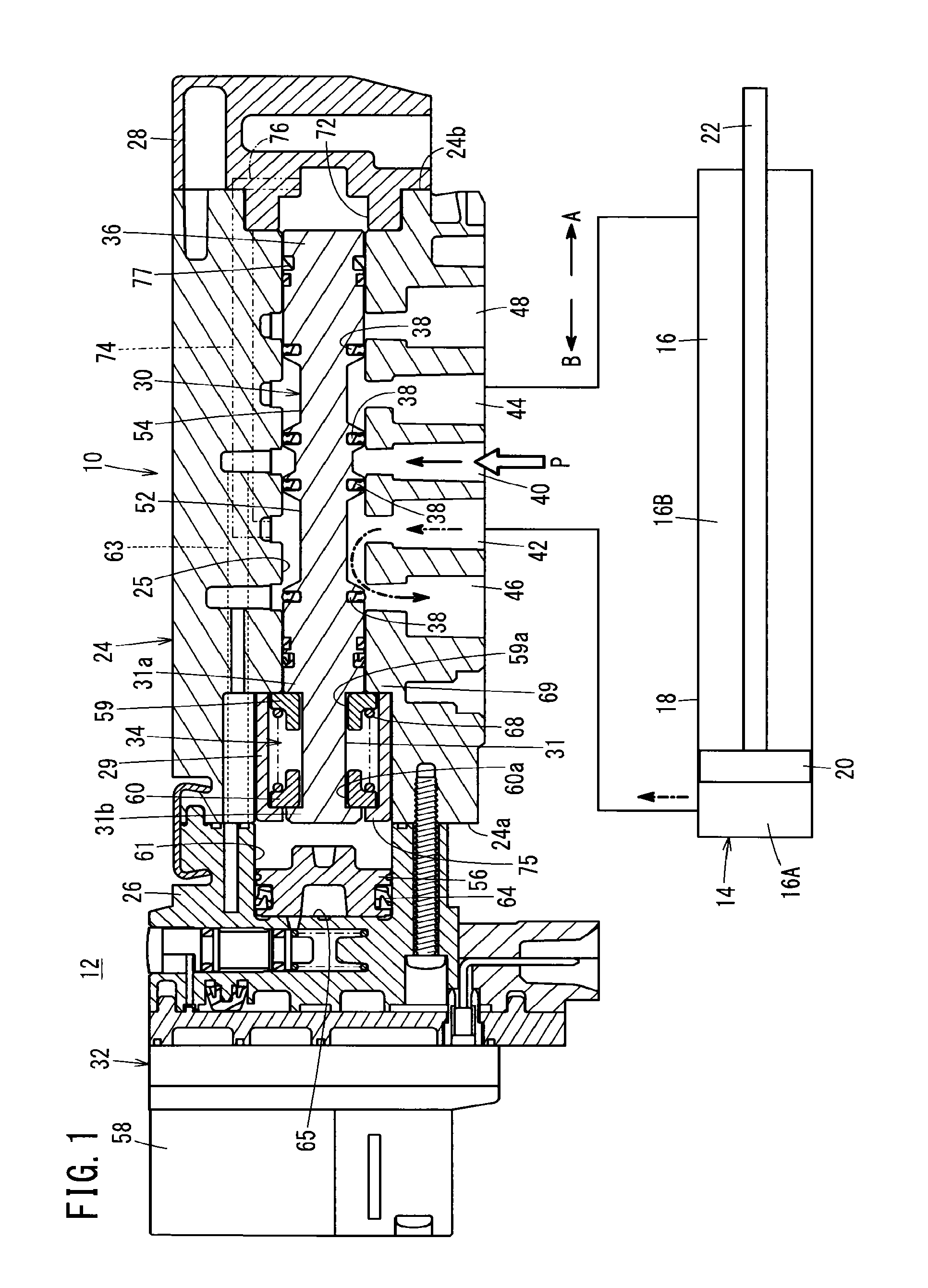

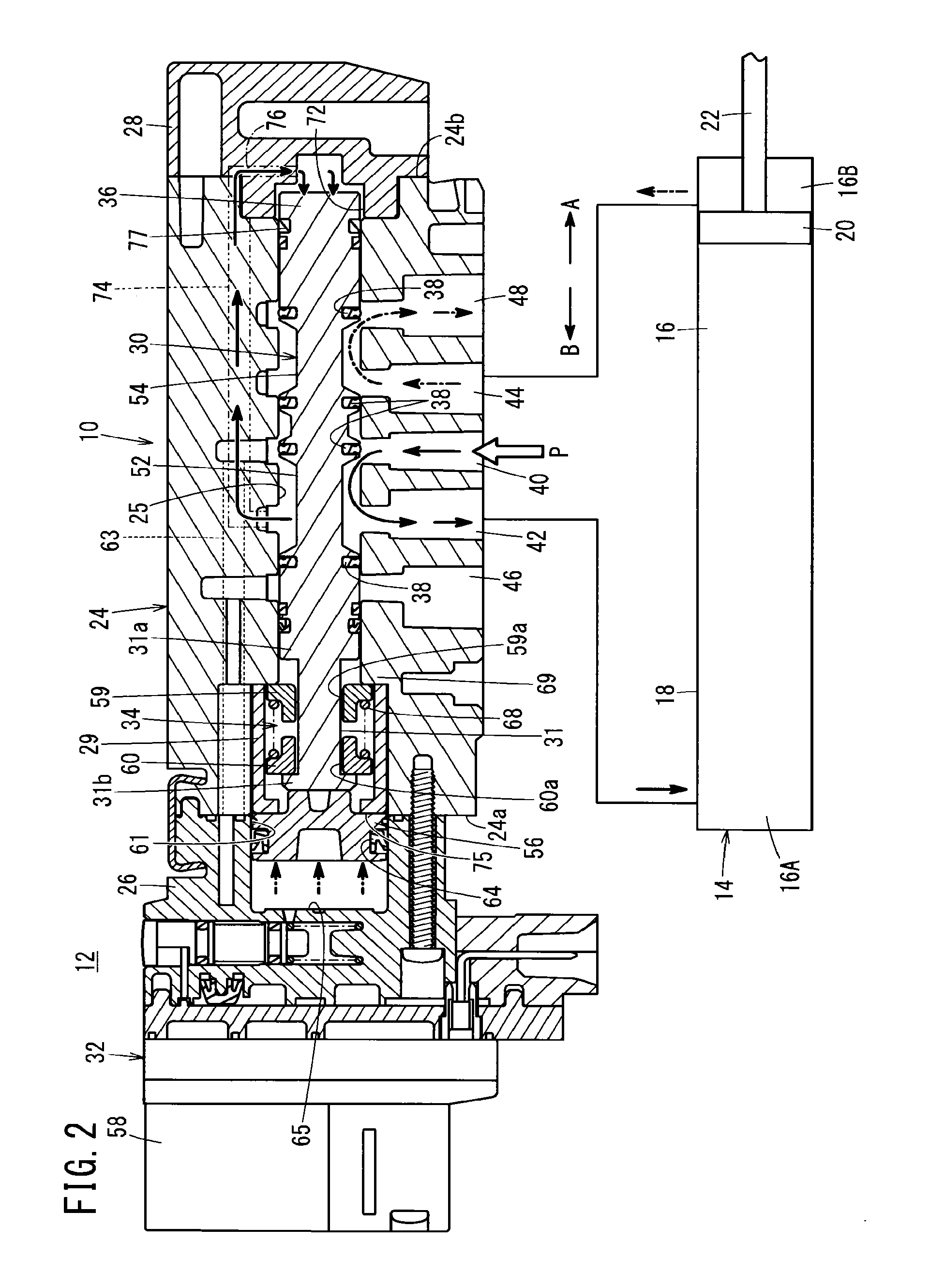

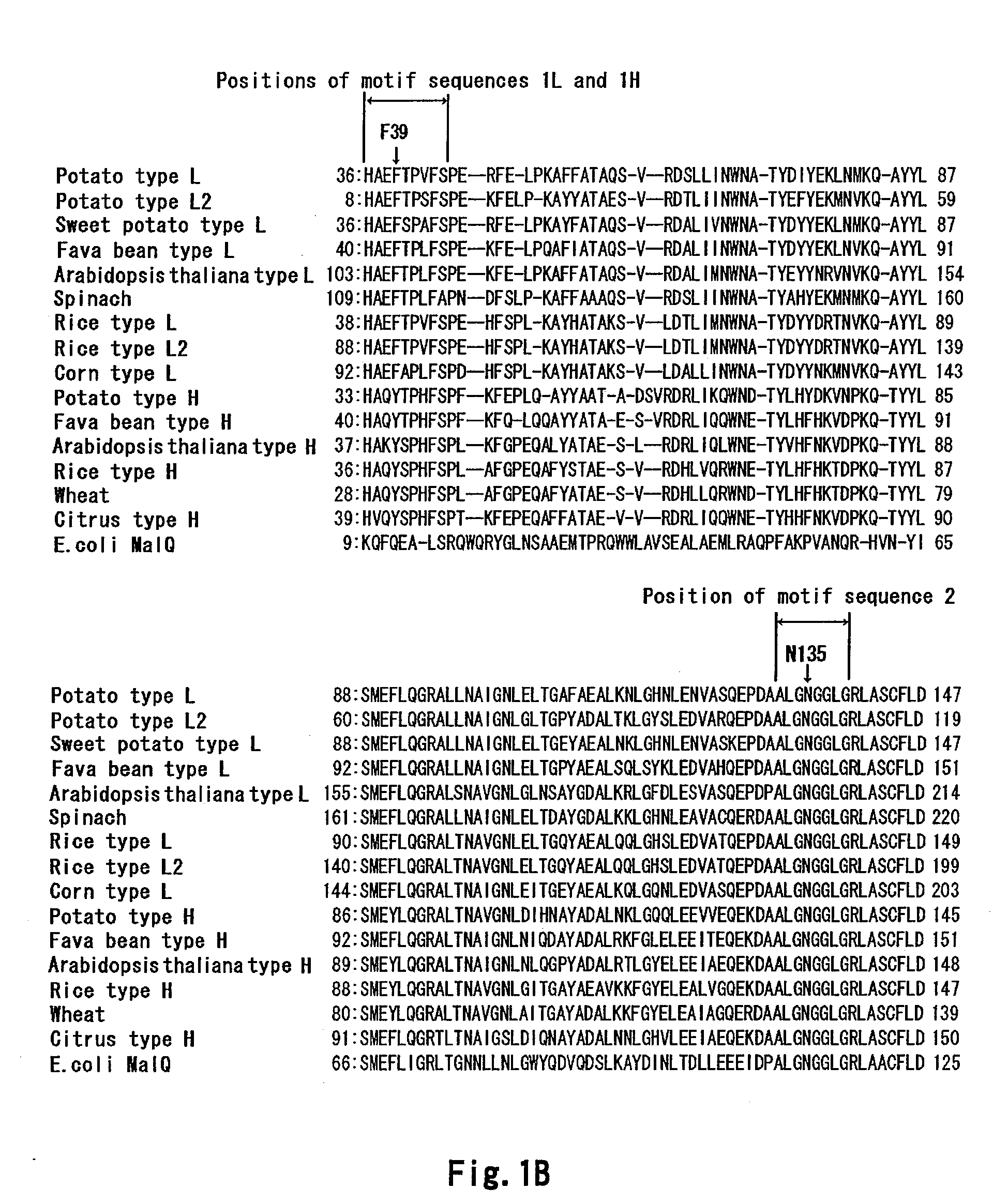

Flow passage switching unit

ActiveUS20160327168A1Suppressing running cost costSuppressing cost initial costOperating means/releasing devices for valvesServomotor componentsMechanical engineeringPiston

A flow passage switching unit includes a valve body in which plural ports are formed, a spool arranged slidably in axial directions in the interior of the valve body, a spool drive unit for driving the spool in an A direction, a biasing mechanism that is configured to bias the spool elastically in the interior of the valve body, and a piston section that exerts a force on the spool in a B direction based on the pressure of a first output port.

Owner:SMC CORP

Therapy system

InactiveUS7212858B2Quality improvementExpensive and complicated to operateHeart stimulatorsArtificial respirationComputer moduleEngineering

A medical therapy system has logic and / or signal processing stages between sensors on the input side and therapy applicators on the output side. A signal parameter is determined from the input signals using the logic / processing stages, and / or an indicator signal is determined from the input signals using a logic / processing module consisting of several logic / processing stages. The indicator signal is a measure of the probability of a future event requiring therapy, or a measure of the success of the therapy.

