Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Concentrated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

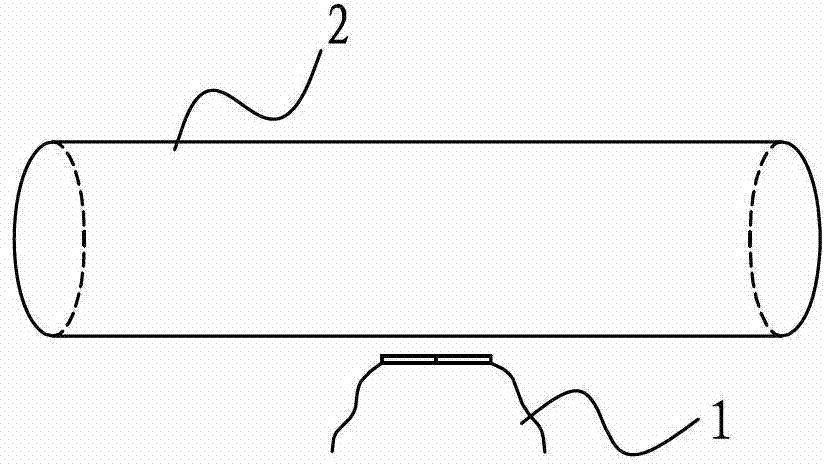

Resistive random access memory and manufacturing method thereof

InactiveCN102738386AEnhance local electric field strengthConcentratedSolid-state devicesSemiconductor devicesStatic random-access memoryRandom access memory

The invention provides a resistive random access memory and a manufacturing method thereof. The memory comprises a lower electrode, a local control electrode located on the lower electrode, a storage medium layer located on the lower electrode and the local control electrode, and an upper electrode located on the storage medium layer. Through the local control electrode located on the lower electrode, local electric field intensity in the storage medium is enhanced, so formation of conductive filaments along the control electrode is facilitated, so that the formation and disconnection of the conductive filaments are effectively controlled, thereby the programming voltage discrete problem caused by the random formation of the conductive filaments is solved, so the concentricity of a programming voltage of a device is facilitated, and the working stability of the device is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

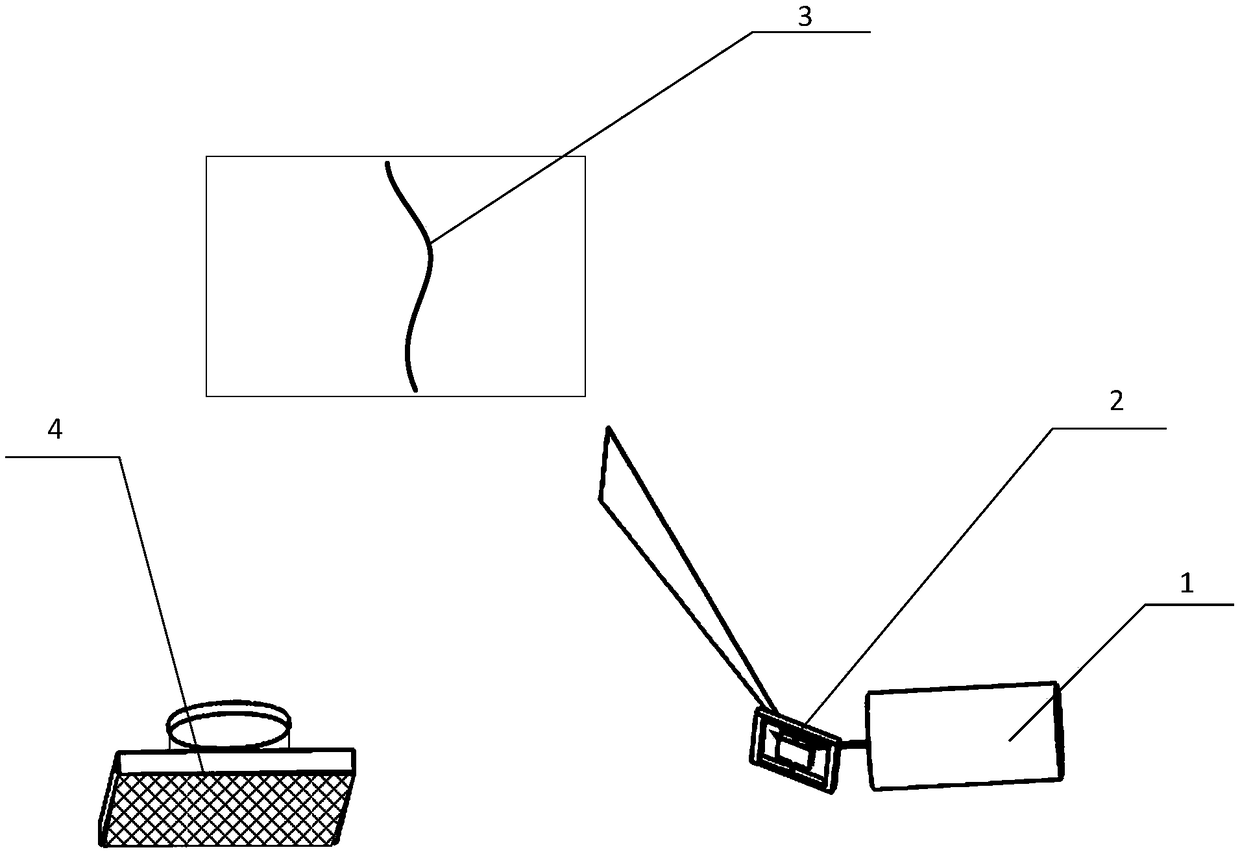

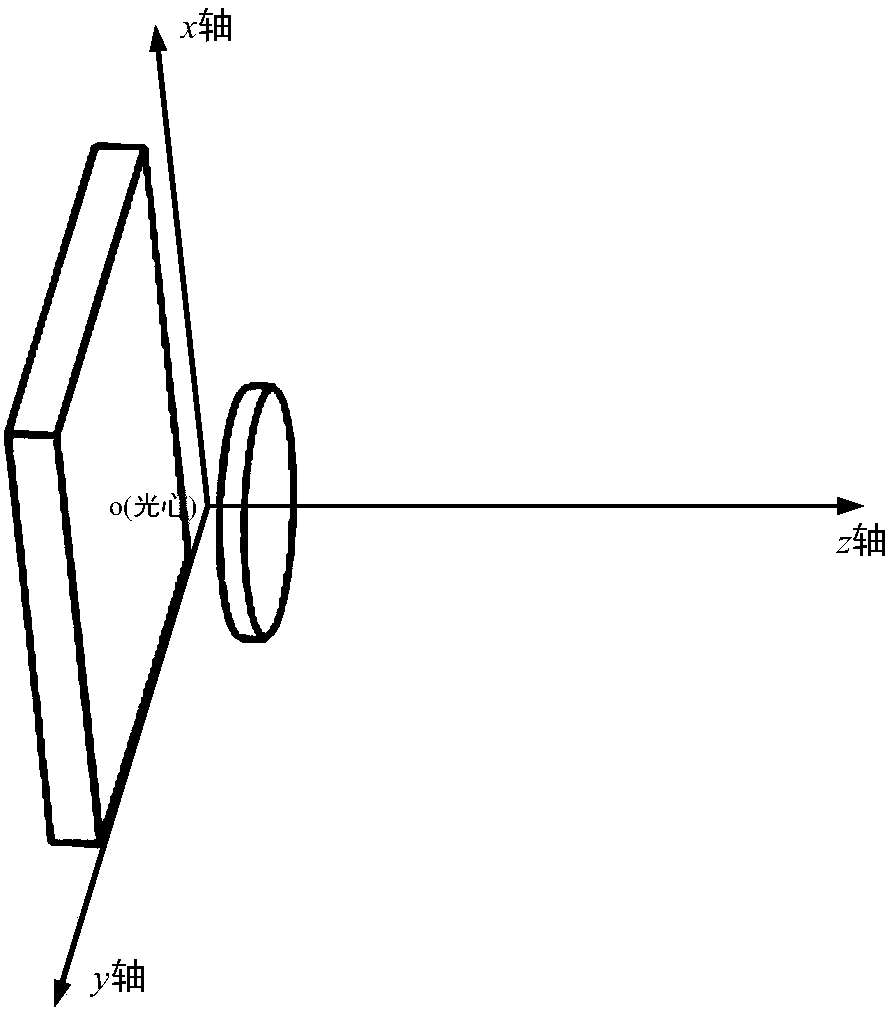

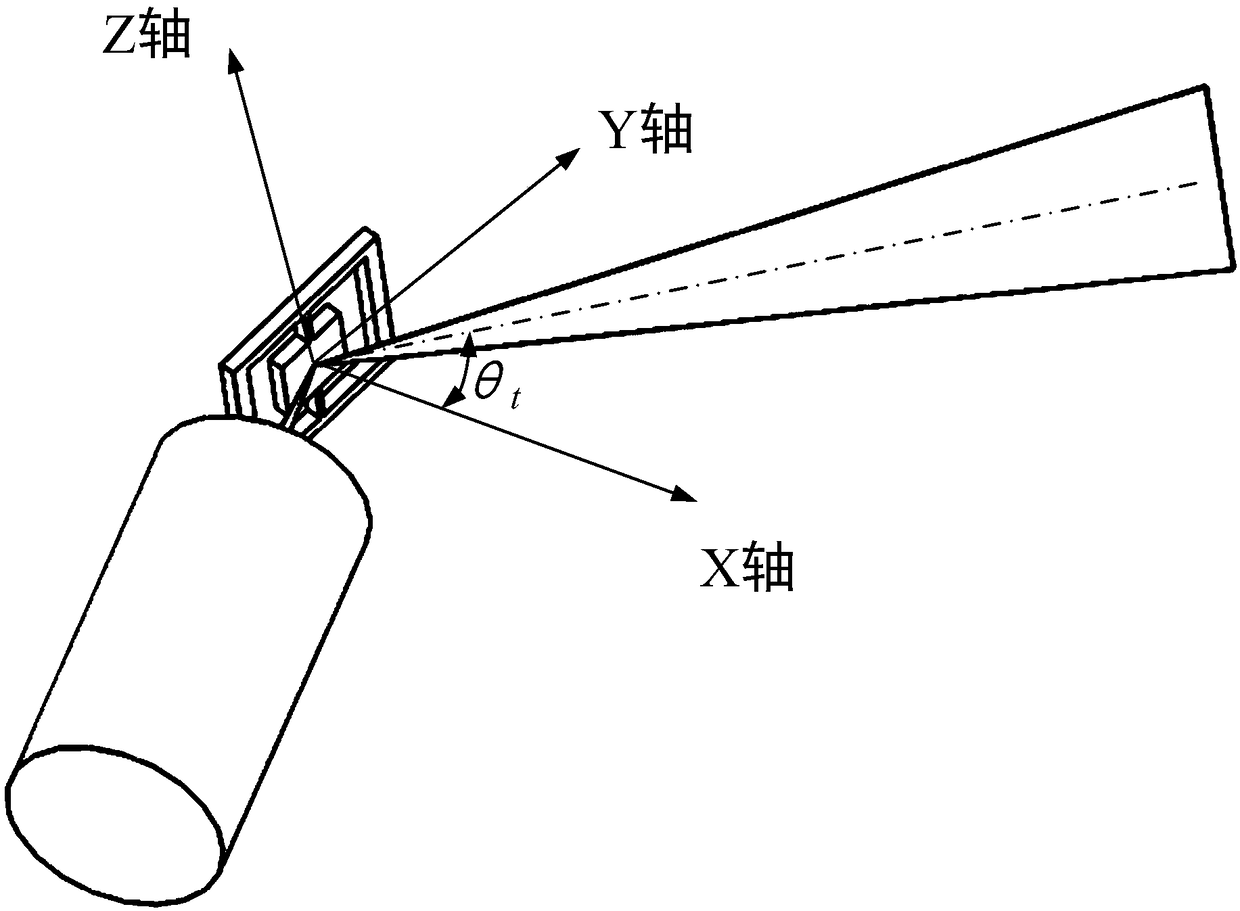

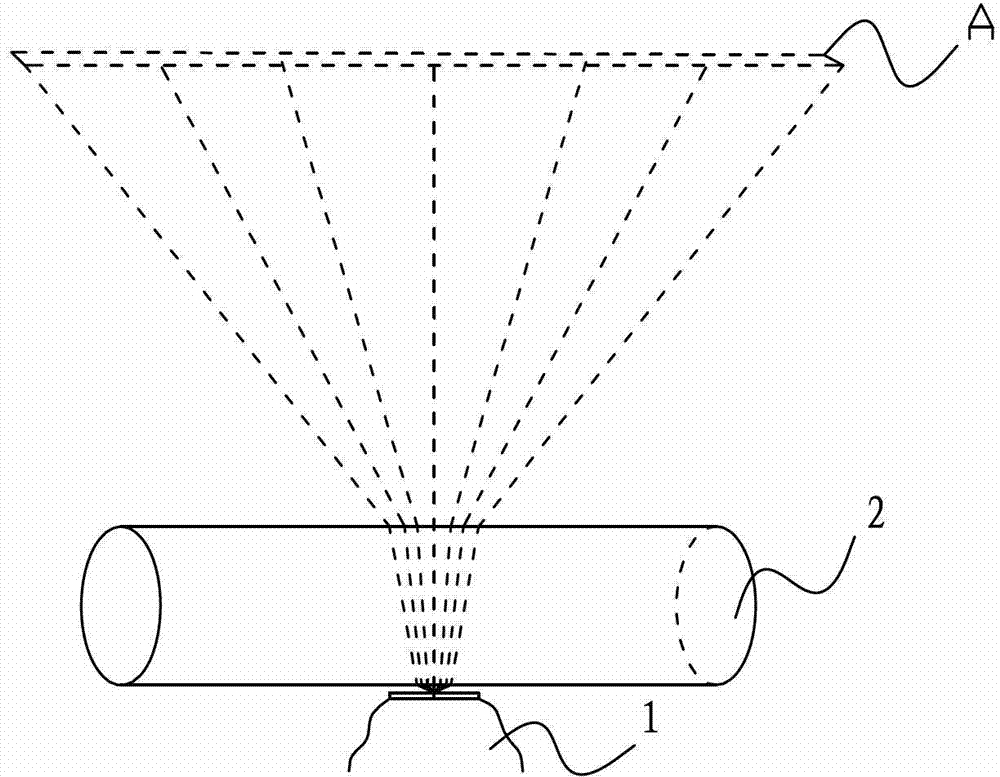

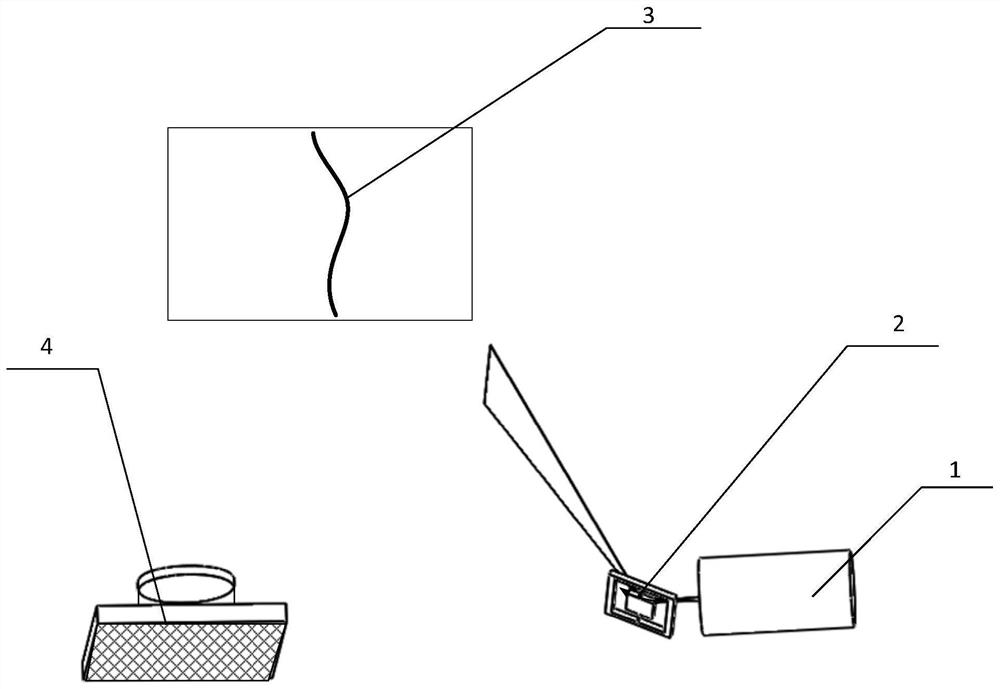

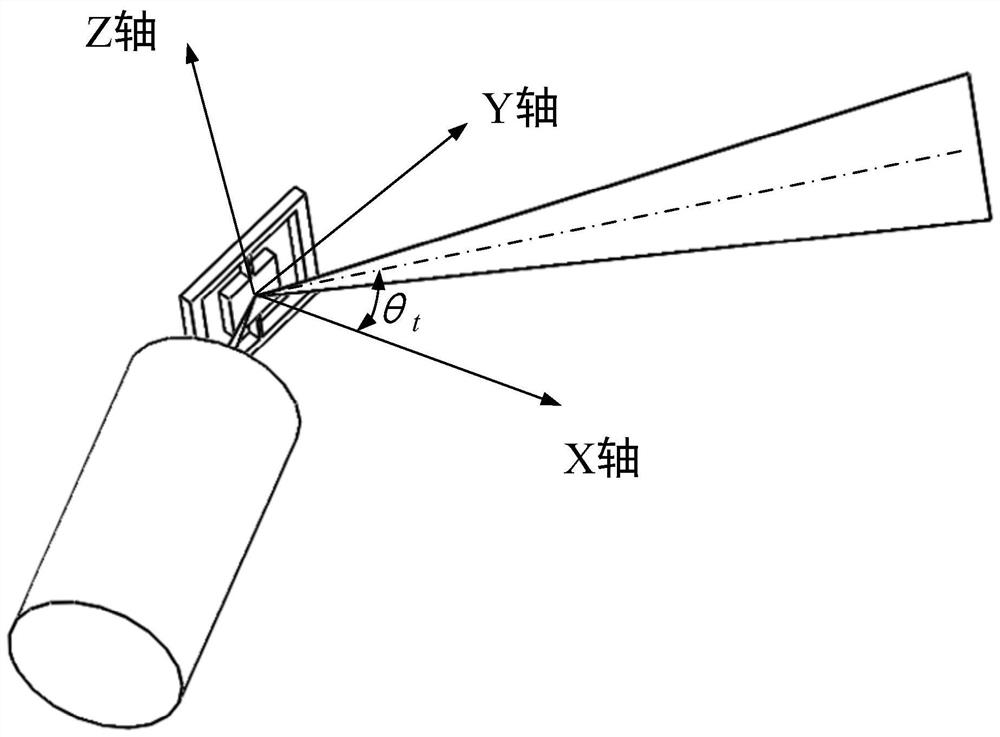

Laser line scanning 3D detection method and system based on scanning galvanometer and event camera

ActiveCN109458928ASimple algorithmSmall amount of calculationUsing optical meansGalvanometerLaser scanning

The invention belongs to the field of 3D detection and measurement, and particularly relates to a laser line scanning 3D detection method and system based on a scanning galvanometer and an event camera. The method comprises the following steps: the laser line is reflected to an object to be detected by the scanning galvanometer, so that laser line scanning is achieved; the event camera is adoptedto collect laser line signal information reflected from the object to be measured, and pixel points with changed brightness on the object to be measured and corresponding time points are stored and output; the position coordinate of the space point of the object to be detected scanned by the laser line at the moment is calculated through the relative position between the scanning galvanometer andthe event camera, the pixel point output in the step 2 and the scanning galvanometer rotation angle corresponding to the moment point corresponding to the pixel point; the steps are repeated to complete all space point coordinates of the object to be measured so as to obtain 3D point cloud data of the object to be measured, thereby solving the limitations of frame rate, resolution and illuminationresistance in the current 3D scheme.

