Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Excellent in abrasion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin-reinforced elastomer, process for producing same and pneumatic tire using same

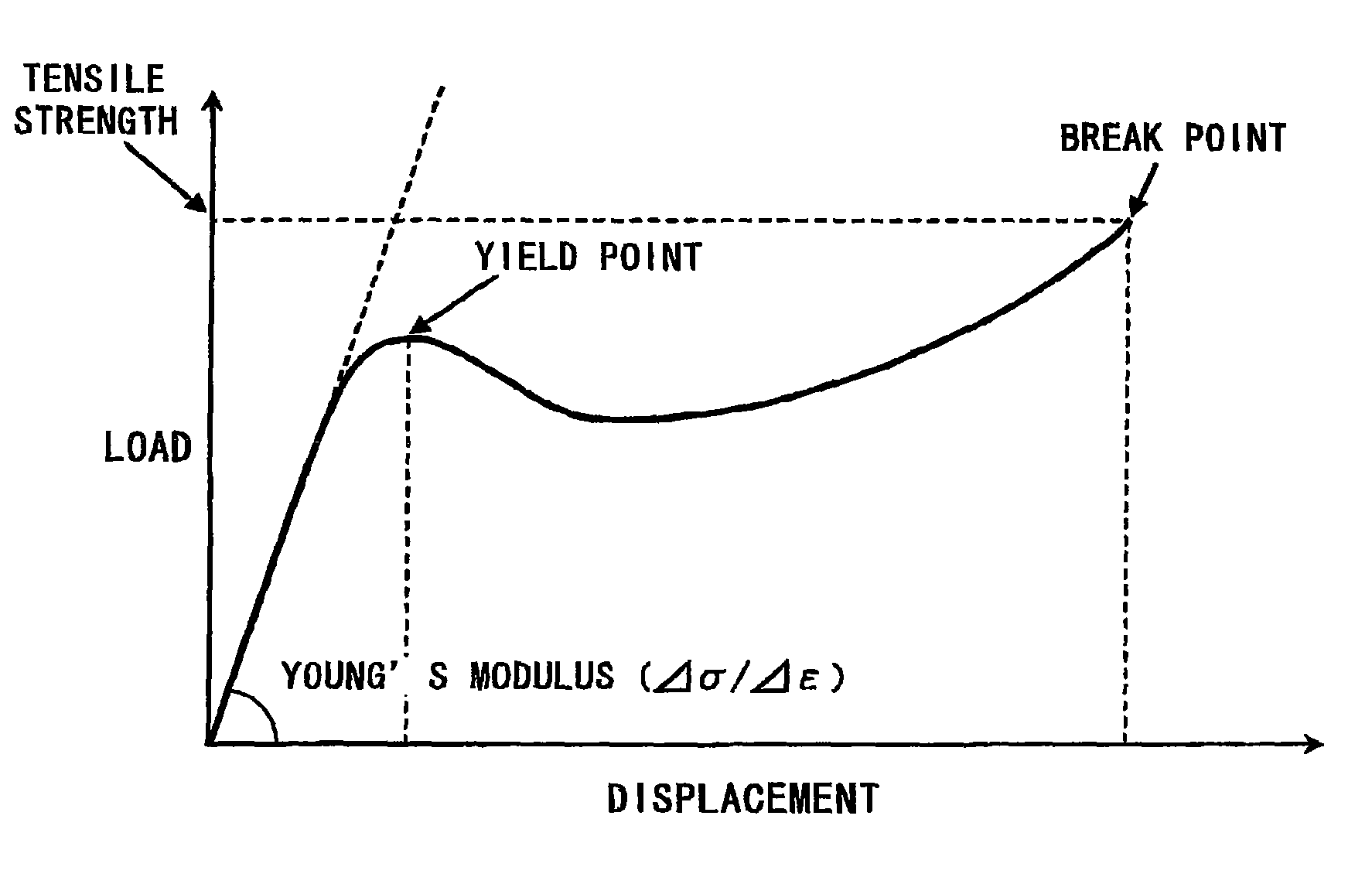

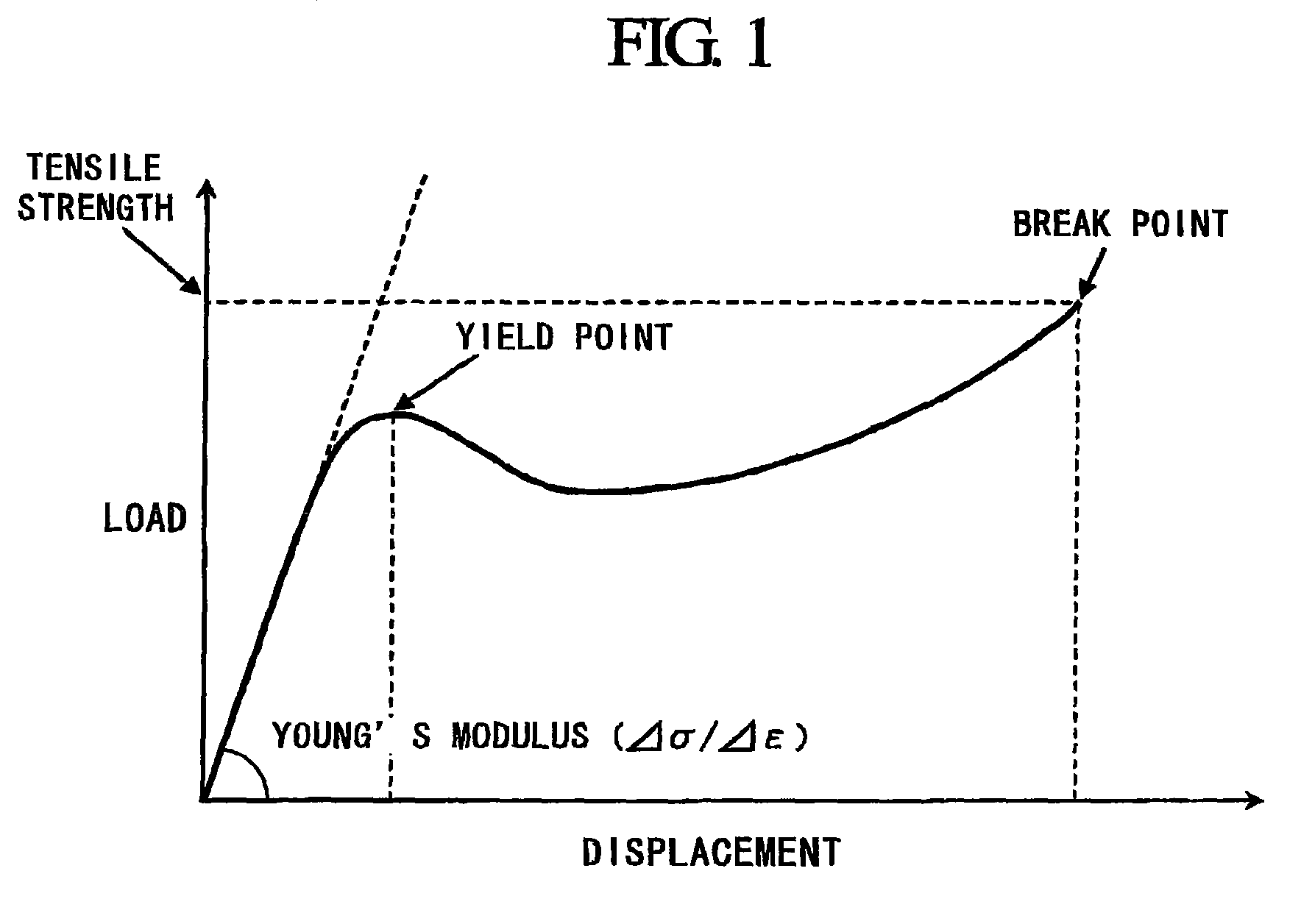

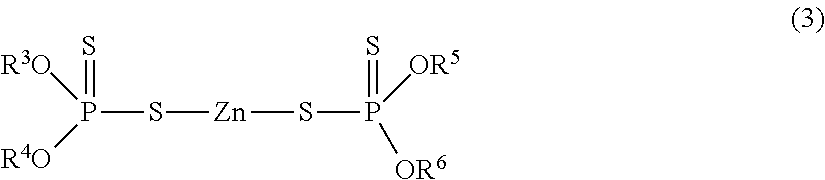

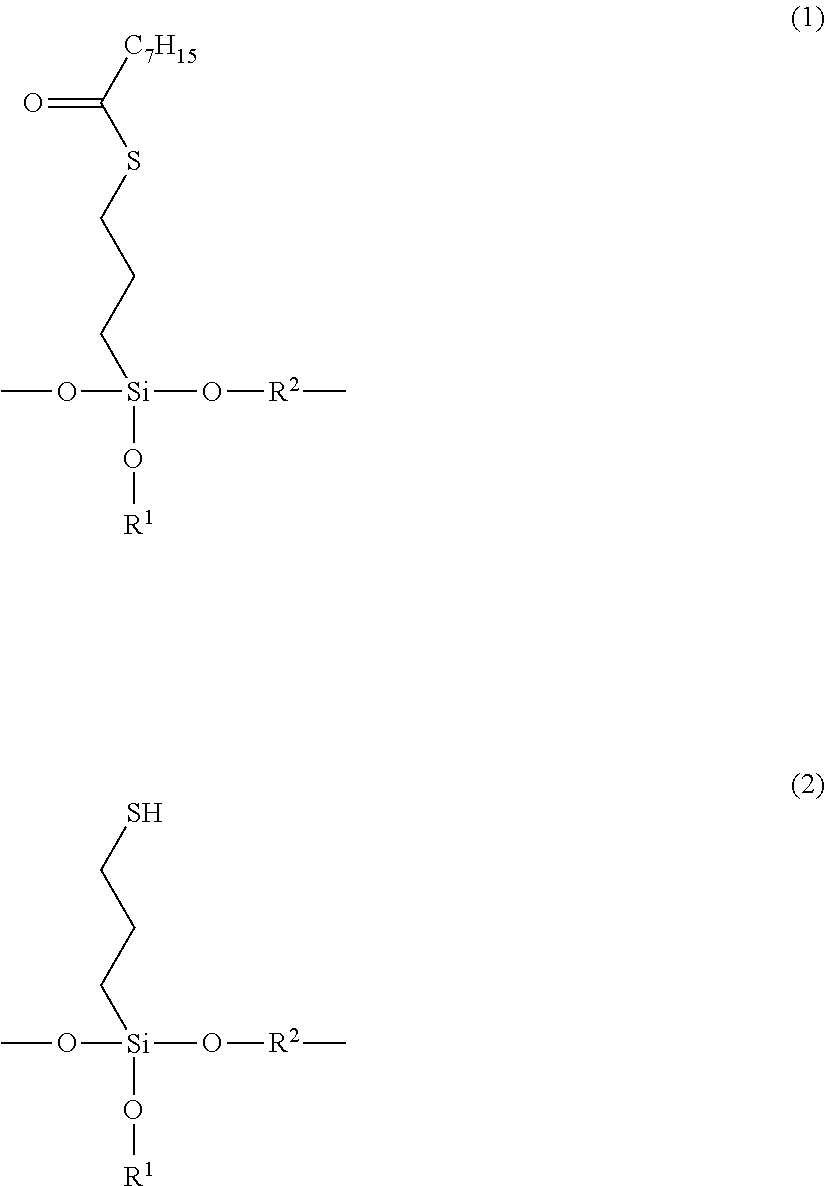

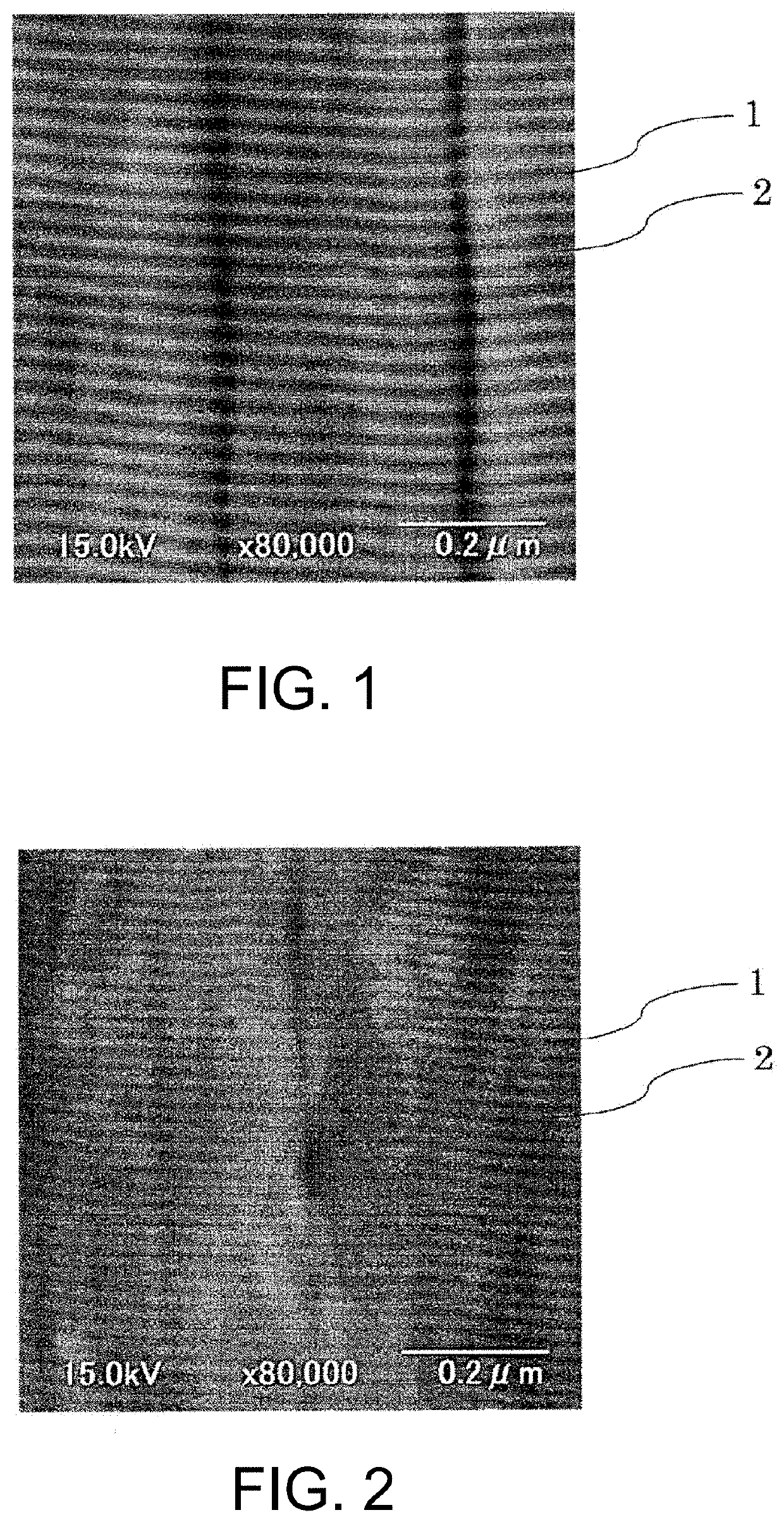

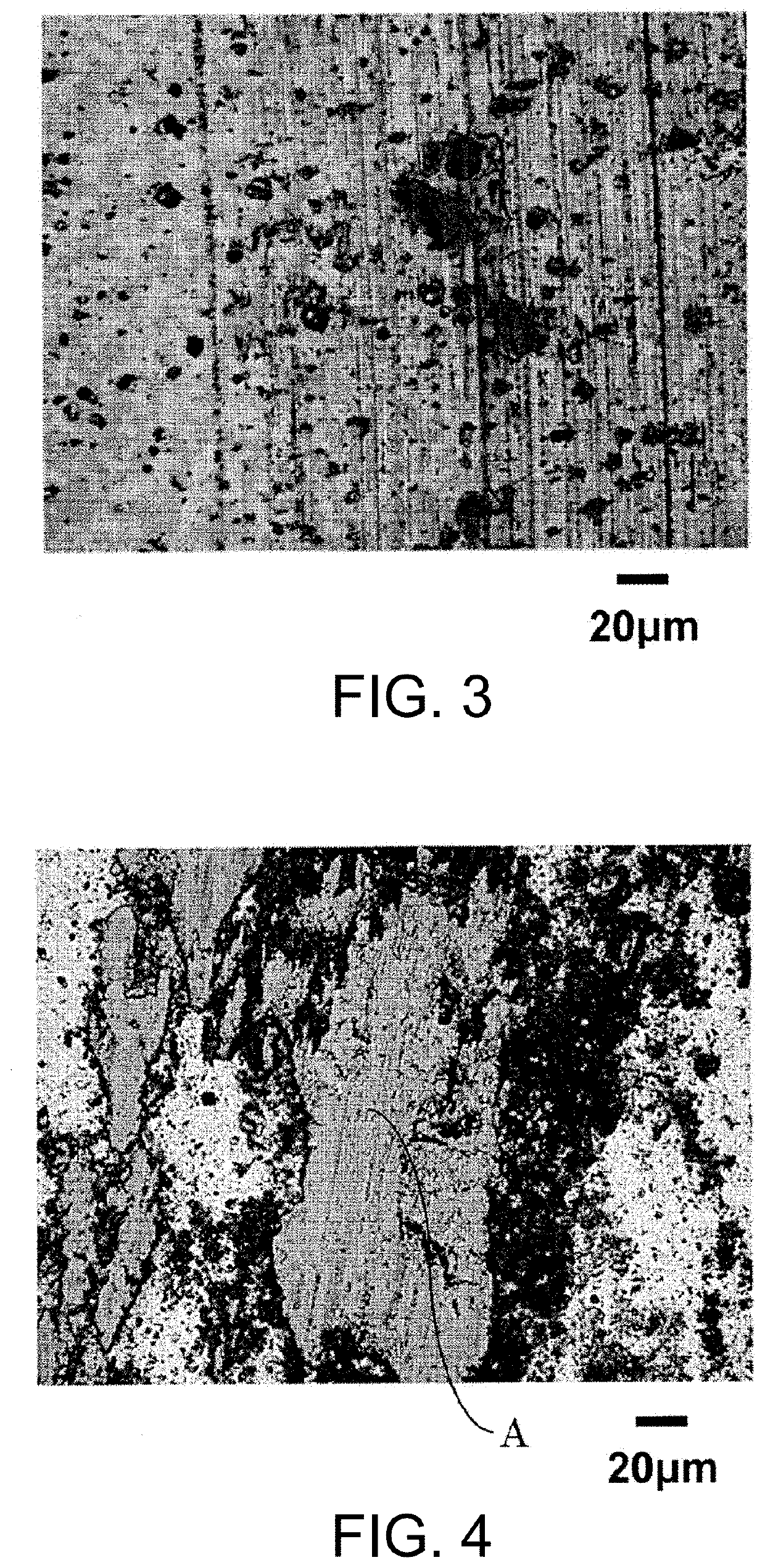

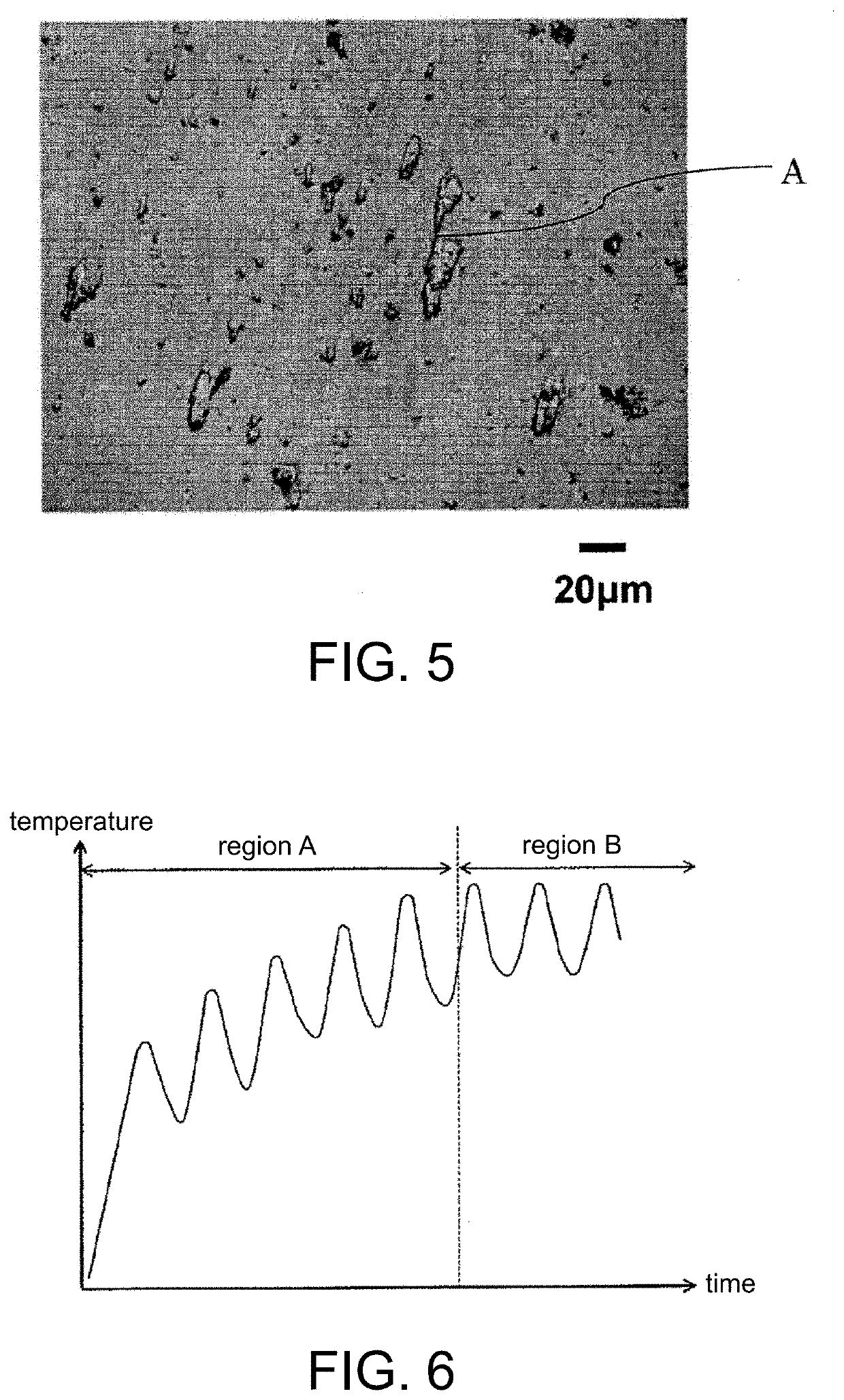

There are disclosed a resin-reinforced elastomer which comprises as principal components, a rubber and a polyolefin having an average particle diameter of at most 1 .mu.m, and in which the rubber and the polyolefin are linked together; a process for producing the resin-reinforced elastomer by melt kneading a polyolefin, a No.1 rubber and a binding agent to prepare a thermoplastic composition, adding a No.2 rubber to the resultant thermoplastic composition and melt kneading the mixture thus formed to disperse the polyolefin in the rubber components; and a pneumatic tire using the resin-reinforced elastomer in its tread. The above resin-reinforced elastomer has a uniform modulus and a low density, is minimized in directionality, and is excellent in tensile strength, fatigue resistance and abrasion resistance.

