Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Maximum bubble pressure method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, the maximum bubble pressure method, or in short bubble pressure method, is a technique to measure the surface tension of a liquid, with surfactants.

Aqueous ink, ink jet recording method, ink cartridge, recording unit and ink jet recording apparatus

ActiveUS20080018722A1Efficient aggregationEffective diffusionMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater insoluble

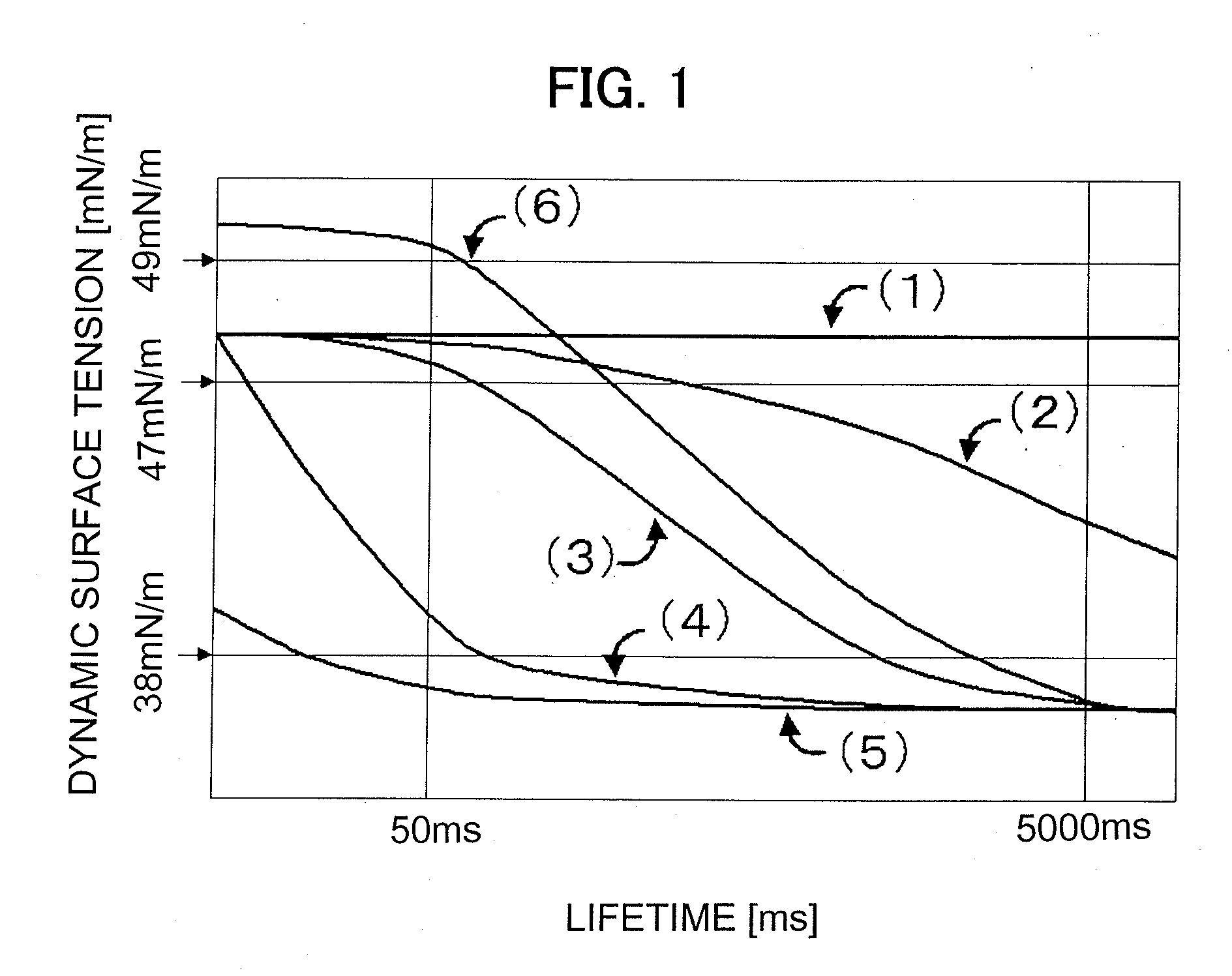

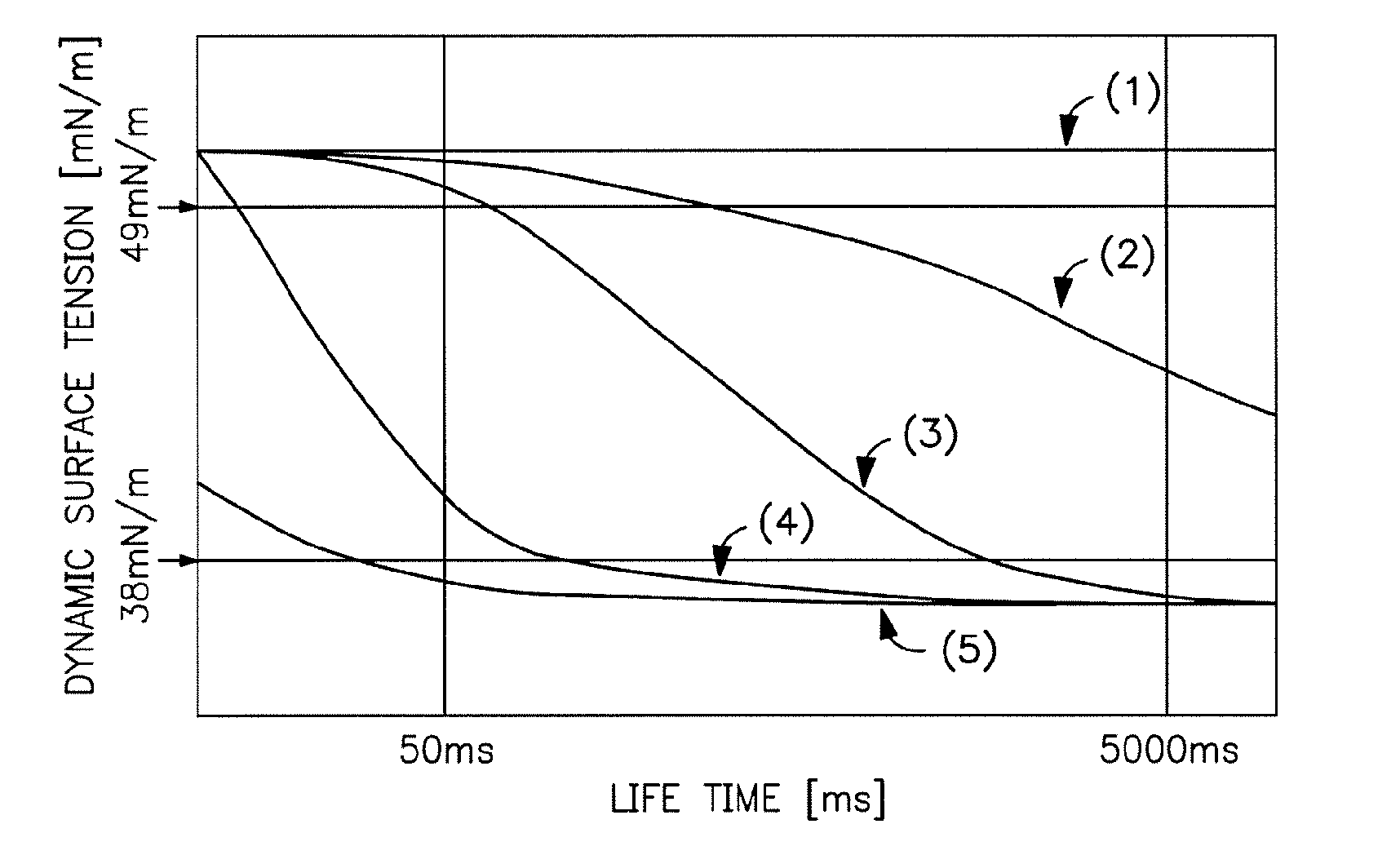

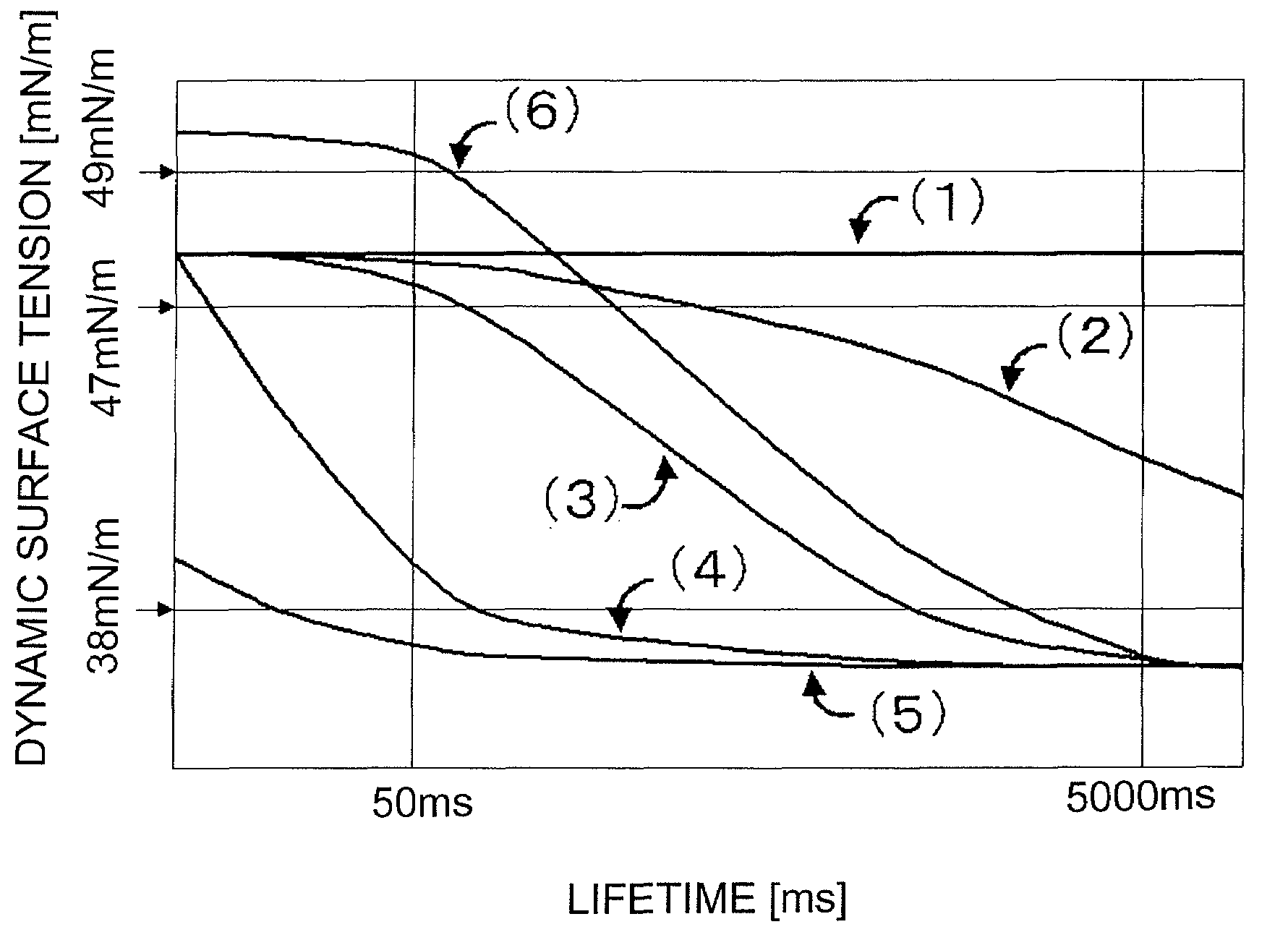

