Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Color unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

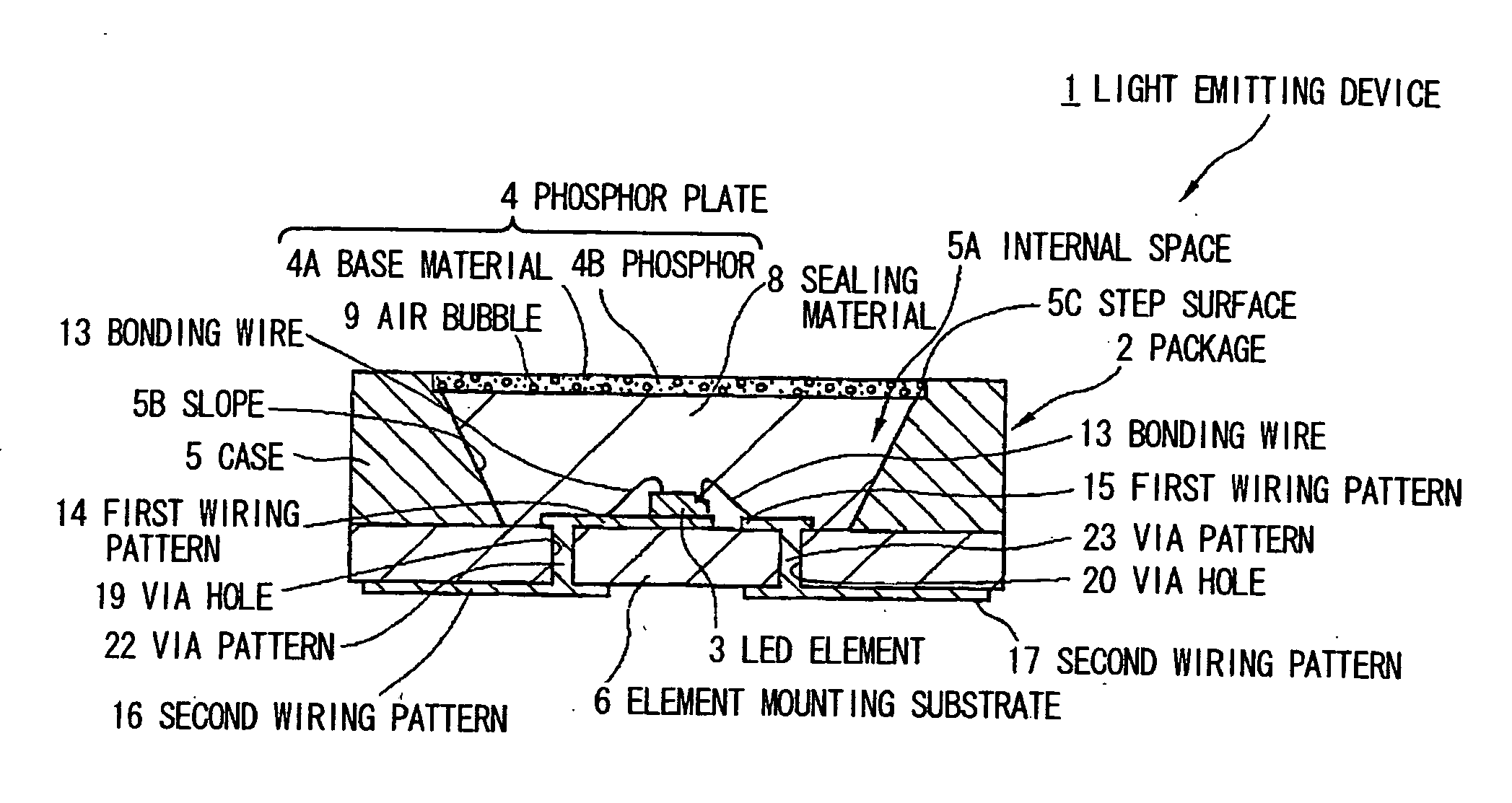

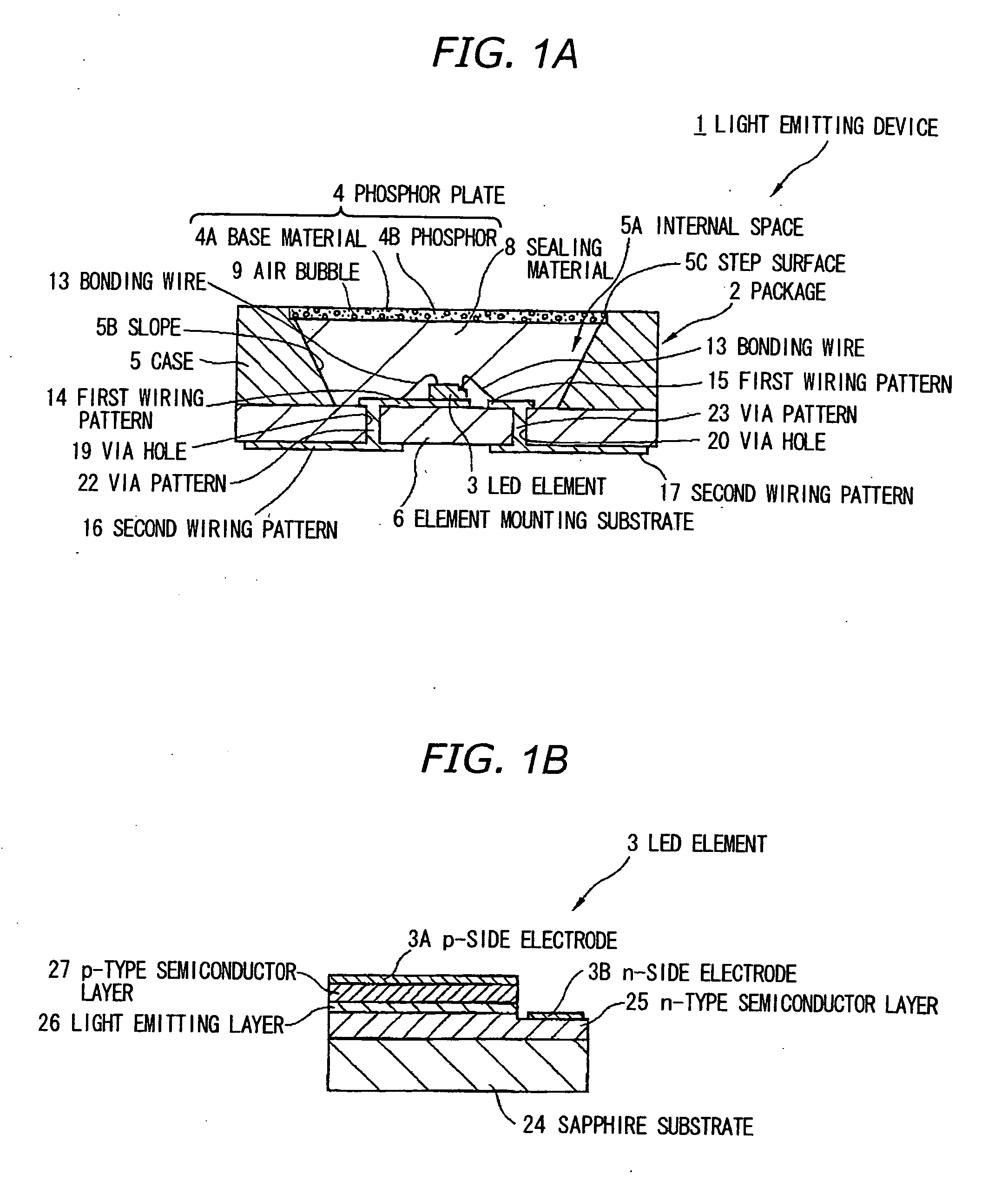

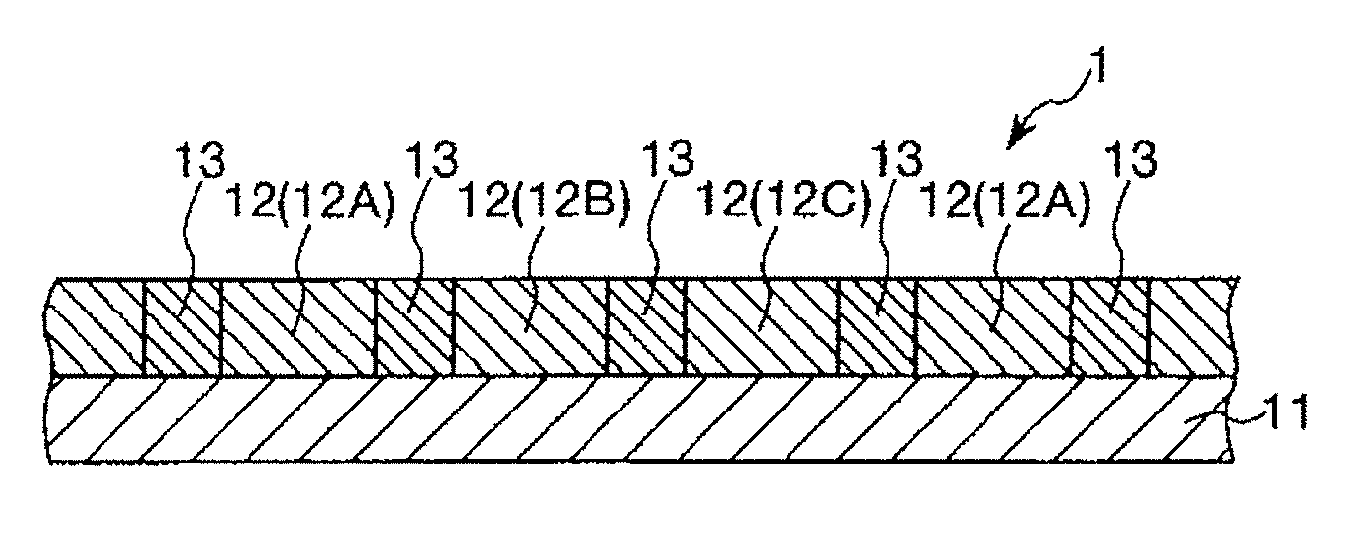

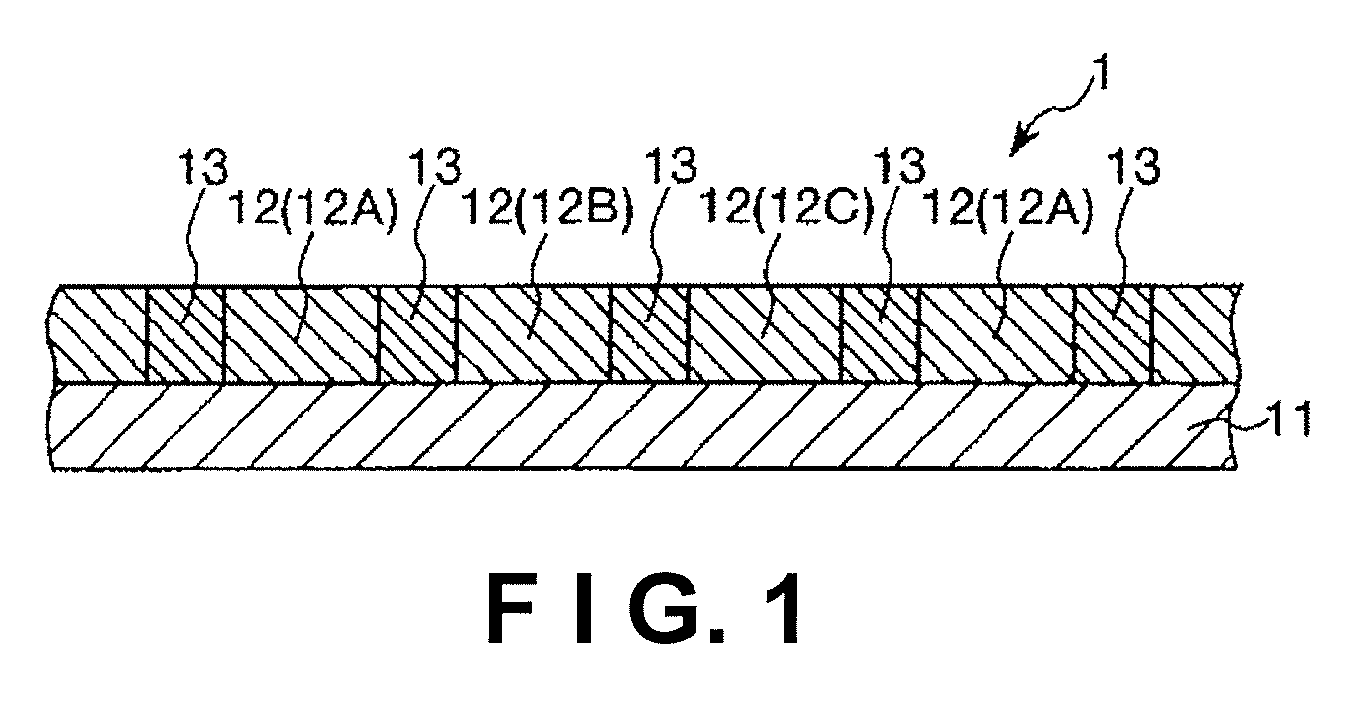

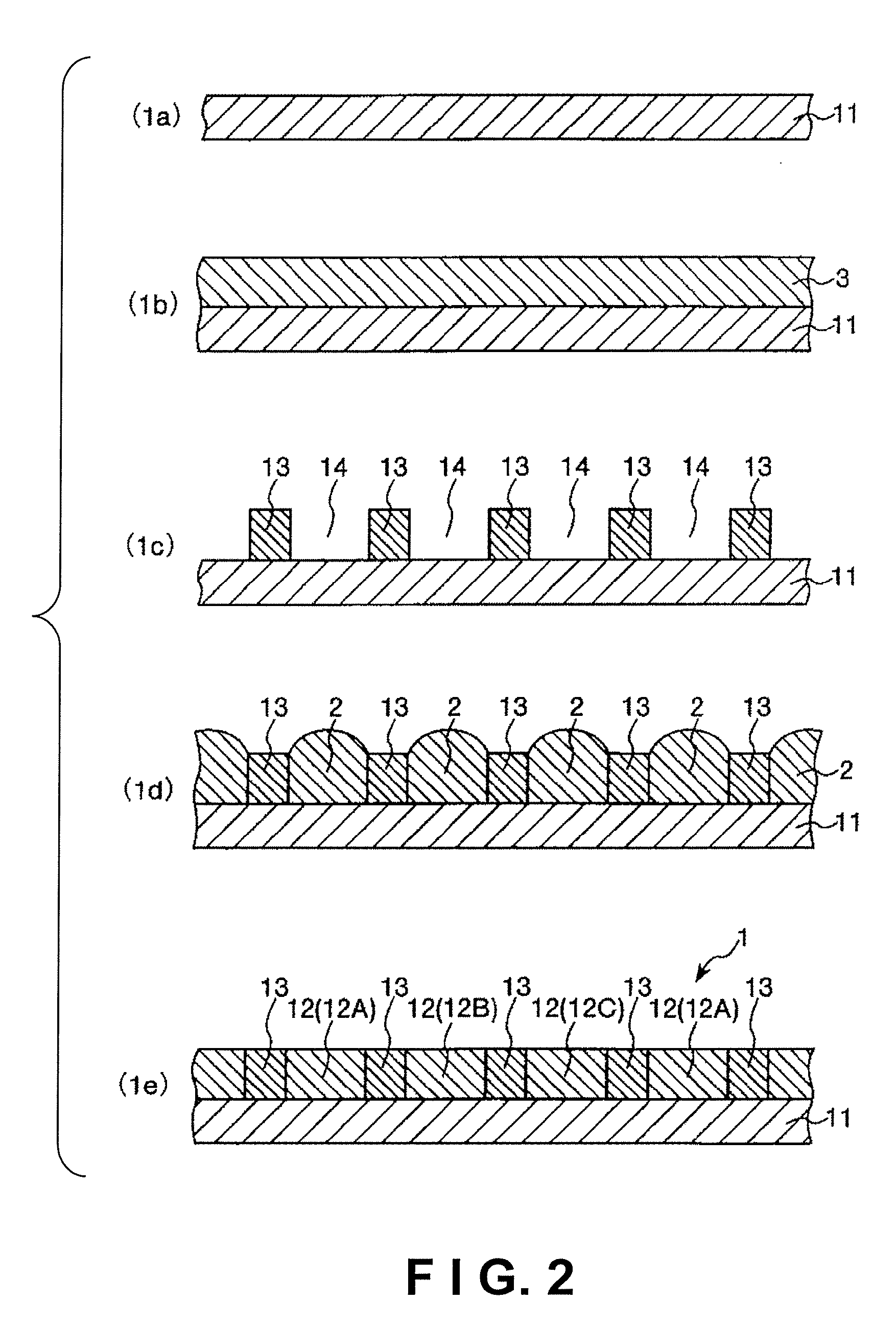

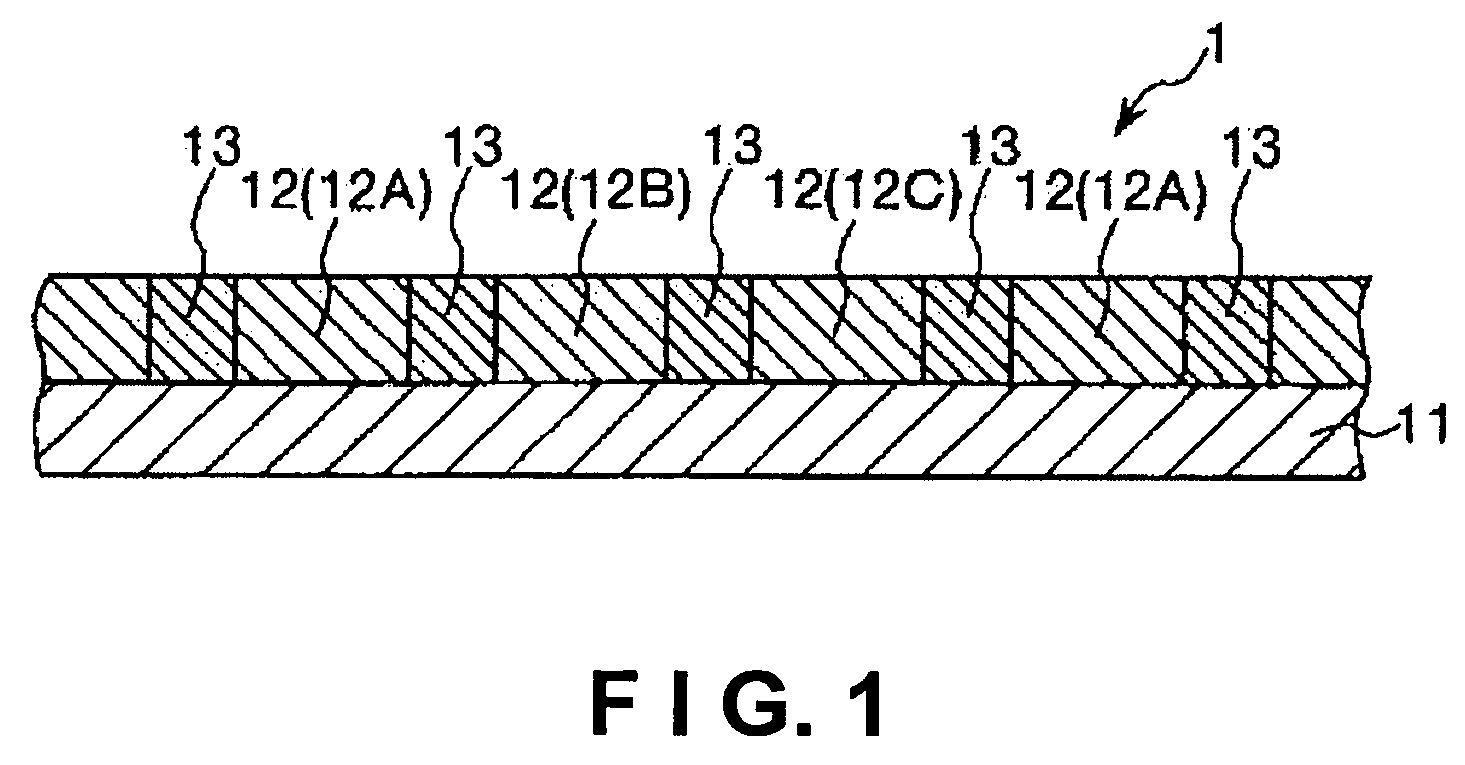

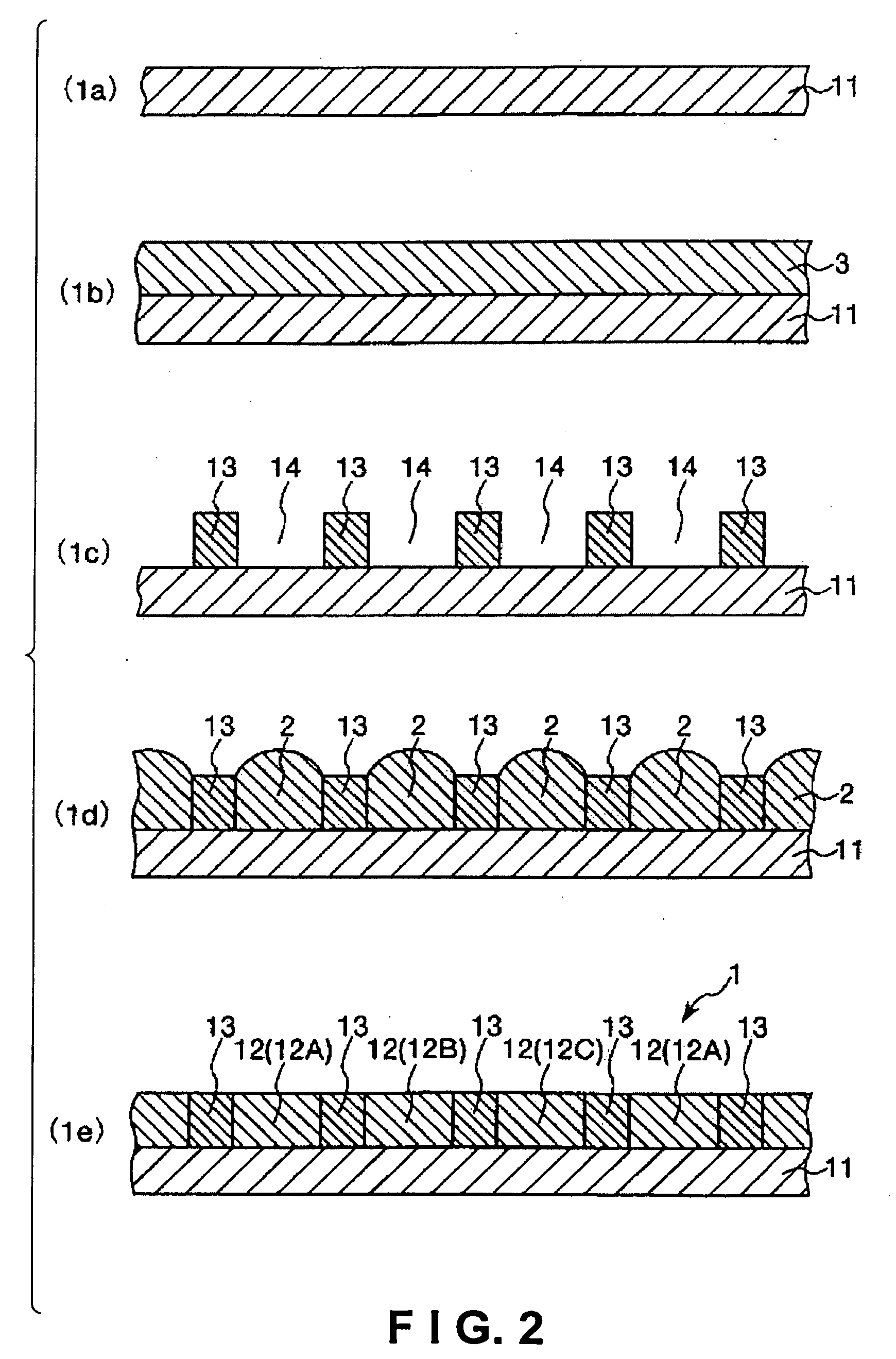

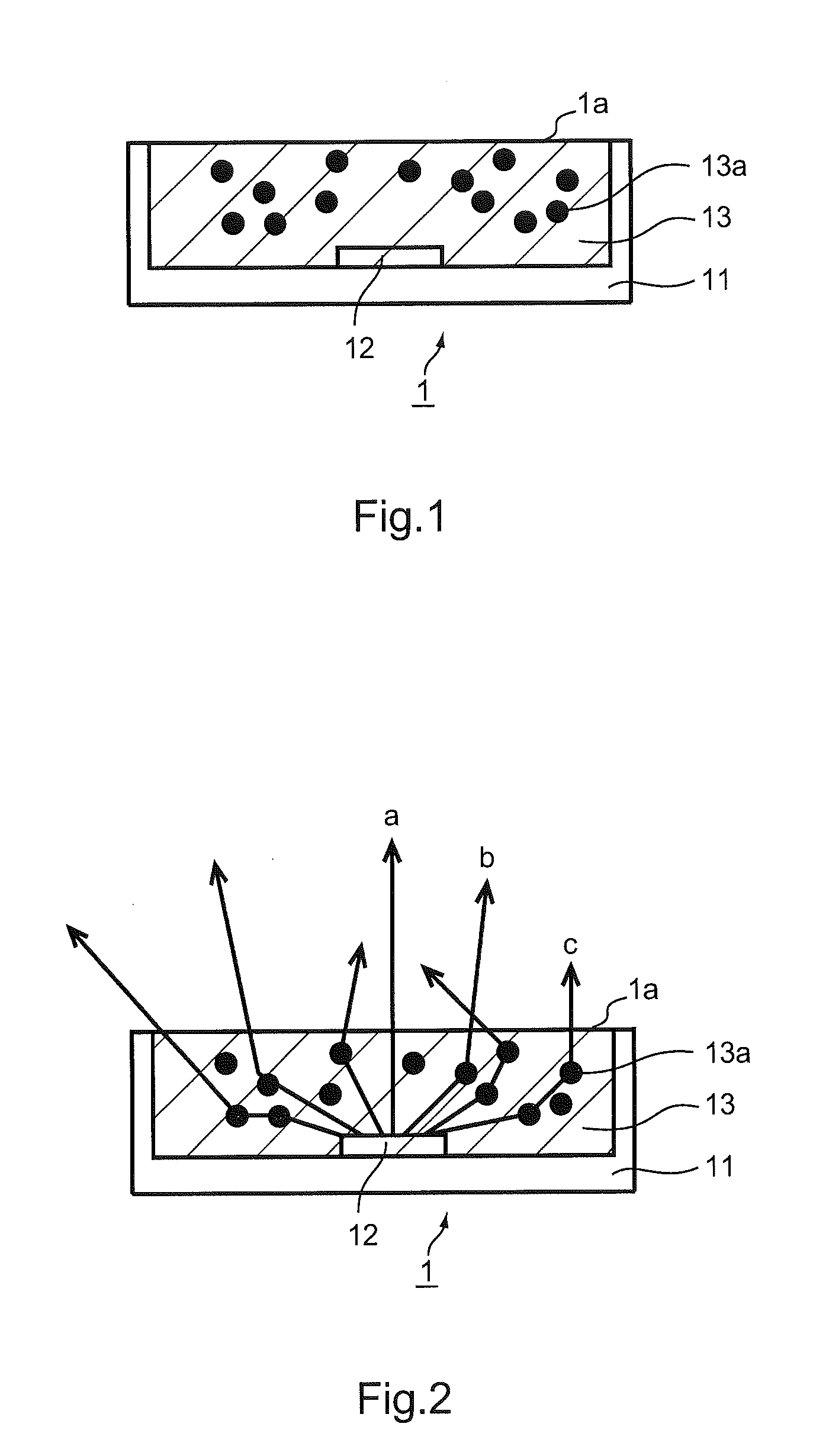

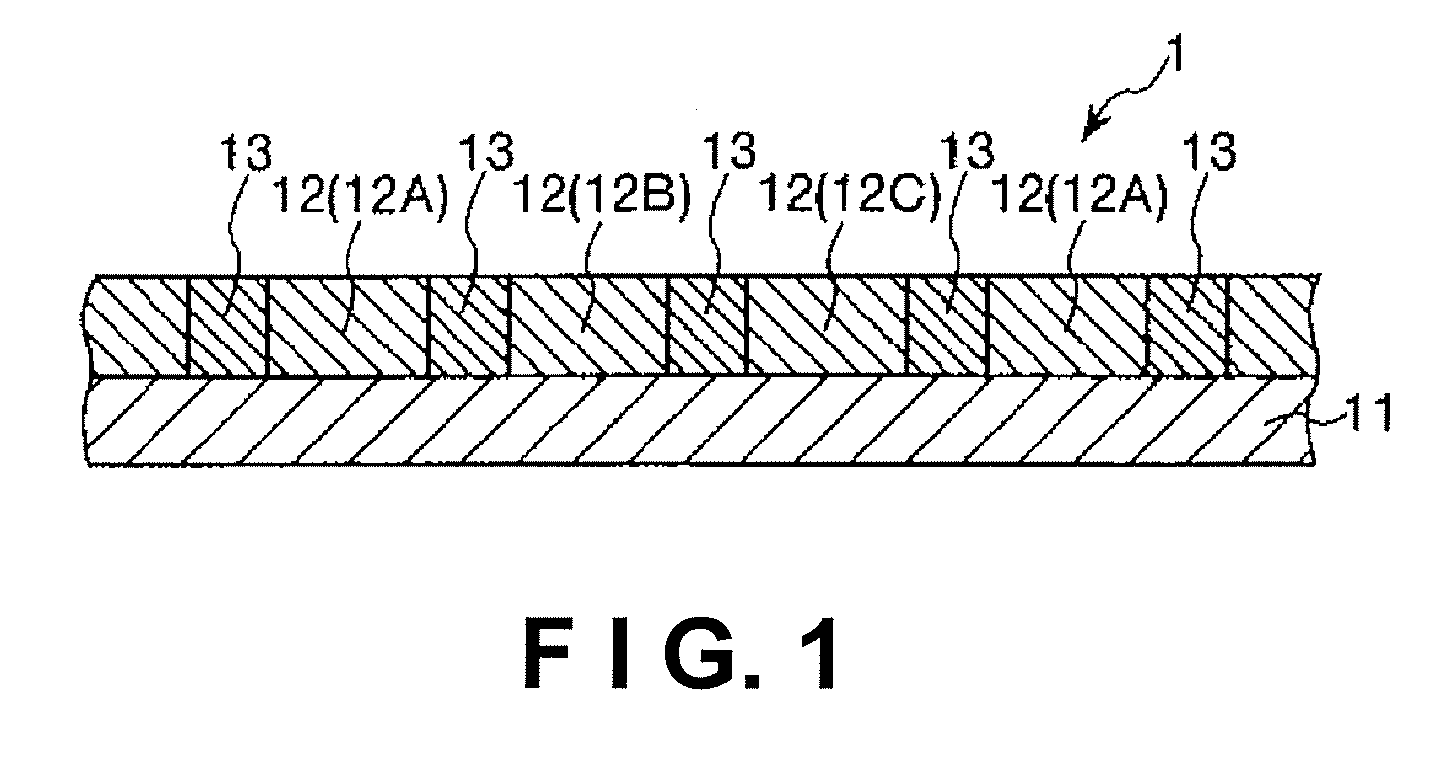

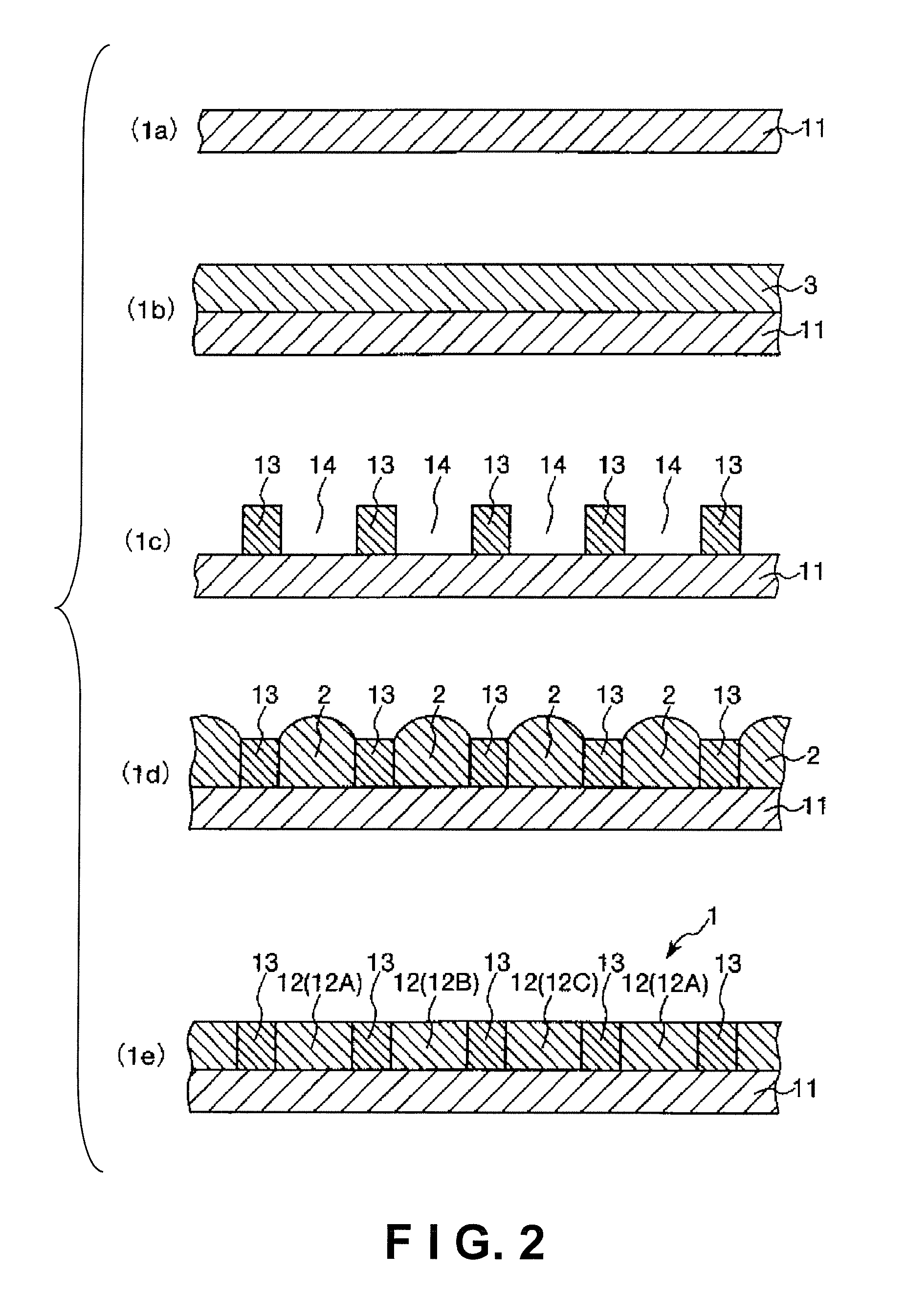

Phosphor plate and light emitting device having same

InactiveUS20070120463A1Light extraction efficiencyColor unevennessDischarge tube luminescnet screensLamp detailsPhosphorLength wave

A phosphor plate has a wavelength conversion plate member formed of a base material with a phosphor included therein. The phosphor is operable to radiate a wavelength-converted light by being excited by a light emitted from a light emitting element. The base material further has a converter of light travel direction.

