Preparation method of strontium ion Sr<2+>-targeting adsorption material

A technology for adsorbing materials and strontium ions, which is applied in chemical instruments and methods, other chemical processes, nuclear engineering, etc., and can solve the problems of difficult solution separation and hindering the application of palygorskite clay materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

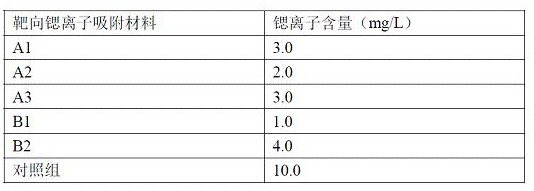

Examples

preparation example Construction

[0021] The invention provides a targeted strontium ion Sr 2+ A method for preparing an adsorbent, the method comprising the following steps:

[0022] 1) Mix palygorskite clay powder, surfactant, and water, adjust the pH, perform magnetic stirring to obtain a modified system, centrifuge, discard the supernatant to obtain a powder, and dry the powder in an oven to obtain a modified system. Palygorskite clay powder after curing;

[0023] 2) The modified palygorskite clay powder is fully mixed with sodium alginate, and the peristaltic pump is used to drip calcium chloride solution into granules at a uniform speed, and after drying, the targeted strontium ion adsorption material is obtained.

[0024] In step 1) of the present invention, the type of surfactant can be selected in a wide range, but in order to further improve the effect of adsorbing strontium ions on the targeted strontium ion adsorption material, preferably, in step 1), select twelve At least one of sodium alkylsul...

Embodiment 1

[0041] 1) Set palygorskite clay powder, surfactant (sodium tetradecylsulfonate), and water at a ratio of 10:1:50, and use a magnetic stirrer to stir at 60r / min for 12h; after that, the mixed solution is centrifuged Machine 3000r / min, centrifuged for 10min; after that, dried at 105°C for 4h.

[0042]2) Mix the modified palygorskite clay powder, sodium alginate, and water in a ratio of 100:5:300. After stirring well, use a peristaltic pump at 2mL / min to drop the mixed solution into 0.05g / L of chloride Calcium solution, and then dried at 110°C for 2 hours to obtain the targeted strontium ion adsorption material A1.

Embodiment 2

[0044] 1) Set palygorskite clay powder, surfactant (sodium dodecylsulfonate), and water at a ratio of 10:0.6:50, and use a magnetic stirrer to stir at 60r / min for 12h; after that, the mixed solution is centrifuged Machine 3000r / min, centrifuged for 10min; after that, dried at 105°C for 4h.

[0045] 2) Mix the modified palygorskite clay powder, sodium alginate, and water in a ratio of 100:5:400. After fully stirring, use a peristaltic pump at 2mL / min to drop the mixed solution into 0.05g / L chloride Calcium solution, and then dried at 110°C for 2 hours to obtain the targeted strontium ion adsorption material A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com