Owner:BIOTRONIK MESS UND THERAPIEGERAETE GMBH & CO

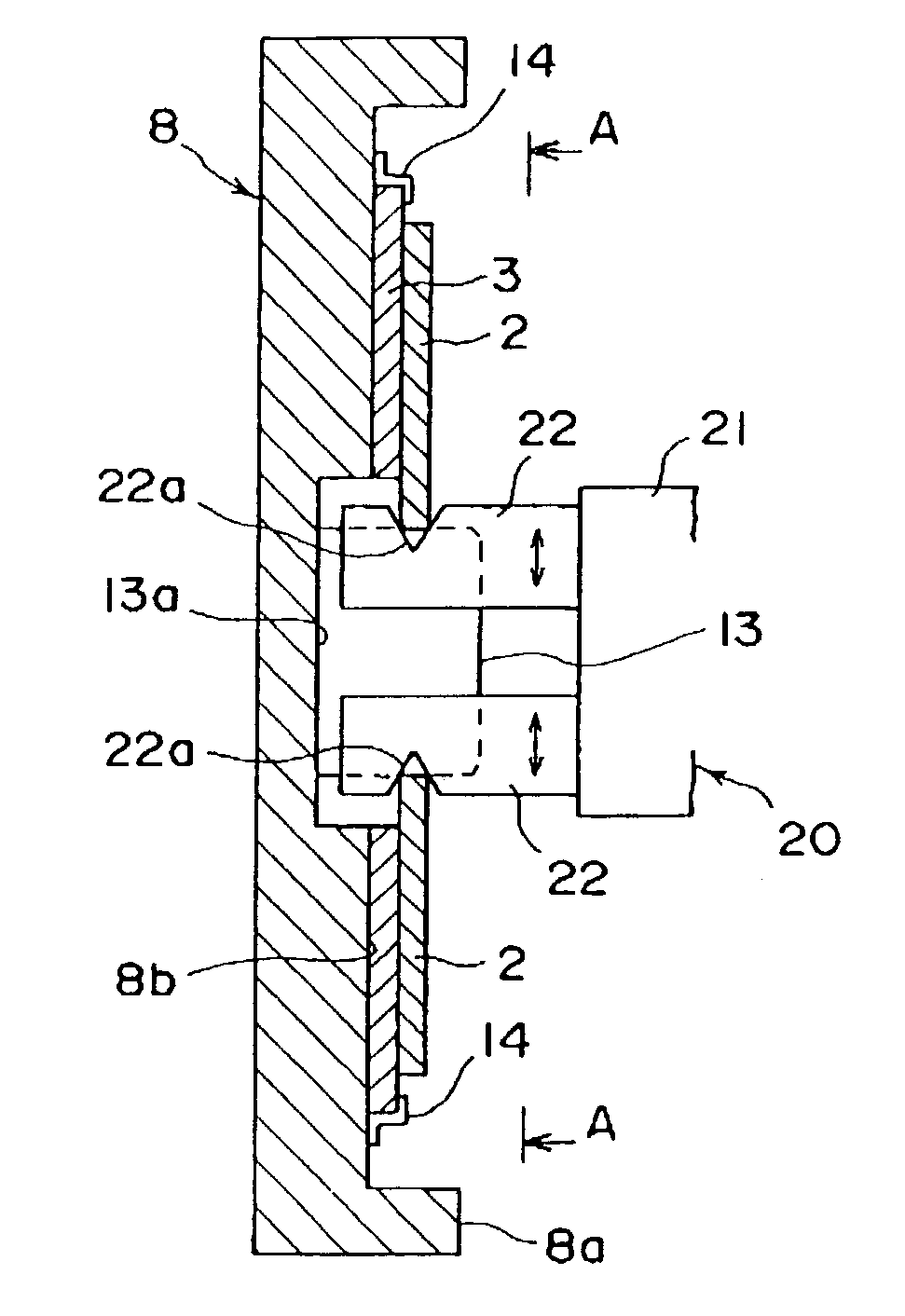

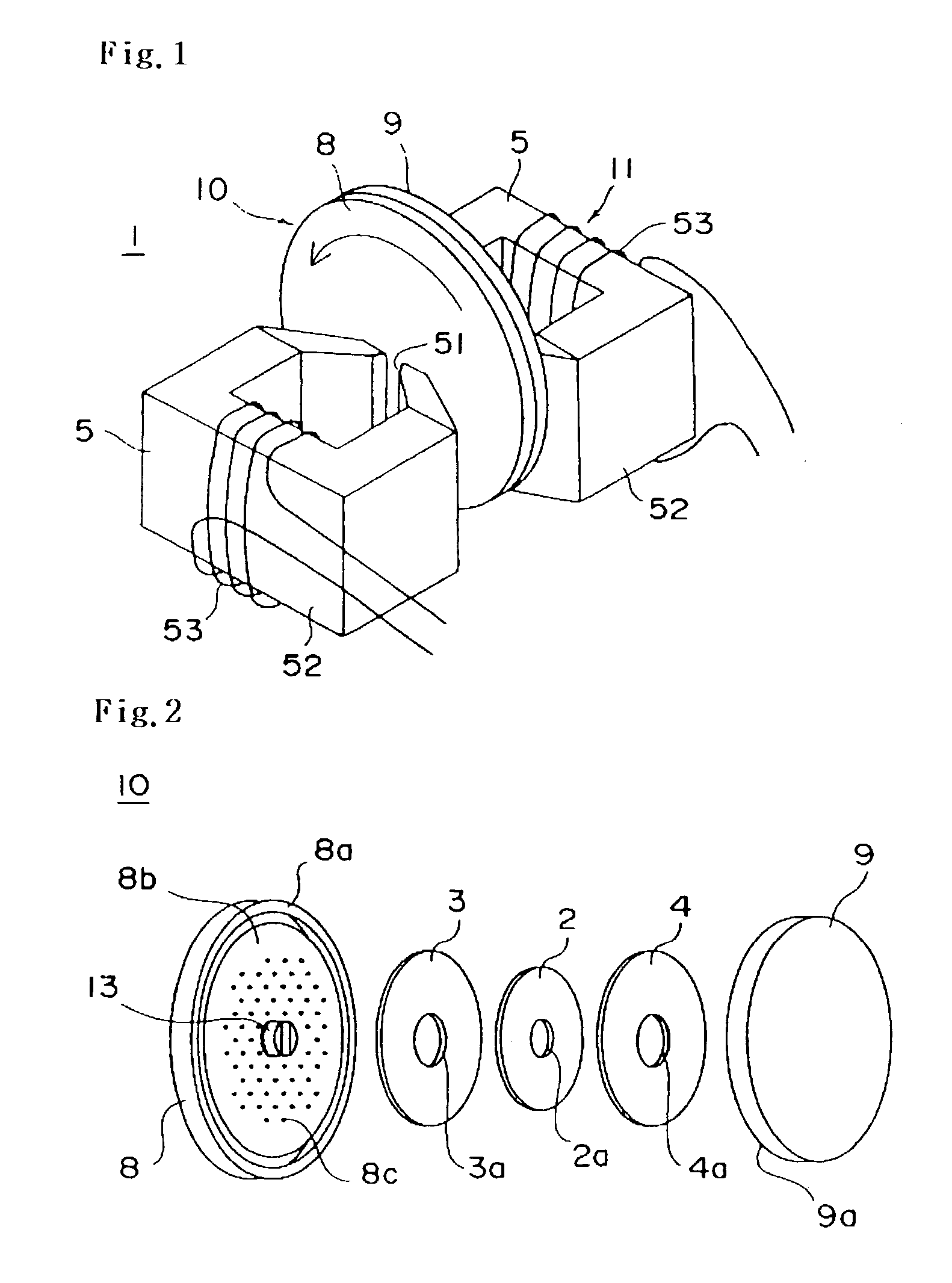

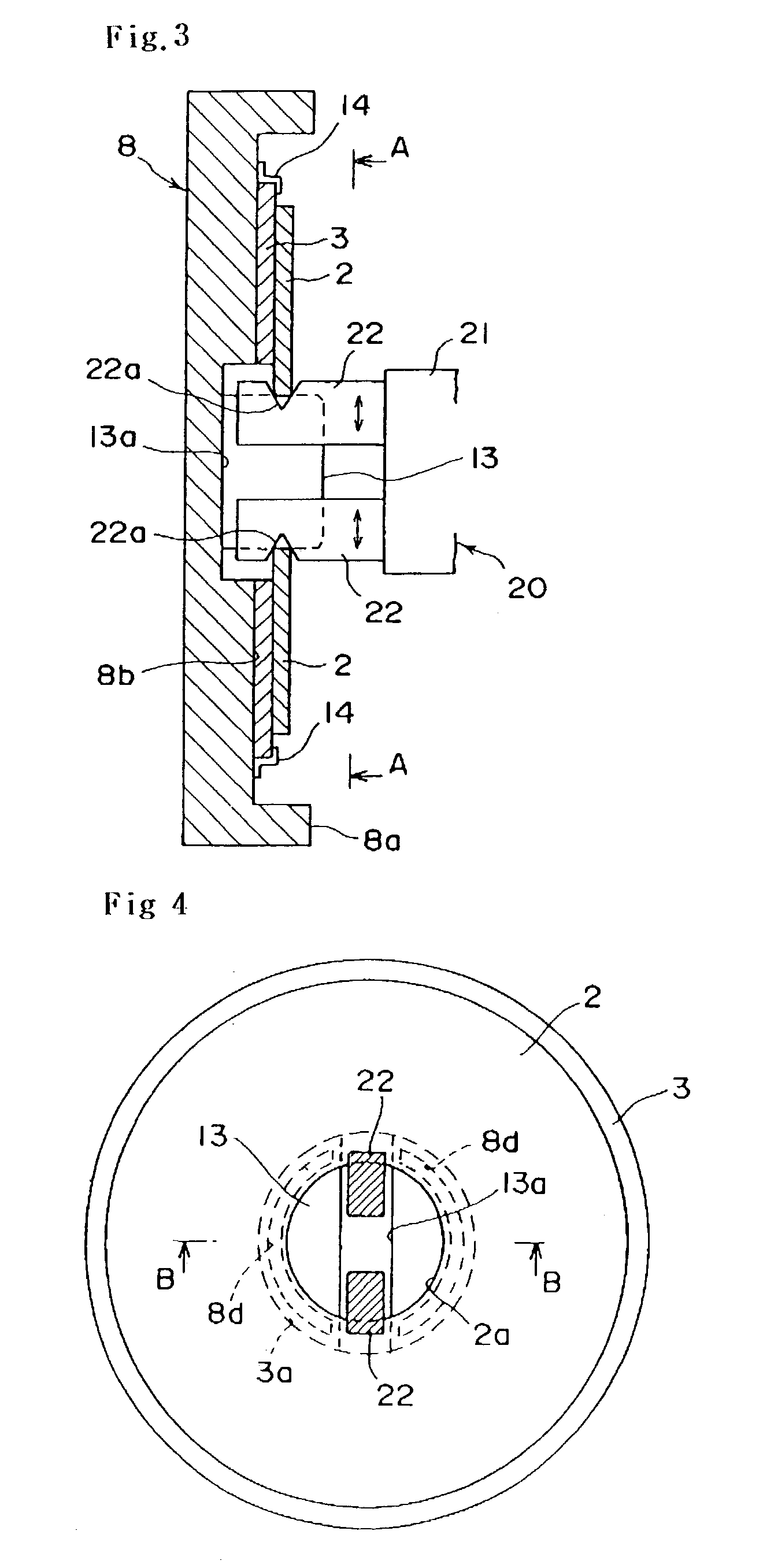

Magnetic transfer apparatus

InactiveUS7170698B2Prevent poor transferPreventing poor transferRecord information storageFlat record carrier containersElectrical and Electronics engineeringMaster controller

Disclosed is a magnetic transfer apparatus capable of performing good magnetic transfer, including a holder for accommodating a master carrier with transfer patterns corresponding to transfer information, a slave-feeding unit for feeding a slave medium with a magnetic recording part to be transferred to the master carrier, and a magnetic field application unit for applying a magnetic field in a state that the slave medium is in close contact with the master carrier, wherein the holder is provided with a slave holding shaft for positioning a central opening of the slave medium at a central portion thereof, and an inner diameter of the central opening of the slave medium is set to be smaller than that of a central opening the master carrier, and the slave-feeding unit holds an inner diameter portion of the slave medium. The inner diameter portion of the slave medium fed to the master carrier is sucked by use of suction grooves, and the slave medium is preferably brought into temporary contact with the master carrier.

