Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Comply with energy saving and environmental protection policy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

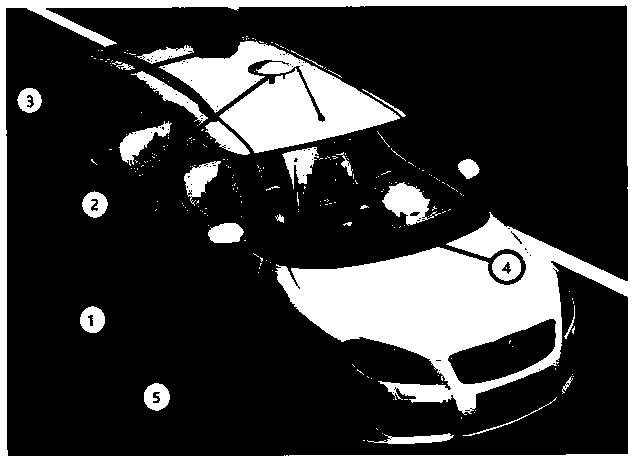

Roadside parking management system

InactiveCN108242152AAvoid private profitSolve the problem of difficult evidence collection for illegal parkingTicket-issuing apparatusRoad vehicles traffic controlParking spaceComputer terminal

A roadside parking management system includes a parking space data module, a cruise device, a camera device, a panoramic camera, a positioning module, an intelligent processing terminal, and a parkingcharging server. The camera device is installed on the cruise device, the roadside parking image is taken at a predetermined time interval and route, and the patrol time, location and image information are transmitted to the intelligent processing terminal in real time; and the intelligent processing terminal receives the information and transmits the information of the reasonable parking to theparking charge server, and the parking charge server charges according to the parking place and the duration of the parking. The system utilizes the movable camera device to complete the inspection ofthe roadside parking space, intelligently obtains the license plate number information of the vehicle parked in the parking space and the parking time thereof, instead of the manual timing charge, toavoid the charge for the private person to profit; there is no need to install the device on the road, which avoids the impact of road construction on traffic, reduces construction cost and maintenance cost; and the system is easy to implement, more environmentally friendly, and in line with national energy conservation and environmental protection policies.

Owner:沈志强

Synthesis method of photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propyl ketone

ActiveCN103613492AReduce consumptionQuick responseOrganic compound preparationCarbonyl compound preparation by condensationKetone synthesisCatalytic effect

The invention relates to a synthesis method of a photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propyl ketone, which comprises the following steps: reacting high-purity gas phosgene with isobutyric acid to synthesize isobutyryl chloride; and carrying out chlorine substitution reaction by a cascade technique: exhaust of a first reaction kettle after chlorine introduction is connected into a second reaction kettle in cascade, and hydrogen chloride and chlorine in the exhaust released by the first reaction enter the second reaction kettle to catalyze the absorption and utilization. The method can well enhance the purity of isobutyryl chloride and further enhance the purity and yield of the product 2-hydroxy-2-methyl-1-phenyl-1-propyl ketone; and the catalytic action of hydrogen chloride in the exhaust is utilized to increase the reaction speed, lower the chlorine consumption and enhance the product content. The generated exhaust is recycled after innocent treatment, thereby solving the problem of environmental pollution of the exhaust.

Owner:岳阳市国发植物用药工程技术研究中心有限公司

Method for using pennisetum hydridum lignin for preparation of active carbon and application of active carbon

ActiveCN105399872ALoose structureFacilitate chemical reactionsLignin derivativesPaper material treatmentActivated carbonPhosphoric acid

The present invention discloses a method for using pennisetum hydridum lignin for preparation of active carbon and application of the active carbon, the method comprises the following steps: hydrothermal coke can be prepared from the pennisetum hydridum lignin as a raw material by a hydrothermal method, the hydrothermal coke is impregnated with a solution of phosphoric acid, then the impregnated hydrothermal coke is put into a muffle furnace for carbonization, and finally the impregnated hydrothermal after the carbonization is activated by a hydrochloric acid solution, washed and dried to obtain the active carbon. The active carbon prepared from a pennisetum hydridum waste residue is just suitable for detoxification and decoloration of a hydrolyzate after pennisetum hydridum hydrolysis due to the pore size of the active carbon, and compared with the decolorization effect of purchased commodity active carbon, the decolorization effect of the active carbon is better.

Owner:QILU UNIV OF TECH

Spinning forming technique of environment-friendly flame-retardant viscose fiber colored filament and staple

InactiveCN101701362AEnvironmentally friendlyComply with energy saving and environmental protection policyArtificial filaments from viscoseSpinning solutions preparationNitrogenEngineering

The invention relates to a spinning forming technique of environment-friendly flame-retardant viscose fiber colored filament and staple, comprising: leading flame retardant and color paste to be contacted and mixed with viscose filtered by a first stage or a second stage, treating the mixture by the technique of balancing, defoaming, filtering, spinning and curing, and obtaining the finished product; wherein the flame retardant is nitrogen and silicon series of environment-friendly flame retardant. Therefore, the spinning forming technique solves the problem of dye of the environment-friendly flame-retardant viscose fiber colored filament and staple, can reduce or avoid the pollution for the environment caused by spinning printing and dyeing waste water to the utmost extent, and has the characteristics of energy conservation and emission reduction as well as environmental protection.

Owner:HENAN HAIYANG CHEM FIBER

Spinning forming method of non-dyed flame-retardant viscose colored filament

InactiveCN104831386AWith flame retardant curing effectAcid bath coagulation effect is goodFlame-proof filament manufacturePigment addition to spinning solutionDyeing wastewaterSodium sulfate

The invention relates to a spinning forming method of non-dyed flame-retardant viscose colored filaments. The spinning forming method comprises the following steps: providing spinning mixed liquid prepared by mixing a silicon-nitrogen flame retardant, color paste and alpha cellulose glue; providing a spinning acid bath prepared by mixing sulfuric acid, zinc sulfate and sodium sulfate; deforming and filtering the spinning mixed liquid, feeding the spinning mixed liquid into the spinning acid bath by virtue of a metering pump and a spinning nozzle, and carrying out solidification forming and spinning drafting so as to obtain colored continuous filaments; providing a curing treatment liquid containing positive ions Ti<4+> and Ca<2+>; curing the colored continuous filaments; and respectively carrying out water washing, drying and packaging on the cured filaments, so as to obtain the finished colored filaments. According to the spinning forming method, a downstream dyeing procedure is omitted, so that the environmental pollution caused by spinning printing and dyeing wastewater as well as the injury caused by dyed products to human bodies are maximally reduced or avoided.

Owner:SOL FLAME RETARDANT FIBER

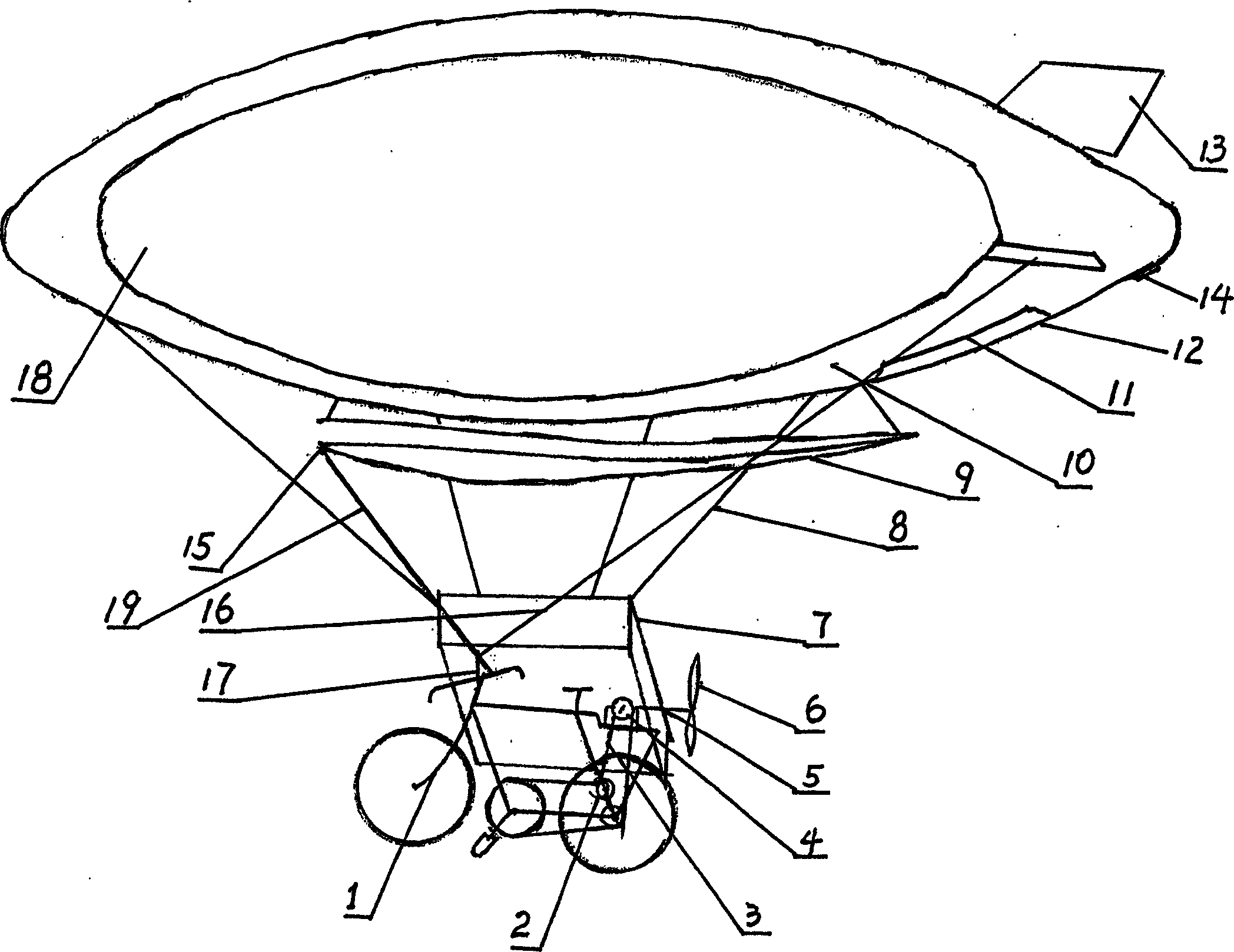

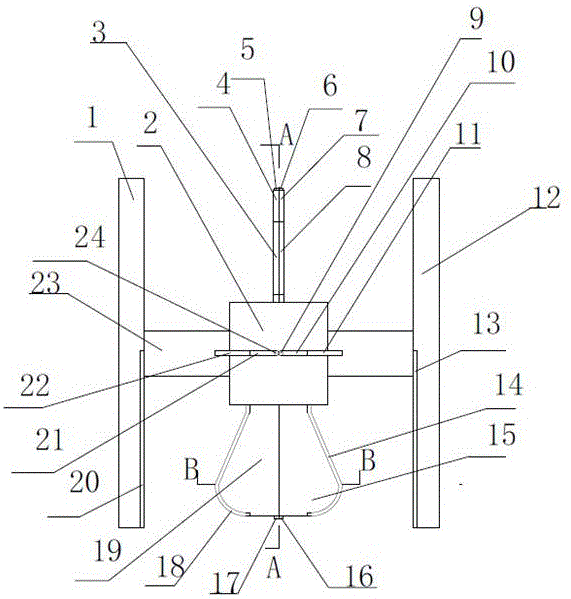

Flight device

InactiveCN1730305AFulfill the purpose of flightAchieve the effect of exerciseAircraft convertible vehiclesAviationFlight vehicle

The invention relates to a low-altitude airborne craft. It includes a multi-speed roadster, an elevating gear like paraglider and a buoyancy machine like airship. An airscrew, driving sprocket and gear for conveying power to the airscrew are arranged in the multi-speed roadster. The buoyancy machine like airship connects to a frame, located in the multi-speed roadster, by several connecting strings. The back of the buoyancy machine positions four symmetrical tailpiece, which connects to the rudder of the roadster by guide line, while the lower part of the buoyancy machine overhangs the elevating gear like paraglider. The invention combines the advantages of airship, paraglider, aerial screw and bicycles, not only realizing flies in low-altitude, but also exercises, without special propulsion unit, which meets the energy-saving and environment protection policy.

