Method for recovering and purifying ethanol-ethyl acetate-piperazine waste solvent

A technology of ethyl acetate and a purification method, which is applied in the field of waste liquid purification, can solve the problems of reduced distillation effect and efficiency, low liquid output efficiency, and high difficulty in purification, and achieves reduced waste solvent generation, stable operation, and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

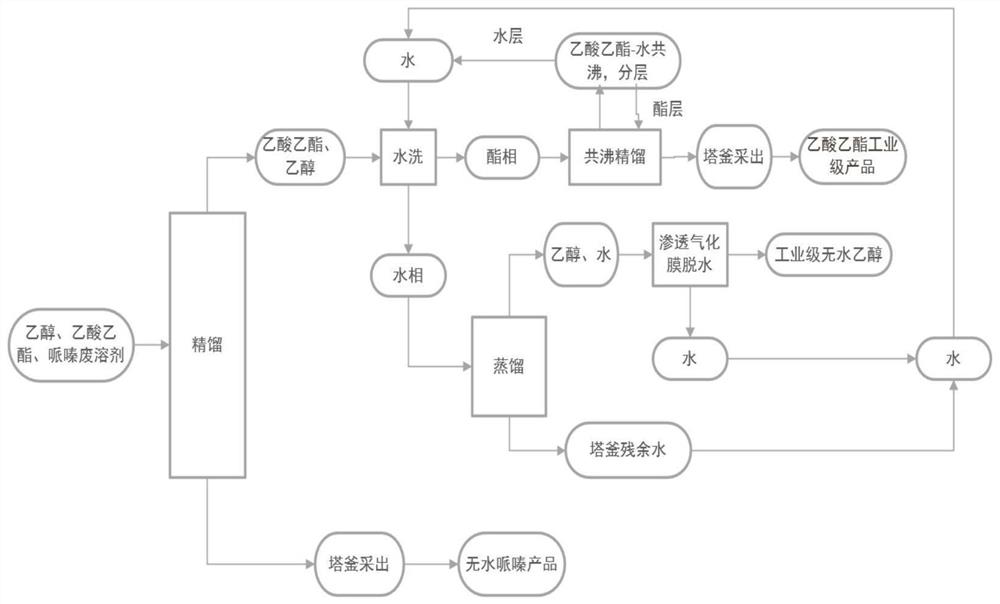

Image

Examples

Embodiment 1

[0027] Waste solvent ethanol-ethyl acetate-piperazine recovery and purification method, the extraction steps include:

[0028] Take waste solvent containing 53% ethanol, 42% ethyl acetate, 4% piperazine, rectify, and the conditions of rectification are: rectification still bottom temperature 112°C, liquid temperature in the still 109°C, still top temperature 70~78°C , control the reflux ratio of 10:1; separate ethanol, ethyl acetate and a small amount of water; piperazine is extracted from the tower kettle, and after passing the test, it can be packed and stored with nitrogen gas to obtain anhydrous piperazine with a purity ≥ 99.5% (wt). .

[0029] The ethanol and ethyl acetate obtained by the above rectification were added to 1.45 times the volume of waste solvent water, washed with water, the upper layer obtained an organic phase composed of ethyl acetate and water, and the lower layer obtained an aqueous phase composed of ethanol and water.

[0030] The above-mentioned org...

Embodiment 2

[0033] Waste solvent ethanol-ethyl acetate-piperazine recovery and purification method, the extraction steps include:

[0034] Take the waste solvent containing 55% ethanol, 39% ethyl acetate, 5% piperazine, rectify, the conditions of rectification are: rectification still bottom temperature 112°C, liquid temperature in the still 109°C, still top temperature 70~78°C , Control the reflux ratio to 6:1; separate out ethanol, ethyl acetate and a small amount of water; extract piperazine from the tower kettle, pack it in a tank after passing the test, and store it with nitrogen gas to obtain anhydrous piperazine with a purity ≥ 99.5% (wt) .

[0035]The ethanol and ethyl acetate obtained by the above rectification were added to 1.35 times the volume of waste solvent water, washed with water, the upper layer obtained an organic phase composed of ethyl acetate and water, and the lower layer obtained an aqueous phase composed of ethanol and water.

[0036] The above-mentioned organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com