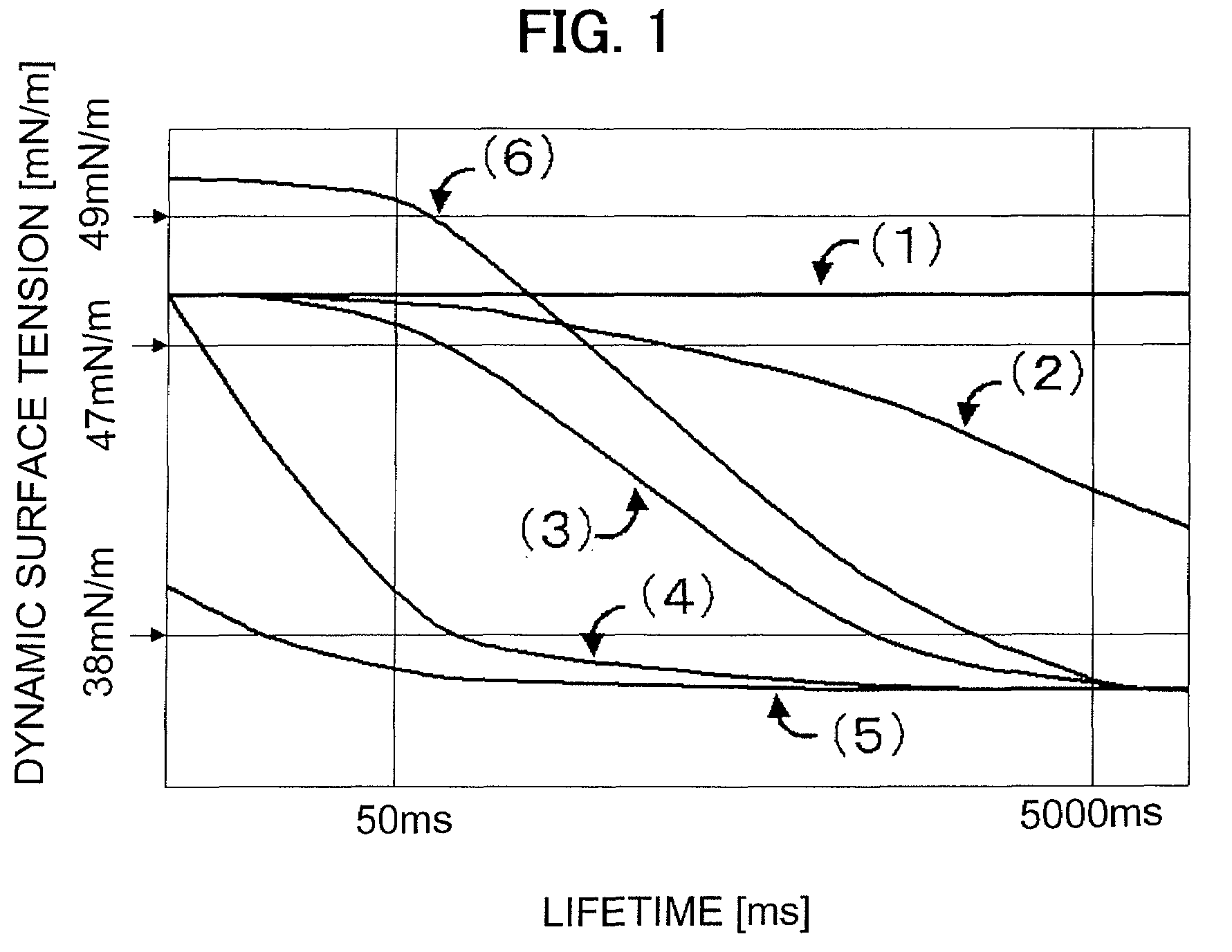

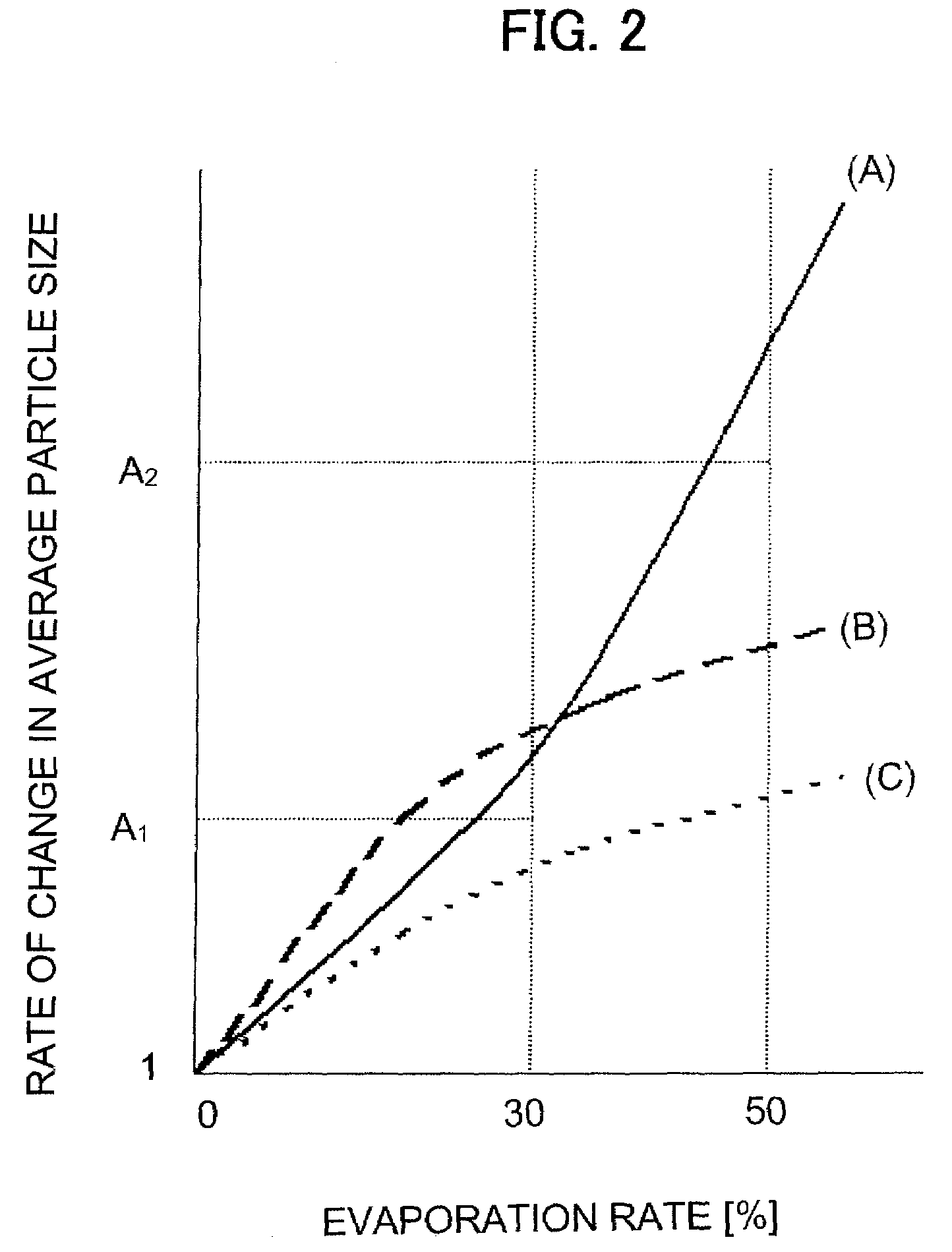

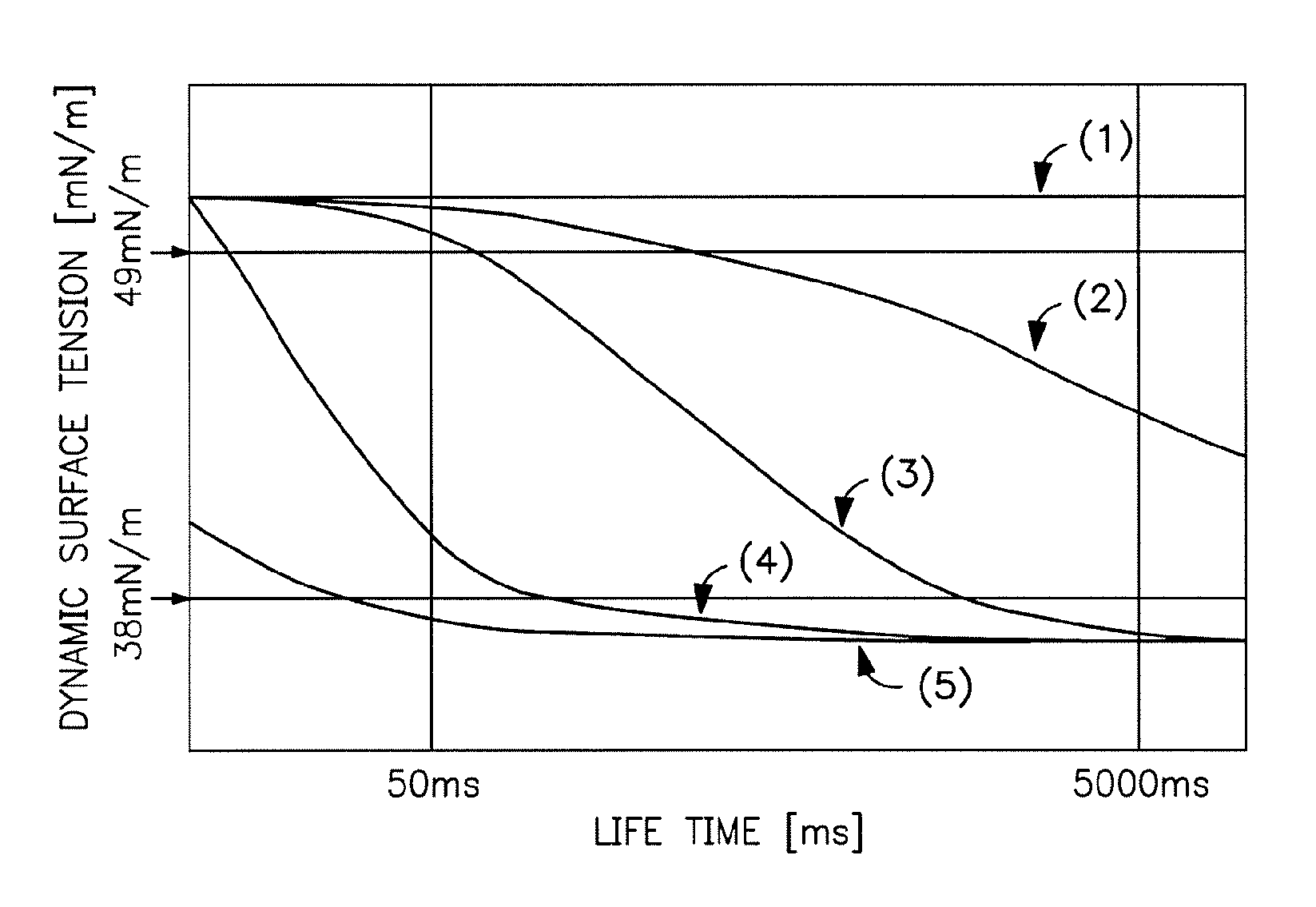

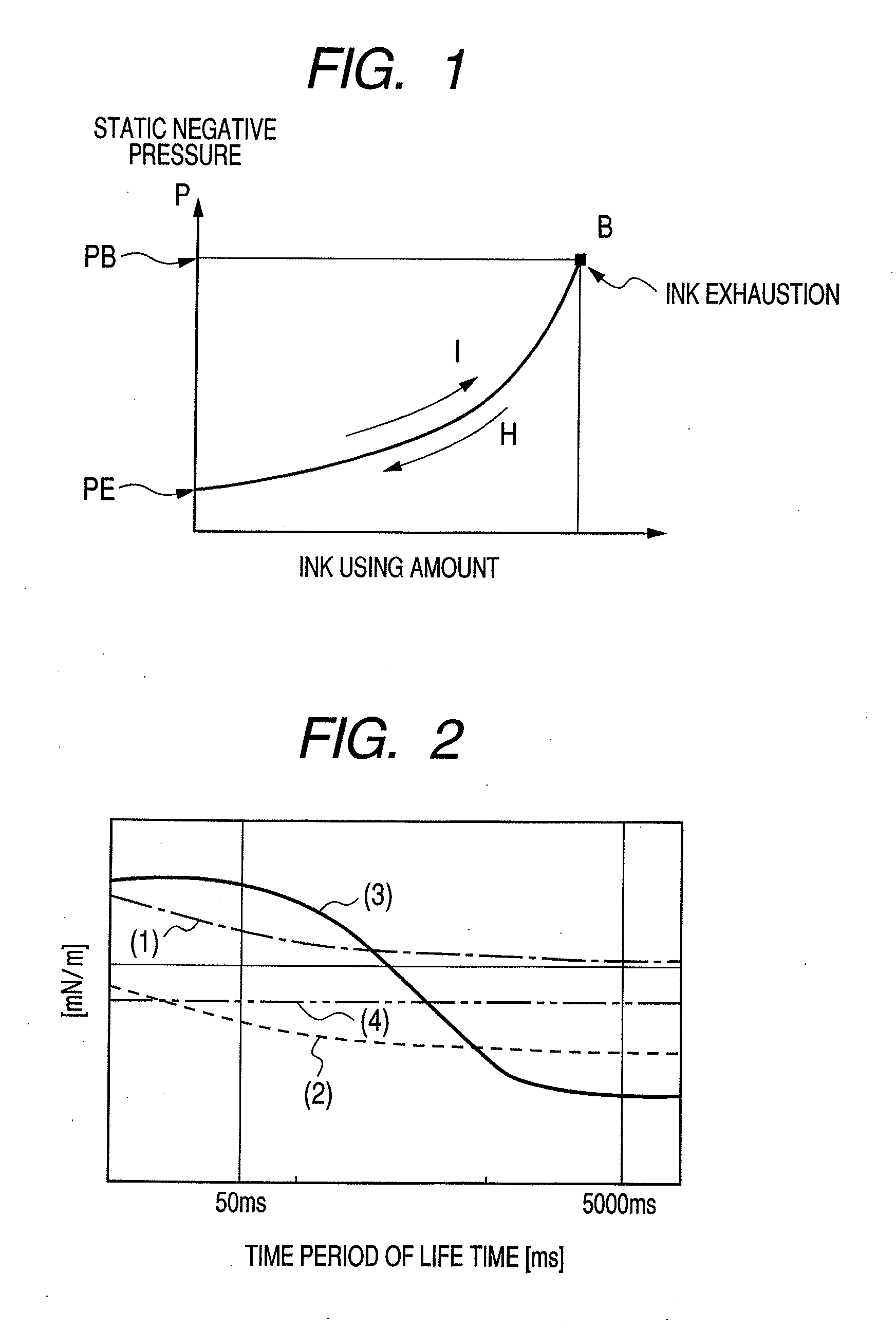

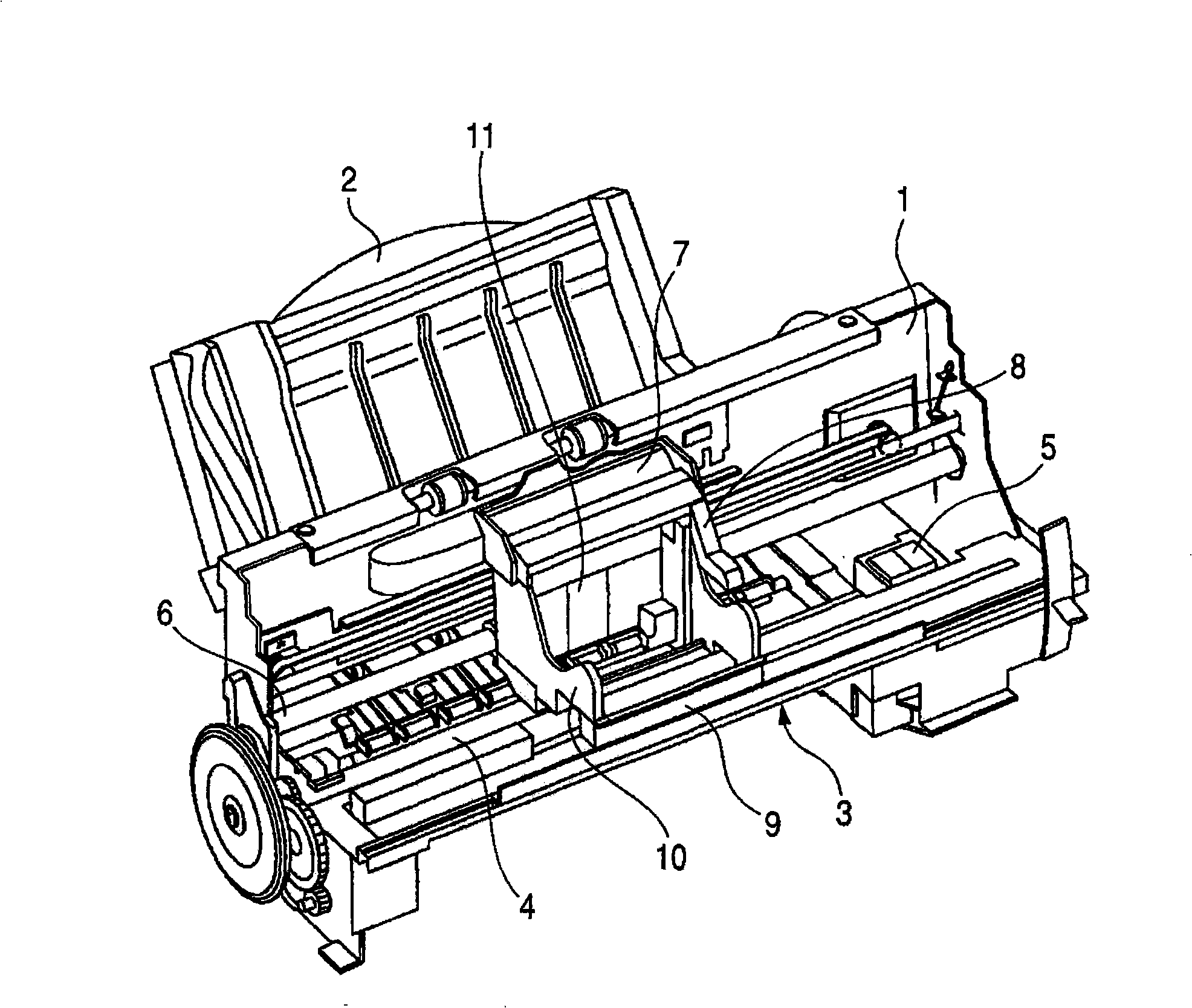

Provided herein is an aqueous ink, which is excellent in both image density and fixing ability irrespective of the kind of a recording medium even when the volume of an ink droplet is small and has such excellent properties that white stripes are not caused even when high-speed recording is conducted. The aqueous ink comprises at least water, a water-soluble organic solvent, a water-insoluble coloring