Owner:BRIDGESTONE CORP +1

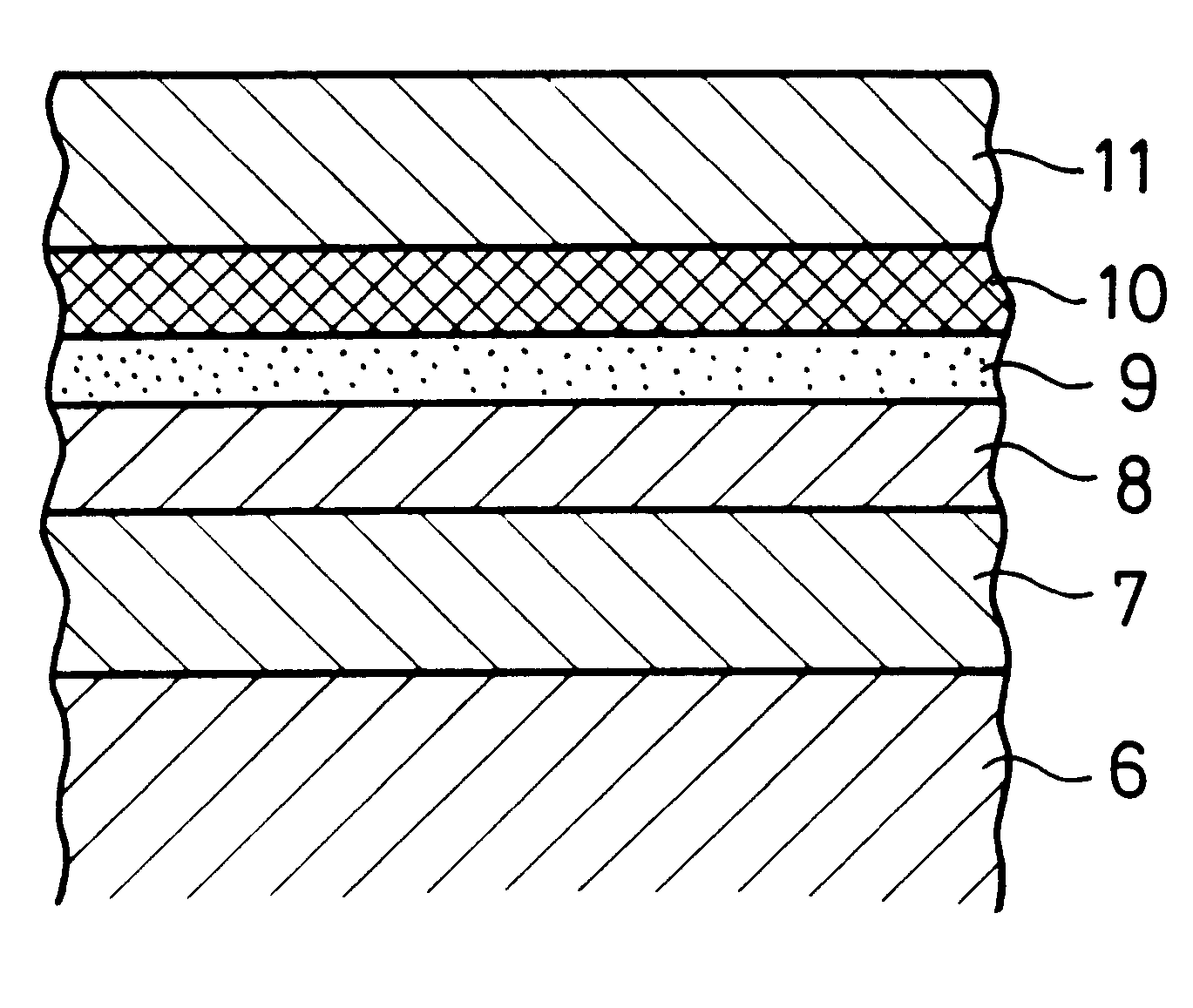

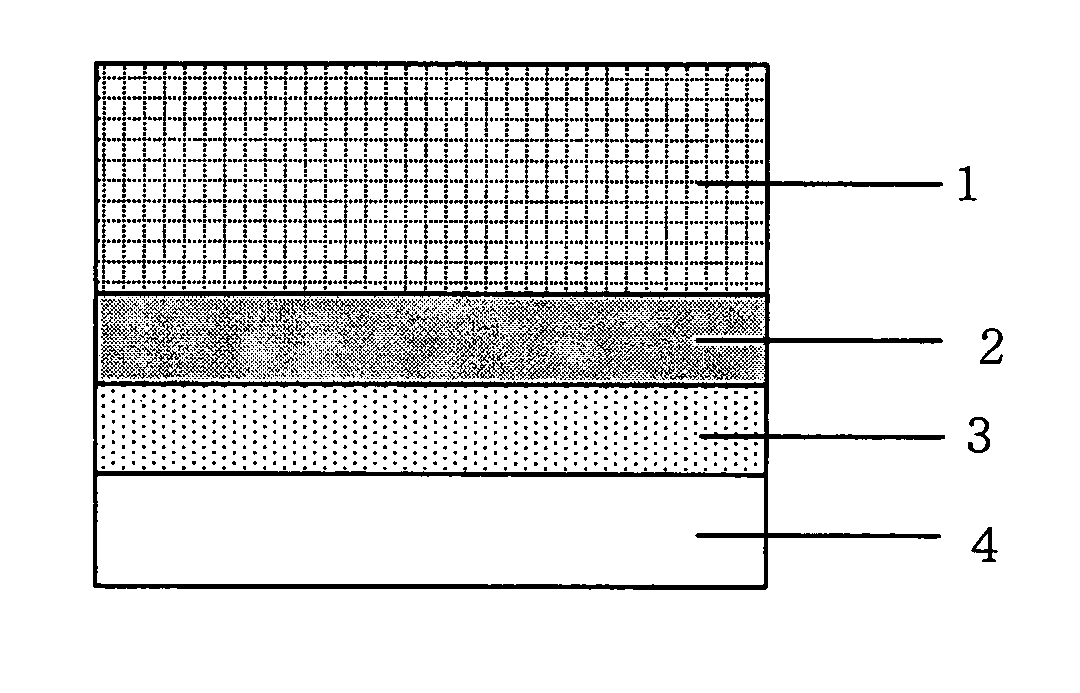

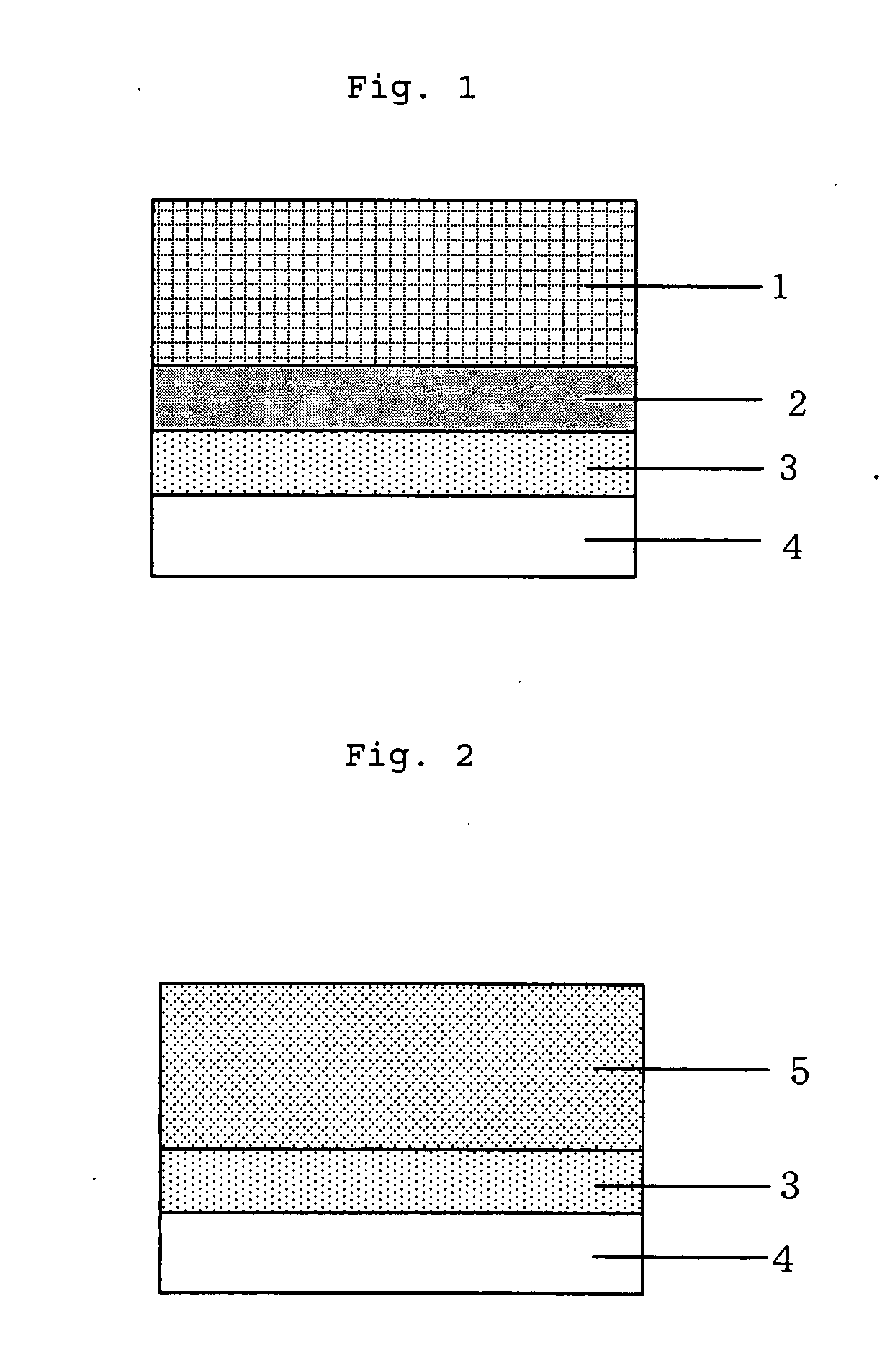

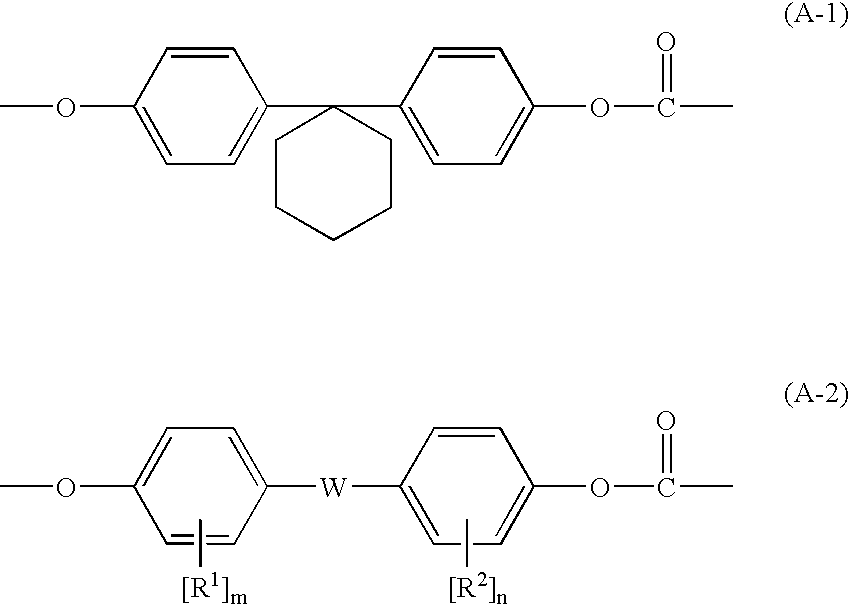

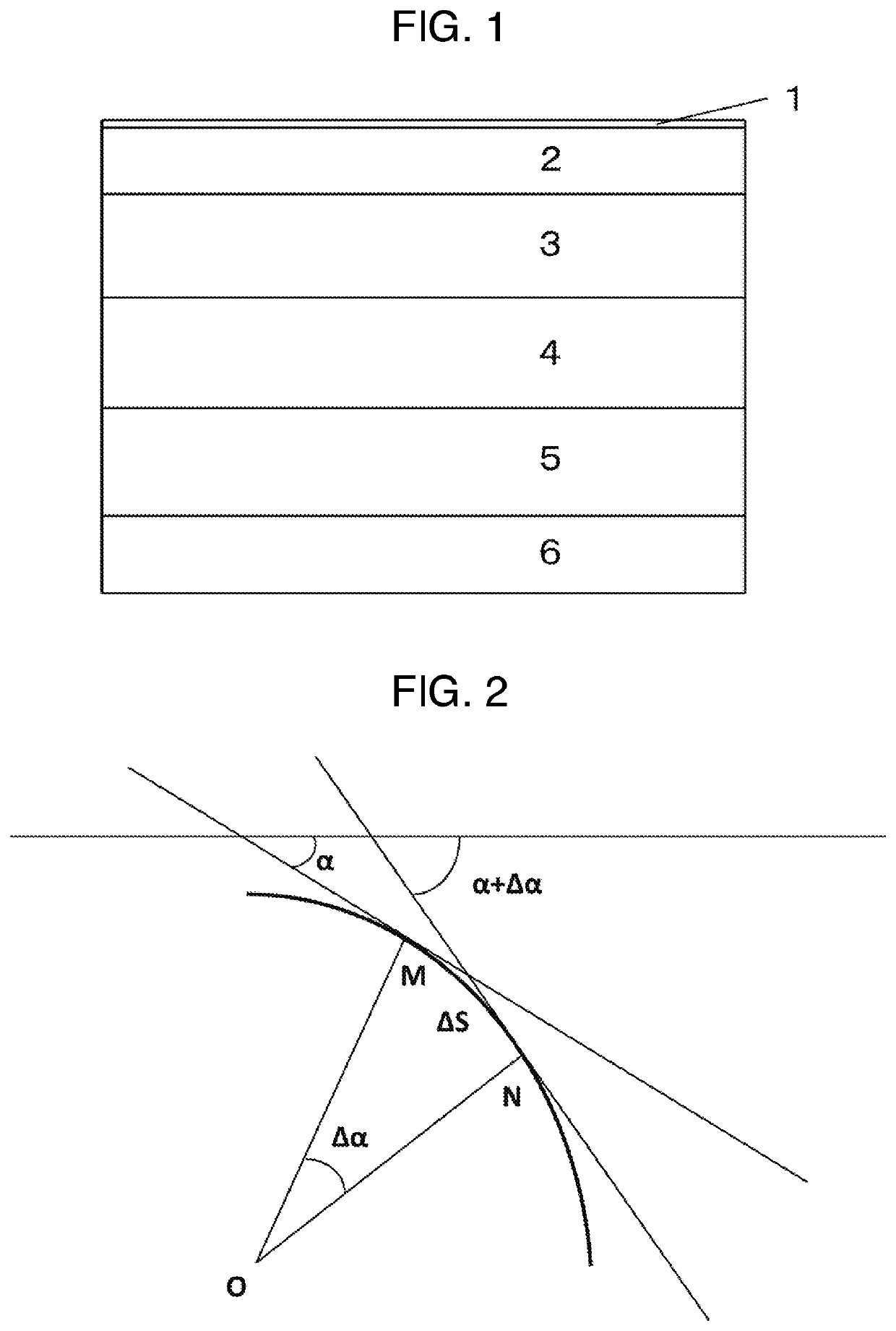

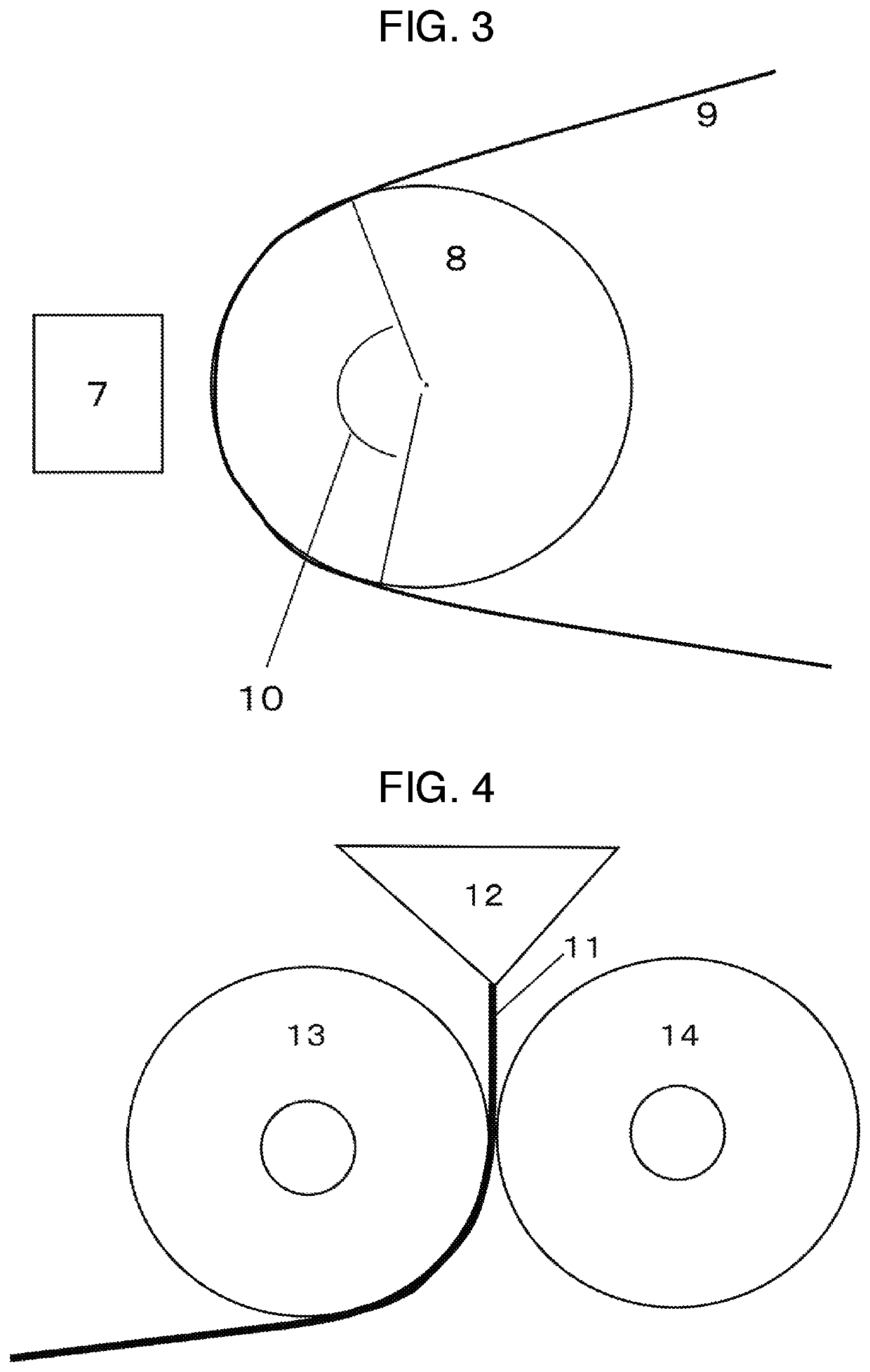

Charge-transporting compound, electrophotographic photoreceptor, image-forming apparatus, and process cartridge

ActiveUS20060216619A1Improve stabilityProlong lifeElectrographic process apparatusCorona dischargeTO-18Organic group

An electrophotographic photoreceptor comprising: a conductive support; and a photosensitive layer, wherein the photosensitive layer comprises a functional layer that comprises at least one of a first compound represented by formula (I); and a second compound derived from the first compound: wherein F represents a hole-transporting, n-valent organic group; R independently represents an organic group having from 1 to 18 carbon atoms; T represents a divalent group; m indicates 0 or 1; and n indicates an integer of from 1 to 4.