Owner:杨克成

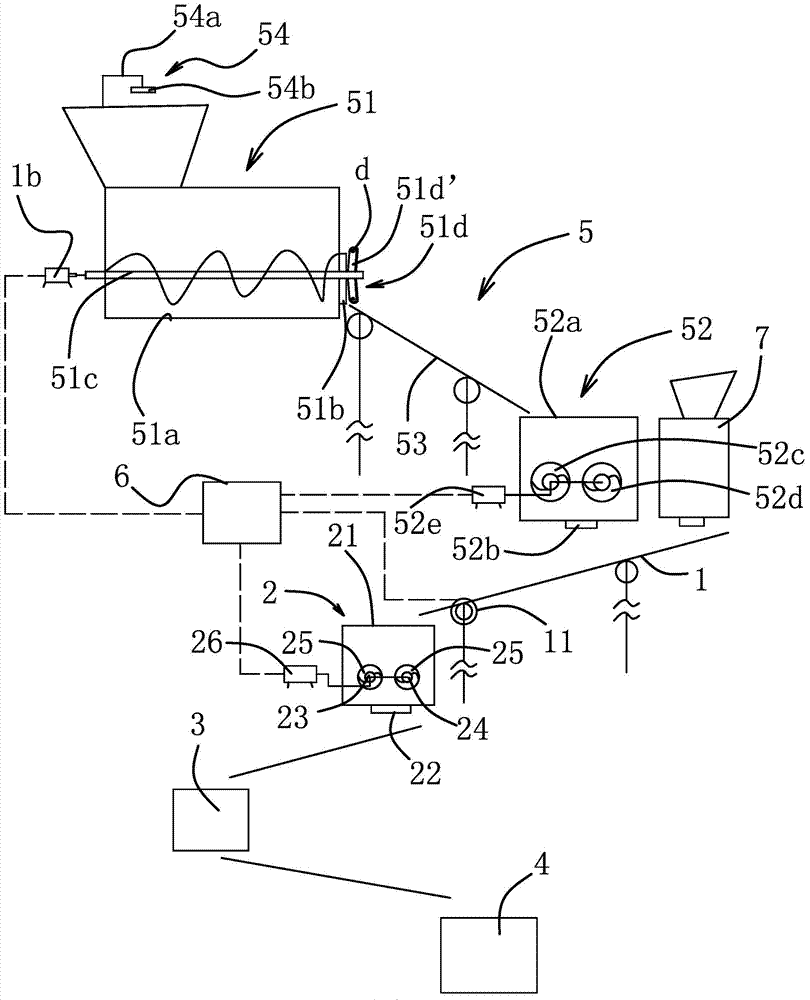

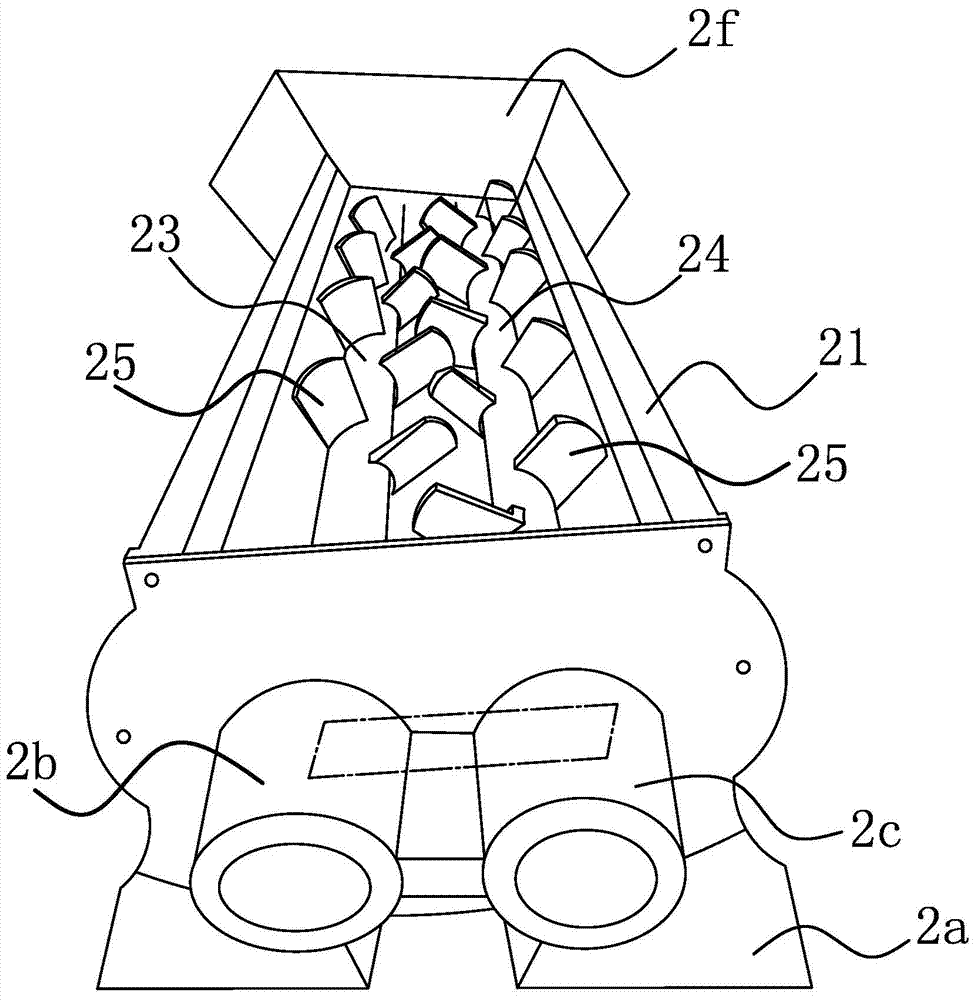

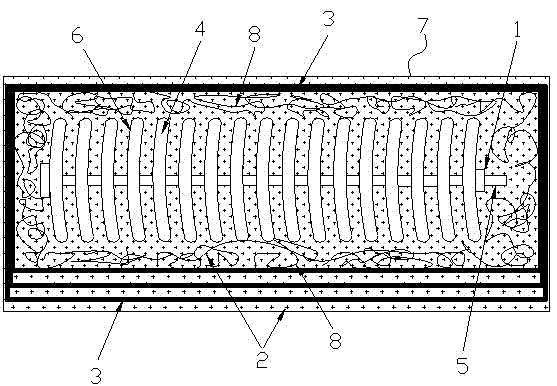

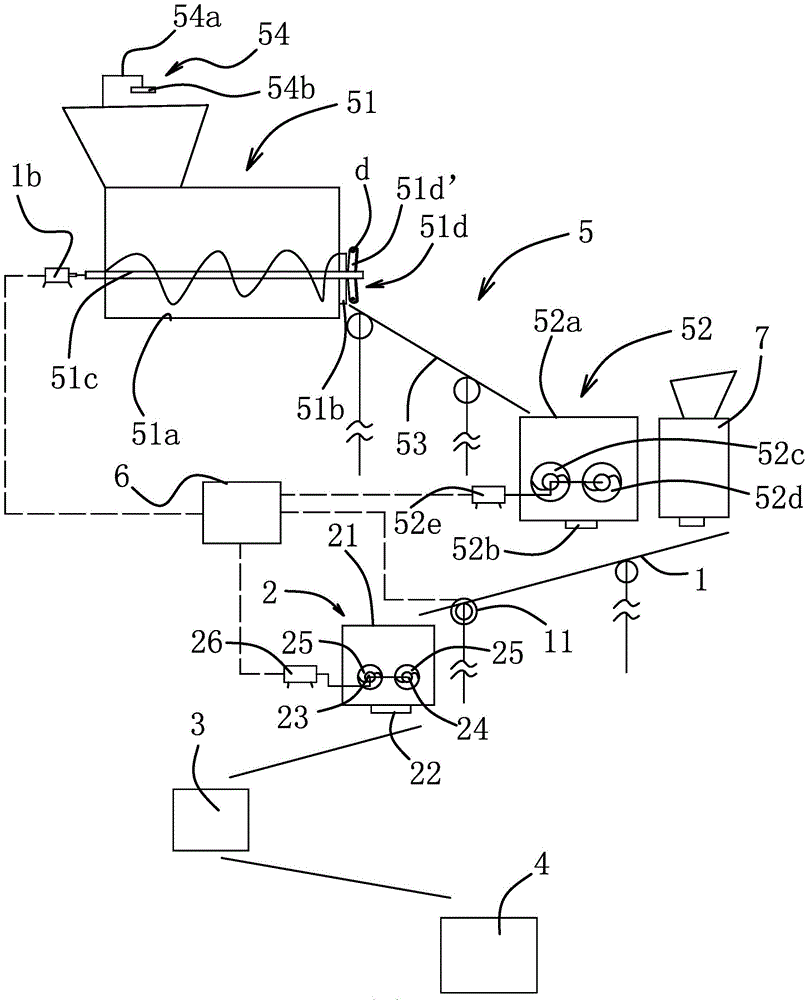

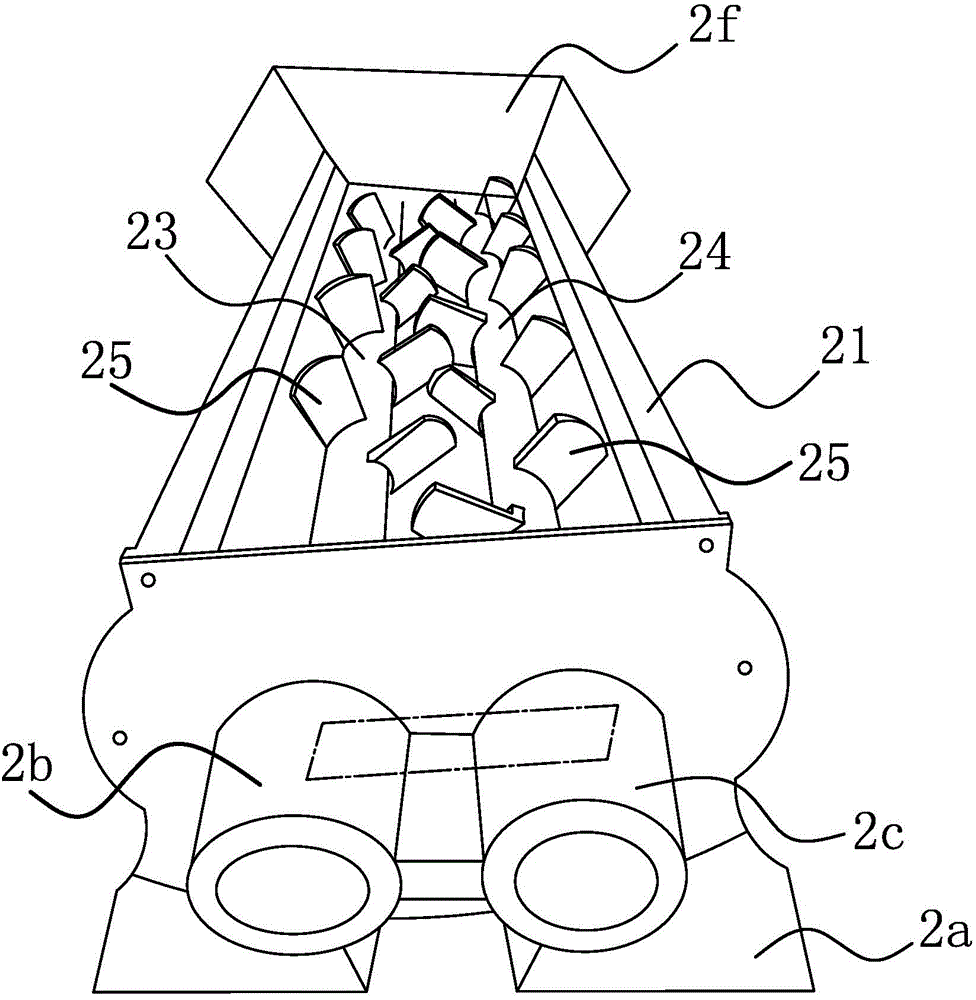

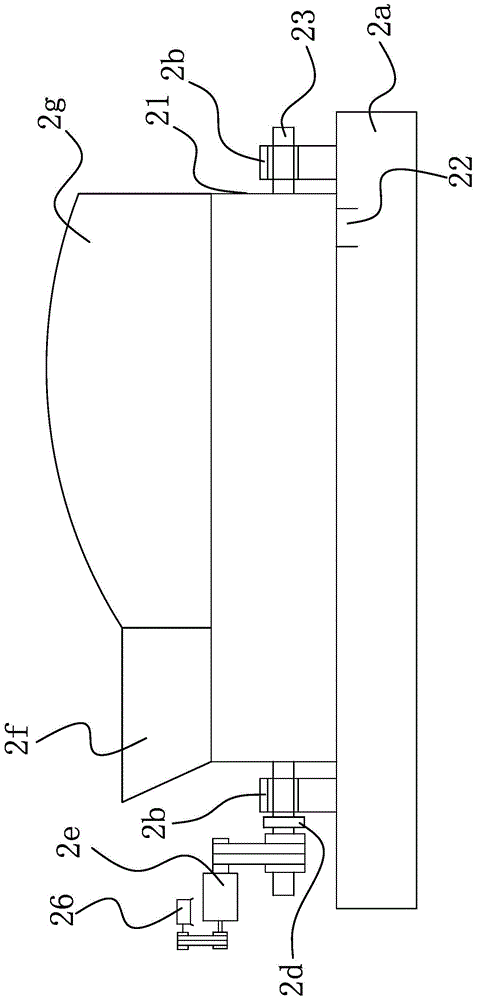

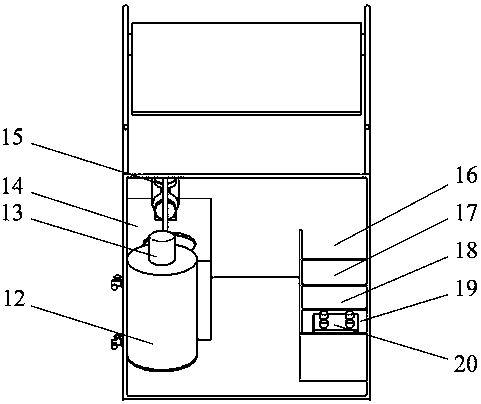

Production system and production process for producing bricks by utilizing paper pulp sludge