Owner:FUJIFILM HLDG CORP +1

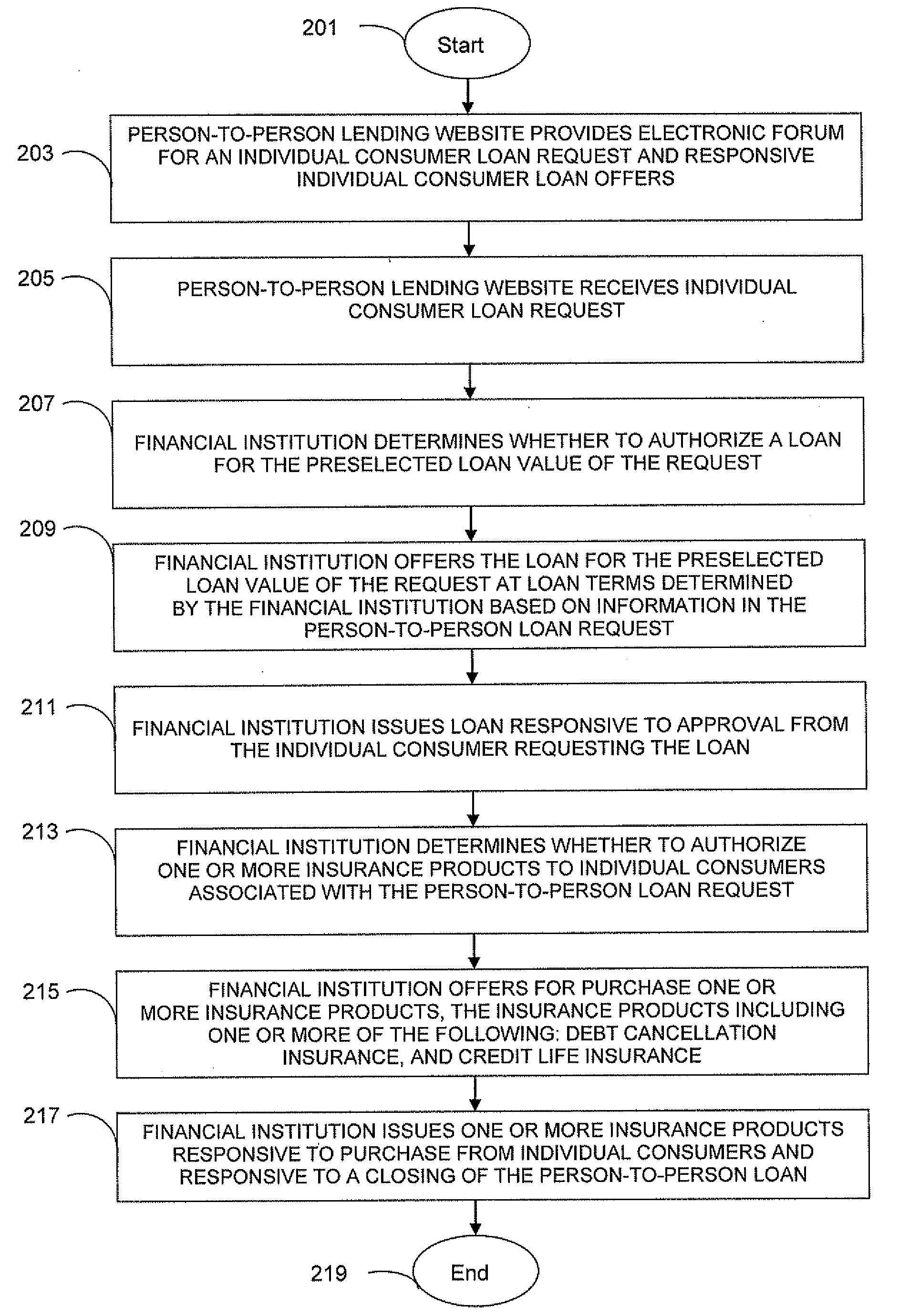

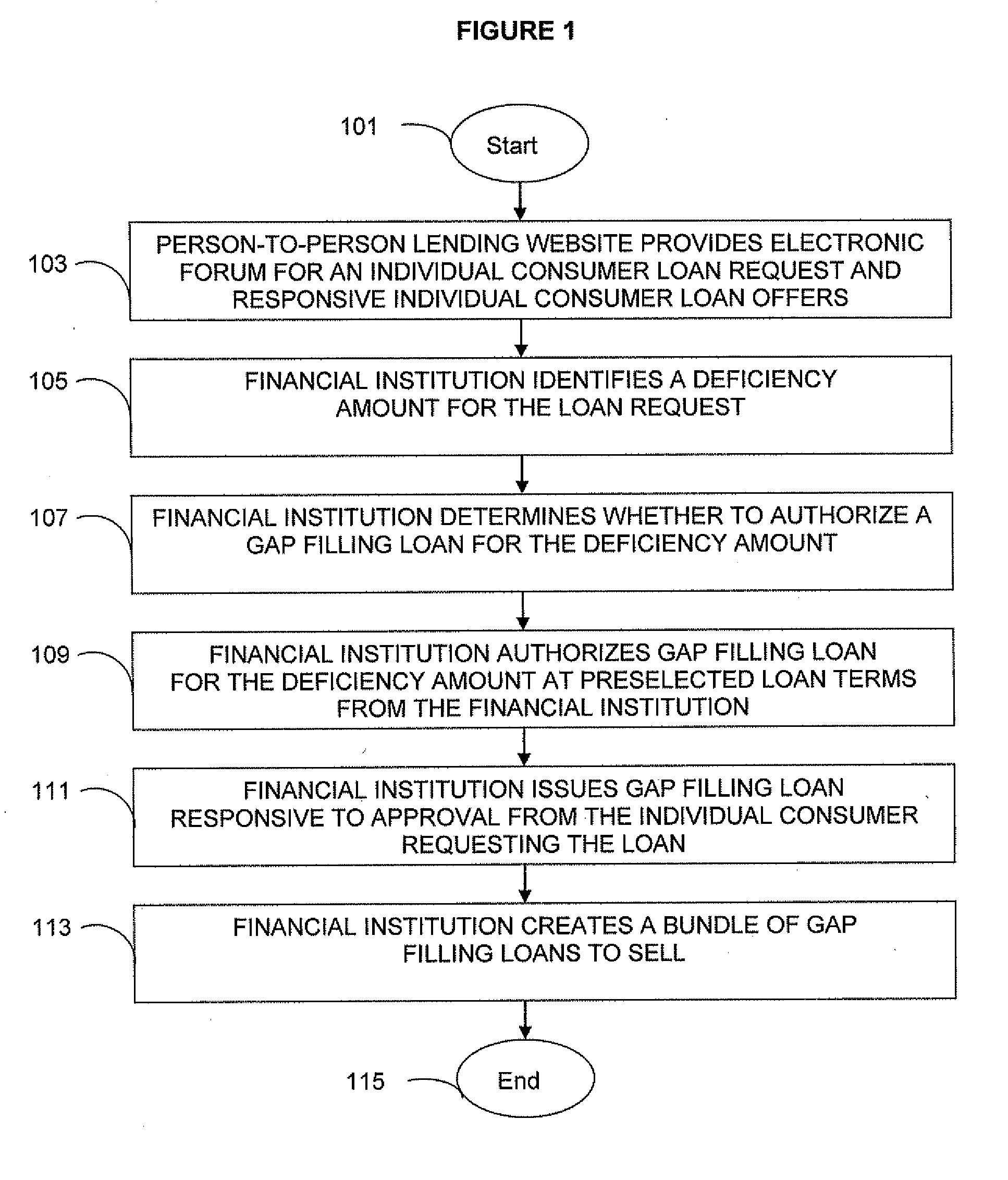

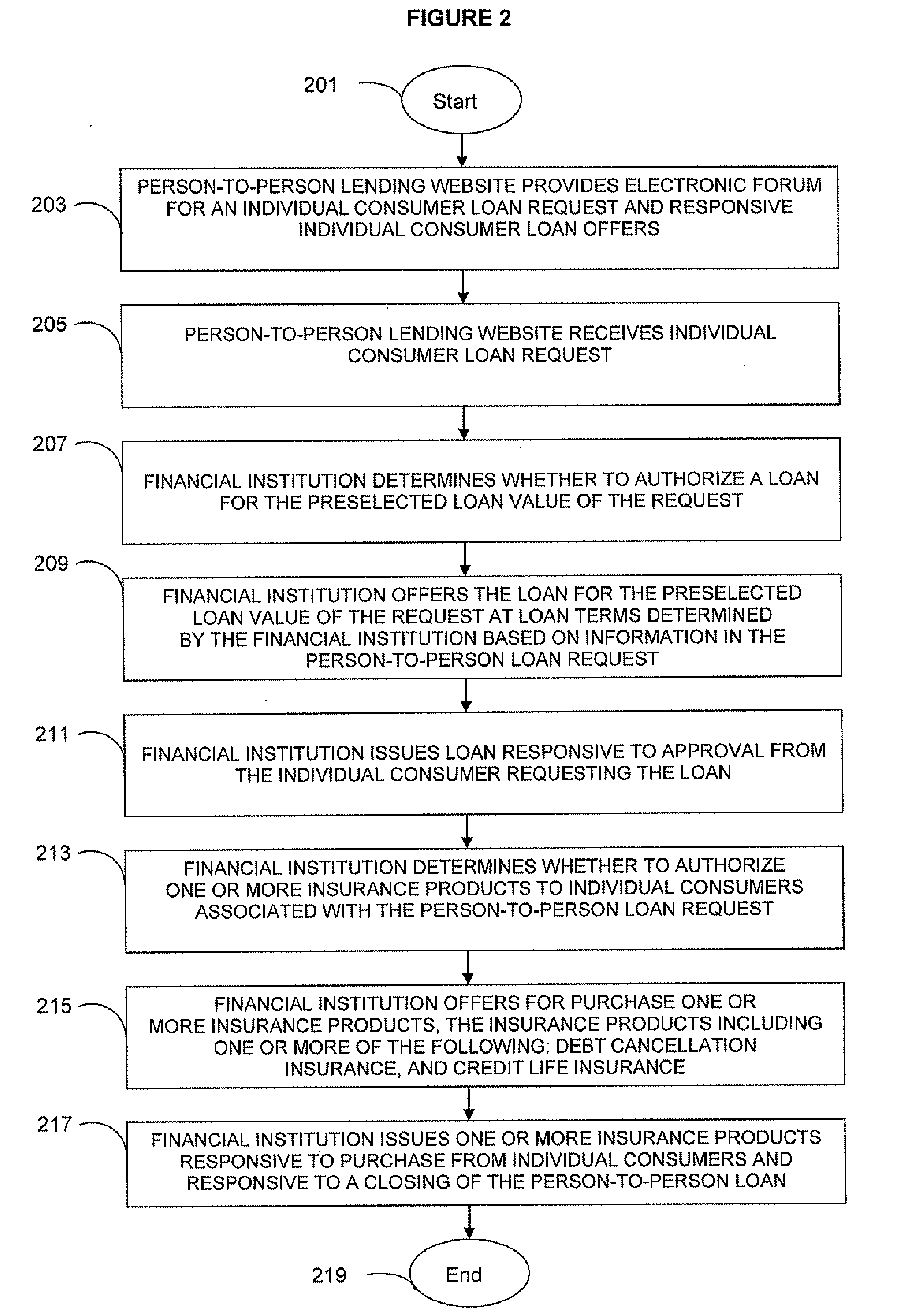

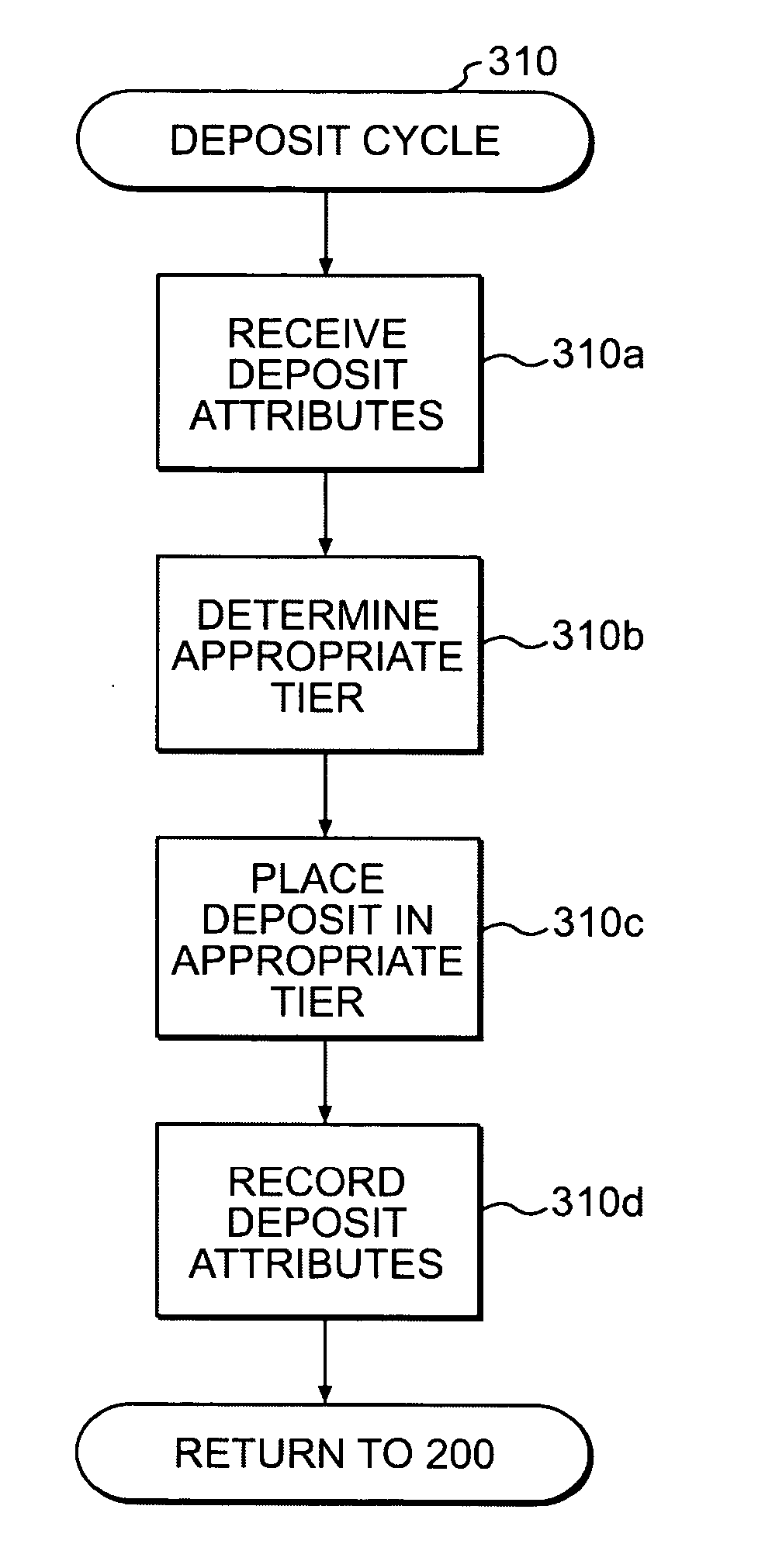

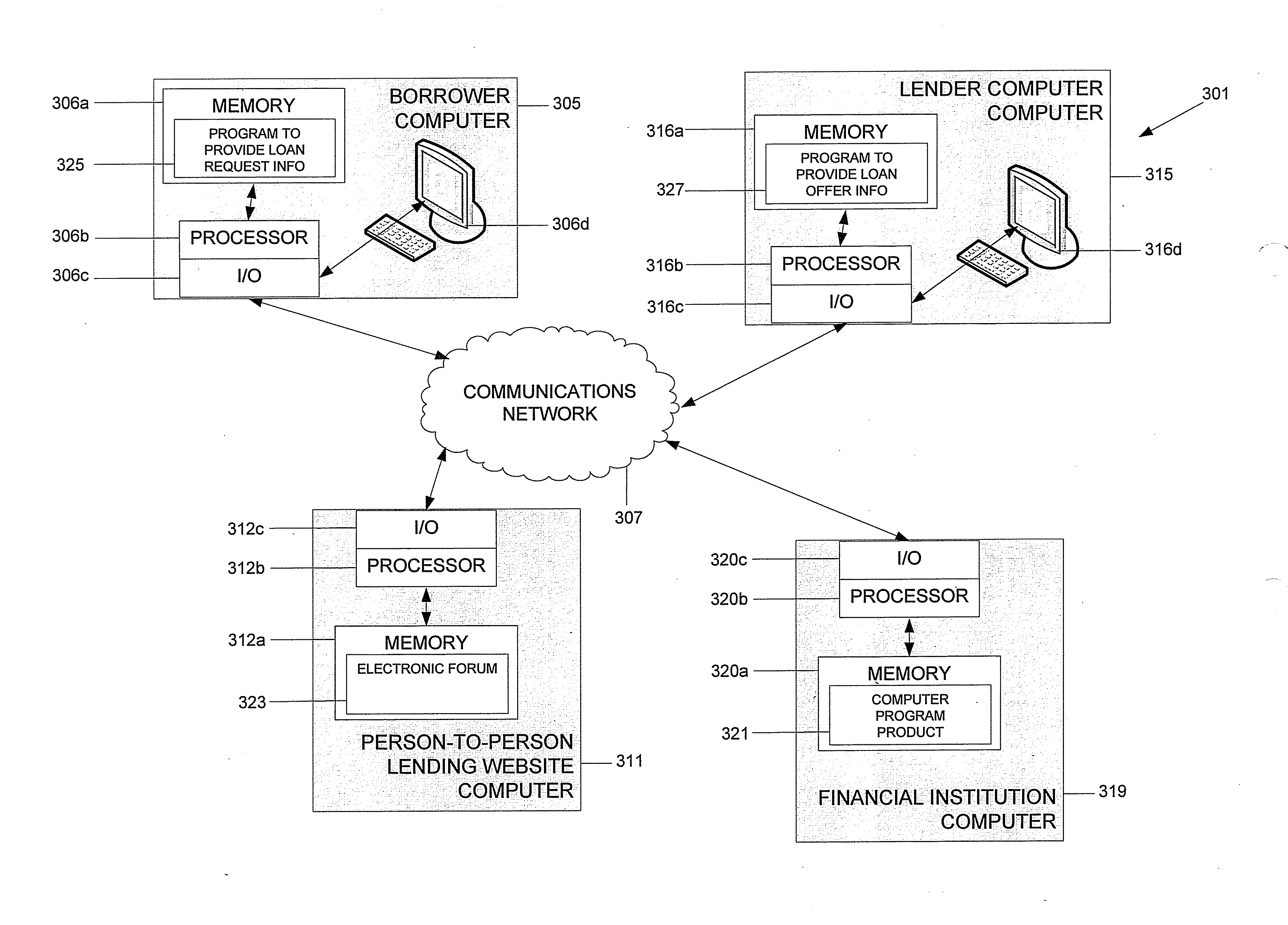

Person-to-person lending program product, system, and associated computer-implemented methods