Owner:XI AN ZHISENSOR TECH CO LTD

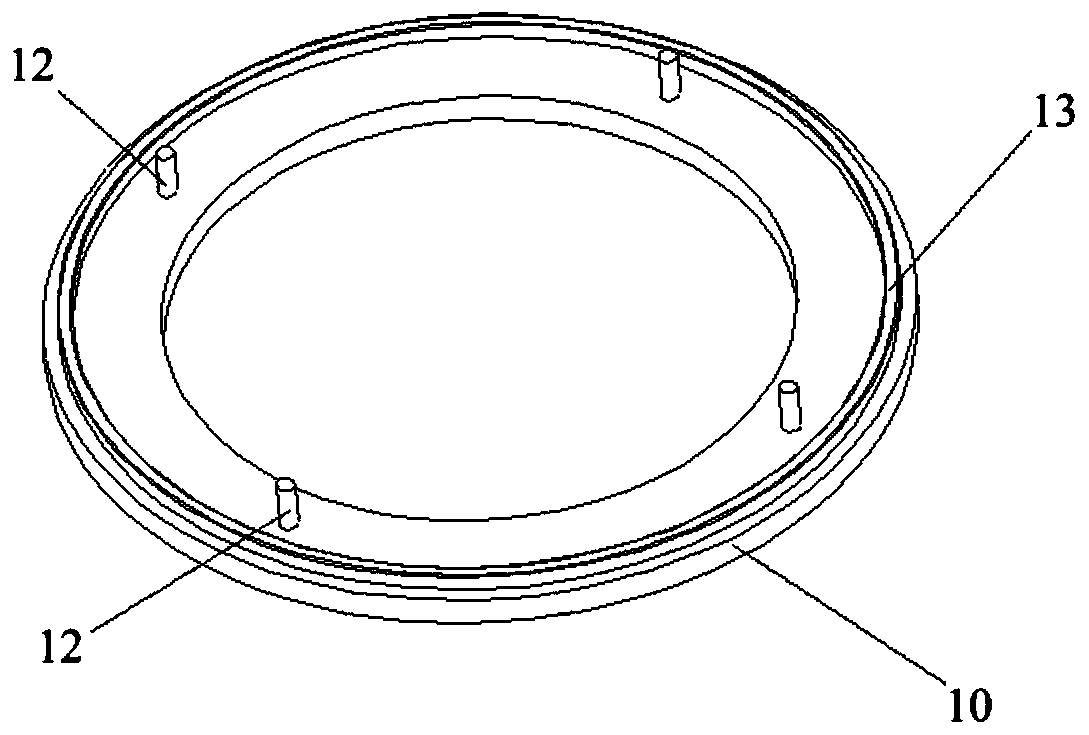

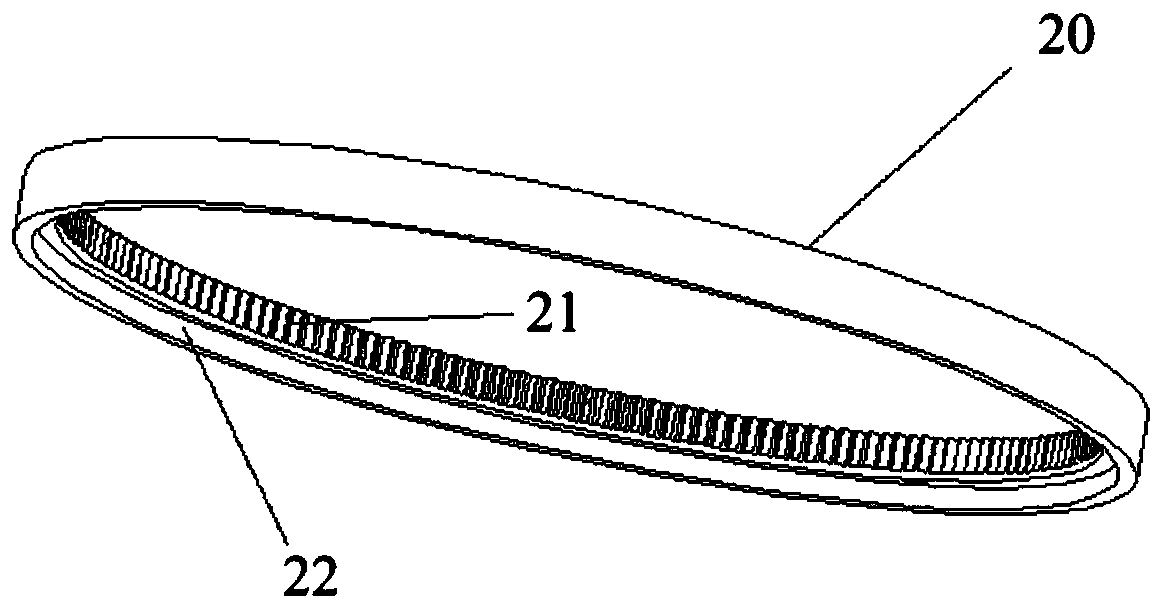

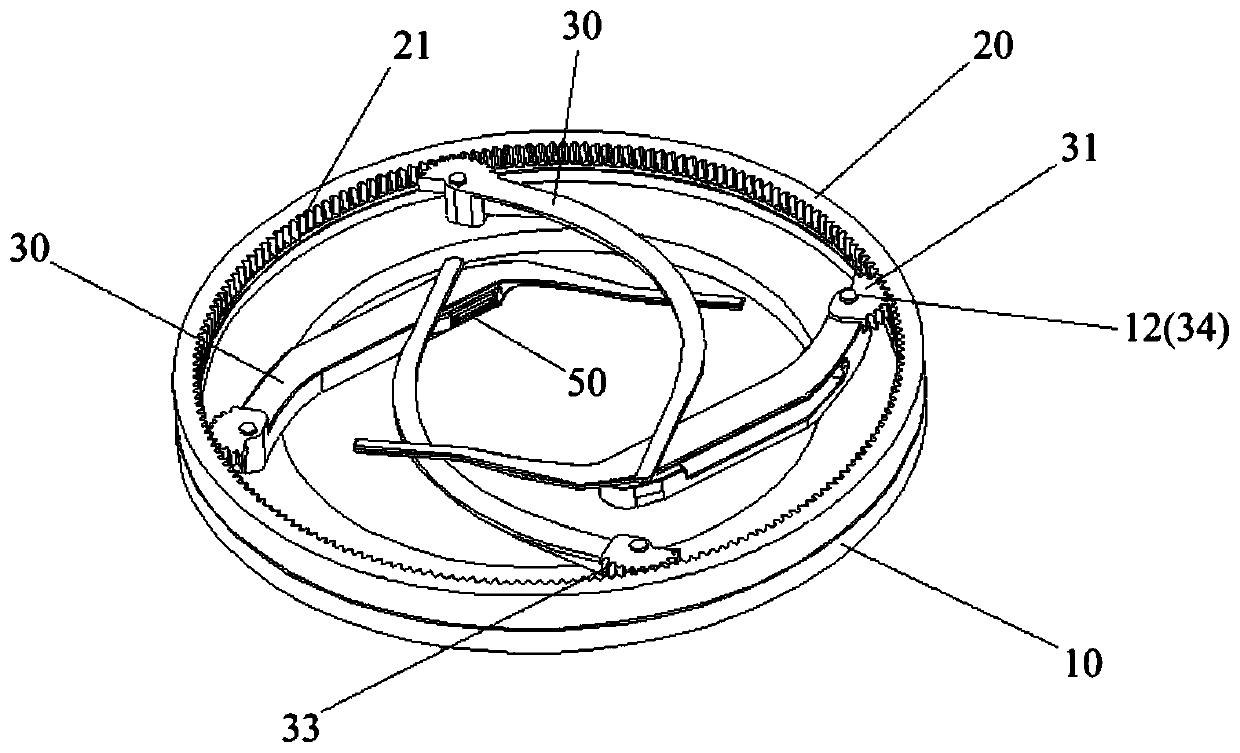

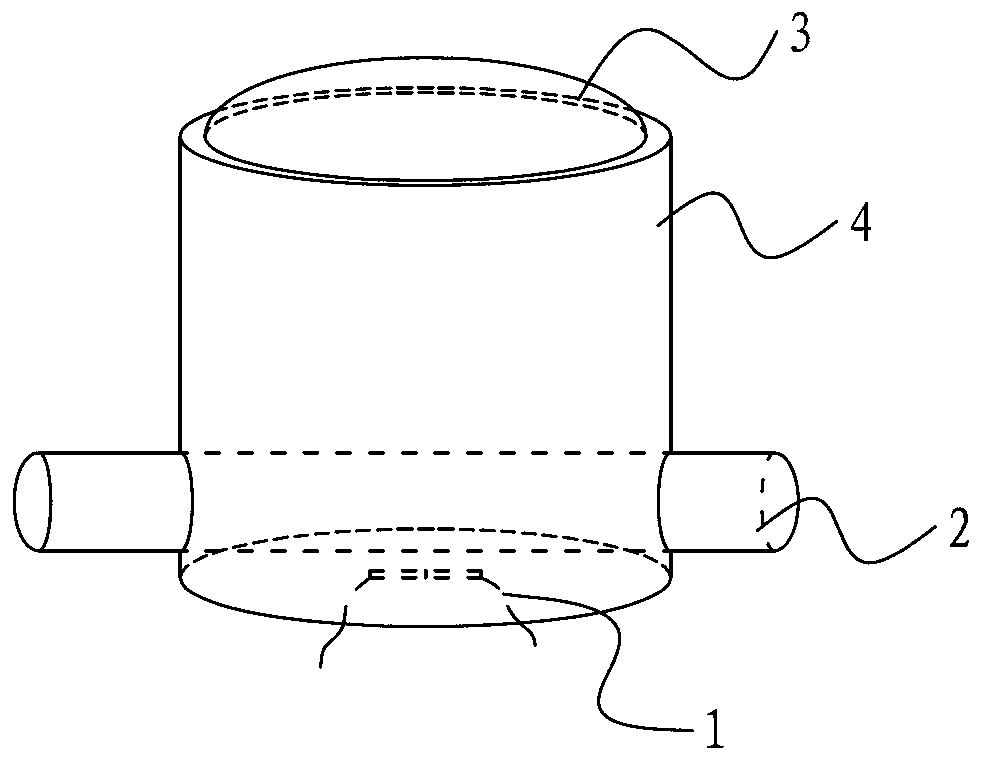

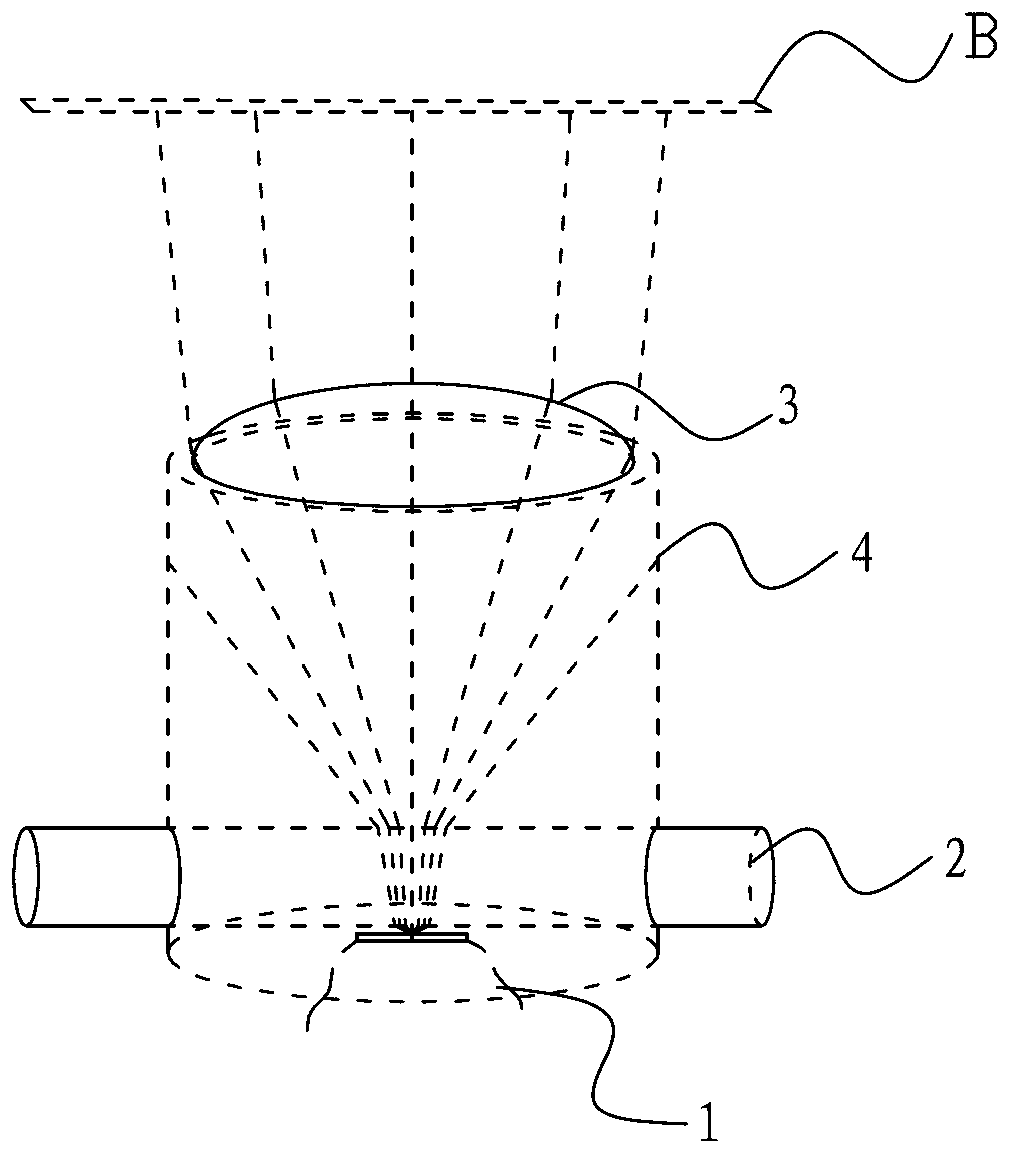

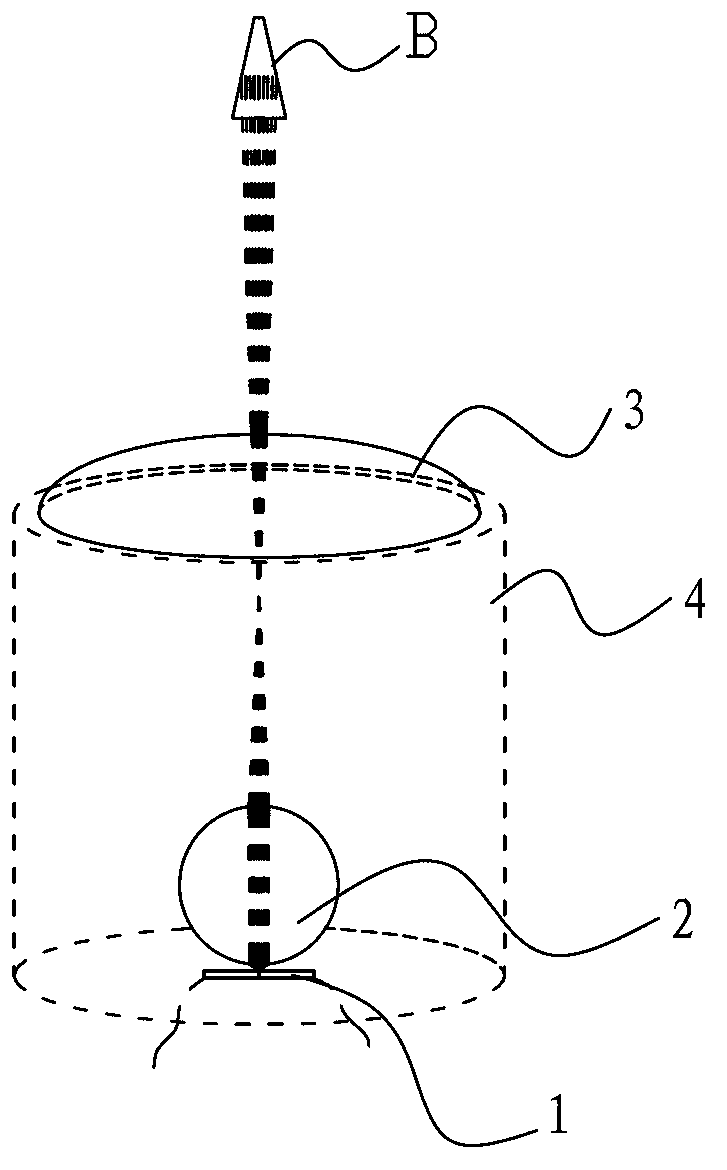

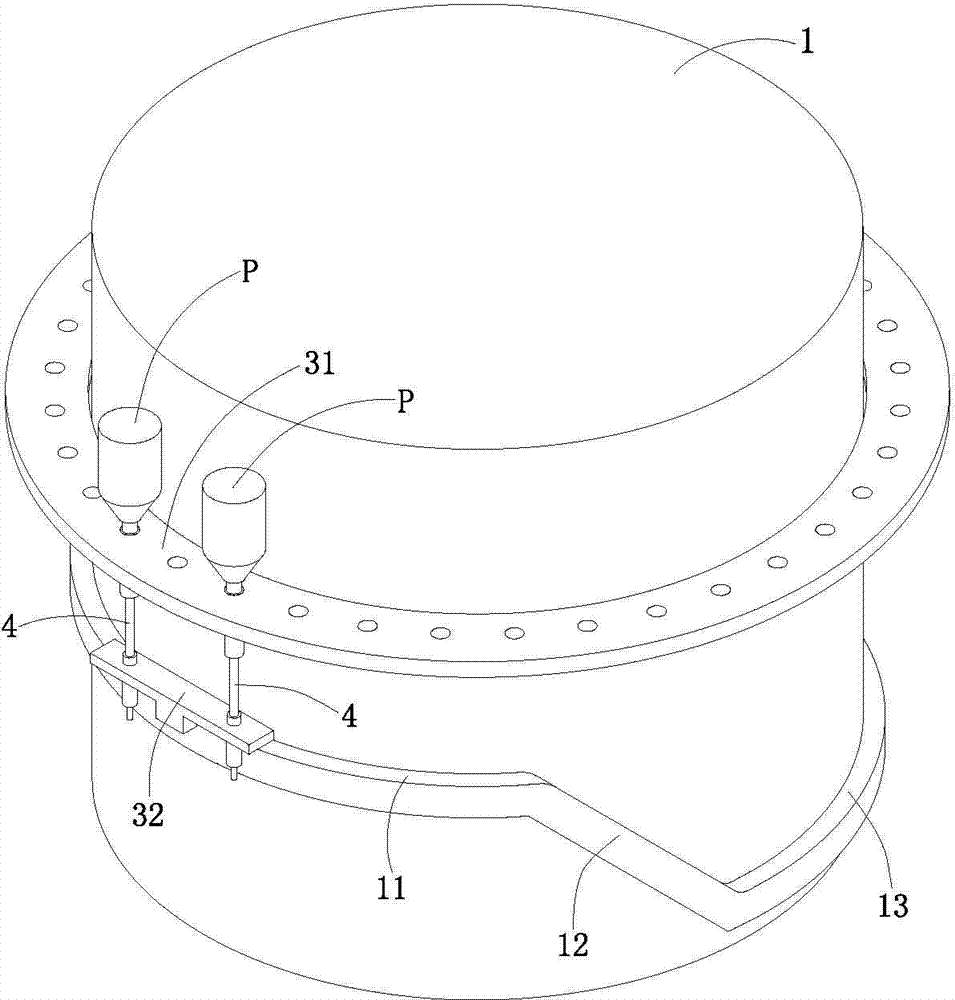

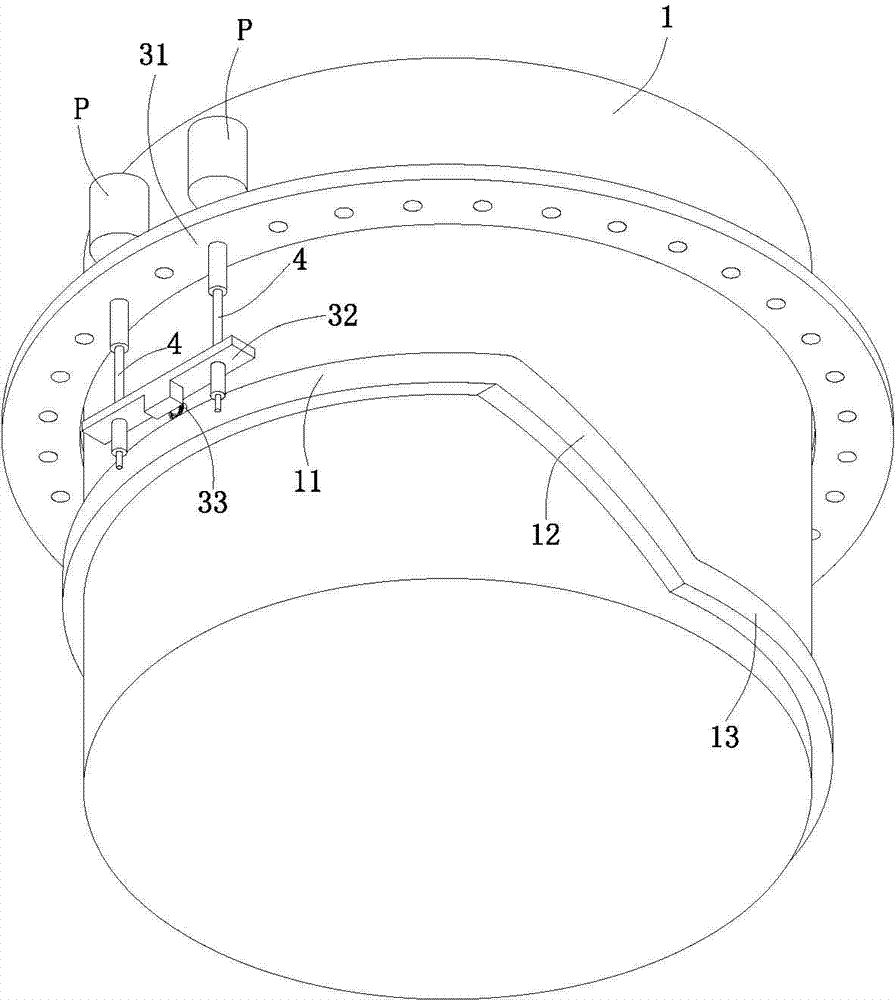

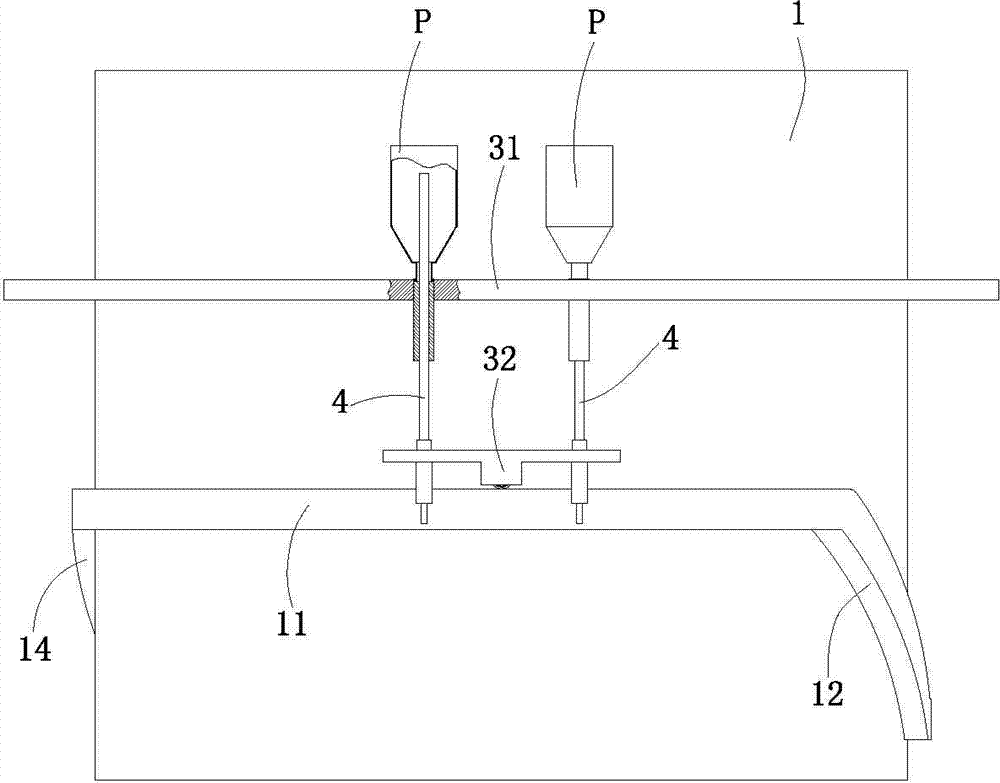

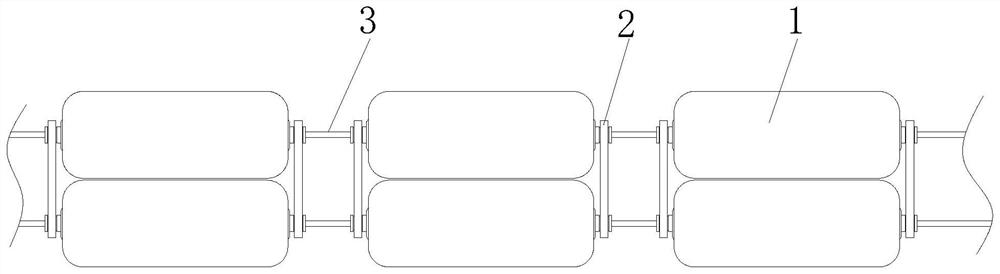

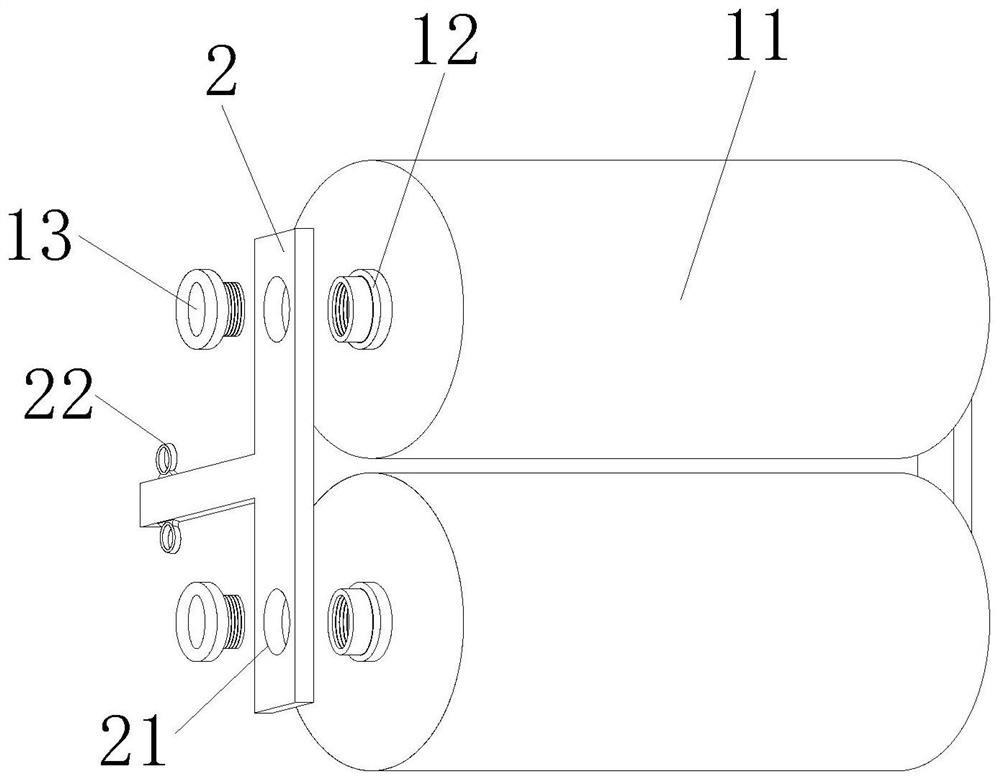

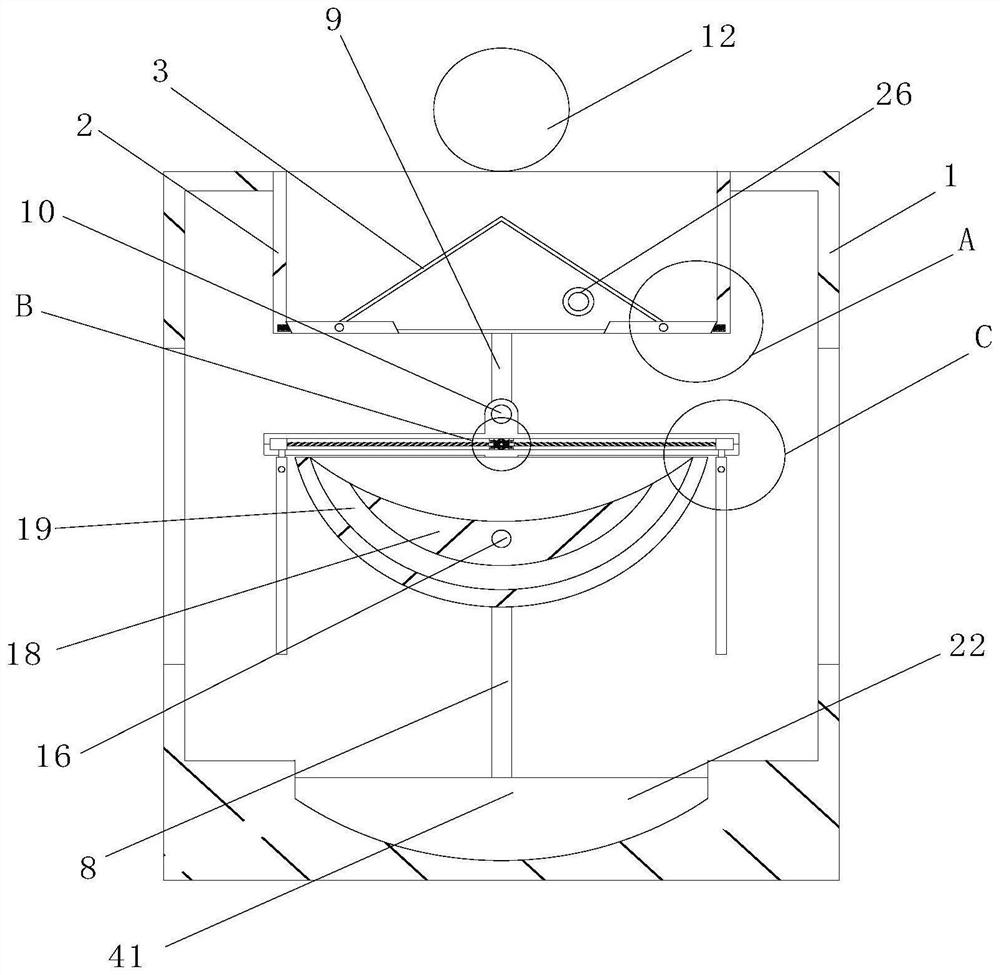

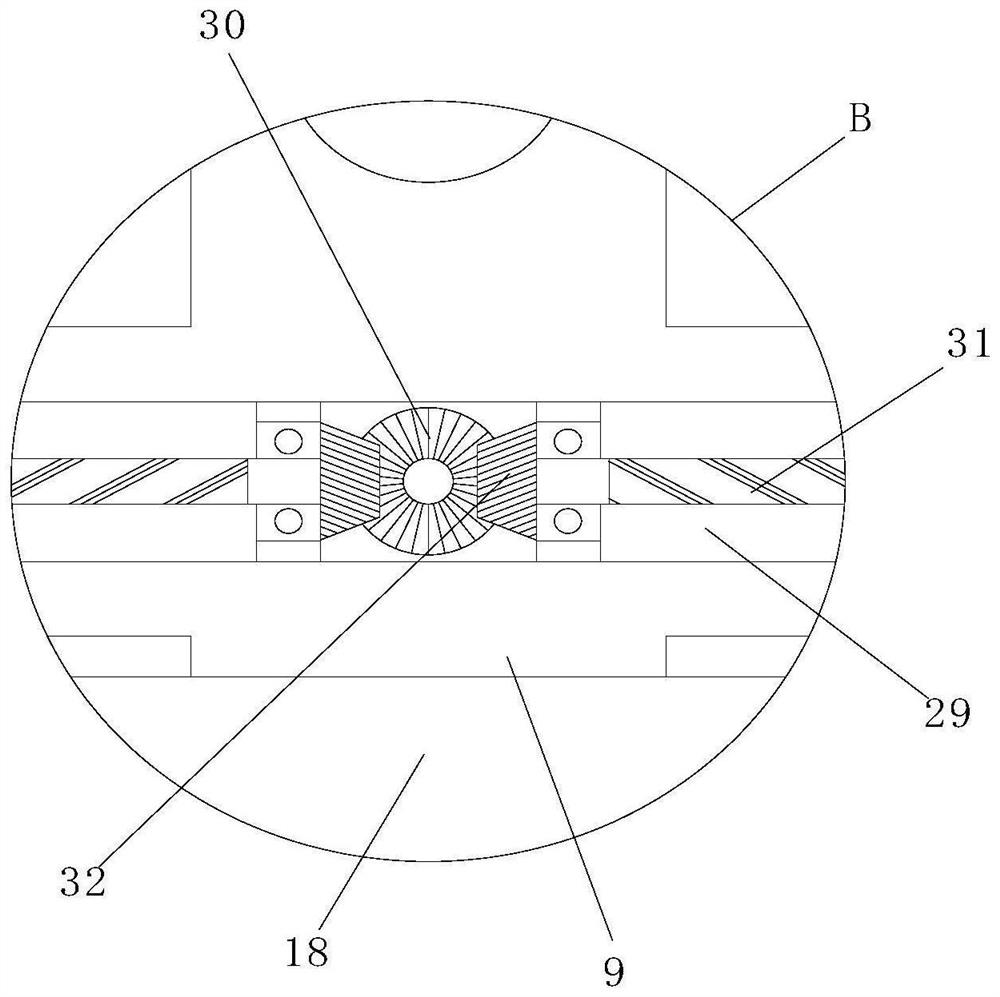

Garbage bag packaging mechanism and intelligent garbage can

PendingCN109911455AConcentratedReduce wasteRefuse receptaclesWrapper twisting/gatheringMechanical engineering

The invention discloses a garbage bag packaging mechanism. The garbage bag packaging mechanism comprises a base, an annular driving part and a plurality of bag closing pressing rods. An annular guidelocating structure is arranged on the base. The annular driving part is rotationally arranged on the guide locating structure, and a first driving connecting structure is arranged on one side of the annular driving part. The first tail end of each bag closing pressing rod is rotationally mounted on the base, and a second driving connecting structure corresponding to the first driving connecting structure on the annular driving part is arranged outside. The second driving connecting structure is directly or indirectly connected with the first driving connecting structure. The second tail ends of the bag closing pressing rods are free end and are used for closing a garbage bag. Due to the fact that the garbage bag is closed and