InactiveCN103771898AImprove structural strengthReasonable designCeramicwareSludgePulp and paper industry

The invention belongs to the technical field of construction materials, in particular relates to a production system and a production process for producing bricks by utilizing paper pulp sludge, and aims to solve the technical problems of unreasonable design, complicated production process and the like in the prior art. The system sequentially comprises a brick making material conveying device used for conveying a brick making material, an agitation device used for agitating the brick making material, a molding device used for processing the brick making material into an adobe and a brick kiln used for firing the adobe into a brick finished product, as well as a paper pulp sludge adding mechanism used for adding paper pulp sludge into the brick making material, wherein the blanking end of the paper pulp sludge adding mechanism is positioned above the brick making material conveying device. The production process comprises the following steps: A, preparing raw materials; B, fermenting; C, molding an adobe; and D, firing a brick. The production system and the production process have the advantages of more reasonable design, simpler structure and simple process, and is easy to operate and produce.

Owner:黄 建华

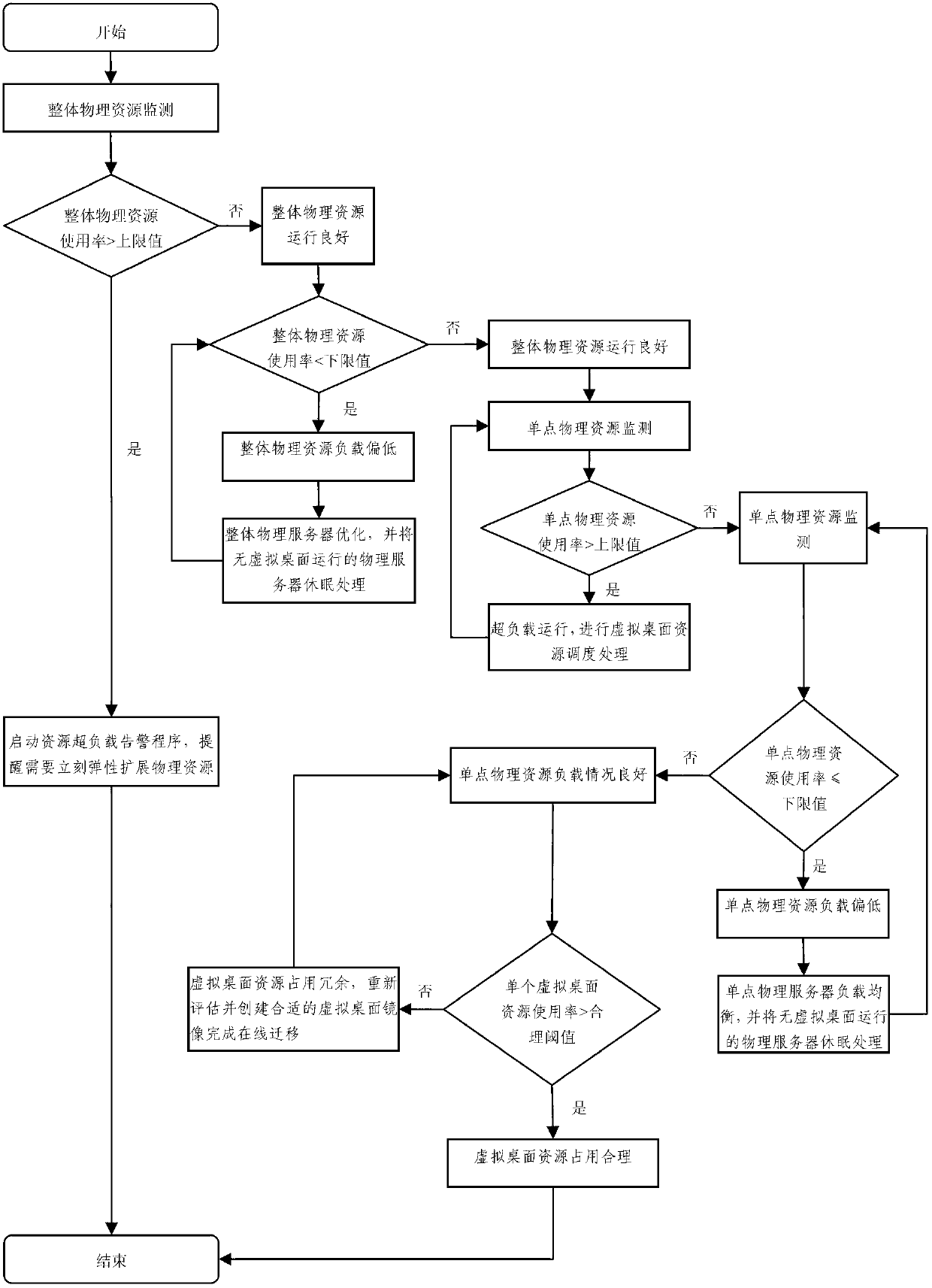

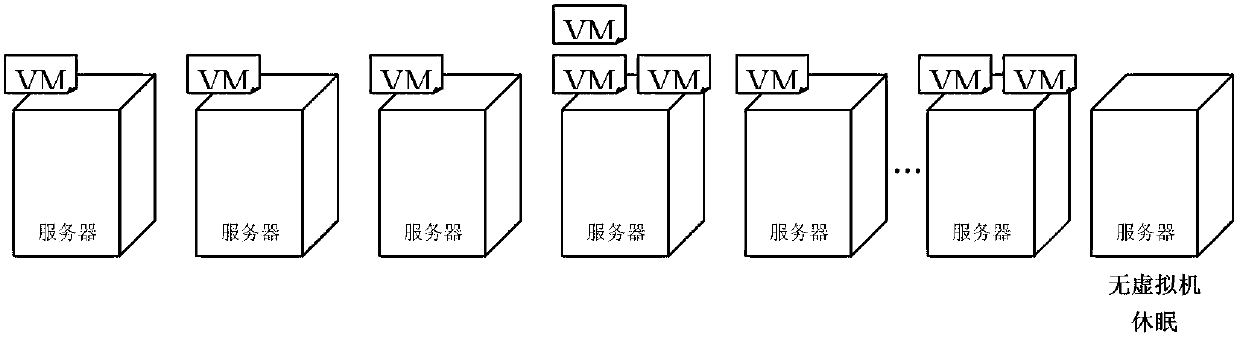

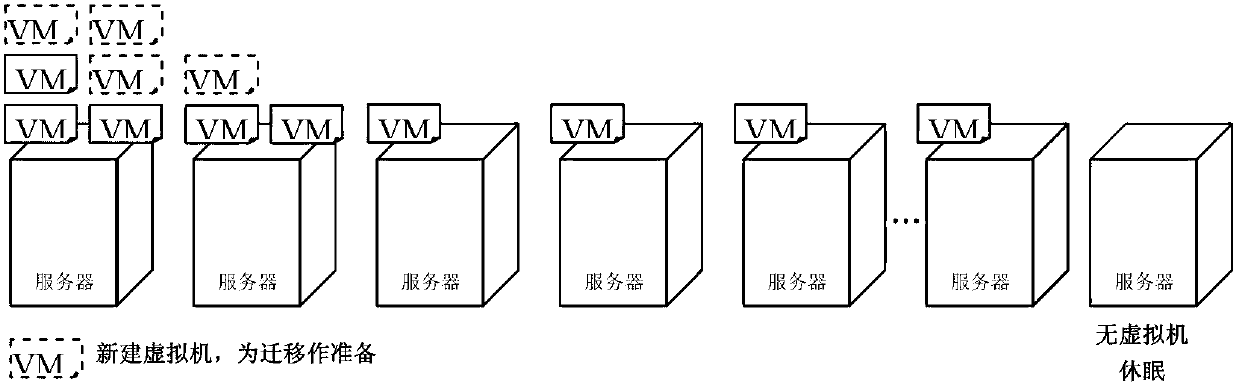

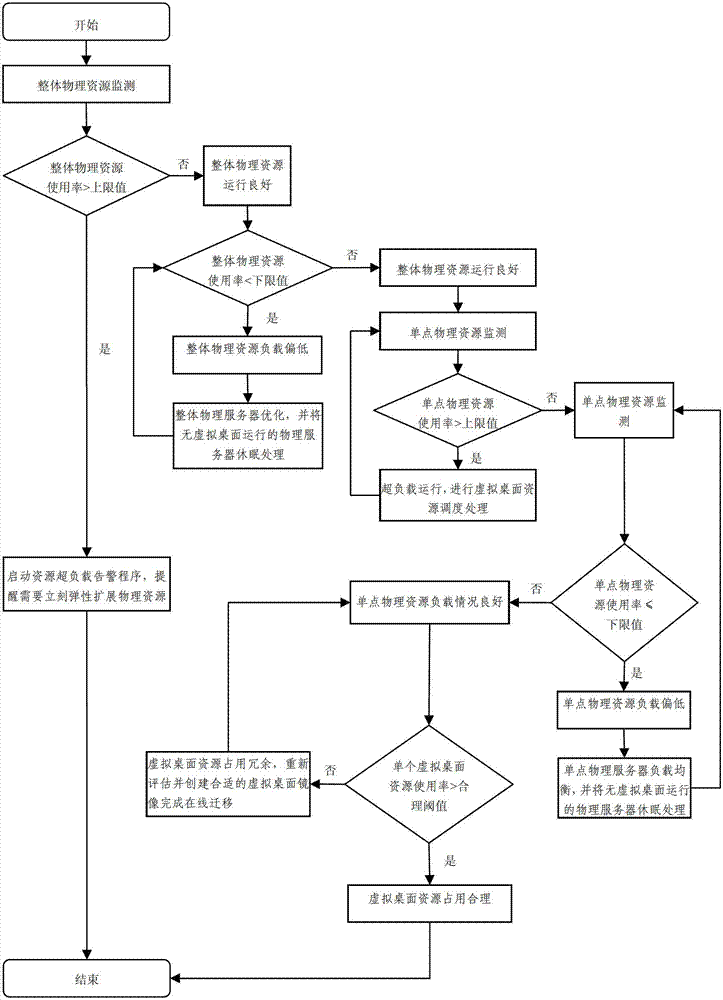

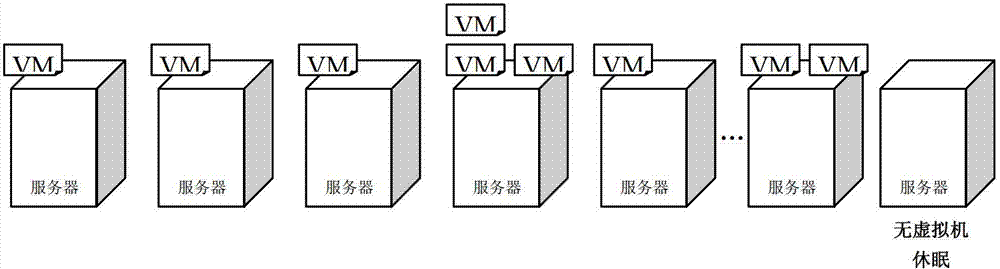

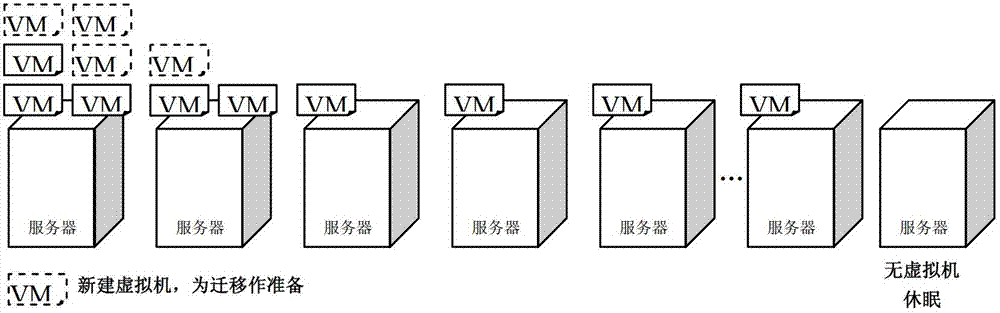

Dynamic dispatching method for virtual desktop resources for multiple power tenants

ActiveCN102999376AGood serviceImplement dynamic schedulingEnergy efficient ICTResource allocationResource utilizationOperating system

The invention provides a dynamic dispatching method for virtual desktop resources for multiple power tenants, comprising the step of starting an overall physical resource monitoring mode, a single-point physical resource monitoring mode and a virtual desktop resource monitoring mode to monitor the running states of virtual desktops until an overall physical server optimally runs, a single-point physical server is balanced in load, and the resource occupancy of a single virtual desktop is reasonable. The dynamic dispatching method for virtual desktop resources for multiple power tenants provided by the invention is completely realized via an independent design. Compared with the prior art, the method gives consideration to dynamic dispatching for both physical resources and virtual desktop resources, and solves the problems of the optimally running of overall physical resources, the load balance of single-point physical resources and the reasonable resource occupancy of the single virtual desktop, thus being capable of effectively increasing the utilization rate of the resources and meeting the national policies of energy conservation and environmental protection.