Owner:FUJIFILM BUSINESS INNOVATION CORP

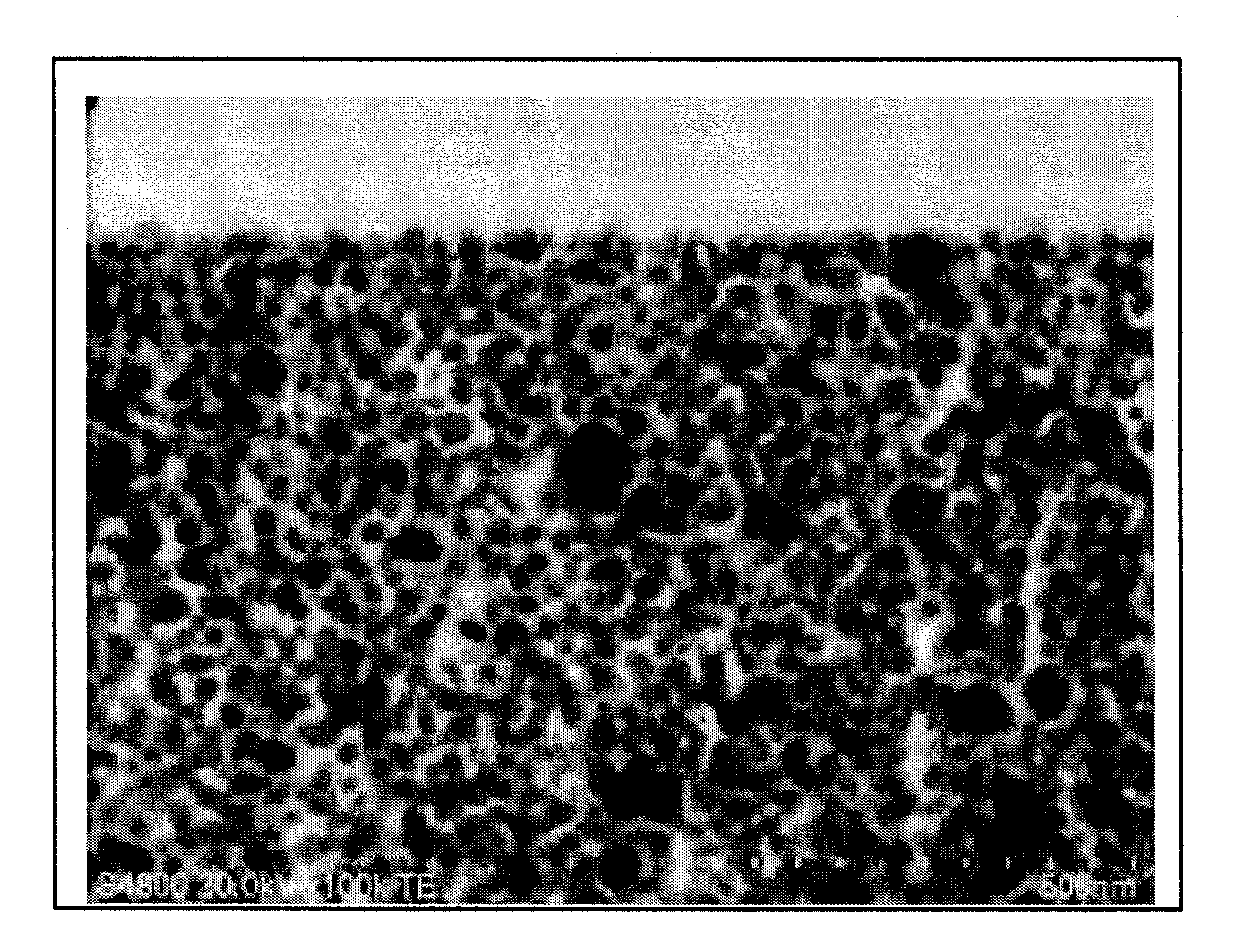

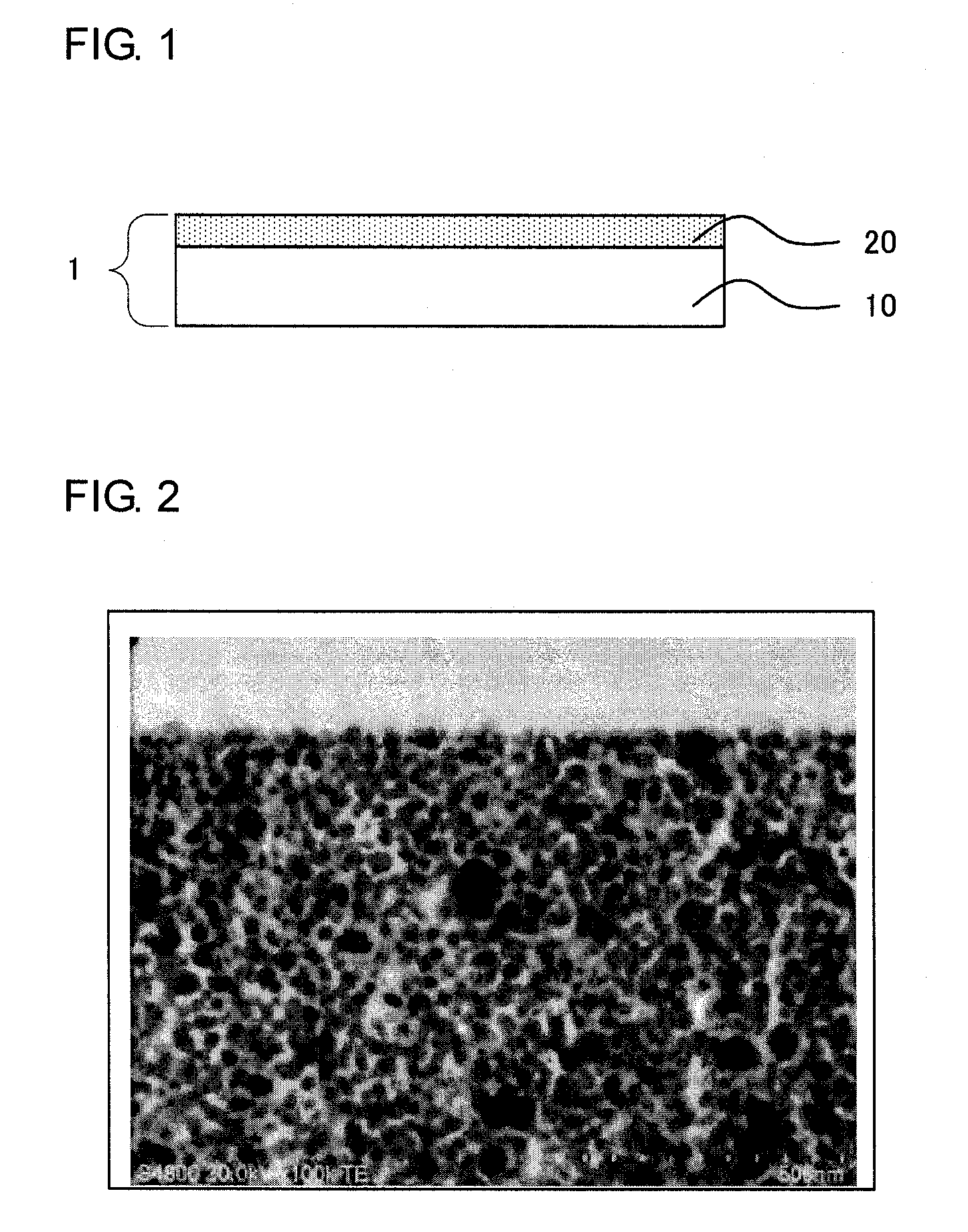

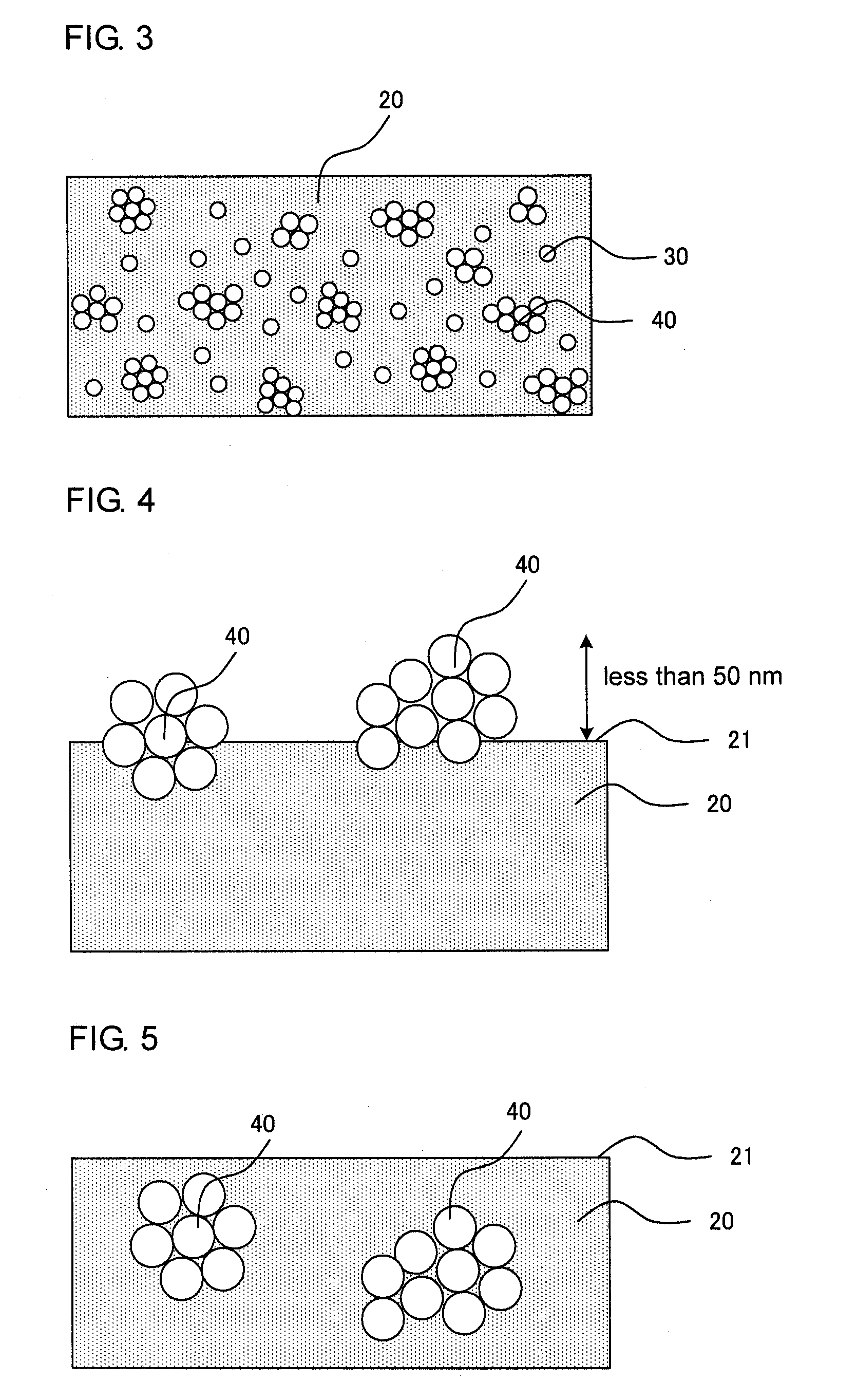

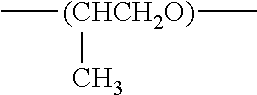

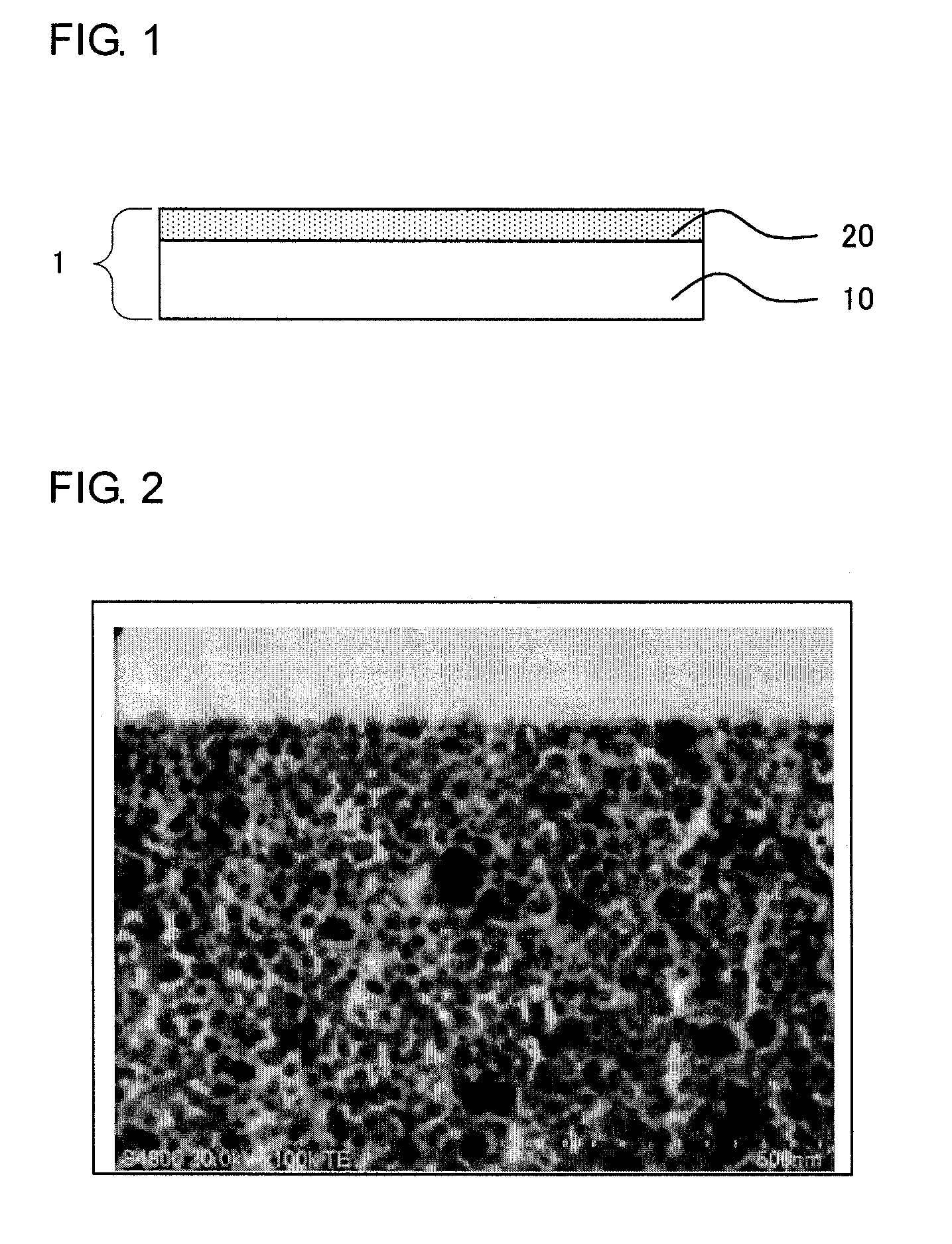

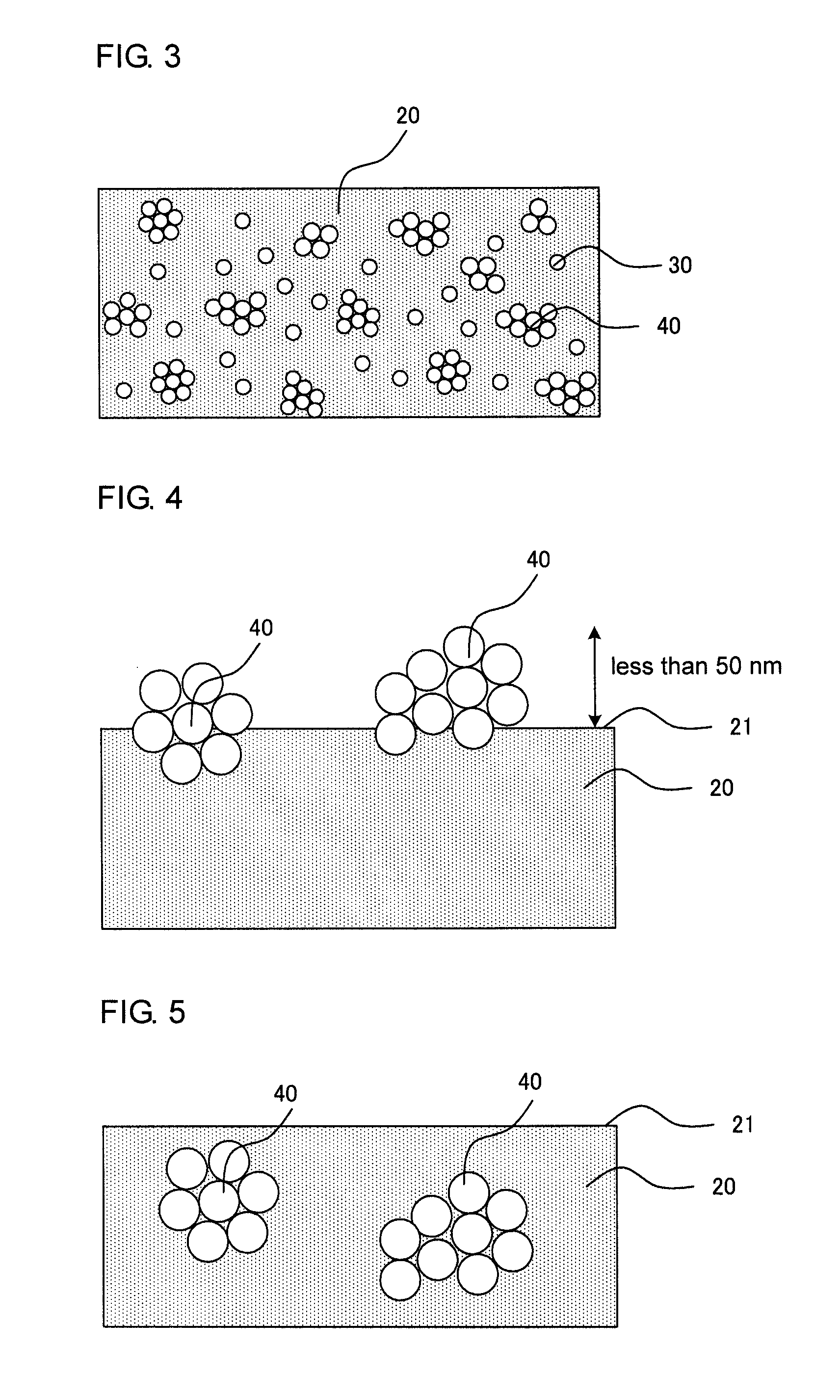

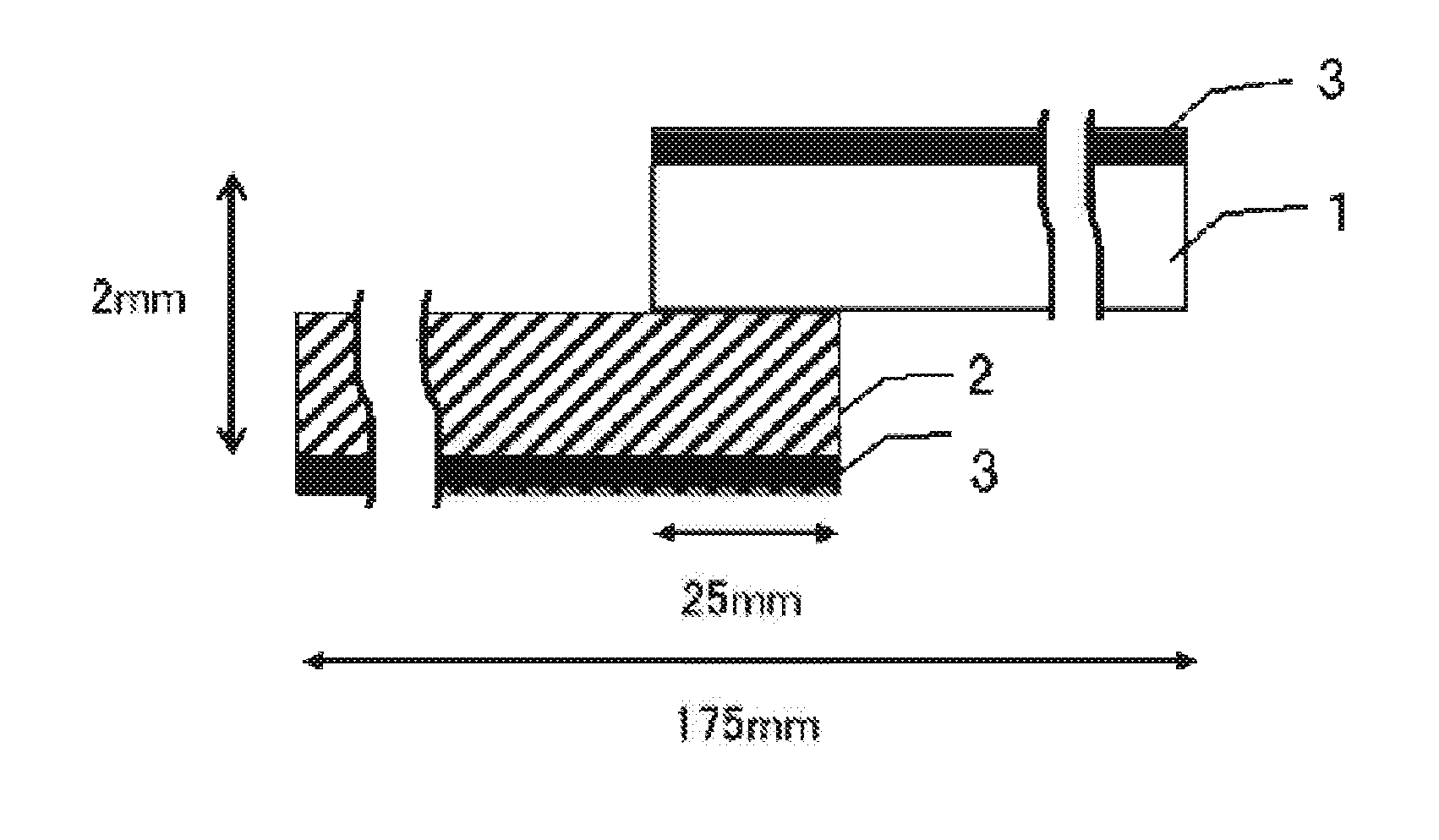

Hard coat film and curable resin composition for hard coat layer

ActiveUS20100104858A1High hardnessIncrease resistanceLayered productsSpecial tyresCross-linkInorganic Chemical

A curable resin composition for a hard coat layer capable of forming a hard coat layer having high hardness even with thin thickness and / or excellent in abrasion resistance and hardness, and a hard coat film using the curable resin composition are provided. A hard coat film in which a hard coat layer is provided on one side of a transparent substrate film, wherein the hard coat layer comprises a matrix in a crosslinked state and an aggregate in which 3 to 100 silica fine particles having an average primary particle diameter of 1 to 100 nm are aggregated, and wherein the aggregate is cross-linked to the matrix, and an irregularly shaped silica fine particle constituted with 3 to 20 silica fine particles having an average primary particle diameter of 1 to 100 nm connected to each other by inorganic chemical bonding is contained as a part of the aggregates. The hard coat layer further contains a silica fine particle preferably.

Owner:DAI NIPPON PRINTING CO LTD

Aqueous ink composition and printing process by ink jet recording system using the composition

ActiveUS20110234682A1Excellent in abrasionImprove printing qualityInksPrintingPolymer chemistryRecording system

The aqueous ink composition according to the invention includes at least a water-insoluble coloring agent, a glycol ether having an HLB value calculated by a Davies' method in the range of 4.2 to 8.0, a 1,2-alkyldiol having 4 to 8 carbon atoms, resin particles, and water.

Owner:SEIKO EPSON CORP

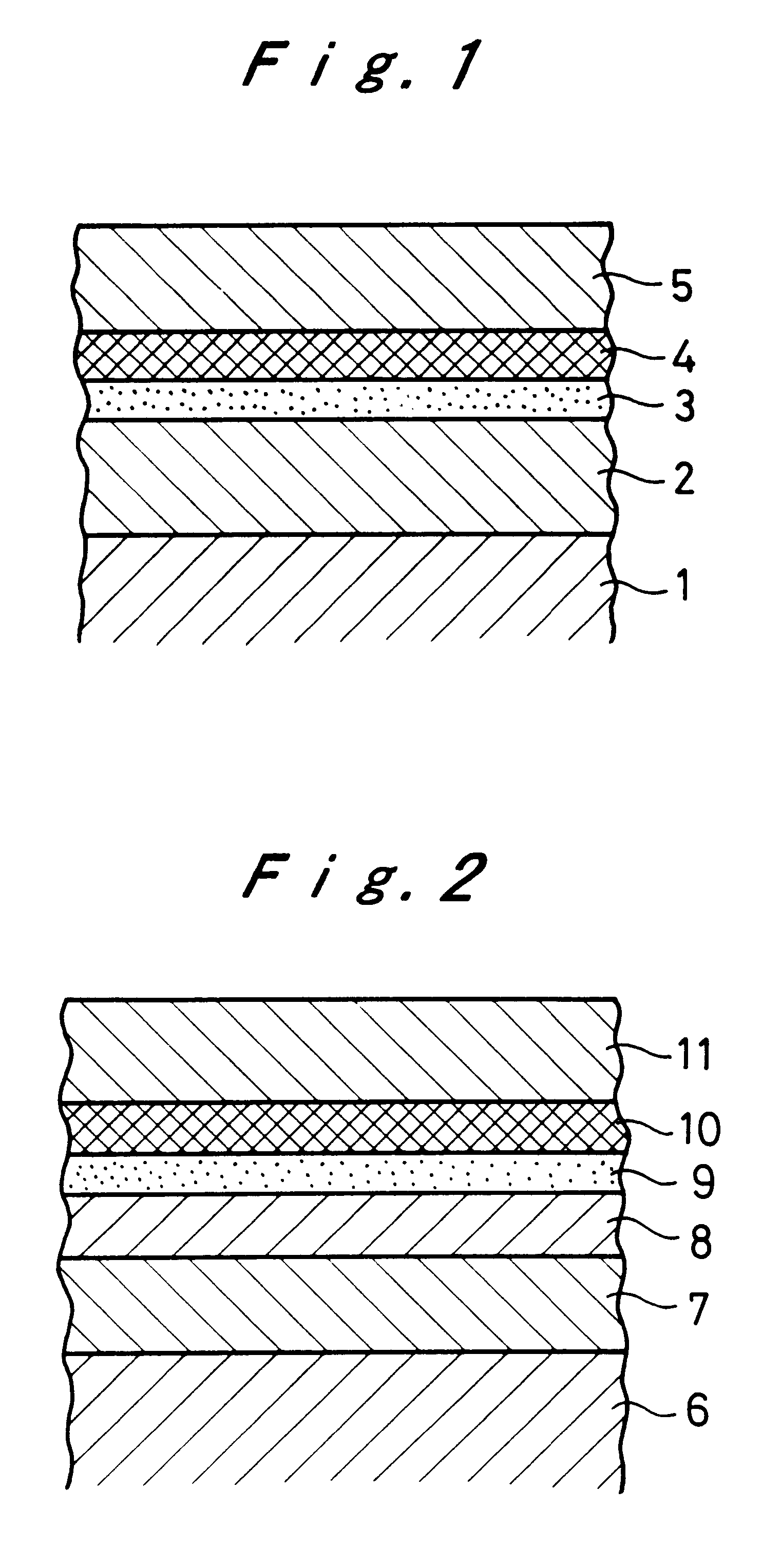

Hard carbon coating-clad base material