Owner:TOYODA GOSEI CO LTD

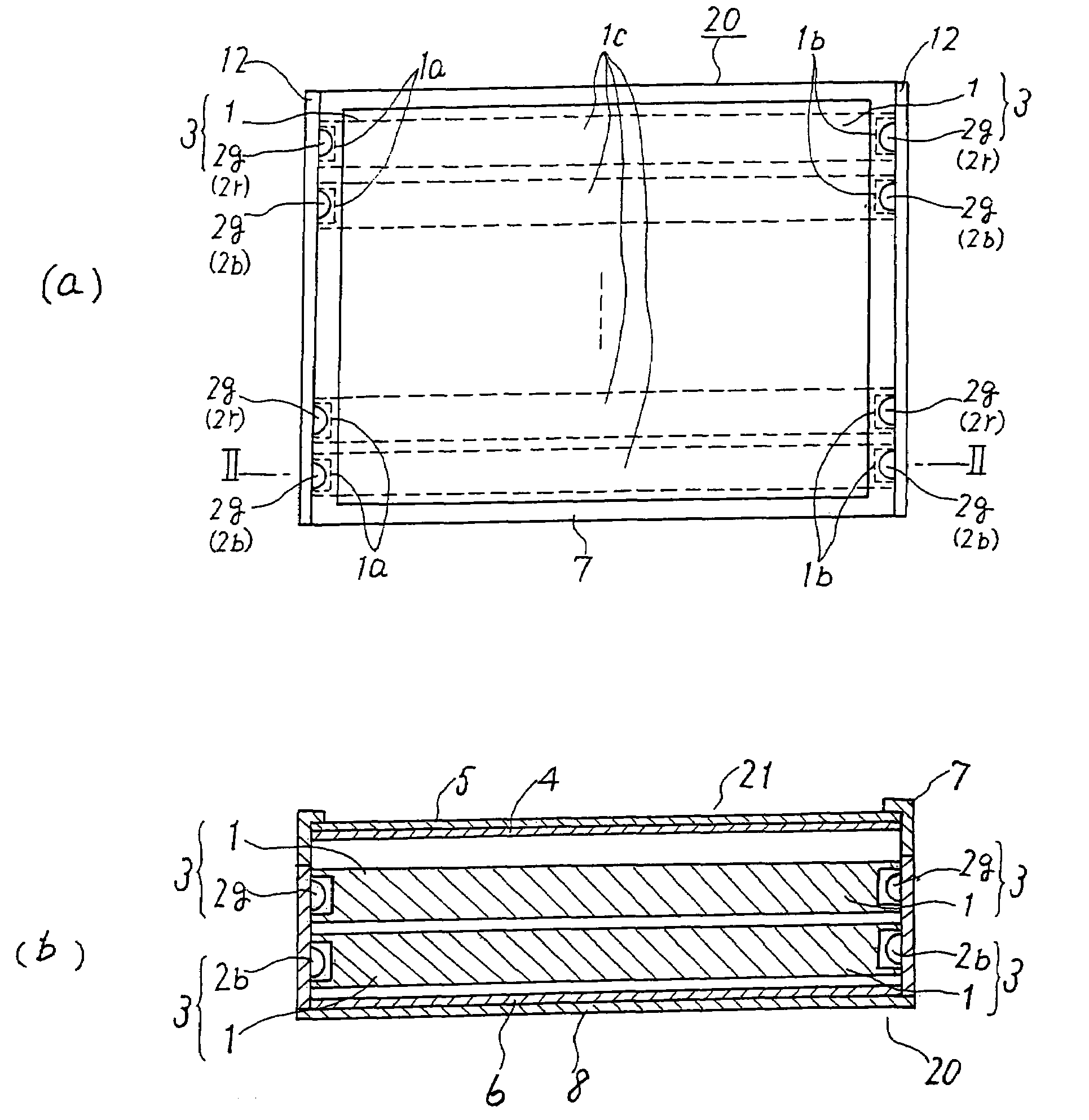

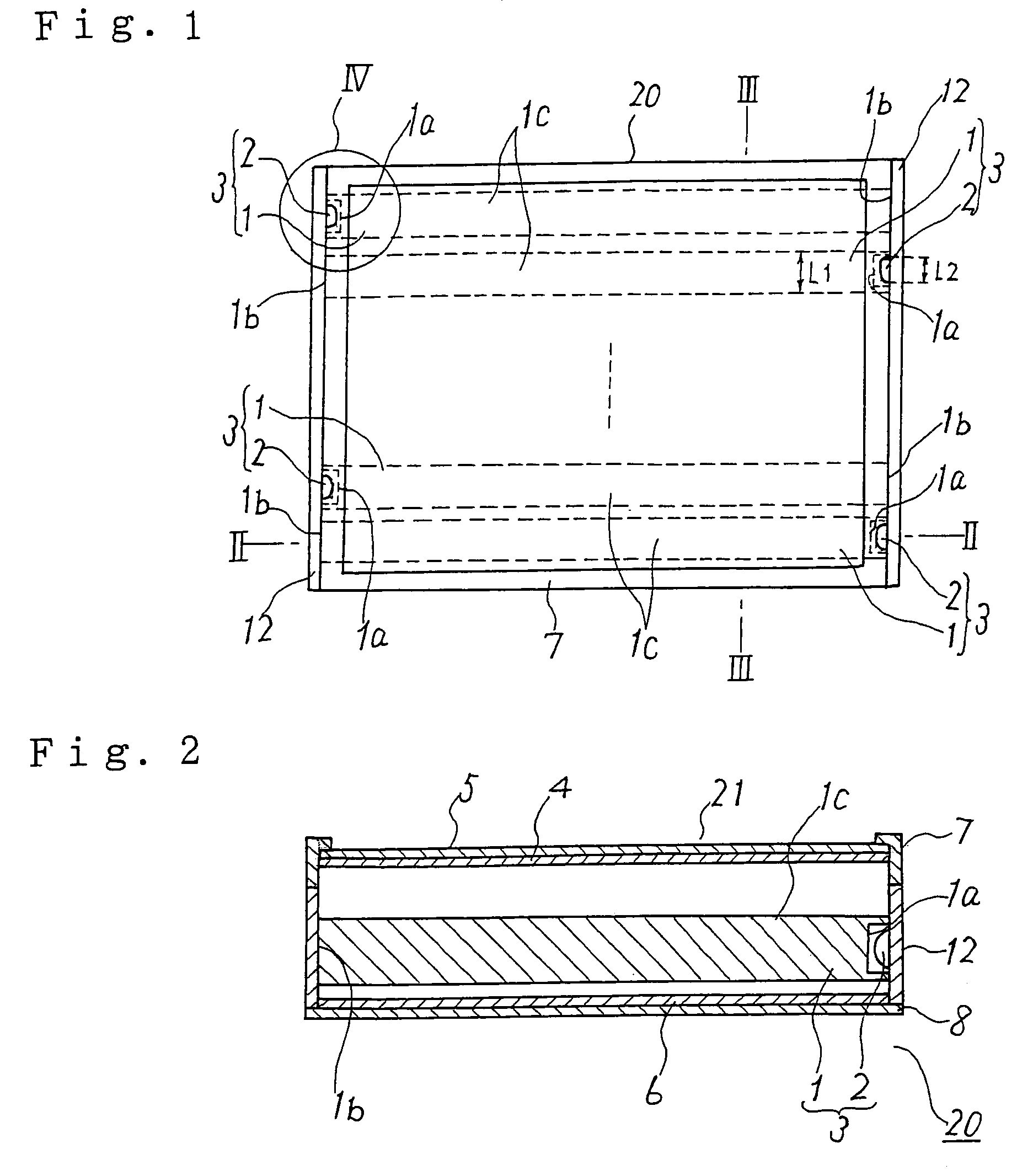

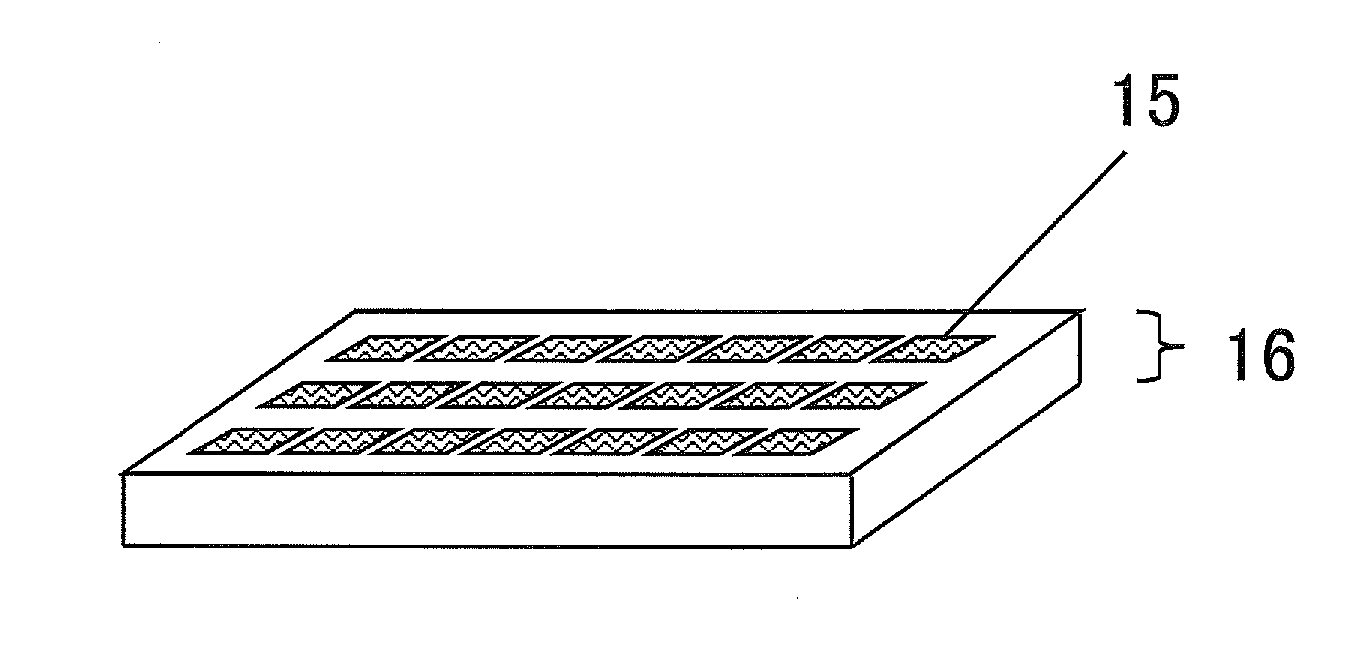

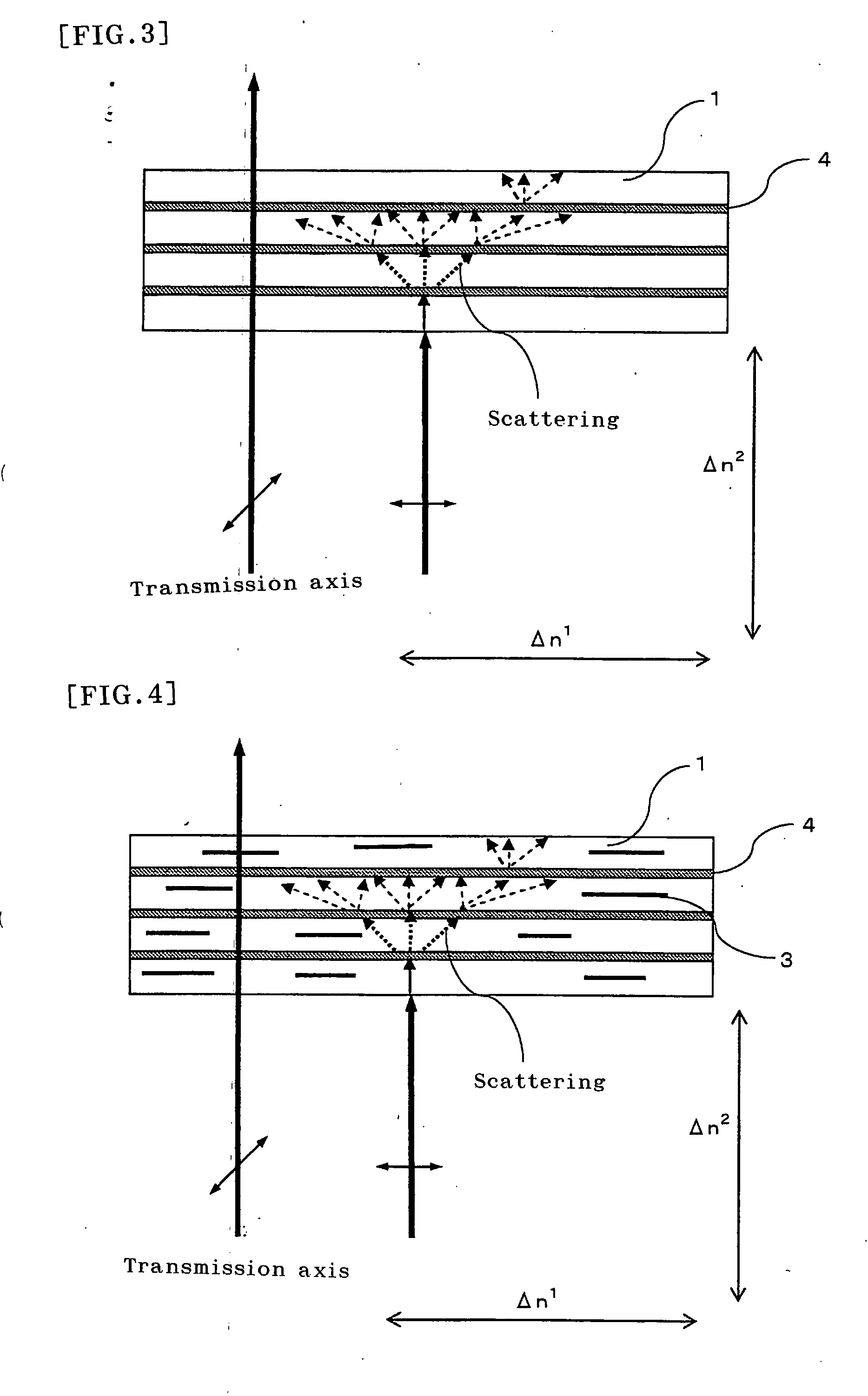

Planar light source device and display device using the same

InactiveUS7300184B2Small volumeLight weightShow cabinetsAircraft componentsLight guideDisplay device

In a planar light guiding device and a display device, plural light guiding rods are arranged in parallel to one another in a housing having an opening portion serving as a light emission face at the upper surface thereof, and a point light source (LED) 2 is disposed so as to oppose to at least one of both the end faces 1a of each light guiding rod through a space, thereby constituting a light source unit. These light source units are arranged in the metal housing to thereby form the planar light guiding device.

Owner:MITSUBISHI ELECTRIC CORP

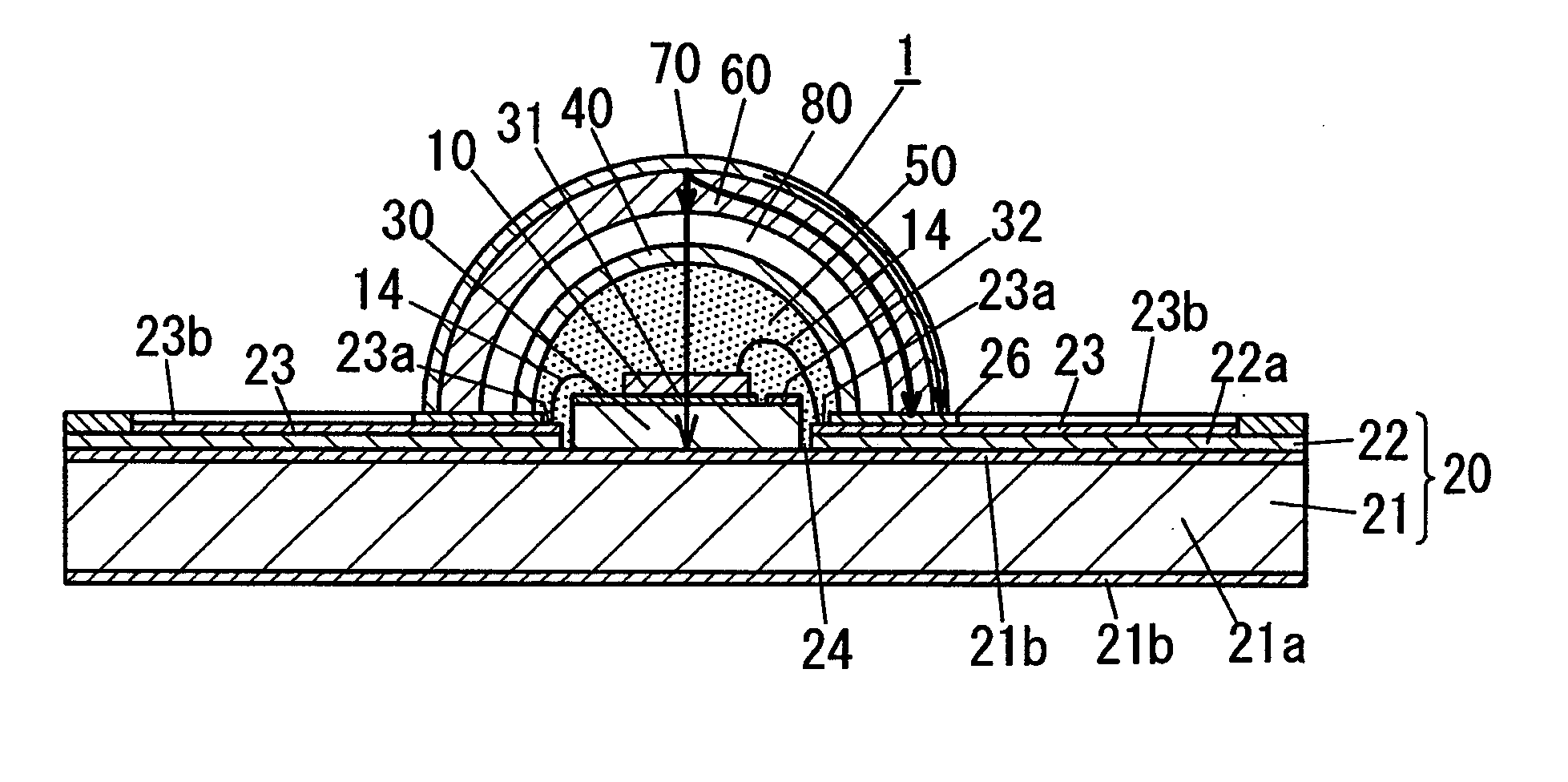

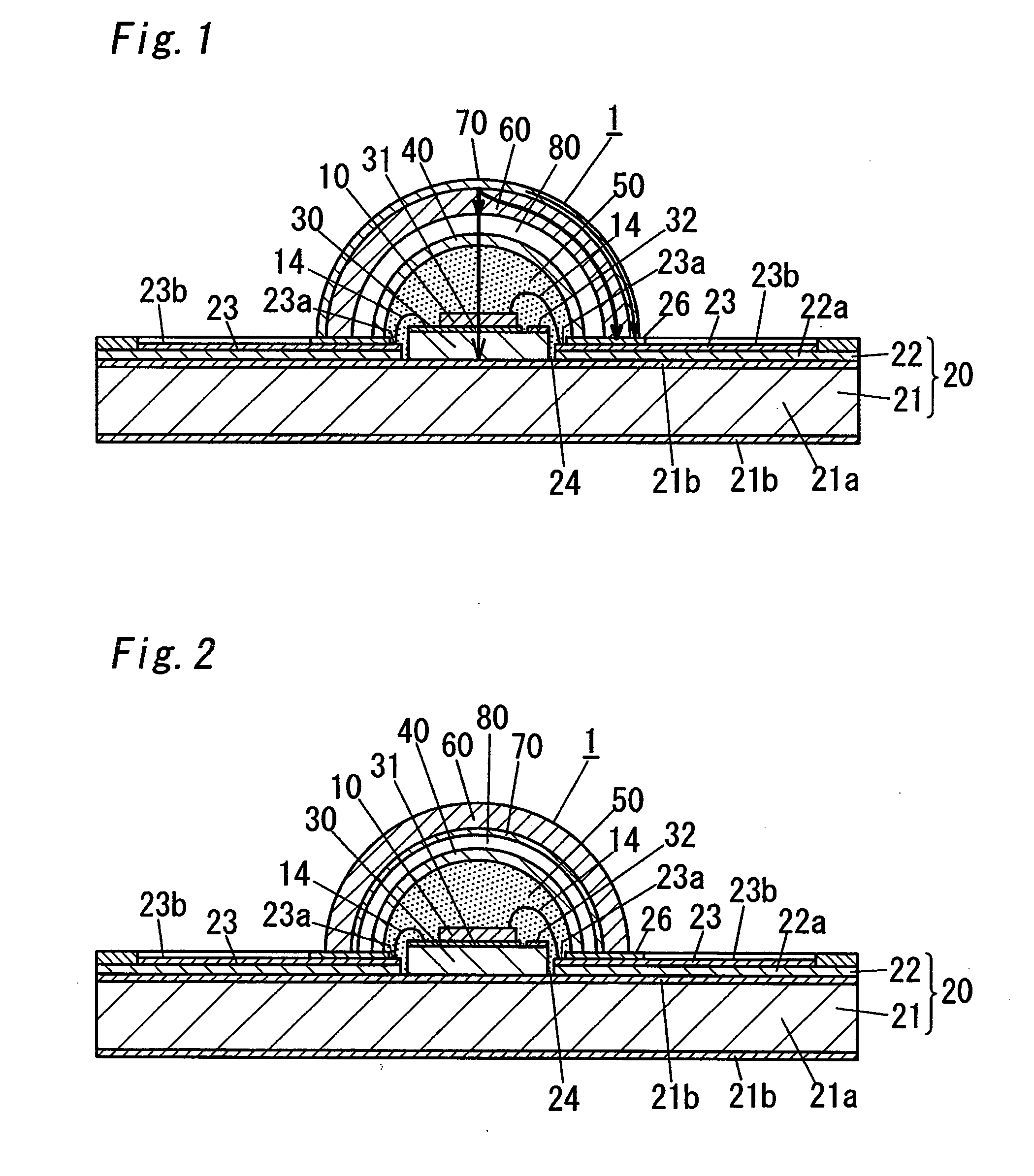

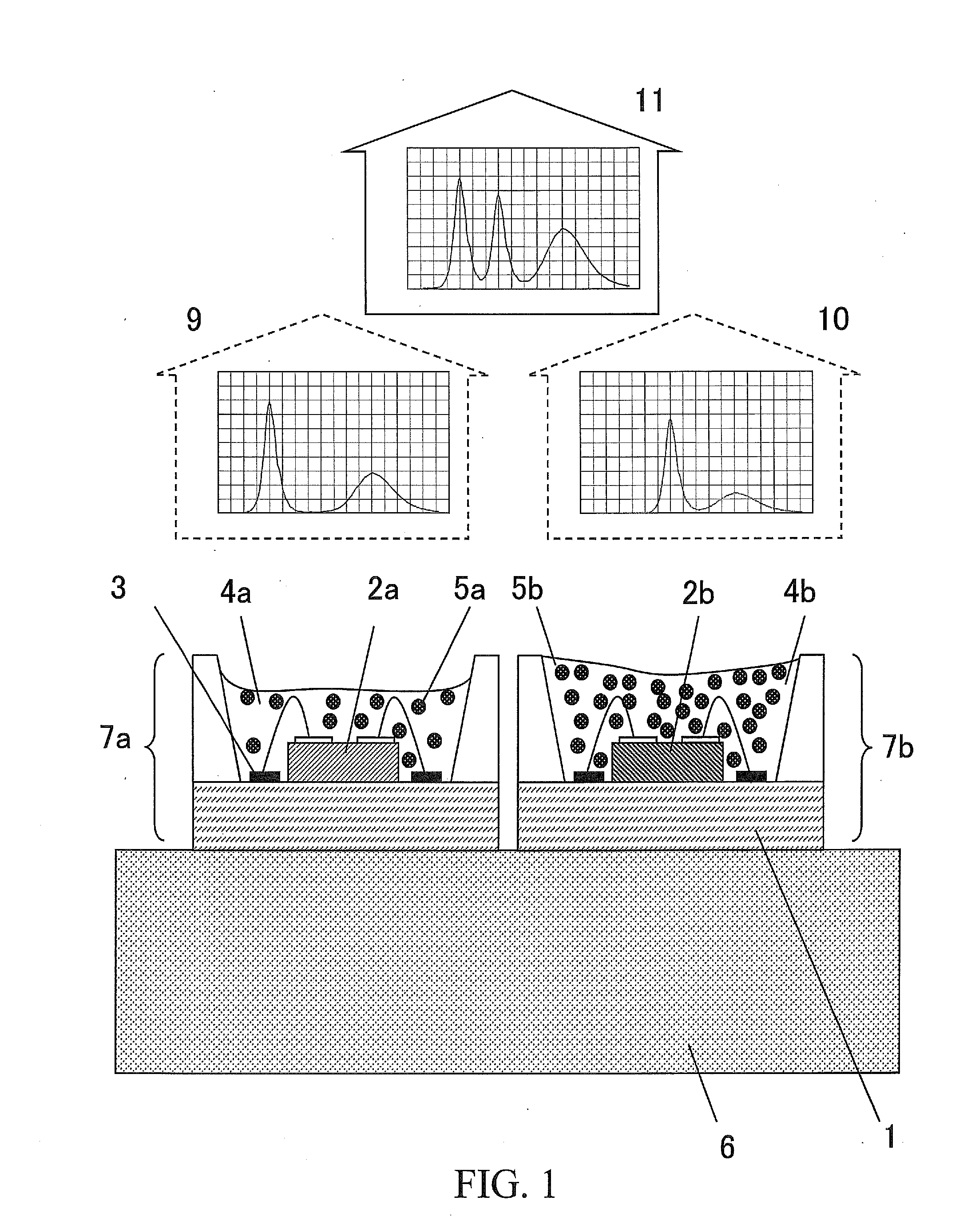

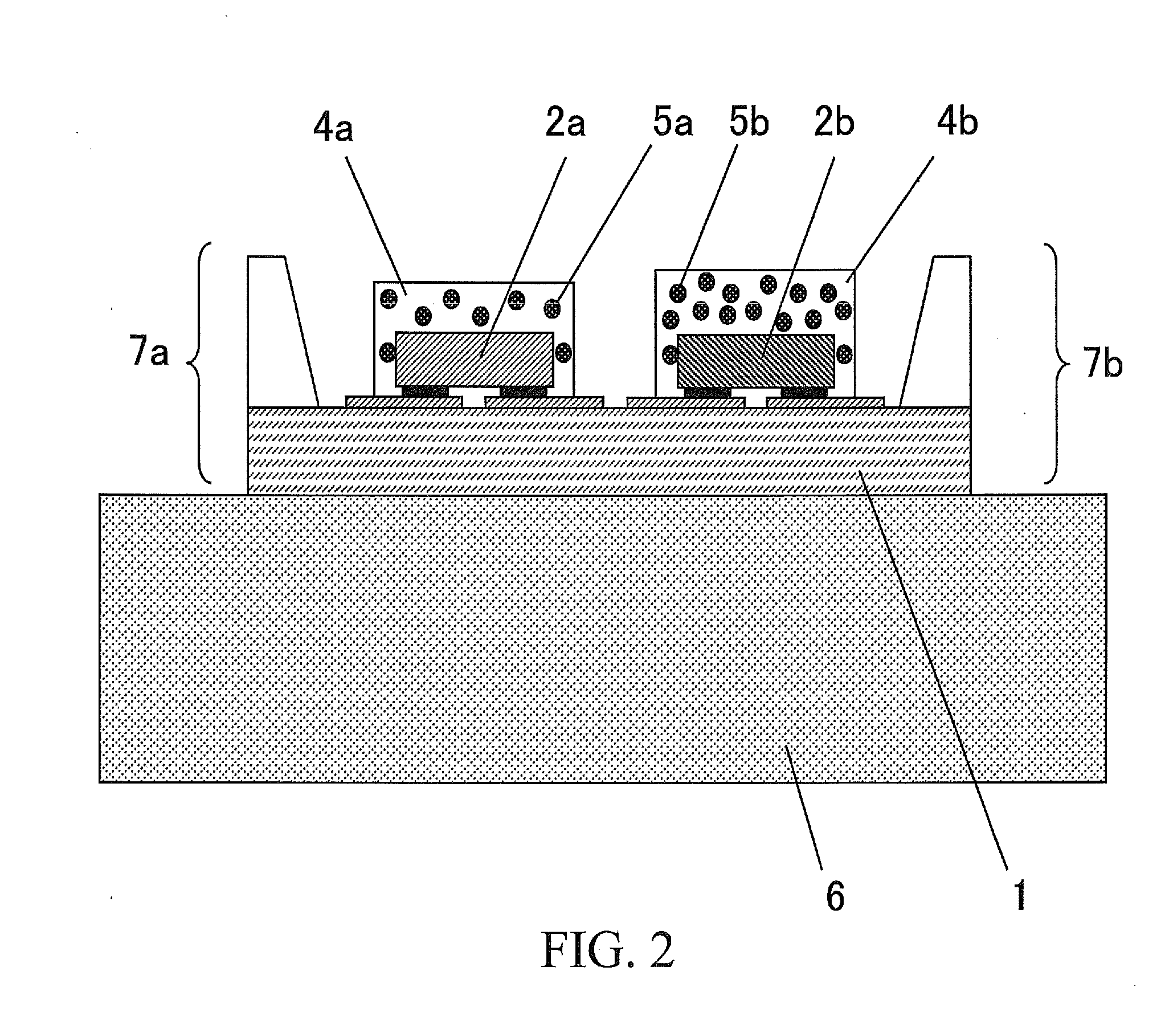

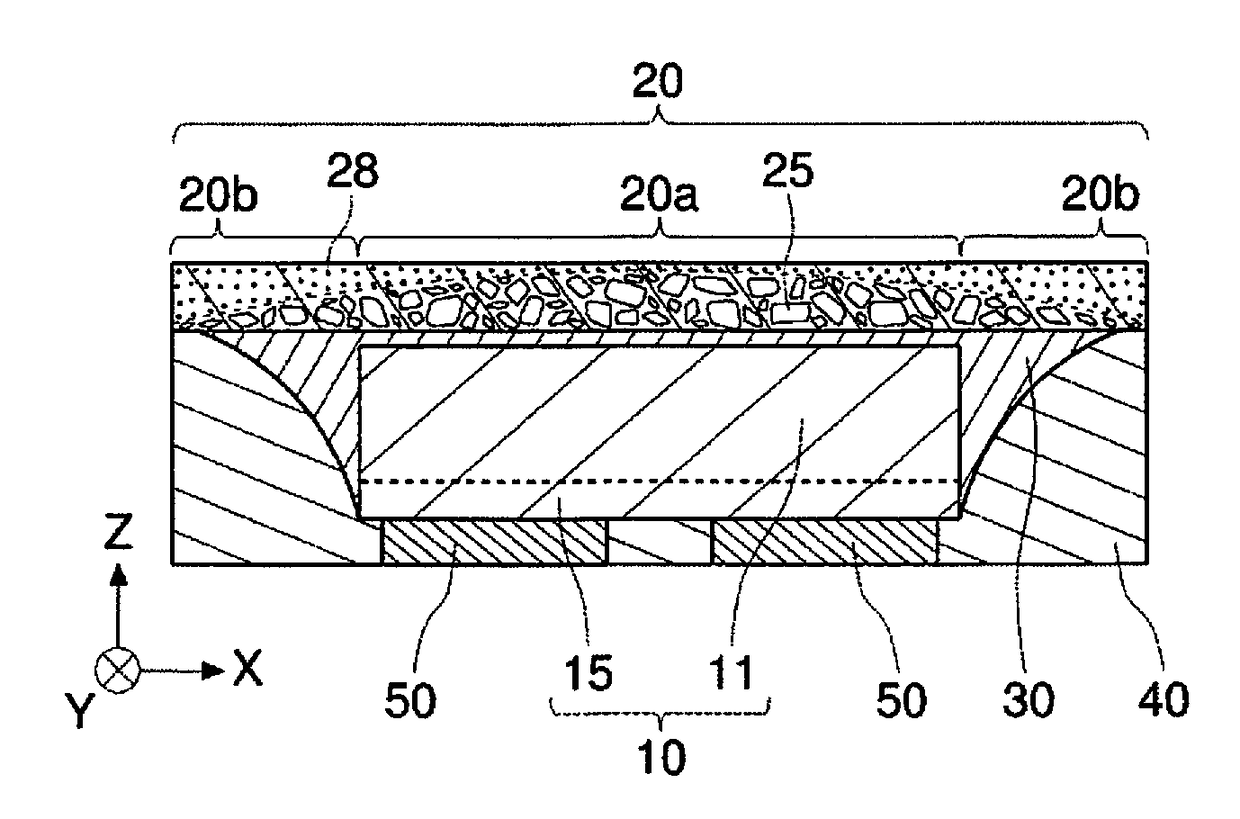

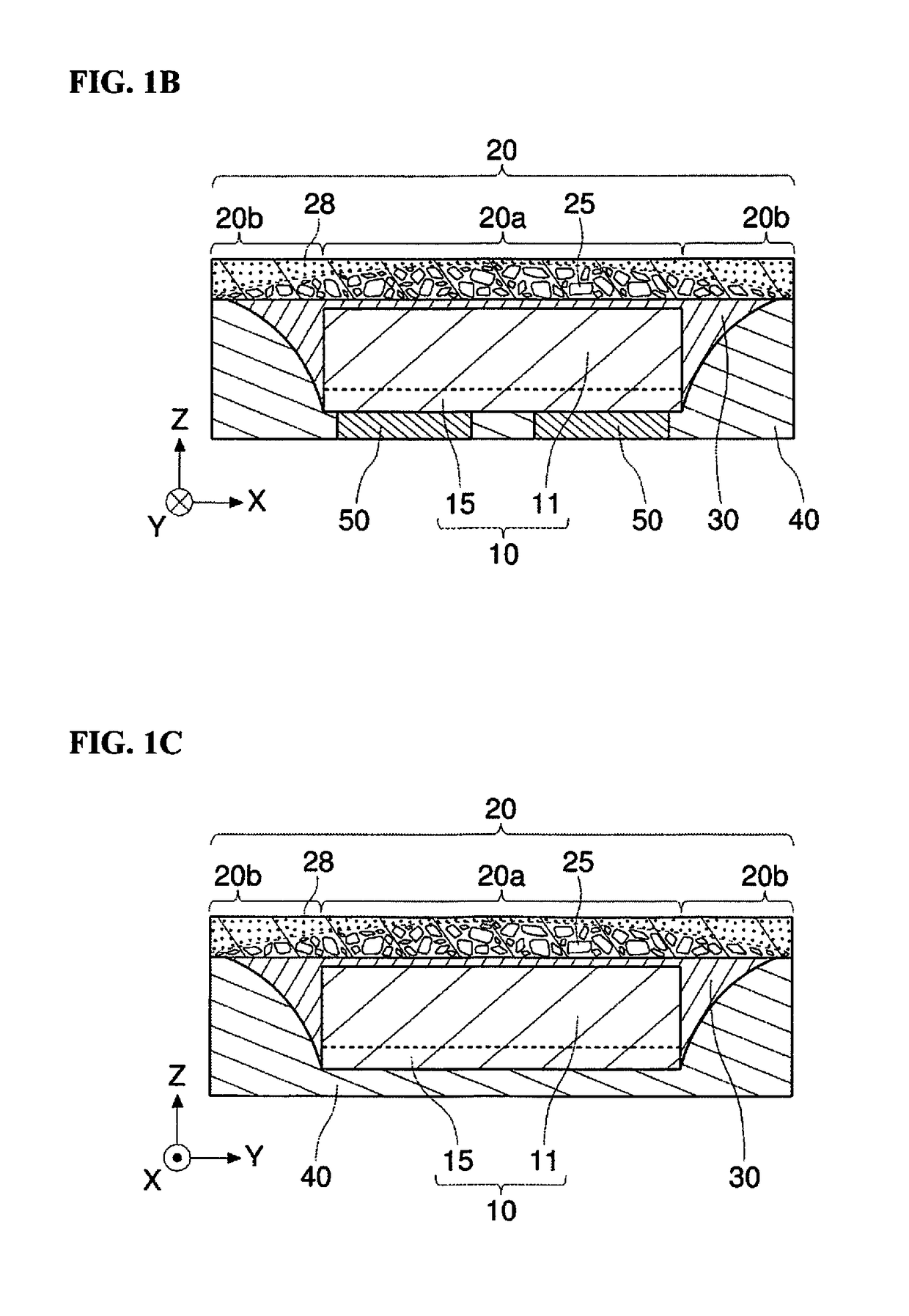

Light Emitting Device

ActiveUS20100237375A1Inhibit temperature riseColor unevennessSolid-state devicesSemiconductor devicesEngineeringLength wave

A light emitting device (1) includes a LED chip (10) as well as a mounting substrate (20) on which the LED chip (10) is mounted. Further, the light emitting device (1) includes a cover member (60) and a color conversion layer (70). The cover member (60) is formed to have a dome shape and is made of a translucency inorganic material. The color conversion layer (70) is formed to have a dome shape and is made of a translucency material (such as, a silicone resin) including a fluorescent material excited by light emitted from the LED chip (10) and emitting light longer in wavelength than the light emitted from the LED chip (10). The cover member (60) is attached to the mounting substrate (20) such that there is an air layer (80) between the cover member (60) and the mounting substrate (20). The color conversion layer (70) is superposed on a light-incoming surface or a light-outgoing surface of the cover member (60).

