Laser line scanning 3D detection method and system based on scanning galvanometer and event camera

A scanning galvanometer and detection method technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of high computing performance of processing chips, low resolution of depth images, and reduced detection rate, etc., and achieves fast data transmission. The effect of simple algorithm and less output data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

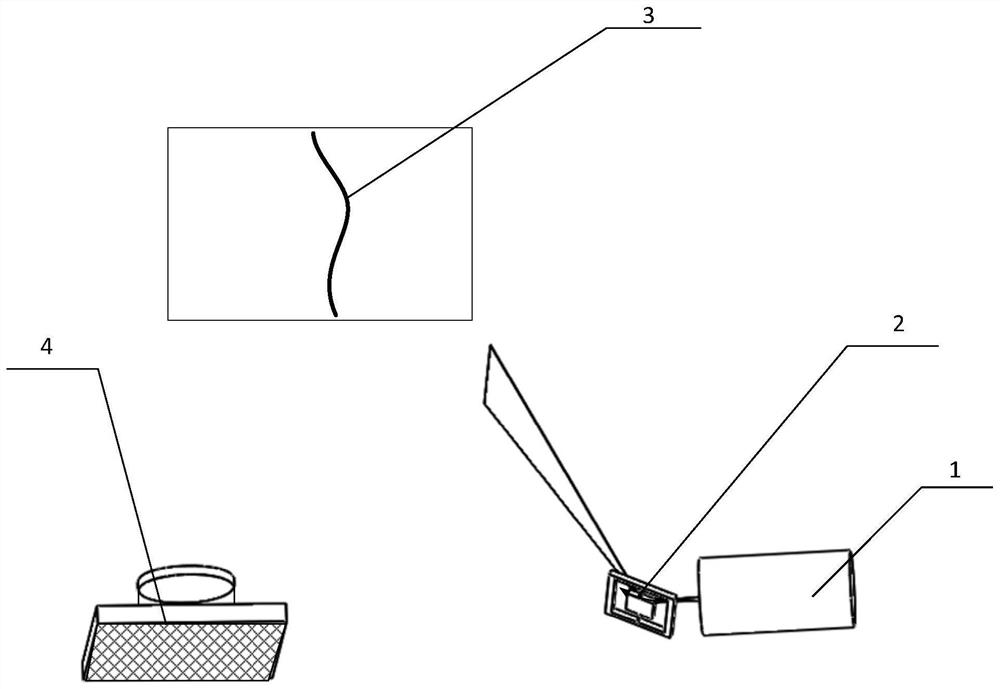

[0067]Such asfigure 1 As shown, this embodiment is based on scanning galvanometer and event camera laser line scanning 3D detection system mainly includes line laser 1, scanning galvanometer 2 and event camera 4. The line laser 1 continues to work and is incident on the scanning galvanometer 2. The direction of the laser line is consistent with the direction of the rotation axis of the scanning galvanometer 2. When the scanning galvanometer 2 rotates around its rotation axis, the line laser can be reflected to the object 3 to be measured to realize the laser line scanning; the event camera 4 collects the reflection from the object 3 The laser line signal information realizes 3D detection of the object 3 to be measured. The detection method is as follows:

[0068]The movement of the scanning galvanometer 2 is:

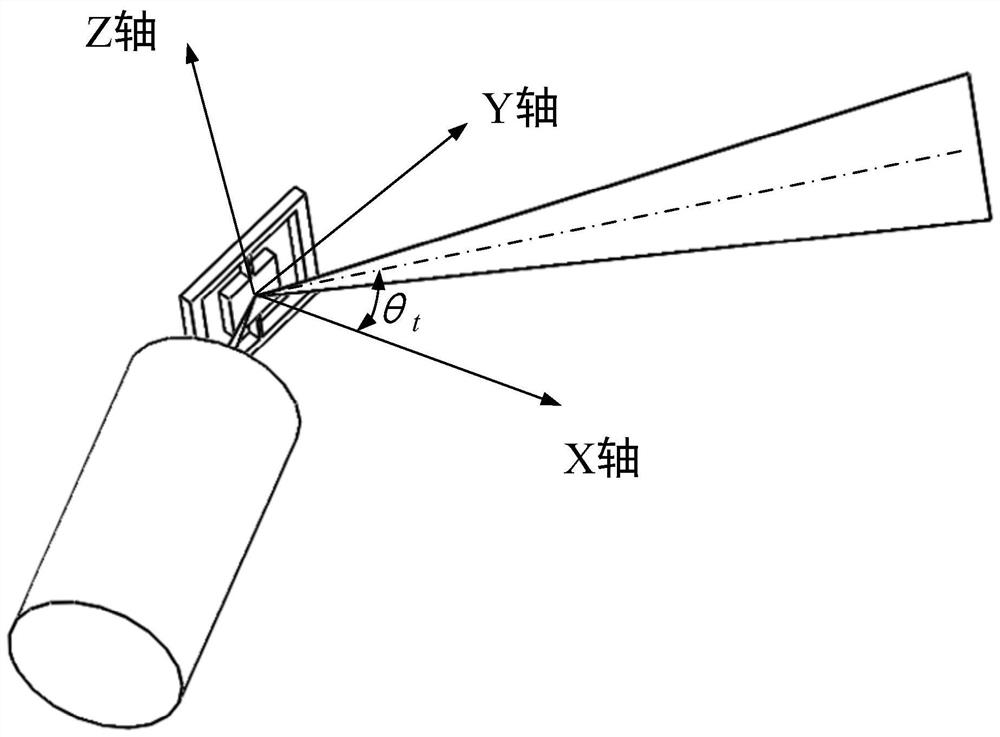

[0069]Where θtIs the rotation angle of the scanning galvanometer at time t, A is the rotation angle amplitude of the scanning galvanometer, f is the scanning frequency of the scann...

Embodiment 2

[0086]The resonant scanning galvanometer has high reliability, small driving force and large rotation angle, and is often used in the laser scanning process. Although the response rate of the event camera is extremely fast, it is limited after all. If the scanning frequency of the scanning galvanometer is too high, the accuracy may be reduced, such asFigure 4 , TnAnd tn+1Are the two time periods that the event camera can continuously distinguish, and the scanned areas are inAnd in+1, If multiple columns of pixels respond at the same time in each time period, that is, time tnAnd tn+1It is equivalent to fringe scanning, not laser line scanning, and the event camera can no longer accurately detect tnAnd tn+1The scanning galvanometer scans the details of the fringe area during the time period.

[0087]This embodiment proposes a method to solve the problem of low 3D detection accuracy caused by the above reasons: control the output of the line laser, let the scanning galvanometer scan at in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com