Magnetic suspension high efficiency multifunctional permanent magnetic motor

A permanent magnet motor and magnetic levitation technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of narrow range of mechanical applications, limited power torque, material waste and surplus, and achieve the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

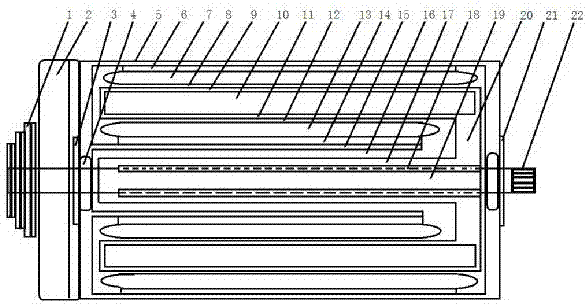

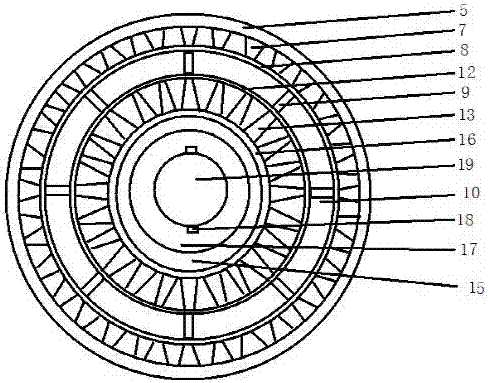

[0020] Example 1 as figure 1 , figure 2 , image 3shown. The magnetic suspension high-efficiency multifunctional permanent magnet motor of the present invention is mainly used for driving power of vehicles and ships. It includes a wind wheel 2 on a traditional permanent magnet motor, a bearing cover and a Hall system device 3, 21, a bearing 4, a motor casing 5 and a main shaft 19. The wind wheel 2 is an internal and external air-cooled wind wheel or oil-cooled water-cooled, which is a cooling system for the motor. The bearing gland and the Hall system device 3, 21 are installed on the outer ends of both sides of the motor casing 5, and are the bearing gland and the Hall control element system. The present invention adds a low-power unit inner wall housing 15 whose one end is integrated with the side wall of the motor housing 5 or is precision-cast in the motor housing 5. The motor housing 5 and the low-power unit inner wall housing 15 are different in diameter and low pow...

Embodiment 2

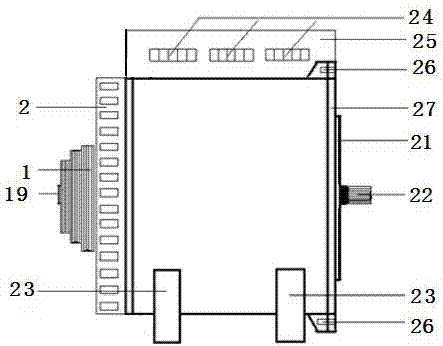

[0021] Example 2 as Figure 4 shown. The difference from Embodiment 1 is that the fuselage is fixed with feet. The fuselage fixing foot 28 of Embodiment 2 is arranged on the side of the motor housing 5, and its shape is horizontal.

[0022] combined with figure 1 , 2 , 1, 2 embodiment shown in 3, 4, introduce working principle of the present invention:

[0023] When the stator core 6 of the high-power unit, the stator bar 7 of the high-power unit, and the stator winding of the power supply of the high-power unit are supplied with power, they are connected with the outer diameter 9 of the magnetic levitation rare earth magnet and the inner diameter 11 of the magnetic levitation rare earth magnet, or precision cast magnetic levitation The positive cylindrical floating magnetic steel body 10 of the magnetic steel integral part and the positive cylindrical body 17 linked and fixed with the main shaft and the integral support side wall 20 interact to generate electromagnetic to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com