Owner:PANASONIC CORP

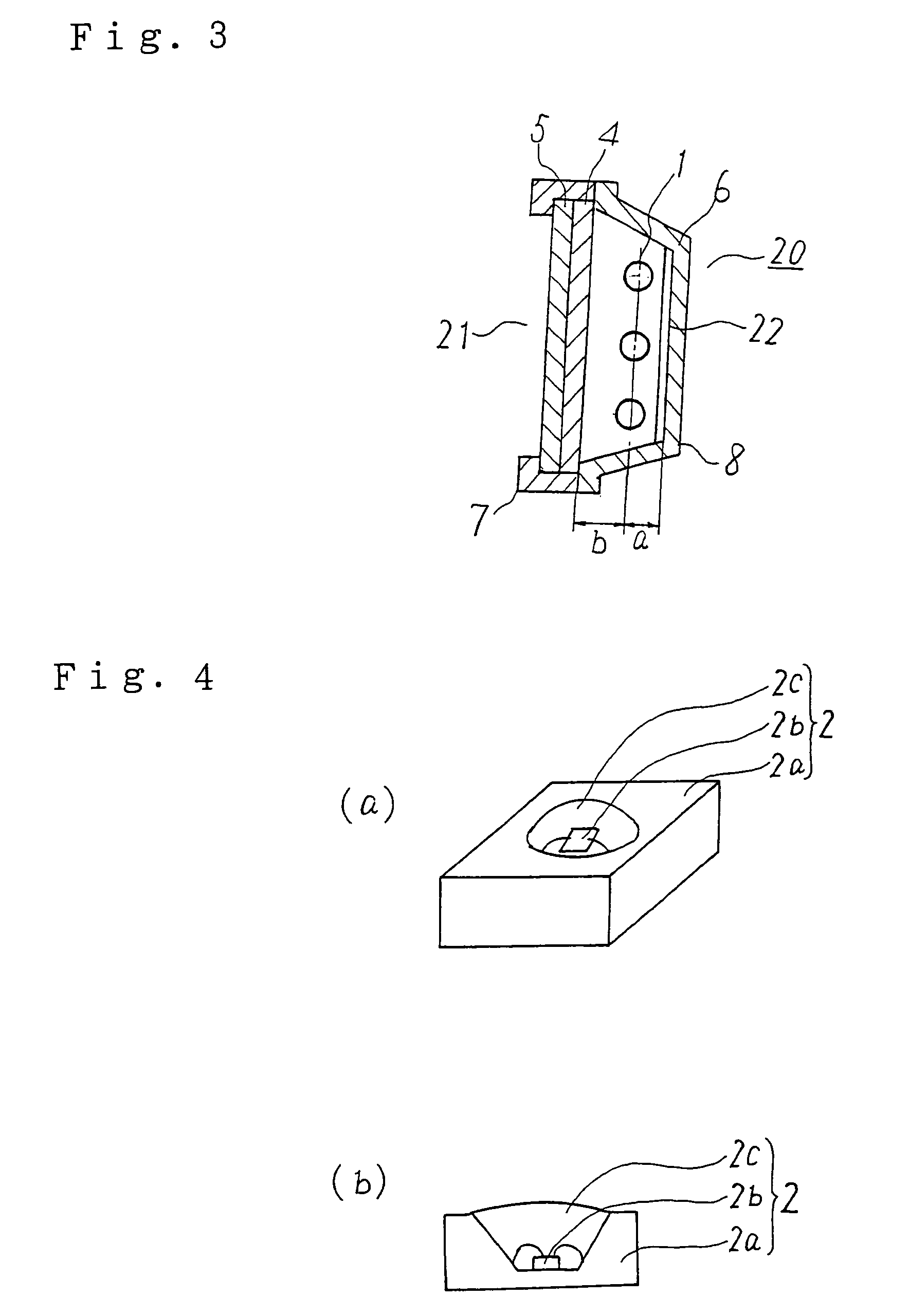

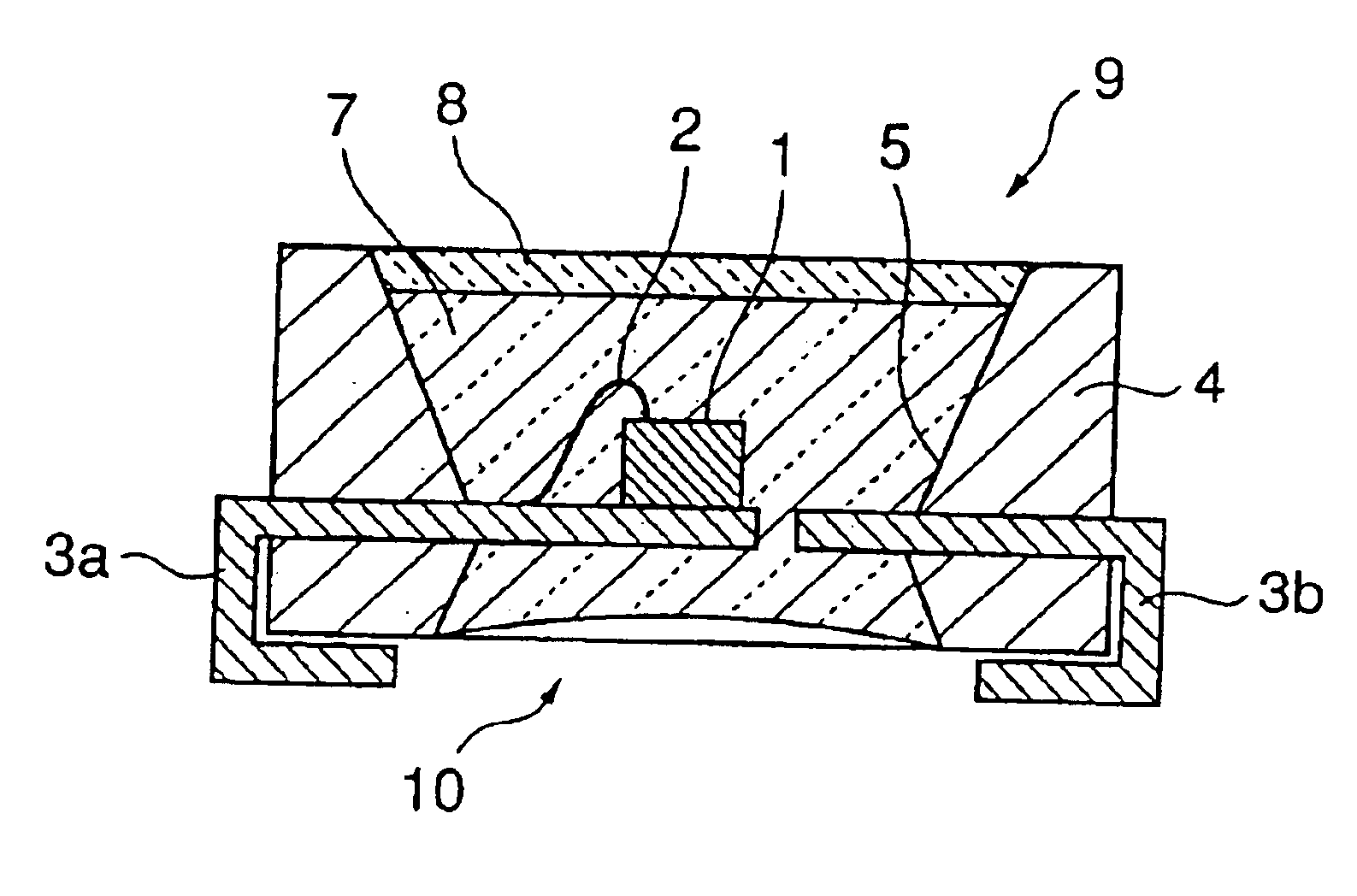

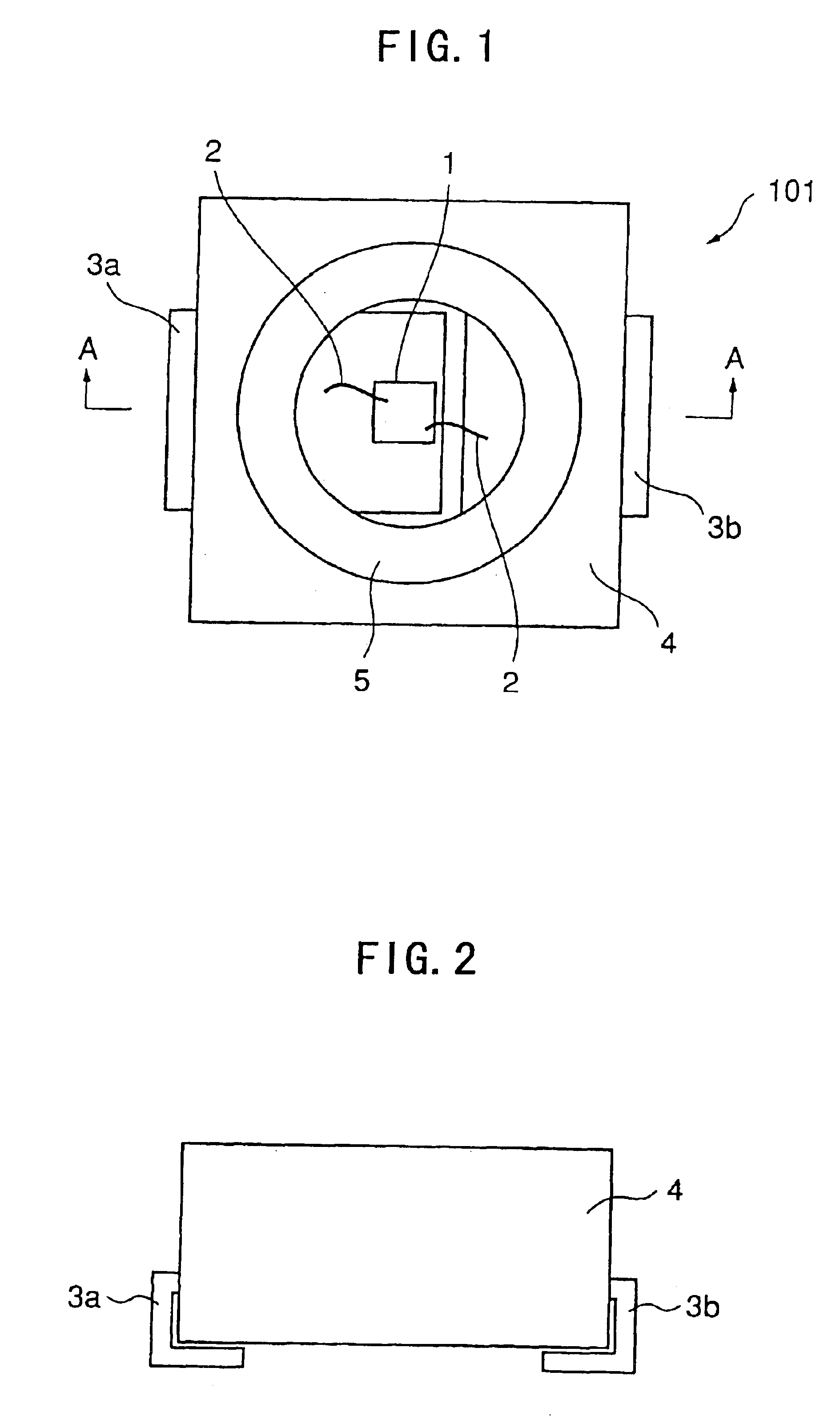

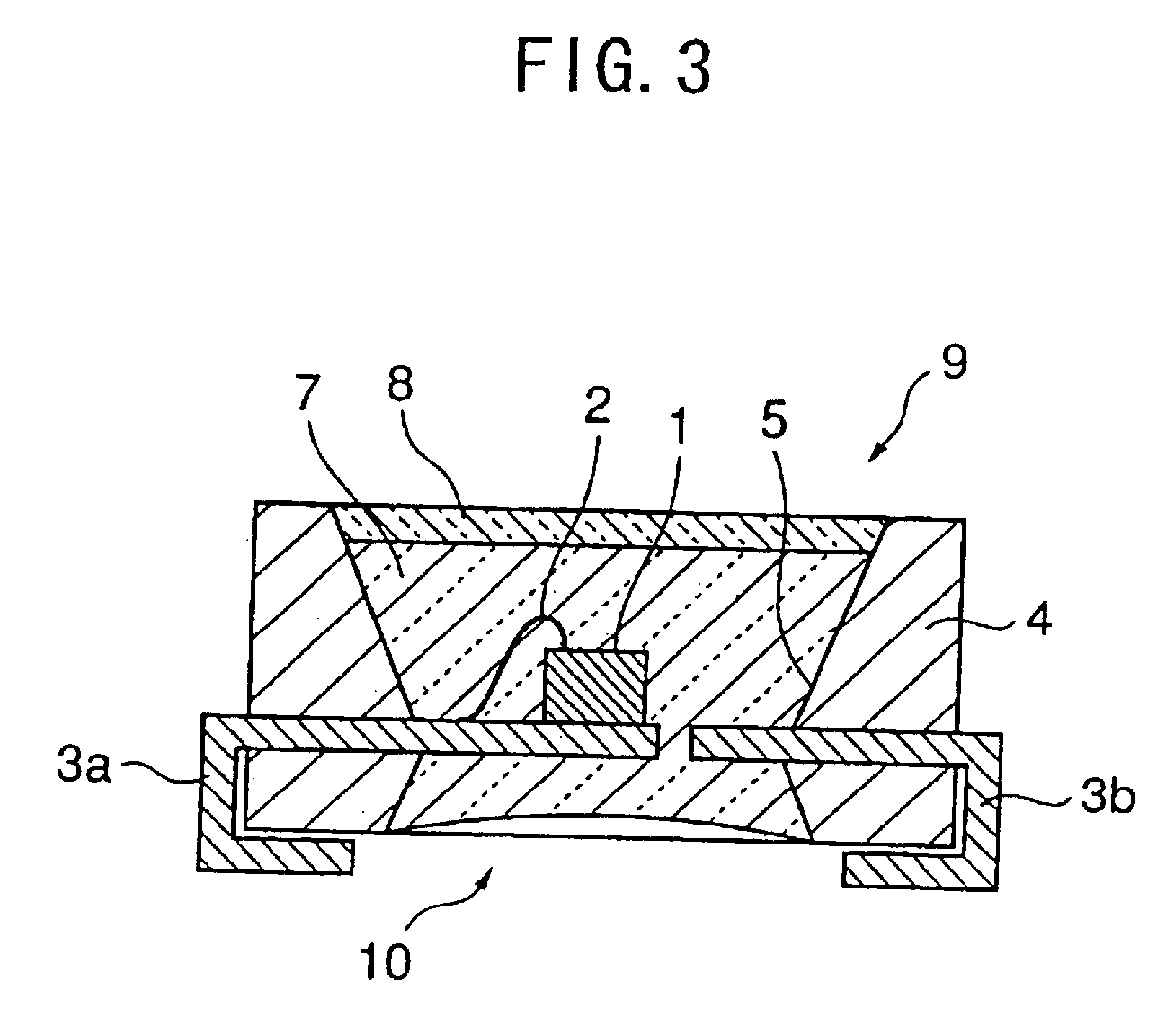

Chip-type LED and process of manufacturing the same

InactiveUS6869813B2Color unevennessLine/current collector detailsSemiconductor/solid-state device detailsEngineering

A chip-type LED including a LED element and a tubular vessel accommodating the LED element therein, wherein the vessel has an upper opening and a lower opening, the LED element is positioned between the upper opening and the lower opening such that the LED element emits light toward the upper opening, and the vessel is filled with a light-transmissive resin from the upper opening to the lower opening.

Owner:SHARP KK

Light emitting device, and illumination light source, display unit and electronic apparatus including the light emitting device

InactiveUS20110211336A1No lot-to-lot variationColor tone is easilySolid-state devicesIlluminated signsOptical fluorescencePeak value

A light emitting device includes: a first semiconductor light emitting element having a solid-state blue light emitting element that emits blue light with a light emission peak in a wavelength range from 420 nm to less than 480 nm, and a first red phosphor layer that covers the solid-state blue light emitting element and includes a first red phosphor that emits red light with a light emission peak in a wavelength range from 600 nm to less than 680 nm; and a second semiconductor light emitting element having a solid-state green light emitting element that emits green light with a light emission peak in a wavelength range from 500 nm to less than 550 nm, and a second red phosphor layer that covers the solid-state green light emitting element and includes a second red phosphor that emits red light with a light emission peak in a wavelength range from 600 nm to less than 680 nm.

Owner:PANASONIC CORP

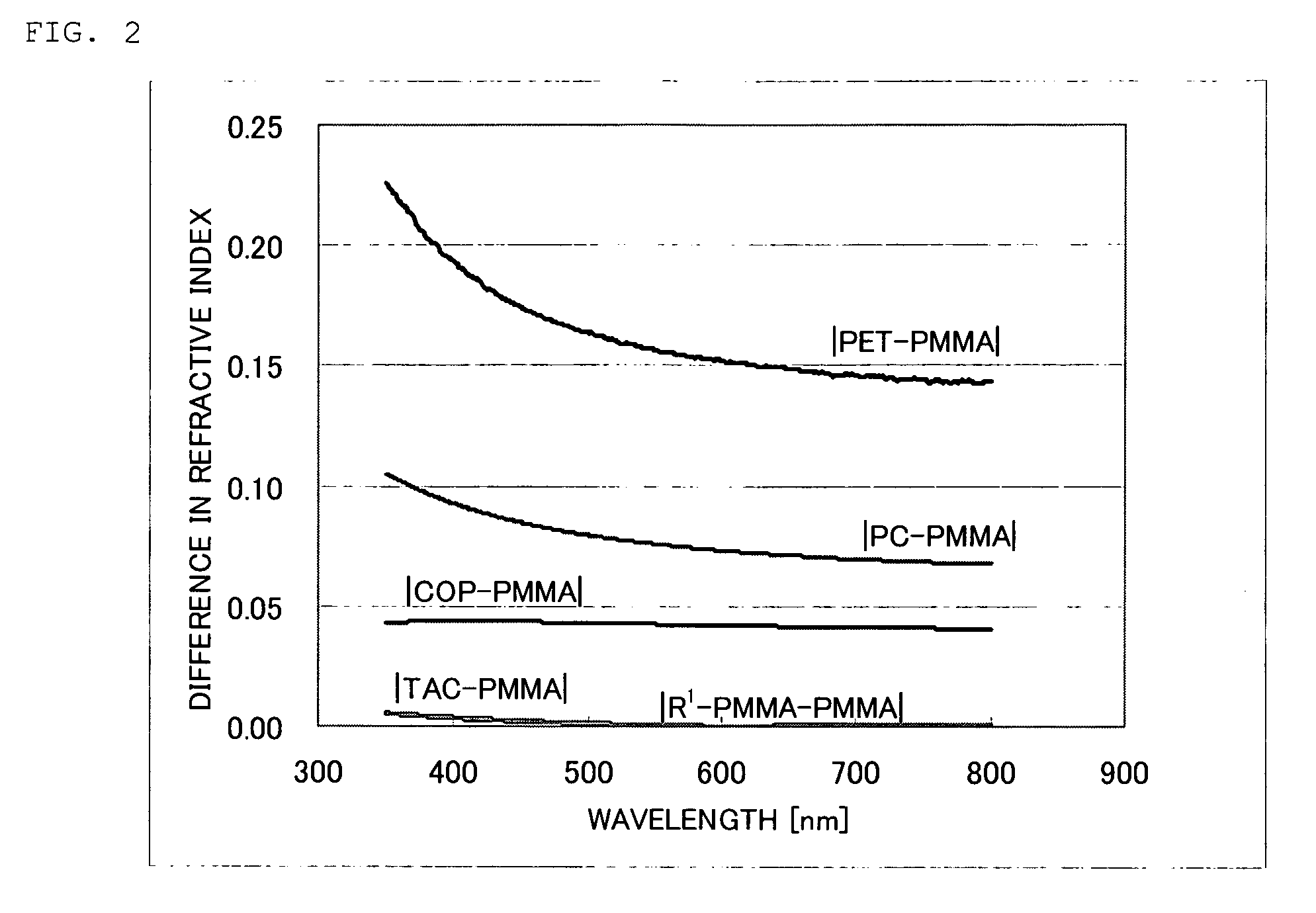

Protective Film for Polarizing Plate

ActiveUS20090237786A1Color unevennessLight leakage unevennessLayered productsPolarising elementsTectorial membraneRefractive index

A protective film for polarizing plate made by laminating k layers (k is an integer of 2 or more) of thermoplastic resin, in which a refractive index ni(λ) at a wavelength in the range of 380 to 780 nm of the i th thermoplastic resin layer as well as a refractive index ni+1(λ) at a wavelength in the range of 380 to 780 nm of the i+1 th thermoplastic resin layer have a relationship of ∥ni(λ)−ni+1(λ)|≦0.05 (where, i is an integer of 1 to k−1); and a polarizing plate comprising a laminate the protective film for polarizing plate and a polarizer.

Owner:ZEON CORP

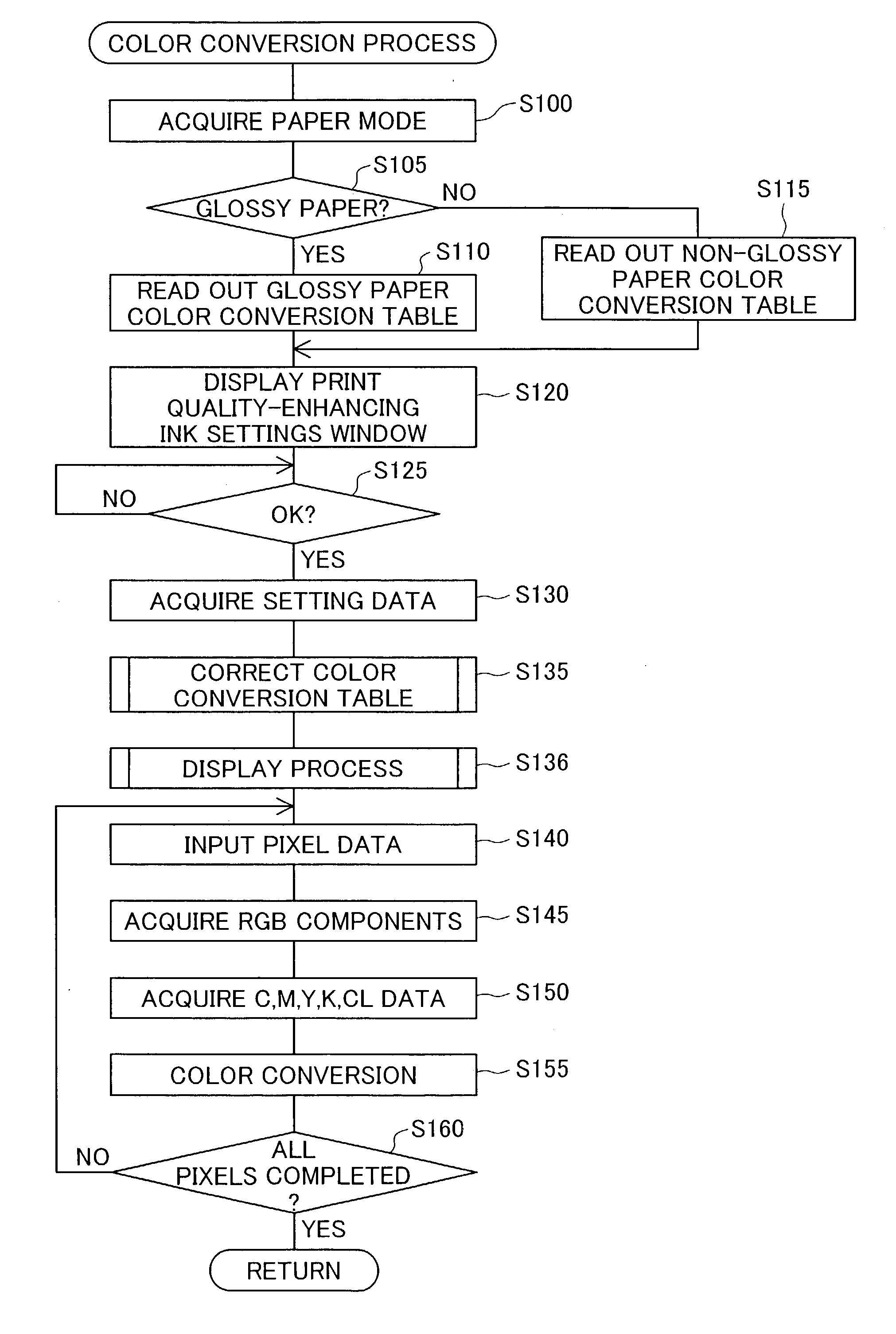

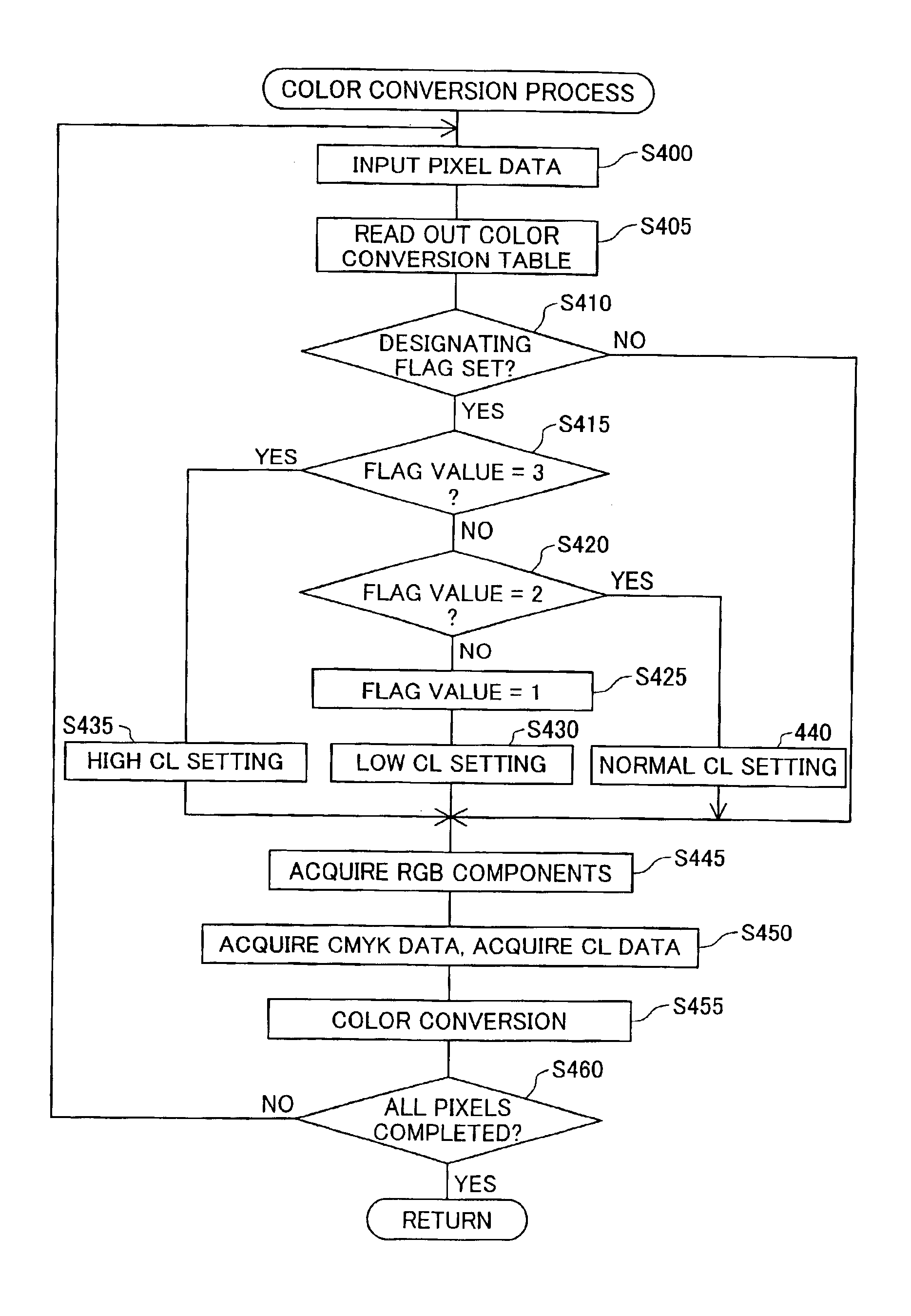

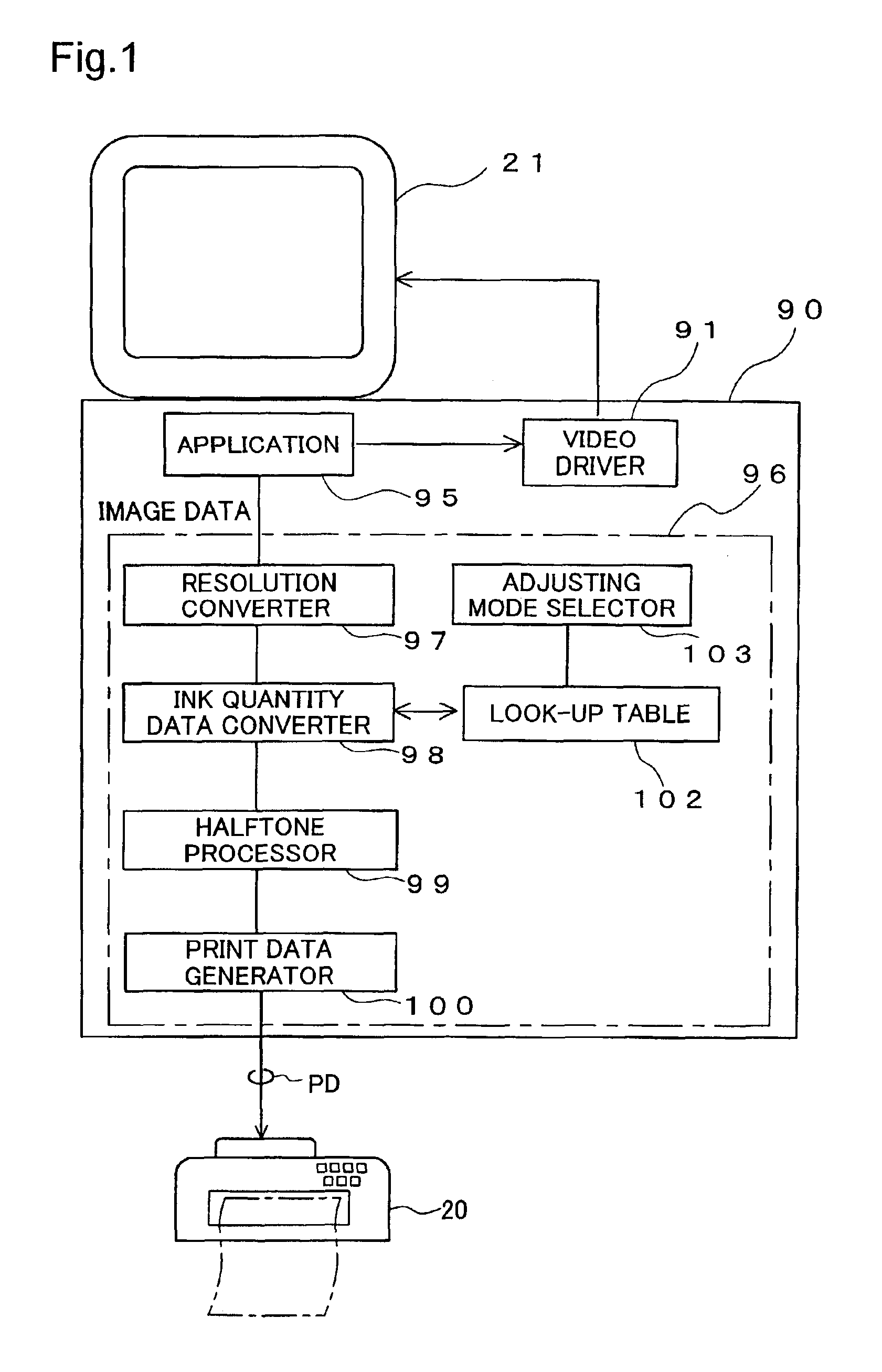

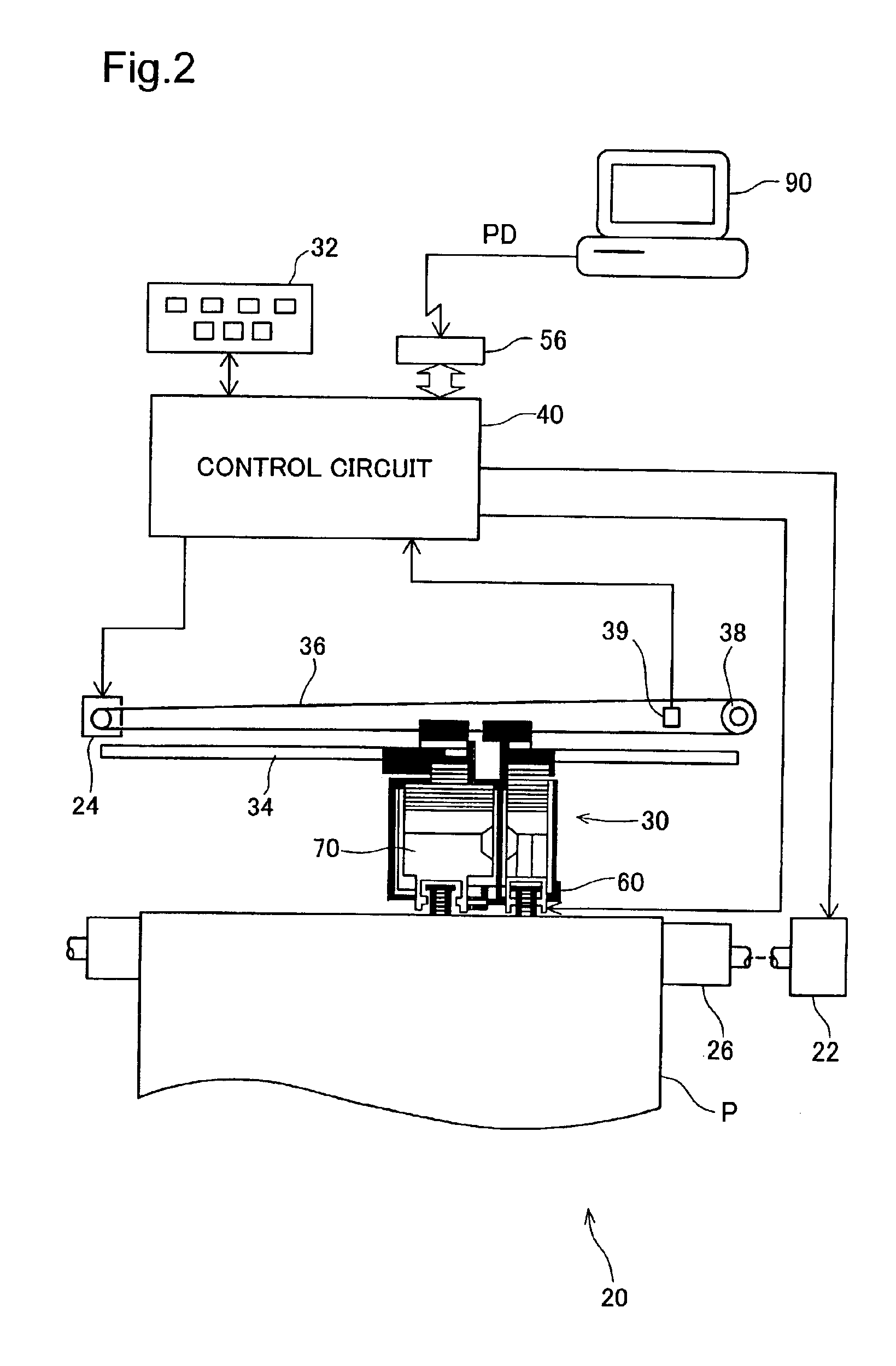

Image printing using print quality enhancing ink

Image quality is improved by adjusting the ejection amount of quality enhancing ink based on the ejection amount of colored ink containing colorant. When a relatively high gross printing medium is used, the quality enhancing ink is ejected in an image area where virtually no colored ink is ejected, thereby improving unevenness in gloss within the print image. When a relatively low gross printing medium is used, on the other hand, the quality enhancing ink is ejected in an image area where the colored ink is ejected on virtually all pixels, thereby improving unevenness in color within the print image. The relationship between the ejection amounts of the quality enhancing ink and the colored ink may be modified by the user.

Owner:NEC CORP +1

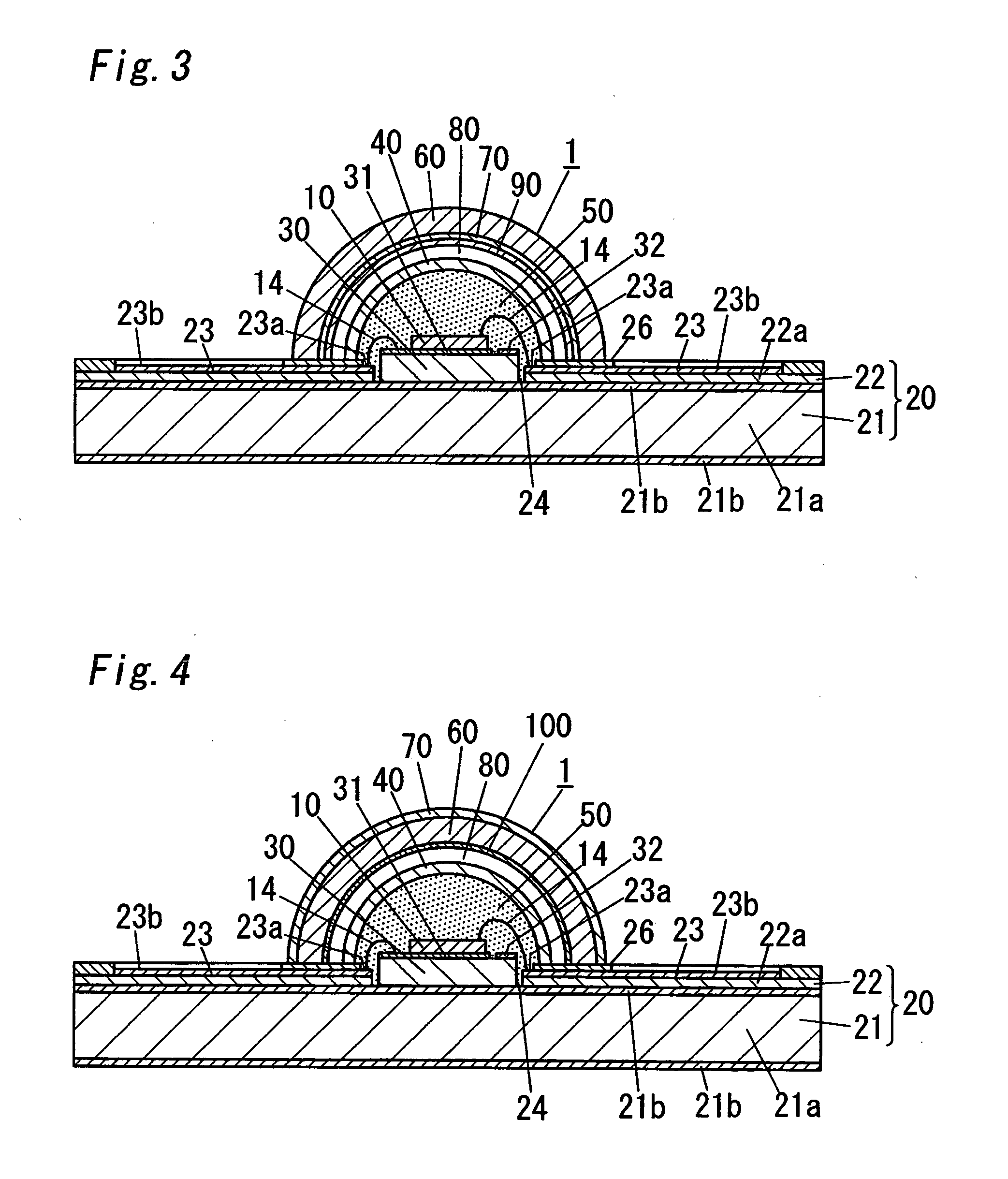

Light guide and image reader

ActiveUS20090218525A1Prevent uneven colorReduce the amount of lightPhotometry using reference valueMechanical apparatusLight guideOptoelectronics

A rod-shaped light guide which does not cause unevenness in color at the portion near an incident face is produced by injection-molding transparent resin such as acryl and its surfaces include a light-emitting surface, a bottom face, left and right sides and end faces. One end face opposes a light emitting unit, and light scattering patterns for scattering light incident from the end face are formed on the bottom face. The light scattering patterns are different in shape between a portion near the end face as the incident face and a portion away from the end face. The light scattering patterns formed at the portion near the incident face are composed of a large number of fine hemispherical concaves, whereas the light scattering patterns at the portion away from the incident face are composed of triangular grooves or half cylindrical grooves, and the axial direction of these triangular grooves or half cylindrical grooves is equal to coincides with the width direction (sub-scanning direction) of the bottom face on which the patterns are formed.