An individual consumer borrower accessing a person-to-person lending website is provided an opportunity to have a loan request wholly or partially satisfied by a financial institution at loan terms from the financial institution. The financial institution, for example, can receive information about a person-to-person loan request, determine whether to authorize a financial institutional loan, offer a loan to the individual on terms determined by the financial institution, and issue the loan to an individual consumer borrower responsive to approval of the terms. Prior to an auction, the individual consumer can choose an immediate loan offer having financial institution terms or choose to solicit individual consumer loan offers with more favorable terms through the person-to-person lending website. The financial institution can also offer a gap filling loan for a deficiency amount so that the loan request can be partially satisfied by individual consumer loan offers.

Owner:SORBE TRENT

Ethylene-vinyl alcohol copolymer, process for producing the same, and laminate

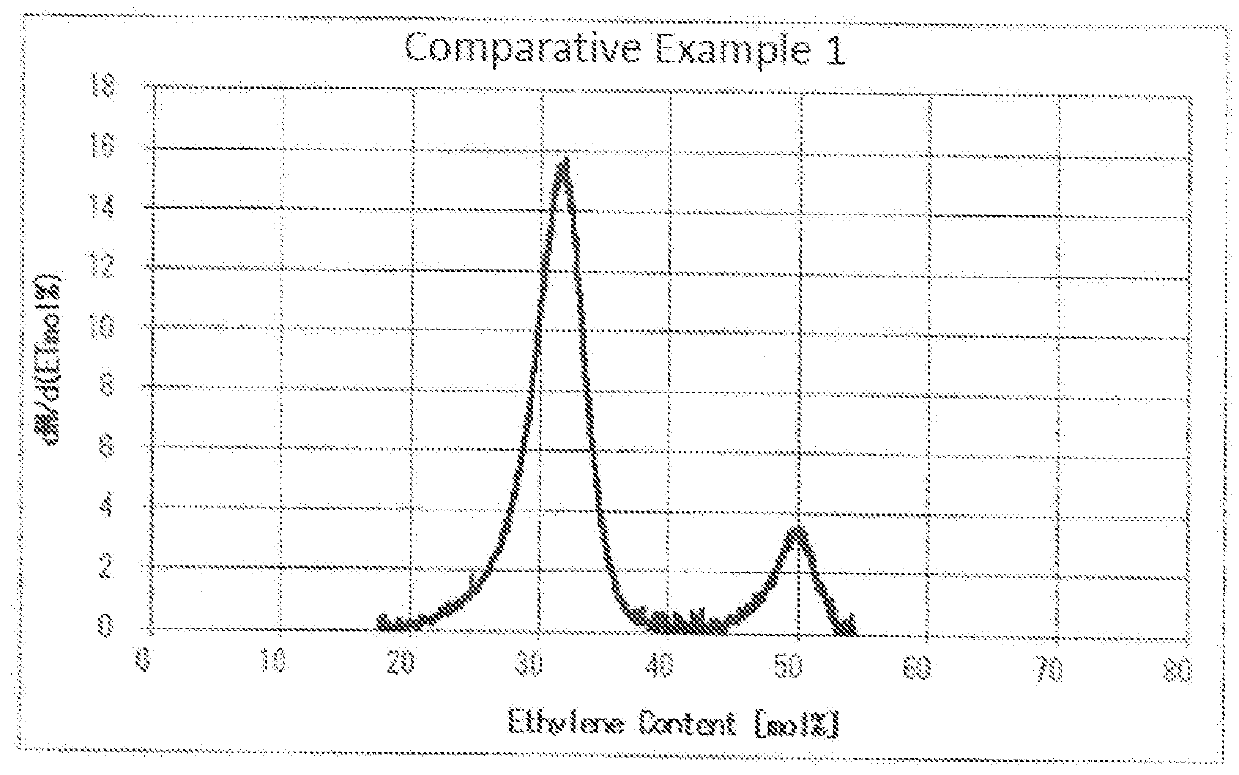

ActiveUS20180105615A1Excellent in termSynthetic resin layered productsDomestic containersContent distributionEthylene vinyl alcohol copolymer

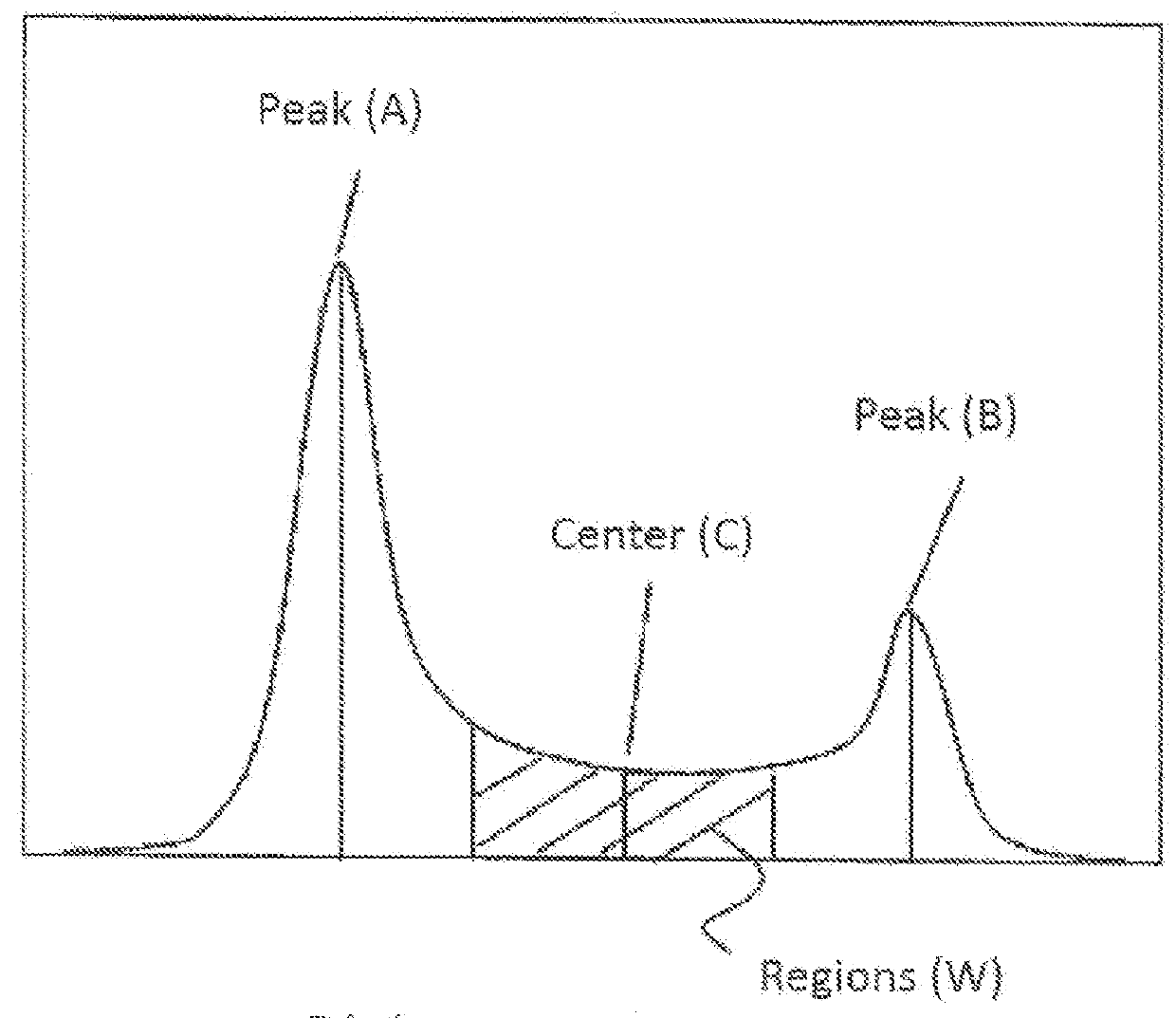

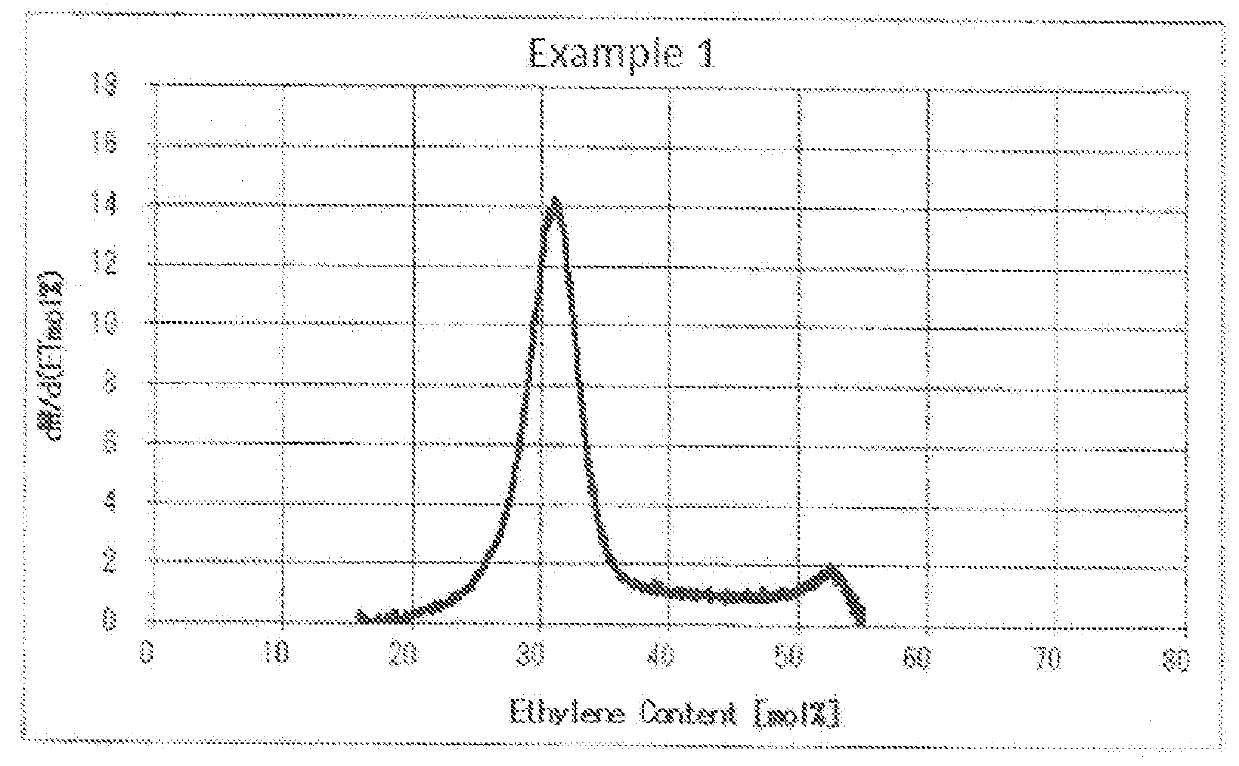

An object of the invention is to provide an EVOH which has improved melt moldability and is excellent in terms of gas barrier property and secondary formability. The present invention relates to an ethylene-vinyl alcohol copolymer that, when examined by liquid chromatography, gives an ethylene content distribution curve which has at least two peaks and in which the ethylene content (a) of a component that shows a highest peak (A), the ethylene content (b) of a component that shows a second highest peak (B), and the proportion (v) and distribution of component(s) (V) having ethylene contents (w) corresponding to specific regions (W) are within specific ranges.