Owner:CHINA ELECTRIC POWER RES INST +2

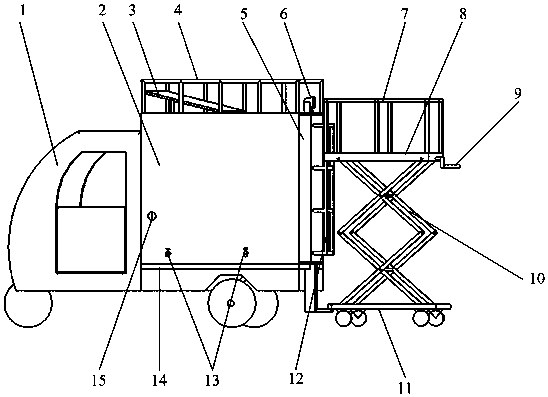

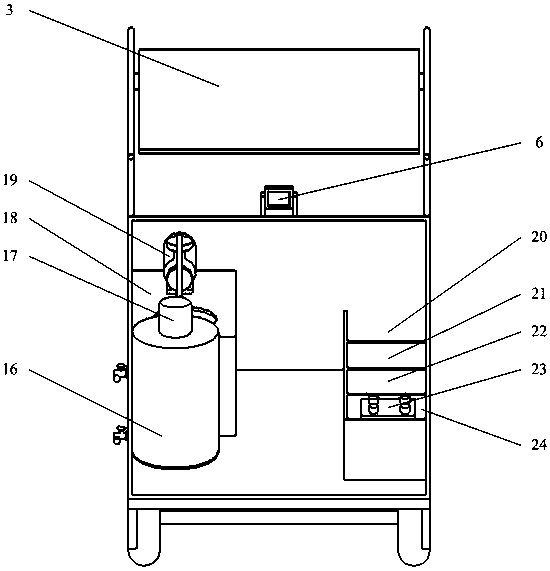

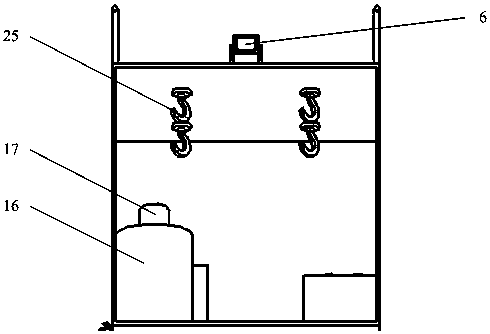

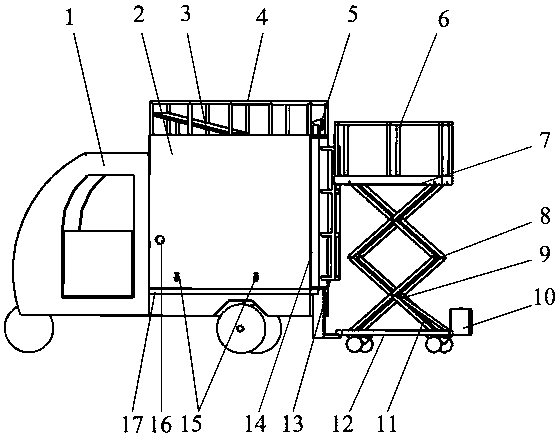

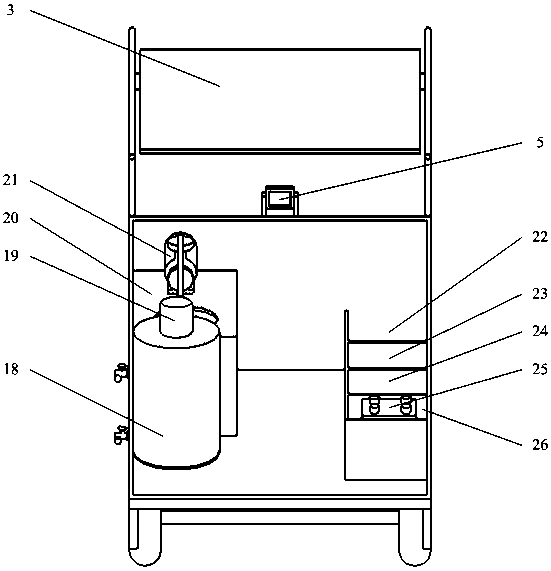

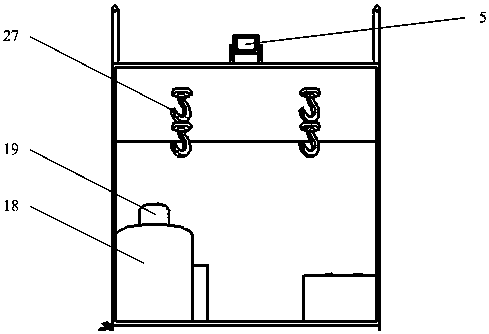

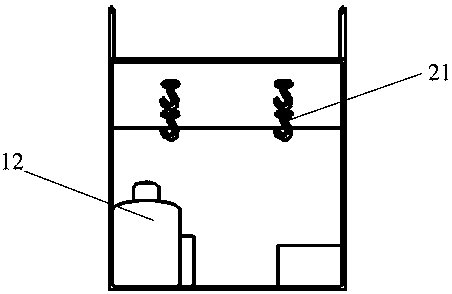

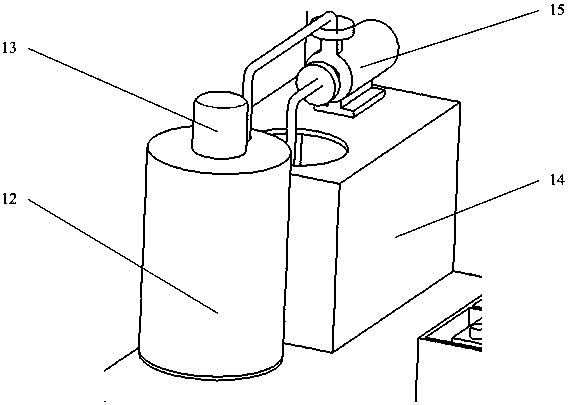

Household light and simple type plant protection unmanned aerial vehicle operation guarantee vehicle with hand lifting platform

InactiveCN109849767ALower requirementSimple structureBatteries circuit arrangementsElectric powerShortest distanceRoad surface

The invention discloses a household light and simple type plant protection unmanned aerial vehicle operation guarantee vehicle with a hand lifting platform. The household light and simple type plant protection unmanned aerial vehicle operation guarantee vehicle with the hand lifting platform is composed of a tricycle chassis device, a carriage device and a hand lifting device. The household lightand simple type plant protection unmanned aerial vehicle operation guarantee vehicle with the hand lifting platform is characterized in that a tricycle is adopted as a chassis and a power device, thevolume is small, the space utilization is reasonable, the manufacturing cost is low, and the household light and simple type plant protection unmanned aerial vehicle operation guarantee vehicle with the hand lifting platform is suitable for families to use. According to the household light and simple type plant protection unmanned aerial vehicle operation guarantee vehicle with the hand lifting platform, a tricycle base body is adopted, so that the requirement on operators is low, the adaptability to road surfaces is high, and the household light and simple type plant protection unmanned aerial vehicle operation guarantee vehicle with the hand lifting platform is suitable for short-distance requirements; a solar panel is arranged at the top of a carriage, so that energy is saved, and the environment is protected, and the household light and simple type plant protection unmanned aerial vehicle operation guarantee vehicle with the hand lifting platform conforms to the energy conservationand environmental protection policy advocated by the state; an operation platform and a protective fence are arranged at the top of the carriage, and the household light and simple type plant protection unmanned aerial vehicle operation guarantee vehicle with the hand lifting platform is suitable for flying plant protection operation of higher shrub crops; a vehicle body has a simple structure, has the functions of transportation, medicine mixing, operation and taking off and landing, and has high reconstruction feasibility; and the household light and simple type plant protection unmanned aerial vehicle operation guarantee vehicle with the hand lifting platform is provided with the lifting operation platform with adjustable height, and the height of the operation platform can be adjustedaccording to the height of crop plants so as to facilitate observation.

Owner:SHANDONG UNIV OF TECH

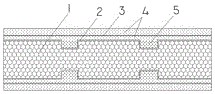

Artificial wood board and manufacture method thereof

InactiveCN102815033ASimple structureImprove structural performanceCeramic shaping apparatusWood layered productsWhole bodySlurry

The invention relates to an artificial wood board and a manufacture method thereof. The artificial wood board comprises a bamboo frame, wherein the bamboo frame is embedded into a slurry layer made of composite materials, and bamboo filaments are filled in the slurry layer. At least one slurry layer is further arranged above and below the slurry layer embedded with the bamboo frame, and fiberglass fabrics and non-woven fabrics are arranged between the slurry layers. The manufacture method includes steps of: pouring the composite materials into a female mold, brushing the surfaces of composite materials flat, and then flatly paving the fiberglass fabrics and the non-woven fabrics; placing the bamboo frame above the fiberglass fabrics and the non-woven fabrics which are arranged in the female mold; pouring the composite materials in the female mold to bury the bamboo frame; folding the fiberglass fabrics and the non-woven fabrics which surpass the female mold onto the upper surface of the innermost slurry layer, continuing to pour the composite materials into the female mold and brushing the upper surfaces f the composite materials flat; and performing air drying for the whole body. The artificial wood board is energy-saving and environment-friendly, can replace woods, is novel in manufacture method and low in manufacture price, and accords with the low carbon and environment protection policy advocated by our country.

Owner:谢娟

Synthesis method of photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propyl ketone

ActiveCN103613492BReduce consumptionQuick responseOrganic compound preparationCarbonyl compound preparation by condensationKetone synthesisPhenyl group

The invention relates to a method for synthesizing photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propyl ketone (1173 aryl ketone), which first uses high-purity gaseous phosgene and isobutyric acid to react to synthesize isobutyric acid Acyl chloride; in the chlorine substitution reaction, the series process is adopted, the tail gas after the first reactor is fed with chlorine is connected in series to the second reactor, and the tail gas hydrogen chloride and chlorine released by the first reaction enter the second reactor for catalytic reabsorption use. This method can improve the purity of isobutyryl chloride well, and further improve the purity and the yield of product 2-hydroxyl-2-methyl-1-phenyl-1-propyl ketone, while utilizing the catalysis of hydrogen chloride in the tail gas, The reaction speed is accelerated, the consumption of chlorine gas is reduced, and the product content is increased. The generated tail gas is recovered through harmless treatment, which solves the pollution of the tail gas to the environment.

Owner:岳阳市国发植物用药工程技术研究中心有限公司

A spinning forming method of non-dyed flame-retardant viscose colored filament

InactiveCN104831386BEnvironmentally friendlyComply with energy saving and environmental protection policyFlame-proof filament manufacturePigment addition to spinning solutionPolymer scienceDyeing wastewater

The invention relates to a spinning forming method of non-dyed flame-retardant viscose colored filaments. The spinning forming method comprises the following steps: providing spinning mixed liquid prepared by mixing a silicon-nitrogen flame retardant, color paste and alpha cellulose glue; providing a spinning acid bath prepared by mixing sulfuric acid, zinc sulfate and sodium sulfate; deforming and filtering the spinning mixed liquid, feeding the spinning mixed liquid into the spinning acid bath by virtue of a metering pump and a spinning nozzle, and carrying out solidification forming and spinning drafting so as to obtain colored continuous filaments; providing a curing treatment liquid containing positive ions Ti<4+> and Ca<2+>; curing the colored continuous filaments; and respectively carrying out water washing, drying and packaging on the cured filaments, so as to obtain the finished colored filaments. According to the spinning forming method, a downstream dyeing procedure is omitted, so that the environmental pollution caused by spinning printing and dyeing wastewater as well as the injury caused by dyed products to human bodies are maximally reduced or avoided.