Owner:NIPPON SHEET GLASS CO LTD

Light emitting device and method of manufacturing the same

ActiveUS20180212128A1Accelerated dissipationIncrease production capacityMechanical apparatusLight guides with fluorescent dopantsLight guideFluorescence

A light emitting device includes a light emitting element, a light-transmissive member, a light guide member and a light reflective member. The light-transmissive member includes a first region directly above a top surface of the light emitting element, and a second region at a lateral side of the first region. The light guide member covers a lateral surface of the light emitting element and a bottom surface of the second region of the light-transmissive member. The light reflective member covers an outer surface of the light guide member. The light-transmissive member contains a fluorescent substance and a light scattering material that is not a fluorescent substance. A concentration of the fluorescent substance in the light-transmissive member is higher in the first region than in the second region. A concentration of the light scattering material in the light-transmissive member is higher in the second region than in the first region.

Owner:NICHIA CORP

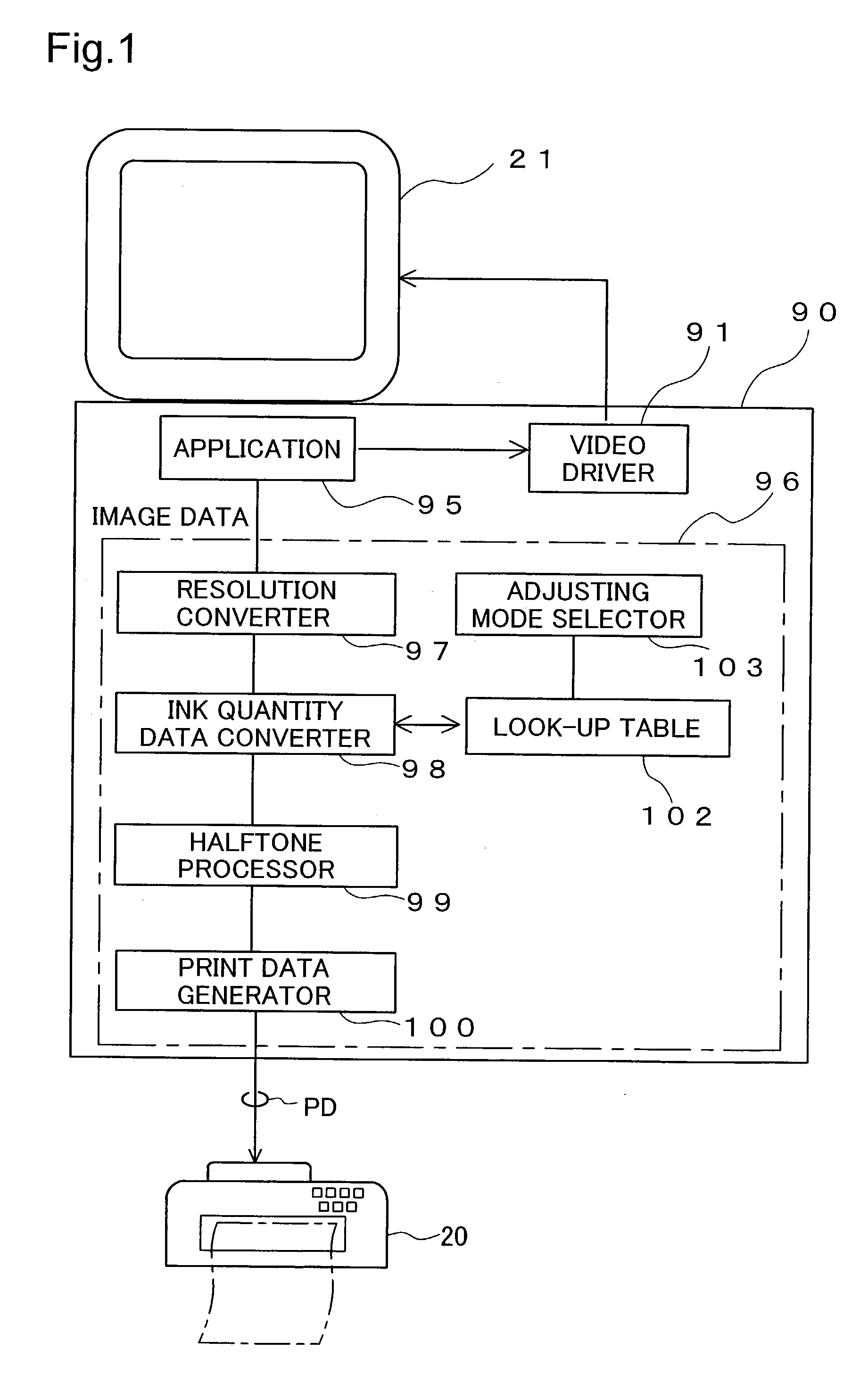

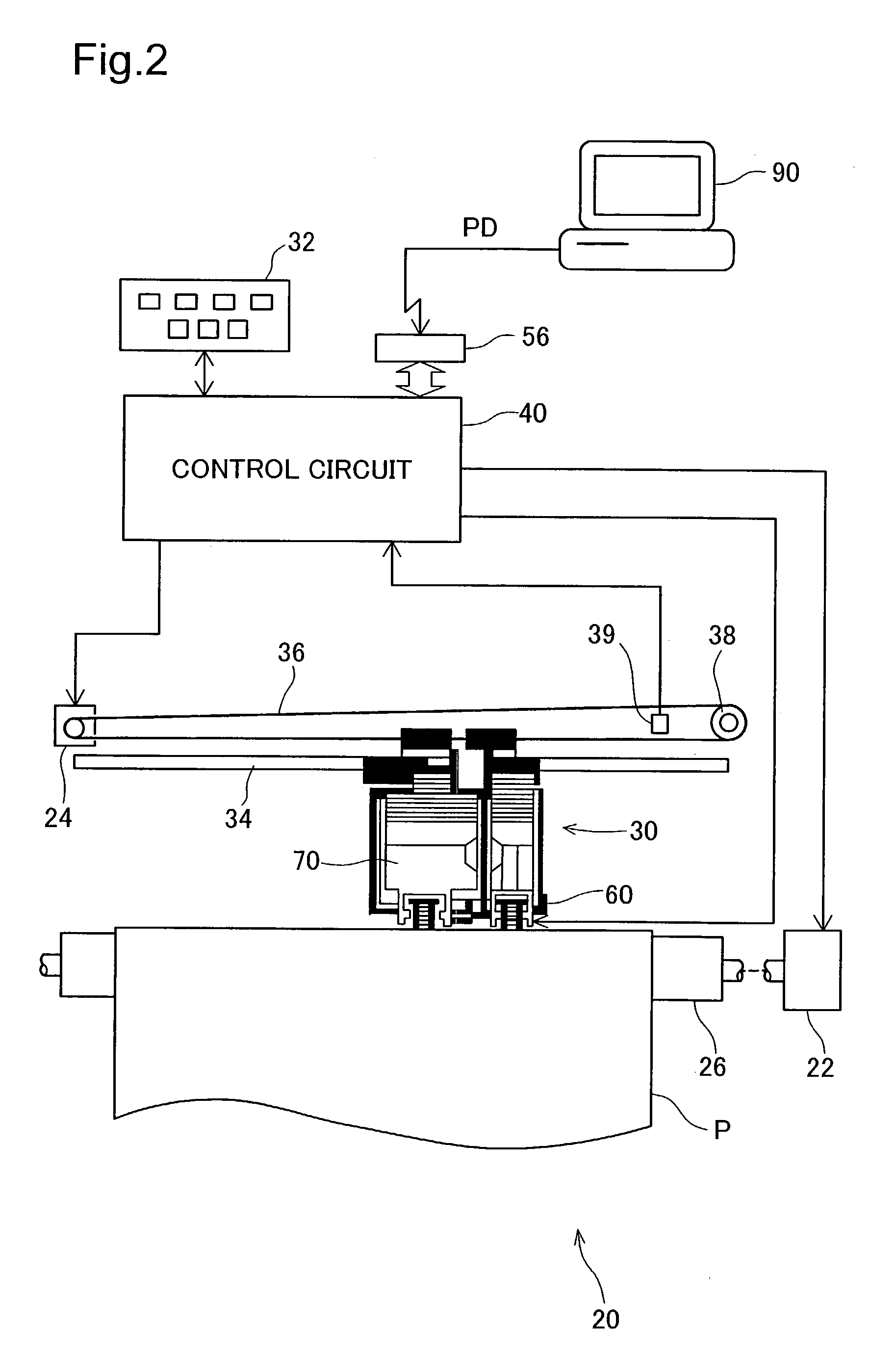

Image printing using print quality enhancing ink

InactiveUS6863374B2Improve image qualityEnhance the imagePrintingImaging qualityPulp and paper industry

Image quality is improved by adjusting the ejection amount of quality enhancing ink based on the ejection amount of colored ink containing colorant. When a relatively high gross printing medium is used, the quality enhancing ink is ejected in an image area where virtually no colored ink is ejected, thereby improving unevenness in gloss within the print image. When a relatively low gross printing medium is used, on the other hand, the quality enhancing ink is ejected in an image area where the colored ink is ejected on virtually all pixels, thereby improving unevenness in color within the print image. The relationship between the ejection amounts of the quality enhancing ink and the colored ink may be modified by the user.

Owner:NEC CORP +1

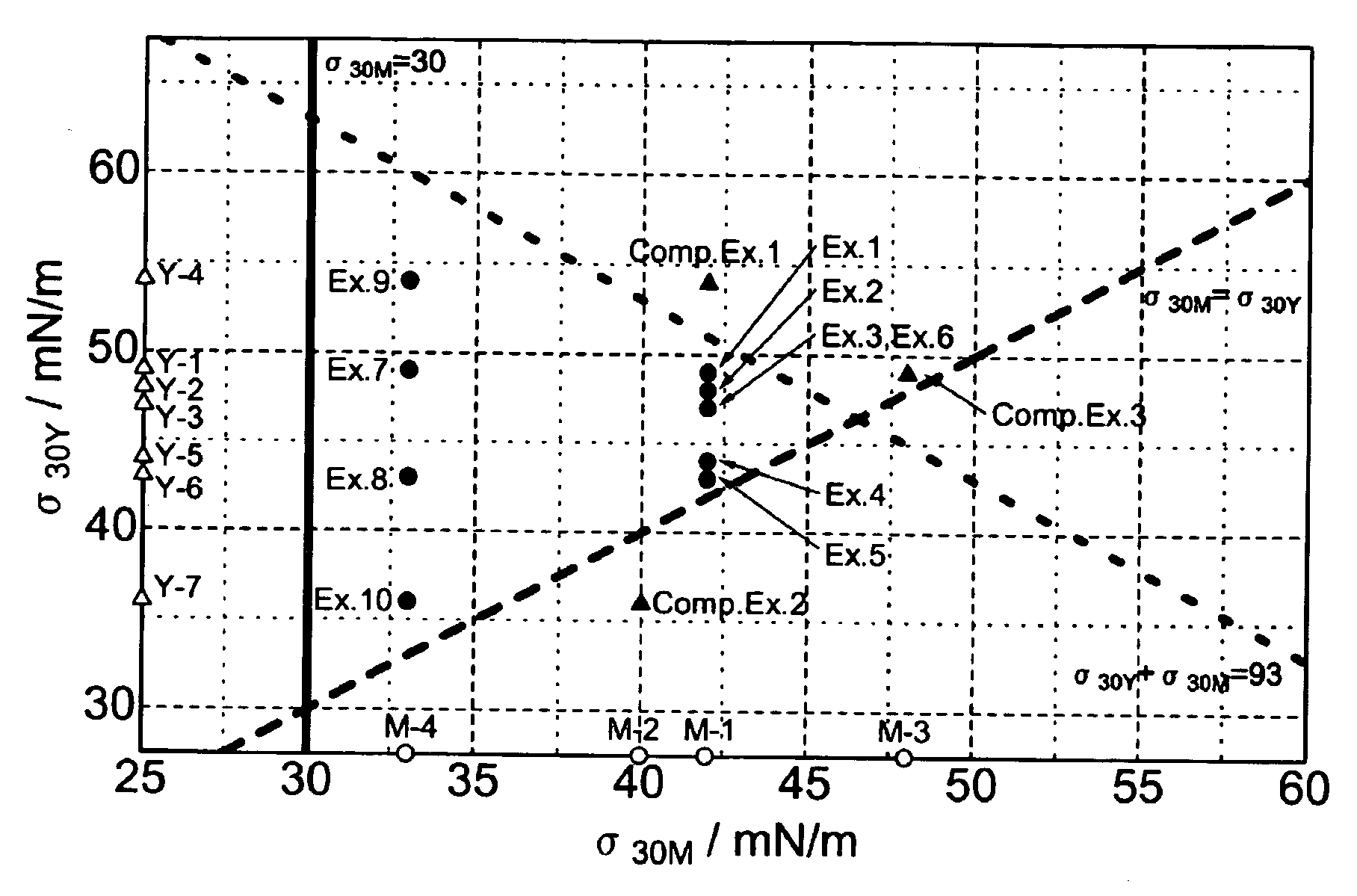

Water-based ink set for ink-jet recording

ActiveUS20070022902A1Reduce both bleedingColor unevennessMeasurement apparatus componentsDuplicating/marking methodsWater basedMagenta

Provided is a water-based ink set for ink-jet recording for reducing bleeding between a black (Bk) ink and a yellow (Y) ink and for reducing color unevenness in a portion formed by color mixing of color inks. The water-based ink set for ink-jet recording includes at least a Bk ink, a Y ink, a magenta (M) ink and a cyan (C) ink. In this configuration, the following relationships are satisfied: (1) σ1000Bk≧35 mN / m; (2) |σ30Y−σ30Bk|≦5 mN / m; (3) σ30M≧30 mN / m, σ30C≧30 mN / m; (4) σ30Y>σ30M, σ30Y>σ30C; and (5) σ30Y+σ30M≦93 mN / m, σ30Y+σ30C≦93 mN / m, wherein σ30Bk, σ30Y, σ30M and σ30C are dynamic surface tensions of the Bk ink, the Y ink, the M ink and the C ink, respectively, at a lifetime of 30 ms as measured by a maximum bubble pressure method at a measurement temperature of 25° C., and σ1000Bk is a dynamic surface tension of the black ink at a lifetime of 1,000 ms as measured by the maximum bubble pressure method at a measurement temperature of 25° C.

Owner:BROTHER KOGYO KK

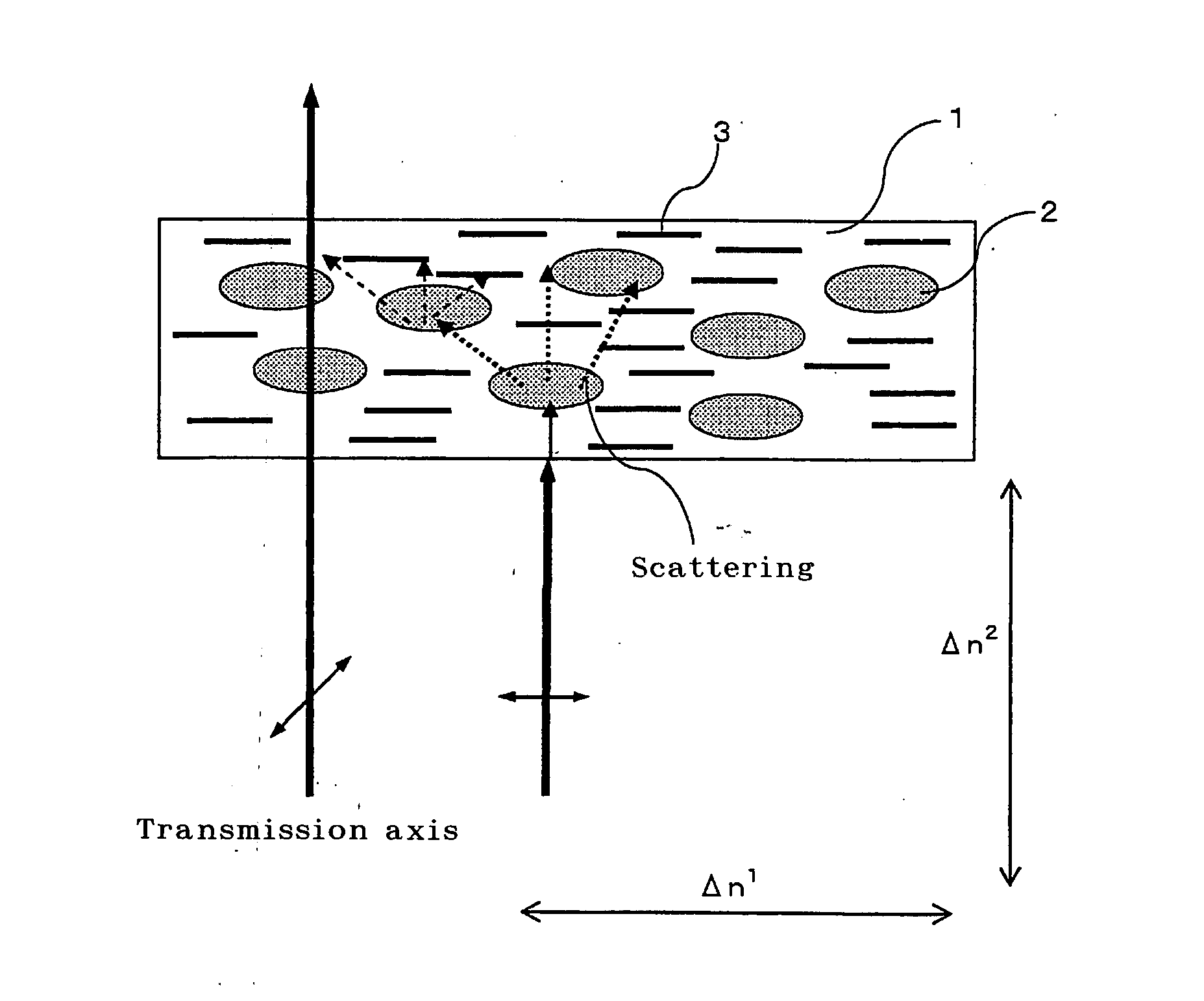

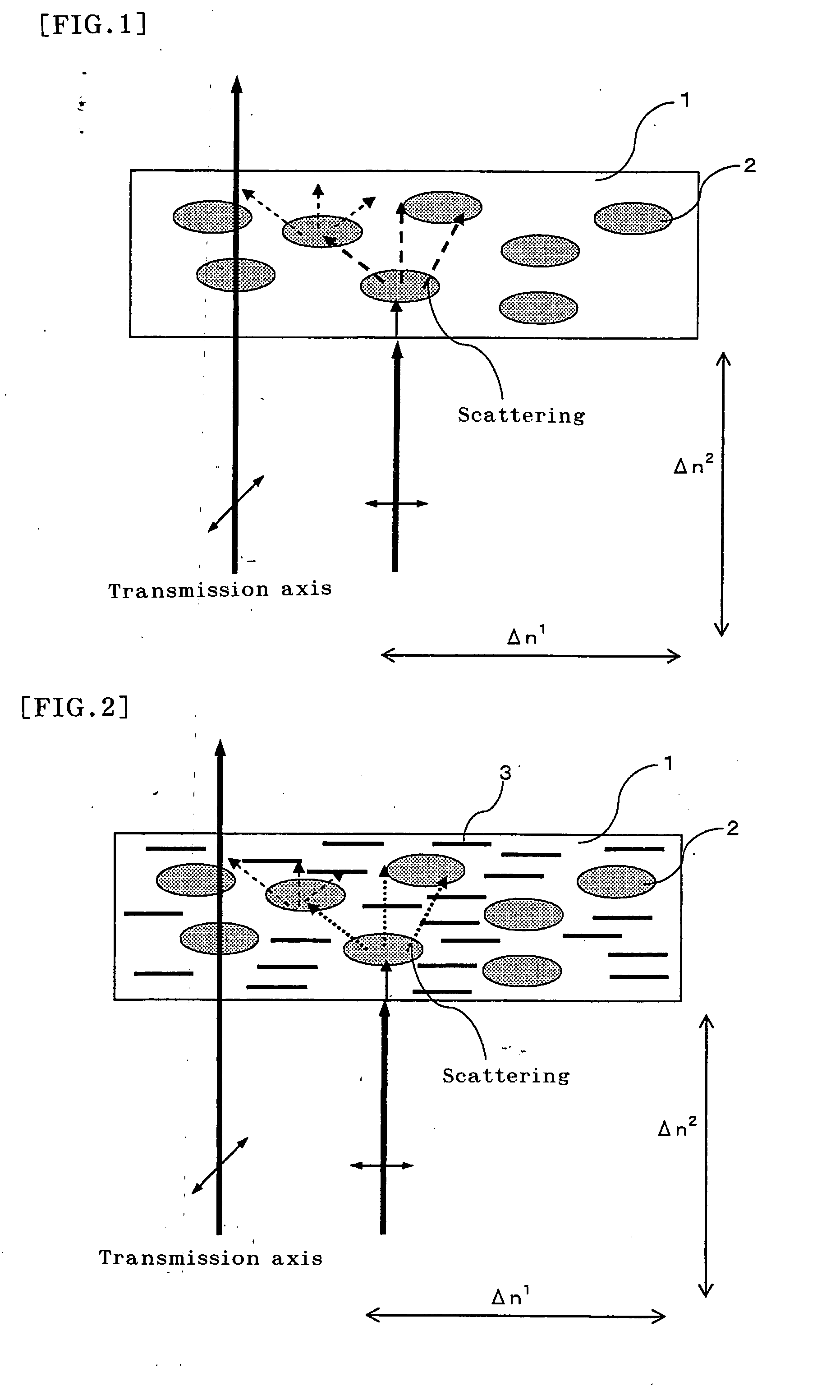

Polarization optical article in which uneven coloring by polarization color has been improved

ActiveUS20120250142A1Improvement in uneven polarization coloringImprove visibilityNon-linear opticsOptical partsOptoelectronicsPolarizer

An object of the present invention is to improve uneven coloring by polarization color due to birefringence of a polarization optical article.Disclosed is a polarization optical article in which uneven coloring by polarization color has been improved, the polarization optical article being a multi-layered polarization optical article including at least a linear polarization functional portion, a retardation functional portion and a back-up resin portion, characterized in that the linear polarization functional portion, the retardation functional portion and the back-up resin portion are arranged in order from an objective side toward an ocular side. The linear polarization functional portion is, for example, a linear polarizer, the retardation functional portion is, for example, a retardation sheet, and the retardation functional portion has, for example, a retardation of 1,000 nm or more. The back-up resin is a polycarbonate resin, a polyamide resin or the like.

Owner:SWANS

Color filter ink, color filter ink set, color filter, image display device, and electronic device

InactiveUS20090189128A1Good uniformityColor unevennessOptical filtersInksColor filter arrayBoiling point

A color filter ink is adapted to be used to manufacture a color filter by an inkjet method. The color filter ink includes a pigment, a dispersing agent and a liquid medium. The pigment includes a halogenated phthalocyanine zinc complex and a pigment derivative represented by a prescribed chemical formula. The dispersing agent disperses the pigment. The liquid medium, in which the pigment is dispersed, includes at least a first liquid and a second liquid different than the first liquid. A boiling point at atmospheric pressure of the first liquid is 180 to 290° C. A content ratio of the second liquid in the color filter ink is 5 to 20 wt %. A relationship |SP (X)−SP (Y)|≦0.8 is satisfied, wherein a value SP (X) indicates a solubility parameter for the dispersing agent, and a value SP (Y) indicates a solubility parameter for the second liquid.

Owner:SEIKO EPSON CORP

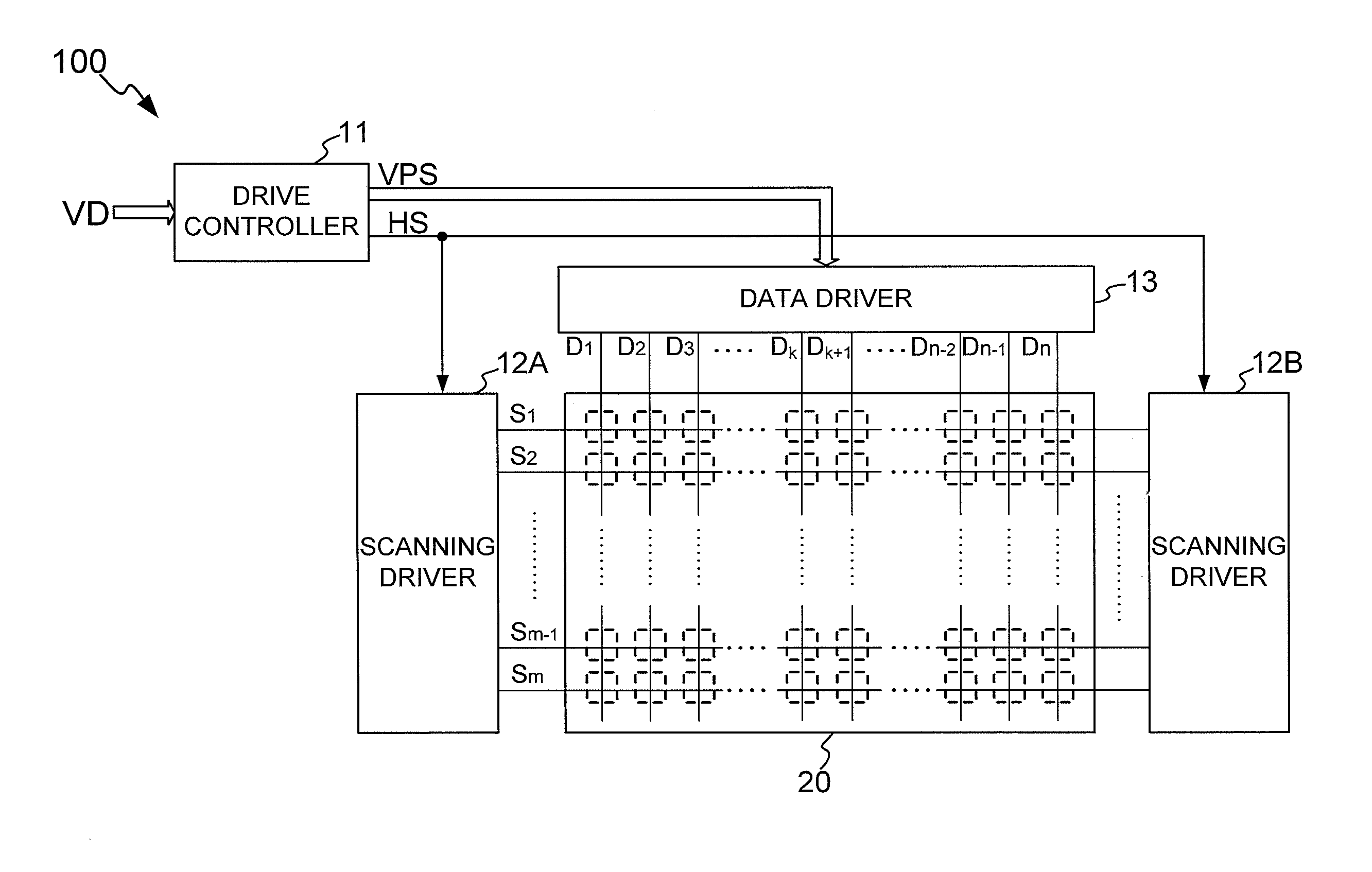

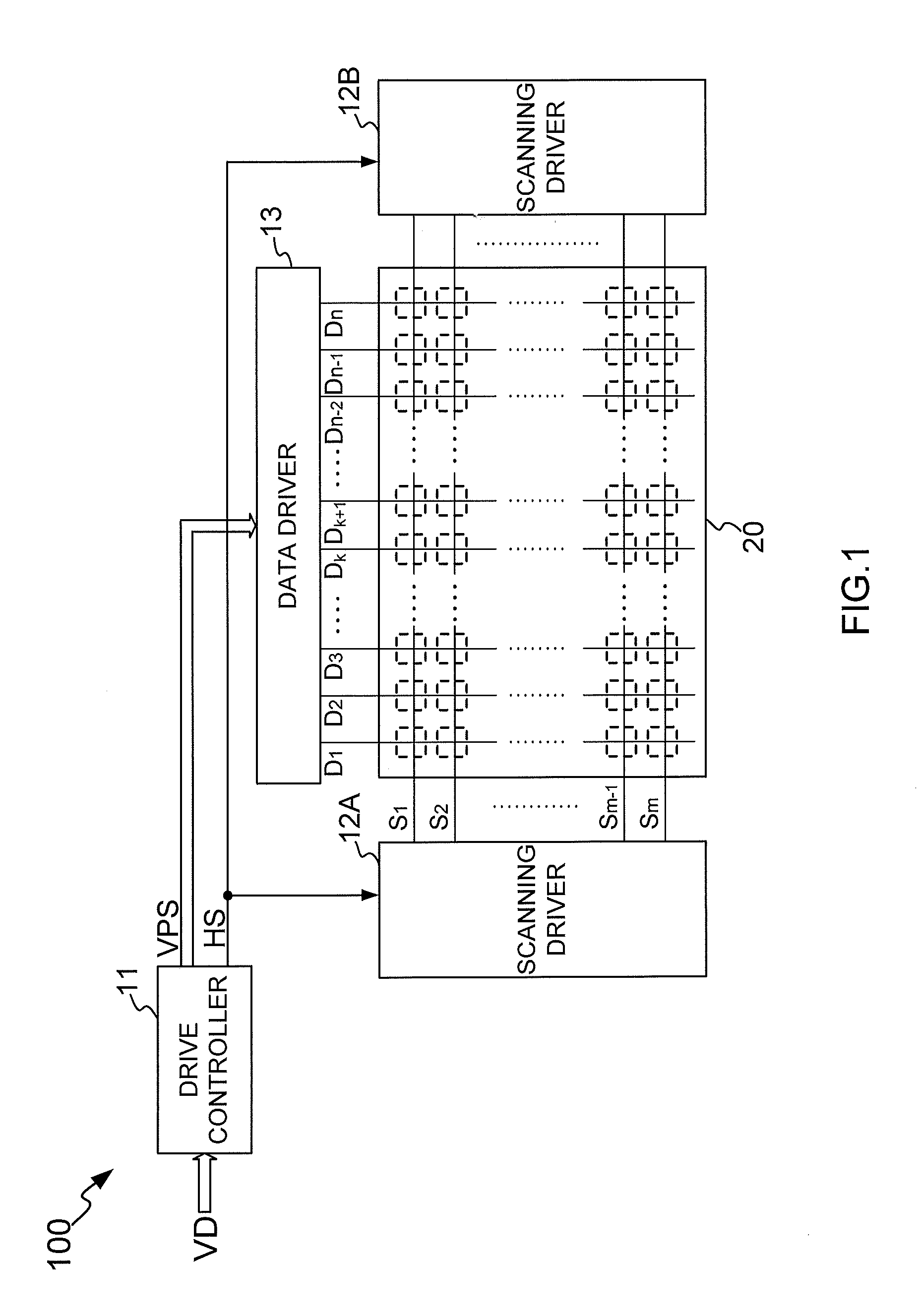

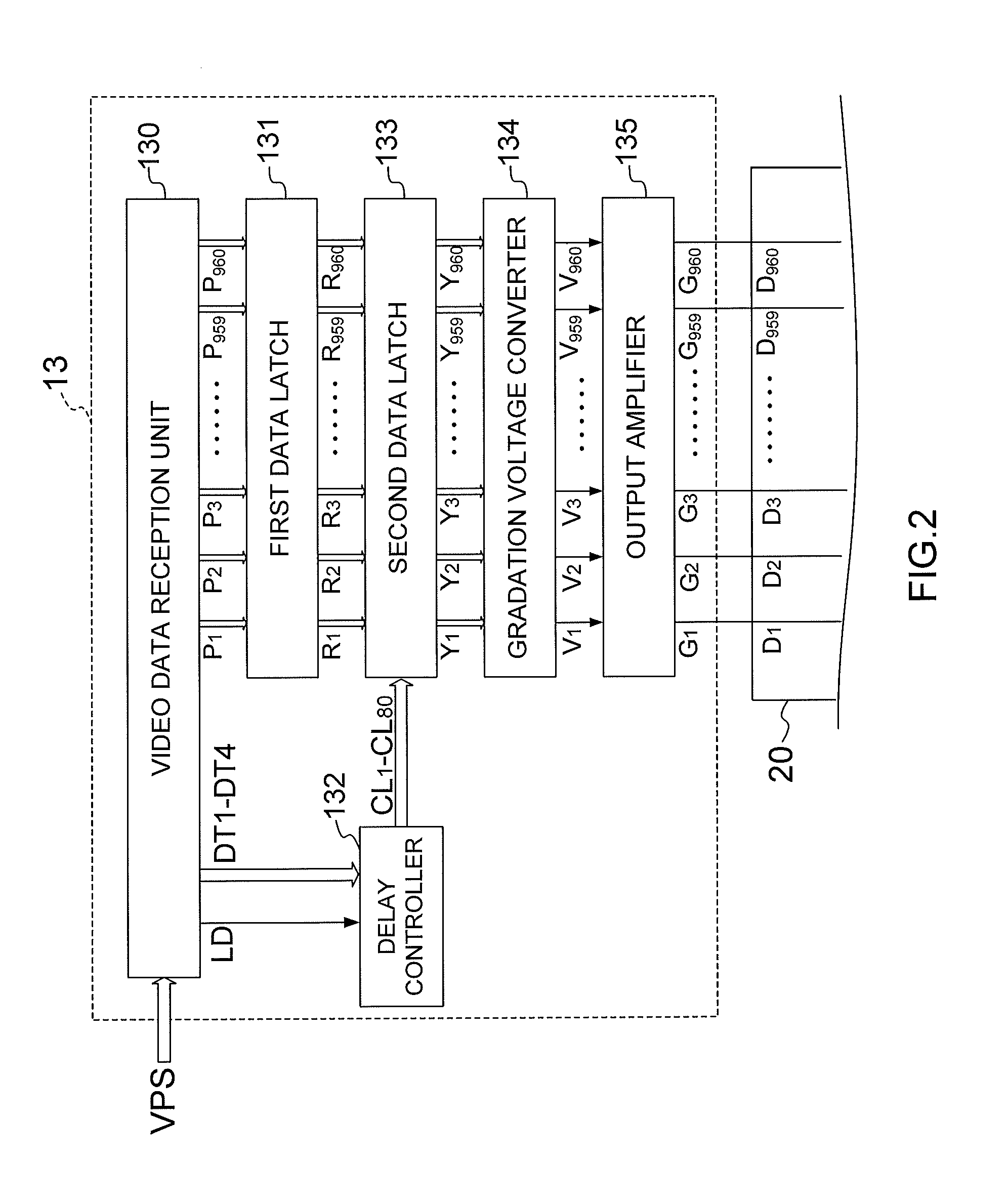

Display device driver

ActiveUS20170011703A1Enhance the imageColor unevennessStatic indicating devicesDisplay devicePixel based

A display device driver includes: a pixel drive voltage application unit; and a delay controller. The pixel drive voltage application unit converts a plurality of pixel data pieces into a plurality of pixel drive voltages, the pixel data pieces respectively representing luminance levels of respective pixels based on a video signal, the pixel drive voltages respectively having voltage values corresponding to the luminance levels, and applies the converted pixel drive voltages to the display device. The delay controller controls the pixel drive voltage application unit to apply the plurality of pixel drive voltages to the display device, the plurality of pixel drive voltages being sequentially delayed in units of groups, the groups each including t pixel drive voltages, and sets delay time designated by delay time designation signals as delay time to delay each of the pixel drive voltages.

Owner:LAPIS SEMICON CO LTD

Color filter ink, color filter, image display device, and electronic device

InactiveUS20090073356A1Improve discharge stabilityImprove uniformityDuplicating/marking methodsOptical filtersEpoxyPolymer science

A color filter ink is adapted to be used to manufacture a color filter by an inkjet method. The color filter ink includes a colorant, a resin material, and a liquid medium that dissolves and / or disperses the colorant. The resin material includes a first polymer and a second polymer. The first polymer includes at least a first epoxy-containing vinyl monomer as a monomer component, and the second polymer includes at least a fluoroalkyl- or fluoroaryl-containing vinyl monomer as a monomer component, which is absent from the first polymer.