Owner:MITSUBISHI CHEM CORP

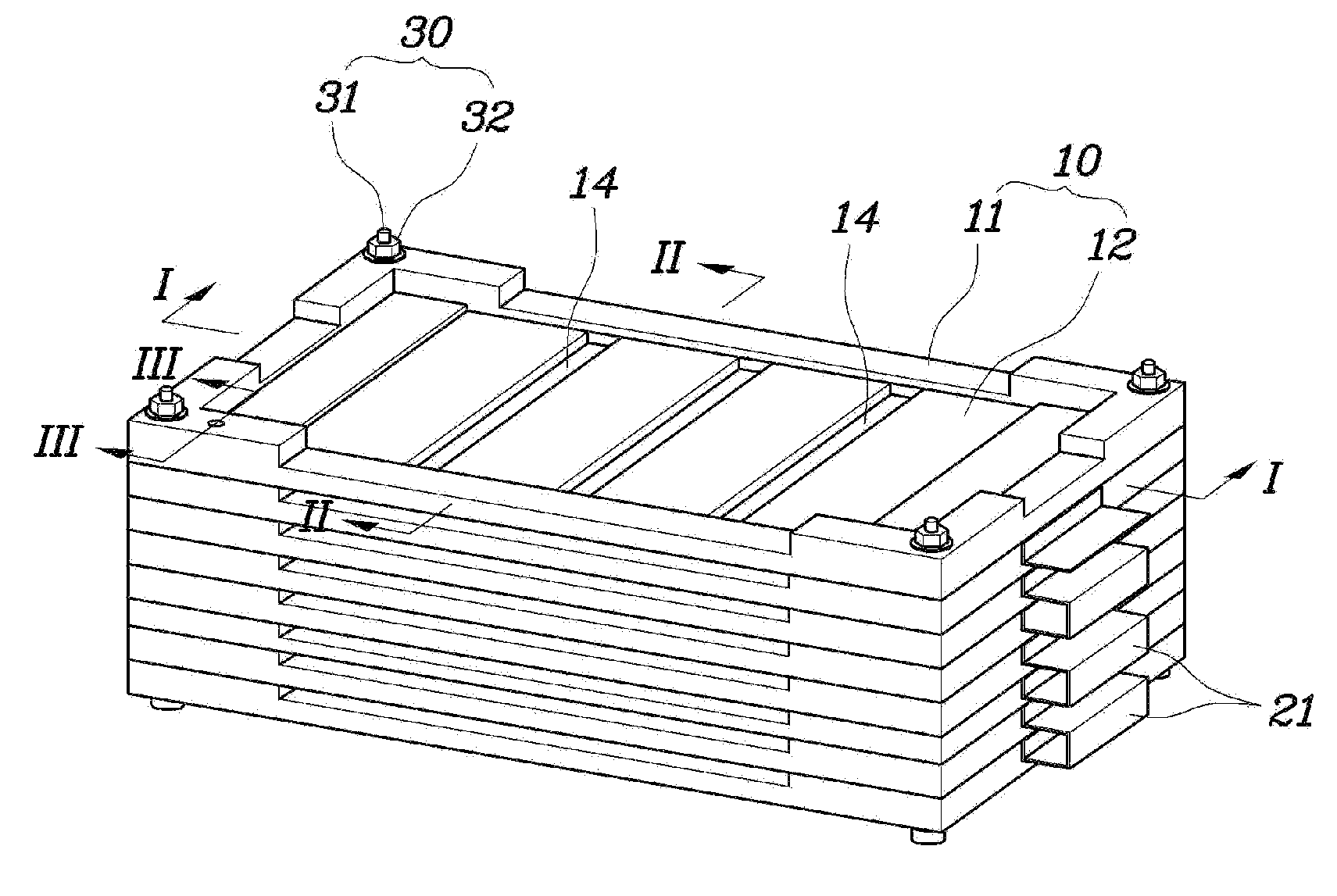

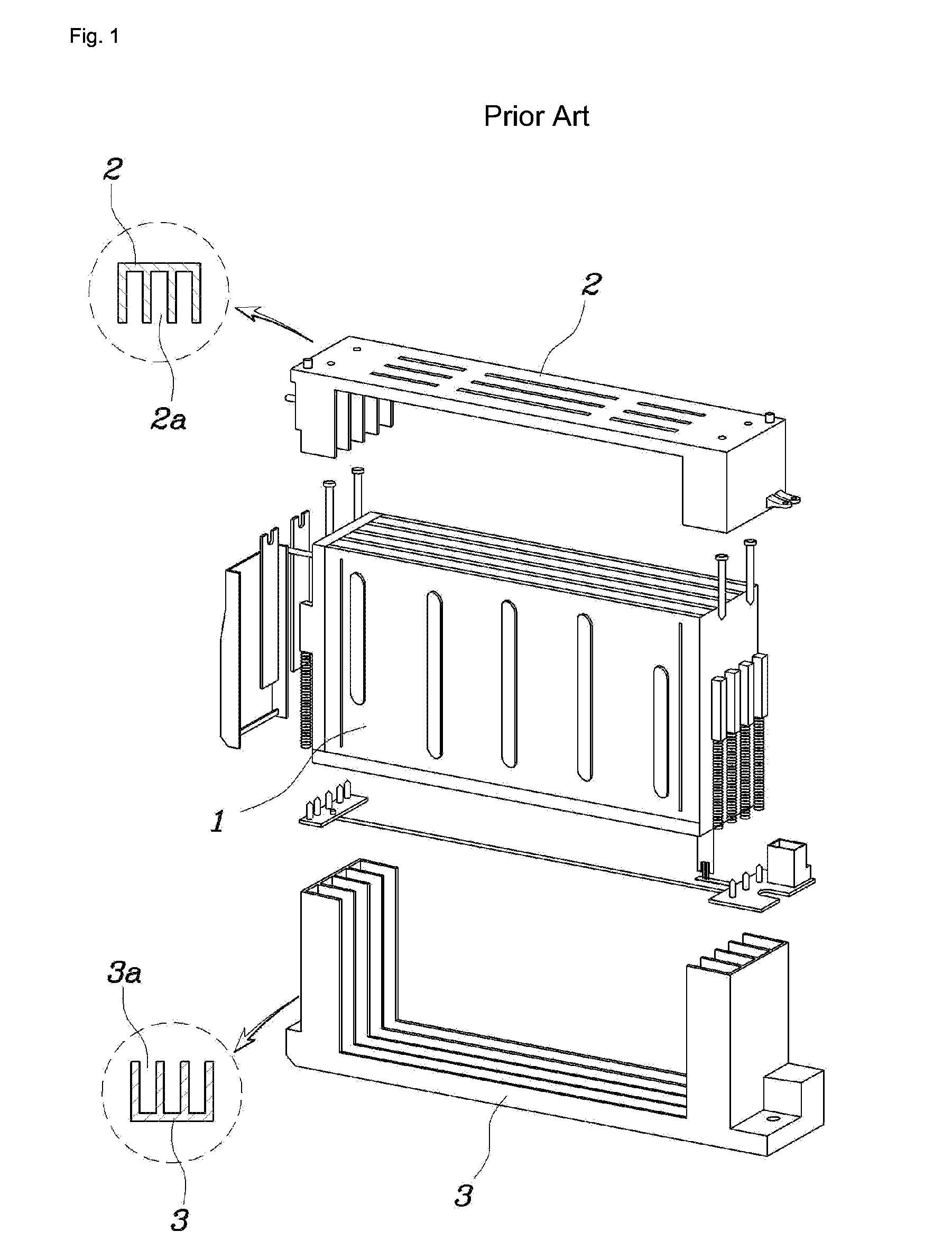

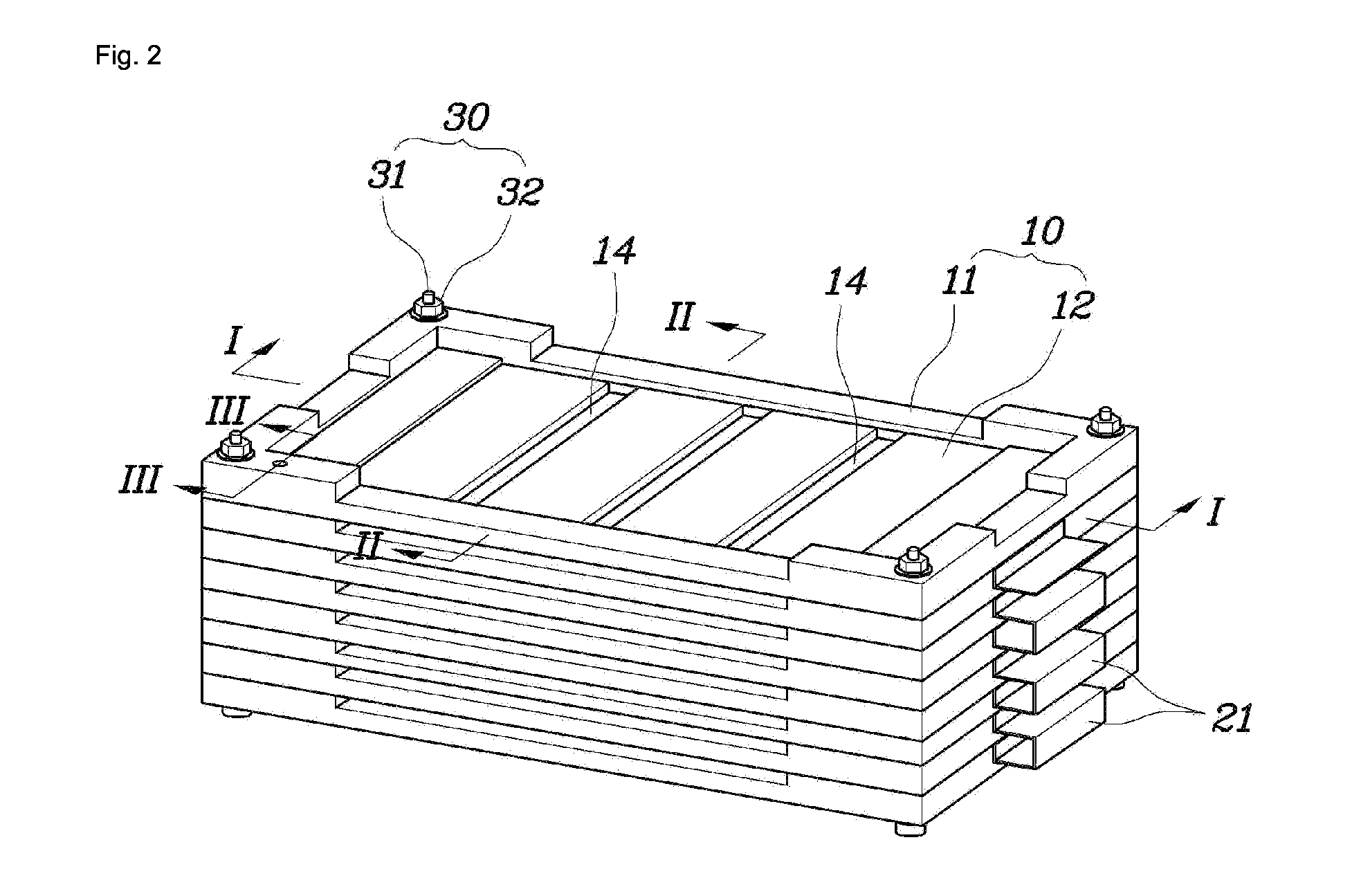

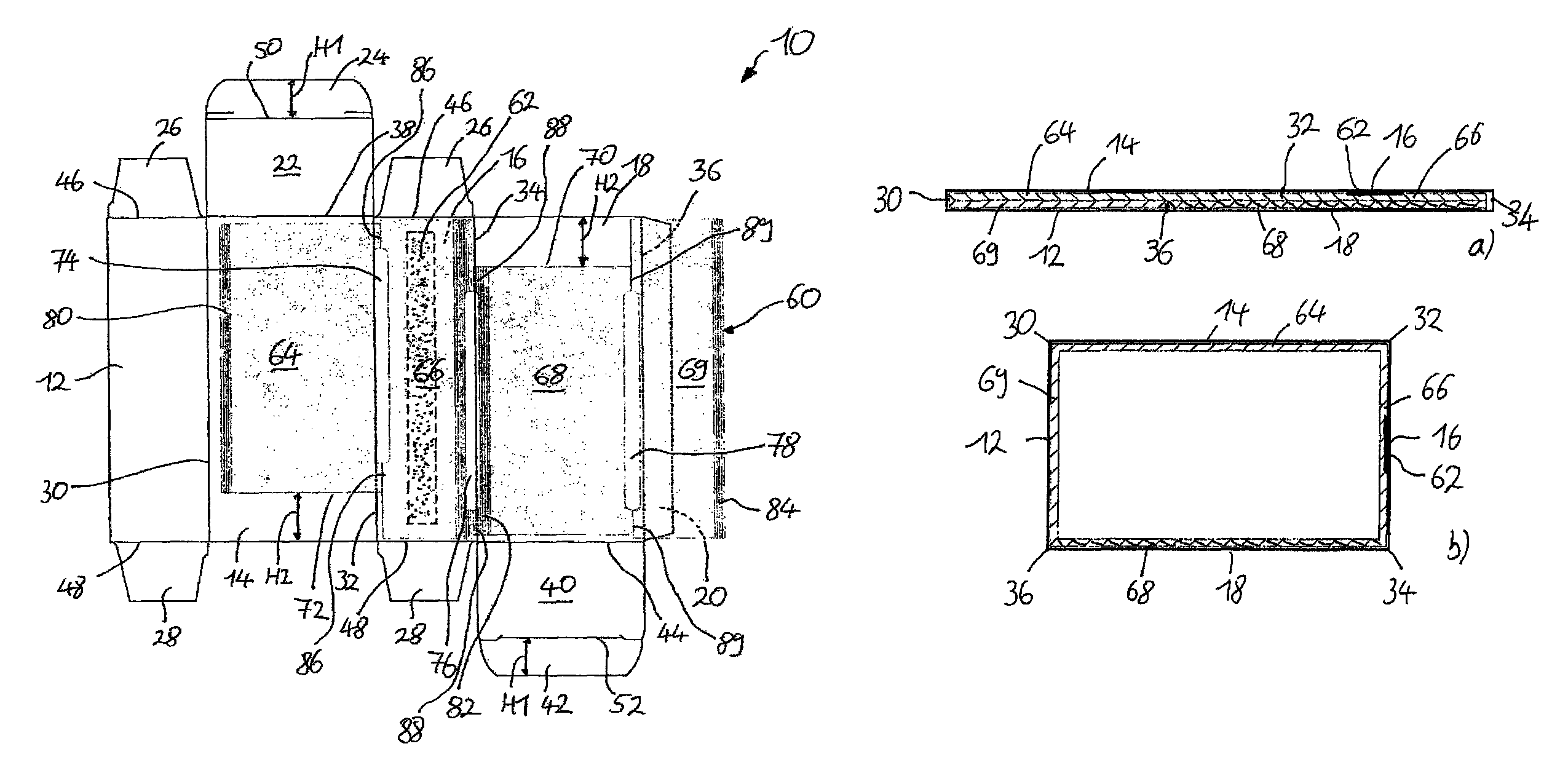

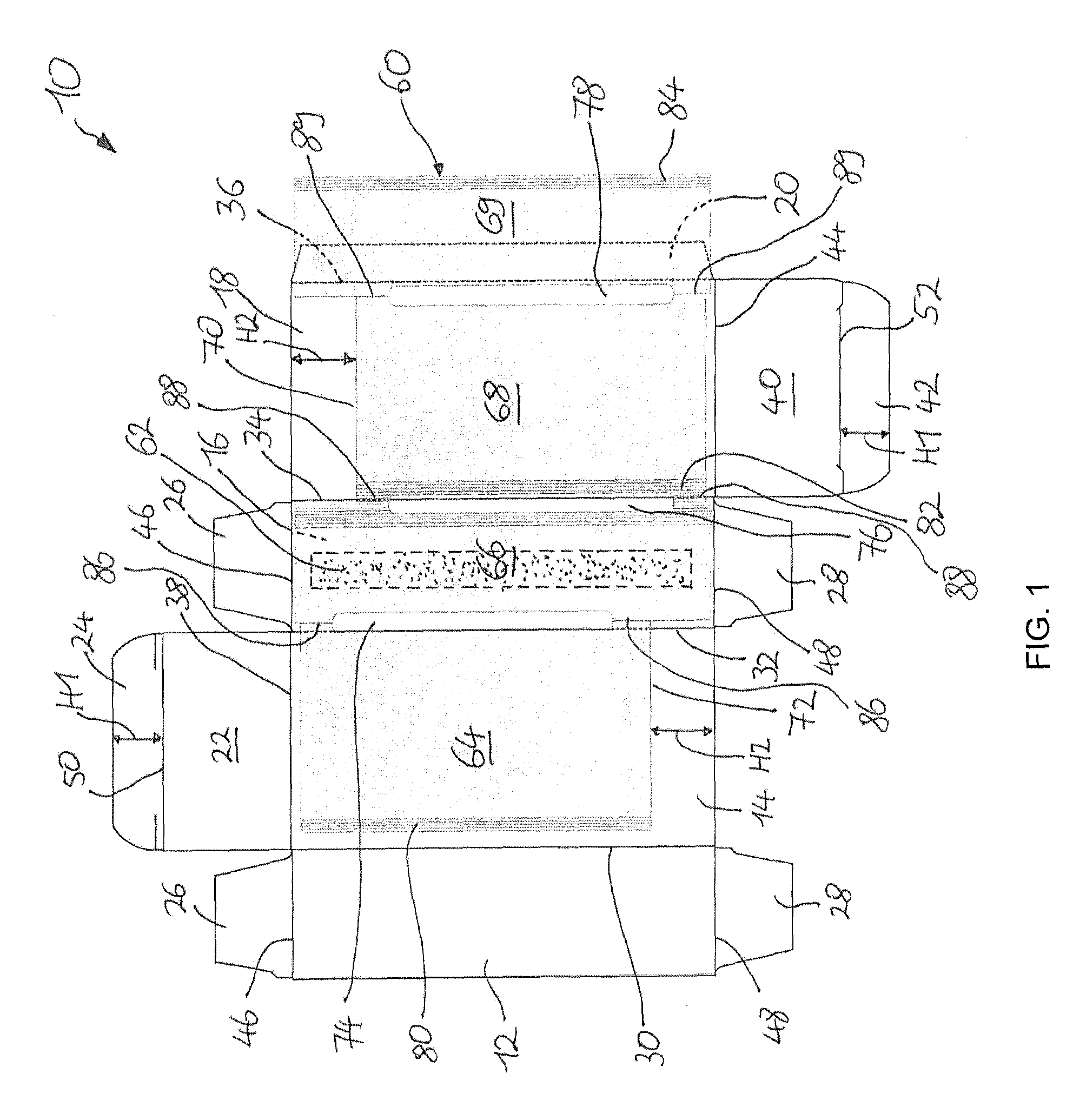

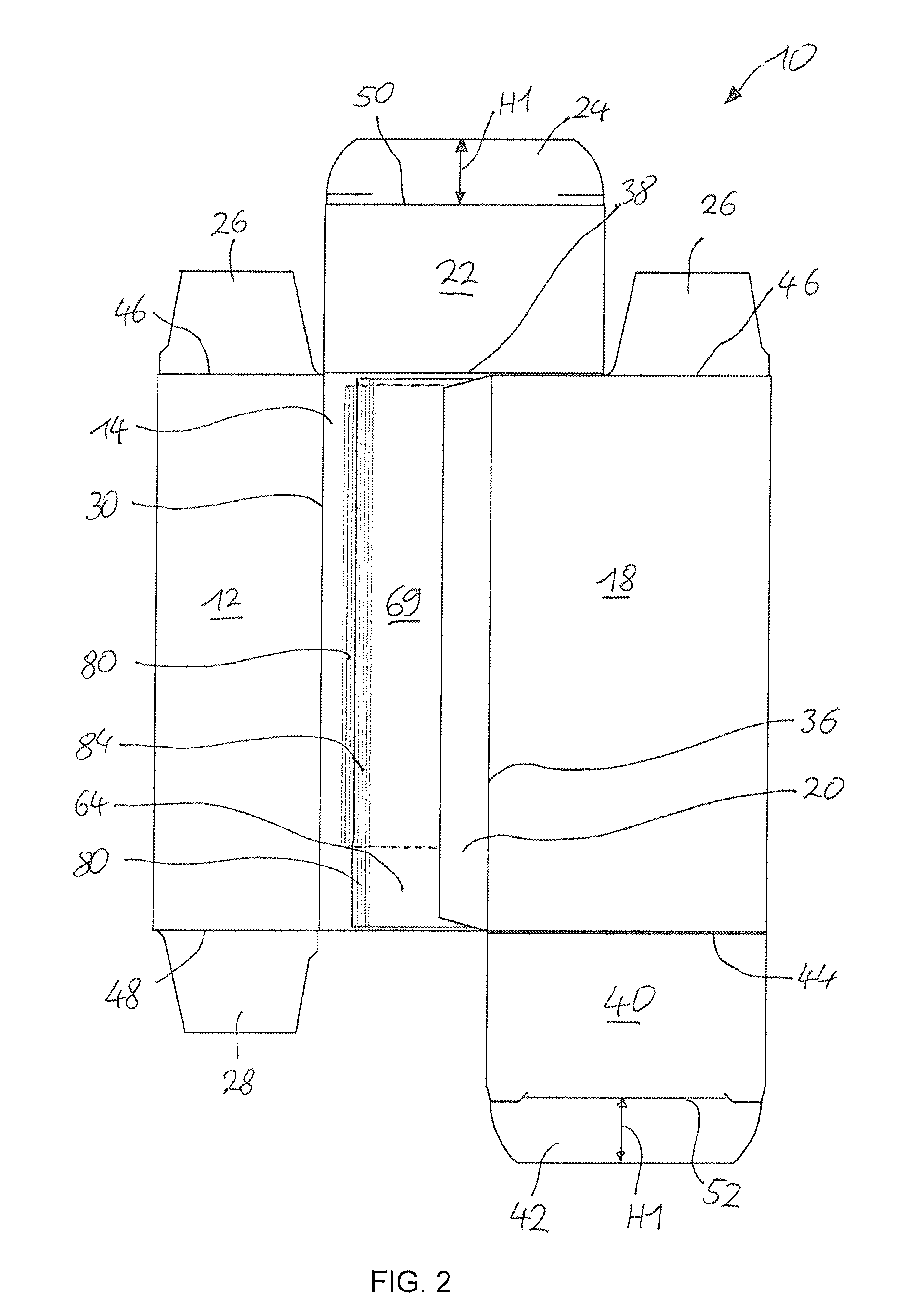

Battery module for high voltage battery pack

InactiveUS20130040180A1Improve cooling effectEasy to packPrimary cell to battery groupingCell temperature controlHigh voltage batteryBattery cell

A battery module is disclosed for a high voltage battery pack The battery module is configured so that a plurality of holder plates and a plurality of battery cells are stacked in a vertical direction, thus preventing a defective product from being produced due to incorrect assembly, and a required number of battery cells is stacked to be modularized, thus being advantageous in terms of a package and improving the cooling performance of the battery cells.

Owner:HYUNDAI MOTOR CO LTD +1

Person-to-person lending program product, system, and associated computer-implemented methods

An individual consumer borrower accessing a person-to-person lending website is provided an opportunity to have a loan request wholly or partially satisfied by a financial institution at loan terms from the financial institution. The financial institution, for example, can receive information about a person-to-person loan request, determine whether to authorize a financial institutional loan, offer a loan to the individual on terms determined by the financial institution, and issue the loan to an individual consumer borrower responsive to approval of the terms. Prior to an auction, the individual consumer can choose an immediate loan offer having financial institution terms or choose to solicit individual consumer loan offers with more favorable terms through the person-to-person lending website. The financial institution can also offer a gap filling loan for a deficiency amount so that the loan request can be partially satisfied by individual consumer loan offers.

Owner:PATHWARD NAT ASSOC

Solid-state image sensor, method of manufacturing the same, and camera

ActiveUS20140078337A1Excellent in termTelevision system detailsSolid-state devicesIon implantationSemiconductor

A method of manufacturing a solid-state image sensor having a first charge accumulation region, a second charge accumulation region, includes implanting ions into a semiconductor substrate through first and second openings of a mask to form the first and second charge accumulation regions. The implanting ions includes a first implantation of implanting ions into a portion below a first transfer gate, and a second implantation of implanting ions into a portion below a second transfer gate in a direction different from a direction of the first implantation.