centralized in the middle of a garbage putting opening to be sealed and packaged, the sealed position of the garbage can is evenly stressed in all directions, and garbage bag waste due to the fact that one edge of the garbage bag is pulled to be too long is reduced; and garbage bag closing is more centralized, and the sealing quality and the reliability of each sealing are improved.

Owner:SHANGHAI TOWNEW INTELLIGENT TECH CO LTD

Alkali solution based cell preservation treating fluid and preparation method thereof

ActiveCN106442078AImprove solubilityWell-preservedPreparing sample for investigationCell adhesionRed blood cell

The invention belongs to the field of cell treating fluid, and particularly relates to alkali solution based cell preservation treating fluid and a preparation method thereof. The alkali solution based cell preservation treating fluid is mainly composed of an egg white dissolution agent, a red blood cell cracking agent, an alkaline substance, a corrosion remover and distilled water. The alkali solution based cell preservation treating fluid is mainly used in cooperation with a membrane type liquid based thin-layer cell slide preparation machine and can enhance the cell adhesion capability of a modified glass slide, promote cervical cell enrichment so as to firmly attach cervical cells to the specially-prepared glass slide and effectively reduce the phenomenon of leak detection. Meanwhile, the novel alkali solution based cell preservation treating fluid has the advantages of being free of toxicity, environmentally friendly, capable of rapidly and thoroughly achieving sterilization, low in cost, convenient to configure, safe and efficient.