InactiveUS6180263B1Excellent in abrasionImprove adhesionSuperimposed coating processThin material handlingCarbon coatingMetal coating

The hard carbon coating-clad base material of the present invention comprises a base material, a substratal metal coating formed on the base material by a wet plating process, an intermediate metal coating comprising a titanium or chromium coating formed on the substratal metal coating by a dry plating process and a silicon coating formed on the titanium or chromium coating by a dry plating process, and a hard carbon coating formed on the silicon coating by a dry plating process. According to the present invention, a highly reliable hard carbon coating which is excellent in corrosion resistance, adhesion and abrasion resistance can be formed even on brass or an iron base material having poor corrosion resistance, such as SK steel and martensitic and ferritic stainless steels.

Owner:CITIZEN WATCH CO LTD

Modified natural rubber, method for producing same, rubber composition, and pneumatic tire

ActiveUS20130066021A1Reduced tanImprove fuel economySpecial tyresRolling resistance optimizationPolymer sciencePotassium

The present invention provides a modified natural rubber having a reduced tan δ, a method for producing the modified natural rubber, a rubber composition produced using the modified natural rubber, and a pneumatic tire produced using the rubber composition. The present invention also provides a modified natural rubber having a reduced tan δ, a method for producing the modified natural rubber, a rubber composition produced using the modified natural rubber and achieving good fuel economy and abrasion resistance at the same time, and a pneumatic tire produced using the rubber composition. The present invention relates to a modified natural rubber having a phosphorus content of 200 ppm or less and a total content of sodium and potassium of 350 ppm or less. The invention also relates to a modified natural rubber having a phosphorus content of 200 ppm or less and a nitrogen content of 0.2% by mass or less.