Owner:SEIKO EPSON CORP

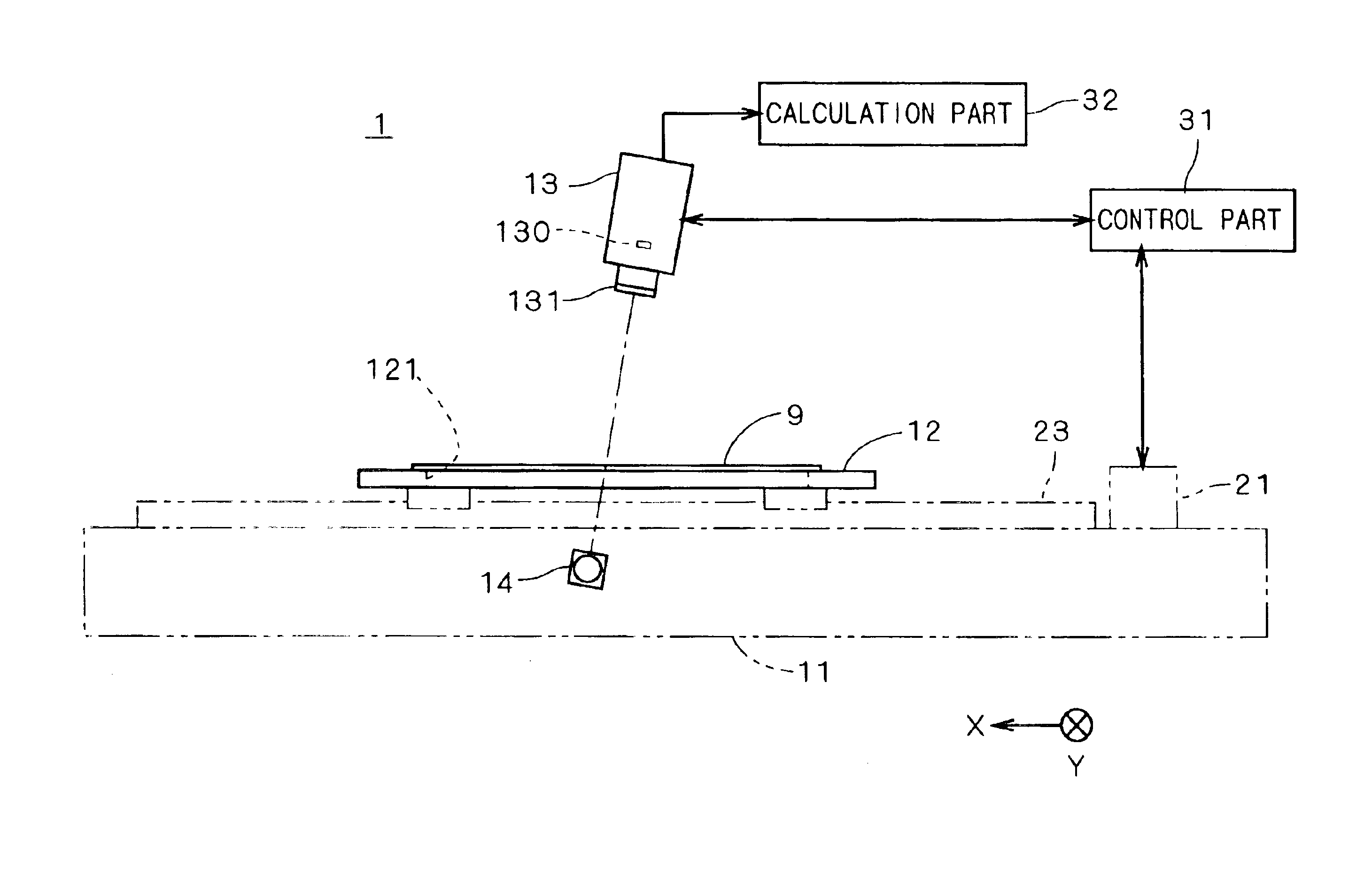

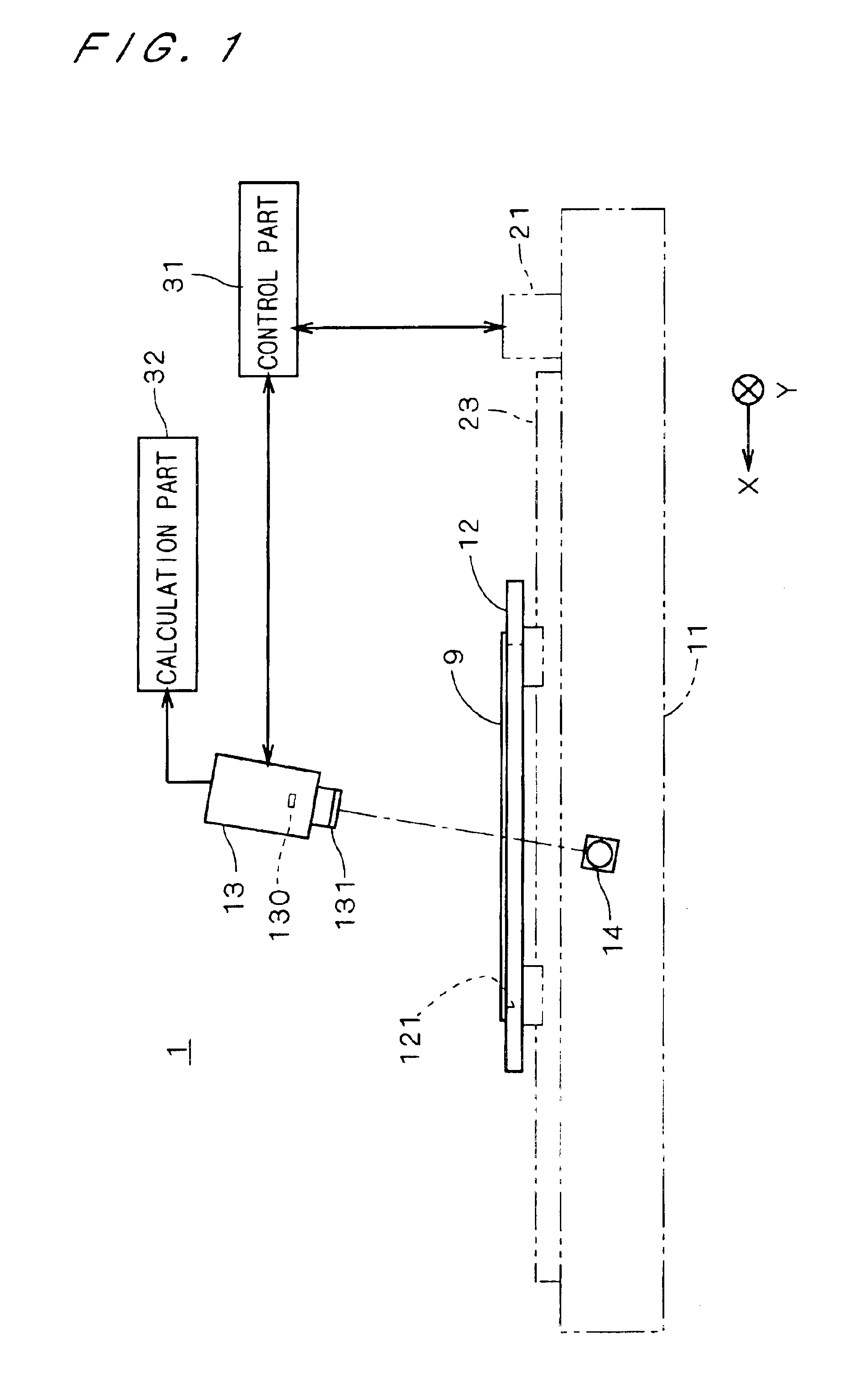

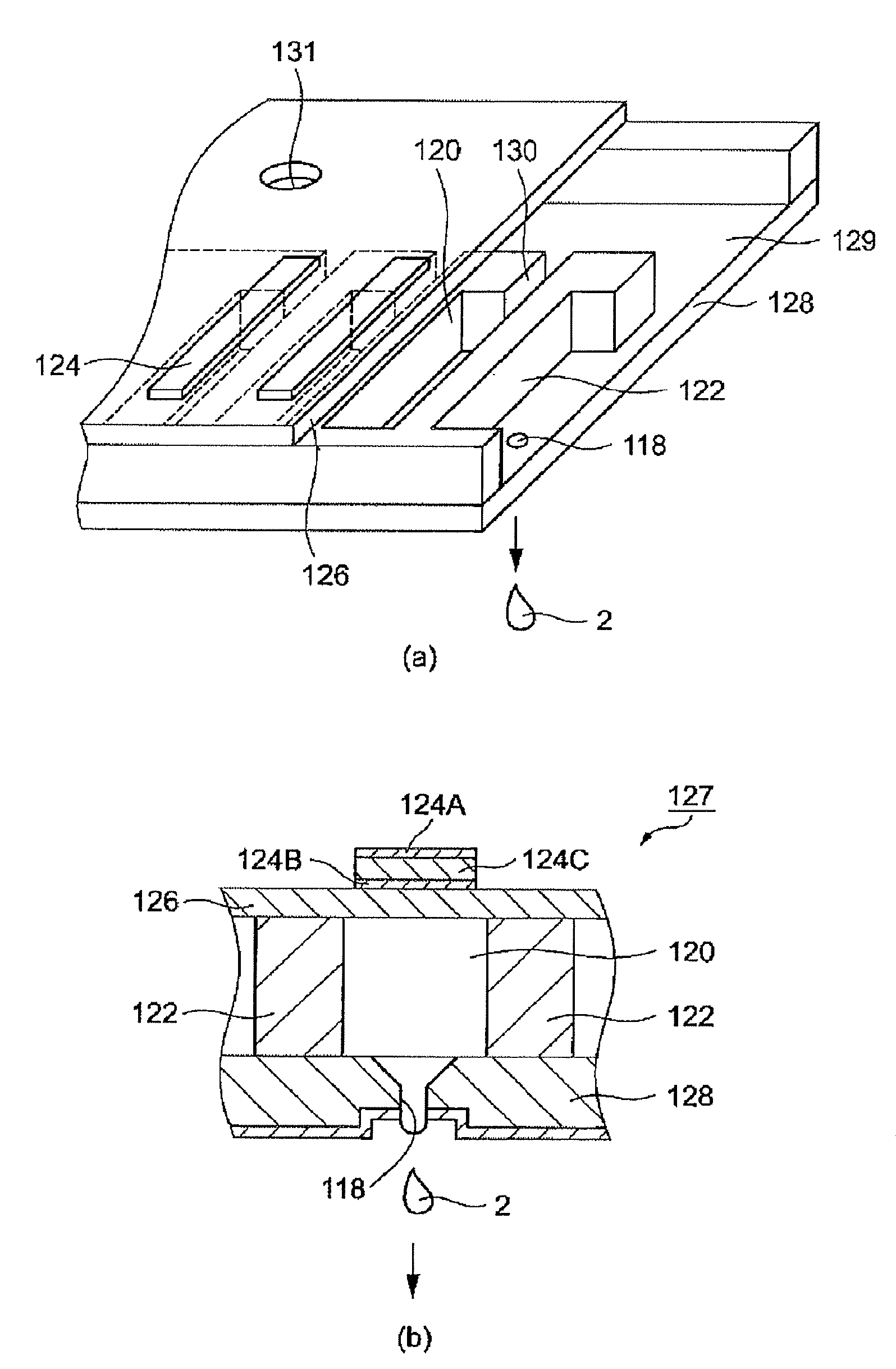

Color filter inspection apparatus

InactiveUS6842240B2Easy to checkImprove accuracyOptically investigating flaws/contaminationOptical apparatus testingLine sensorFluorescence

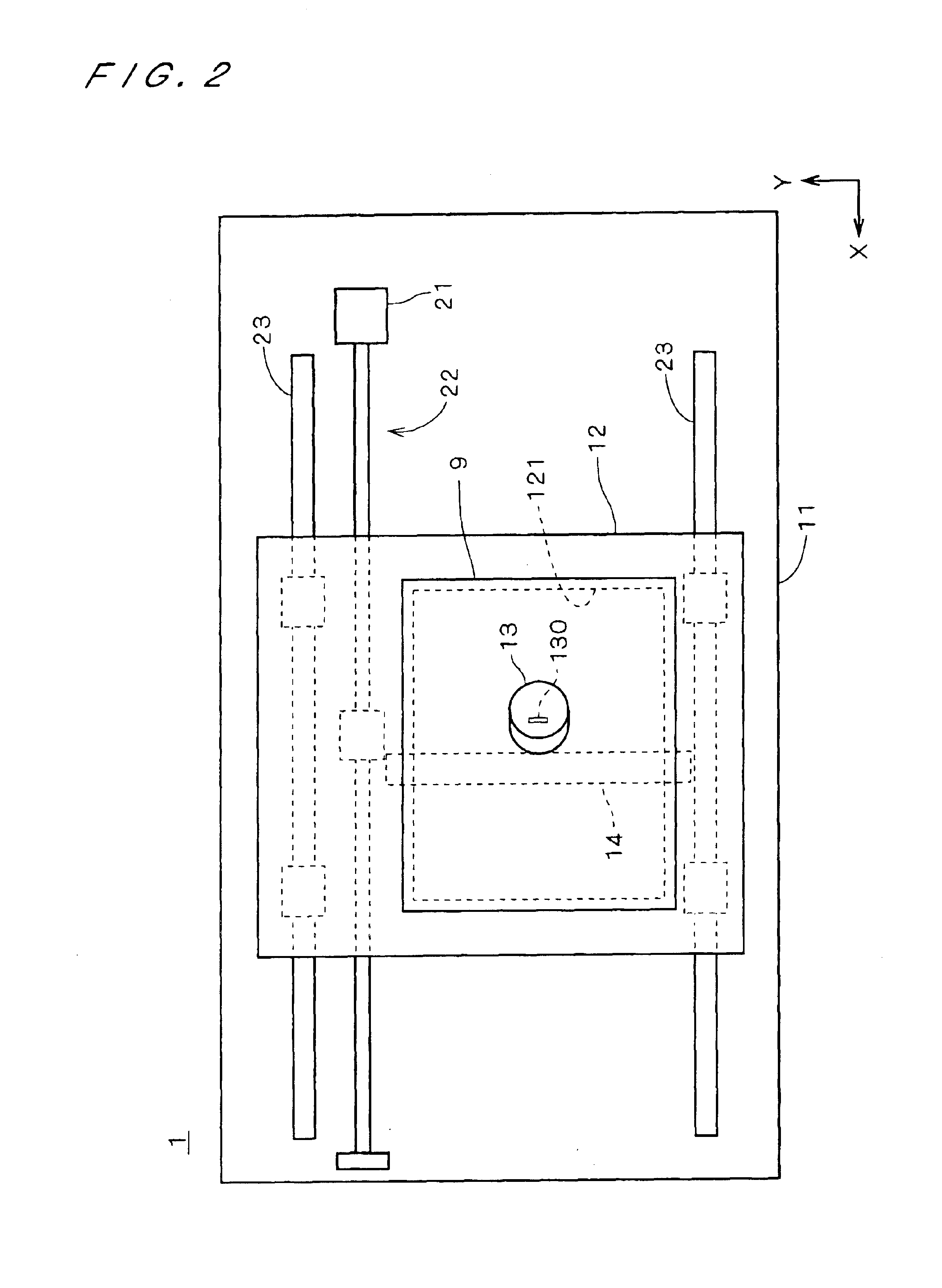

In a color filter inspection apparatus (1), an image pickup part (13) for performing an image pickup of a color filter (9) which travels along guide rails (23) from above with a line sensor (130) and a fluorescence lamp (14) for irradiating the color filter (9) with an illumination light from below are provided and an optical filter (131) which transmits a light in a predetermined wavelength band is attached to the image pickup part (13). A transmission wavelength band of the optical filter (131) is a wavelength band in which the transmittance of one color component filter of the color filter (9) is high and transmittances of other color component filters are low. It is thereby possible to inspect unevenness in color of the color filter (9) with respect to one color component filter with high precision.

Owner:DAINIPPON SCREEN MTG CO LTD

Image processing apparatus, method, and recording medium

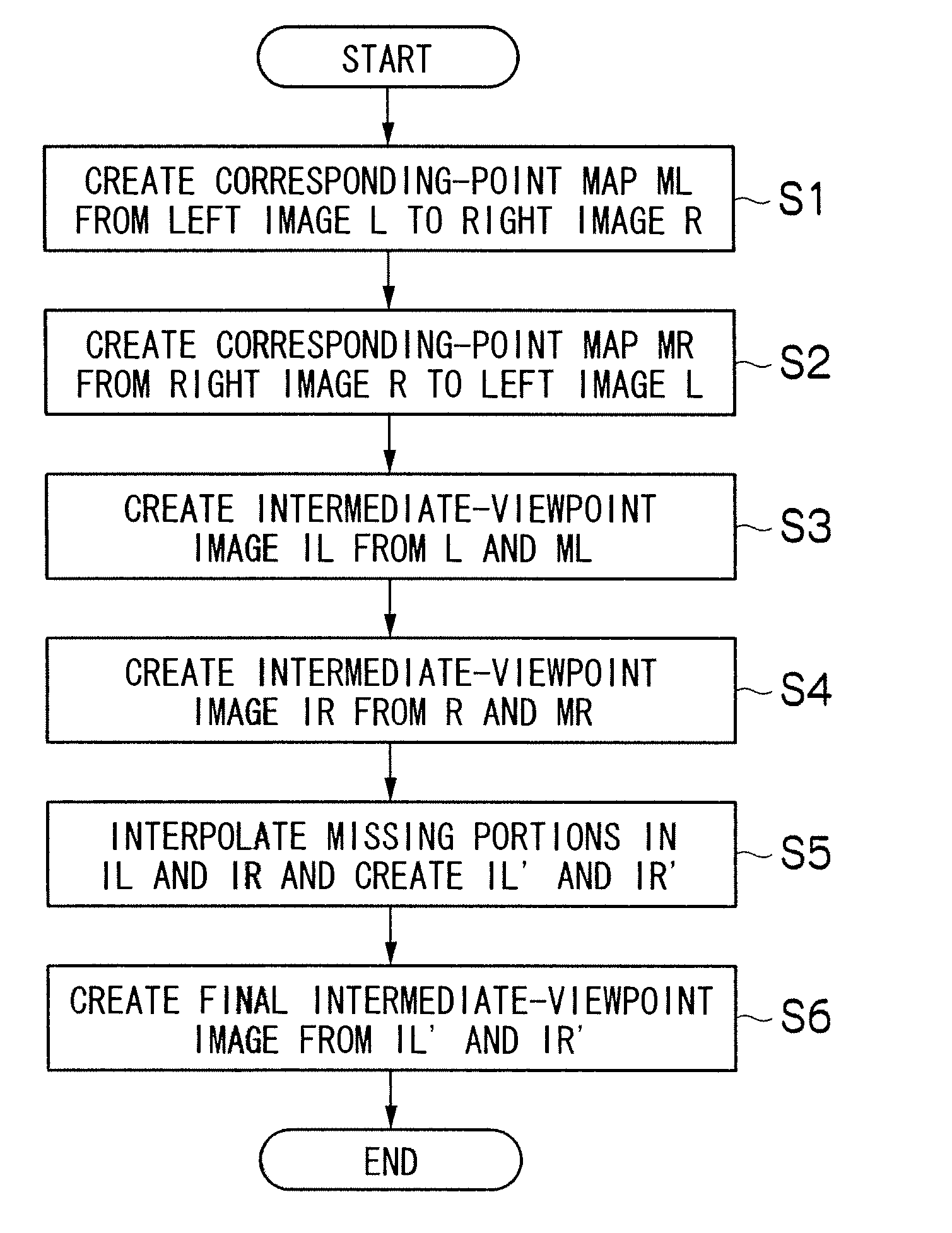

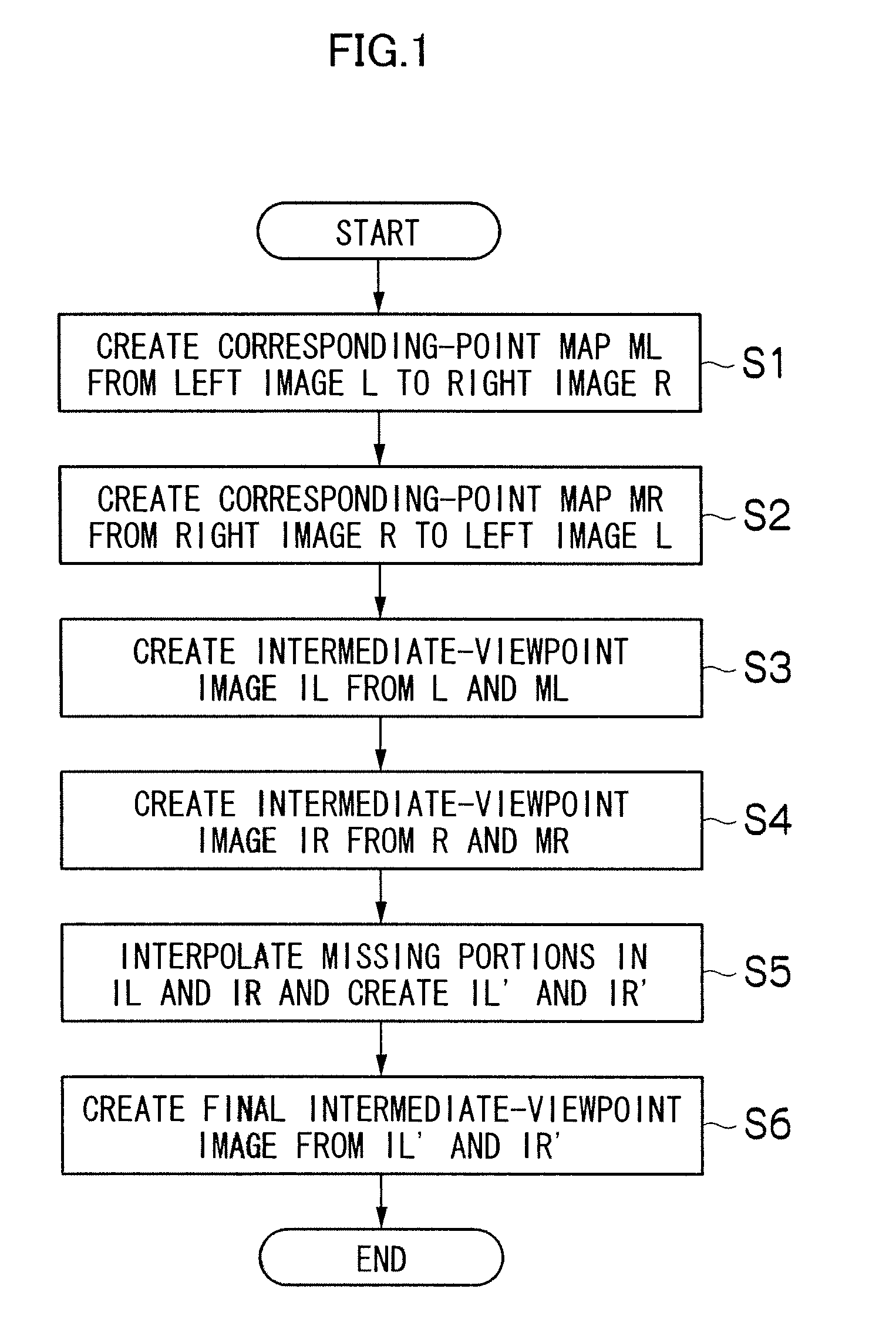

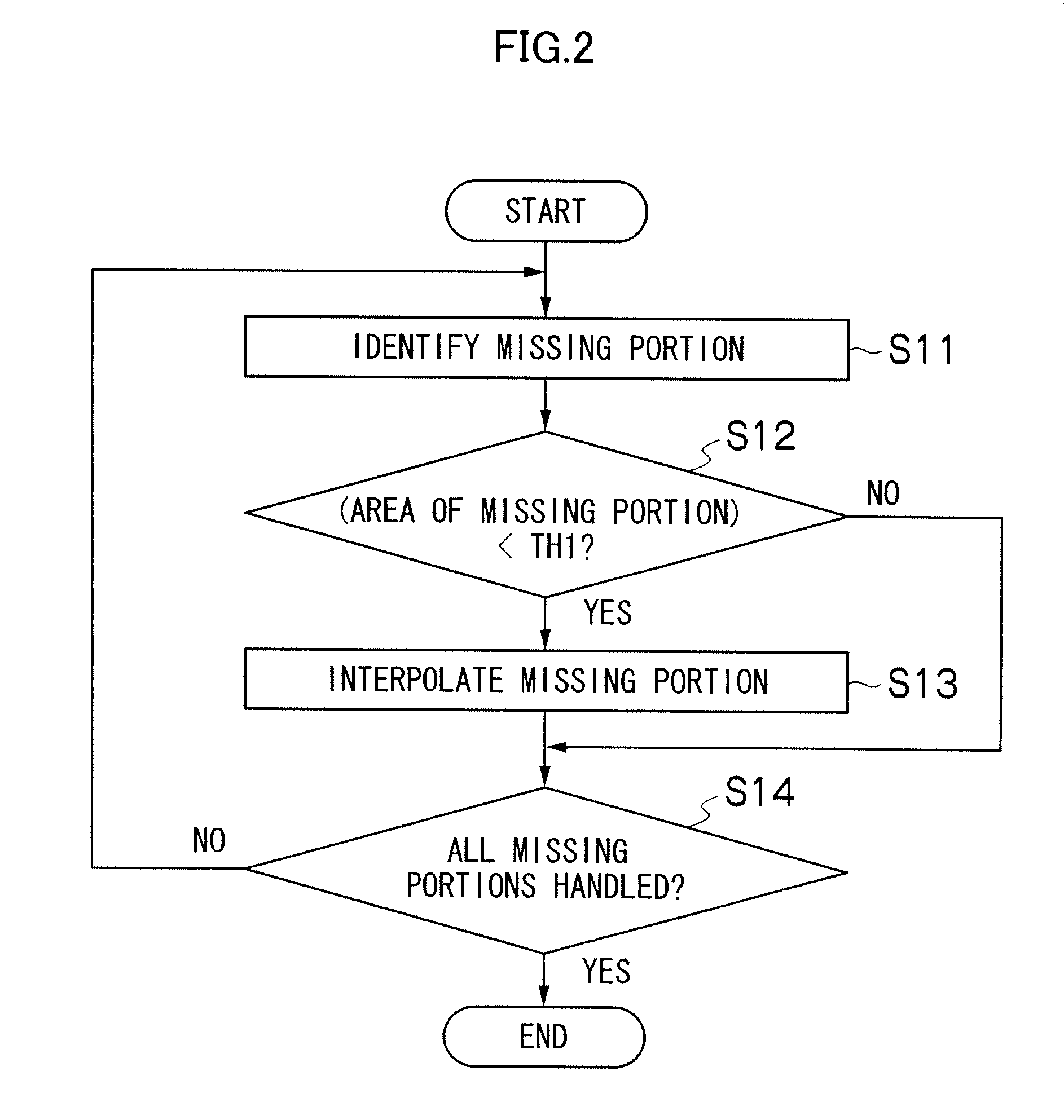

InactiveUS20110080463A1Reduce color unevennessColor unevennessImage enhancementImage analysisImaging processingViewpoints

An image processing method executed in an apparatus, includes steps of: inputting a left-viewpoint image and a right-viewpoint image therebetween to the apparatus; searching for a corresponding point in the right-viewpoint image with respect to the left-viewpoint image, generating a first corresponding-point map based on a result of the searching, and generating a first intermediate-viewpoint image based on the left-viewpoint image; searching for a corresponding point in the left-viewpoint image with respect to the right-viewpoint image, generating a second corresponding-point map based on a result of the searching, and generating a second intermediate-viewpoint image based on the right-viewpoint image; extracting missing portions of pixels in the first and second intermediate-viewpoint images; determining whether a missing portion extracted is a missing portion to be interpolated or not; interpolating the missing portion to be interpolated based on a result of determination; and generating a third intermediate-viewpoint image based on the intermediate-viewpoint images.

Owner:FUJIFILM CORP

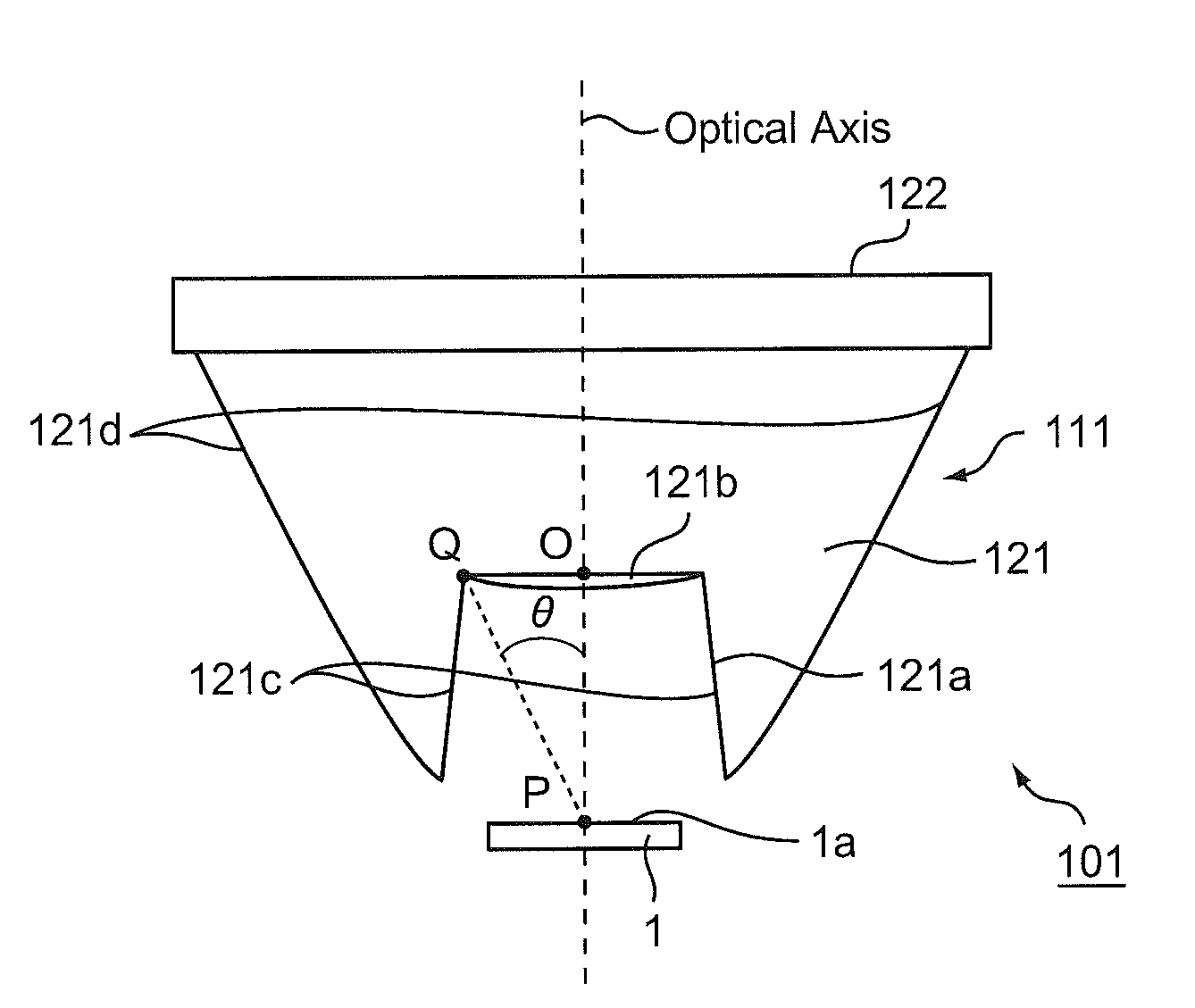

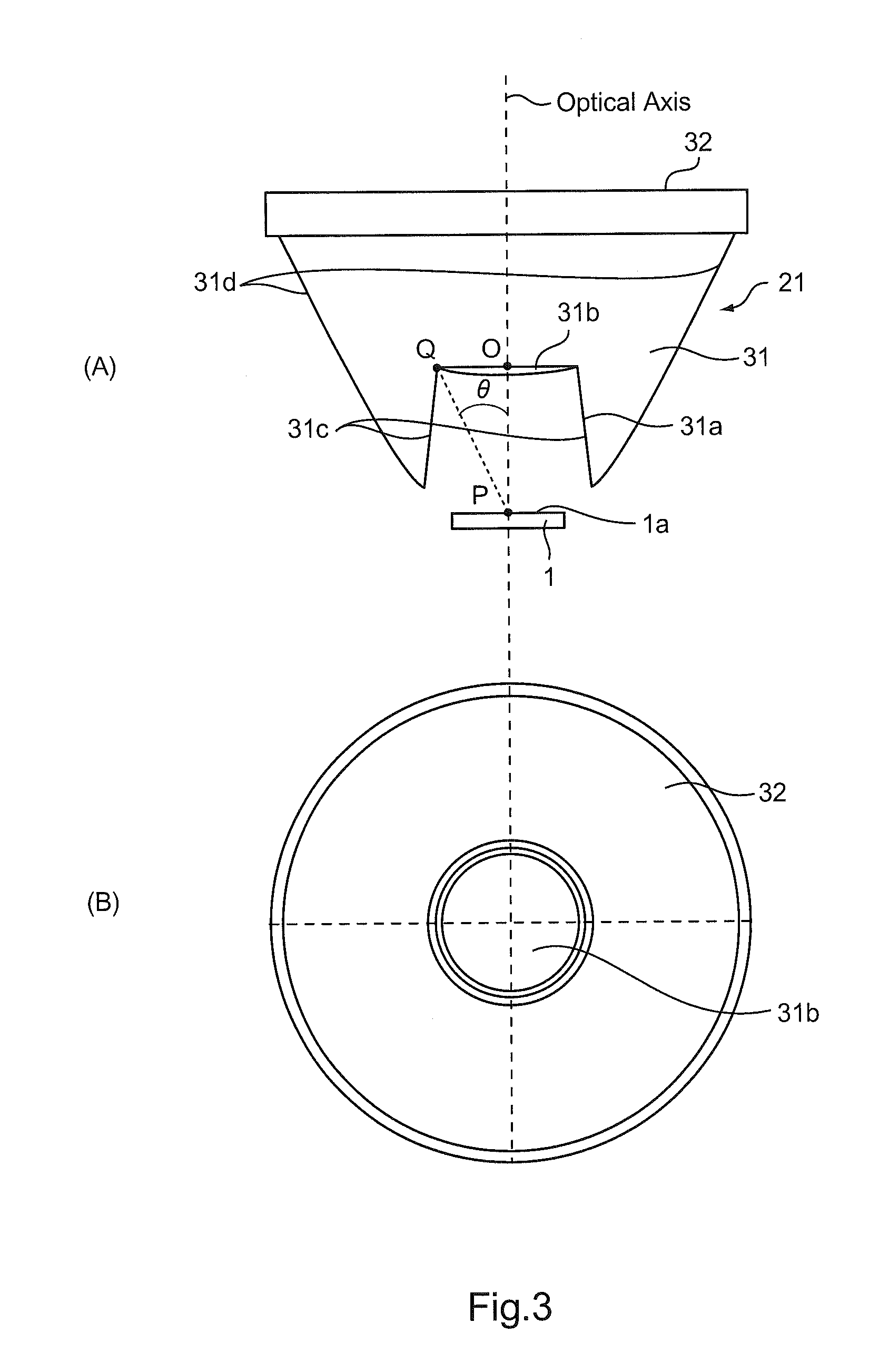

Illumination apparatus and image-taking apparatus

InactiveUS20050264686A1Efficient ConcentrationUneven light distributionTelevision system detailsPoint-like light sourceLight irradiationOptical axis

An illumination apparatus is disclosed, which can efficiently condense light from a light source such as an LED. The illumination apparatus has a light source and an optical member disposed on the side of light irradiation of the light source. The optical member has an incident surface, an emergent surface having a positive optical power, and a reflecting surface reflecting part of light from the incident surface and leading it to the emergent surface. The reflecting surface is formed further away from an irradiation optical axis than a normal to the emergent surface at a position of the emergent surface closest to the reflecting surface.