Owner:SICHUAN KINGMED DIAGNOSTICS CENT

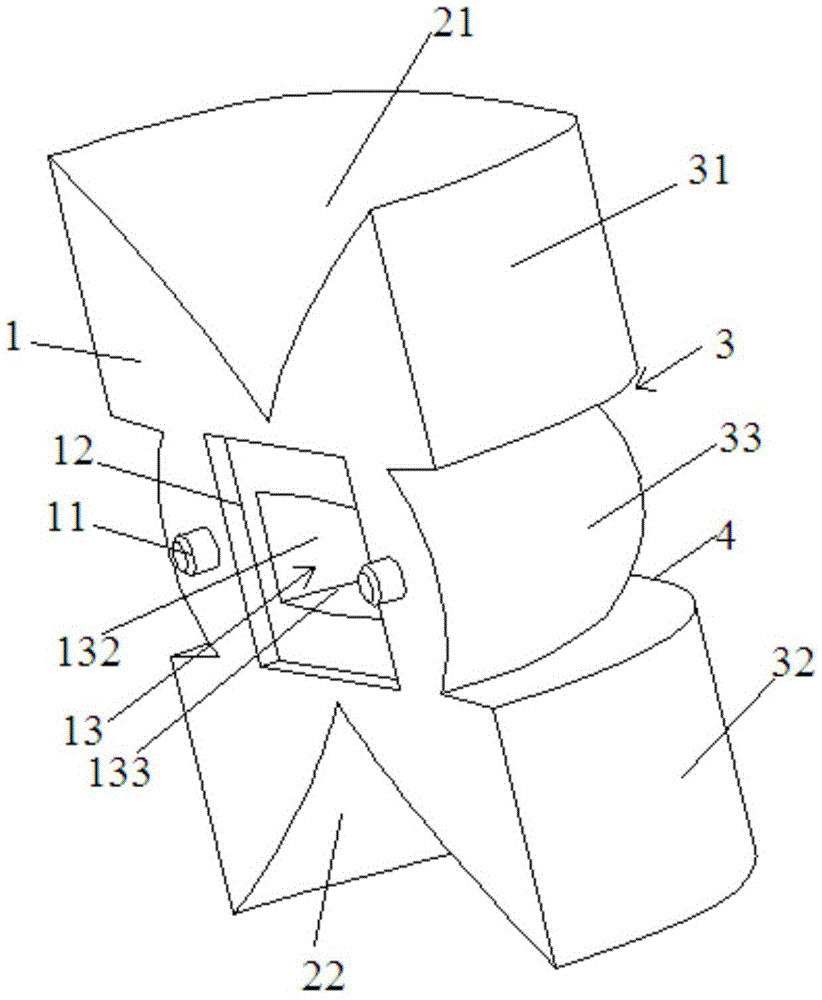

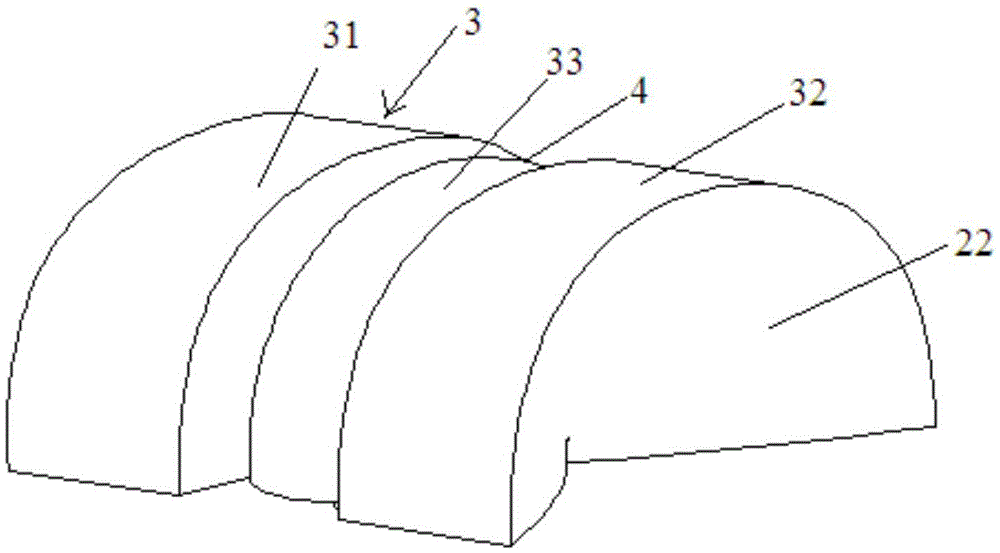

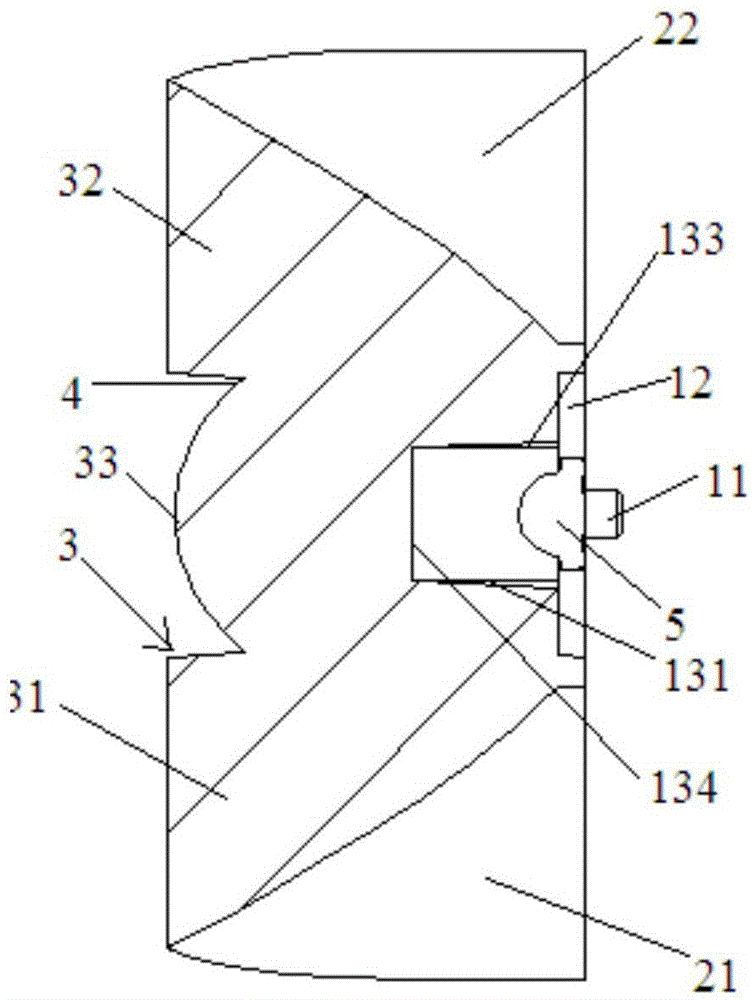

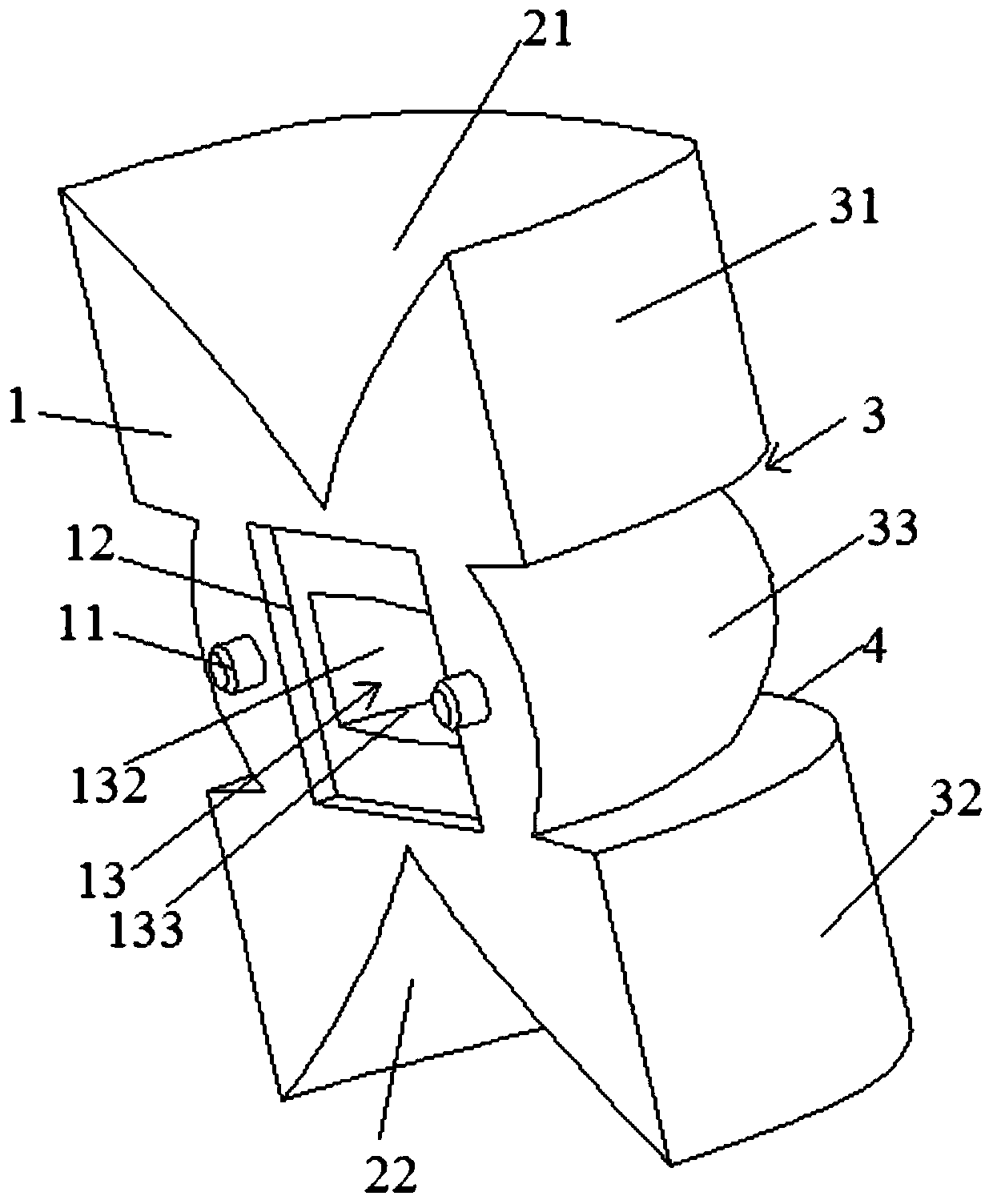

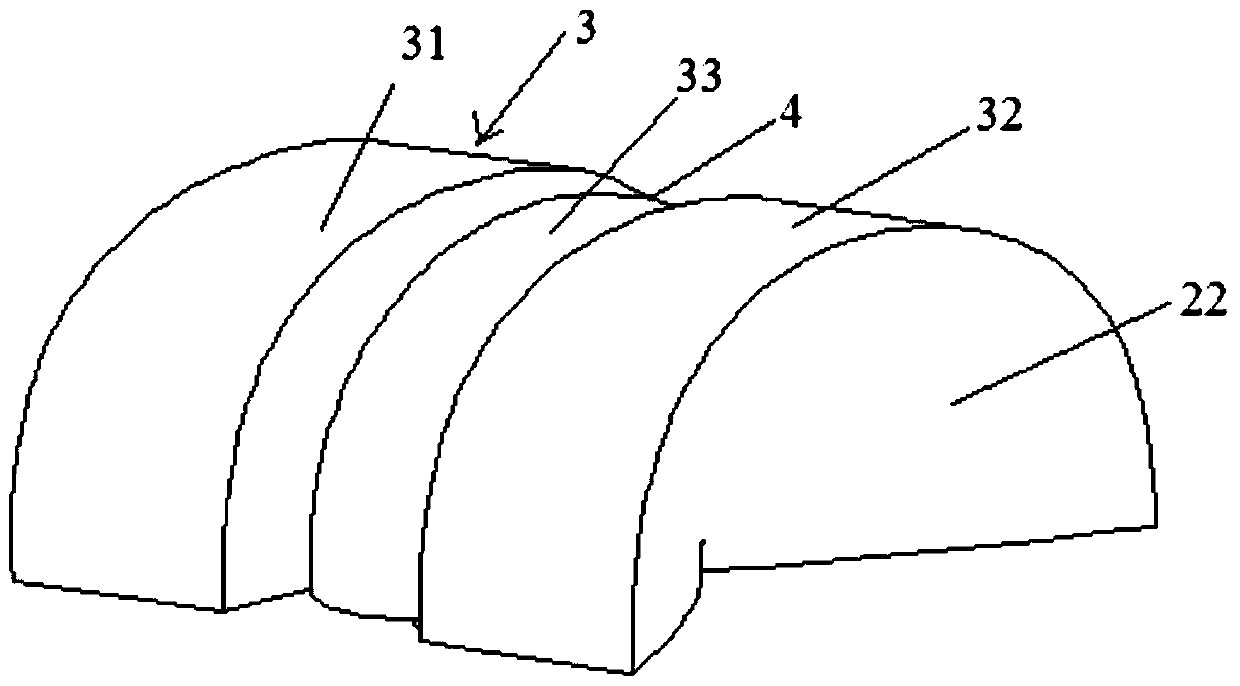

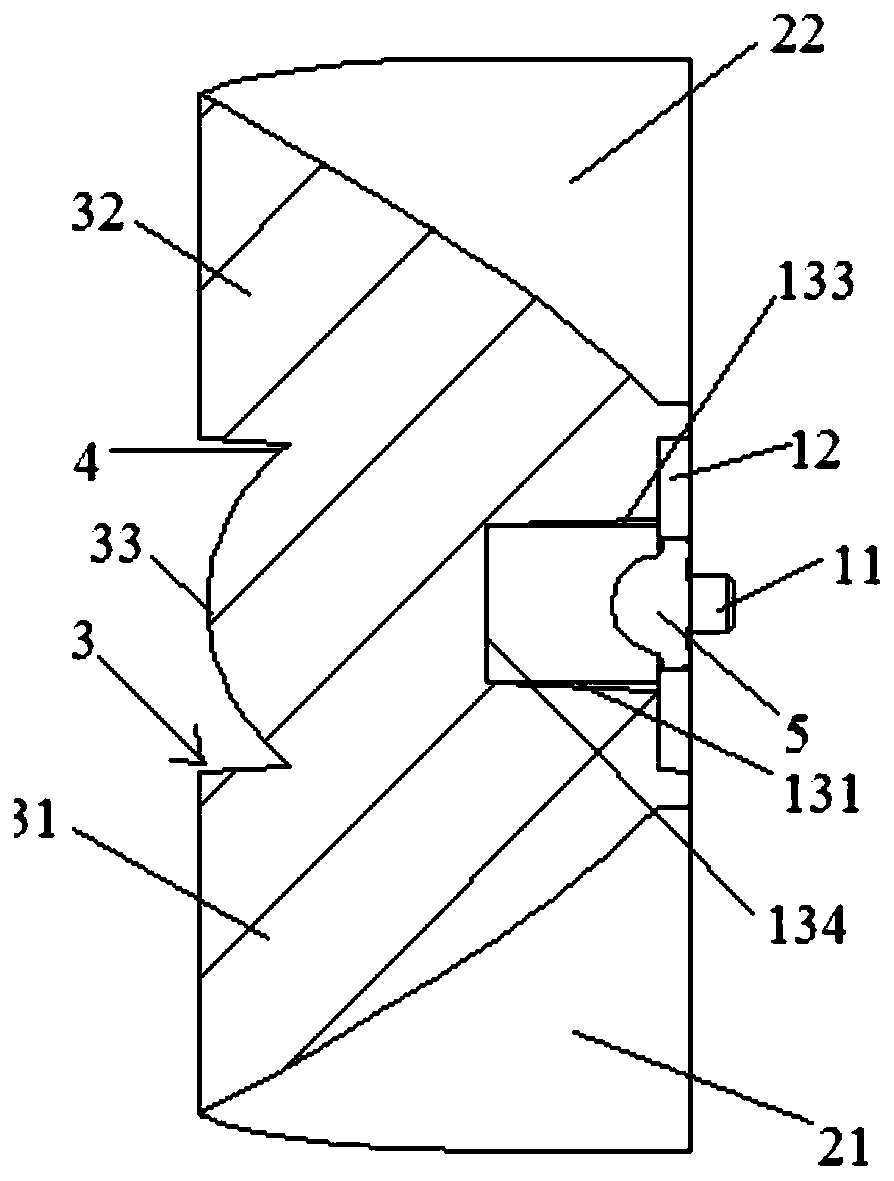

LED arched lens with long and narrow light spot

ActiveCN105627252AIncrease in sizeConcentratedGas-tight/water-tight arrangementsLight fasteningsTotal internal reflectionLight spot

The invention belongs to the technical field of lenses, and particularly relates to an LED arched lens with a long and narrow light spot. The lens comprises an LED lamp bead, an incident hole formed in the bottom of the lens, a first reflecting face, a second reflecting face, a first arched part, a second arched part and a third arched part. The first reflecting face and the second reflecting face are formed on the two sides of the lens. The first arched part, the second arched part and the third arched part are formed on the top of the lens. The third arched part is formed between the first arched part and the second arched part. The LED lamp bead is located in the incident hole. Compared with the prior art, the total internal reflection theory and a free-form surface are combined, and light emitted by an LED lamp can be emitted out in a collimation manner in the width direction of the lens. The arched structure and the free-form surface are combined, and the light emitted by the LED lamp can be emitted to a place with a larger angle in the length direction of the lens. Therefore, the LED arched lens has the beneficial effects of being centralized in light condensation, small in light loss, simple in structure, small in size and the like, and the narrower and longer light spot can be generated.

Owner:东莞市鑫叶光学有限公司

Xylose production process

InactiveCN105219892ASolve the problem of longevitySolve efficiency problemsSaccharides productionFiberHydrolysate

The invention discloses a xylose production process. The xylose production process comprises the following steps: adding pretreated pentosan-enriched plant fiber into a 1.0%-1.5% sulfuric acid solution to generate hydrolysis reaction, and filtering liquid to obtain hydrolysate; decoloring the hydrolysate by virtue of activated carbon or decoloring resin until the transparency of the hydrolysate is 20%-80%, and filtering to remove impurities by virtue of membrane filter equipment; concentrating the filtered hydrolysate by virtue of membrane concentration equipment, and decoloring the hydrolysate until the transparency of the hydrolysate is 60%-90% to obtain feed liquid, wherein leachate of the membrane concentration equipment is used as inflow water of an electroosmosis concentrated water chamber; desalting the feed liquid by virtue of electroosmosis and ion exchange resin, wherein electroosmosis concentrated water is circularly applied to a hydrolysis step; concentrating the feed liquid until the refractive index is 80%, crystallizing in a crystallization tank, and centrifuging to separate mother liquid, so as to obtain xylose crystals. According to the xylose production process, the problem that the costs for sewage treatments including neutralization and ion exchange in the prior art are high is solved, and the problems of short service life, low desalting efficiency, poor stability and high power consumption of an electroosmosis manner in the production of xylose are solved.

Owner:FUTASTE PHARM CO LTD

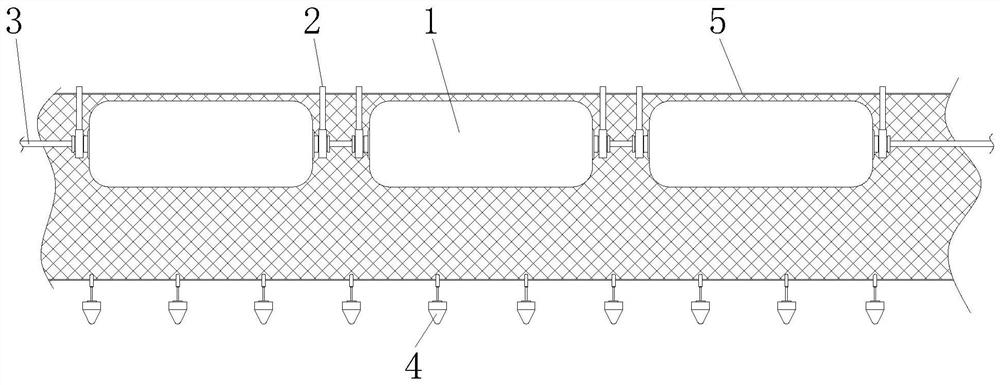

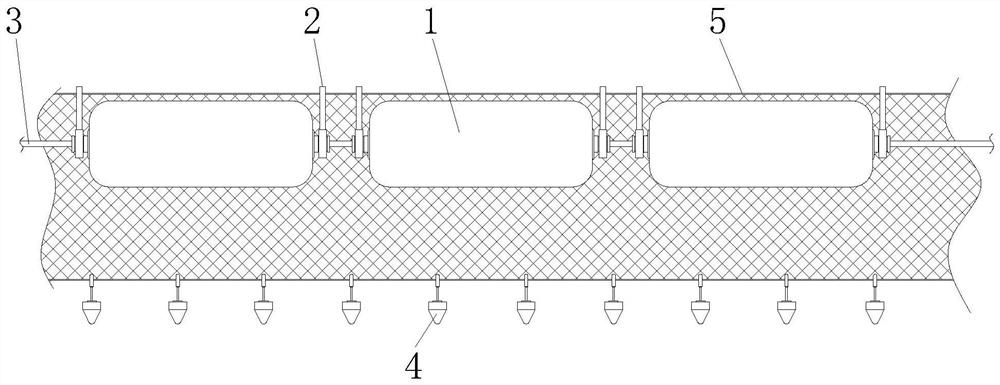

Riverway garbage intercepting device

Owner:江苏天从环保科技有限公司

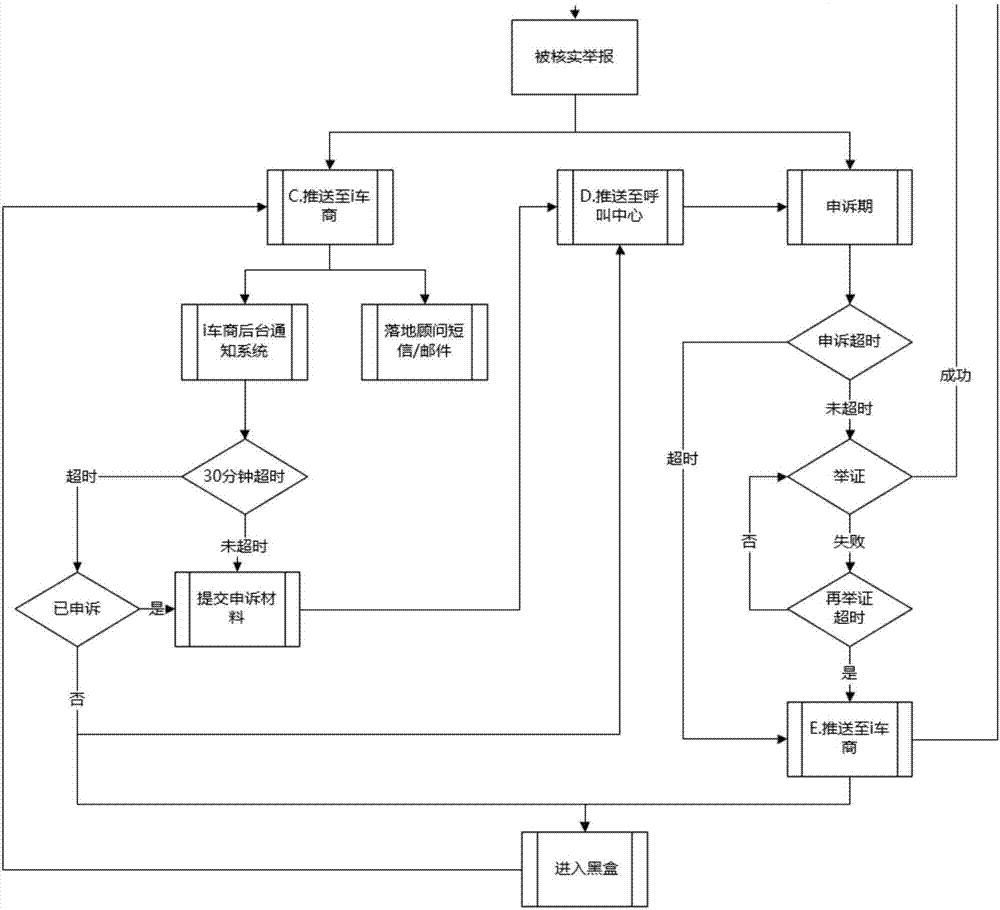

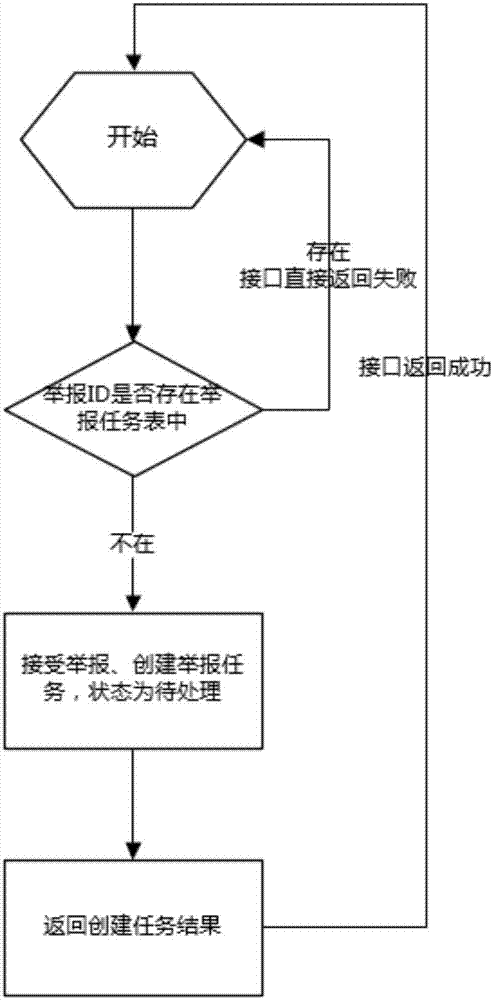

Method and platform for handling complaints and reports based on call center

ActiveCN106899682AConcentratedProfessionalSpecial service for subscribersTransmissionE-commerceData treatment

The invention discloses a method and a platform for handling complaints and reports based on a call center, and relates to the technical field of e-commerce website data handling. Through a flexible configuration and by enabling the reports and the complaints of a client side to uniformly centralize to a call center platform for management, the method and the platform have the characteristics of centrality, professionalism and timeliness, etc., an effective scheme is provided to timely and effectively solve a problem encountered by a client, and the dilemmas of scatter and failure to solve the problem in former in the past are changed.