Owner:SUMITOMO RUBBER IND LTD

Molded body

ActiveUS10596739B2Excellent surface hardnessExcellent in abrasionLiquid surface applicatorsSynthetic resin layered productsMethacrylateCoated surface

One embodiment provides a molded body that includes a resin substrate and in which: a part or all of the surface of the substrate is coated with a hard coat; a first hard coat is formed from a coating material that does not contain inorganic particles and that contains (A) 100 parts by mass of a polyfunctional (meth)acrylate, (B) 0.01-7 parts by mass of a water-repelling agent, and (C) 0.01-10 parts by mass of a silane coupling agent; and a second hard coat is formed from a coating material containing (A) 100 parts by mass of the polyfunctional (meth)acrylate and (D) 50-300 parts by mass of fine inorganic particles having an average particle size of 1-300 nm. Another embodiment provides a molded body that includes a resin substrate and in which a part or all of the surface of the substrate is coated with a hard coat, a first hard coat is formed from a coating material that does not contain inorganic particles, a second hard coat is formed from a coating material containing inorganic particles, (i) the total light transmittance is 85% or more, and (ii) the pencil hardness of the surface of the first hard coat is 5H or more.

Owner:RIKEN TECHNOS CORP

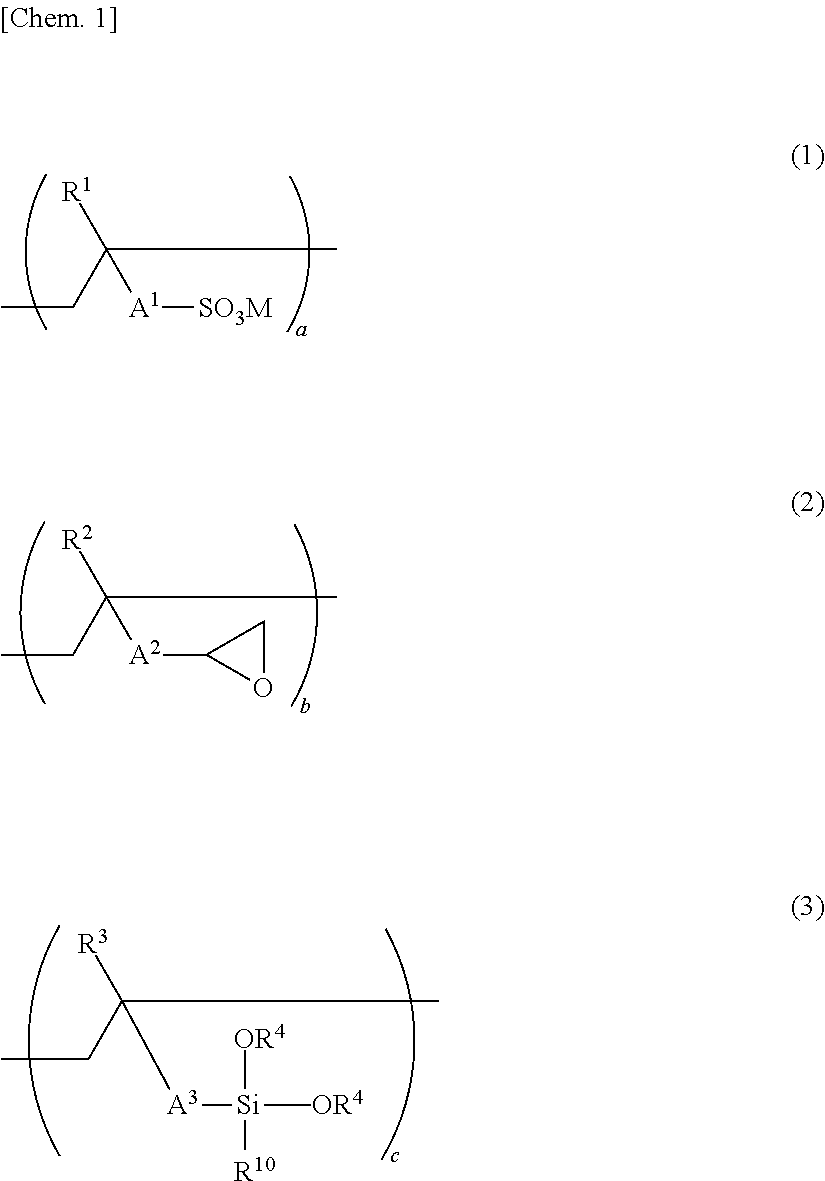

Hydrophilic materials including sulfonate copolymer and amino resin

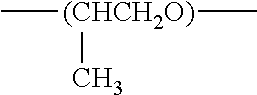

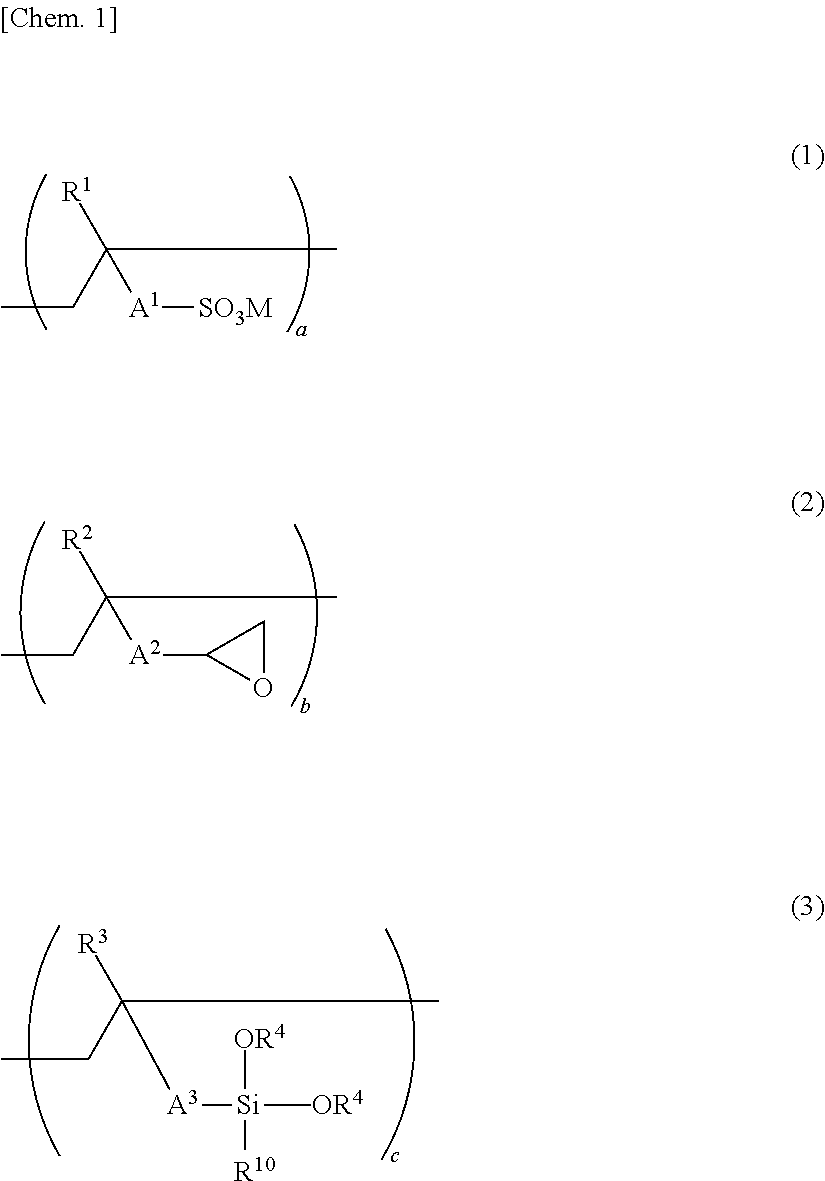

ActiveUS20170210937A1Excellent in abrasionHigh hardnessOptical articlesMedical devicesWear resistanceStructural unit

The invention provides a cured product (for example, a film including the cured product) which has an excellent balance between hydrophilicity and abrasion resistance, can retain high hydrophilicity even when washed with water, and can remain hydrophilic and resistant to the attachment of (or can be easily cleaned of) contaminants even when subjected to long storage or heating, and a composition which can give such cured products. A cured product is obtained by curing a composition which includes a copolymer (i) including structural units represented by specific chemical formulae, and an amino resin (ii).

Owner:MITSUI CHEM INC

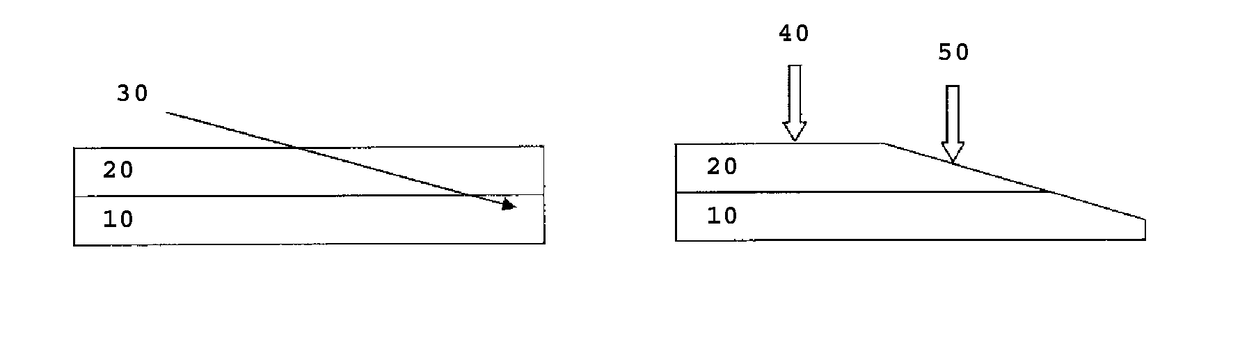

Coating agent for solar cell module, and solar cell module and production method for the solar cell module

InactiveUS20120073628A1Low costPromote conversionMaterial nanotechnologyPV power plantsWeather resistanceElectrical battery

The present invention relates to a coating agent for a solar cell module obtained by dispersing silica fine particles (A) with an average particle diameter of 15 nm or less and low-refractive index resin particles (B) with a refractive index of 1.36 or less in an aqueous medium, in which the solid content is 5% by mass or less, and the mass ratio of the silica fine particles (A) to the low-refractive index resin particles (B) in the solid content (silica fine particles (A) / low-refractive index resin particles (B)) is more than 20 / 80 and less than 70 / 30. The coating agent for a solar cell module is capable of forming an anti-reflection film at room temperature with excellent reflectance-reducing effect, abrasion resistance and weather resistance.

Owner:MITSUBISHI ELECTRIC CORP

Curable composition, cured product, prepreg and fiber-reinforced molded product

InactiveUS20180298155A1Excellent abrasion resistanceGood lookingMetal layered productsShell moldingWear resistance

To provide a curable composition capable of obtaining a cured product excellent in outer appearance and abrasion resistance; a cured product excellent in outer appearance and abrasion resistance; a prepreg capable of obtaining a fiber-reinforced molded product excellent in outer appearance and abrasion resistance; and a fiber-reinforced molded product excellent in outer appearance and abrasion resistance. The curable composition comprises a thermosetting resin, a fluororesin powder and a curing agent, wherein the fluororesin powder is made of a resin material containing a melt-moldable fluororesin having a melting point of from 100 to 325° C. and having functional groups of at least one type selected from the group consisting of carbonyl group-containing groups, hydroxy groups, epoxy groups and isocyanate groups, and in 100 mass % of the total of the thermosetting resin and the fluororesin powder, the proportion of the thermosetting resin is from 70.0 to 99.9 mass % and the proportion of the fluororesin powder is from 0.1 to 30 mass %.

Owner:ASAHI GLASS CO LTD

Coating agent composition and use thereof

InactiveUS20070287823A1Sufficient moisture permeabilityLow degree of swellingPolyurea/polyurethane coatingsThin material handlingOrganic acidPolymer science

The invention relates to a coating agent composition comprising an isocyanate-group-containing prepolymer obtained by reacting a polyol comprising a polyoxyalkylene polyol having 2-4 hydroxyl groups on average, an oxyethylene group content of 85-100% by mass based on all oxyalkylene groups (100% by mass), and an arithmetic-average molecular weight of 800-2,500 with an alicyclic isocyanate and / or an aliphatic isocyanate in the presence of an organic acid bismuth salt catalyst, the isocyanate(s) being used in such an amount as to result in an isocyanate index of 150-300. The invention can provide a coating agent composition which forms a coating film or film having moisture permeability, excellent in mechanical properties and yellowing resistance, having laundering durability and resistance to sweat deterioration, and containing no organotin compounds.

Owner:ASAHI GLASS CO LTD

Resin composition

InactiveUS20070243488A1Excellent abrasion resistanceHigh hardnessPhotosensitive materialsPhotomechanical apparatusPolymer sciencePolycarbonate

Provided is a resin composition that gives a molded article excellent in hardness and abrasion resistance and that is suitable for a photosensitive layer of an electrophotographic photoreceptor. This invention provides a resin composition containing an aromatic polycarbonate resin containing 90 to 100 mol% of a recurring unit from 1,1-bis(4-hydroxyphenyl)cyclohexane and a polyphenylene resin and also provides an electrophotographic photoreceptor using the above resin composition as a binder for a photosensitive layer.

Owner:TEIJIN KASEK KK

Flame-retardant thermoplastic resin composition, molded product thereof and electric wire

ActiveUS7799857B2Reduced flexibilityHigh elastic modulusInsulated cablesInsulatorsShell moldingThermoplastic elastomer

A flame-retardant thermoplastic resin composition, comprising a thermoplastic resin (a) and an inorganic flame-retarder (b), the content of the component (b) being 50 to 250 parts by mass with respect to 100 parts by mass of the component (a), wherein the component (a) includes at least one selected from the group consisting of an α-olefin (co)polymer (a-1), a thermoplastic elastomer (a-2) and a rubber (a-3); the component (a) (100% by mass) includes 0.01 to 0.5% by mass of a constituent unit derived from an unsaturated monomer having a carboxylic acid group or acid anhydride group; the component (b) includes 40 to 95% by mass of inorganic metal hydrate (b-1) and 5 to 60% by mass of inorganic filler (b-2); and the average particle diameter of the inorganic filler (b-2) is not more than 2 μm and the aspect ratio of the inorganic filler (b-2) is not more than 1.5.