material, a surfactant and a poor medium for the water-insoluble coloring material and / or a salt. The dynamic surface tension of the aqueous ink at a lifetime of 50 milliseconds determined by a maximum bubble pressure method is higher than 47 mN / m, and the dynamic surface tension at a lifetime of 5,000 milliseconds determined by the maximum bubble pressure method is 38 mN / m or lower.

Owner:CANON KK

Inkjet recording method and inkjet recording device

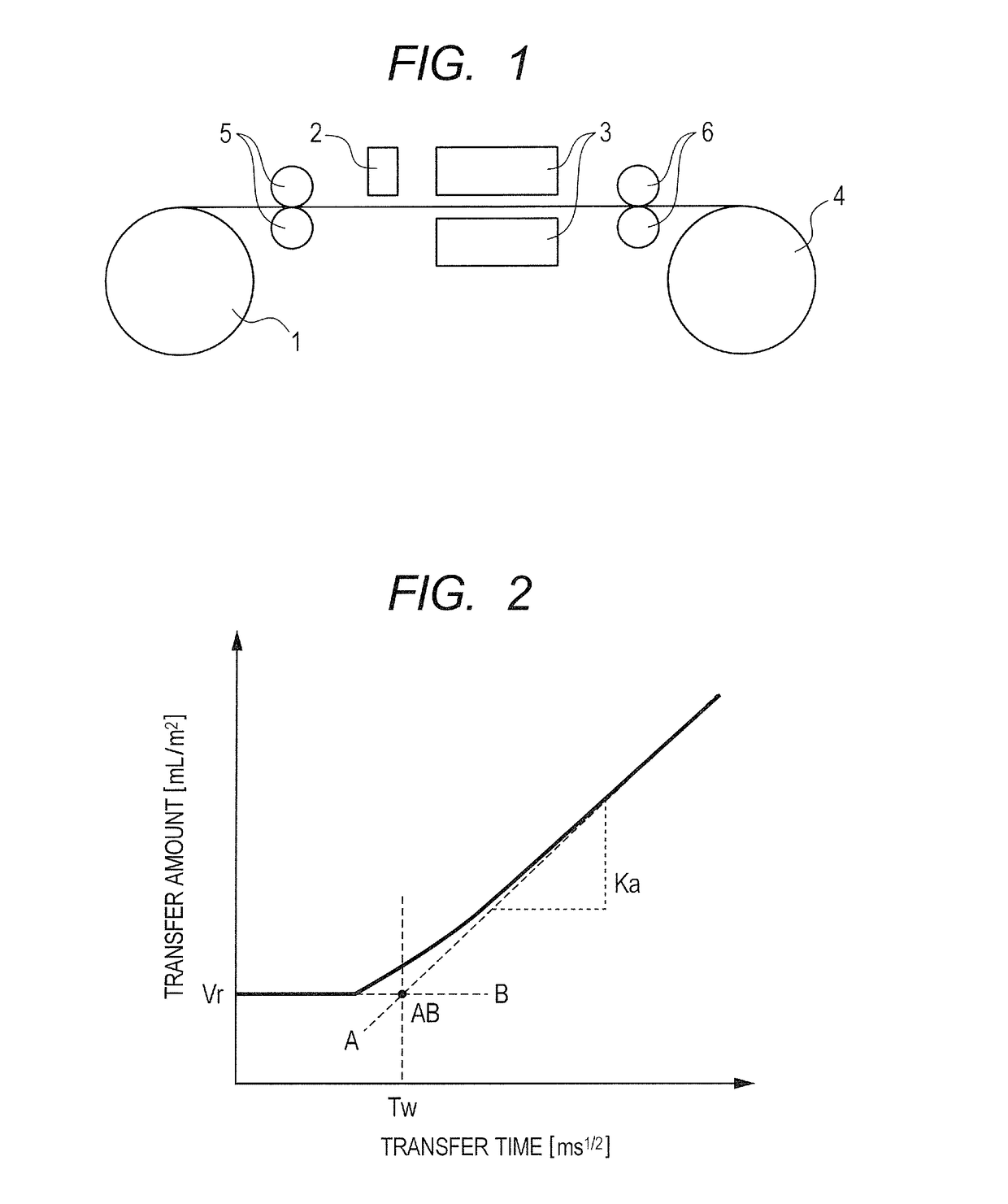

ActiveUS20150035896A1High quality full-color recordingKeep dryDuplicating/marking methodsInksSurface layerWater dispersible