Owner:CHEZHI HULIAN BEIJING SCI & TECH CO LTD

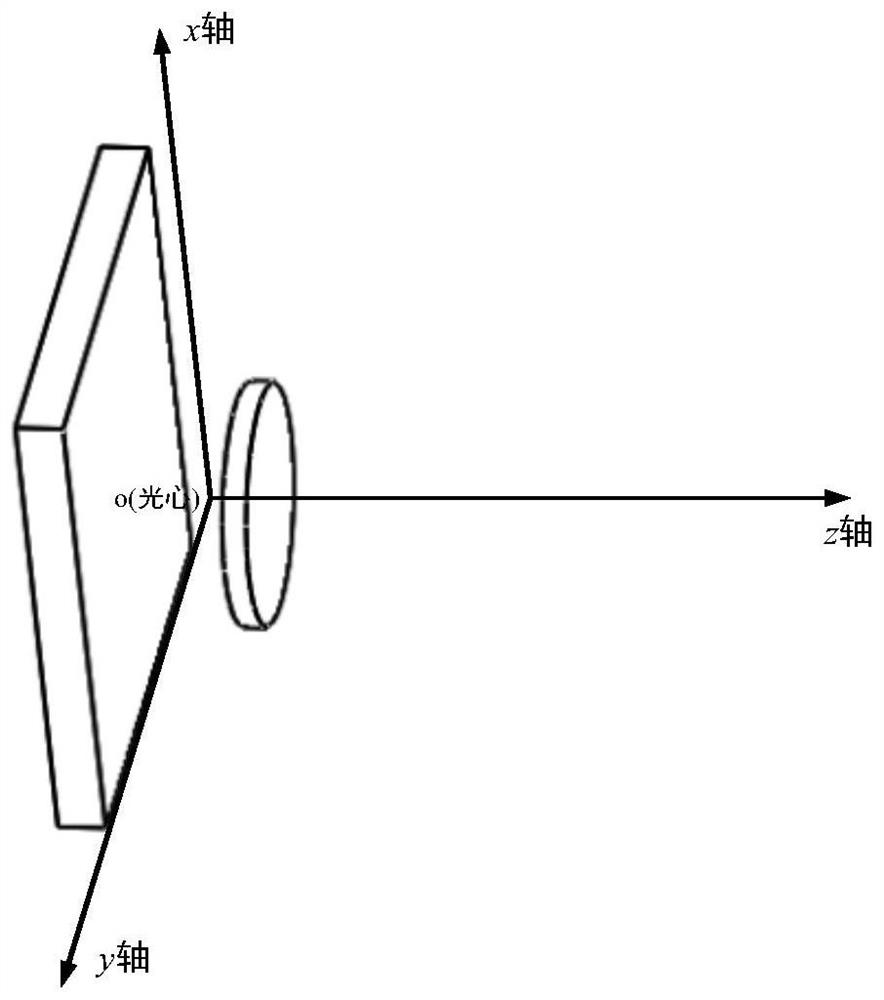

Spotlight with double lens for generating rectangular light spots

InactiveCN102798041AConcentratedReduce light lossRefractorsFixed installationLight spotOptoelectronics

The invention discloses a spotlight with double lens for generating rectangular light spots, and the spotlight comprises a light source. The spotlight is characterized in that a cylindrical light-transmitting lens used for converging the scattered rays emitted by the light source, and enabling the light spots formed by irradiating the rays emitted by the light source on an irradiated body to be rectangular light spots is arranged on the front part of the light source; and a convex lens used for further converging the rays is arranged at the front end of the cylindrical light-transmitting lens. A light-shielding barrel is arranged between the cylindrical light-transmitting lens and the convex lens. The convex lens is fixed on the top of the light-shielding barrel, and the cylindrical light-transmitting lens is fixed on the bottom of the light-shielding barrel. By virtue of the refraction principle and the reflection principle of rays, the scattered rays are collected in a rectangular range by using the lenses, so as to generate the rectangular light spots. Compared with the prior art, the spotlight disclosed by the invention has the advantages of being wide in application range, centralized in light convergence, high in brightness, and less in light loss. In addition, the spotlight is convenient in production, low in cost, and suitable for wide popularization.

Owner:DALIAN XINQIHUI TECH

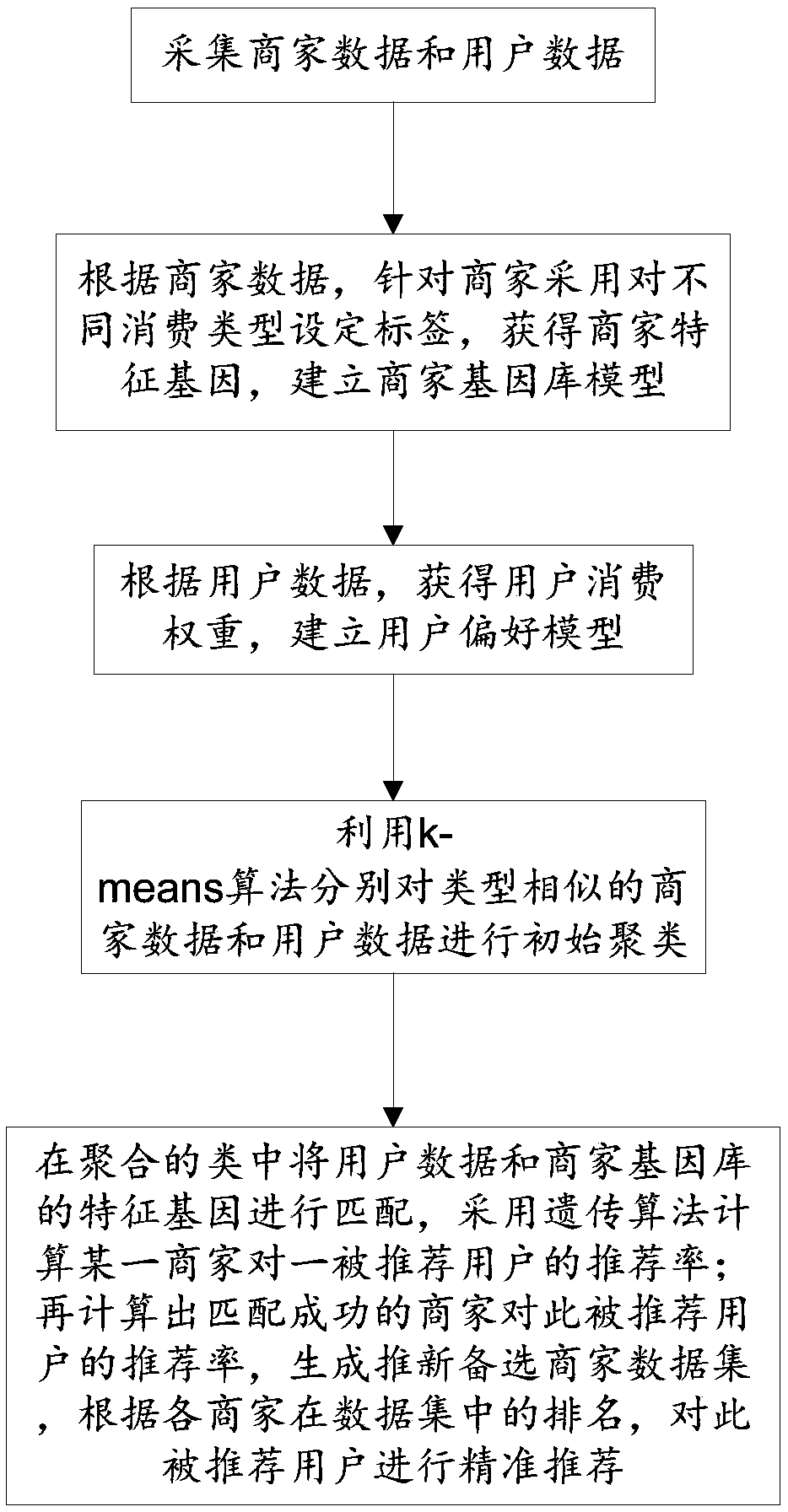

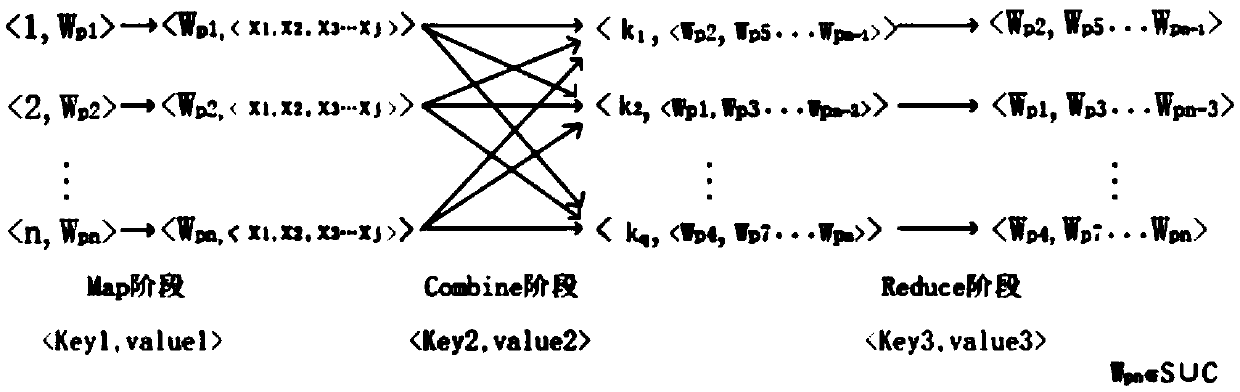

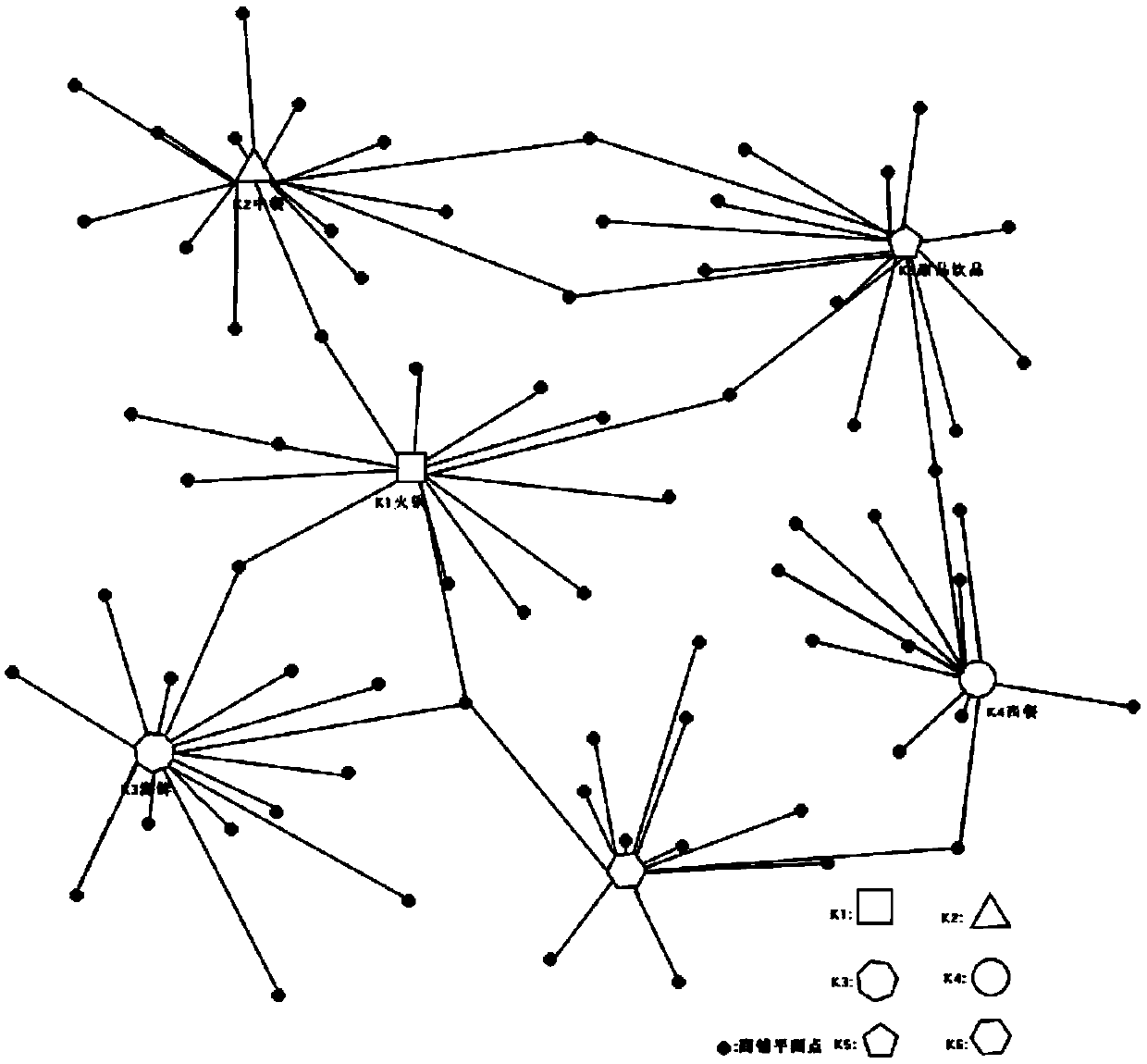

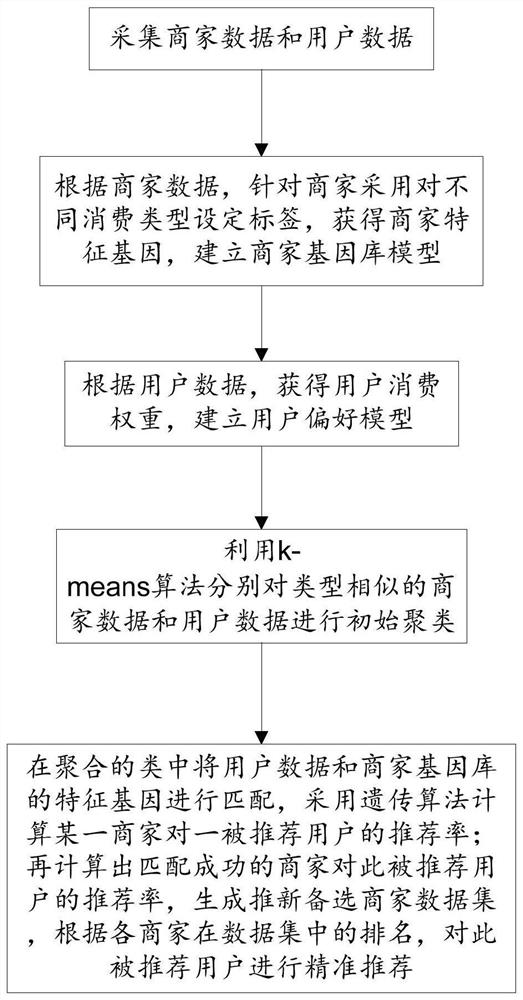

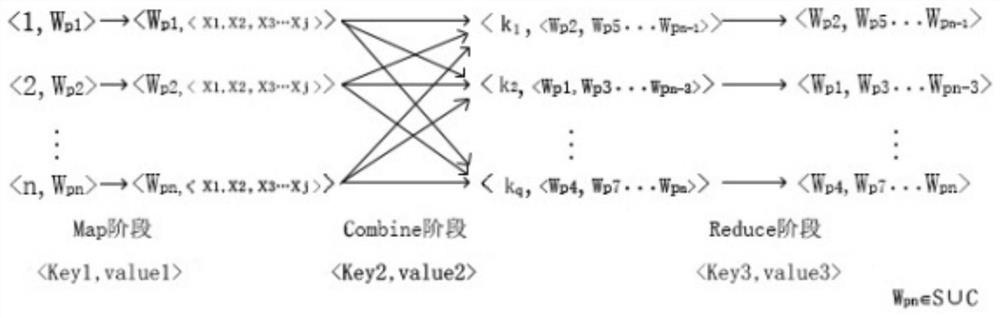

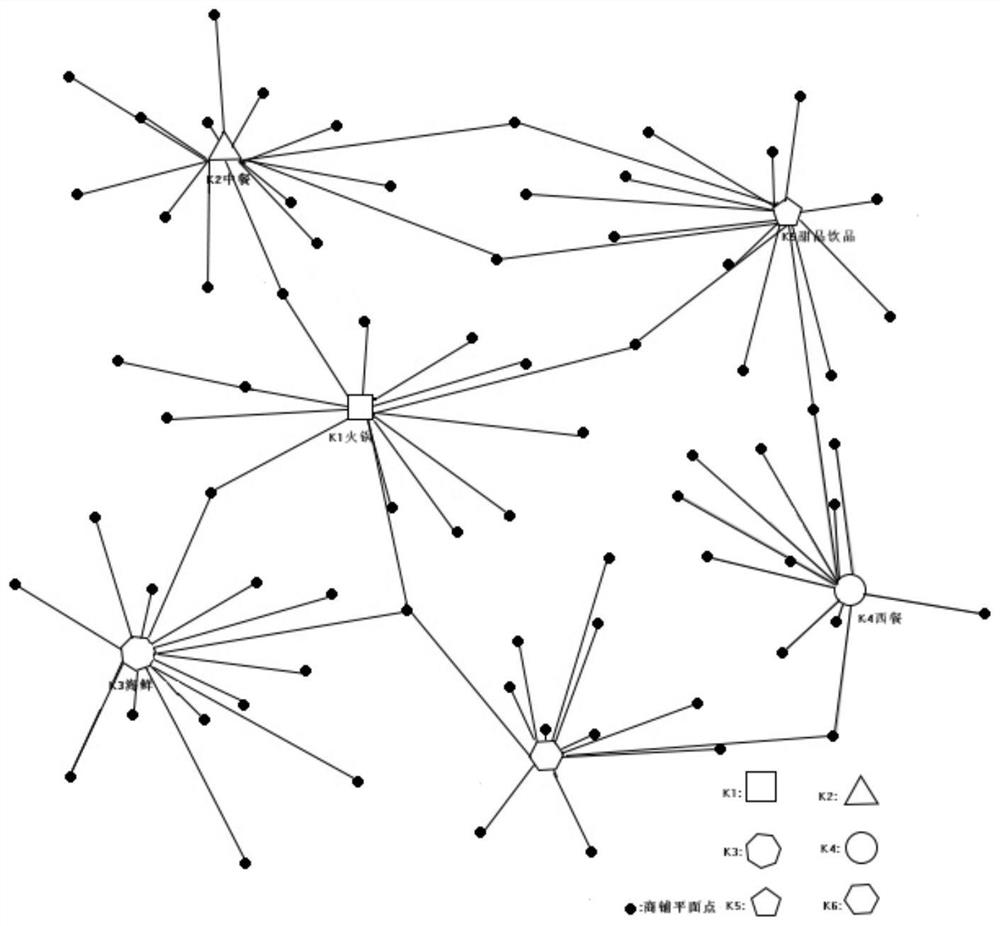

Entity business marketing method based on genetic algorithm

InactiveCN108805199AConcentratedCharacter and pattern recognitionGenetic algorithmsData setGenetic algorithm

The invention discloses an entity business marketing method based on a genetic algorithm, and relates to the field of marketing methods. The method comprises the following steps: collecting merchant data and user data; setting labels of different consumption types for merchants according to the merchant data, obtaining a merchant characteristic gene (the formula is shown in the specification), andestablishing a merchant gene pool model; obtaining a user consumption weight according to the user data, and establishing a user preference model; respectively performing initial clustering on similar types of merchant data and user data by using a k-means algorithm; calculating a recommendation rate of a certain merchant to a recommended user by using the genetic algorithm, and solving the recommendation rate of a user; and calculating the recommendation rates of merchants satisfying the condition to the recommended user, generating a recommendation candidate merchant data set, and performing accurate recommendation on the recommended user according to the rankings of the merchant in the data set. By adoption of the entity business marketing method disclosed by the invention, the problemthat the current entity business marketing market cannot perform accurate marketing on the user, resulting in low competitiveness in the commercial market, is solved.