Owner:SOL FLAME RETARDANT FIBER

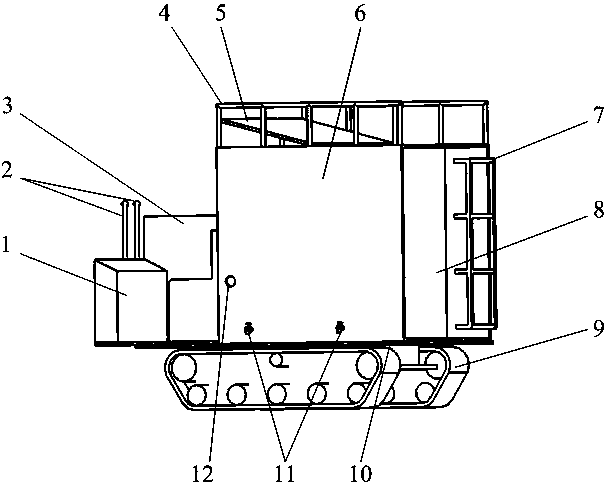

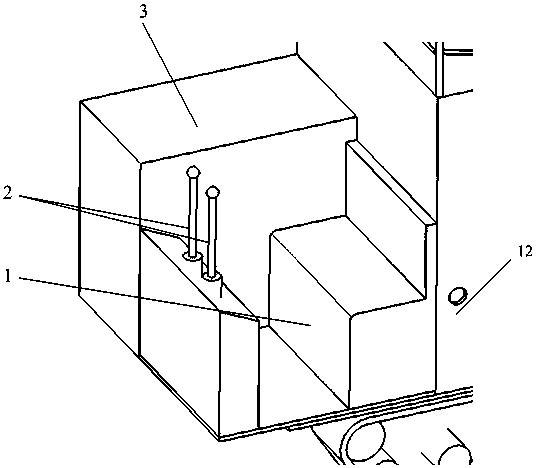

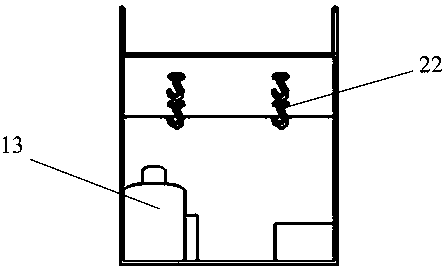

Crawler-type household light and simple plant protection UAV (unmanned aerial vehicle) work support vehicle

InactiveCN109808573ASuitable for useSimple structureBatteries circuit arrangementsElectric powerShortest distanceRoad surface

The invention discloses a crawler-type household light and simple plant protection UAV (unmanned aerial vehicle) work support vehicle. The vehicle comprises a crawler chassis device and a carriage device, and has the characteristics that with the adoption of the crawler chassis device and a power device, the vehicle has strong adhesion with the ground, strong driving force can be provided, adaptability to the pavement is high, and the vehicle meets the short-distance demand; with the adoption of a small car chassis and the power device, the vehicle is small in size, reasonable in space utilization, low in cost and suitable for household use; a solar cell panel is arranged at the top of the carriage, so that the vehicle is energy-saving and environmentally friendly and meets the nationallyadvocated policies of energy conservation and environmental protection; a work platform is arranged at the top of the carriage, a protection fence is arranged, and the vehicle is applicable to flightoperation for high shrub crops; the vehicle is simple in structure, has functions of transportation, pesticide mixing, operation and lifting, and is high in reconstruction feasibility.

Owner:SHANDONG UNIV OF TECH

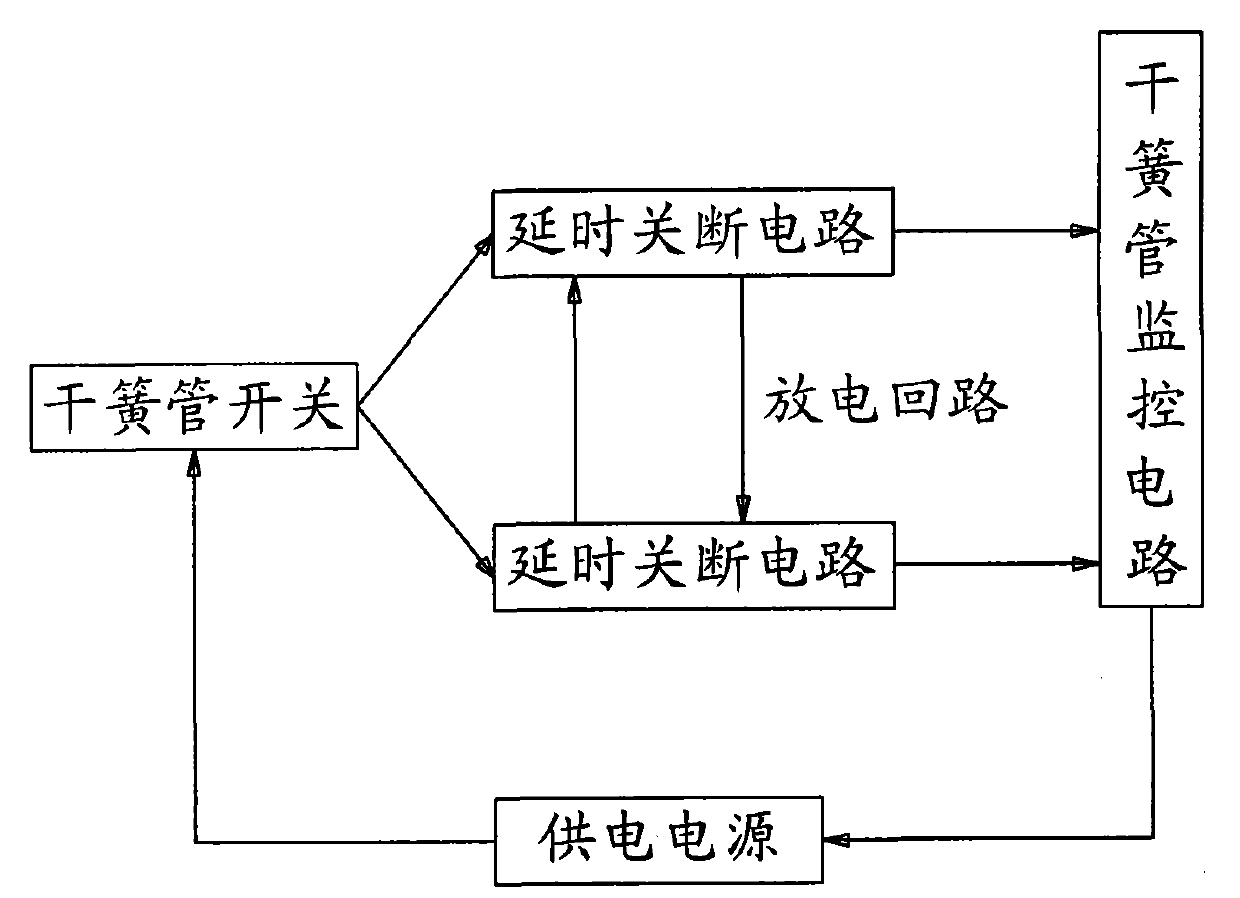

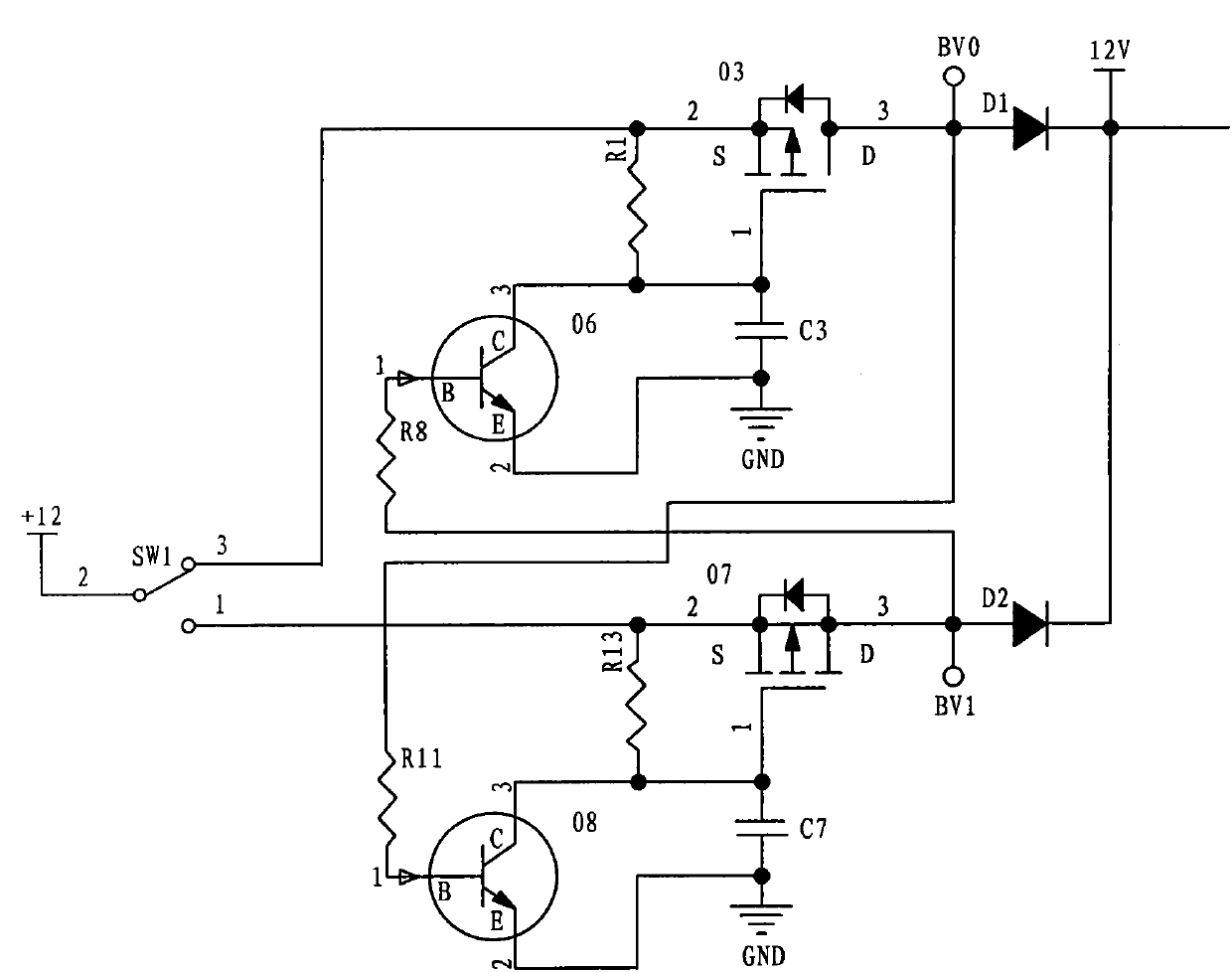

Reed power-on switchover time-delay shutdown circuit

InactiveCN103812479ASave electricityComply with energy saving and environmental protection policyElectronic switchingElectricityTime delays