Owner:CANON KK

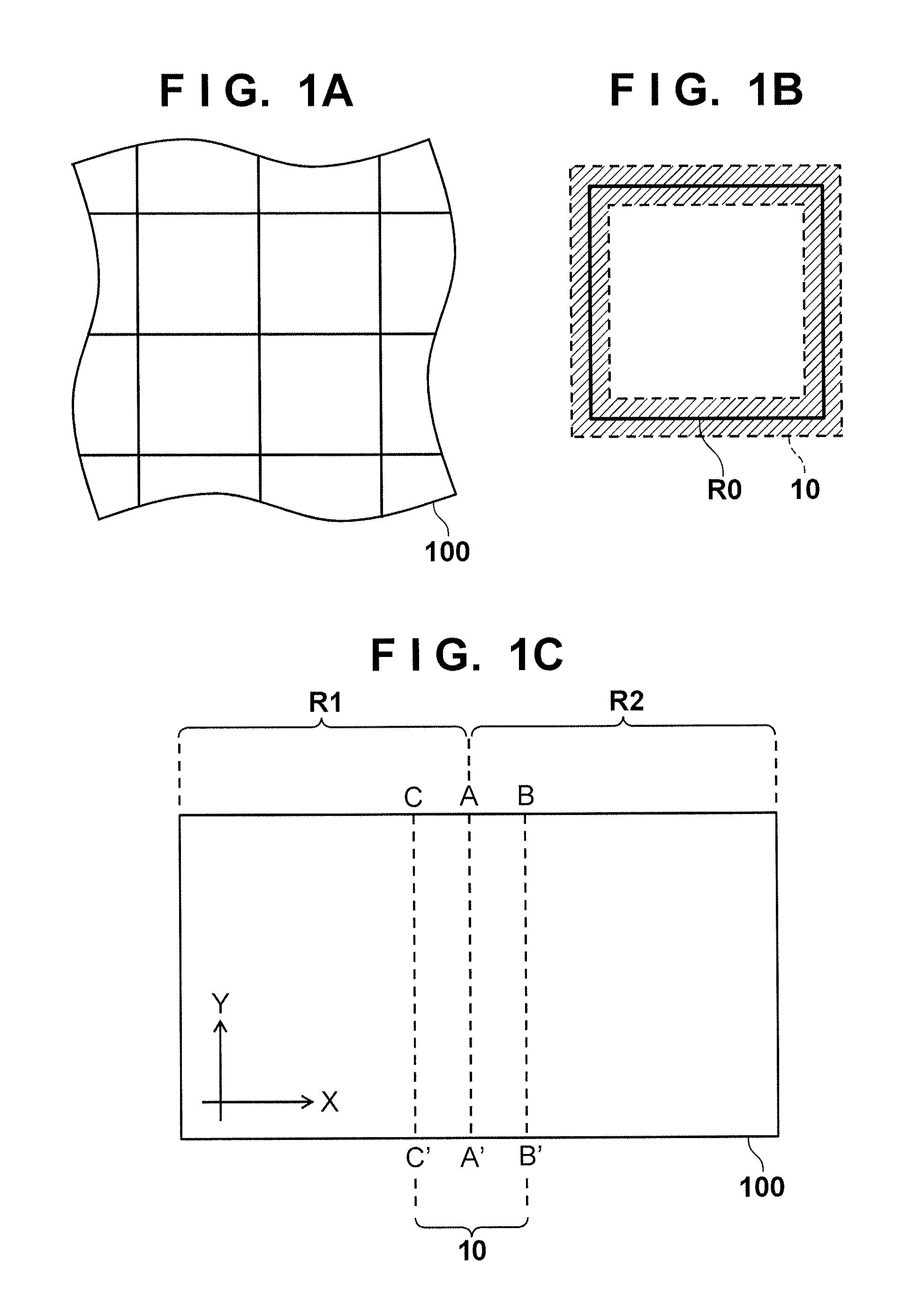

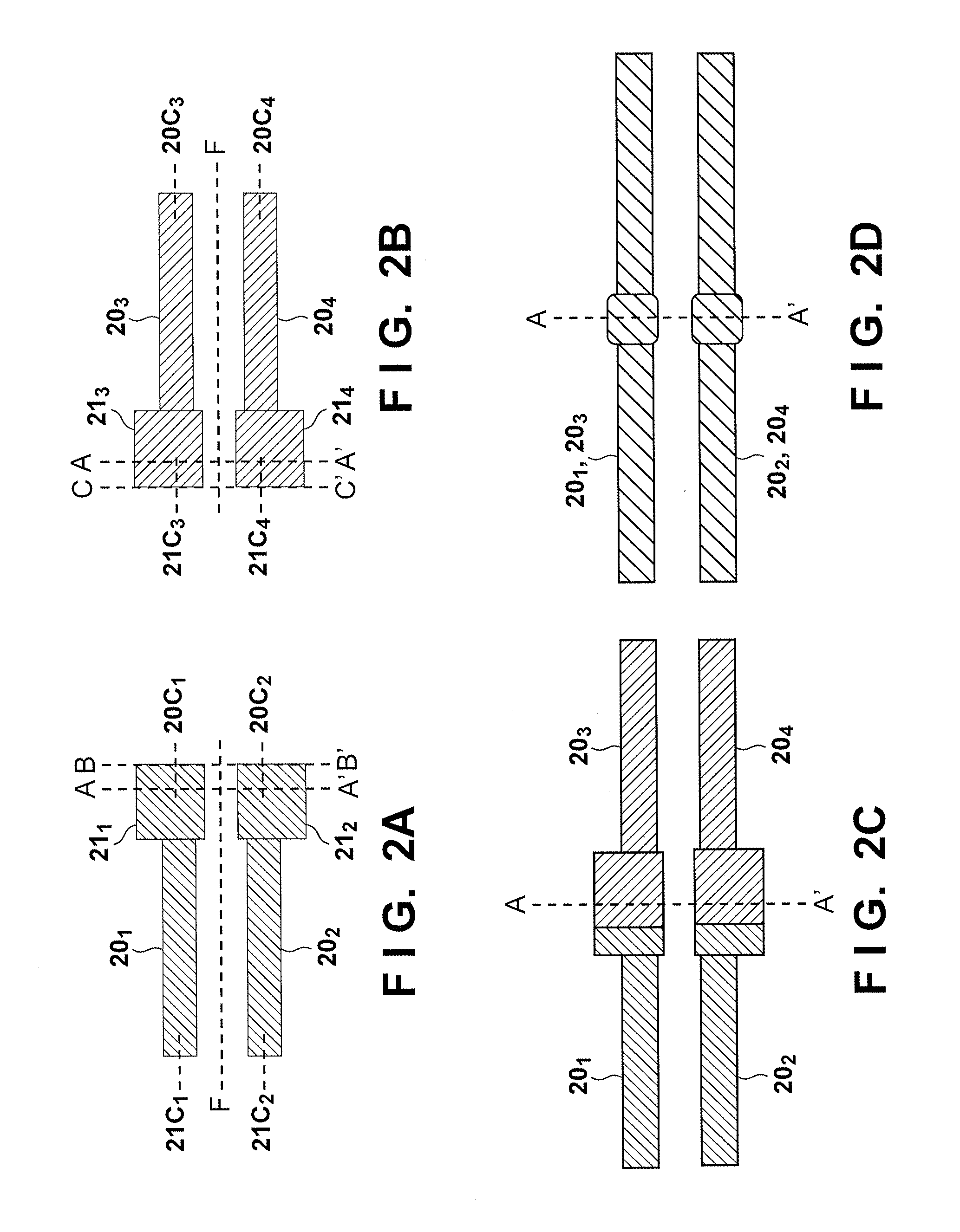

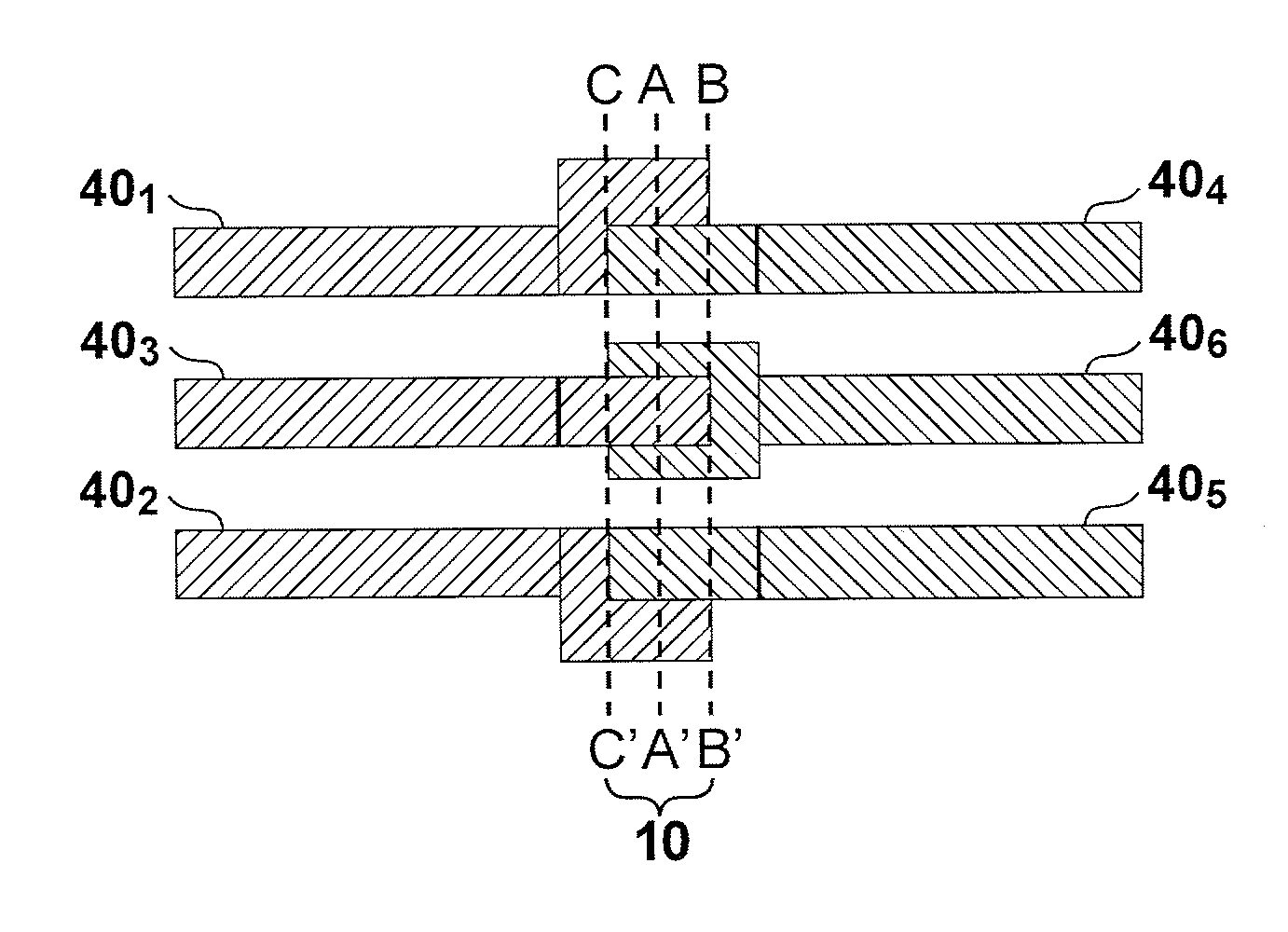

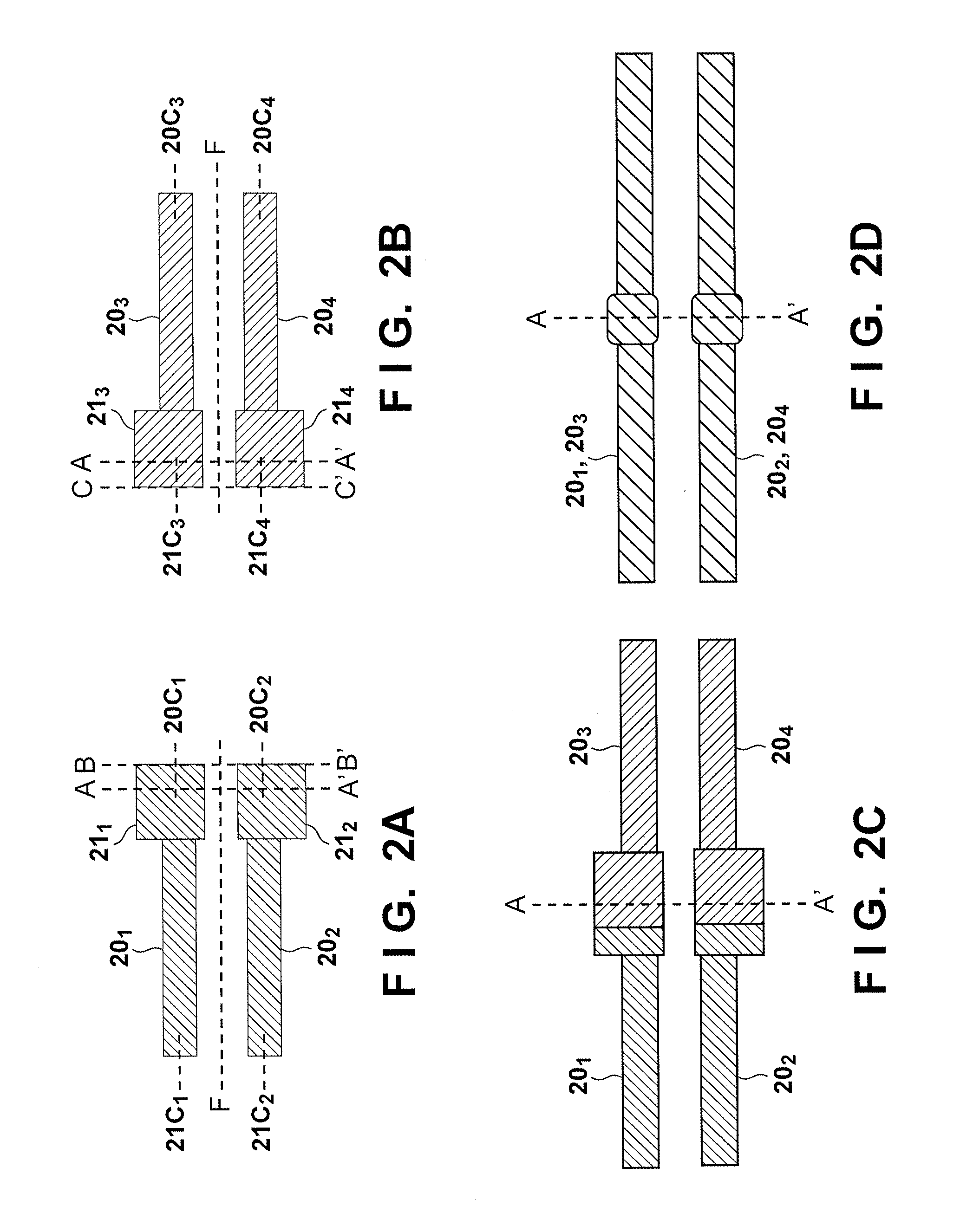

Photomask and semiconductor apparatus manufacturing method

ActiveUS8852830B2Excellent in termPhoto-taking processesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A photomask for exposing a region on a substrate, with a mask pattern, including a first line pattern, a second line pattern, a first connection pattern for a peripheral portion of the region and a second connection pattern for the peripheral portion, wherein the first connection pattern is wider than the first line pattern and the second connection pattern is wider than the second line pattern, a distance from a virtual line between the first line pattern and the second line pattern to a center line of the first connection pattern is larger than a distance from the virtual line to a center line of the first line pattern and a distance from the virtual line to a center line of the second connection pattern is larger than a distance from the virtual line to a center line of the second line pattern.

Owner:CANON KK

Folding box cutout and folding box folded therefrom

Owner:MULTI PACKAGING SOLUTIONS

METHOD OF HEAT-STABILIZING alpha-GLUCAN PHOSPHORYLASE (GP)

InactiveUS20100047891A1Improve thermal stabilityExcellent in termTransferasesFermentationAlpha-glucan phosphorylaseThermal stability

An α-glucan phosphorylase having improved thermostability, which obtained by modifying natural α-glucan phosphorylase, and a method for producing this α-glucan phosphorylase having improved thermostability are provided. The natural α-glucan phosphorylase is derived from a plant, this α-glucan phosphorylase having improved thermostability has an amino acid residue which is different from that of the natural α-glucan phosphorylase in at least one position selected from the group consisting of a position corresponding to position 4 in a motif sequence 1L or 1H, a position corresponding to position 4 in a motif sequence 2, and a position corresponding to position 7 in a motif sequence 3L or 3H, and wherein the enzyme activity of α-glucan phosphorylase having improved thermostability at 37° C., after heating in a 20 mM citrate buffer (pH 6.7) at 60° C. for 10 minutes, is 20% or more of the enzyme activity of the α-glucan phosphorylase having improved thermostability at 37° C., before heating.

Owner:EZAKI GLICO CO LTD

Photomask and semiconductor apparatus manufacturing method

ActiveUS20130224637A1Good techniqueExcellent in termSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringSemiconductor

A photomask for exposing a region on a substrate, with a mask pattern, including a first line pattern, a second line pattern, a first connection pattern for a peripheral portion of the region and a second connection pattern for the peripheral portion, wherein the first connection pattern is wider than the first line pattern and the second connection pattern is wider than the second line pattern, a distance from a virtual line between the first line pattern and the second line pattern to a center line of the first connection pattern is larger than a distance from the virtual line to a center line of the first line pattern and a distance from the virtual line to a center line of the second connection pattern is larger than a distance from the virtual line to a center line of the second line pattern.