Owner:电子科技大学成都学院

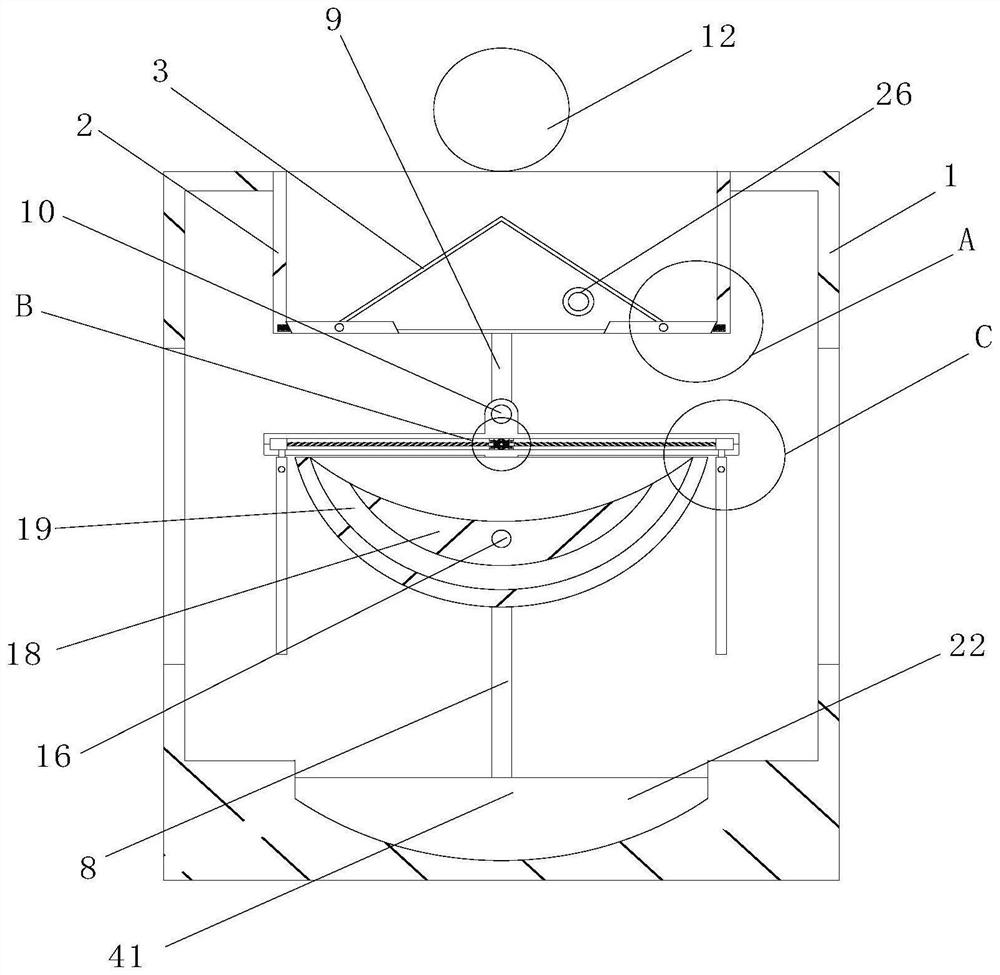

Aluminum alloy recycling and cleaning equipment

The invention relates to the technical field of aluminum alloy, and discloses aluminum alloy recycling and cleaning equipment which comprises a box body, a sliding hole is formed in the back side faceof the box body, a rotating shaft A is connected to the inner wall of the sliding hole in a sleeving manner, a sliding plate is fixedly connected to the end, located in the box body, of the rotatingshaft A, a hole is formed in the front face of the sliding plate and located below the rotating shaft A, a rotating shaft B is connected into the hole in a sleeving manner, one end, located on the back face of the box body, of the rotating shaft B is fixedly connected with a ratchet wheel, the ratchet wheel and a straight gear A are distributed front and back, and one end, located in the box body,of the rotating shaft B is fixedly connected with a cleaning barrel. Quantitative aluminium alloy and cleaning fluid are obtained in a sector-shaped groove of the cleaning barrel, so that the amountof the cleaning fluid is enough to disinfect and clean the aluminium alloy, the disinfecting and cleaning effect of the aluminium alloy is enhanced, the aluminium alloy is extruded by using the increased weight after the cleaning barrel accommodates the aluminium alloy and the cleaning fluid, and the automatic cleaning, disinfecting and extruding of the aluminium alloy is realized under the condition that an extra extruding mechanism is not required through the arrangement of a structure such as a toothed plate A.

Owner:江苏宏元达光伏新材料有限公司

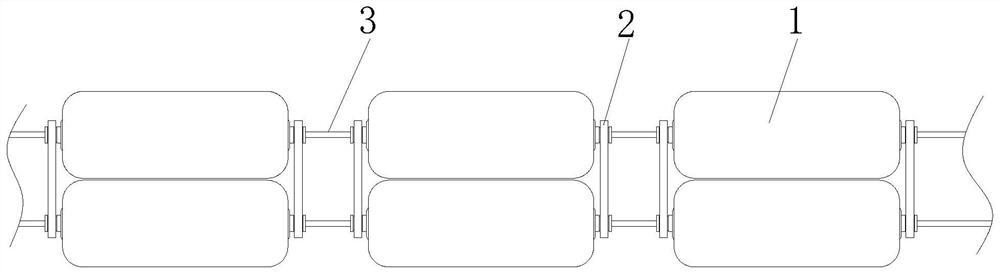

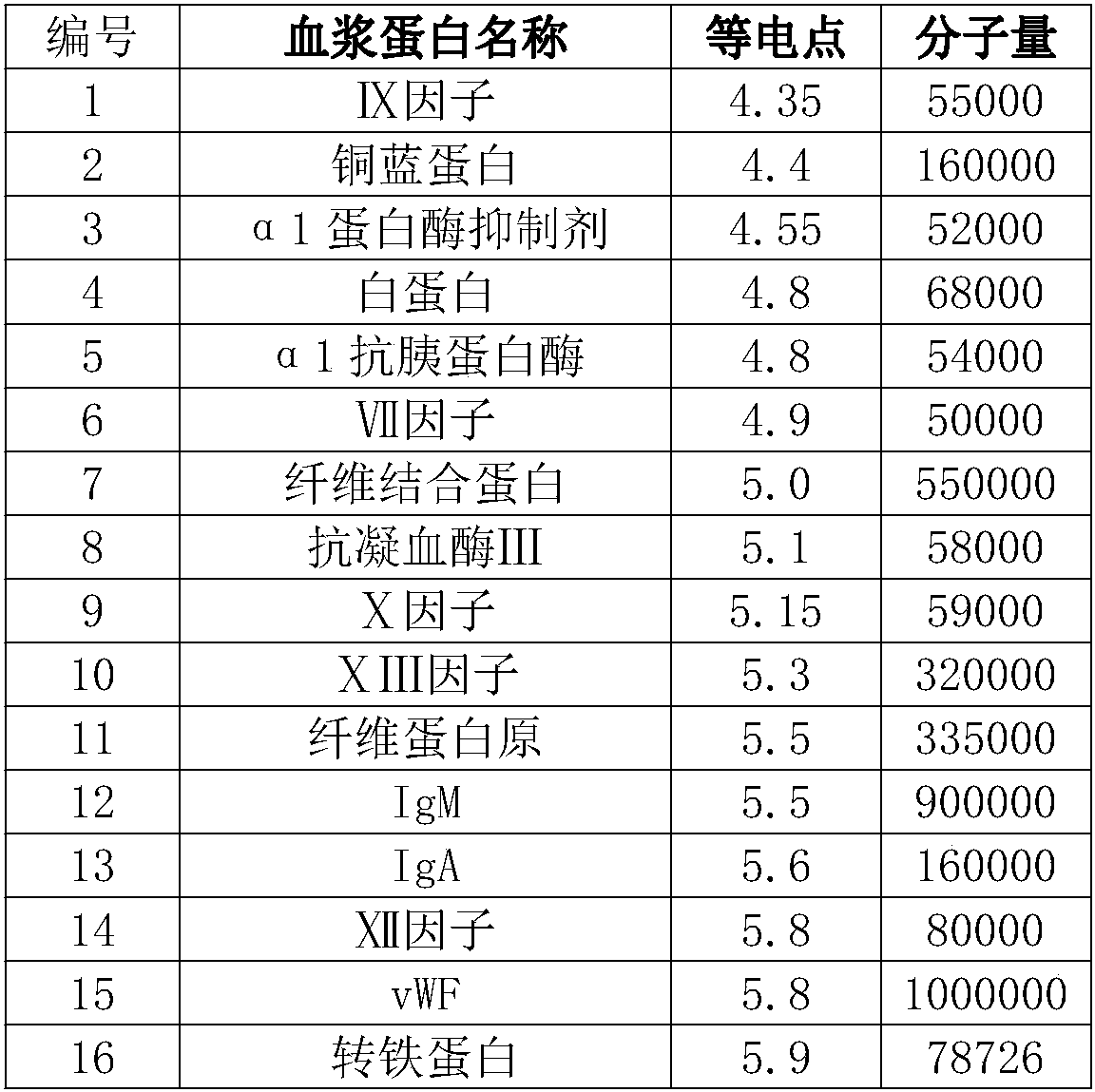

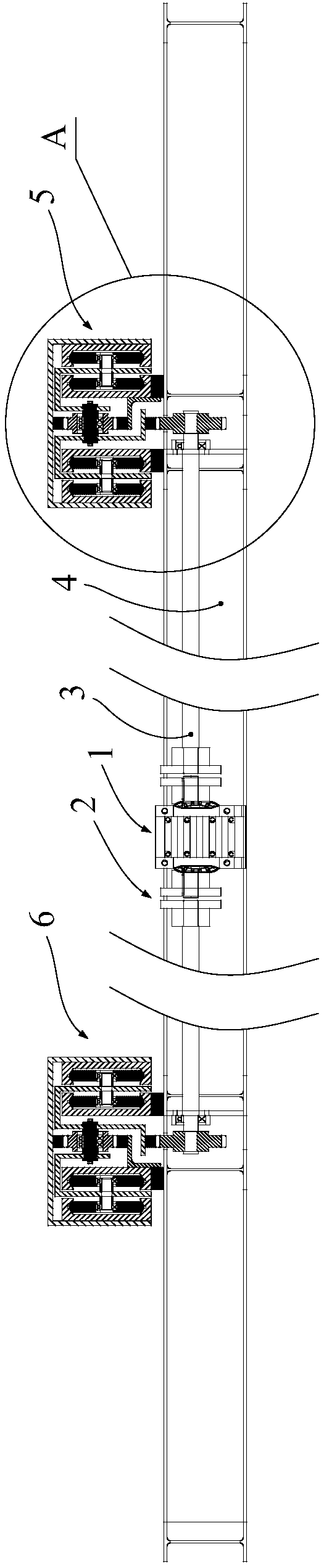

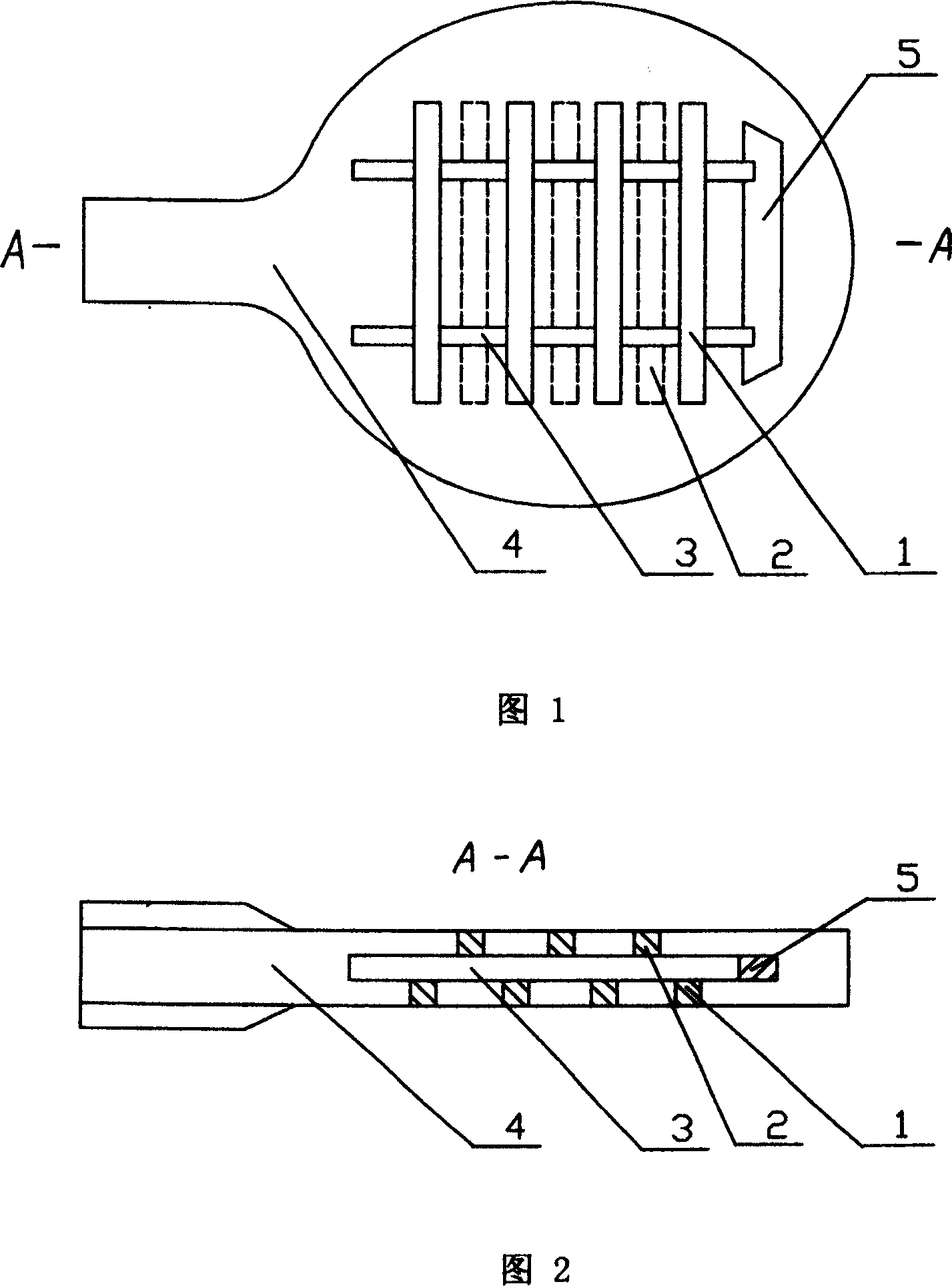

Protein electrophoretic separation and purification method and protein electrophoretic separation and purification device

PendingCN108794567AHigh separation purityFluid concentrationPeptide preparation methodsChemistryIonic strength

The invention discloses a protein electrophoretic separation and purification method. To-be-separated liquid can be separated by the aid of an electrophoretic separation and purification device. The protein electrophoretic separation and purification method includes steps that the PH (potential of hydrogen) value of the to-be-separated liquid is adjusted so that to-be-separated components are electrically neutral under the effects of isoelectric points of the to-be-separated components, the ionic strength of the to-be-separated liquid is adjusted to be 0.05-0.1, and the temperature of the to-be-separated liquid is 0-6 DEG C under the control; voltages of electrophoretic power sources in the electrophoretic separation and purification device range from 50 V to 300 V under the control, currents of the electrophoretic power sources are 25-30 mA, and the linear flow velocity of the to-be-separated liquid which flows into a sample loading liquid inlet slit of the electrophoretic separationand purification device is 0.7-1 cm / min; the to-be-separated liquid downwardly moves in the electrophoretic separation and purification device, and separated different protein components can be collected by isokinetic collecting grooves in the lower portion of the electrophoretic separation and purification device. Compared with the prior art, the protein electrophoretic separation and purification method and the electrophoretic separation and purification device have the advantages that batches of proteins can be separated by the aid of the protein electrophoretic separation and purificationmethod and the electrophoretic separation and purification device, and excellent separation effects can be realized by the protein electrophoretic separation and purification method and the electrophoretic separation and purification device.

Owner:HUALAN BIOLOGICAL ENG CHONGQING +1

Focus lamp capable of generating rectangular light spots by single lens

InactiveCN102767765AConcentratedReduce light lossRefractorsFixed installationOptoelectronicsBrightness perception

The invention discloses a focus lamp capable of generating rectangular light spots by a single lens, comprising a light source. The focus lamp is characterized in that a cylindrical light-transmitting lens is arranged at the front part of the light source; and the cylindrical light-transmitting lens is used for collecting scattered light sent by the light source and enabling light spots which are formed by illuminating an illuminated object by the light sent by the light source to be the rectangular light spots. The focus lamp of the rectangular light spots has the characteristics of wide application range, intensive light collection, high brightness and less light loss. Furthermore, the focus lamp is convenient to manufacture and low in cost, so that the focus lamp is suitable for wide popularization.

Owner:DALIAN XINQIHUI TECH

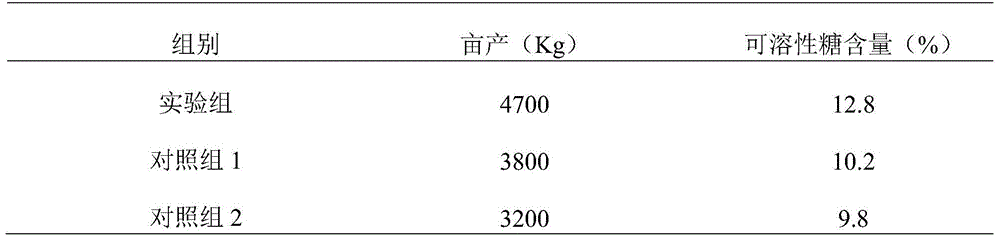

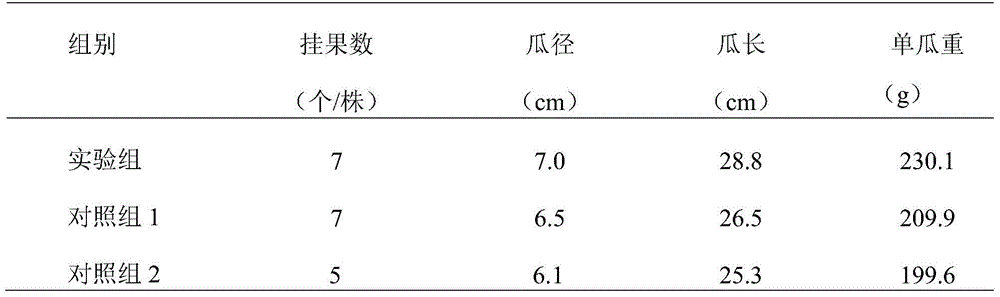

Shrimp peptide marine life organic liquid fertilizer as well as preparation method and application thereof

InactiveCN105732183AImprove resistance to pests and diseasesImprove absorption and utilizationMagnesium fertilisersBioloigcal waste fertilisersInsect pestPlant disease

The invention discloses a shrimp peptide marine life organic liquid fertilizer as well as a preparation method and an application thereof. The organic liquid fertilizer is mainly prepared from the following raw materials in parts by weight: 60-70 parts of soybean molasses, 20-30 parts of shrimp peptide, 5-10 parts of a chitosan solution, 1-2 parts of magnesium sulfate, 0.2-1 part of borax, 0.2-1 part of zinc sulfate and 0.2-1 part of manganese sulfate. The preparation method comprises: uniformly mixing the raw materials, boiling the mixture with big fire, and then boiling the mixture continuously for 3-4h by keeping slight boiling until the liquid specific gravity reaches 1.25g / cm<3> to obtain the organic liquid fertilizer, wherein the shrimp peptide marine life organic liquid fertilizer is used for spray application or drip application after being diluted. The shrimp peptide marine life organic liquid fertilizer disclosed by the invention has the characteristics of high activity, long fertilizer effect period, high plant absorption utilization rate and the like, has a certain effect of improving the capability of resisting plant diseases and insect pests of crops, is nontoxic to human bodies, and can be used for a long time on the crops; and the preparation method disclosed by the invention is easy to operate, is low in equipment requirement, can realize clean production with zero pollution discharge, and has producing capacity of large-scale industrialization.

Owner:宋德放

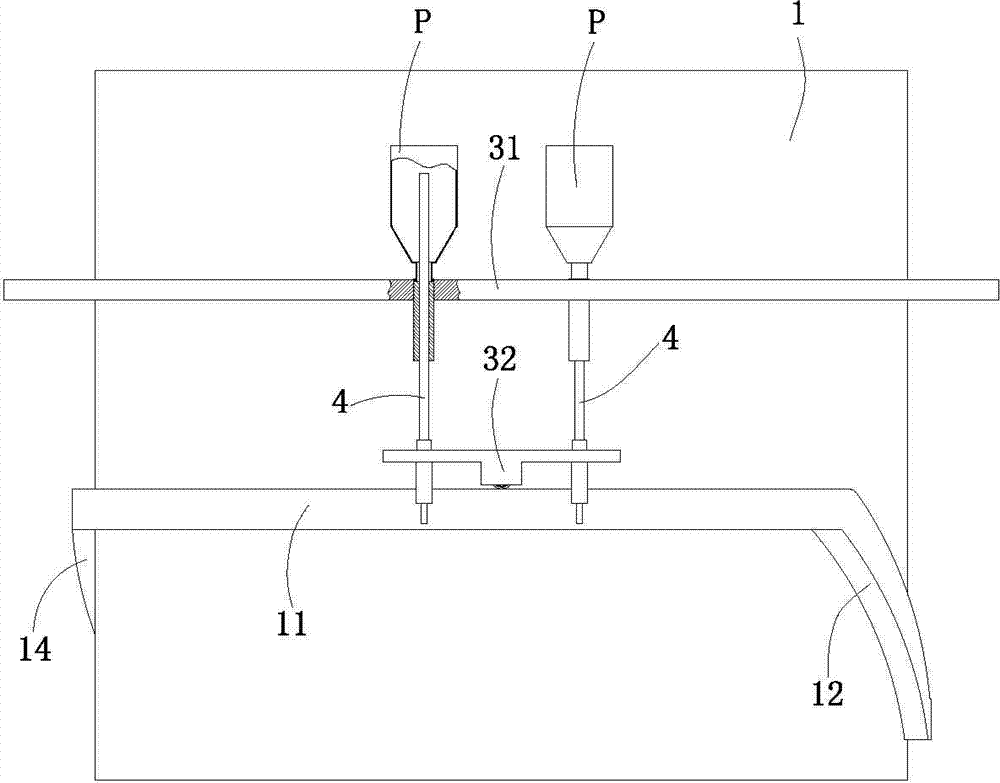

Plastic bottle gas-wash control device in plastic bottle large-infusion washing-filling-sealing machine

ActiveCN102765692AReduce the numberGood cleaning effectBottle-handling machinesProgramme control in sequence/logic controllersEngineeringCam

The invention discloses a plastic bottle gas-wash control device in a plastic bottle large-infusion washing-filling-sealing machine. The plastic bottle gas-wash control device is structurally characterized in that the number of proximity switches is N, N is not less than 6 and is a natural number divided exactly by 360, and the proximity switches are uniformly distributed on the outer wall of an inner rotating drum along the circumferential direction; the number of cams is one, the cam is arranged on the inner wall of an outer fixing drum, and the central angle corresponding to the cam is 360 / N degrees; and each electromagnetic valve is communicated with at least 36 / 2N blowing nozzles arranged on adjacent clamping components. With the adoption of the device, the gas-wash quality of the plastic bottle is better.