An inkjet recording method including applying stimuli to inkjet recording ink to make the ink jet onto recording medium, wherein the recording medium includes support, and surface layer provided on at least one surface of the support, where transfer amount of pure water with contact time of 100 ms determined by measuring the surface of the recording medium to which the surface layer is provided by dynamic scanning absorptometer is 1 to 10 mL / m2, the recording medium is surface-treated through corona discharge or plasma treatment, the ink contains water-dispersible colorant, organic solvent, surfactant, and water, the organic solvent contains at least one polyhydric alcohol having equilibrium moisture content of 30% by mass or greater at 23° C. and 80% RH, and dynamic surface tension of the ink, as measured by maximum bubble pressure method with surface lifetime of 15 ms, is 35 mN / m or lower at 25° C.

Owner:RICOH KK

Aqueous ink, ink jet recording method, ink cartridge, recording unit and ink jet recording apparatus

ActiveUS20070252881A1High image densityEasy to fixMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater soluble

Novel conditions in the physical properties of an ink have been found out to provide an aqueous ink, which can give a high image density and achieve excellent fixing ability. The aqueous ink comprises at least water, a water-soluble organic solvent, a surfactant and a coloring material, wherein the dynamic surface tension at a lifetime of 50 milliseconds as determined by a maximum bubble pressure method is 49 mN / m or more, and the dynamic surface tension at a lifetime of 5,000 milliseconds as determined by the maximum bubble pressure method is 38 mN / m or less.

Owner:CANON KK

Inkjet recording method, inkjet recording device, and ink recorded matter

ActiveUS20130307912A1Avoid bleedingReduce surface tensionMeasurement apparatus componentsInksOrganic solventAdhesive

An inkjet recording method, containing: applying a stimulus to an inkjet recording ink to jet the ink, to form an image on a recording medium, wherein the ink contains water, a water-soluble organic solvent, a colorant, and a surfactant, and has a predetermined surface life time as measured by a maximum bubble pressure method and a predetermined static surface tension, wherein the recording medium contains a support, and a recording layer provided at least one surface of the support, where the recording layer contains a cationic resin in a predetermined amount, and is a medium for a concealing postcard where the recording medium is folded to bond a surface of the recording layer to face each other with an adhesive after information is recorded on the surface of the recording layer, in which the surface of the recording layer has a predetermined 10-sec Cobb size degree.

Owner:RICOH KK

Water-based ink set for ink-jet recording

ActiveUS20070022902A1Reduce both bleedingColor unevennessMeasurement apparatus componentsDuplicating/marking methodsWater basedMagenta

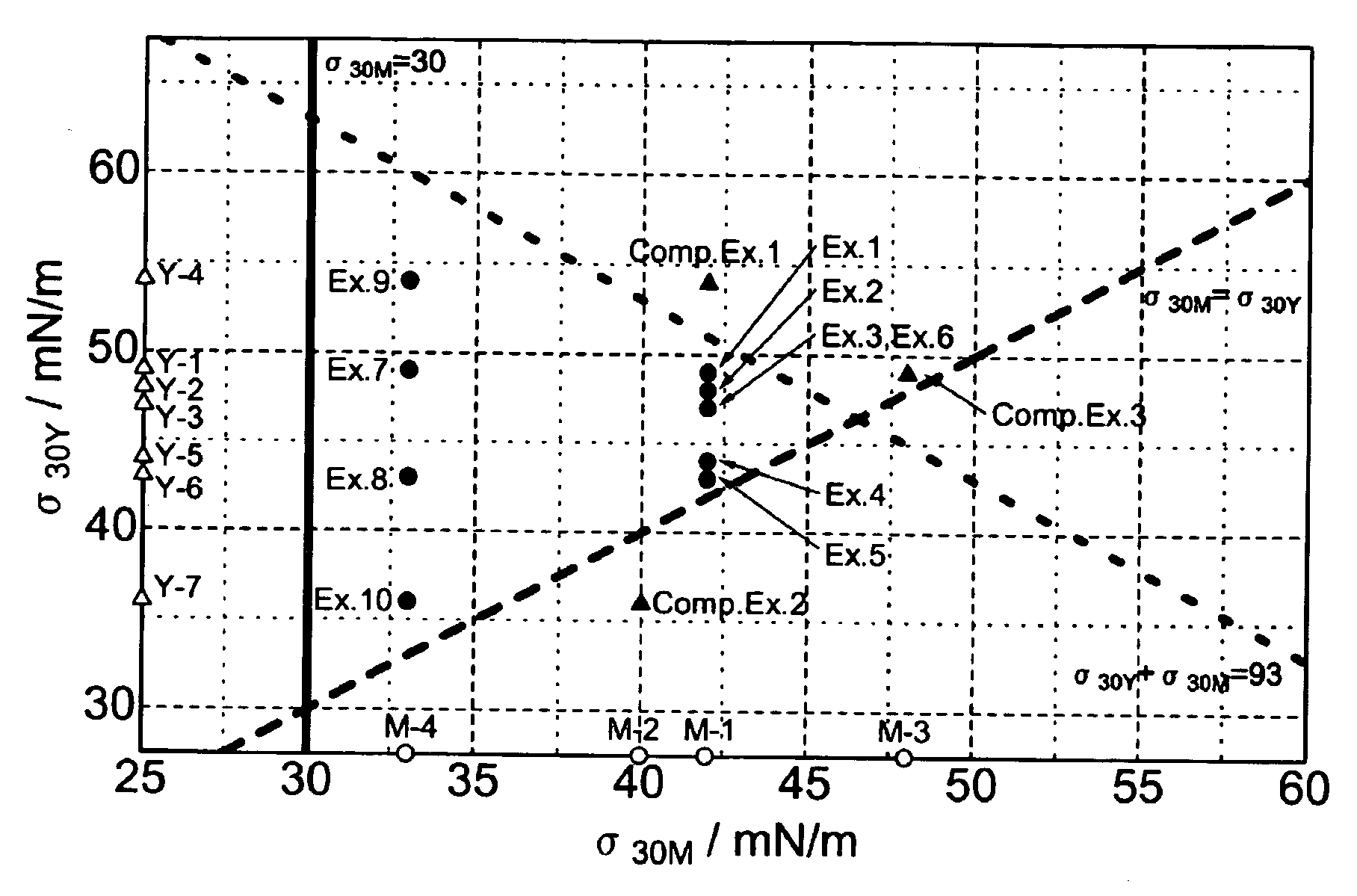

Provided is a water-based ink set for ink-jet recording for reducing bleeding between a black (Bk) ink and a yellow (Y) ink and for reducing color unevenness in a portion formed by color mixing of color inks. The water-based ink set for ink-jet recording includes at least a Bk ink, a Y ink, a magenta (M) ink and a cyan (C) ink. In this configuration, the following relationships are satisfied: (1) σ1000Bk≧35 mN / m; (2) |σ30Y−σ30Bk|≦5 mN / m; (3) σ30M≧30 mN / m, σ30C≧30 mN / m; (4) σ30Y>σ30M, σ30Y>σ30C; and (5) σ30Y+σ30M≦93 mN / m, σ30Y+σ30C≦93 mN / m, wherein σ30Bk, σ30Y, σ30M and σ30C are dynamic surface tensions of the Bk ink, the Y ink, the M ink and the C ink, respectively, at a lifetime of 30 ms as measured by a maximum bubble pressure method at a measurement temperature of 25° C., and σ1000Bk is a dynamic surface tension of the black ink at a lifetime of 1,000 ms as measured by the maximum bubble pressure method at a measurement temperature of 25° C.