Owner:CANON KK

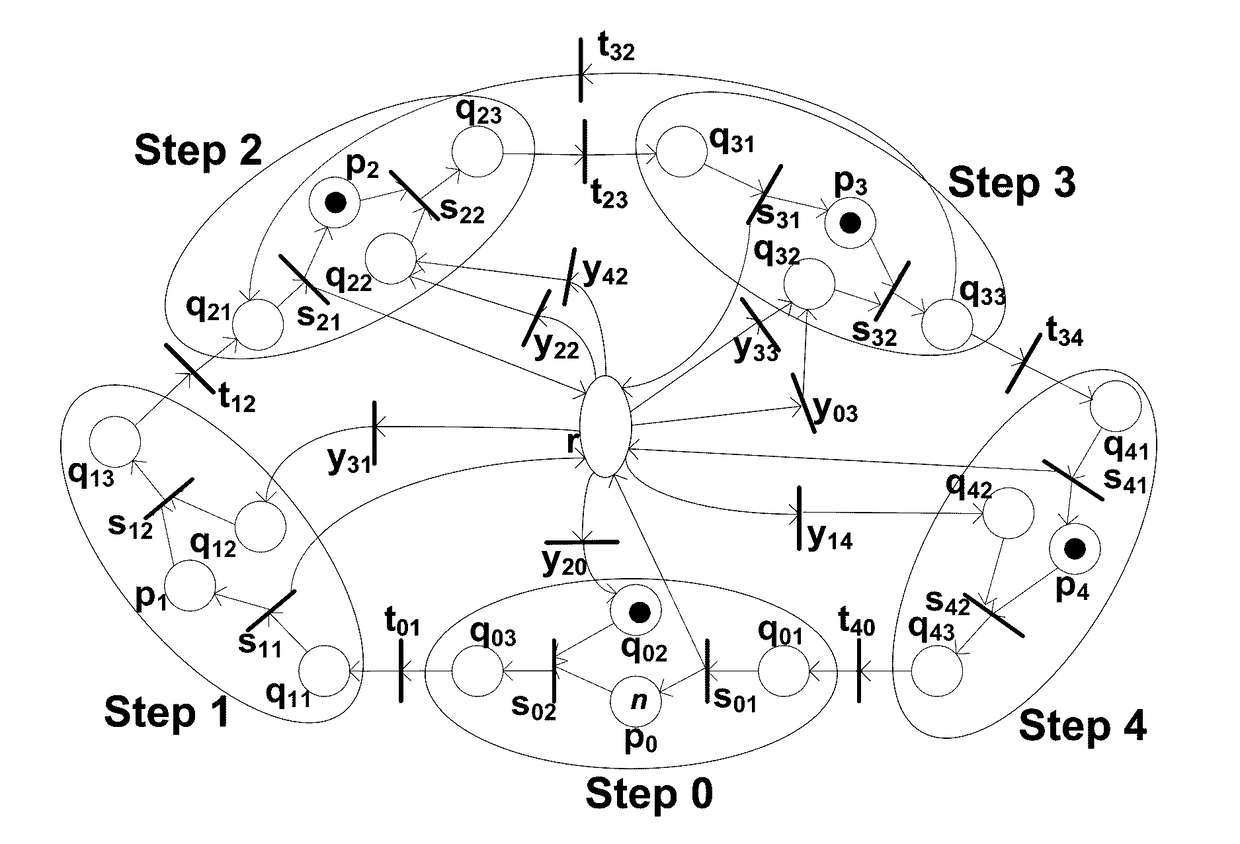

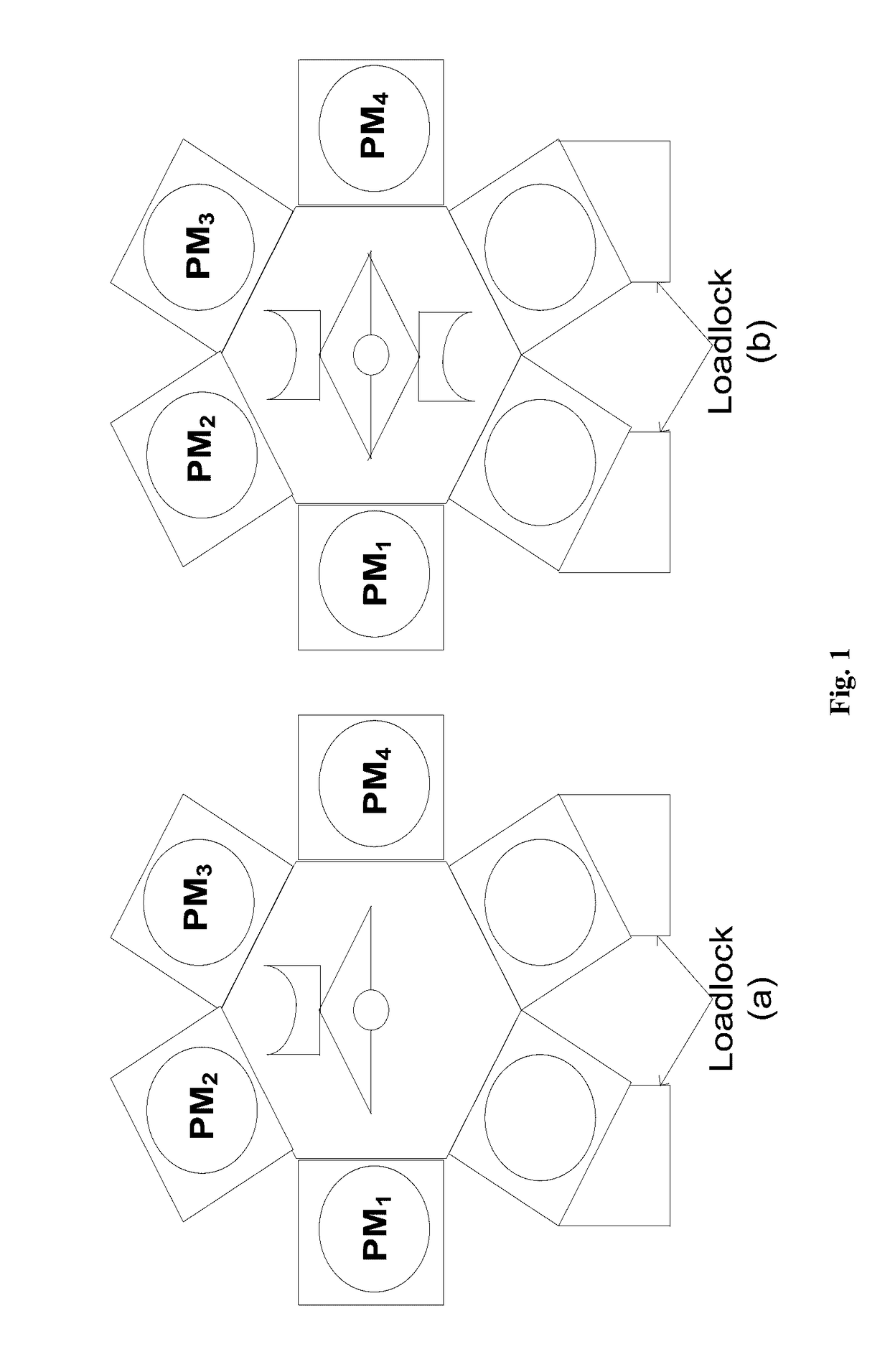

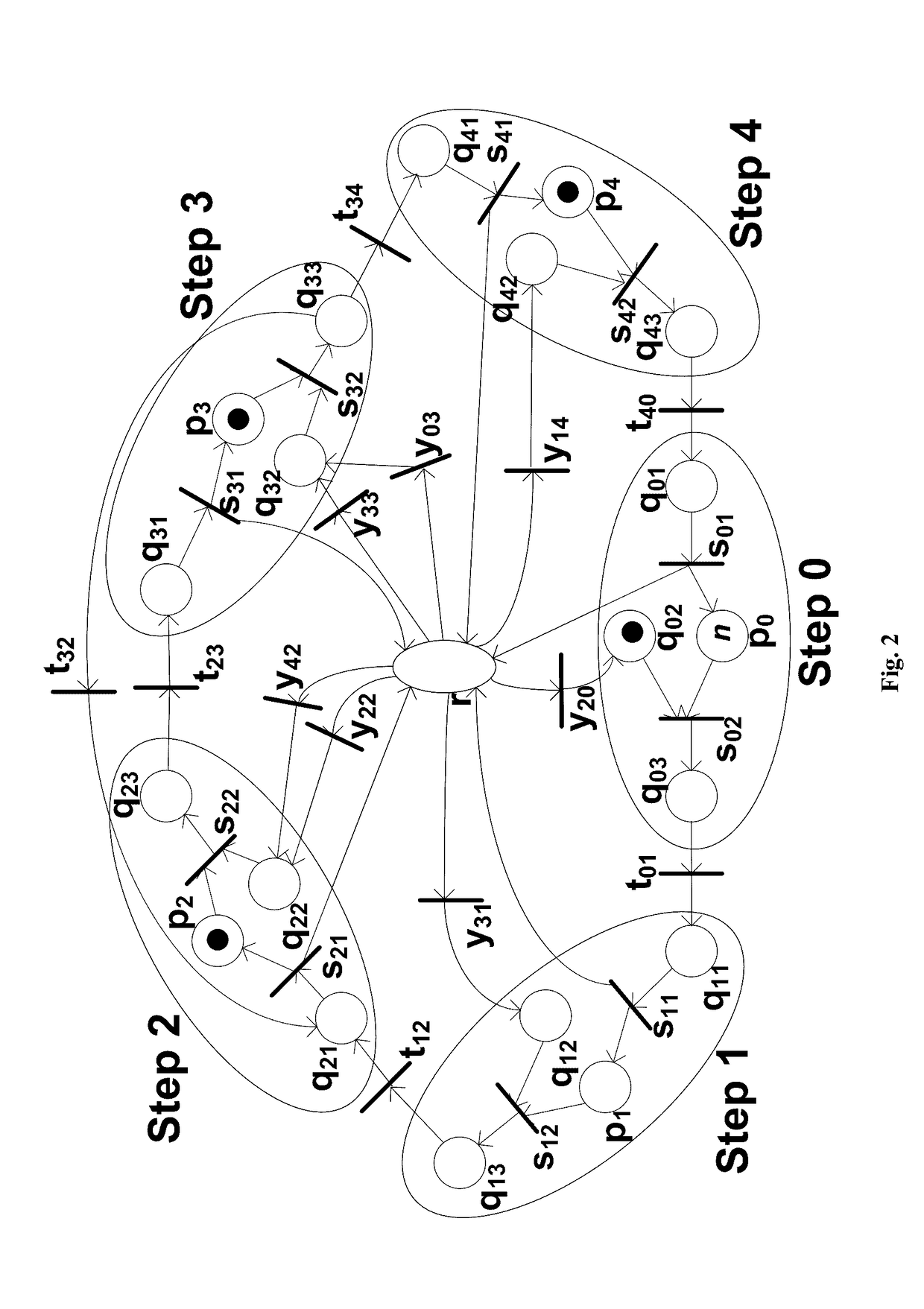

Petri Net-based Scheduling of Time Constrained Single-arm Cluster Tools with Wafer Revisiting

InactiveUS20170083000A1Excellent in termProgramme controlProgramme-controlled manipulatorProgram planningPetri net

It is very difficult to schedule a single-arm cluster tool with wafer revisiting such that wafer residency time constraints are satisfied. The present invention conducts a study on this challenging problem for a single-arm cluster tool with atomic layer deposition (ALD) process. With a so called p-backward strategy being applied, a Petri net model is developed to describe the dynamic behavior of the system. Based on the model, existence of a feasible schedule is analyzed, schedulability conditions are derived, and scheduling algorithms are presented if there is a schedule. A schedule is obtained by simply setting the robot waiting time if schedulable and it is very computationally efficient. The obtained schedule is shown to be optimal. Illustrative examples are given to demonstrate the proposed approach.

Owner:MACAU UNIV OF SCI & TECH

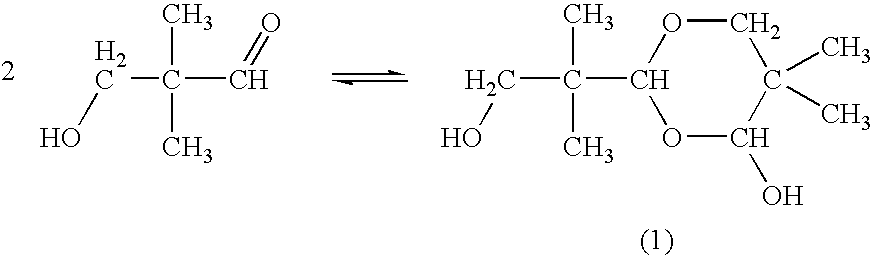

Method of producing high-purity hydroxypivalaldehyde and/or dimer thereof

ActiveUS20070032682A1High yieldIncrease productionOrganic compound preparationCarbonyl compound separation/purificationOrganic solventBoiling point

The present invention provides a method of producing high-purity hydroxypivalaldehyde and / or dimer thereof, including: reacting isobutyl aldehyde with formaldehyde in a presence of a basic catalyst; distilling a low boiling point component including unreacted isobutyl aldehyde to obtain an aqueous solution; adding a diluent to the aqueous solution; cooling the aqueous solution to crystallize the hydroxypivalaldehyde and / or the dimer thereof; and subjecting the aqueous solution to a solid-liquid separation, followed by washing with an organic solvent and / or water, in which the diluent and a basic compound are added to the aqueous solution containing the hydroxypivalaldehyde and / or the dimer thereof obtained by distilling the low boiling point component off so that a concentration of the hydroxypivalaldehyde and / or the dimer becomes 5 to 23% by mass, the concentration of formaldehyde becomes 0.2 to 2.5% by mass, and a pH value becomes 5.0 or more, the solution is crystallized at a temperature of 20 to 45° C. and subjected to the solid-liquid separation. In this method, handling of a high-viscosity slurry and carrying out any complicated operation such as regeneration of an ion exchange resin are not required, so the high-purity HPA and / or the dimer thereof can be obtained in high yield with an energetically advantageous manner.

Owner:MITSUBISHI GAS CHEM CO INC

Method for manufacturing of high strength cold rolled steel sheet of excellent phosphatability

ActiveUS8668789B2High strengthImprove phosphating effectFurnace typesQuenching agentsSheet steelHigh intensity

A method for the manufacturing of high strength cold rolled steel sheets includes continuously annealing a cold rolled steel sheet that has a composition containing C: 0.05-0.3% mass, Si: 0.6-3.0% mass, Mn: 1.0-3.0% mass, P: ≦0.1% mass, S: ≦0.02% mass, Al: 0.01-1% mass, N: ≦0.01% mass, and Fe and inevitable impurities: balance, in a manner such that the cold rolled steel sheet is heated in a furnace using an oxidizing burner to a steel sheet temperature of ≧700° C., then soak-annealed in a reducing atmosphere furnace at 750-900° C., then cooled so the average cooling rate between 500° C. and 100° C. is ≧50° C. / s. High-Si cold rolled steel sheets with high strength and good phosphatability while containing Si≧0.6% are obtained without controlling conditions so as to increase the dew point in the reducing atmosphere in the soaking furnace or to increase the vapor hydrogen partial pressure ratio.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com