Owner:ANHUI GLOBAL PHARM CO LTD

A device for intercepting river garbage

The invention relates to the technical field of river channel cleaning, and discloses a river channel garbage interception device, which includes a buoy, a connecting frame, a rope, a counterweight assembly and an intercepting net; two buoys form a group, and the two buoys are connected by a Two connecting frames are provided and installed at both ends of the two buoys; two ropes are provided and pass through multiple groups of buoys, and the top of the interception net is installed on the connecting frames through buckles. The river garbage interception device is placed in the river and will float on the water surface, intercepting the garbage on the water surface, avoiding the garbage flowing downstream, and making the garbage concentrated, so that the intercepted garbage can be salvaged regularly, and a large amount of river garbage can be removed ; The device has a simple structure, is easy to assemble, can be quickly installed, saves time, and has a low price.

Owner:江苏天从环保科技有限公司

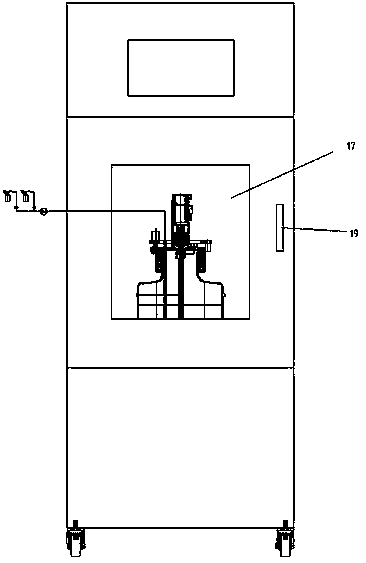

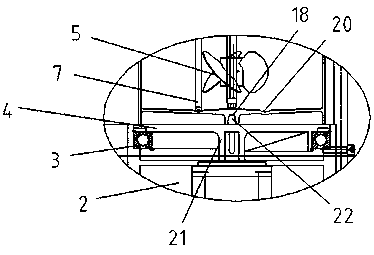

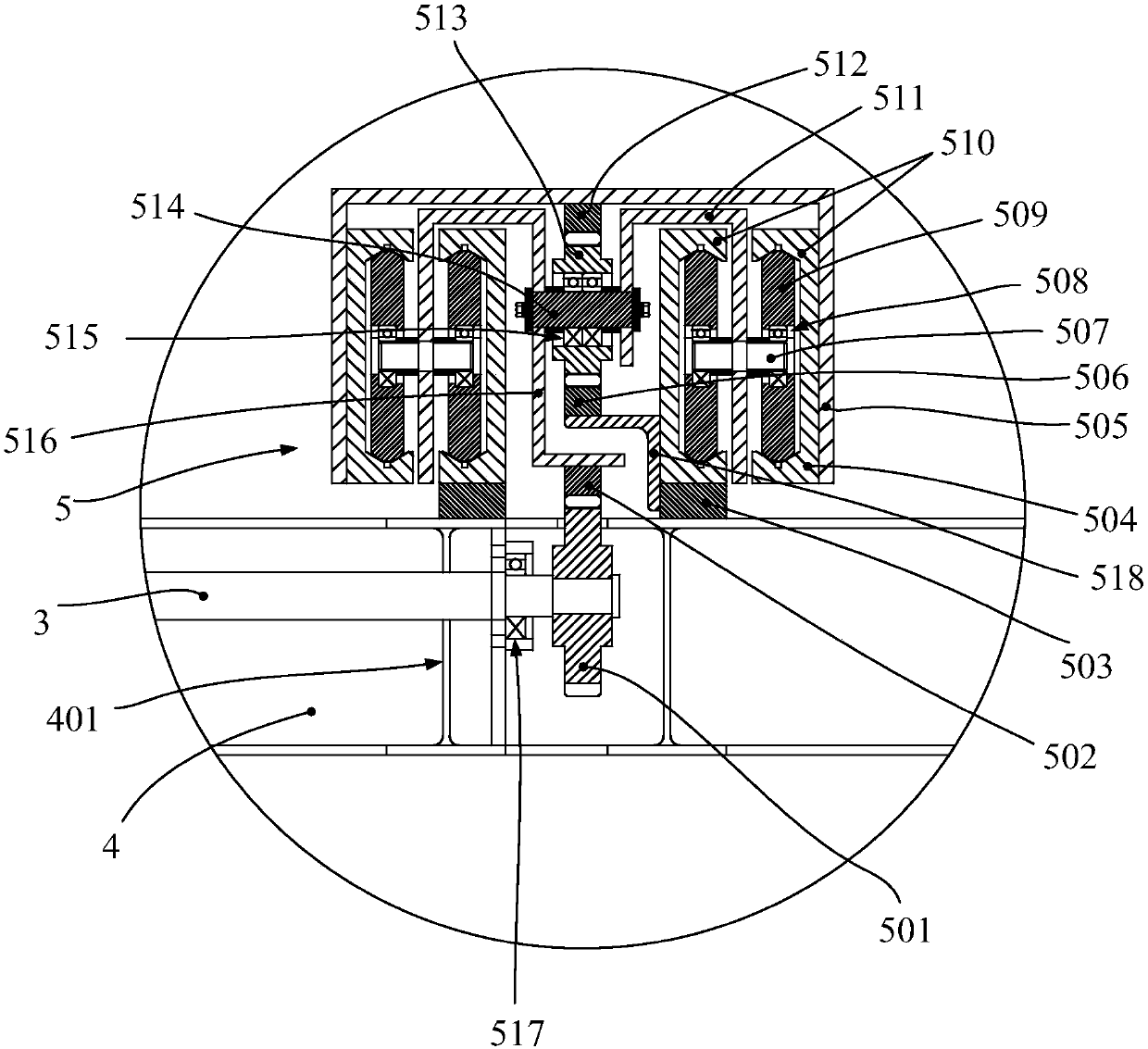

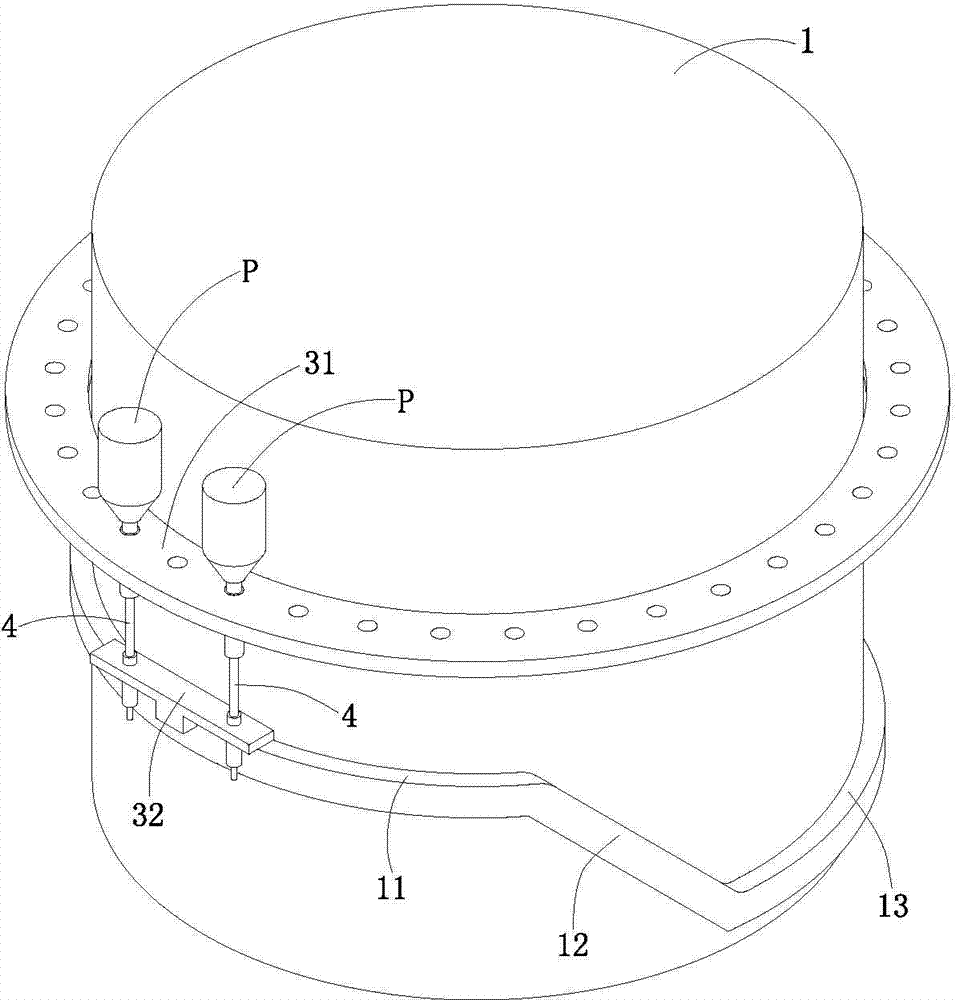

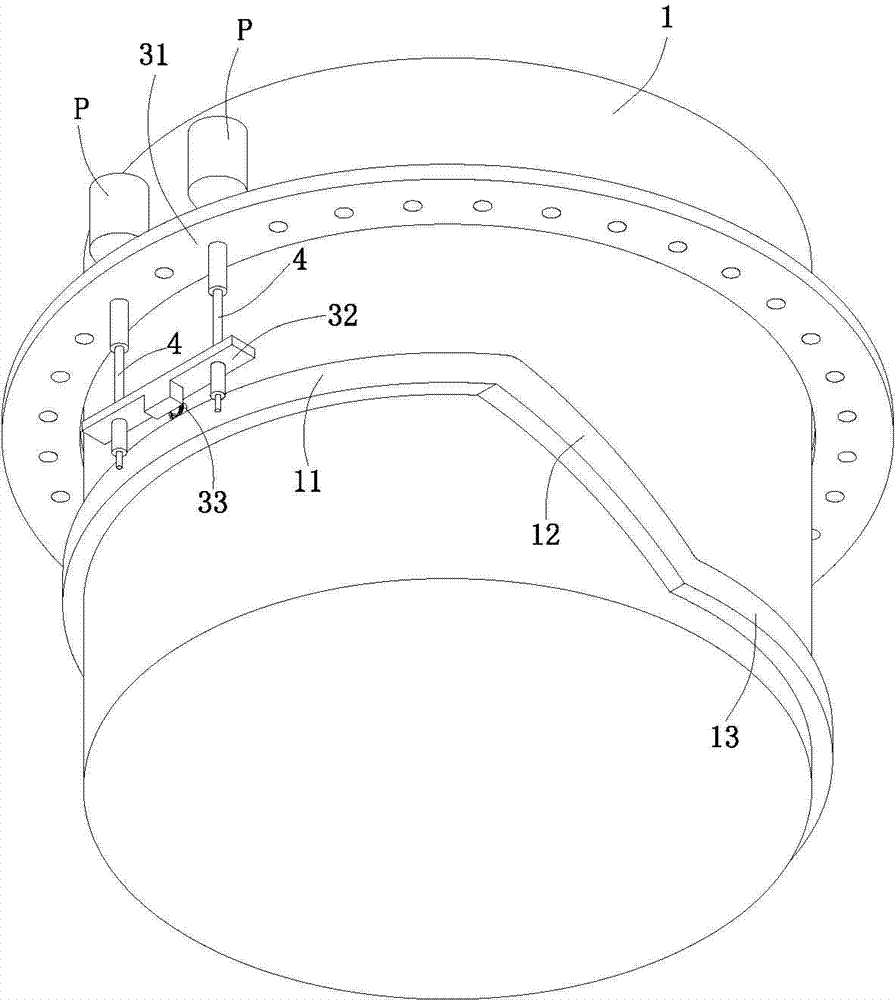

Vertical type rotary tank bioreactor for large-scale cell culturing

PendingCN110016437AReduce production linksAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlCell separation

The invention discloses a rotary bioreactor for large-scale cell culturing. The rotary bioreactor comprises a rotatable culture tank, wherein a tank cover is arranged at a tank opening of the culturetank in a sealing manner; a rotating driving device is arranged below the bottom of the culture tank, and can drive the culture tank to rotate along a vertical central axis of the culture tank; the tank cover of the culture tank is fixed and does not rotate; a plurality of interfaces are formed in the tank cover; a rotary joint is arranged between the tank cover and the tank opening, and is used for realizing the sealing rotation of the culture tank; and an electrode, a feeding and discharging pipeline, an on-line cell detecting system, a stirring system, a perfusion system and a ventilating system are also connected to the interfaces in the tank cover. The rotary bioreactor disclosed by the invention is suitable for the whole preparation process of a cell therapy preparation; and all preparation steps of cell separation, magnetic separation transfection, amplifying, concentrating, washing, configuring and subpackaging can be completed in a full-sealed full-automatic controlled bioreactor.

Owner:南京比瑞生物科技有限公司

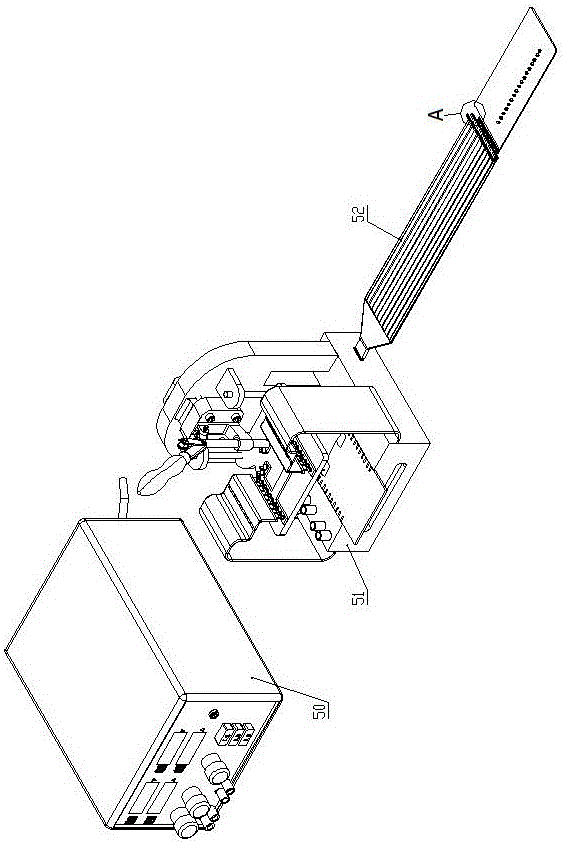

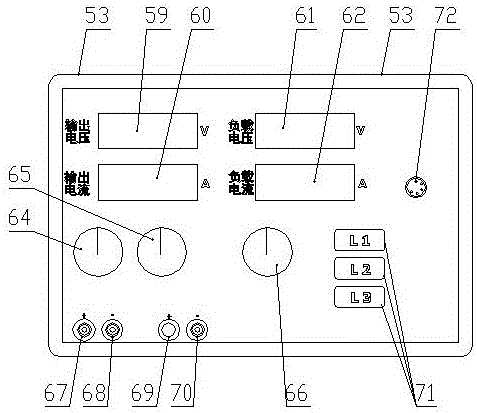

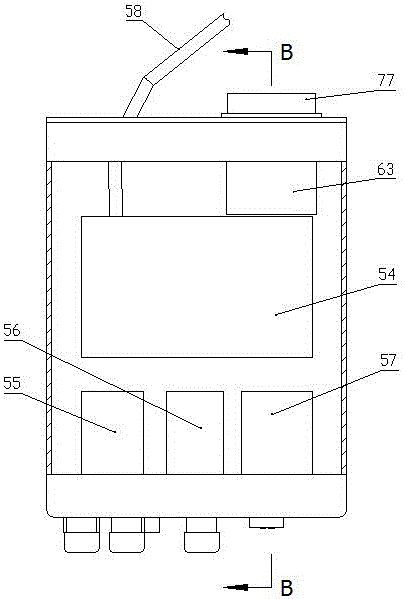

Multifunctional integrated circuit debugging instrument

ActiveCN106324480AAvoid adverse situationsQuick releaseElectronic circuit testingElectronic loadObservation unit

A multifunctional integrated circuit debugging instrument comprises a control host machine, a circuit board testing clamp and a testing signal output observation unit. The testing signal output end of the circuit board testing clamp is connected with the signal input end of the testing signal output observation unit. The control host machine comprises a cuboid housing which is internally provided with a power driving module, a switching mode power supply control module, a load control module and a welder constant-temperature heating module. The back portion in the housing is provided with a heat radiator which contacts with the power driving module. The load control module is connected with the power driving module. The load control module is connected with the switching mode power supply control module and the welder constant-temperature heating module. The multifunctional integrated circuit debugging instrument has advantages of simple structure and easy operation. Functions of instruments such as an adjustable stabilized power supply, an oscilloscope and an electronic load instrument are integrated. Multiple functions and high integration degree are realized. Furthermore the multifunctional integrated circuit debugging instrument has advantages of easy operation in the use process, reliable connection, high testing accuracy, and great efficiency improvement in performing debugging on the circuit board.

Owner:河南捷安新能源科技有限公司

Three-stage telescopic fork

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

Bottom board of ping-pong racket

The invention relates to a table tennis bat back board which includes handle, bat board, and middle core board. The middle of the core board is embedded door shape force frame of which gatepost two sides are embedded elastic bar. The force frame, elastic bar, and core board are at the same plane. Thus the invention has the advantages of wide elastic range, good elastic effect, stability, reasonable conceive, good using effect etc.

Owner:丁晓矛

Laser line scanning 3D detection method and system based on scanning galvanometer and event camera

The invention belongs to the field of 3D detection and measurement, and particularly relates to a laser line scanning 3D detection method and system based on a scanning galvanometer and an event camera. The method comprises the following steps: the laser line is reflected to an object to be detected by the scanning galvanometer, so that laser line scanning is achieved; the event camera is adoptedto collect laser line signal information reflected from the object to be measured, and pixel points with changed brightness on the object to be measured and corresponding time points are stored and output; the position coordinate of the space point of the object to be detected scanned by the laser line at the moment is calculated through the relative position between the scanning galvanometer andthe event camera, the pixel point output in the step 2 and the scanning galvanometer rotation angle corresponding to the moment point corresponding to the pixel point; the steps are repeated to complete all space point coordinates of the object to be measured so as to obtain 3D point cloud data of the object to be measured, thereby solving the limitations of frame rate, resolution and illuminationresistance in the current 3D scheme.

Owner:XI AN ZHISENSOR TECH CO LTD

A led arch lens with narrow and long light spot

ActiveCN105627252BIncrease in sizeConcentratedGas-tight/water-tight arrangementsLight fasteningsTotal internal reflectionFree form

The invention belongs to the technical field of lenses, and particularly relates to an LED arched lens with a long and narrow light spot. The lens comprises an LED lamp bead, an incident hole formed in the bottom of the lens, a first reflecting face, a second reflecting face, a first arched part, a second arched part and a third arched part. The first reflecting face and the second reflecting face are formed on the two sides of the lens. The first arched part, the second arched part and the third arched part are formed on the top of the lens. The third arched part is formed between the first arched part and the second arched part. The LED lamp bead is located in the incident hole. Compared with the prior art, the total internal reflection theory and a free-form surface are combined, and light emitted by an LED lamp can be emitted out in a collimation manner in the width direction of the lens. The arched structure and the free-form surface are combined, and the light emitted by the LED lamp can be emitted to a place with a larger angle in the length direction of the lens. Therefore, the LED arched lens has the beneficial effects of being centralized in light condensation, small in light loss, simple in structure, small in size and the like, and the narrower and longer light spot can be generated.