Owner:SYSTERM GREEN TECH SUZHOU

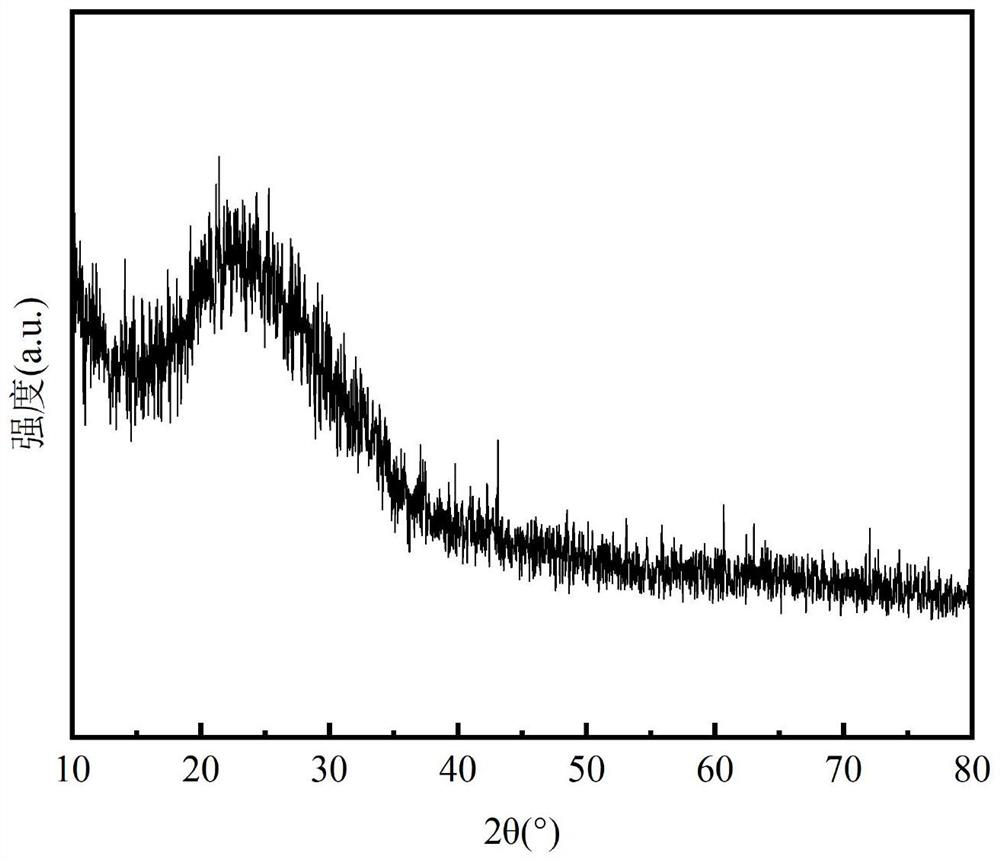

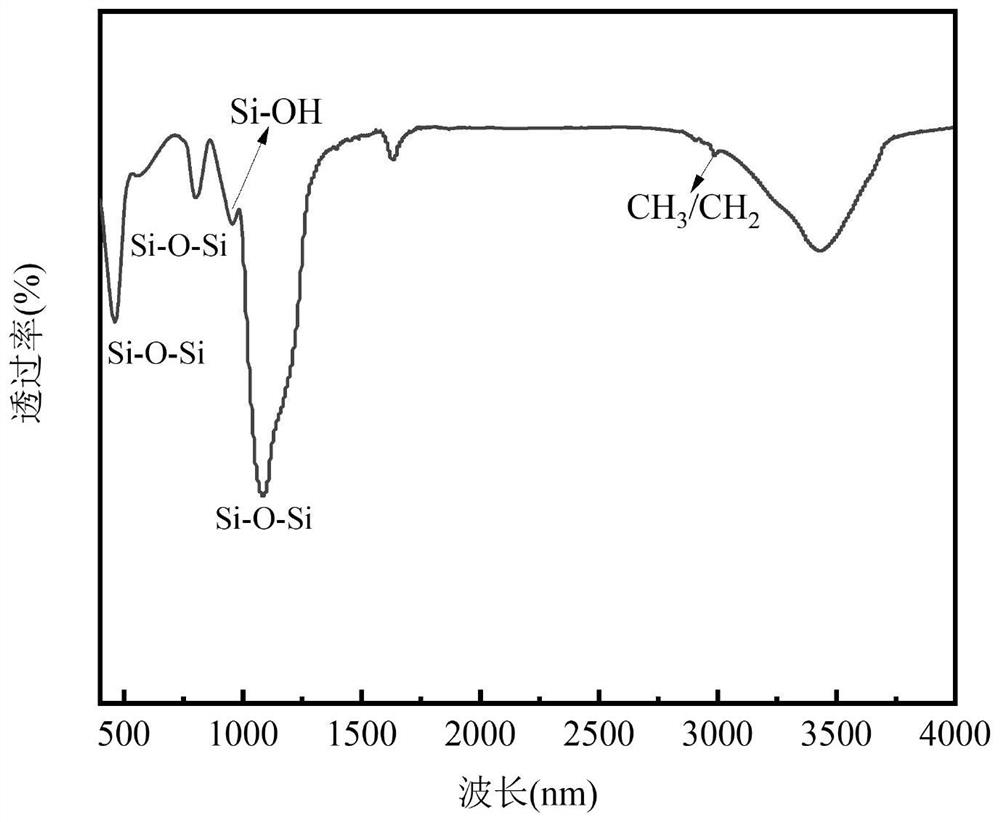

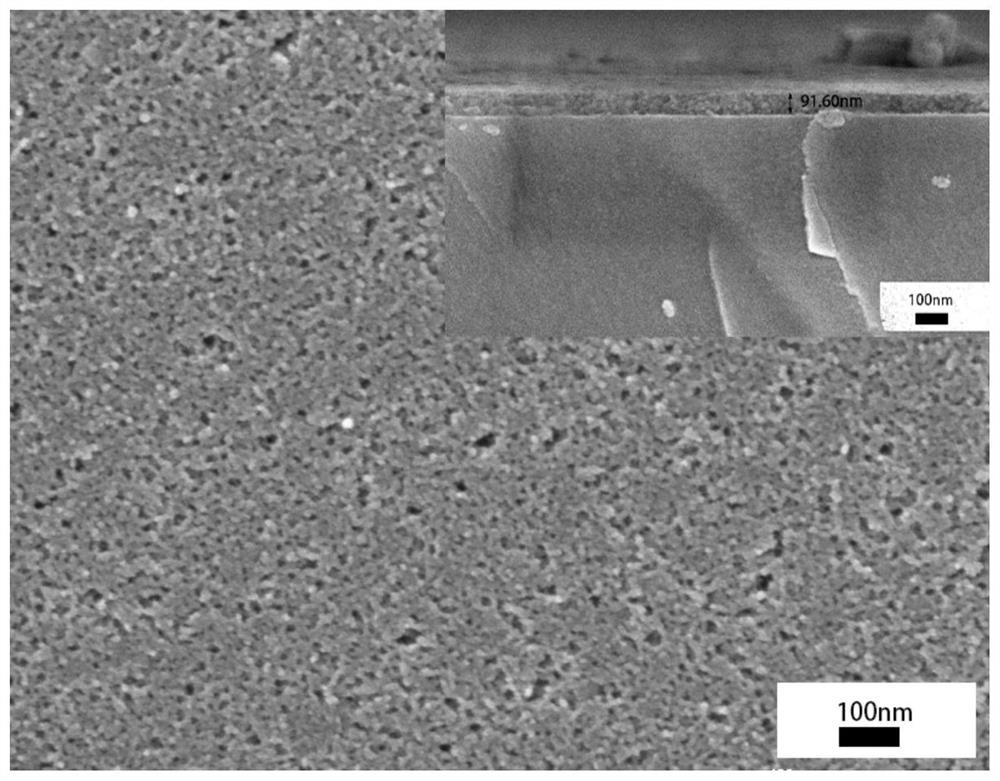

Antireflection film based on carbon dioxide atmosphere heat treatment and preparation method and application thereof

PendingCN114436542AImprove transmittanceGood anti-reflection effectCoatingsThin membraneNear infra red

The invention discloses an antireflection film based on carbon dioxide atmosphere heat treatment and a preparation method and application thereof. The antireflection film is prepared by carrying out heat treatment on a silicon dioxide film in a carbon dioxide-containing atmosphere. According to the method, the visible-near infrared transmittance of the thin film can be remarkably improved only by introducing the atmosphere containing carbon dioxide for heat treatment during thin film annealing, operation is easy, the requirement for preparation conditions is low, cost is low, repeatability is good, the thin film can be formed on a large-area substrate in a coating mode, and industrial application is facilitated.

Owner:WUHAN UNIV OF TECH

A kind of production method of hypoeutectic casting pig iron

ActiveCN104561409BSolve genetic problemsSolve puzzlesBlast furnace detailsAlkalinityChemical composition

The invention discloses a production method for hypoeutectic cast pig iron. The production method is characterized in that the pig iron comprises the following chemical elements by mass fraction: 3.400-4.000% of C, less than or equal to 0.600% of Si, less than or equal to 0.100% of Mn, less than or equal to 0.040% of P, less than or equal to 0.030% of S and less than or equal to 0.040% of Ti. The production method comprises the following working procedures: (1), blast furnace smelting: 65-70 wt% of a high basicity sinter and 30-35 wt% of pellets are taken as raw materials, and the basicity of the high basicity sinter is 1.90-2.00; during smelting, the content of Si is controlled to be less than or equal to 0.50 wt%, and the furnace slag binary basicity R2 is controlled to be from 1.15 to 1.20; (2), electric furnace smelting: an electric furnace is heated to smelt iron by utilizing a blast furnace molten iron and waste steel method; a first inoculation treatment is performed when the iron is discharged, and the addition amount of an inoculant is controlled in a range of 2-3 kg / t molten iron; (3), casting moulding: the inoculant is added along an iron flow during casting to perform second inoculation treatment, and the addition amount of the inoculant is less than or equal to 2 kg / t molten iron. According to the production method for the hypoeutectic cast pig iron, factors, such as utilization factors, yield and hot air temperature, are improved; furthermore, the comprehensive coke ratio is remarkably reduced; the problem of thick graphite heredity in casting industry is solved.

Owner:河北龙凤山铸业有限公司

Method for preparing activated carbon from wheat straw waste residues obtained through xylitol preparation technology

The invention discloses a method for preparing activated carbon from wheat straw waste residues obtained through an xylitol preparation technology. The method includes the following steps that 1, the wheat straw waste residues are screened, a phosphoric acid solution and a set amount of boric acid are added and mixed uniformly, and the wheat straw waste residues are soaked at the temperature of 70 DEG C-90 DEG C; 2, the soaked sample is taken out and put into a muffle furnace, and the temperature is kept at 450 DEG C-550 DEG C for 0.5-2 h; 3, the wheat straw waste residues carbonized in the step 2 are ground and cleaned to be neutral; 4, powdered activated carbon can be obtained by drying and grinding the neutral activated carbon in the step 3; 5, the activated carbon obtained in the step 4 is activated with a HCl solution to obtain the activated carbon. The wheat straw waste residues from which hemicellulose is extracted are prepared into the powdered activated carbon through a simple chemical physics method, the powdered activated carbon is used for decoloration and detoxification in the process of extracting hemicellulose from a wheat straw raw material to prepare xylooligosaccharide, and high-value utilization of the wheat straw raw material is achieved.

Owner:QILU UNIV OF TECH

Production system and production process for producing bricks from pulp sludge

InactiveCN103771898BImprove structural strengthReasonable designCeramicwareSludgePulp and paper industry

Owner:黄 建华

Plastic construction formwork and steel structure construction system technology

InactiveCN104179350ASimple processQuality improvementBuilding material handlingForming/stuttering elementsArchitectural engineeringSteel frame

The invention discloses a plastic construction formwork and steel structure construction system technology. The technology includes manufacturing and producing a plastic formwork according to general specification at first; then producing a steel frame, supports and connector with general specifications through high-performance galvanized steel; then completing the combination of the plastic formwork and the steel frame, according to design drawings of different projects, matching a die through a four-dimensional formwork design system, and producing a small amount of non-conventional plastic formwork steel frames according to the requirements; finally completing assembly and construction on construction site. By the aid of the technology, the unique effects of production factorization, construction assemblage, component instrumentalization, process simplification, quality refinement and construction efficiency are achieved, the national policy of energy saving and environmental protection are met, and the development of green construction project is promoted; meanwhile, construction cost and engineering construction cost are reduced greatly, benefit is increased, pollution is reduced, and resource is saved.

Owner:JIANGSU CHANGSHENG ENVIRONMENTAL PROTECTION TECH

Dynamic dispatching method for virtual desktop resources for multiple power tenants

ActiveCN102999376BSolve load balancingSolve the problem of reasonable occupancyEnergy efficient ICTResource allocationResource utilizationOperating system

The invention provides a dynamic dispatching method for virtual desktop resources for multiple power tenants, comprising the step of starting an overall physical resource monitoring mode, a single-point physical resource monitoring mode and a virtual desktop resource monitoring mode to monitor the running states of virtual desktops until an overall physical server optimally runs, a single-point physical server is balanced in load, and the resource occupancy of a single virtual desktop is reasonable. The dynamic dispatching method for virtual desktop resources for multiple power tenants provided by the invention is completely realized via an independent design. Compared with the prior art, the method gives consideration to dynamic dispatching for both physical resources and virtual desktop resources, and solves the problems of the optimally running of overall physical resources, the load balance of single-point physical resources and the reasonable resource occupancy of the single virtual desktop, thus being capable of effectively increasing the utilization rate of the resources and meeting the national policies of energy conservation and environmental protection.