Owner:BROTHER KOGYO KK

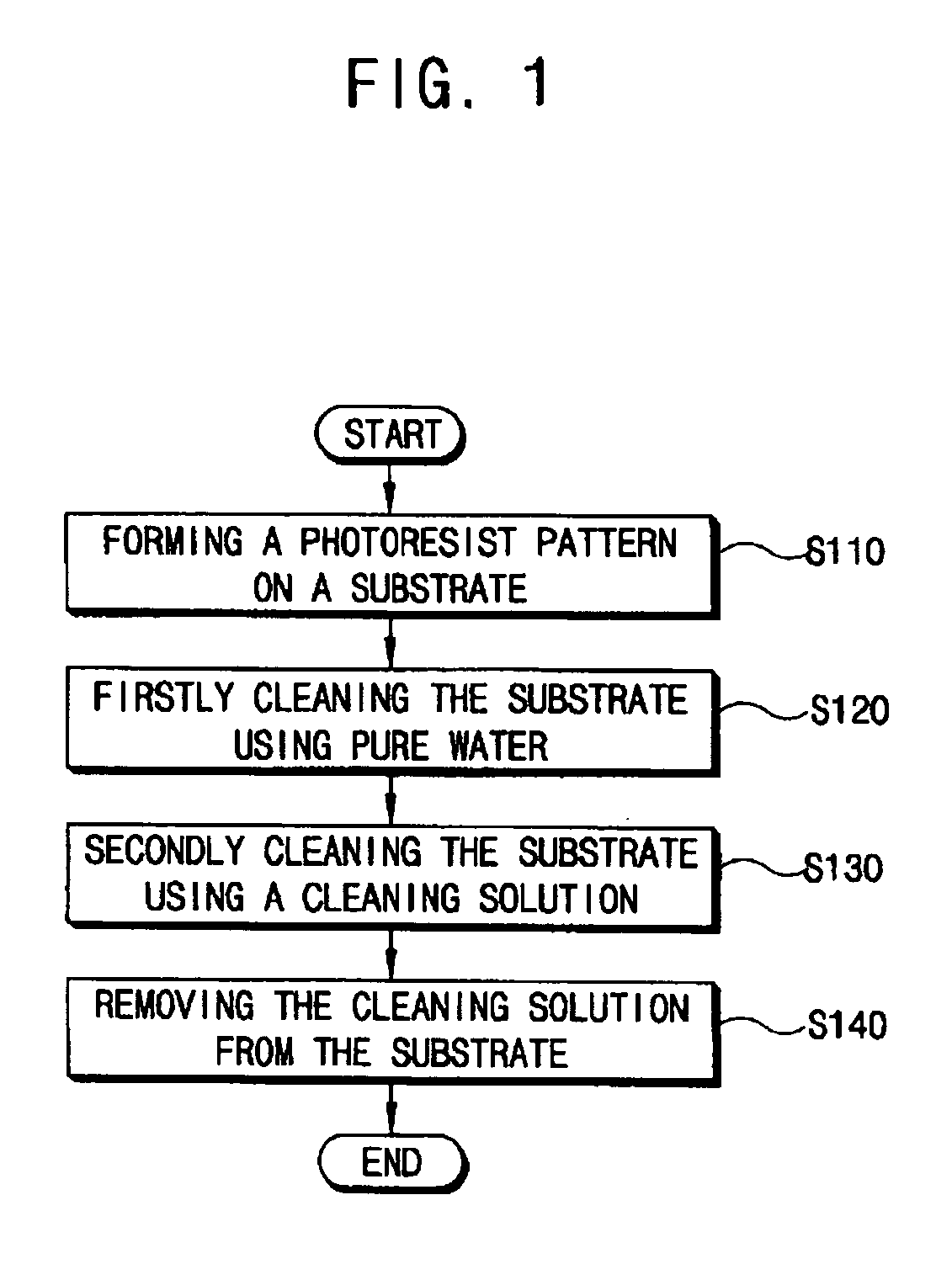

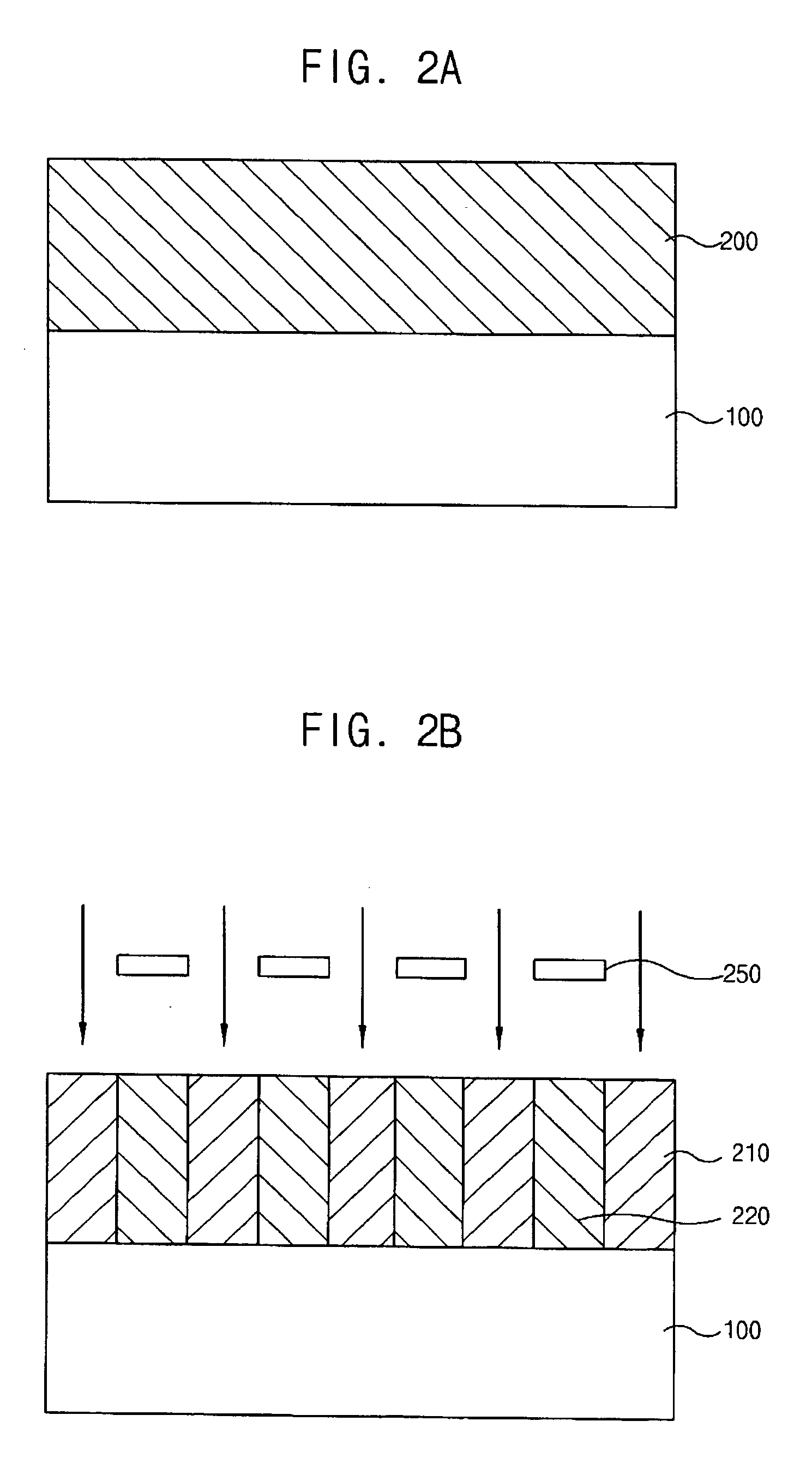

Cleaning solution and method of cleaning semiconductor devices using the same

InactiveUS20050233922A1Accurately and advantageously formedGood dynamic surface tensionInorganic/elemental detergent compounding agentsSurface-active detergent compositionsResistHigh concentration

A cleaning solution for preventing the collapse of photoresist patterns and a method of cleaning a semiconductor device using the cleaning solution; the cleaning solution includes a solvent and a surfactant and has a dynamic surface tension of about 50 dyne / cm or less at about 6 bubbles / seconds when measured by a maximum bubble pressure method. The collapse of the photoresist pattern can be prevented using the cleaning solution when forming minute photoresist patterns having about 100 nm or less pattern width. The cleaning solution containing a surfactant in a high concentration also can be prepared to reduce distribution expenses.

Owner:SAMSUNG ELECTRONICS CO LTD

Water based ink set for ink-jet recording and inkjet recording method

ActiveUS20060082630A1Improved lightfastnessImprove waterproof performanceMeasurement apparatus componentsDuplicating/marking methodsWater basedOrganic solvent

A water based ink set for ink-jet recording has a yellow ink, a magenta ink and a cyan ink each having at least a coloring agent, water and a water soluble organic solvent. The coloring agent of each of the black ink and the red ink is a pigment and the coloring agent of each of the yellow ink, the magenta ink and the cyan ink is a water soluble dye. The black ink and the red ink each have a dynamic surface tension at a lifetime of 100 ms of 40 mN / m or more and 45 mN / m or less as measured by a maximum bubble pressure method at 25° C.

Owner:BROTHER KOGYO KK

Aqueous ink, ink jet recording method, ink cartridge, recording unit and ink jet recording apparatus

ActiveUS7699924B2Efficient aggregationEffective diffusionMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater insoluble

Provided herein is an aqueous ink, which is excellent in both image density and fixing ability irrespective of the kind of a recording medium even when the volume of an ink droplet is small and has such excellent properties that white stripes are not caused even when high-speed recording is conducted. The aqueous ink comprises at least water, a water-soluble organic solvent, a water-insoluble coloring material, a surfactant and a poor medium for the water-insoluble coloring material and / or a salt. The dynamic surface tension of the aqueous ink at a lifetime of 50 milliseconds determined by a maximum bubble pressure method is higher than 47 mN / m, and the dynamic surface tension at a lifetime of 5,000 milliseconds determined by the maximum bubble pressure method is 38 mN / m or lower.

Owner:CANON KK

Printing device and printing method

A printing device including an inkjet head including a nozzle plate, where the printing device is configured to eject an ink from the inkjet head and the ink includes a colorant, at least one organic solvent, and water, wherein a dynamic surface tension A of the ink at 25° C. with a surface lifetime of 15 msec as measured by a maximum bubble pressure method is 34.0 mN / m or less, and the dynamic surface tension A and a static surface tension B of the ink at 25° C. satisfy a formula below,10.0%≦[(A−B) / (A+B)]×100≦19.0%, andwherein a receding contact angle of the ink relative to the nozzle plate is 35° or greater.