Owner:东莞市鑫叶光学有限公司

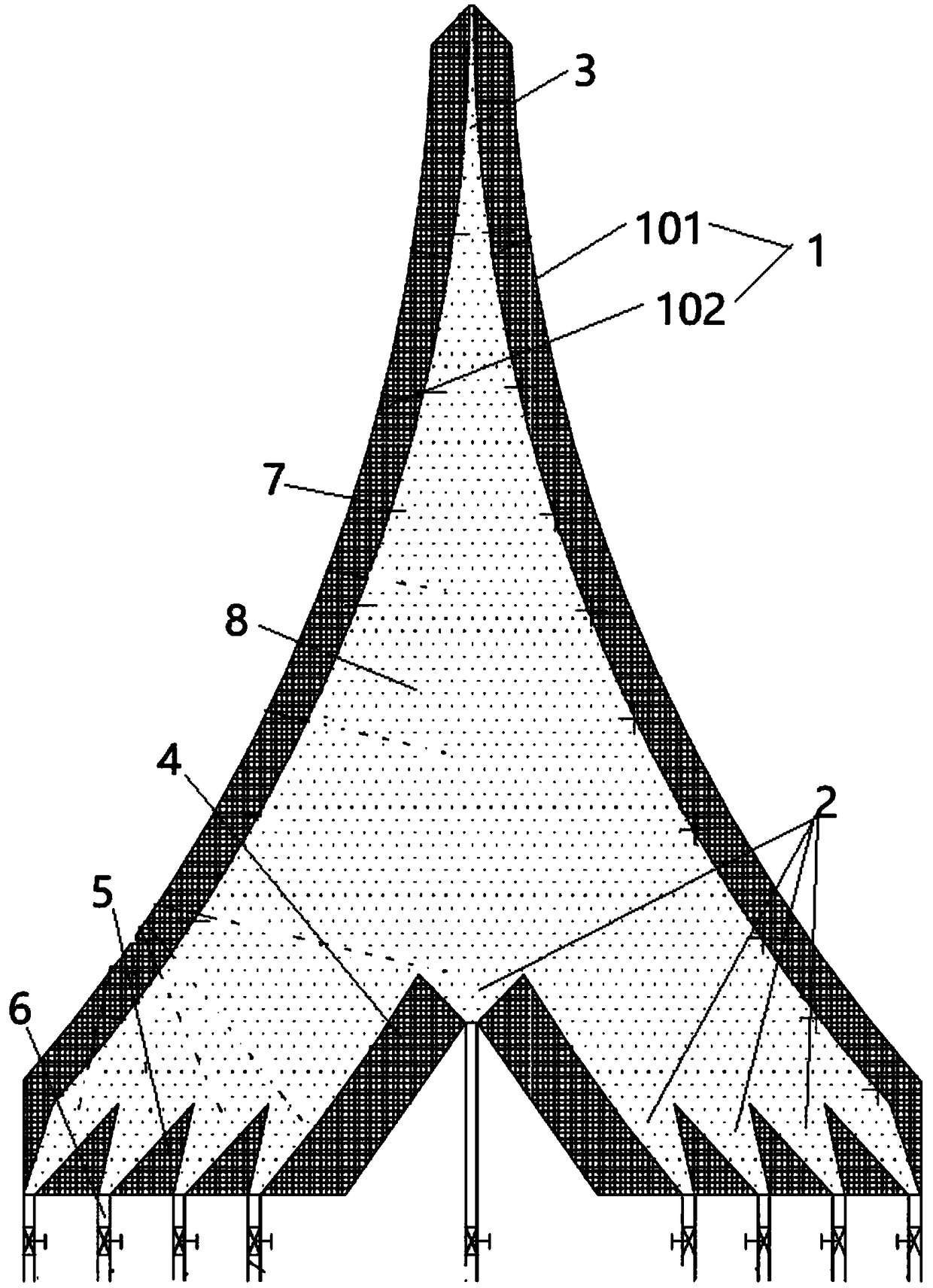

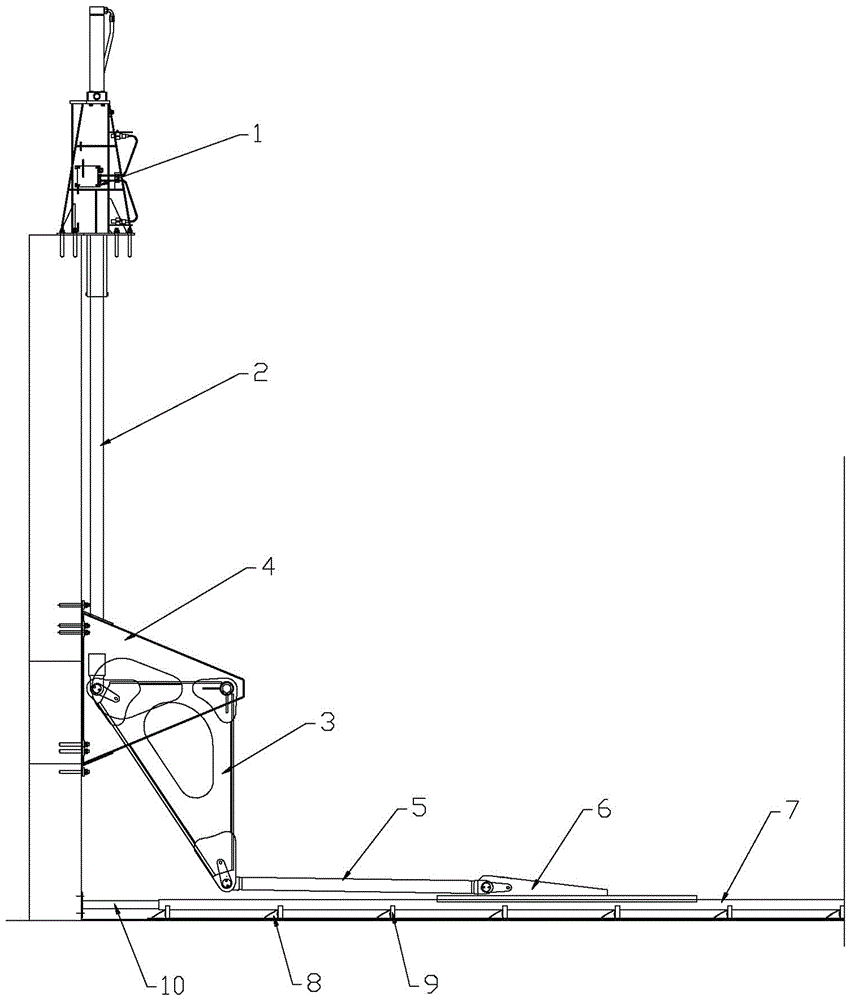

Hydraulic pushing-pulling type pool bottom mud scraper

InactiveCN106540479AFew moving partsReduce maintenanceSettling tanks feed/dischargePush pullEngineering

The present invention discloses a hydraulic pushing-pulling type pool bottom mud scraper, which comprises a hydraulic oil cylinder (1), wherein the drive end of the piston support rod (2) of the hydraulic oil cylinder (1) is connected to one corner of a triangular arm (3) so as to drive a horizontal pushing rod (5) arranged on another corner of the triangular arm (3), the horizontal pushing rod (5) is fixed above a center shaft (7) through a connection plate (6), a plurality of mutually parallel scraping plates (8) perpendicular to the center shaft (7) are arranged below the center shaft (7), the scraping plate (8) has a wedge-shaped concave surface structure, the wedge-shaped concave surface of the scraping plate (8) pushes sludge to move toward a sludge ditch when the scraping plate (8) moves forwardly, and when the scraping plate (8) returns, the wedging point of the scraping plate (8) is inserted into the covering sludge layer so as to make the sludge flow from the upper surface of the scraping plate (8) to the sludge ditch. The mud scraper of the present invention has advantages of less movement parts, continuous sludge transportation, uninterrupted precipitation process, high reliability, convenient installation, sludge concentration, and wide application range.

Owner:宜兴市苏嘉环保设备有限公司

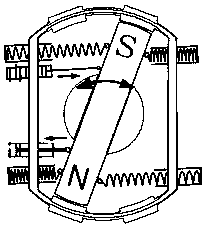

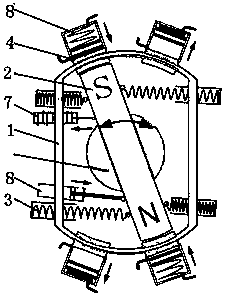

Permanent magnet power device

The invention discloses a permanent magnet power device and aims to provide an energy-saving and environment-friendly permanent magnet power device. The permanent magnet power device comprises a casing made of a non-magnetic material, a strip-shaped permanent magnet in a vertical state, four springs, two upper magnetic conductors, two lower magnetic conductors, a two-way cylinder and a travel switch, wherein the middle of the strip-shaped permanent magnet is rotationally mounted in the casing, one end of each of the four springs is fixedly connected with the casing, the other ends pull two sides of an S pole of the strip-shaped permanent magnet and two sides of an N pole of the strip-shaped permanent magnet; the two upper magnetic conductors are mounted at the upper end of the casing and symmetrically located on two sides of the strip-shaped permanent magnet, the two lower magnetic conductors are mounted at the lower end of the casing and symmetrically located on two sides of the strip-shaped permanent magnet, a cylinder body of the two-way cylinder is connected with the casing, and a piston rod is connected with one end of the strip-shaped permanent magnet; the travel switch is mounted on the casing, is connected with the strip-shaped permanent magnet and has a time delay function; the strip-shaped permanent magnet is close to adjacent end surfaces of the upper magnetic conductors and the lower magnetic conductors. The permanent magnet power device is applicable to multiple kinds of equipment requiring power drive.

Owner:朱伟

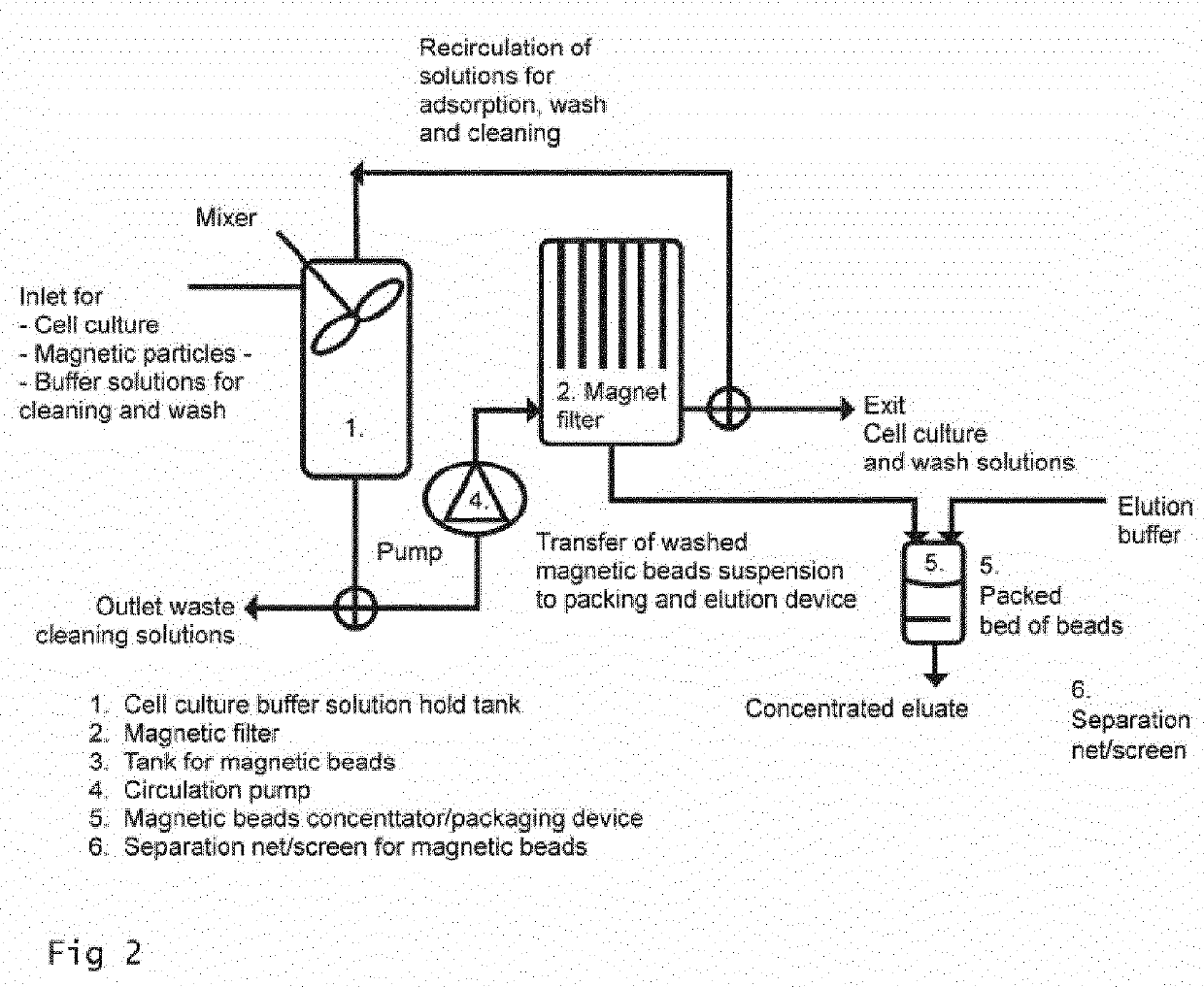

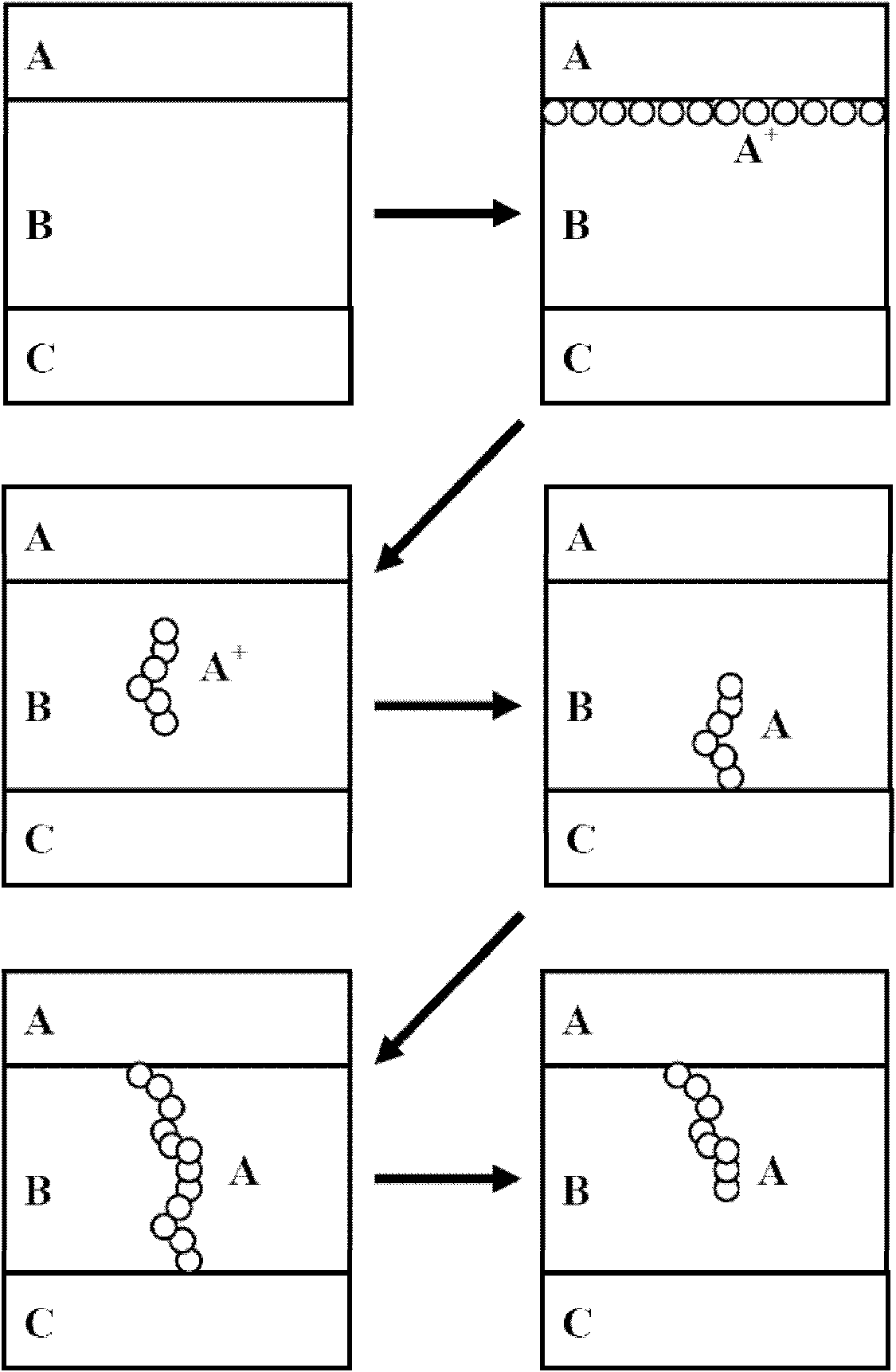

Combinatory separation

PendingUS20200114369A1ConcentratedProcess becomes simple quickerElectrostatic separationHigh gradient magnetic separatorsVirus inactivationMagnetic bead

There is disclosed a combinatory separation system comprising: a first compartment adapted to handle a mixture with magnetic beads having an affinity for molecules, comprising a magnet to attract the beads, a second compartment adapted to receive said magnetic beads transferred thereto with a flow of liquid, and said at least one second compartment is adapted to elute said at least one type of molecules to be separated from said magnetic beads, said at least one second compartment has an outlet comprising means for retaining said magnetic beads in the at least one second compartment. Advantages include that the process becomes simpler quicker and thereby less expensive, since the method is able to remove cells and particles, separate molecules and perform virus inactivation in fewer steps compared to the prior art. Further the method is able to provide a more concentrated end product.

Owner:LAB ON A BEAD AB

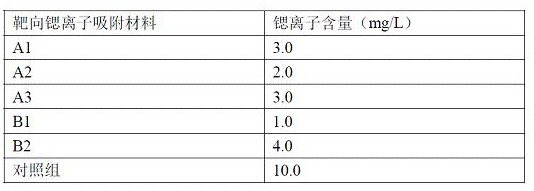

Preparation method of strontium ion Sr<2+>-targeting adsorption material

InactiveCN113274984AReach recoveryConcentratedOther chemical processesRadioactive decontaminationPeristaltic pumpActive agent

The invention discloses a preparation method of a strontium ion-targeting adsorption material, which comprises the following steps: mixing palygorskite clay powder, a surfactant and water, adjusting the pH value, conducting stirring by using a magnetic stirrer to obtain a modified system, conducting centrifuging, discarding the supernatant, and drying the powder in a drying oven to obtain modified palygorskite clay powder; and fully mixing the modified palygorskite clay powder with sodium alginate and water according to a certain ratio, dropwise adding the mixed solution into a calcium chloride solution by using a peristaltic pump, granulating, and conducting drying in a drying oven to obtain the strontium ion-targeting adsorption material. The strontium ion-targeting adsorption material can effectively enrich strontium ions in nuclear emission wastewater, liquid-solid separation is easy, and meanwhile the preparation method is few in procedure and easy to operate.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

A Marketing Method of Entity Business Based on Genetic Algorithm

InactiveCN108805199BConcentratedCharacter and pattern recognitionGenetic algorithmsData setMarket place

The invention discloses a genetic algorithm-based entity commercial marketing method, which relates to the field of marketing methods and includes the following steps: collecting merchant data and user data; according to the merchant data, setting labels for different consumption types for the merchant, and obtaining merchant characteristic gene establishment Merchant gene pool model; according to user data, user consumption weight is obtained, and user preference model is established; k-means algorithm is used to perform initial clustering of merchant data and user data of similar types; genetic algorithm is used to calculate a certain merchant to be recommended The recommendation rate of the user, and calculate the recommendation rate for the user; then calculate the recommendation rate of the recommended user for the merchant that meets the conditions, and generate a new candidate merchant data set. According to the ranking of each merchant in the data set, the recommended user Precise recommendation; the present invention solves the problem that the current entity commercial market cannot carry out precise marketing to users, which makes it less competitive in the commercial market.

Owner:电子科技大学成都学院

A kind of aluminum alloy recovery and cleaning equipment

Owner:江苏宏元达光伏新材料有限公司

Plastic bottle gas-wash control device in plastic bottle large-infusion washing-filling-sealing machine

ActiveCN102765692BConcentratedQuality improvementBottle-handling machinesProgramme control in sequence/logic controllersEngineeringCam

The invention discloses a plastic bottle gas-wash control device in a plastic bottle large-infusion washing-filling-sealing machine. The plastic bottle gas-wash control device is structurally characterized in that the number of proximity switches is N, N is not less than 6 and is a natural number divided exactly by 360, and the proximity switches are uniformly distributed on the outer wall of an inner rotating drum along the circumferential direction; the number of cams is one, the cam is arranged on the inner wall of an outer fixing drum, and the central angle corresponding to the cam is 360 / N degrees; and each electromagnetic valve is communicated with at least 36 / 2N blowing nozzles arranged on adjacent clamping components. With the adoption of the device, the gas-wash quality of the plastic bottle is better.

Owner:ANHUI GLOBAL PHARM CO LTD

Resistive random access memory and manufacturing method thereof

ActiveCN102708919BSolve randomly formed problemsConcentratedSolid-state devicesSemiconductor/solid-state device manufacturingElectricityStatic random-access memory

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com