Owner:CANON KK

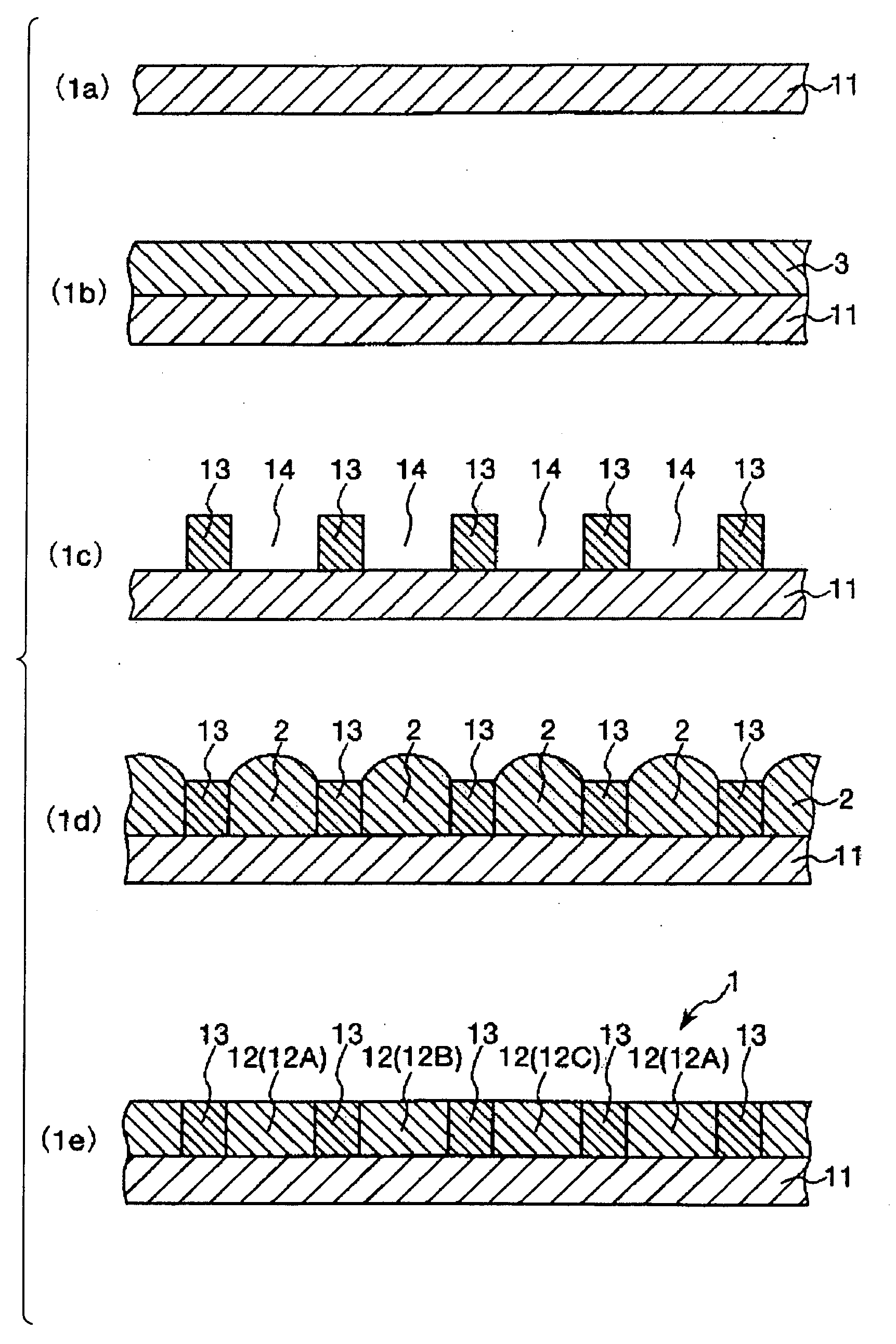

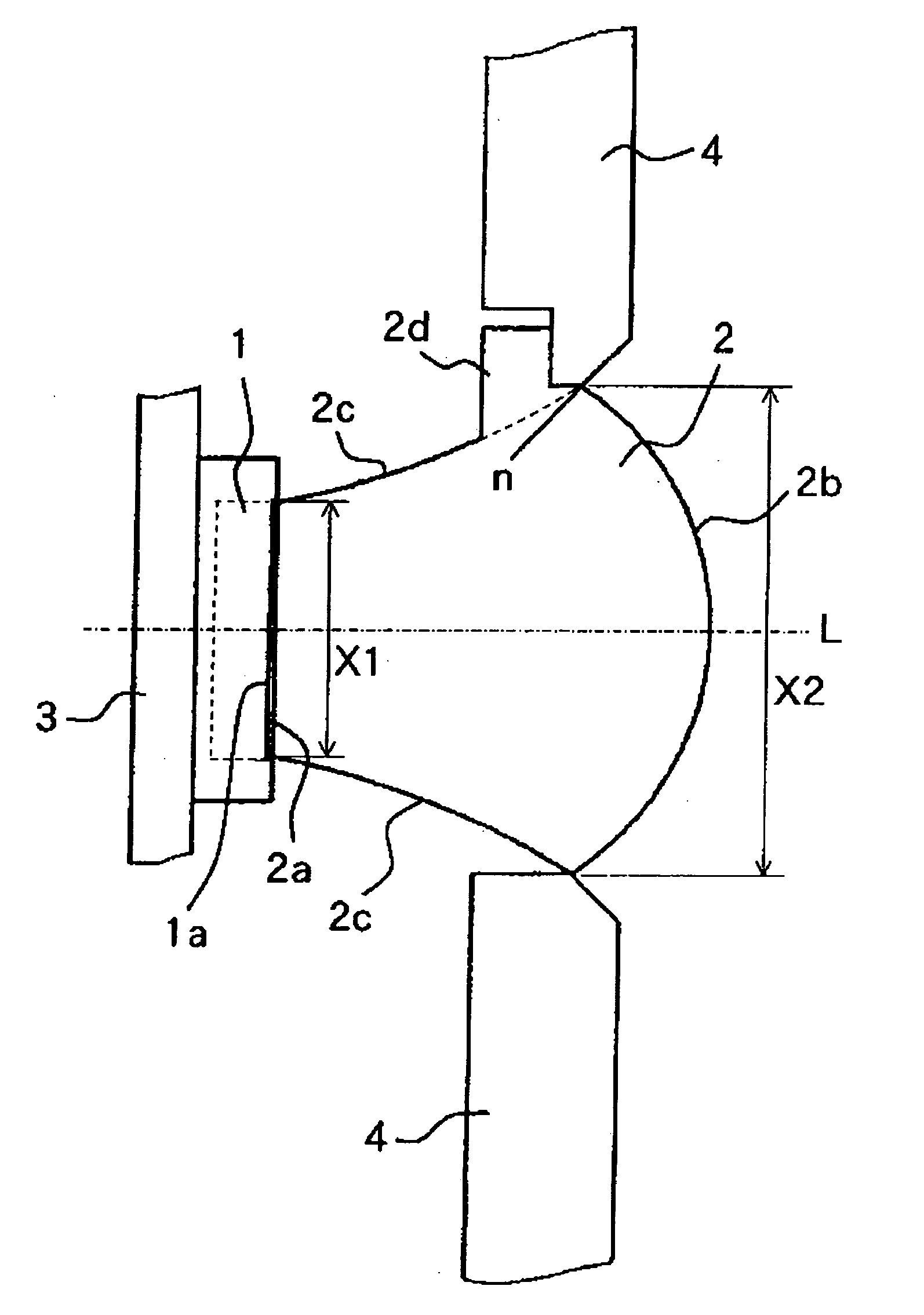

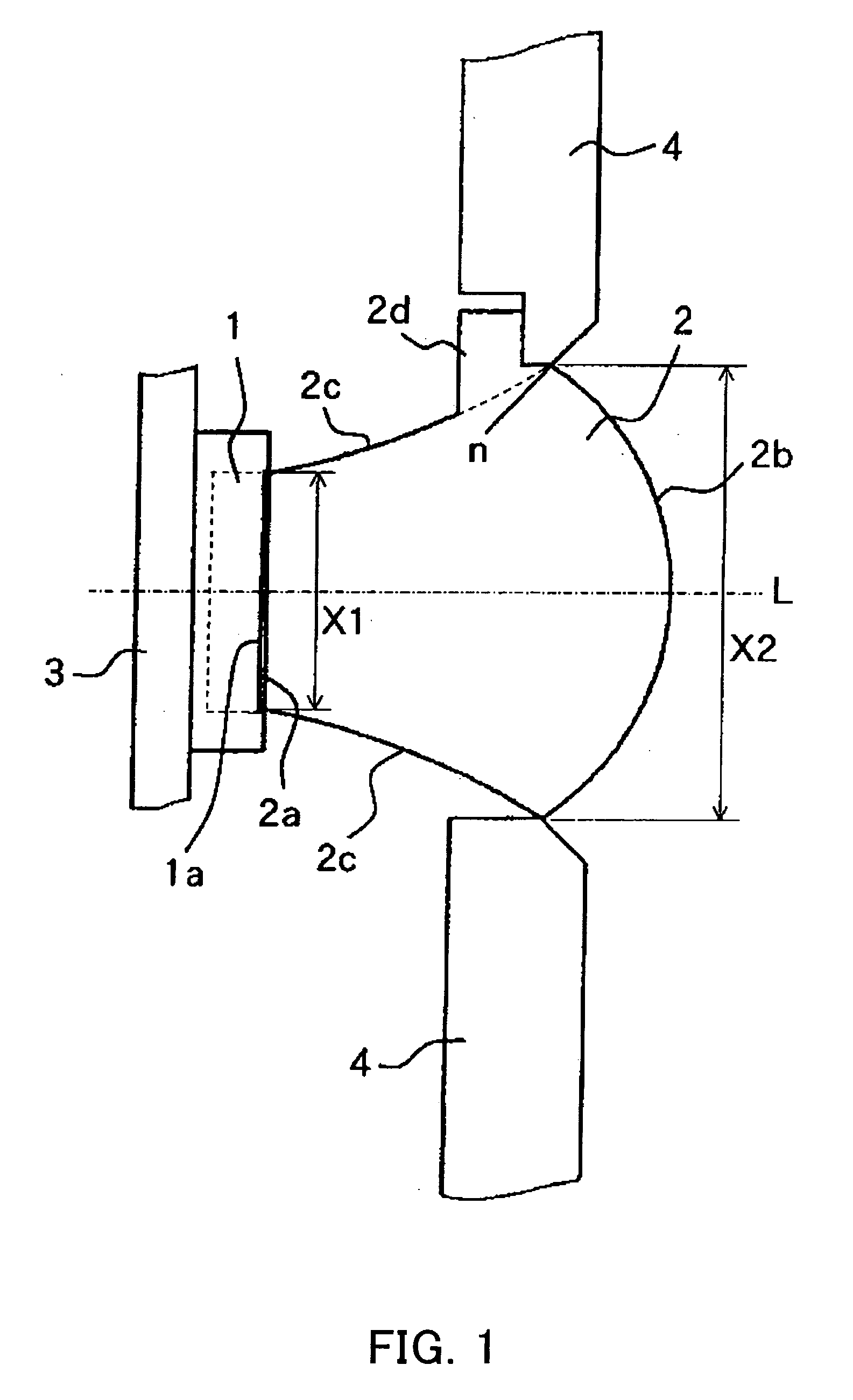

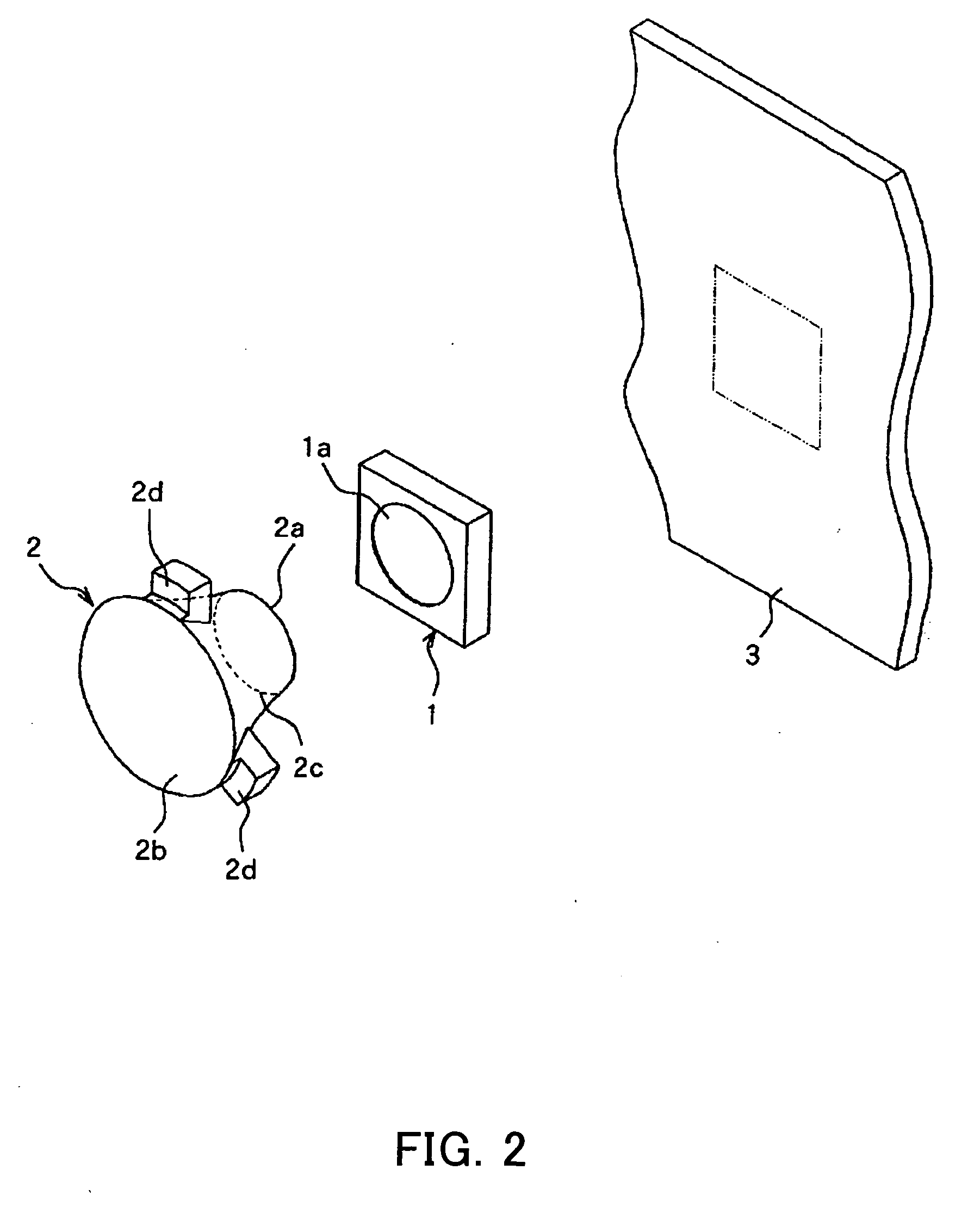

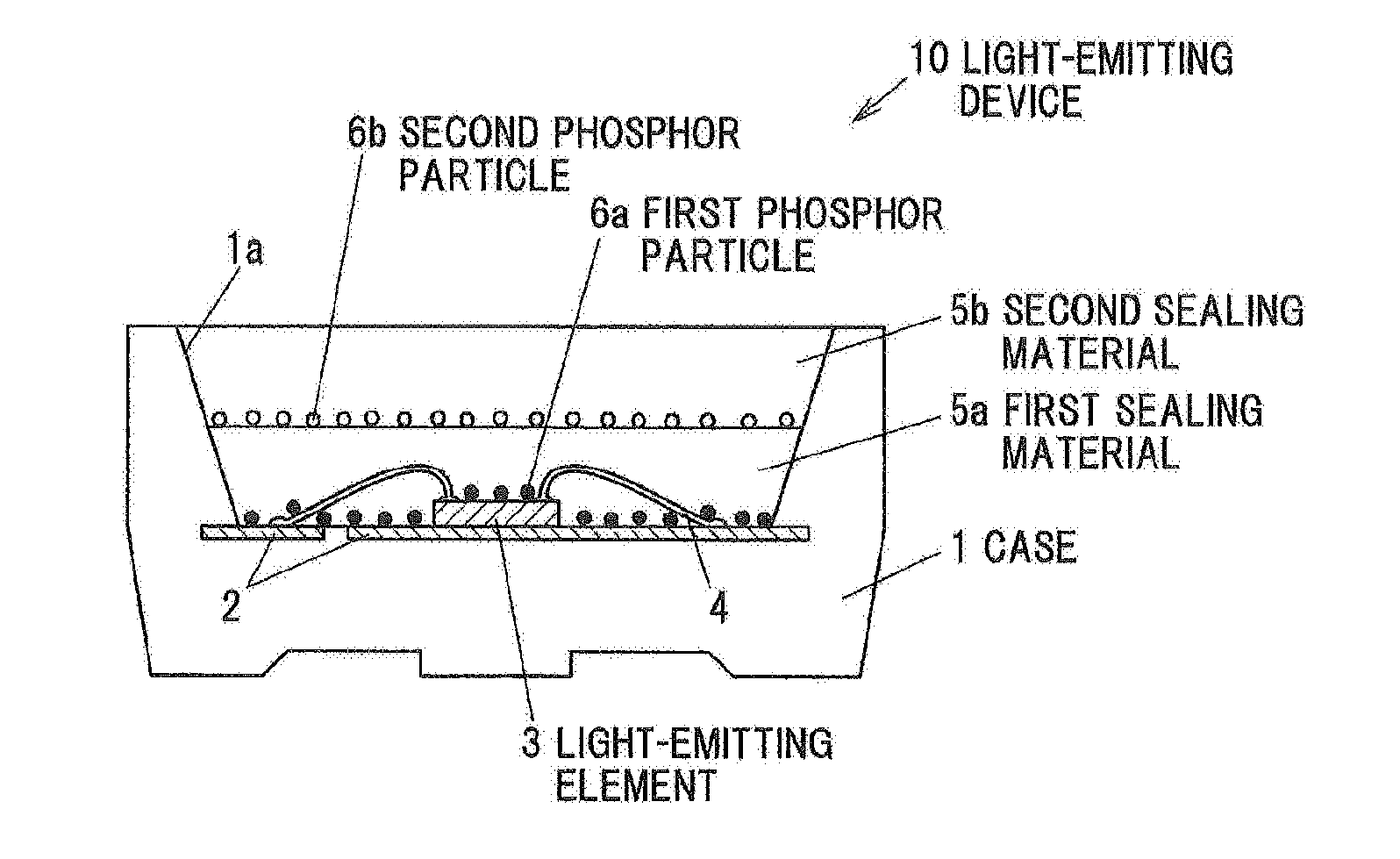

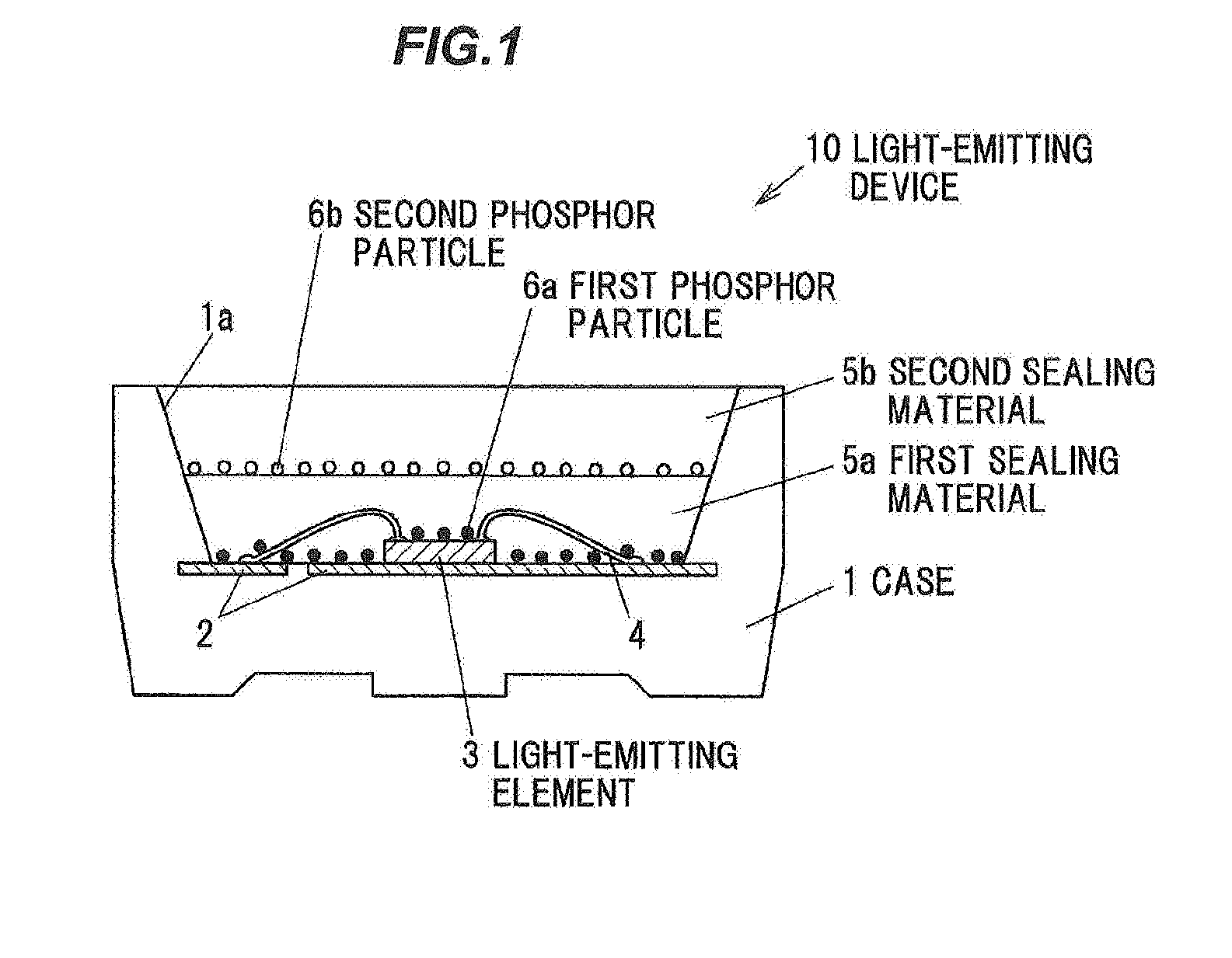

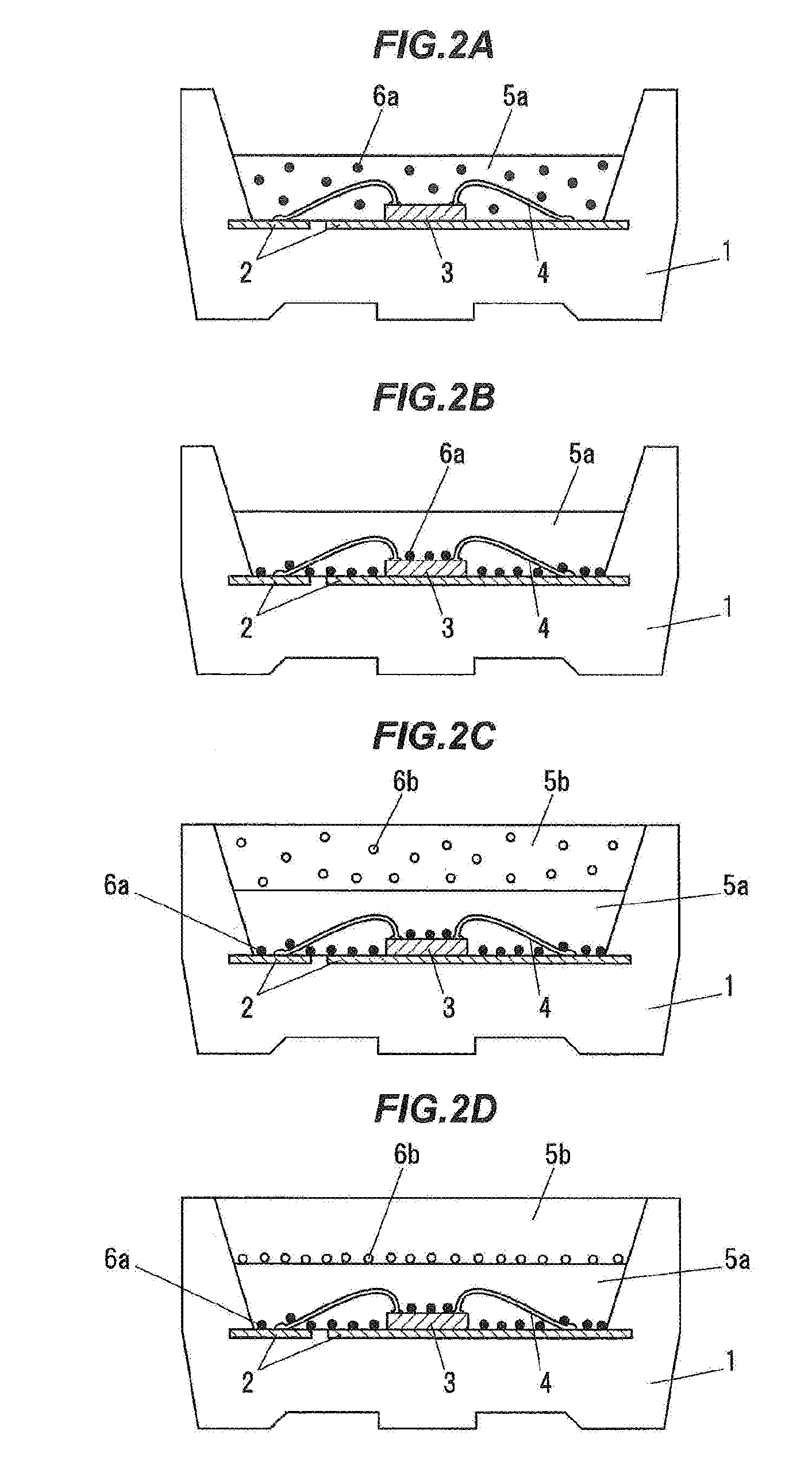

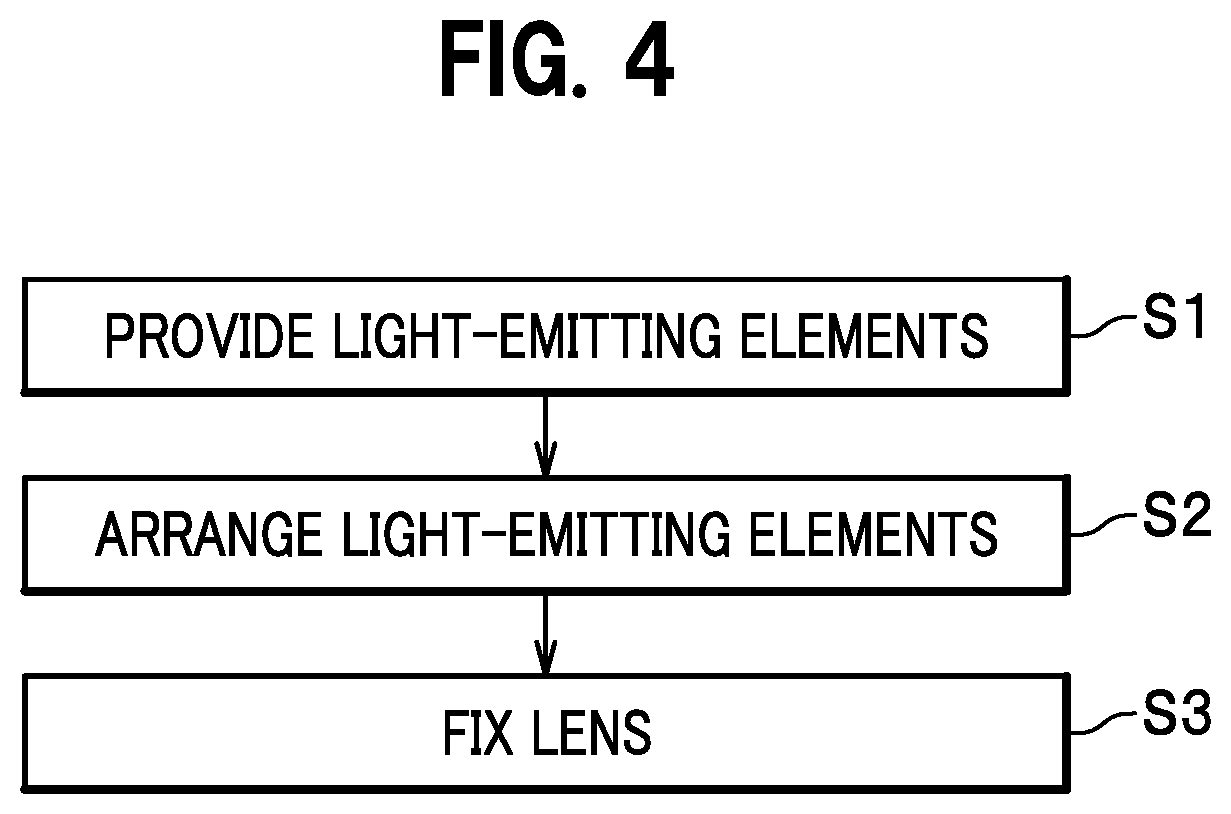

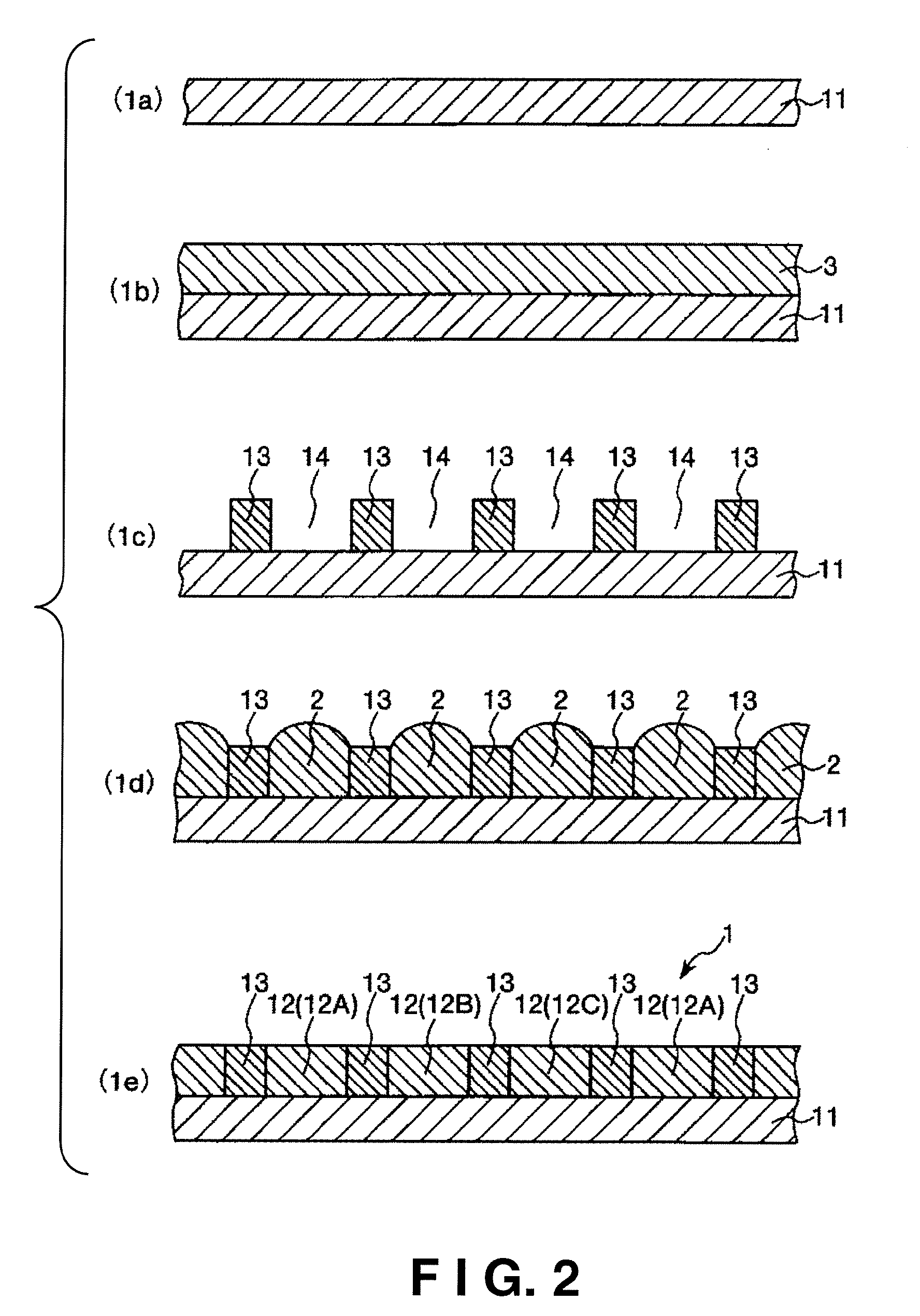

Method of manufacturing light-emitting device

ActiveUS20160268485A1Color unevennessElectroluminescent light sourcesSolid-state devicesPhosphorLight emitting device

A method of manufacturing a light-emitting device includes providing a case including a recessed portion and mounting a light-emitting element on a bottom of the recessed portion, putting a first sealing material including a first phosphor particle into the recessed portion, putting a second sealing material including a second phosphor particle on the first sealing material in the recessed portion, and precipitating the second phosphor particle before the second sealing material cures. The second phosphor particle is located above the first phosphor particle after the first and second sealing materials cure.

Owner:TOYODA GOSEI CO LTD

Inorganic decorative building board and manufacturing method for the same

InactiveUS20100068458A1Reduce adhesionImprove adhesionLiquid surface applicatorsSolid waste managementSurface layerSealant

An unhardened inorganic board is shaped by press clamping the surface of an unhardened inorganic mat having a colored surface layer using an embossing template. A semi-hardened inorganic board is obtained by performing primary curing of the unhardened inorganic board, and coating the surface of the semi-hardened inorganic board with a primary sealer. The semi-hardened inorganic board coated with the primary sealer is autoclave cured to obtain a hardened inorganic board. The surface of the hardened inorganic board is coated with a powdery or granular material fixing sealer and, thereafter, an ornamental powdery or granular material is dispersed onto the surface of the hardened inorganic board. The surface of the hardened inorganic board on which the ornamental powdery or granular material has been dispersed is coated with a finishing transparent paint.

Owner:NICHIHA CORP

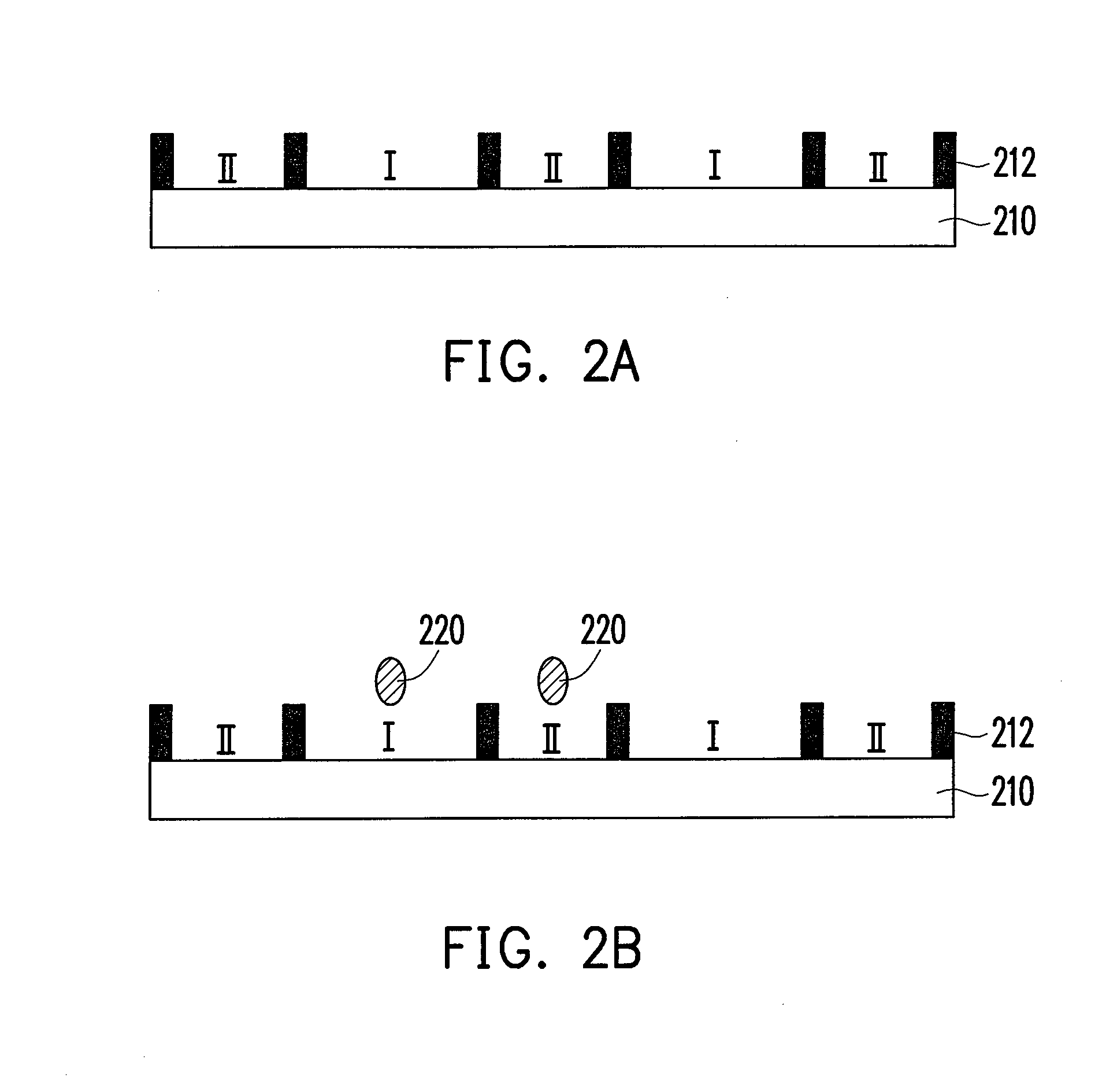

Method of manufacturing color filter

InactiveUS20080231681A1Easily controlImprove process windowPhotomechanical apparatusPattern printingLiquid-crystal displayColor filter array

A method of manufacturing a color filter is provided. First, a substrate is provided and then a partition, for example a black matrix, is formed on the substrate. The black matrix defines a plurality of first color filter areas and a plurality of second color filter areas corresponding to the first color filter areas on the substrate. Thereafter, a first color filter film and a second color filter film are formed in each of the first color filter areas and each of the second color filter areas corresponding thereto, respectively, such that a color filter is provided. The thickness of the first color filter film differs from the thickness of the second color filter film. Thus, images displayed by a transflective liquid crystal display with the aforementioned color filter have even colors.