Owner:CHINA ELECTRIC POWER RES INST +2

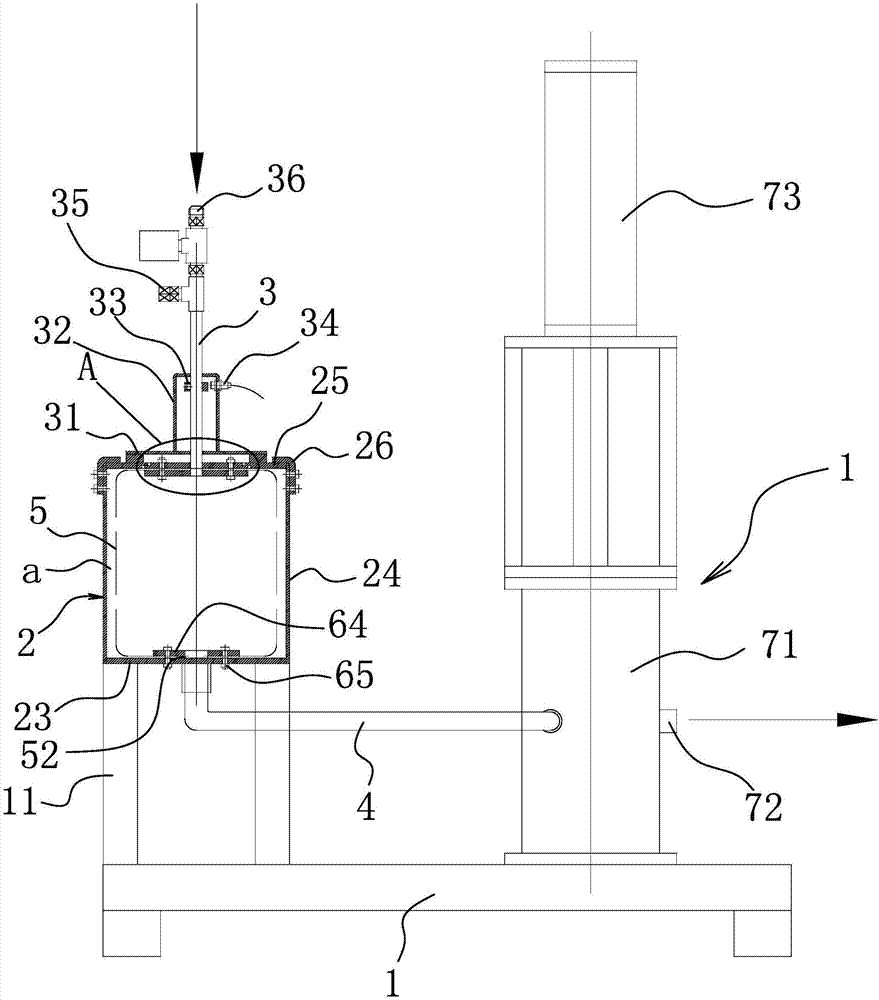

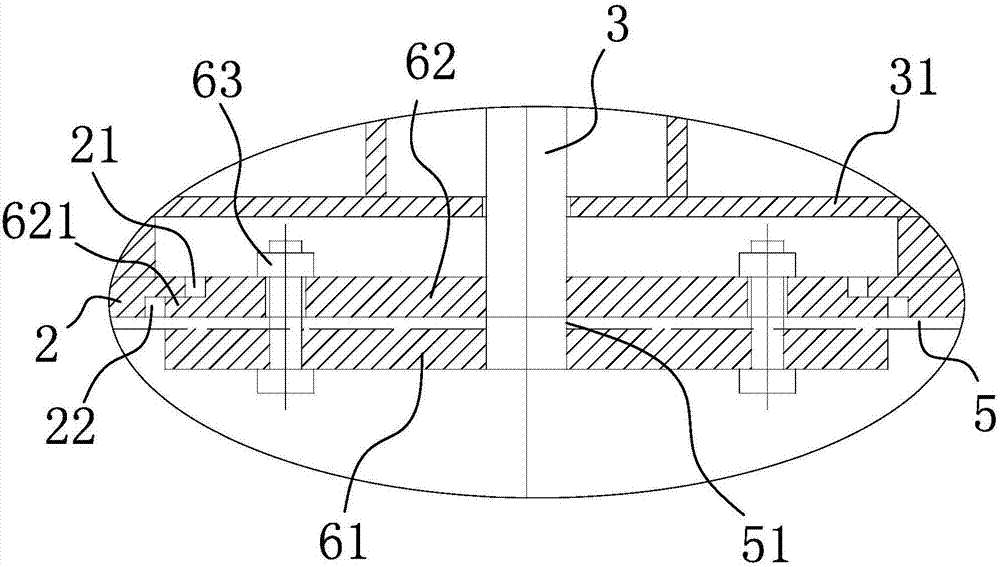

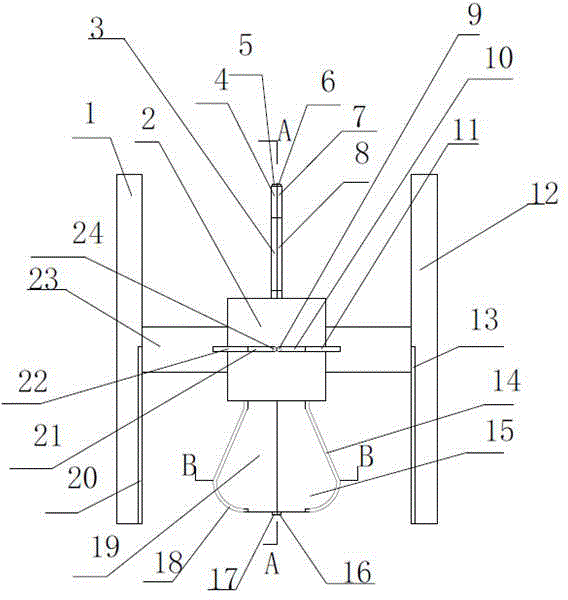

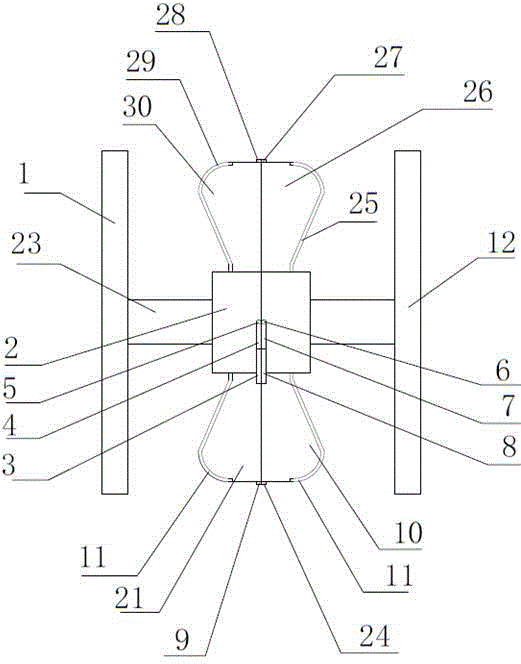

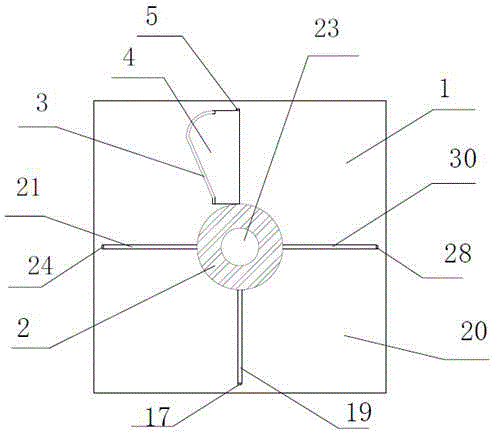

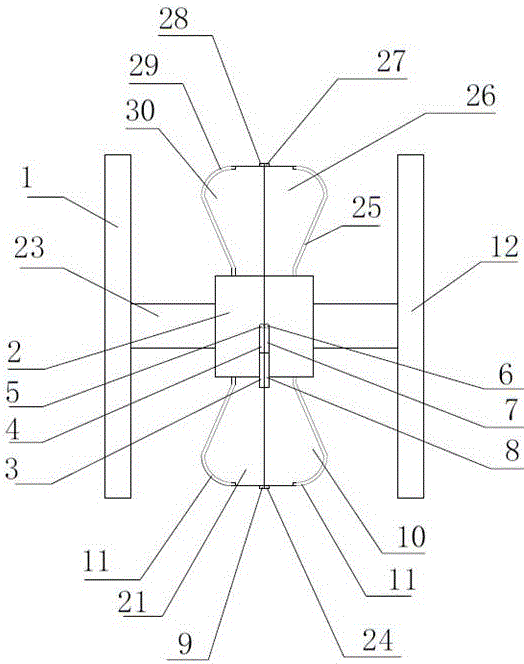

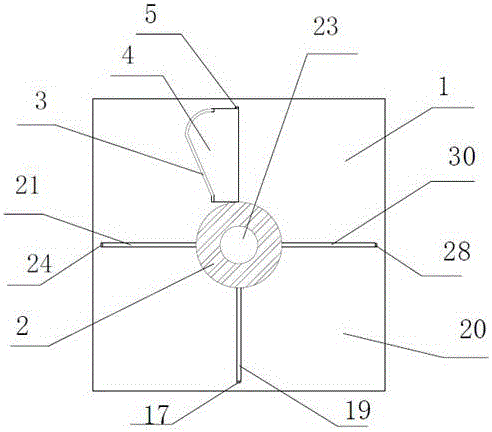

Ferrite injection barrel and equipment thereof

The invention belongs to the technical field of machinery, and particularly relates to a ferrite injection barrel and equipment thereof. The ferrite injection barrel and the equipment thereof solve the problems of unreasonable design in the prior art and the like. The ferrite injection barrel comprises a base, a metal shell provided with a cavity is arranged on the base, a feeding pipe is connected to the top of the metal shell, a discharging pipe is connected to the bottom of the metal shell, a rubber liner fixed to the metal shell is arranged in the cavity, a feeding port communicating with the feeding pipe is formed in the rubber liner, and a discharging port communicating with the discharging pipe is further formed in the rubber liner. The ferrite injection barrel and the equipment thereof have the advantages that more energy is saved and the cost is lower.

Owner:嘉兴天成强磁科技股份有限公司

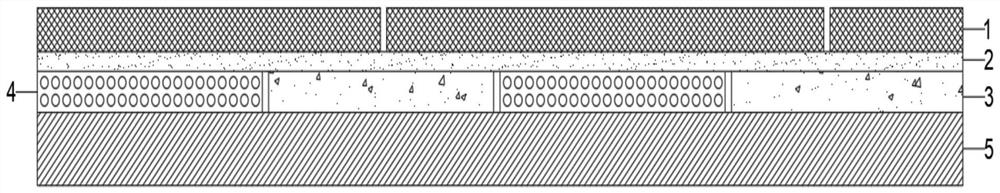

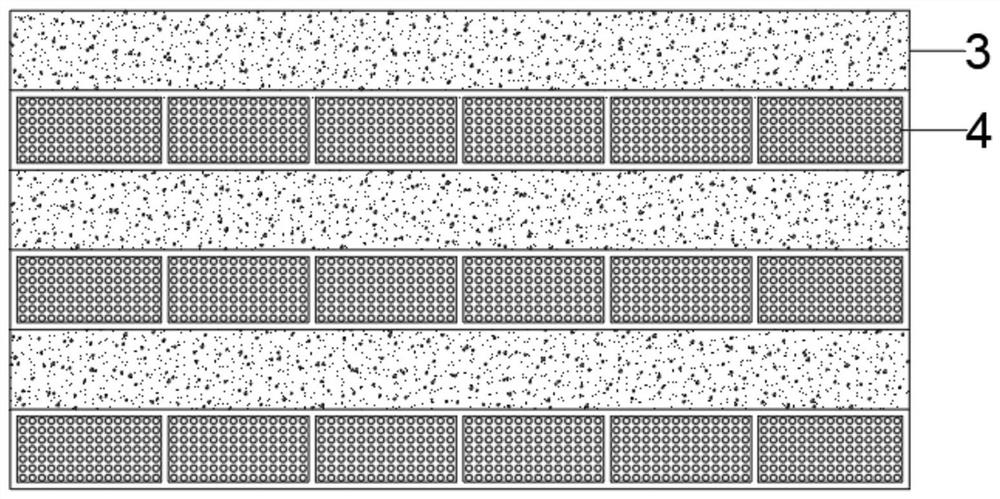

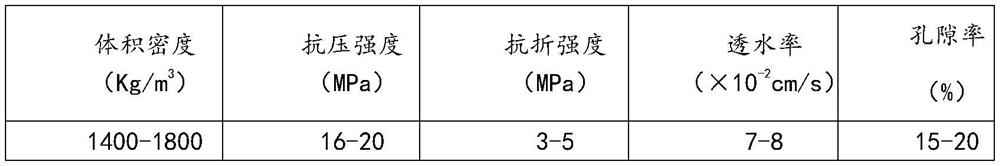

System and method for ceramic-based high permeable brick and high permeable pavement

ActiveCN110510996BHigh permeability coefficientChina Unicom increasedSingle unit pavingsPaving gutters/kerbsBrickRed mud

Owner:中电建路桥集团有限公司

Artificial wood board and manufacture method thereof

InactiveCN102815033BSimple structureImprove structural performanceCeramic shaping apparatusWood layered productsWhole bodySlurry

The invention relates to an artificial wood board and a manufacture method thereof. The artificial wood board comprises a bamboo frame, wherein the bamboo frame is embedded into a slurry layer made of composite materials, and bamboo filaments are filled in the slurry layer. At least one slurry layer is further arranged above and below the slurry layer embedded with the bamboo frame, and fiberglass fabrics and non-woven fabrics are arranged between the slurry layers. The manufacture method includes steps of: pouring the composite materials into a female mold, brushing the surfaces of composite materials flat, and then flatly paving the fiberglass fabrics and the non-woven fabrics; placing the bamboo frame above the fiberglass fabrics and the non-woven fabrics which are arranged in the female mold; pouring the composite materials in the female mold to bury the bamboo frame; folding the fiberglass fabrics and the non-woven fabrics which surpass the female mold onto the upper surface of the innermost slurry layer, continuing to pour the composite materials into the female mold and brushing the upper surfaces f the composite materials flat; and performing air drying for the whole body. The artificial wood board is energy-saving and environment-friendly, can replace woods, is novel in manufacture method and low in manufacture price, and accords with the low carbon and environment protection policy advocated by our country.