Owner:EQUSR CHEM LP

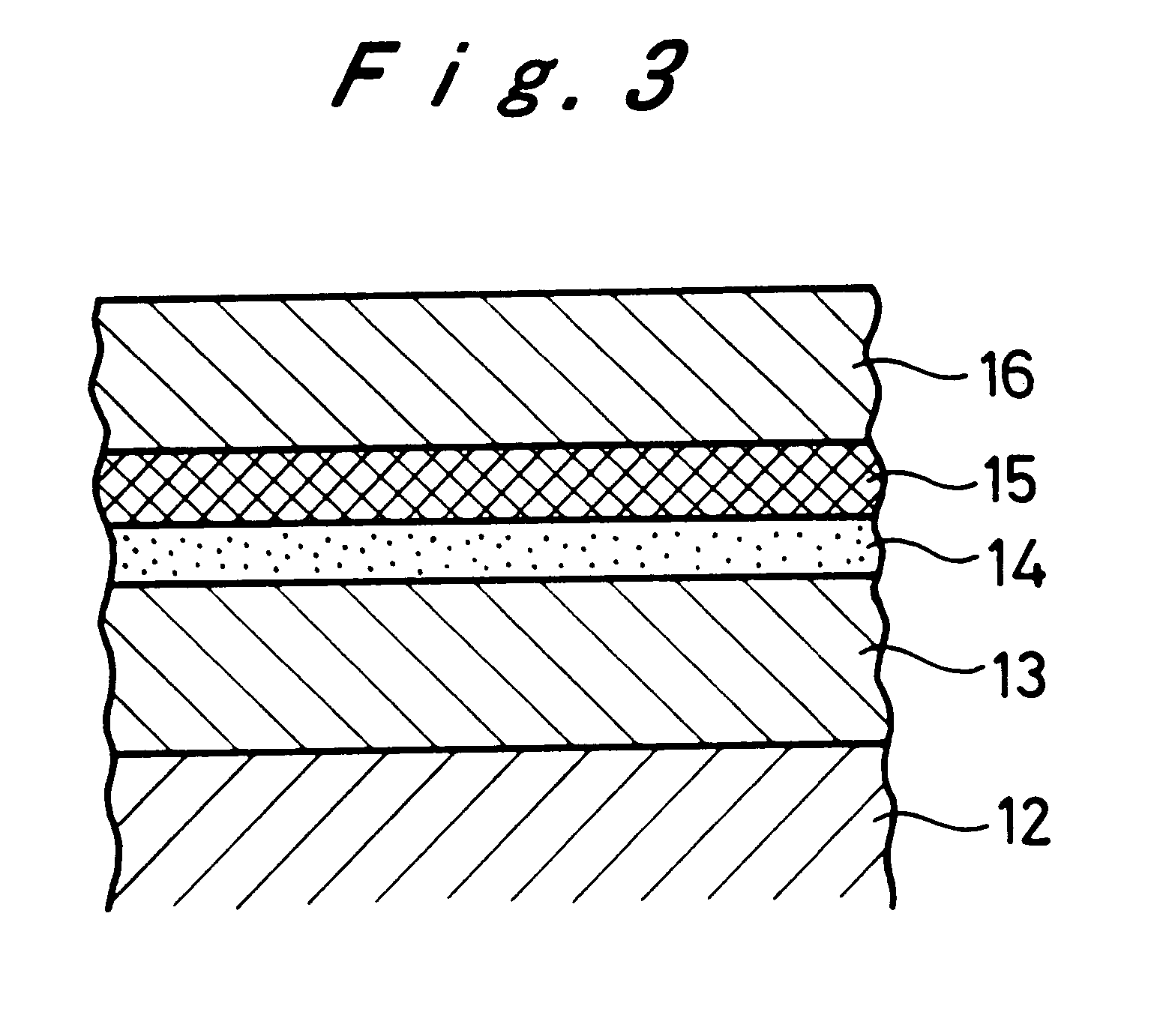

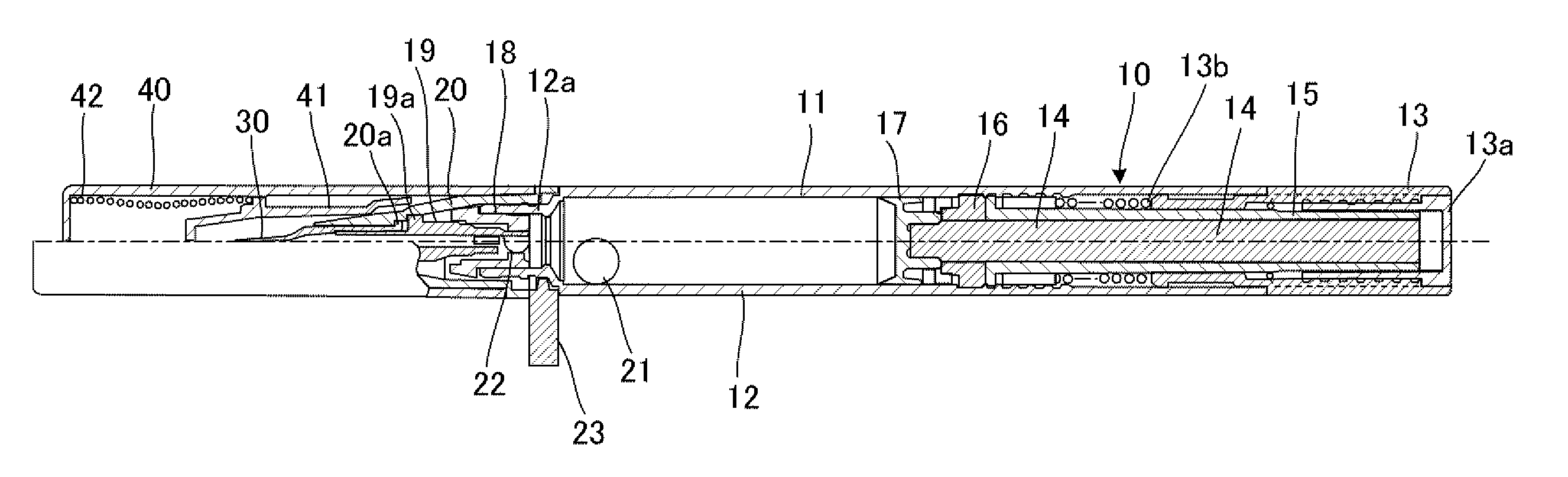

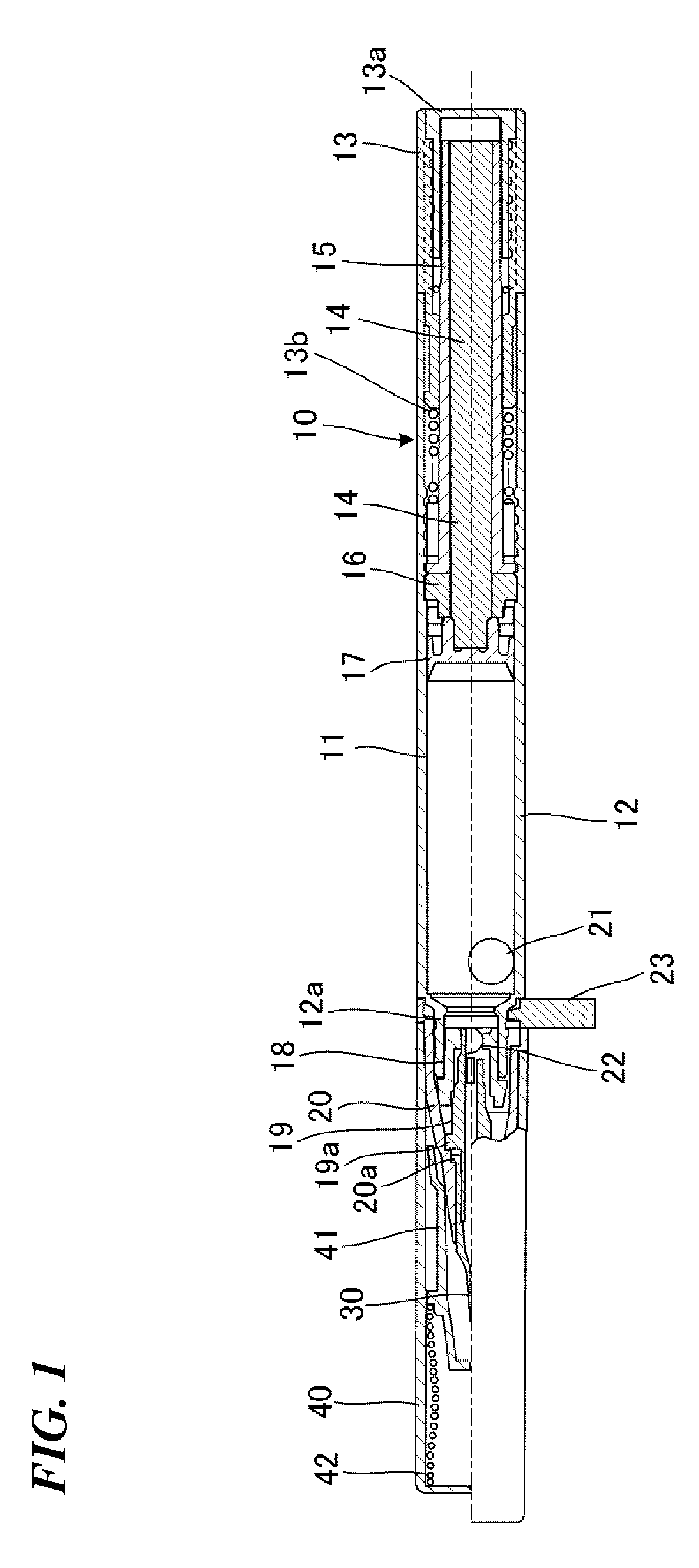

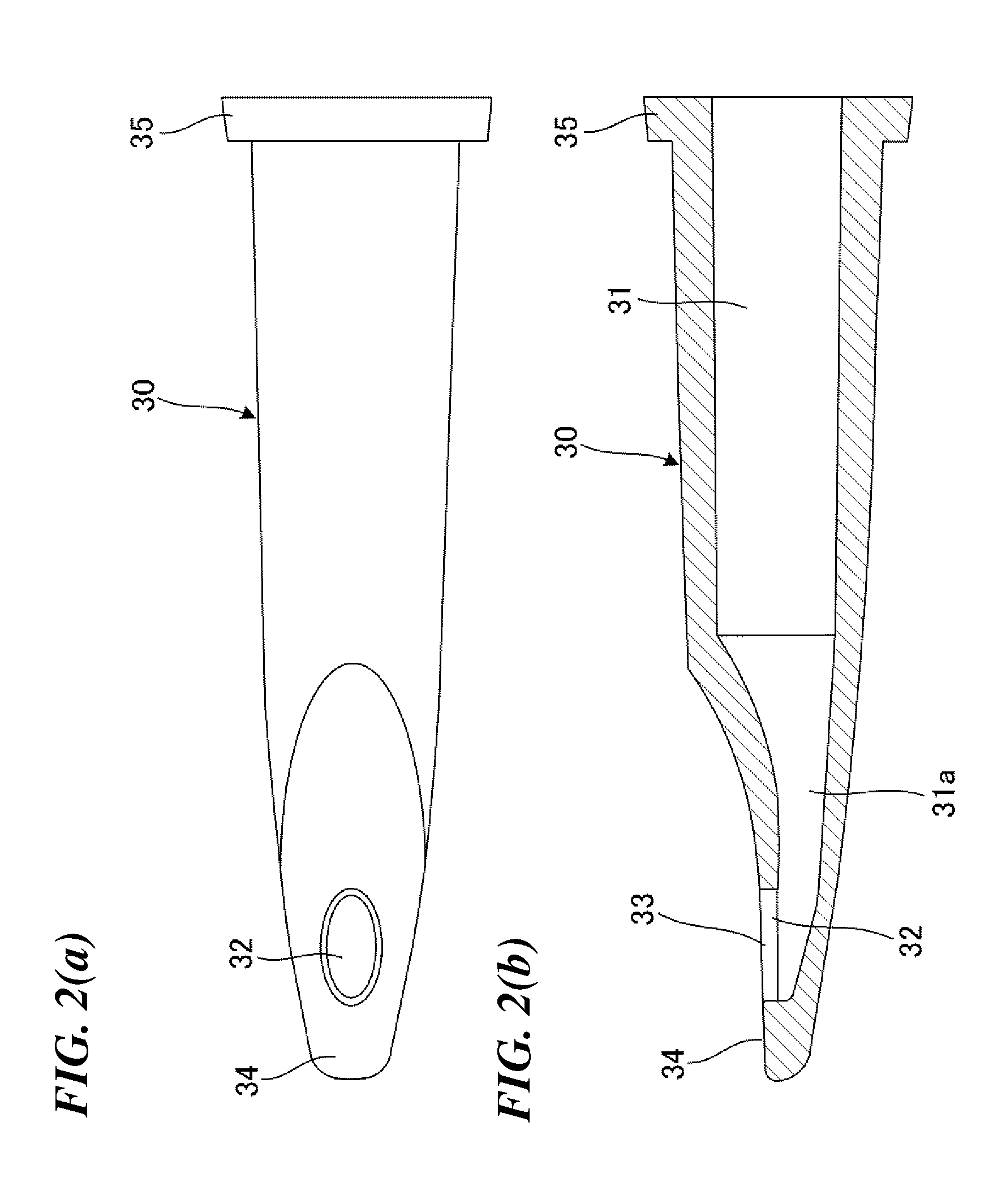

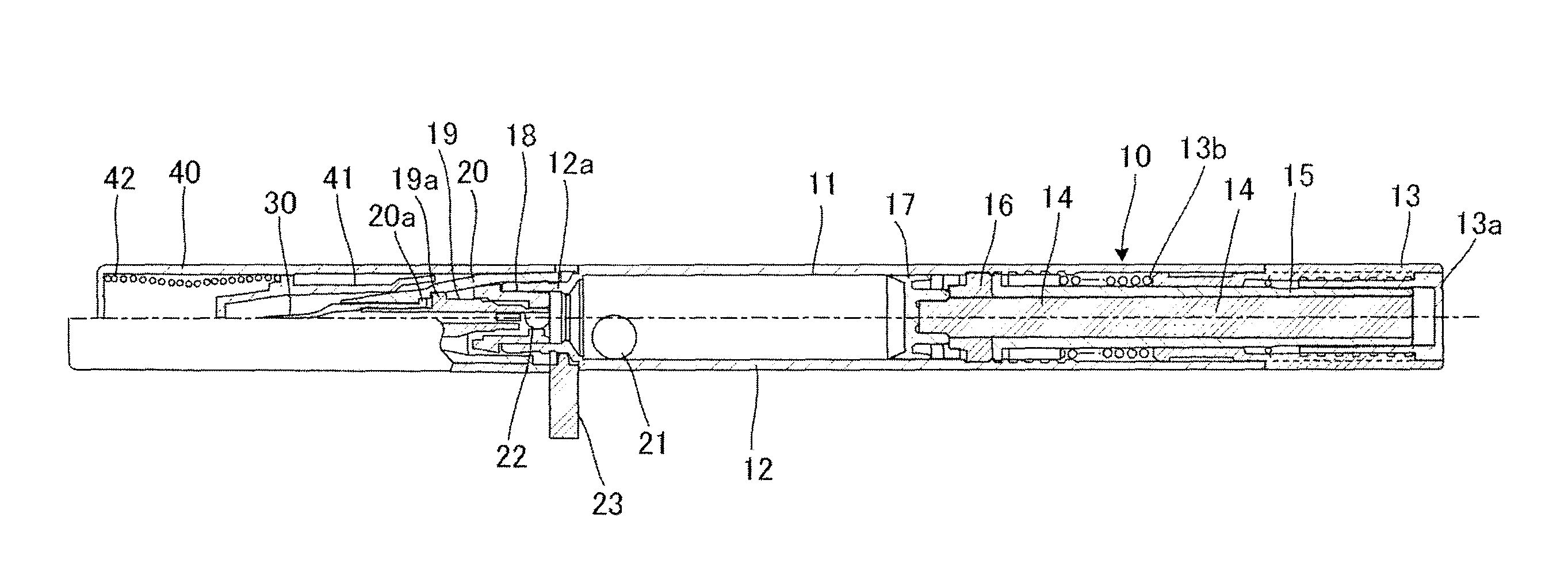

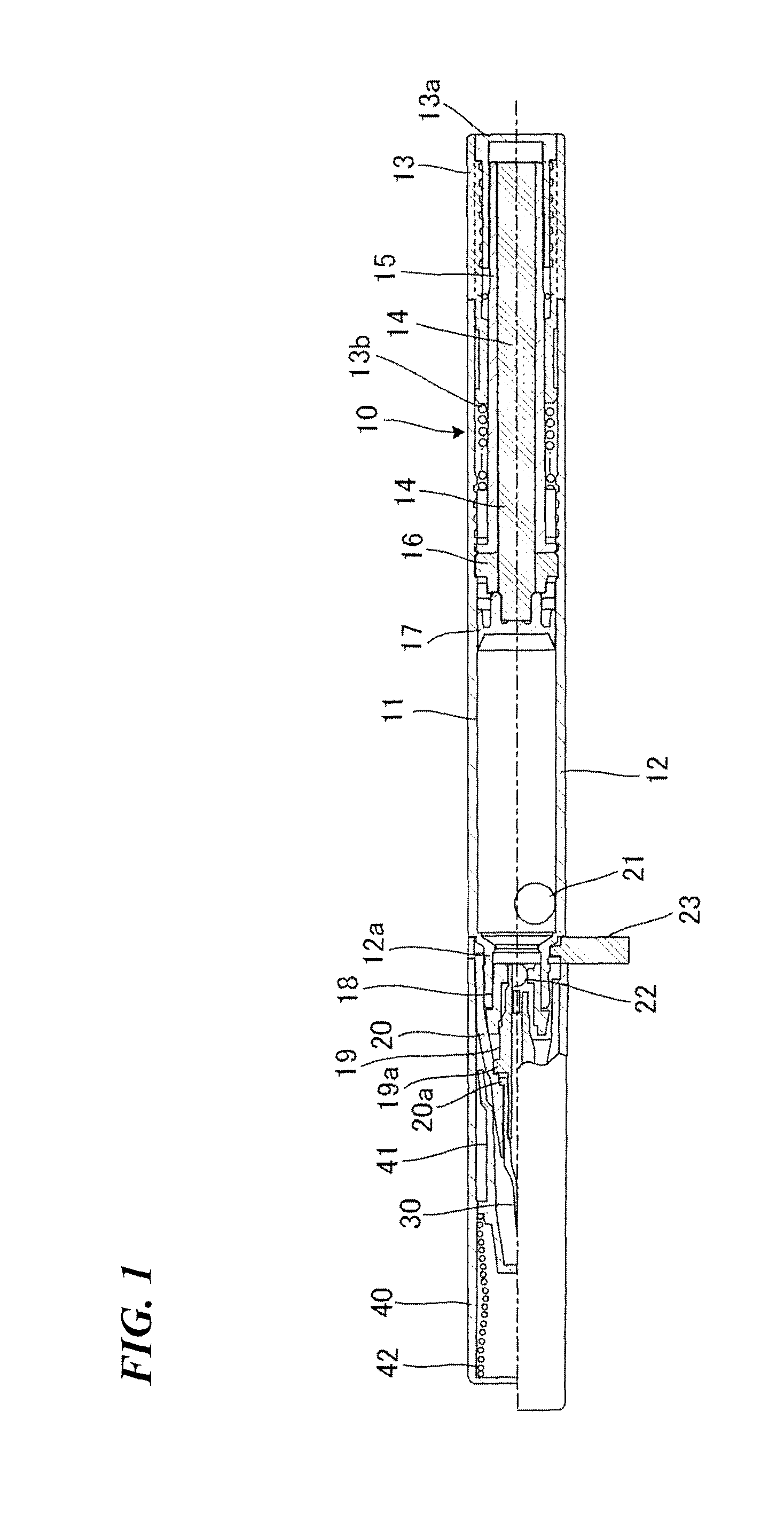

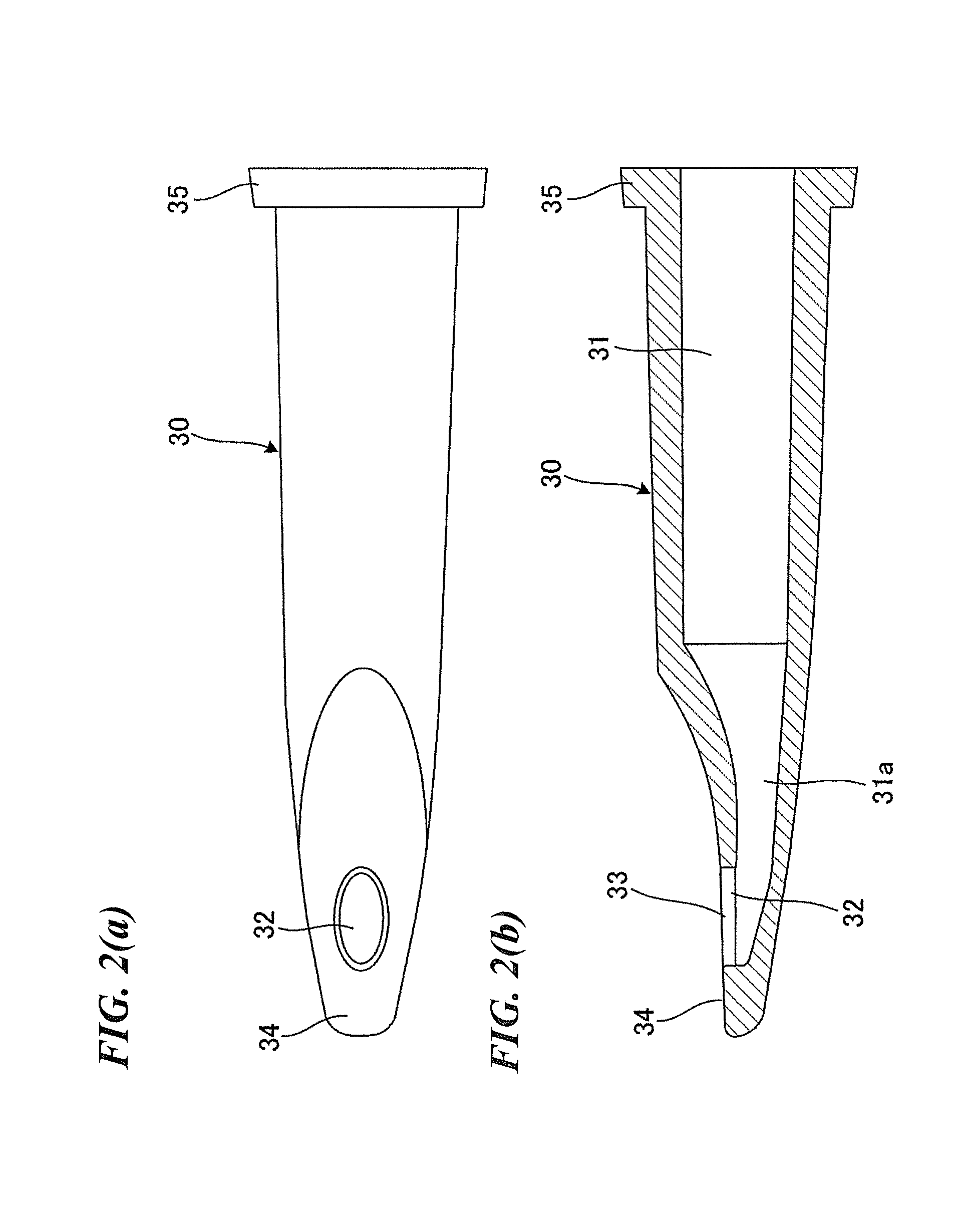

Liquid cosmetic

InactiveUS20130330288A1Increase viscosity of liquidSmoothly ejectCosmetic preparationsMake-upChemistryAnionic polymers

To provide a liquid cosmetic which is loaded into a liquid applicator having an applying part and suitably used as a cosmetic for eye-makeup around the eyes, the liquid cosmetic comprises, at least, 1 to 20% by mass of high-brightness particles, 2 to 10% by mass of film-forming resin, 0.3% by mass or more of an anionic polymer compound having a thickening effect, and water, and is configured such that the viscosity at 25° C. and a shear rate of 76.8 s−1 in an EMD type viscometer falls within the range of 250 to 1,000 mPa·s.