Owner:AU OPTRONICS CORP

White LED lighting device, and optical lens

InactiveUS20120286314A1Efficient workReduce color unevennessPoint-like light sourceCondensersLight guideEffect light

Disclosed are a white LED lighting device and an optical lens used in it. The white LED lighting device comprises a white LED and an optical lens. The white LED includes: a LED chip which emits blue light: and a fluorescent material which is excited by emission light of the LED chip and converts a wavelength into fluorescence of a complementary color of blue. The optical lens is formed with a scattering light guide which is given uniform scattering power in terms of a volume. The scattering light guide includes scattering particles for the scattering efficiency in a short wavelength range of light to be higher than that in a long wavelength range of light.

Owner:NITTO OPTICAL CO LTD +1

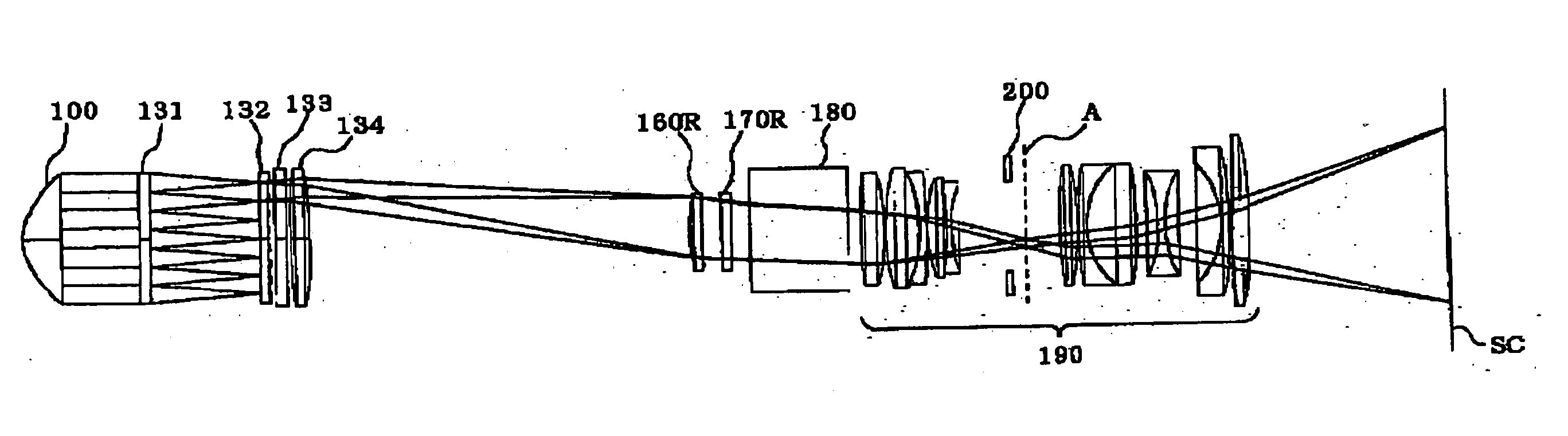

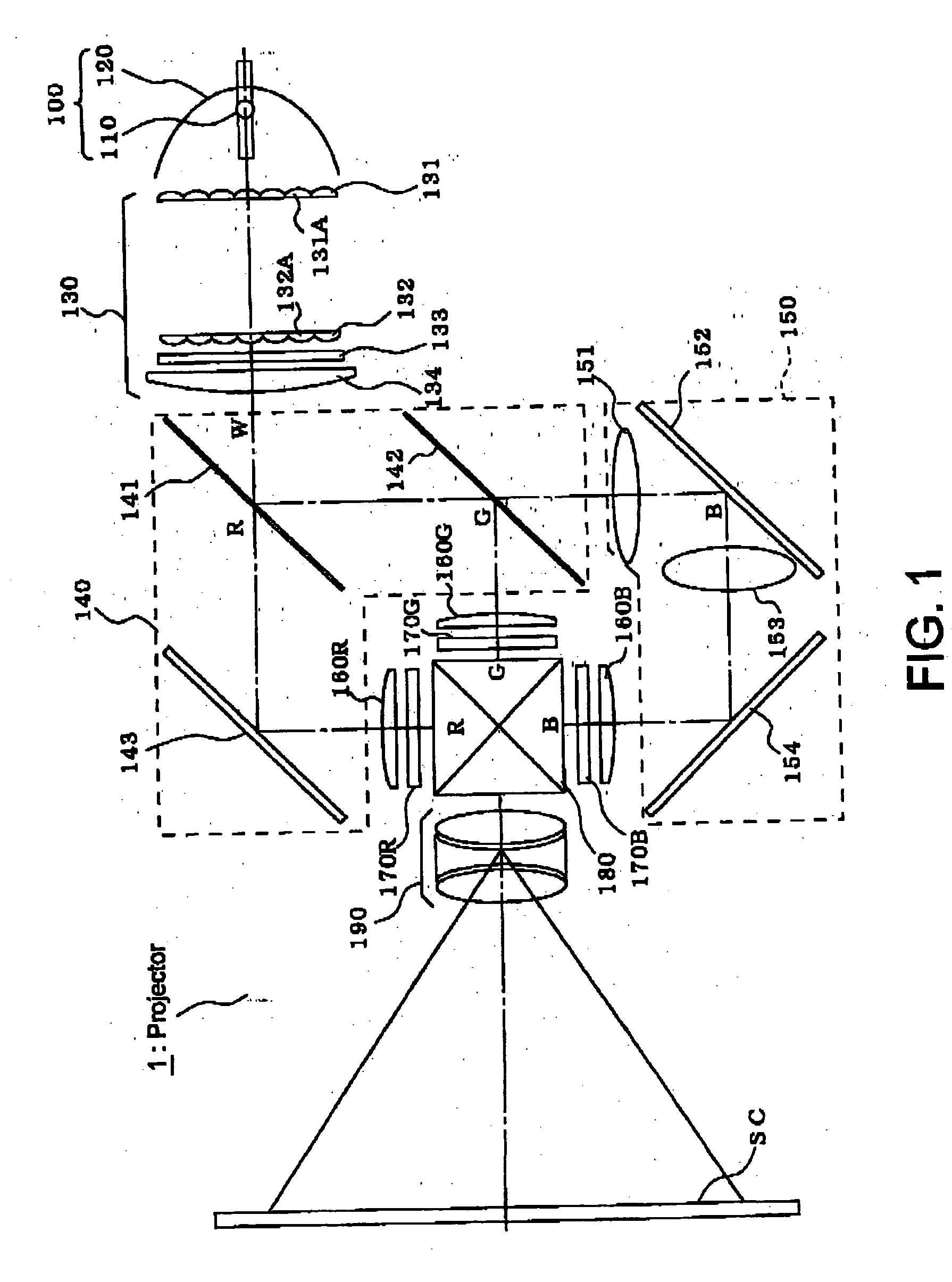

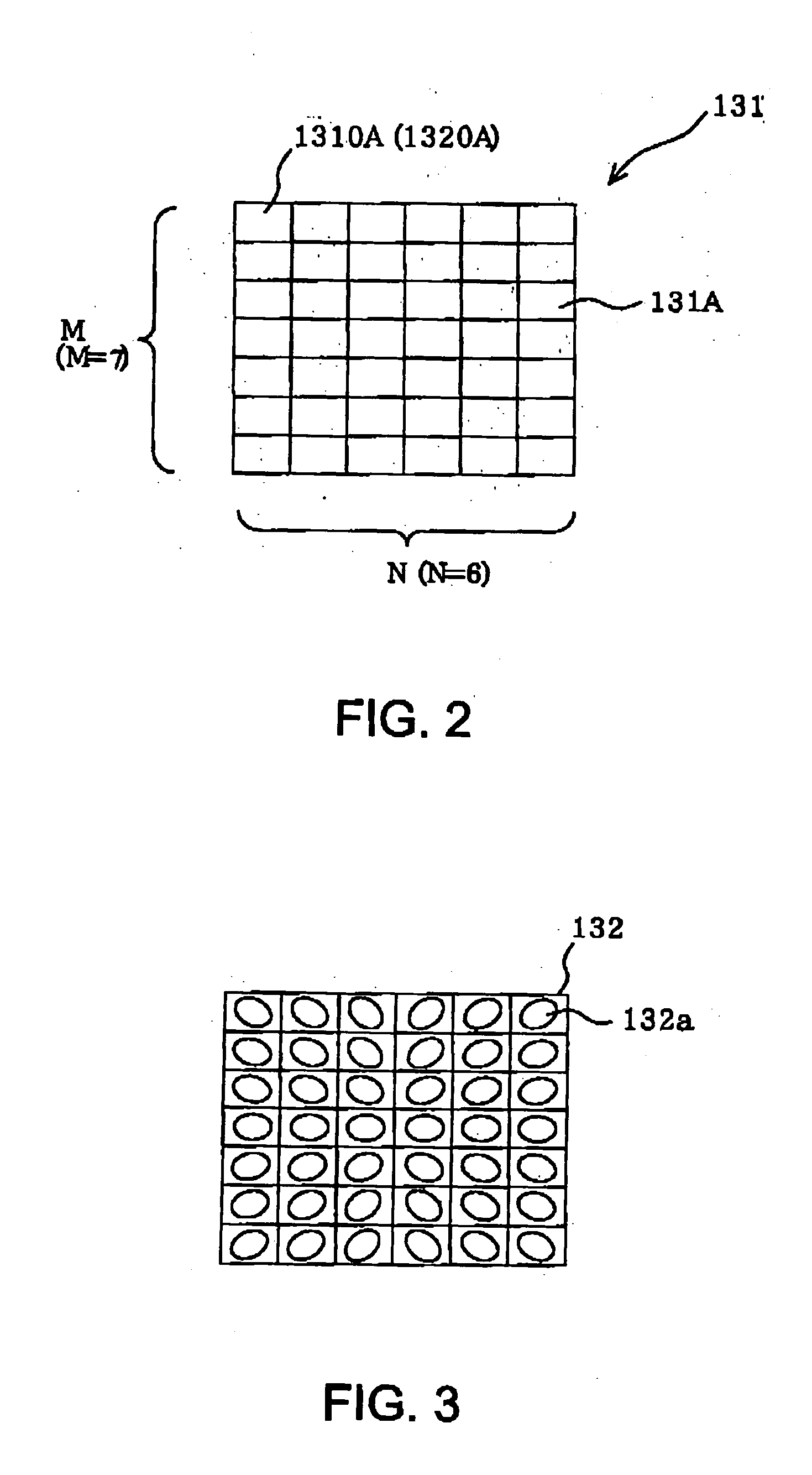

Projector

ActiveUS20040201826A1Increase contrastReduce contrastProjectorsNon-linear opticsLiquid-crystal displayLight beam

A projector is provided to ensure the enhancement of contrasts while reducing the needs for alignment accuracy. The projector includes a light source, a first lens array, second lens array, a superimposing lens, and a projection lens lens. The first lens array splits light emitted by the light source into a plurality of partial light beams with a plurality of small lenses that are arranged in a matrix. The second lens array includes a plurality of small lenses corresponding to the plurality of small lenses of the first lens array. The superimposing lens superimposes a plurality of partial light beams emitted by the first lens array and the second lens array on a liquid crystal panel. The projection lens projects light modulated by the liquid crystal panel. In the projector, a diaphragm having an opening that is shaped to be nearly similar to the outline of the second lens array is provided in the vicinity of an area conjugated with the second lens array.

Owner:SEIKO EPSON CORP

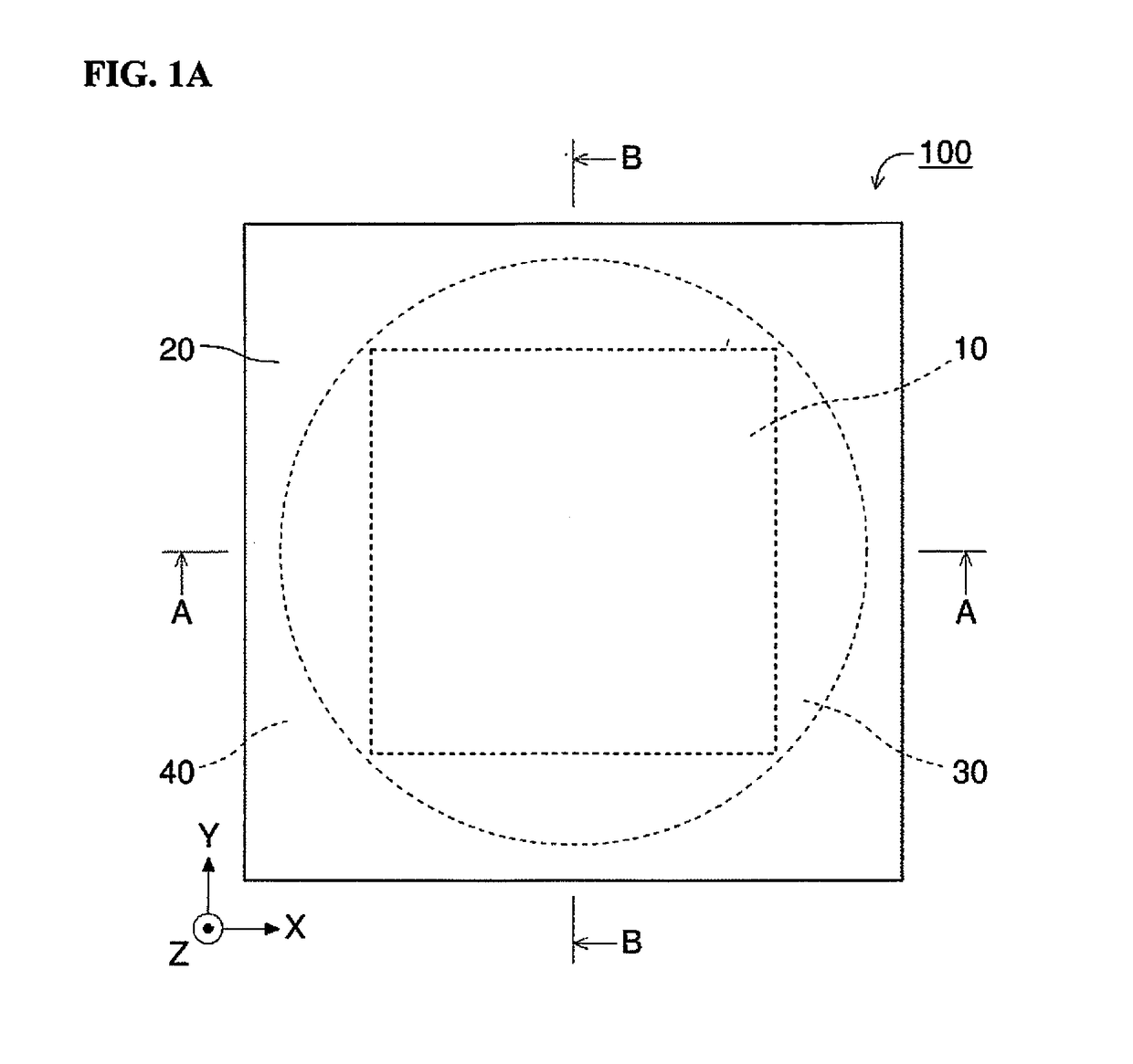

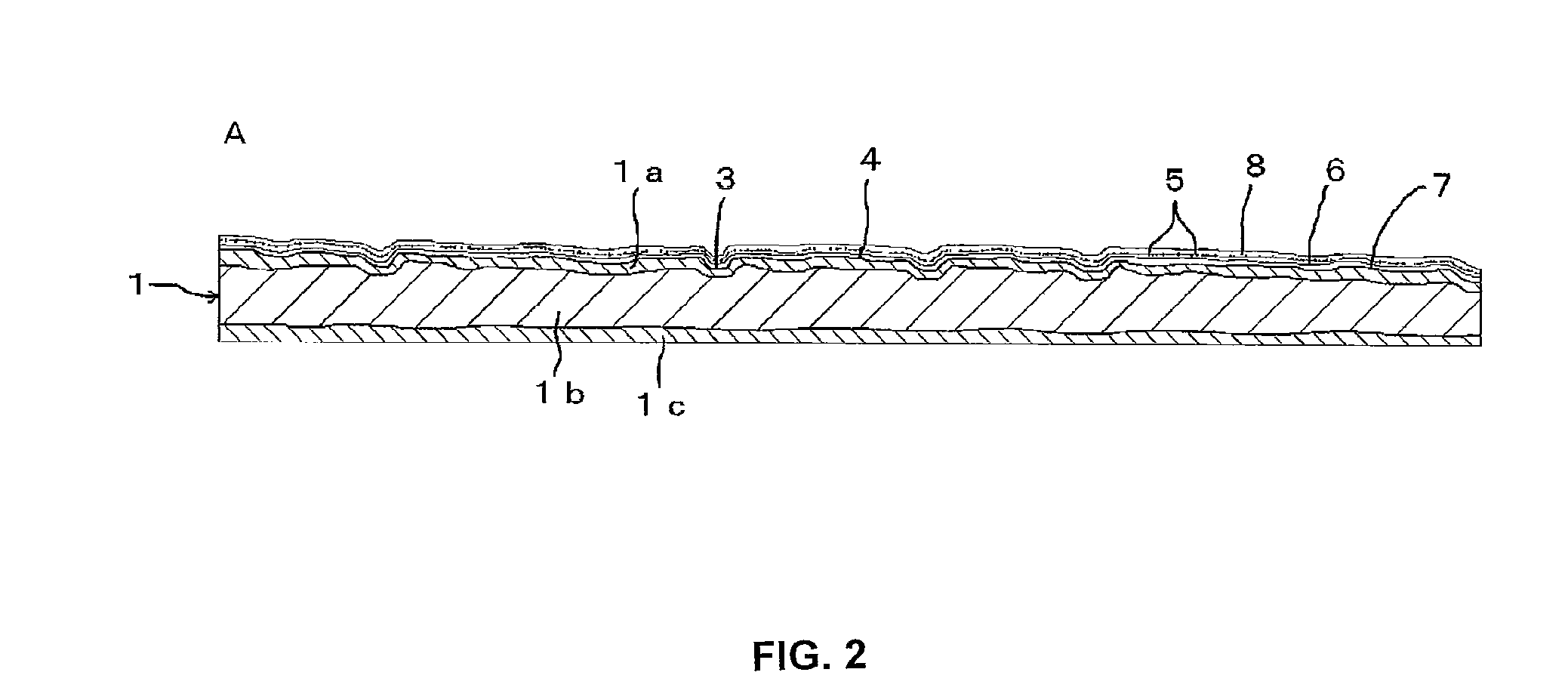

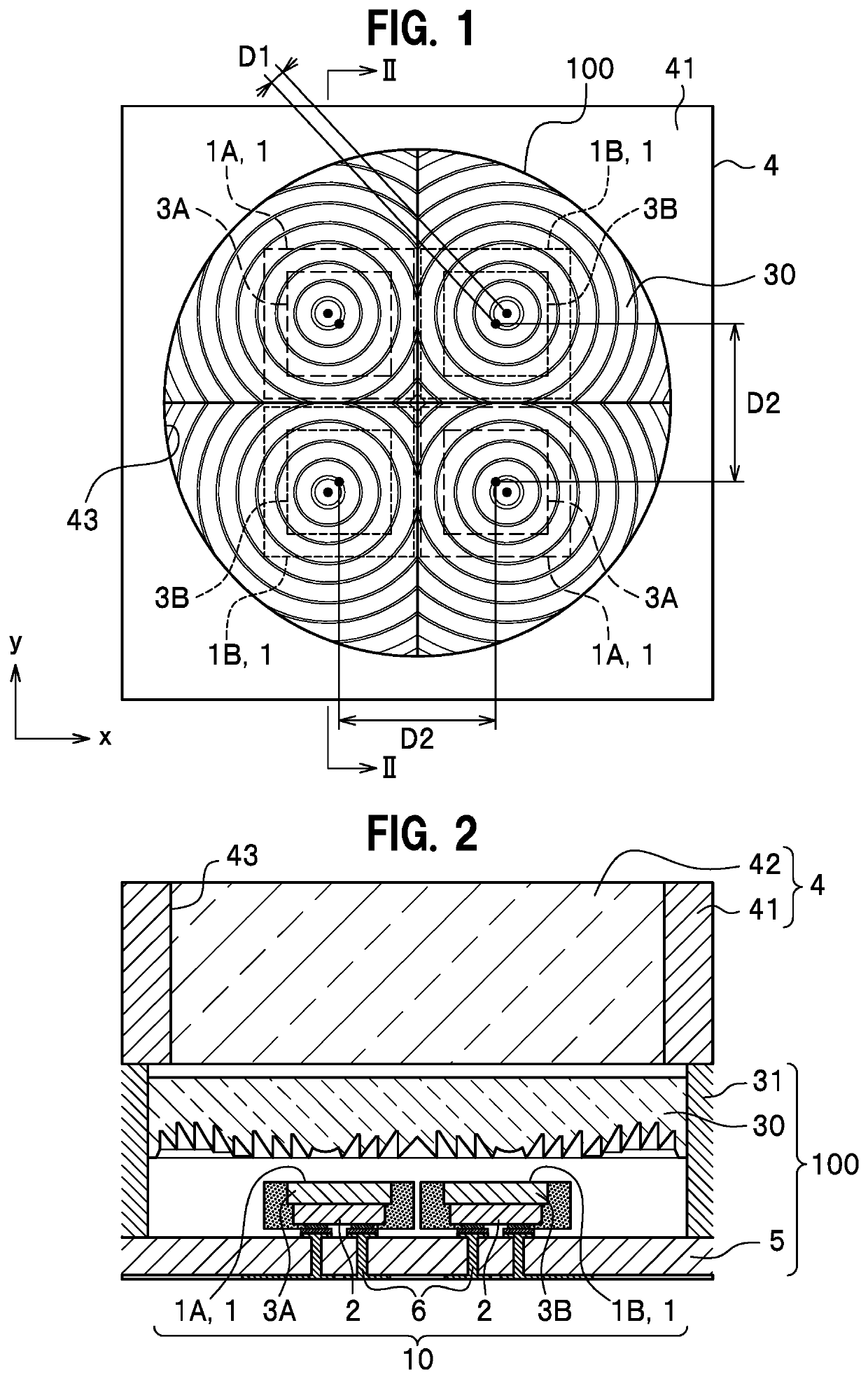

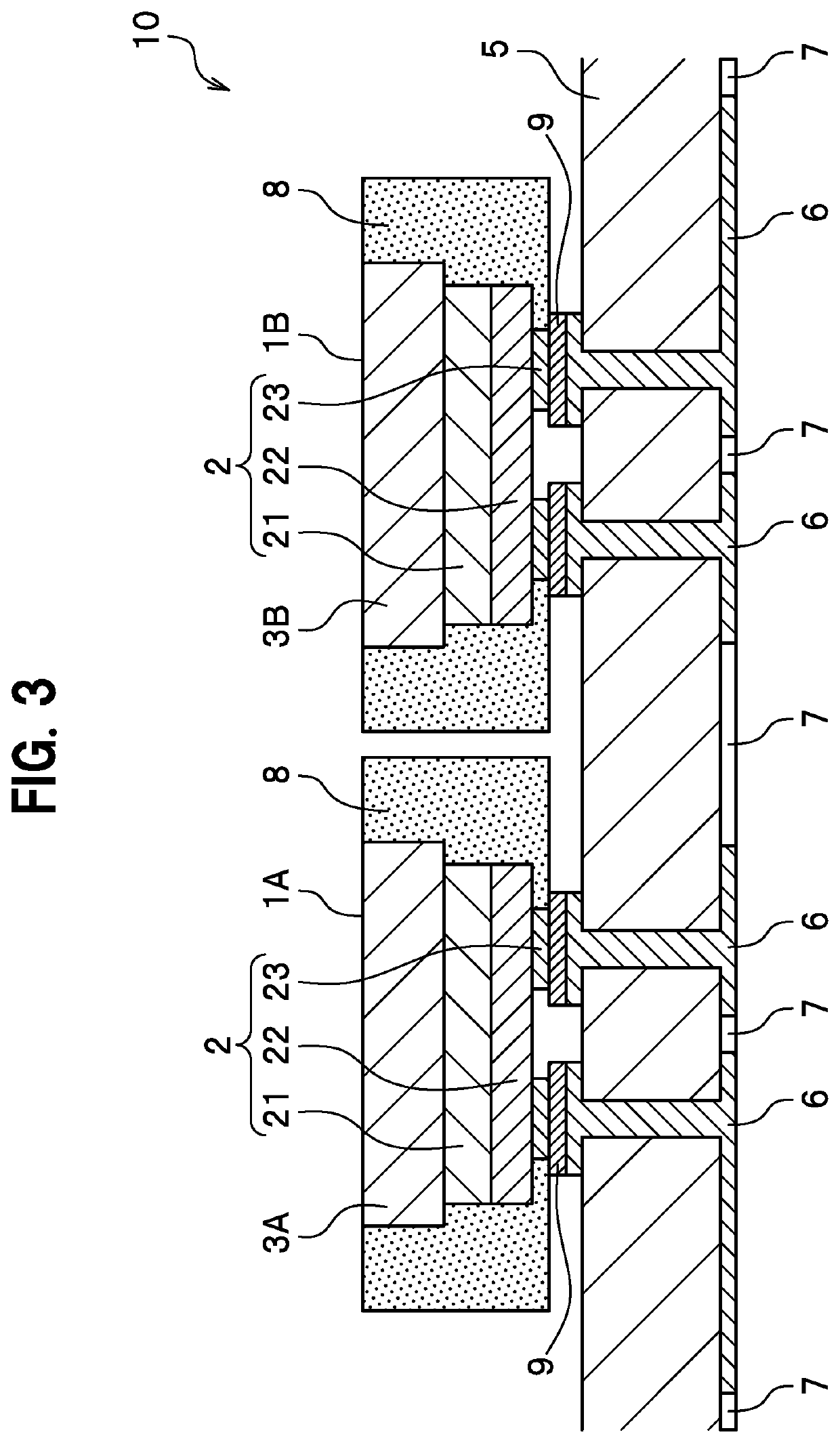

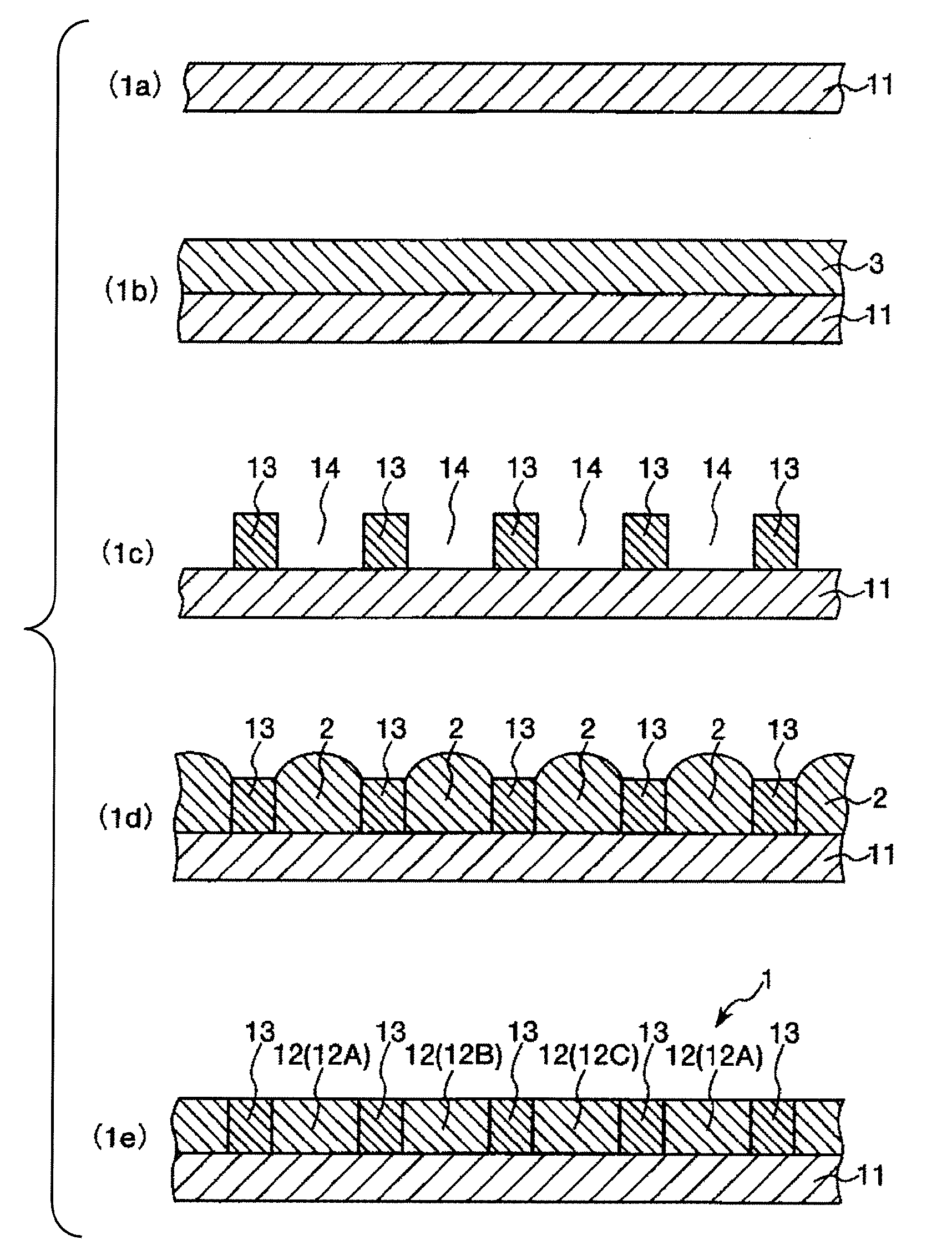

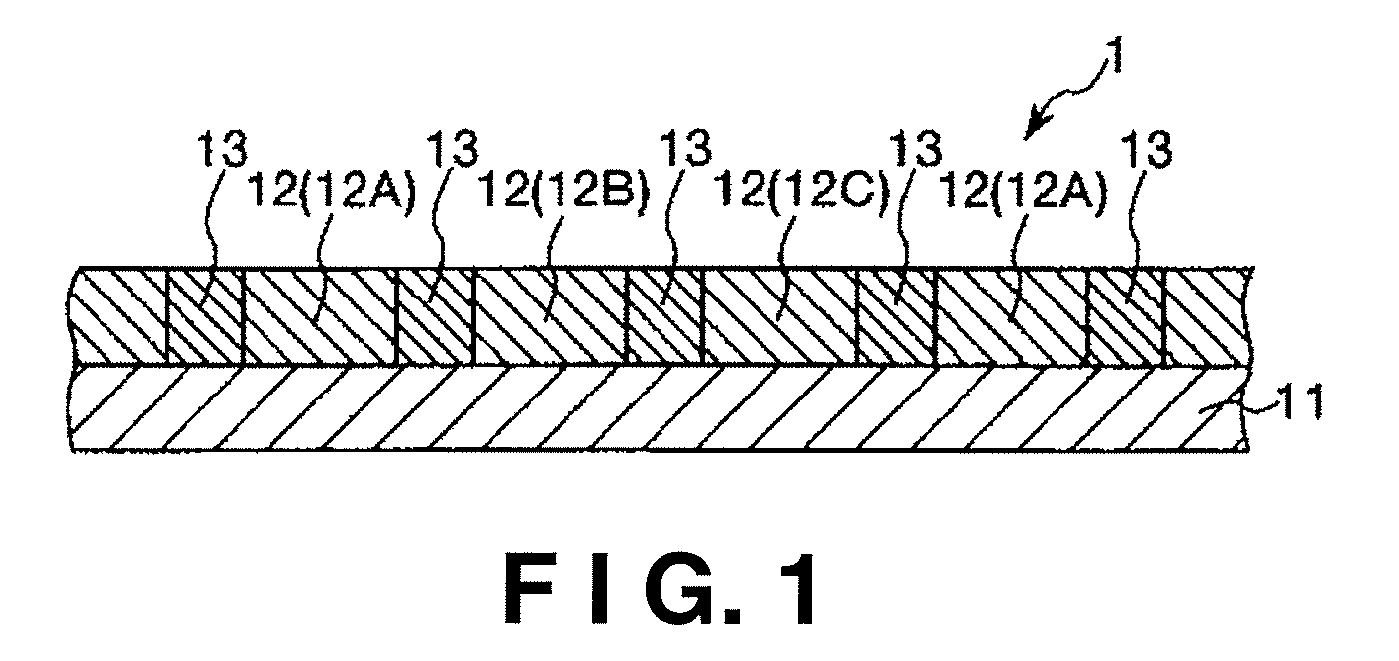

Light-emitting device and method of manufacturing the same

ActiveUS20200073207A1Increase output powerIncrease in sizeCondensersSpectral modifiersFirst lightEngineering

A light-emitting device includes: a plurality of light-emitting elements arranged in an array on a base member; and a compound eye lens that includes a plurality of lens parts disposed above the base member and facing the plurality of light-emitting elements. The plurality of light-emitting elements are arranged such that each of the plurality of light-emitting elements faces a corresponding one of the lens parts, and a center of each of the plurality of light-emitting elements is offset from a lens center of the corresponding one of the lens parts of the compound eye lens in a direction toward a center of the compound eye lens in a plan view. The plurality of light-emitting elements include first light-emitting elements and second light-emitting elements that are alternately arranged, wherein an emission color of the first light-emitting elements is different from an emission color of the second light-emitting elements.

Owner:NICHIA CORP

Color filter ink, color filter, image display device, and electronic device

InactiveUS20090185114A1Increased durabilityImprove uniformityQuinoline dyesOptical filtersEpoxyCarbon number

A color filter ink is adapted to be used to manufacture a color filter by an inkjet method. The color filter ink includes a colorant, a curable resin material and a liquid medium. The curable resin material includes a first polymer containing at least a first epoxy-containing vinyl monomer as a monomer component. The liquid medium dissolves and / or disperses the colorant. The liquid medium includes a compound containing at least one of an alkoxyl group having a carbon number of 4 or higher and an acetyl group at an end of a molecule chain. The liquid medium has a characteristic in which, when a cured epoxy-based adhesive material is put into the liquid medium under a sealed condition at an atmospheric pressure and a temperature of approximately 40° C. and left for ten days, a swelling ratio of the cured epoxy-based adhesive material is 30% or lower.