Owner:谢娟

Method for preparing activated carbon from wheat straw waste residue after xylitol preparation process

ActiveCN105502388BLoose structurePlay a catalytic roleCarbon compoundsActivated carbonPhosphoric acid

The invention discloses a method for preparing activated carbon from wheat straw waste residues obtained through an xylitol preparation technology. The method includes the following steps that 1, the wheat straw waste residues are screened, a phosphoric acid solution and a set amount of boric acid are added and mixed uniformly, and the wheat straw waste residues are soaked at the temperature of 70 DEG C-90 DEG C; 2, the soaked sample is taken out and put into a muffle furnace, and the temperature is kept at 450 DEG C-550 DEG C for 0.5-2 h; 3, the wheat straw waste residues carbonized in the step 2 are ground and cleaned to be neutral; 4, powdered activated carbon can be obtained by drying and grinding the neutral activated carbon in the step 3; 5, the activated carbon obtained in the step 4 is activated with a HCl solution to obtain the activated carbon. The wheat straw waste residues from which hemicellulose is extracted are prepared into the powdered activated carbon through a simple chemical physics method, the powdered activated carbon is used for decoloration and detoxification in the process of extracting hemicellulose from a wheat straw raw material to prepare xylooligosaccharide, and high-value utilization of the wheat straw raw material is achieved.

Owner:QILU UNIV OF TECH

Electromagnetic bionic web capable of being used for underwater propulsion system of hydrographic survey equipment

InactiveCN104943840AReduce resistanceImprove efficiencyPropulsive elements of non-rotary typeElectricityUnderwater explosion

The invention relates to an electromagnetic bionic web capable of being used for an underwater propulsion system of hydrographic survey equipment, in particular to a bionic web which has a small area in the forward direction when resistance is caused, so that the resistance is small, meanwhile an area which makes a dynamic effect in the forward direction is large, so that the power is large, and therefore higher propulsive efficiency and good mute effect can be generated. In addition, the electromagnetic bionic web takes electricity as the energy, so that the electromagnetic bionic web has the advantages of being green, free of pollution, energy saving and good in environmental protection effect. The structure is simple, manufacturing is easy, the use is wide, and the electromagnetic bionic web is suitable for the fields of small-size ship modules, large-size ships, large-size submarines and the like. Meanwhile by means of the inversion of a wheel hub motor, inverse propulsion of the propulsion system can be achieved.

Owner:HENAN UNIVERSITY

Household light and simple plant protection unmanned aerial vehicle operation safeguard vehicle for tracking hydraulic lifting platform

InactiveCN109808575AReduce volumeReasonable use of spaceBatteries circuit arrangementsElectric powerEnvironmentally friendlyEngineering

The invention discloses a household light and simple plant protection unmanned aerial vehicle operation safeguard vehicle for tracking a hydraulic lifting platform. The vehicle comprises a three-wheeled vehicle chassis device, a carriage device and a hydraulic lifting device. The vehicle is characterized in that a three-wheeled vehicle is adopted as a chassis and a power device, is small in volume, reasonable in space utilization, low in manufacturing cost and applicable to use in families; as the three-wheeled vehicle is used as a base, the vehicle is relatively low in requirement on an operator, good in road adaptability and applicable to short distance operation; a solar battery panel is arranged at the top of the carriage, so that the vehicle is energy-saving and environmentally-friendly, and meets the energy-saving and environment protection policies initiated by China; an operation platform and a protection rail are arranged at the top of the carriage, so that the vehicle is applicable to flying plant protection operation of relatively high bush crops; due to adoption of the lifting operation platform with adjustable heights, the height of the operation platform can be adjusted according to heights of crop plants, convenience in observation is achieved, and high selectivity is achieved; the vehicle is simple in structure and has the functions of transportation, pesticidemixing, operation and lifting.

Owner:SHANDONG UNIV OF TECH

Walking crawler type household light and simple plant protection unmanned aerial vehicle operation support vehicle

InactiveCN109808574ASimple structureLower requirementBatteries circuit arrangementsElectric powerShortest distanceHand held

The invention discloses a walking crawler type household light and simple plant protection unmanned aerial vehicle operation support vehicle, which comprises a crawler chassis device and a carriage device. A tricycle is adopted as a chassis and a power device in the invention, so that the walking crawler type household light and simple plant protection unmanned aerial vehicle operation support vehicle is small in size, reasonable in space utilization, cheap in manufacturing cost and suitable for domestic use, and is relatively low in requirement of operators, strong in adaptability to road surfaces and suitable for short-distance needs due to adoption of a hand-held operation mode; a crawler belt device is used as the chassis and the power device in the invention, so that the adhesion to the ground is strong, and the provided driving force is large; a solar panel is arranged at the top of a carriage, thereby saving energy and protecting the environment, and conforming to the energy conservation and environmental protection policy advocated by the state; an operation platform and a protection fence are arranged at the top of the carriage in the invention, so that the walking crawlertype household light and simple plant protection unmanned aerial vehicle operation support vehicle is suitable for flying plant protection operations of relatively high shrub crops; the walking crawler type household light and simple plant protection unmanned aerial vehicle operation support vehicle provided by the invention has a simple vehicle body structure, simultaneously has functions of transportation, pesticide mixing, operating, taking off and landing, and has strong reformation feasibility.

Owner:SHANDONG UNIV OF TECH

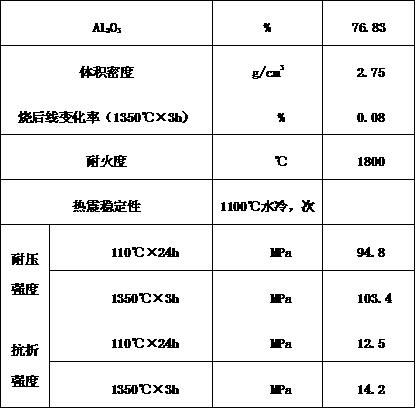

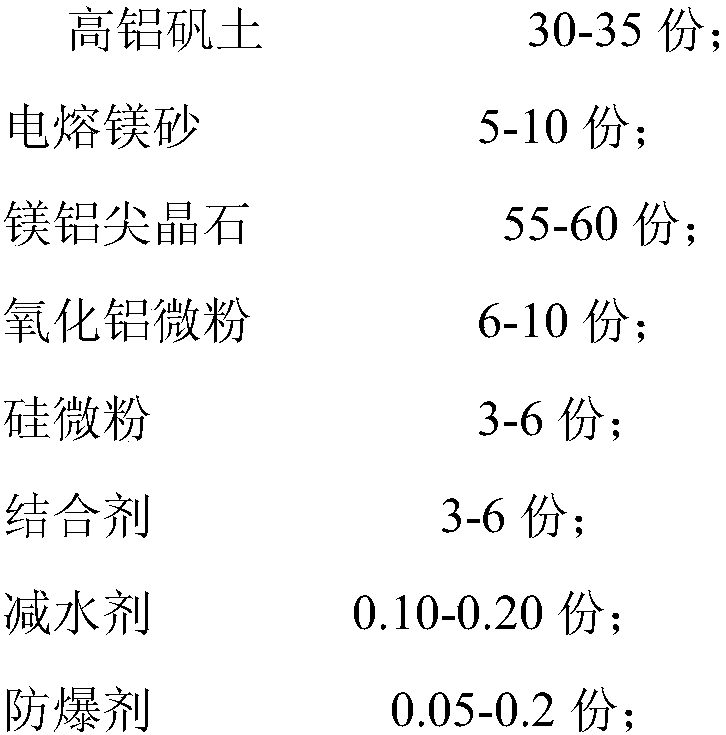

Production process of monolithic refractories and lining bricks for zinc oxide rotary kiln

The invention discloses an unshaped refractory material for a zinc oxide rotary kiln and a production technology for lining bricks, and belongs to the technical field of refractory material production. The lining bricks with the good energy saving effect are prepared by taking magnesium aluminate spinel, high-quality high-aluminum bauxite and fused magnesite as main raw materials and adding a certain quantity of a binding agent, a water reducing agent and an antiknock agent. Compared with a traditional fired product, the unshaped refractory material has the advantages that the procedures are simple, the production processes such as green brick pressing and high-temperature firing are omitted, a large quantity of energy consumption can be reduced in the production and manufacture process, and a large quantity of manpower and material resources can be saved in the production and manufacture process. In the construction process, anchoring parts can be welded to a kiln body, the integrality of the refractory material is enhanced, and the conditions of lotting and brick falling of a shaped product are prevented from occurring; for the portion, difficult to construct, of the shaped product, bed supporting pouring construction can be performed through the unshaped refractory material.

Owner:SHANDONG LUMING HIGH TEMPERATURE MATERIAL TECH

Electromagnetic bionic fins for underwater propulsion systems of hydrographic survey equipment

InactiveCN104943840BReduce resistanceImprove efficiencyPropulsive elements of non-rotary typeEnvironmental resistanceElectricity

The invention relates to an electromagnetic bionic web capable of being used for an underwater propulsion system of hydrographic survey equipment, in particular to a bionic web which has a small area in the forward direction when resistance is caused, so that the resistance is small, meanwhile an area which makes a dynamic effect in the forward direction is large, so that the power is large, and therefore higher propulsive efficiency and good mute effect can be generated. In addition, the electromagnetic bionic web takes electricity as the energy, so that the electromagnetic bionic web has the advantages of being green, free of pollution, energy saving and good in environmental protection effect. The structure is simple, manufacturing is easy, the use is wide, and the electromagnetic bionic web is suitable for the fields of small-size ship modules, large-size ships, large-size submarines and the like. Meanwhile by means of the inversion of a wheel hub motor, inverse propulsion of the propulsion system can be achieved.

Owner:HENAN UNIVERSITY

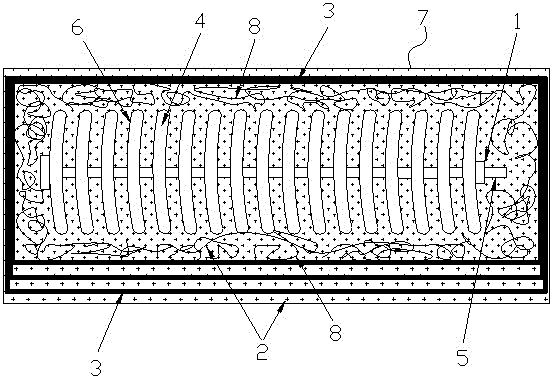

A permanently modified desulfurized gypsum composite thermal insulation formwork and its manufacturing method

InactiveCN104652696BImprove insulation effectReduce usageSynthetic resin layered productsLaminationBuilding energySlurry

The invention discloses a permanent modified desulphurization gypsum compound heat-insulating template which is prepared by the following steps: smearing an adhesion agent outside a polyurethane plate; then smearing modified desulphurization gypsum slurry outside; and filling a reinforcing material in the modified desulphurization gypsum slurry, wherein the modified desulphurization gypsum slurry is prepared by mixing desulphurization gypsum, a mineral activator, a light heat-insulating aggregate and various additives which are uniformly stirred with water. The template disclosed by the invention has the advantages that production process and flow are simple, the cost is low, the efficiency is high, the yield is large, manpower, material and financial materials are saved, a lot of waste solids are used, and thus the template is energy-saving and environmental-friendly. The integral product is small in heat conductivity coefficient and meets a relatively high building energy-saving standard.

Owner:UNIV OF JINAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com