Owner:MITSUBISHI PENCIL CO LTD

Aqueous ink composition and printing process by ink jet recording system using the composition

ActiveUS8702218B2Excellent in abrasionQuality improvementMeasurement apparatus componentsInksWater insolubleGlycol ethers

The aqueous ink composition according to the invention includes at least a water-insoluble coloring agent, a glycol ether having an HLB value calculated by a Davies' method in the range of 4.2 to 8.0, a 1,2-alkyldiol having 4 to 8 carbon atoms, resin particles, and water.

Owner:SEIKO EPSON CORP

Rubber composition and tire using the same

ActiveUS20160053098A1Excellent in abrasionImprove wet grip performanceSpecial tyresRolling resistance optimizationNitrogen adsorptionButadiene-styrene rubber

Provide are a rubber composition for tire which is excellent in a wet grip performance and abrasion resistance and which has small rolling resistance and a low fuel consumption, and a tire prepared by using the above rubber composition. The rubber composition is prepared by compounding 100 parts by mass of a rubber component comprising a styrene-butadiene rubber or a styrene-butadiene rubber and a butadiene rubber with 2 to 200 parts by mass of carbon black as a reinforcing filler, wherein the carbon black has at least a hydrogen release rate of 0.2% by mass or more and / or a ratio N2SA / CTAB of 1.2 to 1.5 in which N2SA is a nitrogen adsorption specific surface area and CTAB is a cetyltributylammonium bromide adsorption specific surface area, and has a N2SA of 160 to 300 m2 / g.

Owner:BRIDGESTONE CORP

Rubber composition and tire using the same

ActiveUS9873778B2Excellent in abrasionImprove performanceSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

Provide are a rubber composition for tire which is excellent in a wet grip performance and abrasion resistance and which has small rolling resistance and a low fuel consumption, and a tire prepared by using the above rubber composition. The rubber composition is prepared by compounding 100 parts by mass of a rubber component comprising a styrene-butadiene rubber or a styrene-butadiene rubber and a butadiene rubber with 2 to 200 parts by mass of carbon black as a reinforcing filler, wherein the carbon black has at least a hydrogen release rate of 0.2% by mass or more and / or a ratio N2SA / CTAB of 1.2 to 1.5 in which N2SA is a nitrogen adsorption specific surface area and CTAB is a cetyltributylammonium bromide adsorption specific surface area, and has a N2SA of 160 to 300 m2 / g.

Owner:BRIDGESTONE CORP

Pneumatic tire

InactiveUS20190367710A1Improve chip-cutting resistanceImprove steering stabilitySpecial tyresTyre tread bands/patternsSilicon dioxideWear resistance

A pneumatic tire having excellent high-temperature grip performance and abrasion resistance is provided. The pneumatic tire is a tire having a tread composed of a predetermined rubber composition comprising a diene rubber comprising isoprene rubber, carbon black, silica, a compound comprising a predetermined bonding unit I and a bonding unit II, and a compound represented by a predetermined formula.

Owner:SUMITOMO RUBBER IND LTD

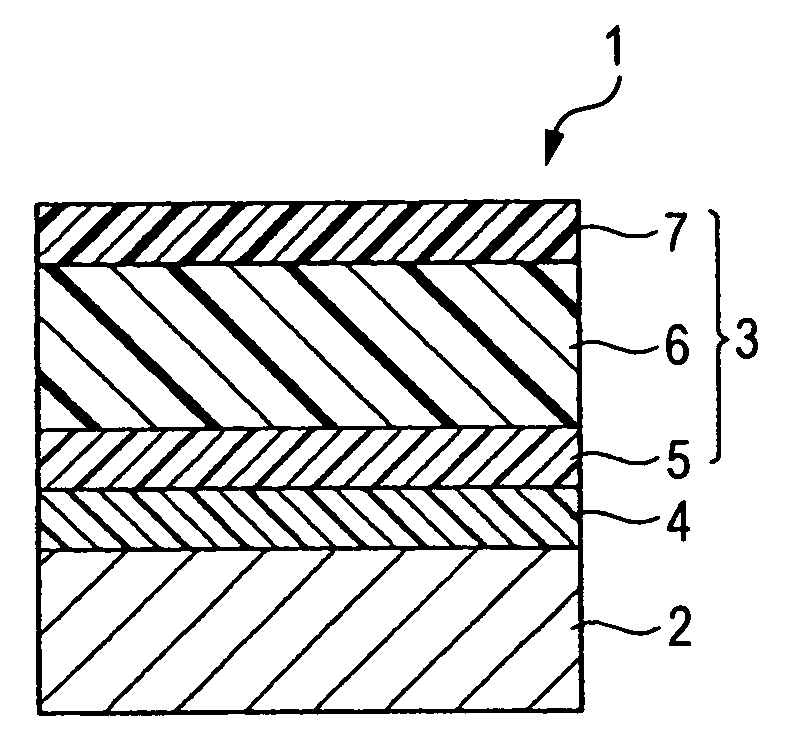

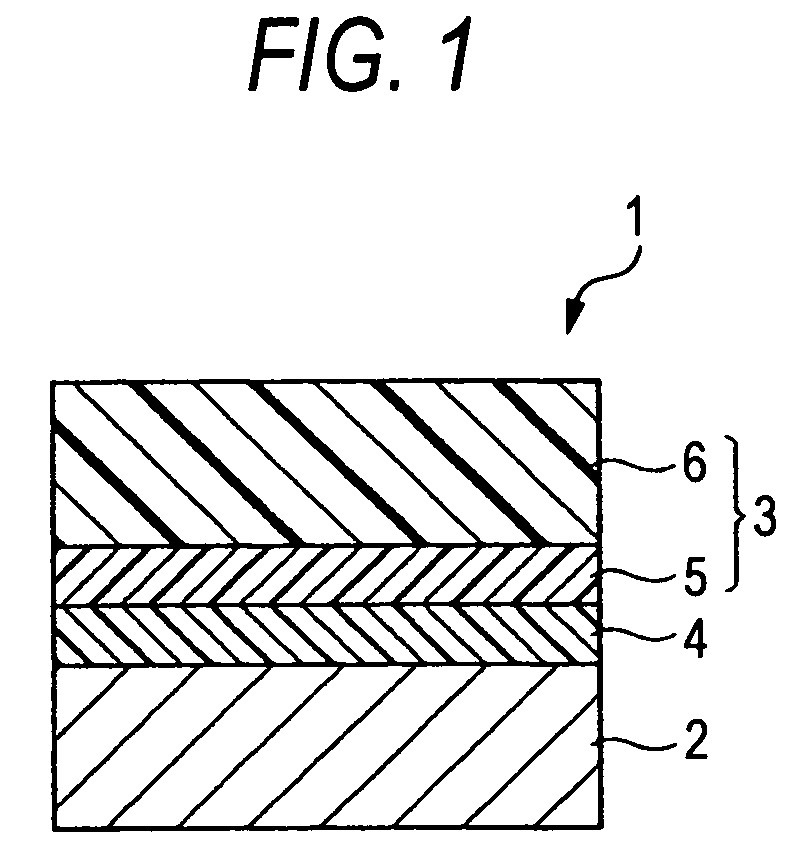

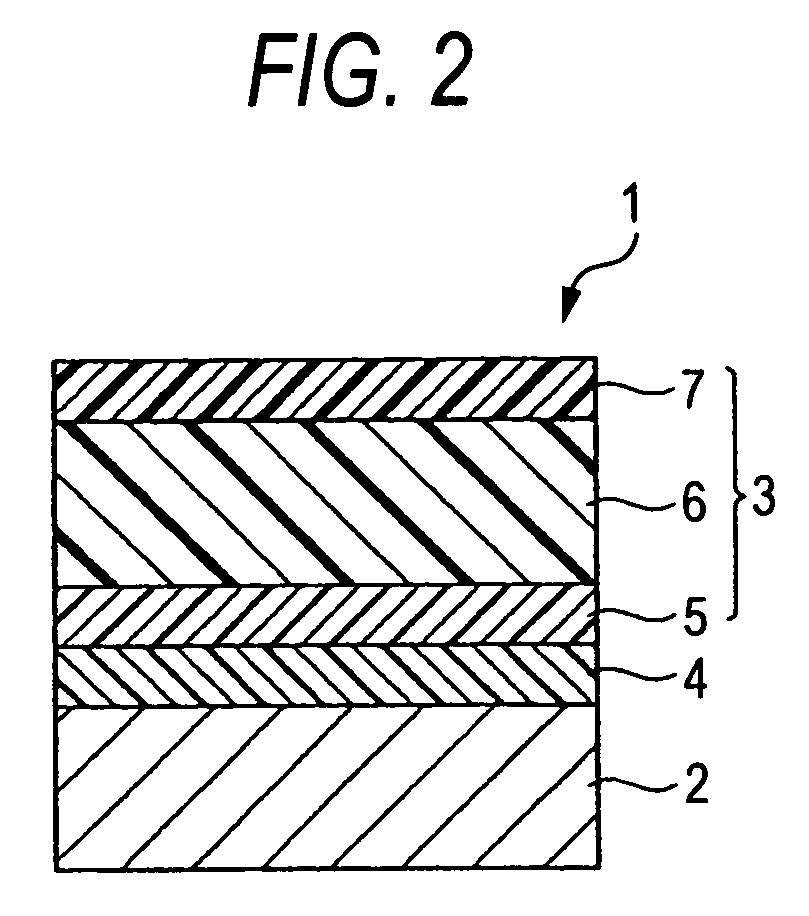

Coated die for use in hot stamping

PendingUS20220032357A1Excellent in abrasionIncrease resistanceShaping toolsVacuum evaporation coatingHot stampingNitride

A coated die for use in hot stamping has a hard film having an alternating lamination section formed by alternating lamination of a1 layers consisting of nitride having 30% or more of chromium in atomic ratio in a metal part, and a2 layers consisting of nitride having 50% or more of vanadium in atomic ratio in a metal part. When ta1 and ta2 are defined as thicknesses of the a1 layer and the a2 layer respectively, a film thickness ratio Xb is defined as a film thickness ratio ta2 / ta1 of a1 layers and a2 layers adjacent to each other in a substrate-side region of the alternating lamination section and a film thickness ratio Xt is defined as a film thickness ratio ta2 / ta1 of a1 layers and a2 layers adjacent to each other in an outermost surface side region of the alternating lamination section, it holds that Xt>Xb.

Owner:PROTERIAL LTD

Anti-fogging article and manufacturing method thereof

InactiveUS20170015863A1Excellent in abrasionMaintain good propertiesOptical articlesVehicle componentsSilica particleSilicon dioxide

An antifogging article excellent in both an antifogging property and abrasion resistance and a manufacturing method thereof are provided. The antifogging article includes: a substrate; a water-absorbing resin layer disposed on the substrate; and an overcoat layer disposed on the water-absorbing resin layer and including: a hydrolyzed condensate of an alkoxysilane compound; and silica particles, wherein a film thickness of the overcoat layer is 20 to 350 nm and the overcoat layer is formed from an overcoat composition containing 90 to 45 parts by mass of the alkoxysilane compound and 10 to 55 parts by mass of the silica particles relative to total 100 parts by mass of the alkoxysilane compound and the silica particles.

Owner:ASAHI GLASS CO LTD

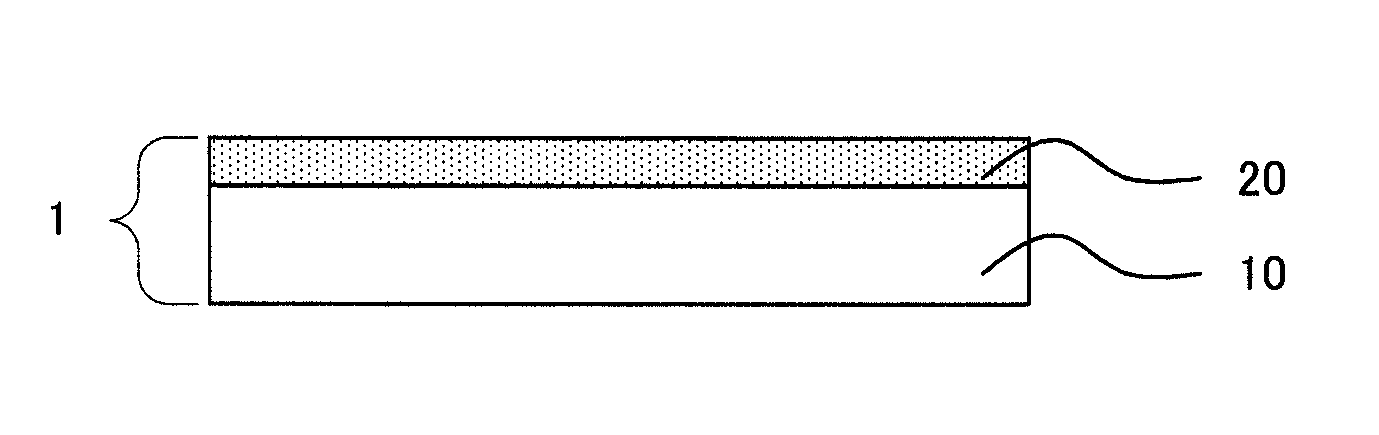

Adhesive film

ActiveUS20180072030A1Excellent in abrasionGood colorLamination ancillary operationsFilm/foil adhesivesCoated surfacePolymer science

An embodiment provides an adhesive film having, in order from the surface layer side, a first hard coat, a second hard coat, a transparent resin film layer, and an adhesive layer. The first hard coat is formed from a coating that does not include inorganic particles. The second hard coat is formed from a coating that includes inorganic particles. The adhesive film satisfies the following conditions: (i) the total light transmittance is at least 85%; and (vii) the pencil hardness of the first hard coat surface is at least 5H. Another embodiment provides an adhesive film having, in order from the surface layer side, a first hard coat, a second hard coat, a transparent resin film layer, and an adhesive layer. The first hard coat is formed from a coating that does not include inorganic particles. The second hard coat is formed from a coating that includes inorganic particles. The adhesive film satisfies the following conditions: (i) the total light transmittance is at least 85%; (iv) the water contact angle at the first hard coat surface is at least 100 degrees; and (v) the water contact angle at the first hard coat surface after 20,000 reciprocal cotton rubs is at least 100 degrees.