Owner:RICOH KK

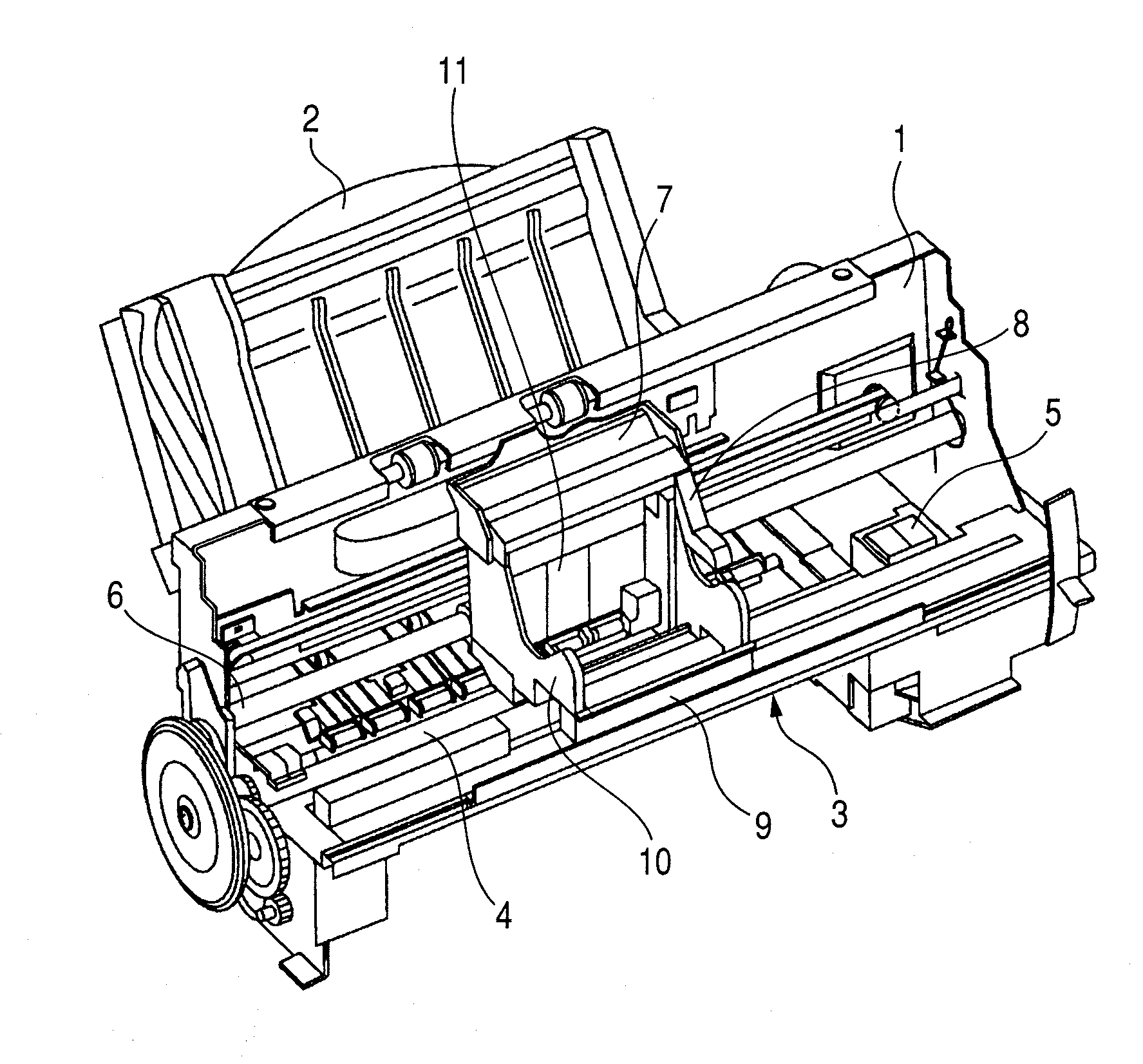

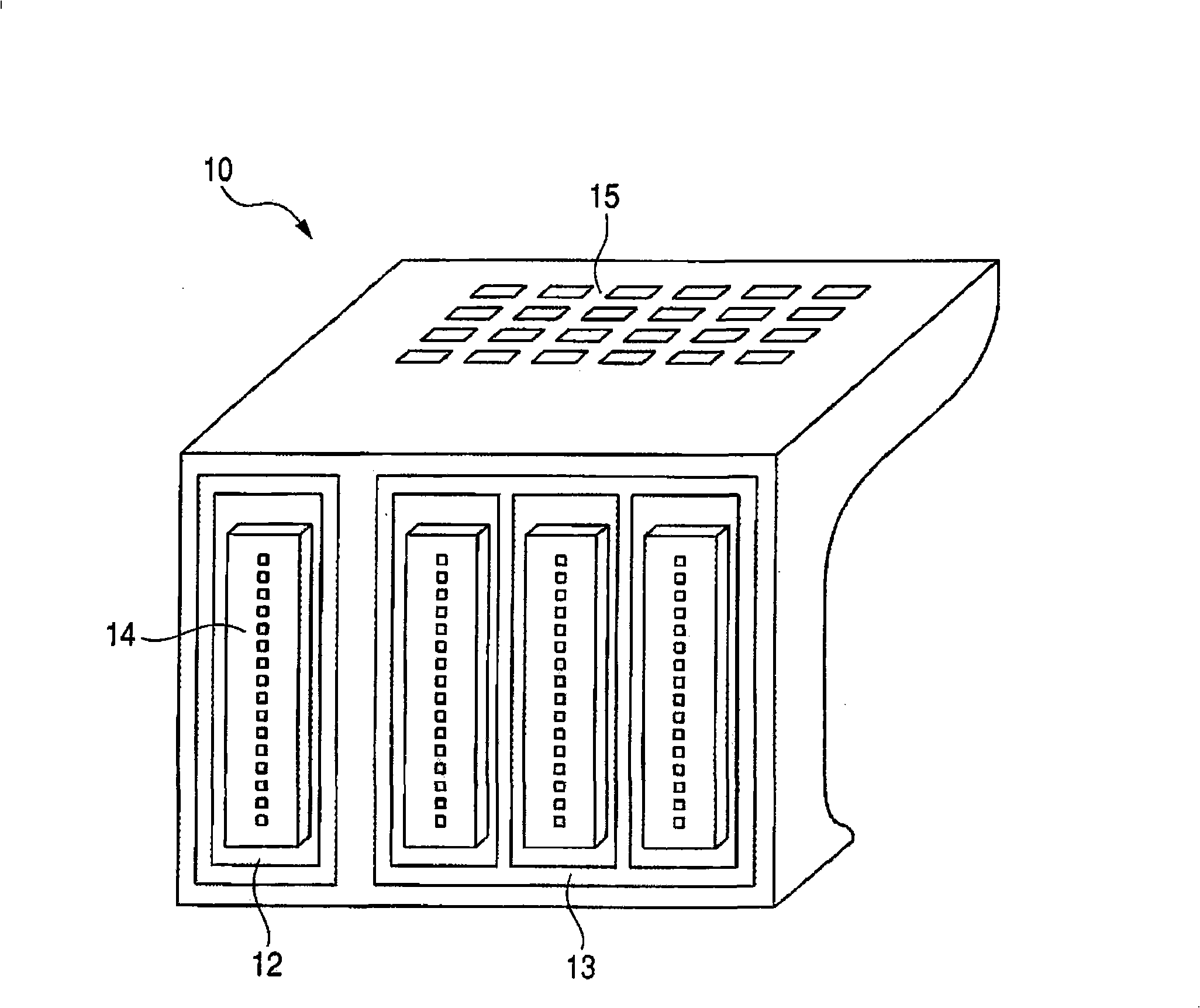

Ink-jet recording apparatus

InactiveUS20070103527A1CompatibilityPrevent precipitationMeasurement apparatus componentsDuplicating/marking methodsWater basedSulfenamide

The ink-jet recording apparatus has an-ink passage into which a water-based ink or a preservation solution is filled. The ink passage employs a rubber member formed from an ethylene propylene diene rubber in which a sulfenamide-based vulcanization accelerator or a thiazole-based vulcanization accelerator is employed. The water-based ink has a dynamic surface tension at a lifetime of 100 ms of about 35 mN / m to about 45 mN / m as measured by means of a maximum bubble pressure method at a measurement temperature of 25° C. Furthermore, the preservation solution has a dynamic surface tension at a lifetime of 100 ms of about 30 mN / m to about 35 mN / m as measured by means of the maximum bubble pressure method at a measurement temperature of 25° C.

Owner:BROTHER KOGYO KK

Aqueous ink, ink jet recording method, ink cartridge, recording unit and ink jet recording apparatus

ActiveUS7862653B2Good fixabilityHigh image densityMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater soluble

Novel conditions in the physical properties of an ink have been found out to provide an aqueous ink, which can give a high image density and achieve excellent fixing ability. The aqueous ink comprises at least water, a water-soluble organic solvent, a surfactant and a coloring material, wherein the dynamic surface tension at a lifetime of 50 milliseconds as determined by a maximum bubble pressure method is 49 mN / m or more, and the dynamic surface tension at a lifetime of 5,000 milliseconds as determined by the maximum bubble pressure method is 38 mN / m or less.

Owner:CANON KK

Aqueous ink, ink set, image forming method and image forming apparatus

ActiveUS20080280041A1High image densityExcellent in abilityMeasurement apparatus componentsFilm/foil adhesivesImage formationReactive components

An aqueous ink to be used together with a pigment ink containing a pigment and a polymer, wherein the aqueous ink contains a reactive component for destabilizing the dispersion state of the pigment, the dynamic surface tension of the aqueous ink at a lifetime of 30 milliseconds is 41 mN / m or more, and the dynamic surface tension of the aqueous ink at a lifetime of 500 milliseconds is from 28 mN / m or more to 38 mN / m or less as determined by a maximum bubble pressure method.

Owner:CANON KK

Aqueous ink, ink set, image forming method and image forming apparatus

ActiveUS8016932B2Avoid it happening againImprove image qualityInksCoatingsPhysical chemistryMaximum bubble pressure method

An aqueous ink used together with a black ink containing a self-dispersion pigment, wherein the aqueous ink contains a reactive component for destabilizing the dispersion state of the self-dispersion pigment, the dynamic surface tension of the aqueous ink at a lifetime of 30 milliseconds is 41 mN / m or more, and the dynamic surface tension of the aqueous ink at a lifetime of 500 milliseconds is from 28 mN / m or more to 38 mN / m or less as determined by a maximum bubble pressure method.

Owner:CANON KK

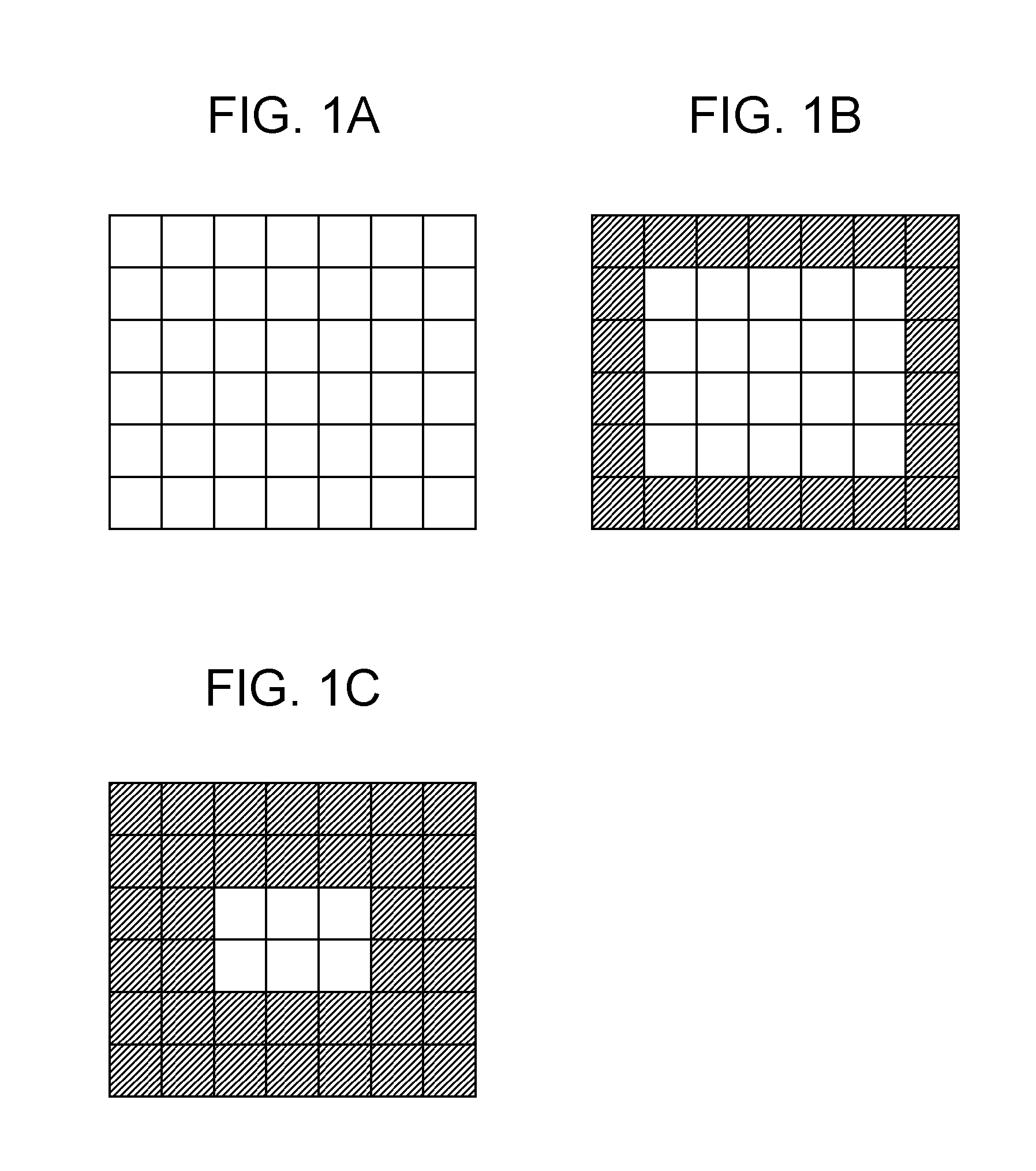

Inkjet recording method

An inkjet recording method includes applying a pigment-containing first black ink to a recording medium to record an edge region of an image, and applying a pigment-containing second black ink to the recording medium to record an inner region of the image. A dynamic surface tension γ1 of the first black ink determined by a maximum bubble pressure method for a lifetime of 100 ms and a dynamic surface tension γ2 of the second black ink determined by a maximum bubble pressure method for a lifetime of 100 ms satisfy relationships of condition (1) of γ1>γ2, condition (2) of γ1−γ2≦20 mN / m, condition (3) of 40 mN / m≦γ1, and condition (4) of 34 mN / m≦γ2.