Owner:SEIKO EPSON CORP

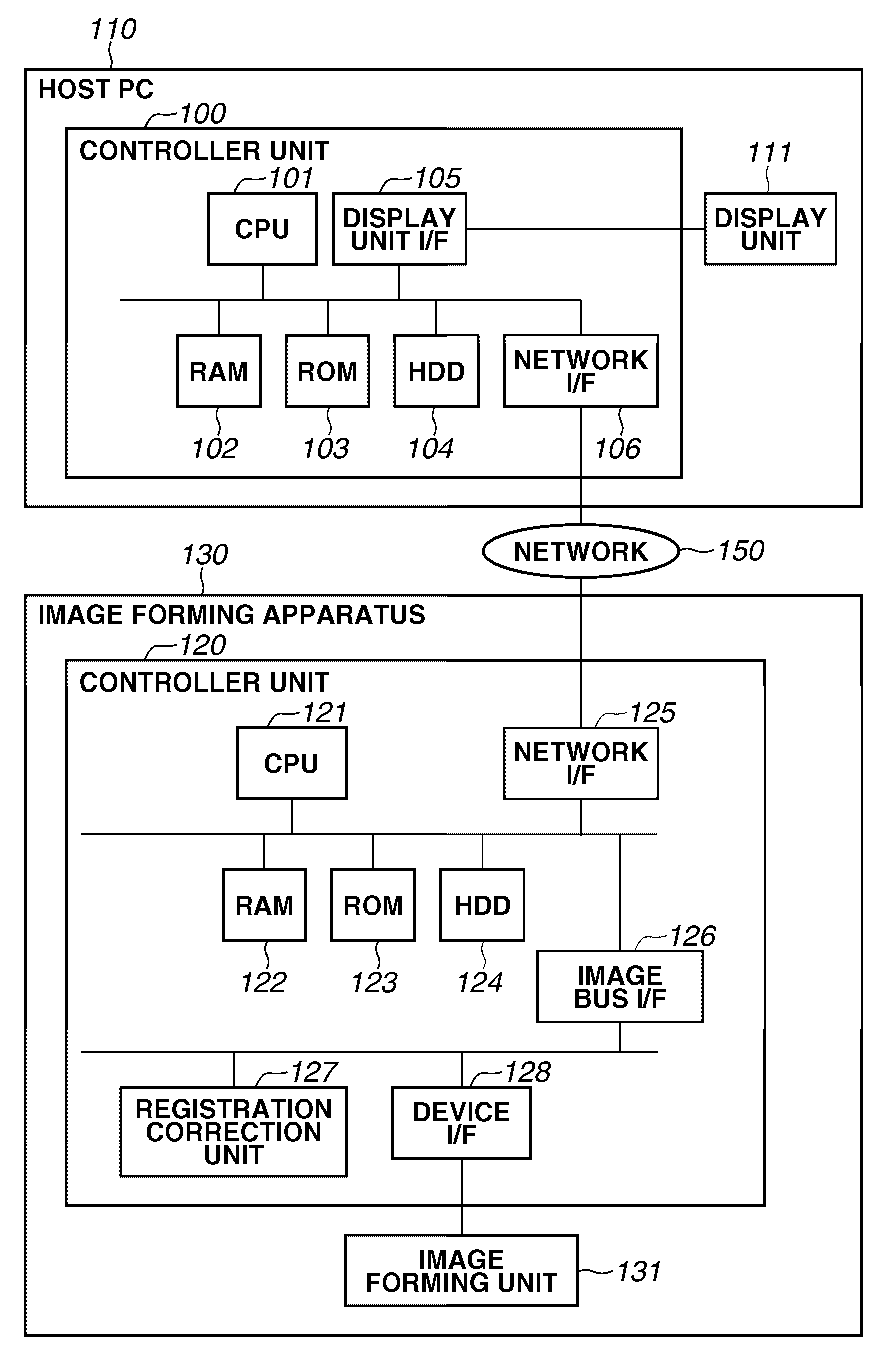

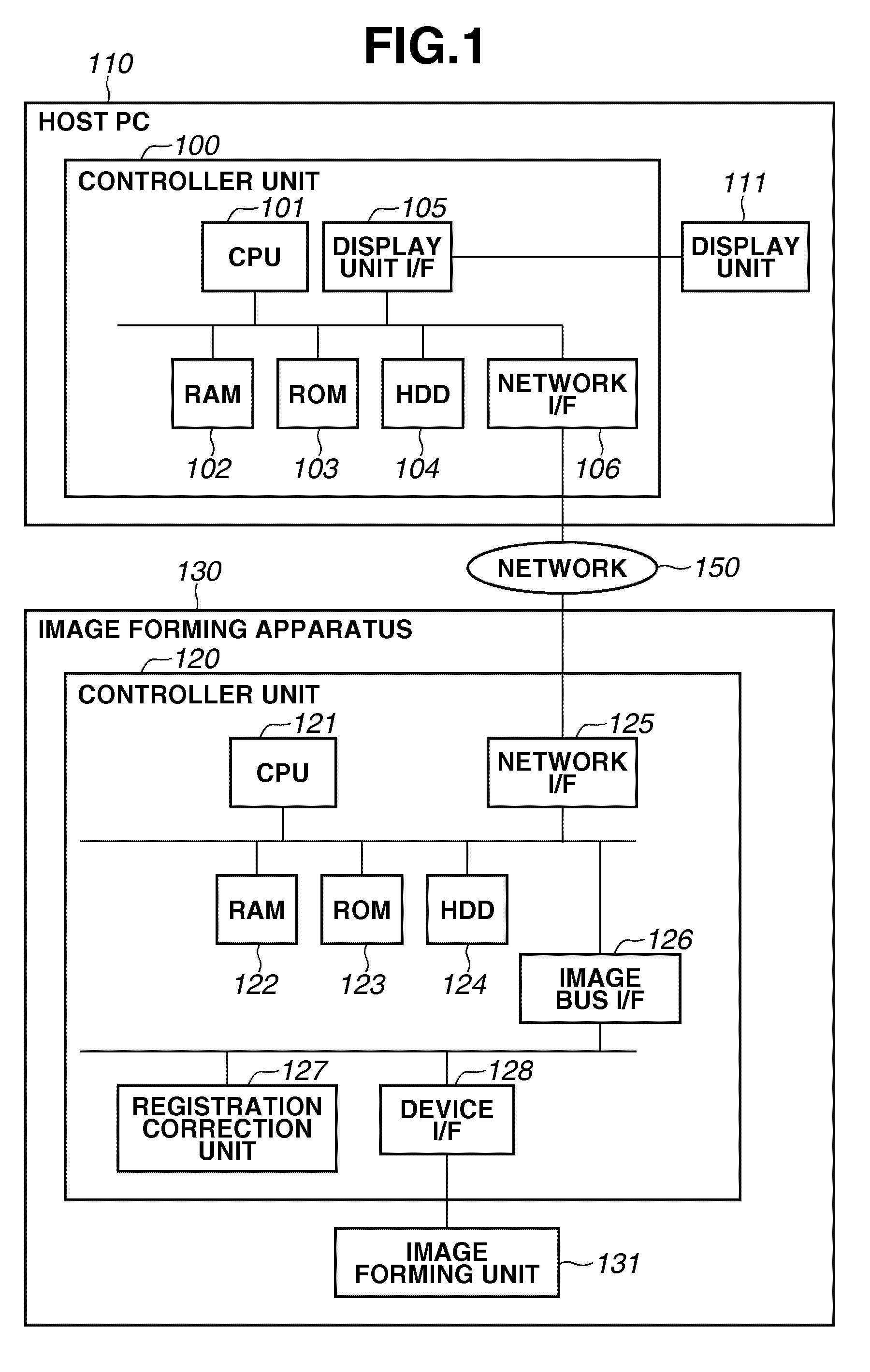

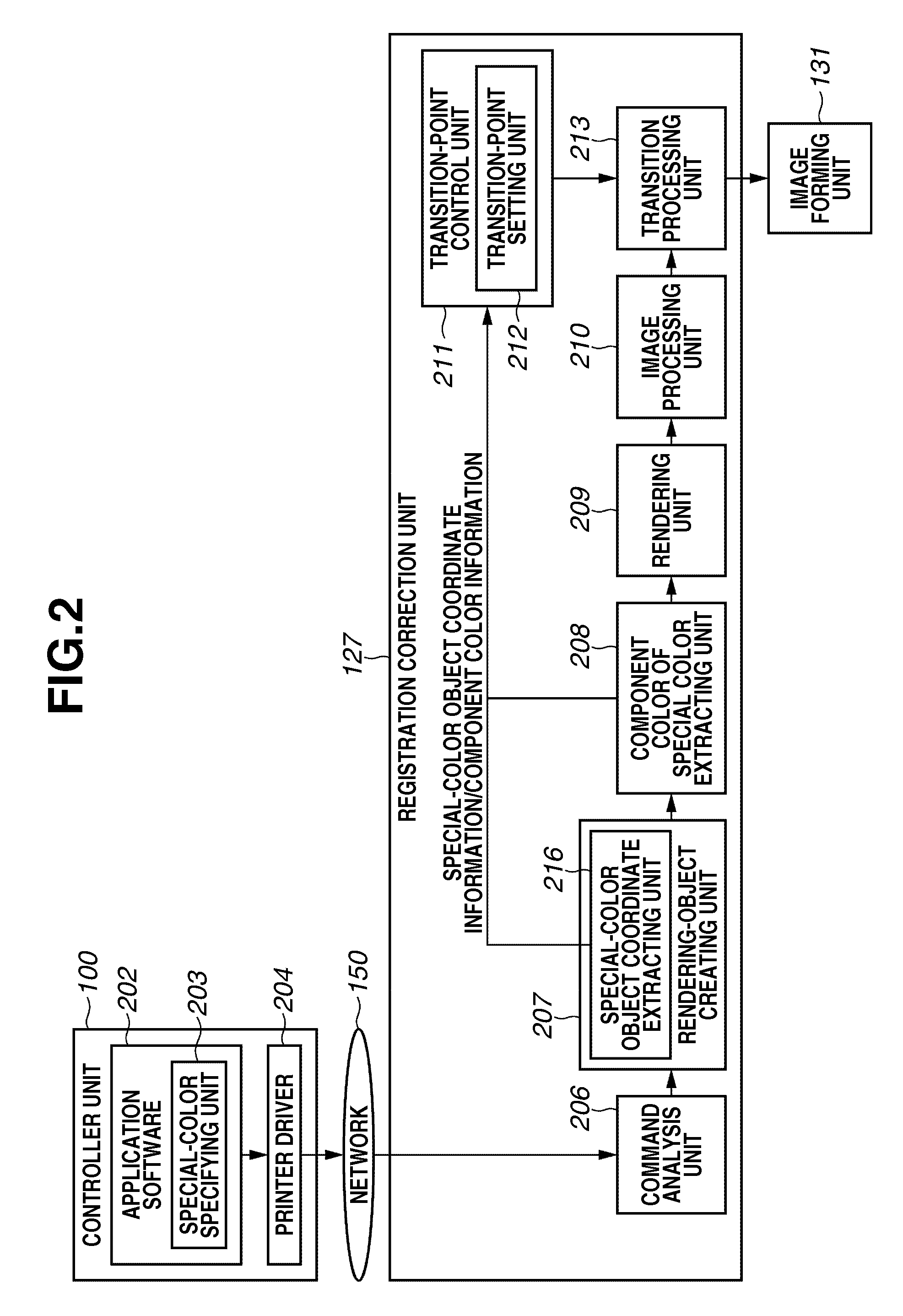

Image processing apparatus, control method thereof, and storage medium

InactiveUS20120281256A1Reduce color unevennessEffective coloringVisual presentation using printersElectrographic process apparatusImaging processingTransition point

An image processing apparatus and a method thereof for setting, in a case where a plurality of component colors of a special-color object specified with a special color is included and a transition point is included in a region of the special-color object in image data, a transition point located in the region at a position where a generation of color unevenness can be reduced.

Owner:CANON KK

Polarizer, Polarizing Plate,Optical Film, and Image Display

InactiveUS20070253060A1High light transmittanceReduce unevennessPolarising elementsNon-linear opticsFiberDisplay device

A polarizer of the invention comprises a film having a structure that includes: a matrix formed of an optically-transparent resin having a polyene structure; and minute domains dispersed in the matrix and / or fibers embedded in the matrix without forming voids. The polarizer has a high transmittance and a high degree of polarization.

Owner:NITTO DENKO CORP

Color filter ink, color filter ink set, color filter, image display device, and electronic device

InactiveUS20090134368A1Increased durabilityImprove uniformityDiffusing elementsOptical filtersPolymer sciencePhthalocyanine

A color filter ink is adapted to be used to manufacture a color filter by an inkjet method. The color filter ink includes a main pigment, a secondary pigment, a solvent and a curable resin material. The main pigment includes a halogenated phthalocyanine zinc complex. The secondary pigment includes a sulfonated pigment derivative. The curable resin material includes a first polymer and a second polymer. The first polymer includes at least an alkoxysilyl-containing vinyl monomer represented by a first prescribed chemical formula as a monomer component. The second polymer includes at least a fluoroalkyl-containing or fluoroaryl-containing vinyl monomer represented by a second prescribed chemical formula as a monomer component.

Owner:SEIKO EPSON CORP

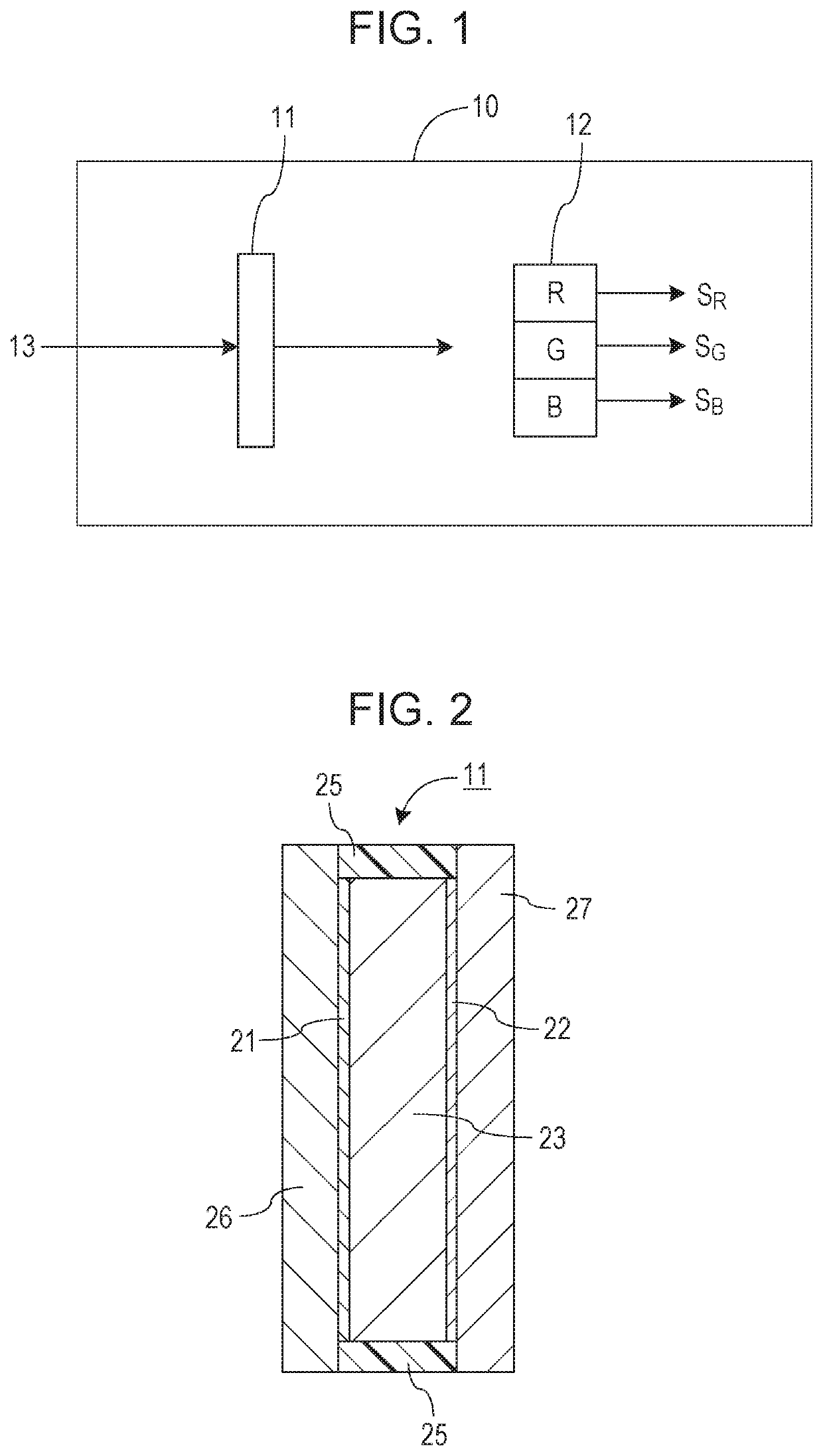

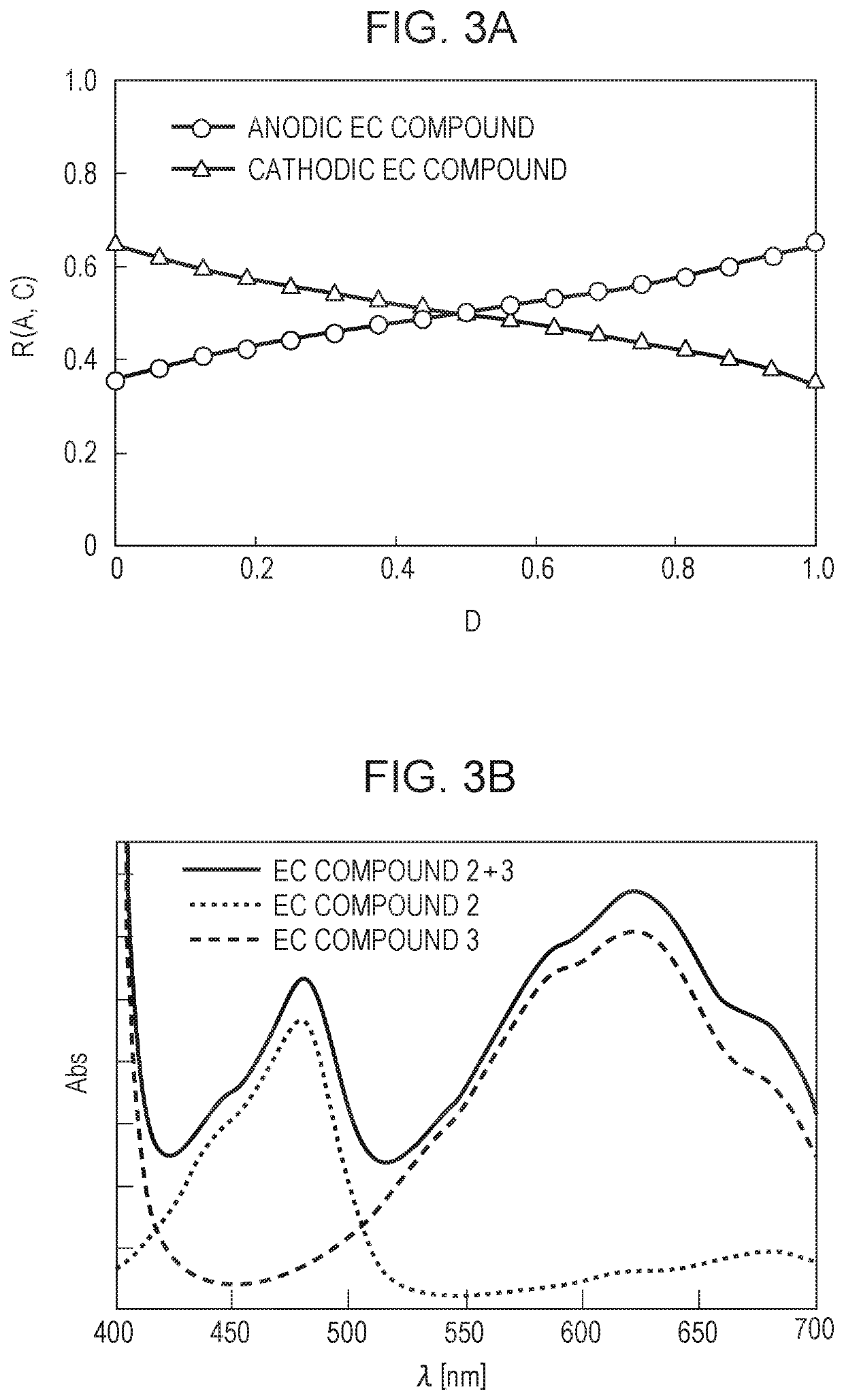

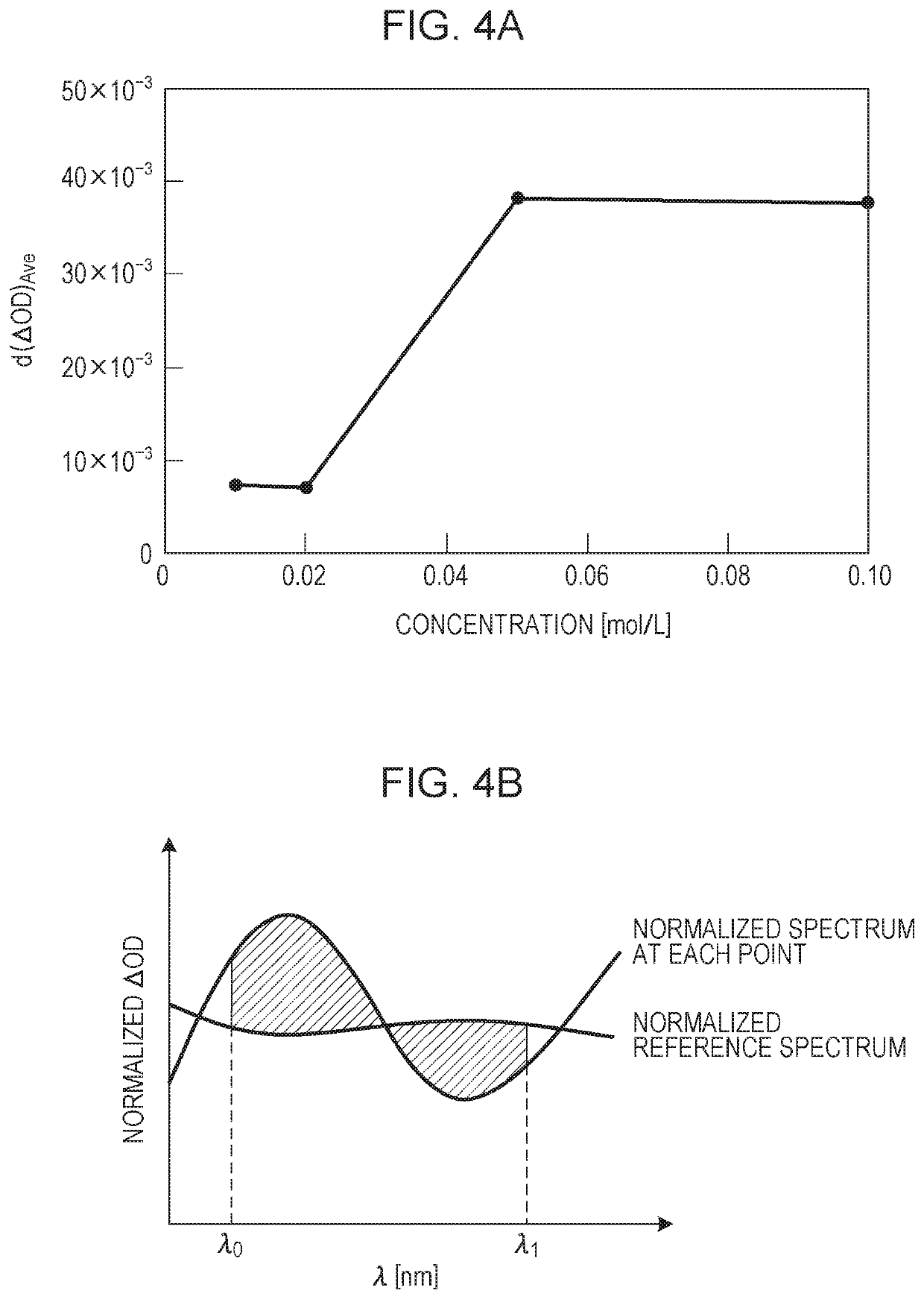

Electrochromic element, optical apparatus, light control window, and image pickup apparatus

An EC element whose coloring unevenness due to concentration unevenness is reduced by bringing the ratio of red and green wavelength ranges of a colored form of an anodic EC compound close to the ratio of red and green wavelength ranges of a colored form of a cathodic EC compound.

Owner:CANON KK

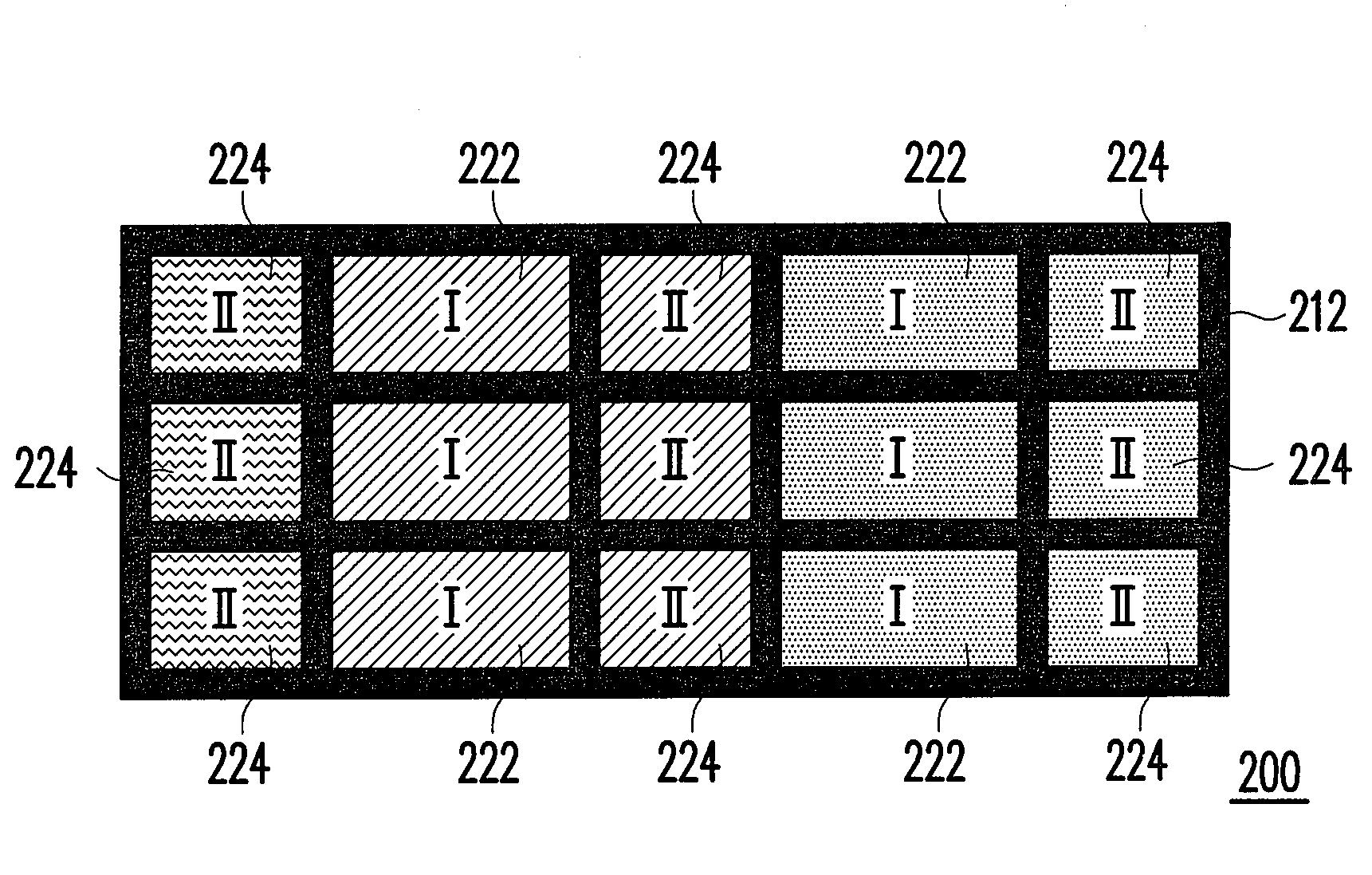

Light source apparatus

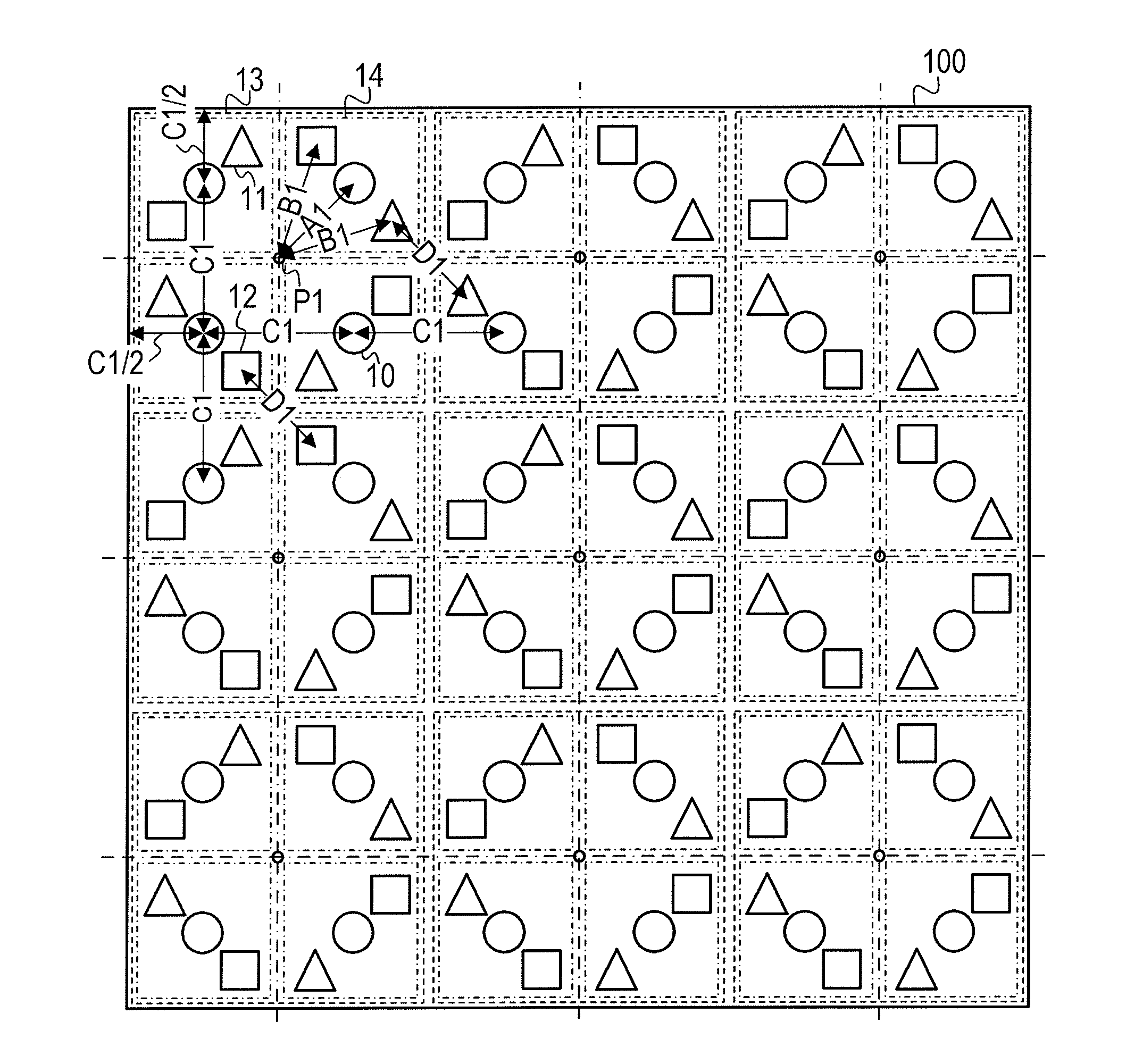

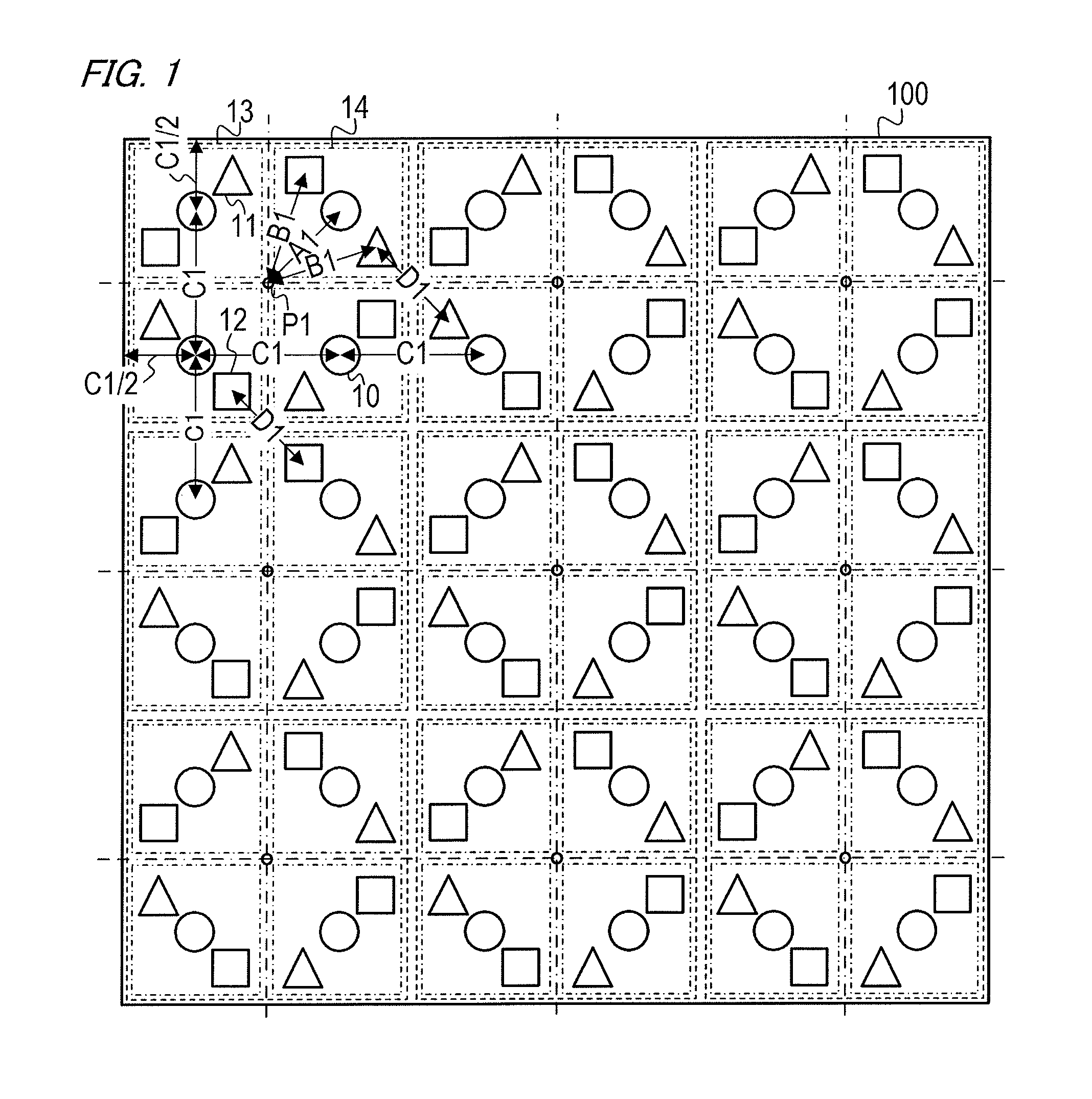

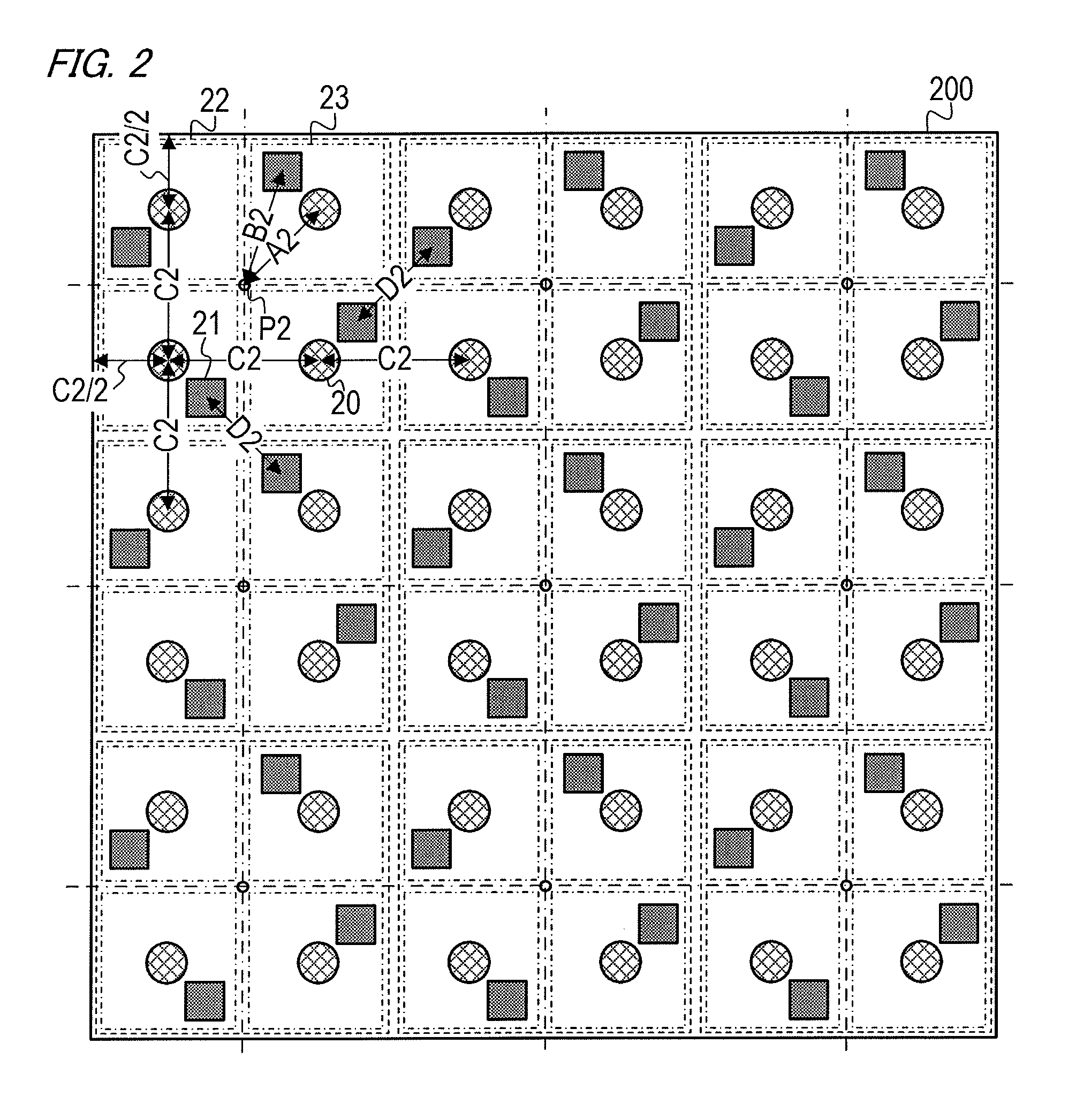

ActiveUS20140334144A1Reduce color unevennessColor unevennessPlanar light sourcesElectric circuit arrangementsLight emissionBrightness perception

A light source apparatus includes a plurality of light emission clusters arranged in a matrix pattern, wherein the light emission cluster has four sub light emission clusters of two rows and two columns, the sub light emission cluster has a plurality of light sources, the plurality of light sources having a first light source that emits light of a first color and a second light source that emits light of a second color, a difference in brightness of the second color being more easily perceived than a difference in brightness of the first color, and an interval between a center of the light emission cluster and the second light source of the light emission cluster is greater than or equal to an interval between the center of the light emission cluster and the first light source of the light emission cluster.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com