Owner:RIKEN TECHNOS CORP

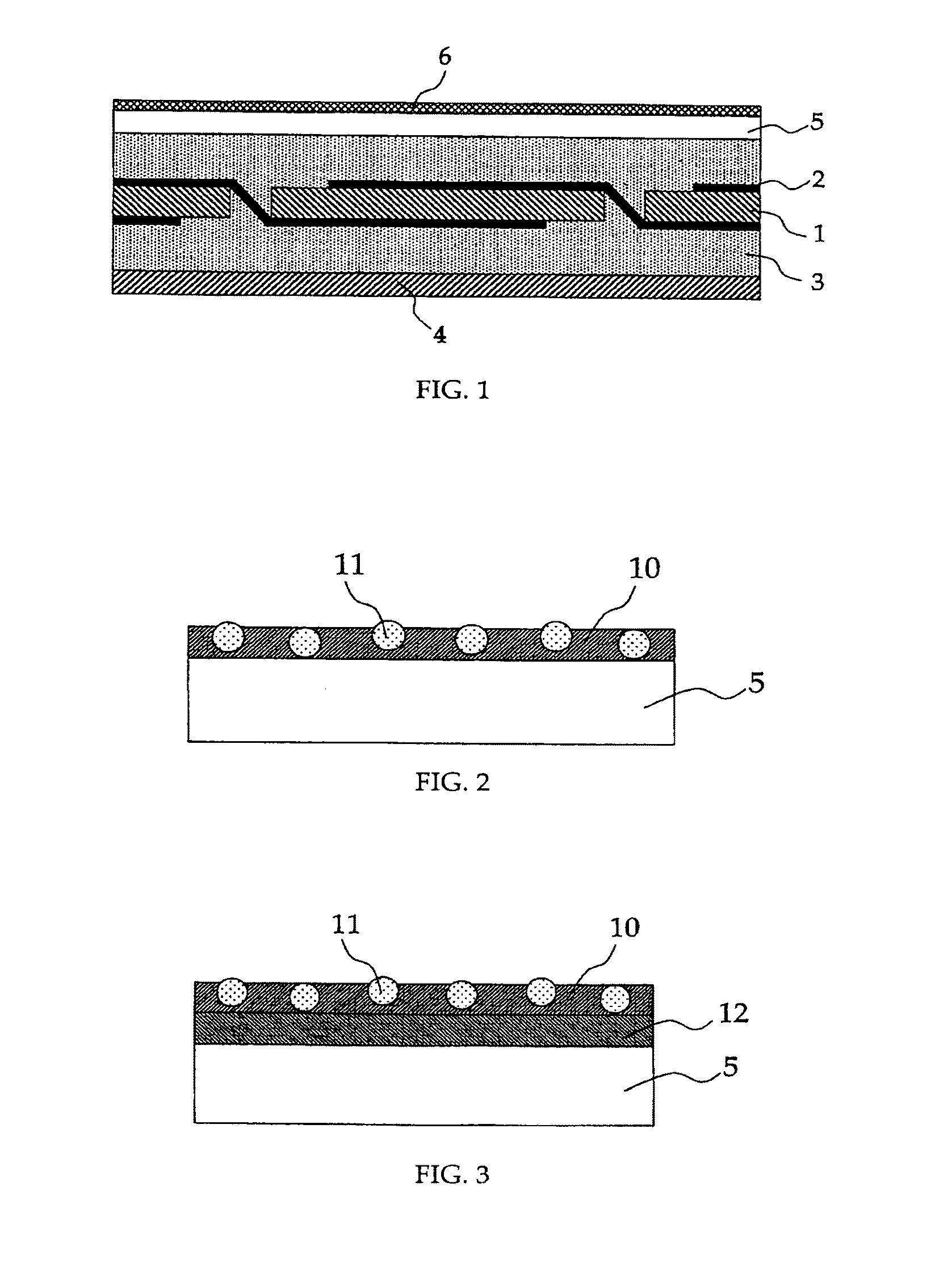

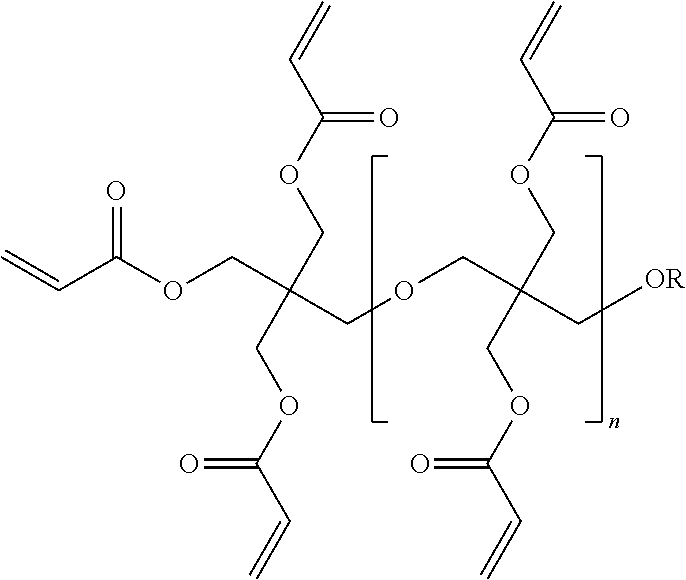

Hard coat layered film

ActiveUS10816700B2Excellent in abrasionGood colorSynthetic resin layered productsElectrical equipmentMethacrylatePolymer science

Embodiments provide a hard coat layered film having a first hard coat, a second hard coat, and a transparent resin film layer in order from an outer layer side, the first hard coat including (A) 100 parts by mass of a polyfunctional (meth)acrylate including 20% by mass or more of a tripentaerythritol acrylate, (B) 0.01-7 parts by mass of a water repellent, and (C) 0.01-10 parts by mass of a silane coupling agent, the first hard coat being formed from a coating material not including inorganic particles, and the second hard coat including (A′) 100 parts by mass of a polyfunctional (meth)acrylate and (D) 50-300 parts by mass of inorganic fine particles having an average particle diameter of 1-300 nm. According to at least one embodiment, component (A) may be a mixture of tripentaerythritol acrylate and one or more species selected from the group consisting of dipentaerythritol acrylate, monopentaerythritol acrylate, and polypentaerythritol acrylate.

Owner:RIKEN TECHNOS CORP

Coating agent composition and use thereof

InactiveUS20090104451A1Excellent in abrasionHigh elongationSynthetic resin layered productsPretreated surfacesPolymer scienceMechanical property

The invention relates to a coating agent composition comprising an isocyanate-group-containing prepolymer obtained by reacting a polyol comprising a polyoxyalkylene polyol having 2-4 hydroxyl groups on average, an oxyethylene group content of 85-100% by mass based on all oxyalkylene groups (100% by mass), and an arithmetic-average molecular weight of 800-2,500 with an alicyclic isocyanate and / or an aliphatic isocyanate in the presence of an organic acid bismuth salt catalyst, the isocyanate(s) being used in such an amount as to result in an isocyanate index of 150-300. The invention can provide a coating agent composition which forms a coating film or film having moisture permeability, excellent in mechanical properties and yellowing resistance, having laundering durability and resistance to sweat deterioration, and containing no organotin compounds.

Owner:ASAHI GLASS CO LTD

Modified natural rubber, method for producing same, rubber composition, and pneumatic tire

ActiveUS9181355B2Reduced tanImprove economySpecial tyresRolling resistance optimizationPolymer sciencePotassium

Owner:SUMITOMO RUBBER IND LTD

Hard coat film and curable resin composition for hard coat layer

ActiveUS9284426B2High hardnessIncrease resistanceLayered productsCoatingsCoated membranePolymer science

Owner:DAI NIPPON PRINTING CO LTD

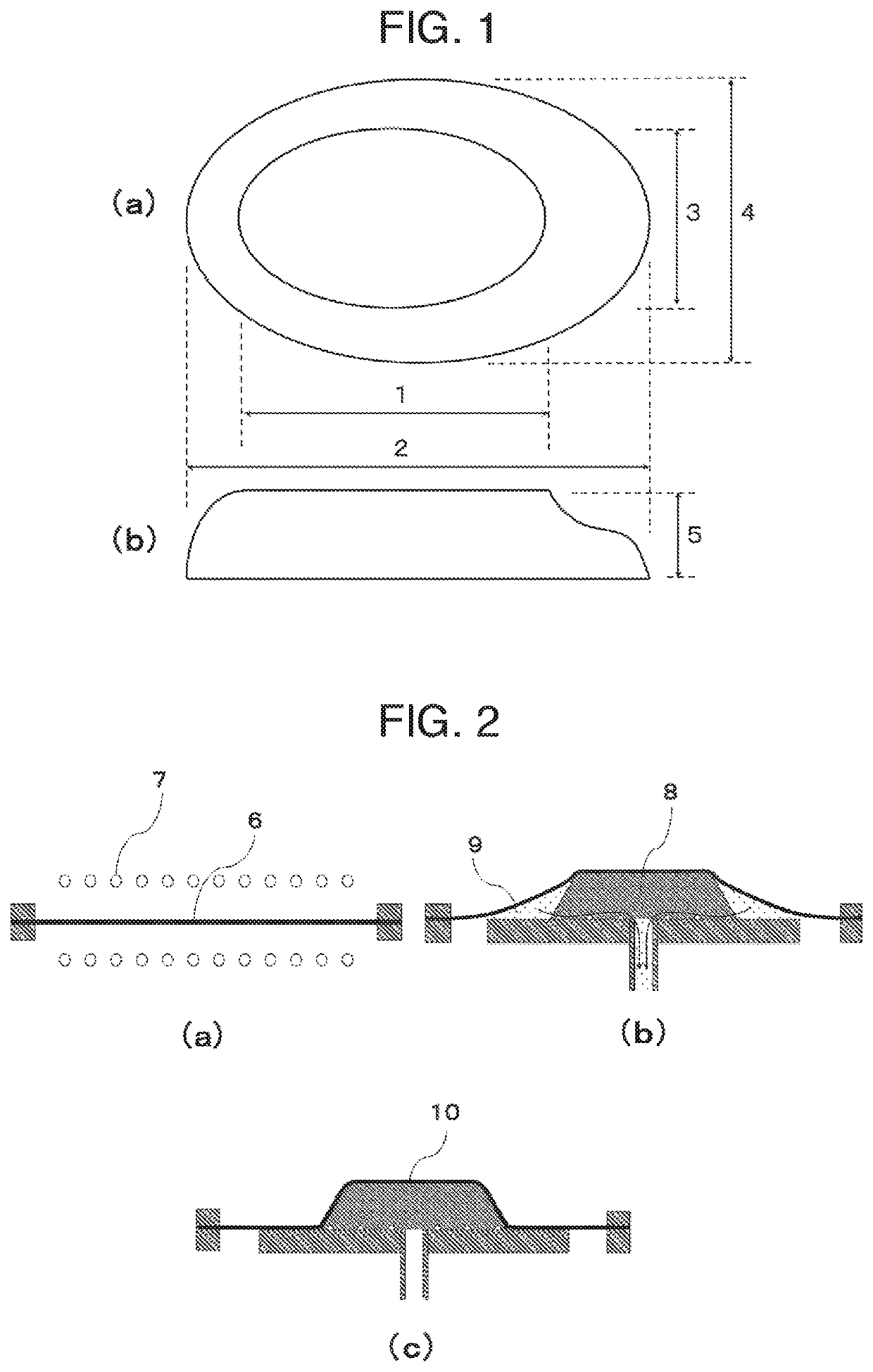

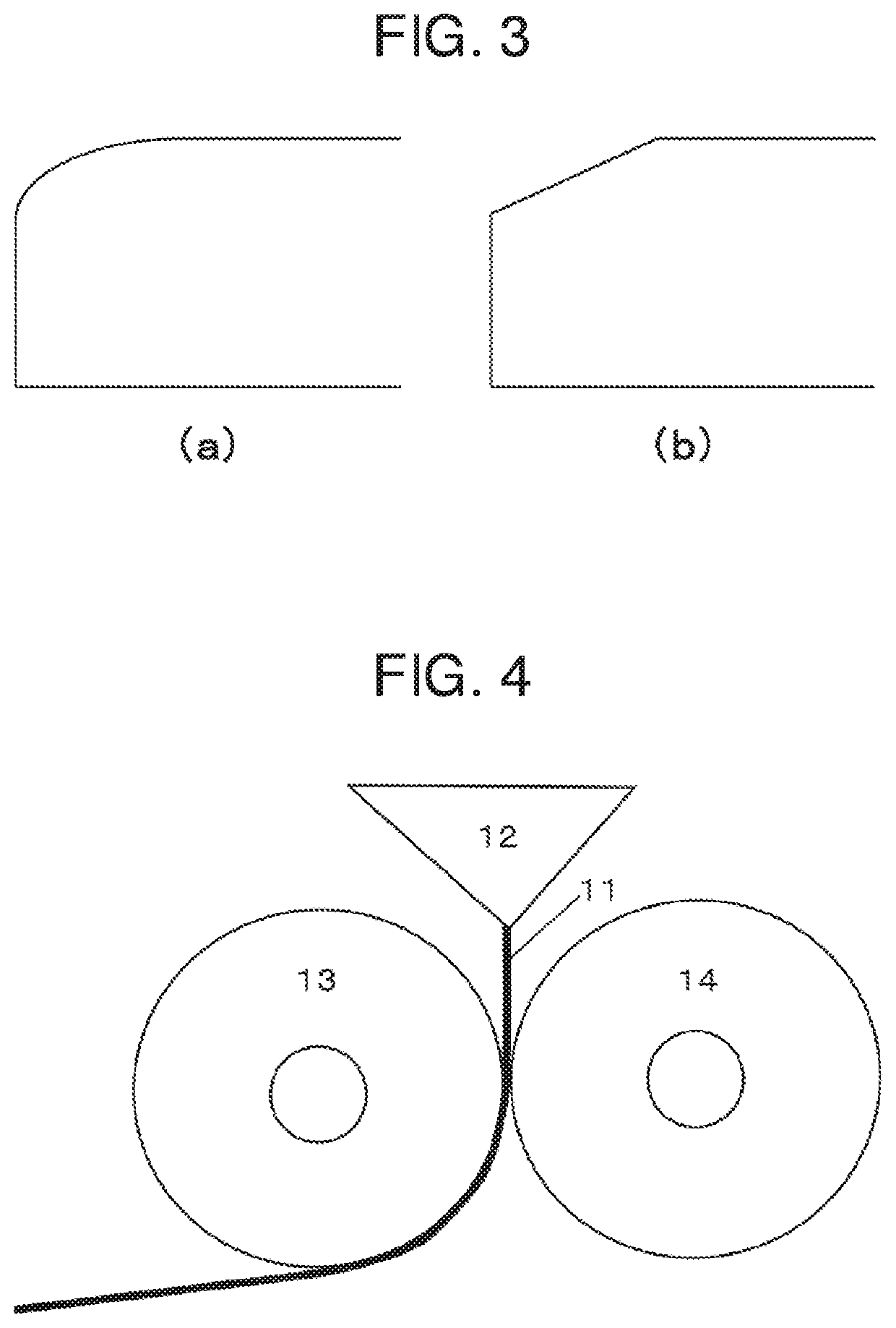

Multifilament and braid

ActiveUS20170107642A1Little changeGood dimensional stabilityDry spinning methodsMonocomponent polyolefin artificial filamentIntrinsic viscosityWear resistance

It is provided that a multifilament and a braid that are capable of being processed into products in a wide range of temperature and are excellent in dimensional stability and abrasion resistance. A multifilament comprising 5 or more monofilaments, wherein the multifilament contains polyethylene having an intrinsic viscosity [η] of 5.0 dL / g or more and 40.0 dL / g or less and substantially including ethylene as a repeating unit, and shows 1000 times or more in number of reciprocating abrasions at break in an abrasion resistance test measured at a load of 5 cN / dtex in accordance with JIS L-1095.

Owner:TOYOBO MC CORP

Laminate

InactiveUS20170015088A1Excellent in abrasionImprove heat resistanceSynthetic resin layered productsOptical articlesMethacrylateHydrogen atom

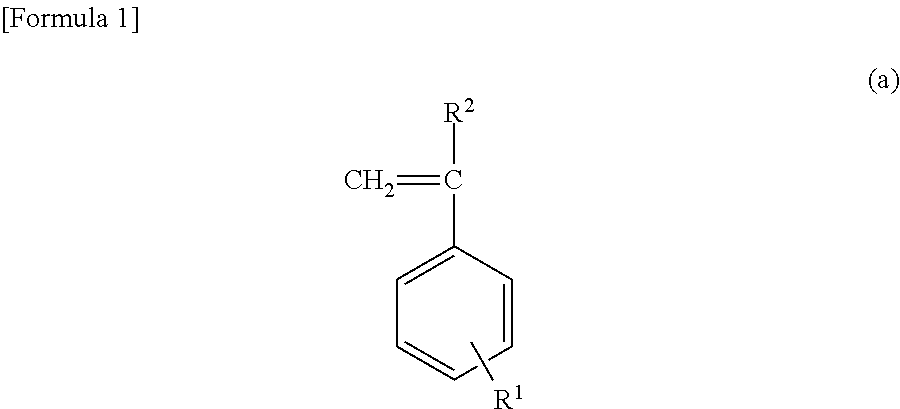

A problem of providing a laminate which is excellent in transparency, heat resistance, moisture resistance, and abrasion. resistance, has a satisfactory bending workability, and includes a layer containing a methacrylate resin and a styrene-based resin, and a layer containing polycarbonate is solved by the invention of a laminate including: a layer including a resin composition containing 5 mass % or more but less than 50 mass % of a methacrylate resin and 50 mass % or more but less than 95 mass % of a copolymer including at least a structural unit derived from an aromatic vinyl compound represented by the following general formula (a) and a structural unit derived from an acid anhydride represented by the following general formula (b); and a layer including polycarbonate.(wherein R1 and R2 are independently represent a hydrogen atom or an alkyl group)(wherein R3 and R4 are independently represent a hydrogen atom or an alkyl group).

Owner:KURARAY CO LTD

Adhesive film

ActiveUS11065852B2Excellent in abrasionGood colorLamination ancillary operationsFilm/foil adhesivesCoated surfacePolymer science

An embodiment provides an adhesive film having, in order from the surface layer side, a first hard coat, a second hard coat, a transparent resin film layer, and an adhesive layer. The first hard coat is formed from a coating that does not include inorganic particles. The second hard coat is formed from a coating that includes inorganic particles. The adhesive film satisfies the following conditions: (i) the total light transmittance is at least 85%; and (vii) the pencil hardness of the first hard coat surface is at least 5H. Another embodiment provides an adhesive film having, in order from the surface layer side, a first hard coat, a second hard coat, a transparent resin film layer, and an adhesive layer. The first hard coat is formed from a coating that does not include inorganic particles. The second hard coat is formed from a coating that includes inorganic particles. The adhesive film satisfies the following conditions: (i) the total light transmittance is at least 85%; (iv) the water contact angle at the first hard coat surface is at least 100 degrees; and (v) the water contact angle at the first hard coat surface after 20,000 reciprocal cotton rubs is at least 100 degrees.

Owner:RIKEN TECHNOS CORP

Hydrophilic materials including sulfonate copolymer and amino resin

ActiveUS9976050B2Excellent in abrasionHigh hardnessOptical articlesMedical devicesStructural unitPolymer chemistry

The invention provides a cured product (for example, a film including the cured product) which has an excellent balance between hydrophilicity and abrasion resistance, can retain high hydrophilicity even when washed with water, and can remain hydrophilic and resistant to the attachment of (or can be easily cleaned of) contaminants even when subjected to long storage or heating, and a composition which can give such cured products. A cured product is obtained by curing a composition which includes a copolymer (i) including structural units represented by specific chemical formulae, and an amino resin (ii).

Owner:MITSUI CHEM INC

Liquid cosmetic

InactiveUS8808672B2Eject evenlyIncreasing the liquid viscosity without any loss of ejection performanceCosmetic preparationsMake-upShear rateAnionic polymers

To provide a liquid cosmetic which is loaded into a liquid applicator having an applying part and suitably used as a cosmetic for eye-makeup around the eyes, the liquid cosmetic comprises, at least, 1 to 20% by mass of high-brightness particles, 2 to 10% by mass of film-forming resin, 0.3% by mass or more of an anionic polymer compound having a thickening effect, and water, and is configured such that the viscosity at 25° C. and a shear rate of 76.8 s−1 in an EMD type viscometer falls within the range of 250 to 1,000 mPa·s.

Owner:MITSUBISHI PENCIL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com