Owner:CANON KK

Ink composition, recording method and recorded image utilizing the same, ink set and ink head

ActiveUS7264664B2Improve discharge stabilityHigh quality recorded imageMeasurement apparatus componentsInksElectricitySURFACTANT BLEND

An ink composition is manufactured to contain a surfactant having difference d1 (σ10−γ) which is difference between dynamic surface tension (σ10) of the solution obtained by making 0.1 wt % solution dissolved in purified water to be measured by using a maximum bubble pressure method at the bubble frequency of 10 Hz at a temperature from 24° C. to 26° C. and static surface tension (γ) to be measured at a temperature from 24° C. to 26° C. and which satisfies 0 mN / m≦d1≦15 mN / m. An image is recorded by applying a voltage to partitions made of a piezoelectric material thereby applying a pressure to the ink composition supplied from an ink tank to an ink chamber of an ink head to discharge a liquid droplet of the ink composition, and depositing the liquid droplet onto a recording material.

Owner:SHARP KK

Ink-jet recording apparatus

ActiveUS20070035588A1Prevent precipitationExcellent ejection stabilityMeasurement apparatus componentsDuplicating/marking methodsWater basedPolymer science

The ink-jet recording apparatus has an ink passage into which a water based ink or a preservation solution is filled. The ink passage employs a rubber member formed from a rubber which is formed of a butyl rubber polymer, a rubber polymer vulcanizable with an organic peroxide, and an organic peroxide. The water-based ink has a dynamic surface tension at a lifetime of 100 ms of about 35 mN / m to about 45 mN / m as measured by means of a maximum bubble pressure method at a measurement temperature of 25° C. The preservation solution has a dynamic surface tension at a lifetime of 100 ms of about 30 mN / m to about 35 mN / m as measured by means of the maximum bubble pressure method at a measurement temperature of 25° C.

Owner:BROTHER KOGYO KK

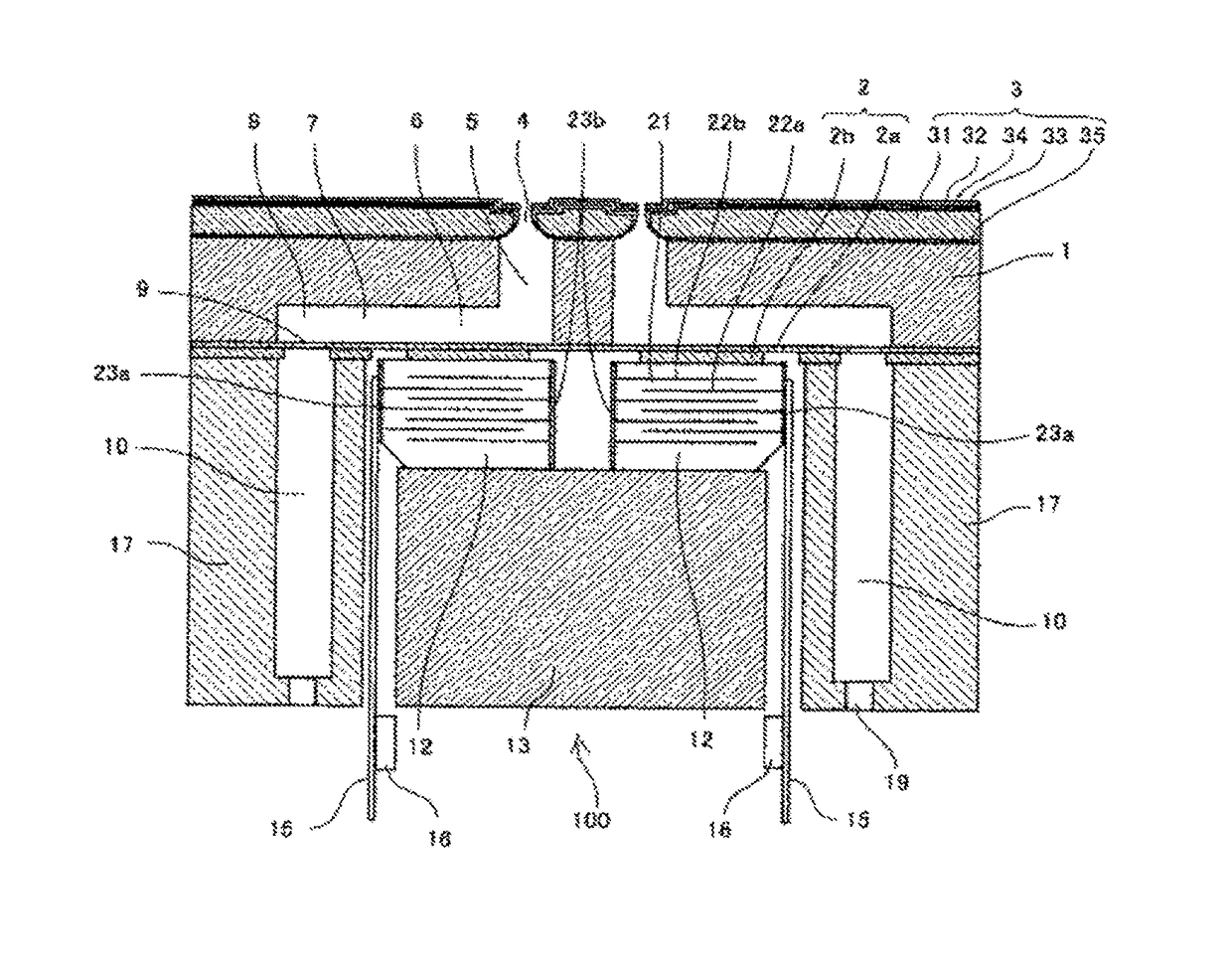

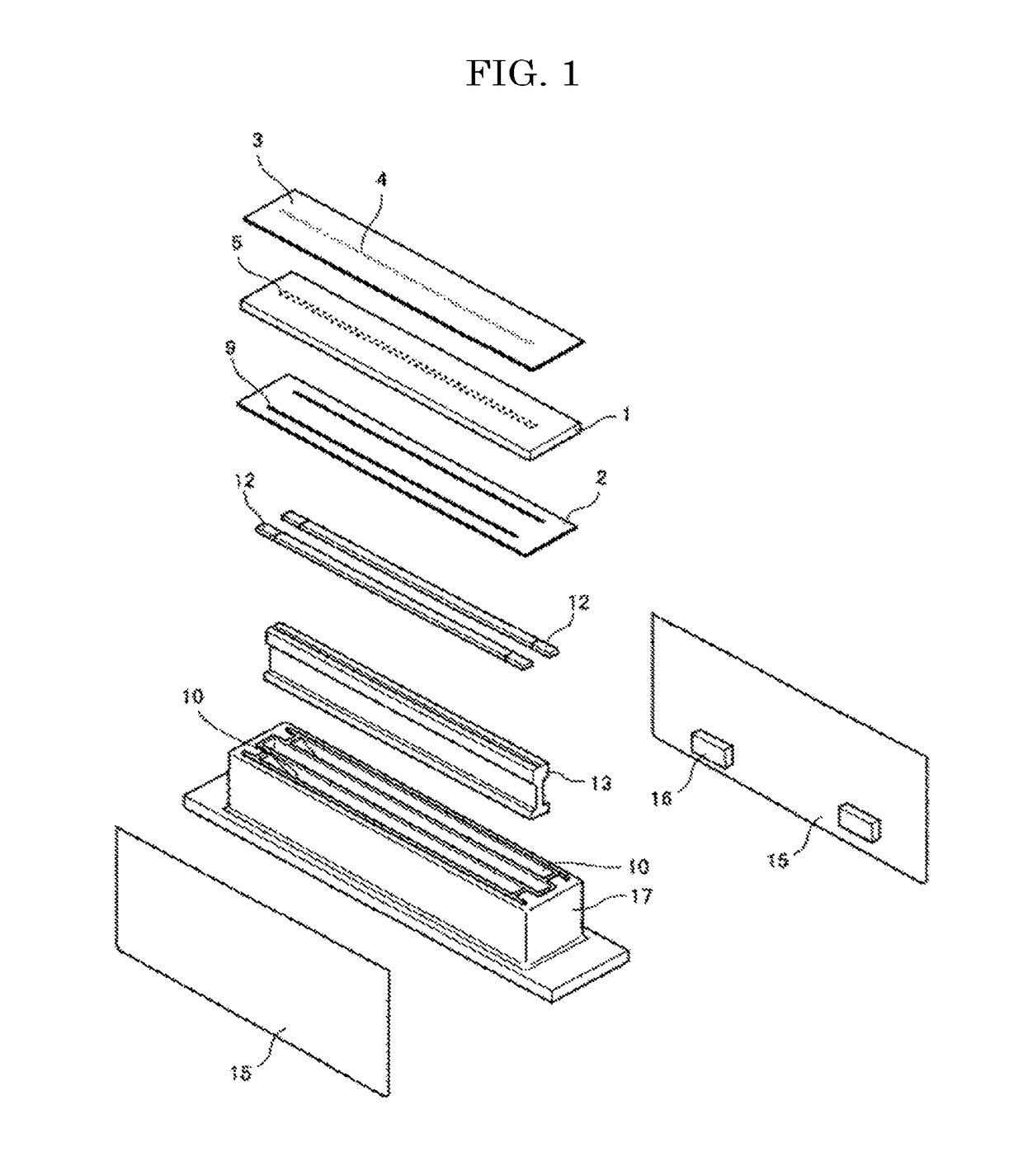

Ink discharge device and ink discharge method

An ink discharge device is provided including an ink, an ink discharge head, and a circulator. The ink discharge head includes a nozzle, an individual liquid chamber communicated with the nozzle, a flow-in channel, and a flow-out channel. The circulator circulates the ink by letting the ink flow into the individual liquid chamber via the flow-in channel and flow out from the individual liquid chamber via the flow-out channel. A flow rate of the circulated ink is 0.10 to 1.50 times a maximum dischargeable rate of the ink discharge head. A dynamic surface tension A of the ink at 25° C. is 34.0 mN / m or less when measured by a maximum bubble pressure method at a surface lifetime of 15 msec, and the dynamic surface tension A and a static surface tension B of the ink at 25° C. satisfy the following relation:10.0(%)≤[(A−B) / (A+B)]×100≤19.0(%).

Owner:RICOH KK

Inkjet recording method and inkjet recording device

ActiveUS9010918B2Keep dryQuality improvementMeasurement apparatus componentsDuplicating/marking methodsWater dispersibleOrganic solvent

An inkjet recording method including applying stimuli to inkjet recording ink to make the ink jet onto recording medium, wherein the recording medium includes support, and surface layer provided on at least one surface of the support, where transfer amount of pure water with contact time of 100 ms determined by measuring the surface of the recording medium to which the surface layer is provided by dynamic scanning absorptometer is 1 to 10 mL / m2, the recording medium is surface-treated through corona discharge or plasma treatment, the ink contains water-dispersible colorant, organic solvent, surfactant, and water, the organic solvent contains at least one polyhydric alcohol having equilibrium moisture content of 30% by mass or greater at 23° C. and 80% RH, and dynamic surface tension of the ink, as measured by maximum bubble pressure method with surface lifetime of 15 ms, is 35 mN / m or lower at 25° C.

Owner:RICOH KK

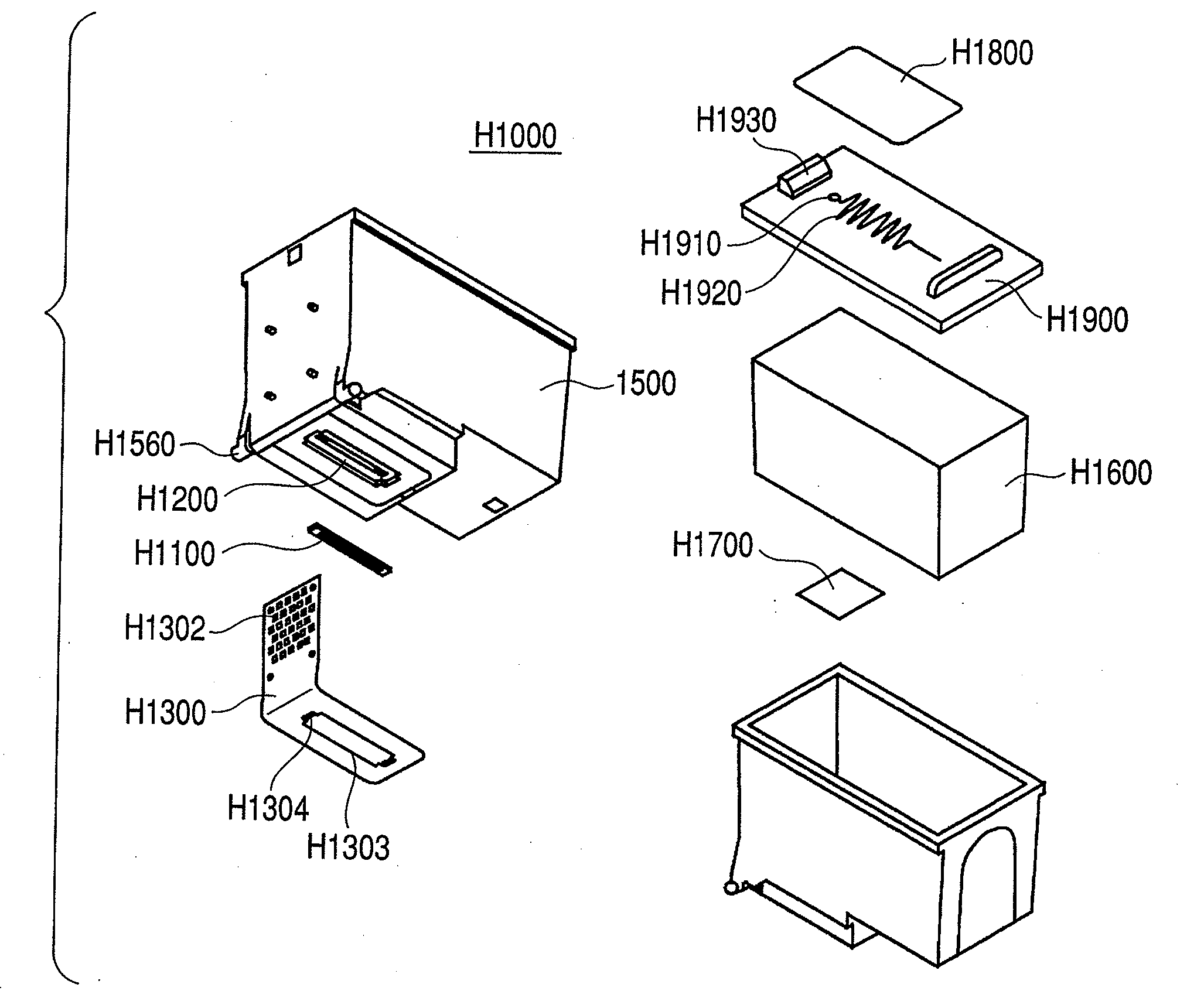

Ink jet recording ink tank

ActiveUS20080278552A1Reliably counter shockEasy to useMeasurement apparatus componentsInksEngineeringMechanical engineering

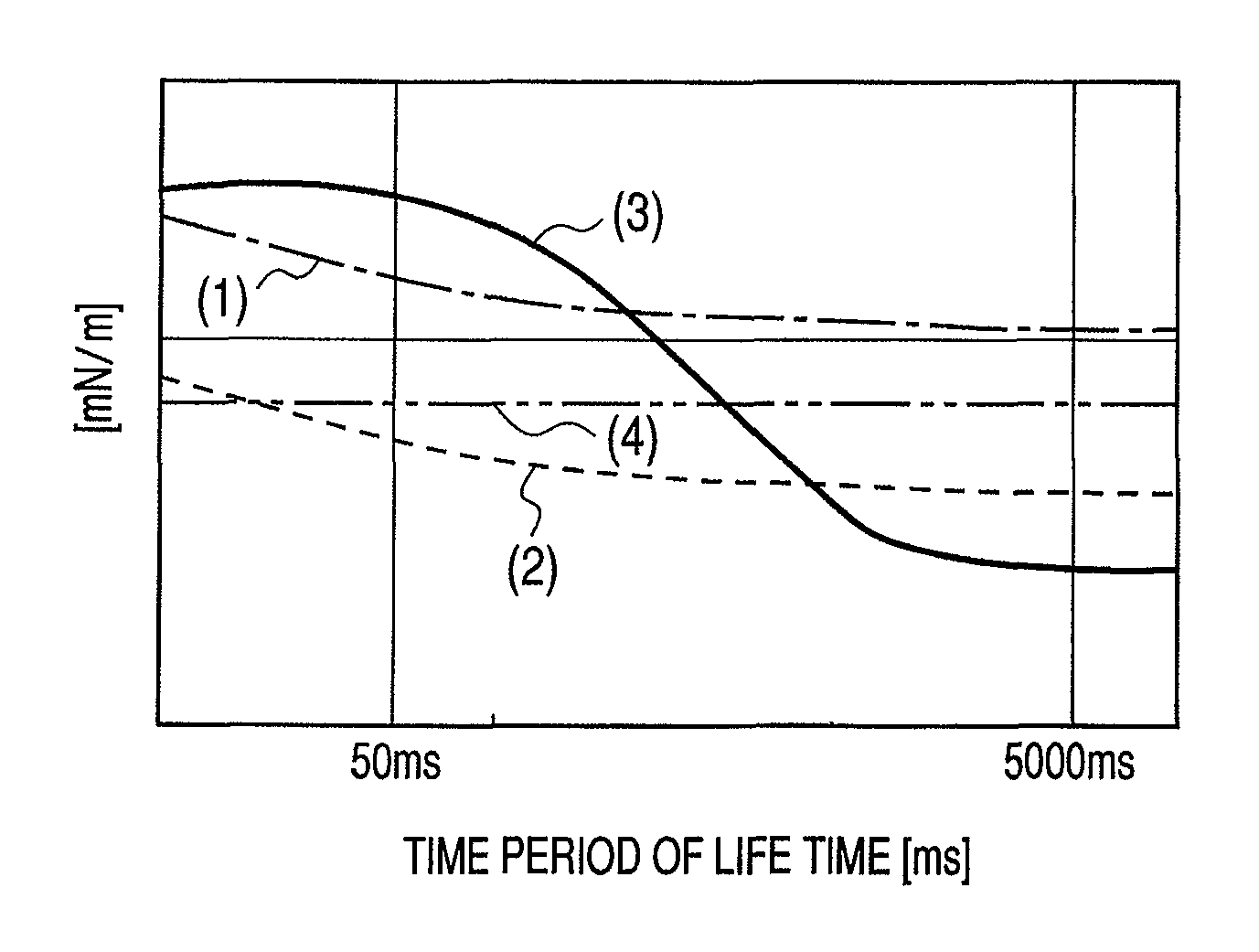

An ink jet recording ink tank includes: an ink retention member, which to hold ink exerts a negative pressure through capillary force; and ink, which is retained in the ink retention member, for which a dynamic surface tension in a lifetime of 50 msec, obtained by a maximum bubble pressure method, is higher than an interfacial tension of the ink retention member, a dynamic surface tension in a lifetime of 5000 msec is lower than the interfacial tension of the ink retention member, and a difference between the dynamic surface tension in the lifetime of 50 msec and the dynamic surface tension in the lifetime of 5000 msec is equal to or greater than 8 mN / m.

Owner:CANON KK

Aqueous ink, ink set, image forming method and image forming apparatus

InactiveCN101302378ANo reduction in jetting stabilityIncrease brightnessDuplicating/marking methodsInksReactive componentsPolymer

An aqueous ink to be used together with a pigment ink containing a pigment and a polymer, wherein the aqueous ink contains a reactive component for destabilizing the dispersion state of the pigment, the dynamic surface tension of the aqueous ink at a lifetime of 30 milliseconds is 41 mN / m or more, and the dynamic surface tension of the aqueous ink at a lifetime of 500 milliseconds is from 28 mN / m or more to 38 mN / m or less as determined by a maximum bubble pressure method.

Owner:CANON KK

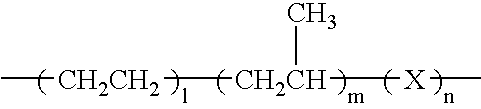

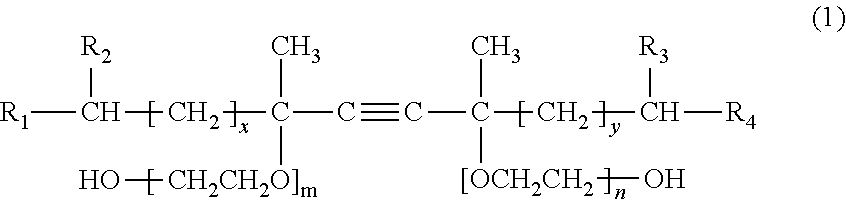

Ink, ink cartridge, and image recording method

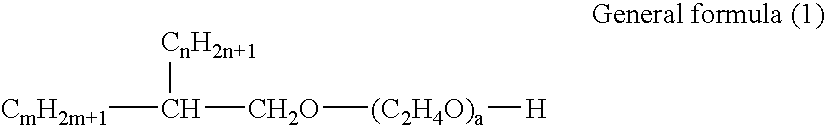

ActiveUS20170210927A1Suppressed in feathering and strike-throughInksPrintingPhysical chemistryImage recording

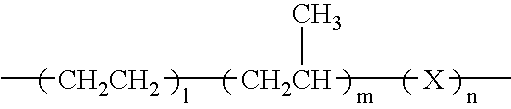

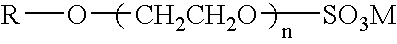

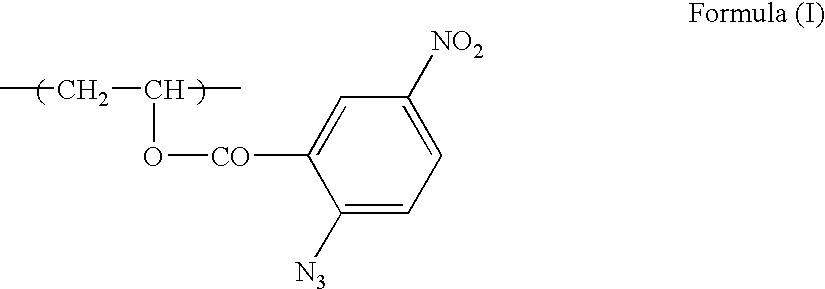

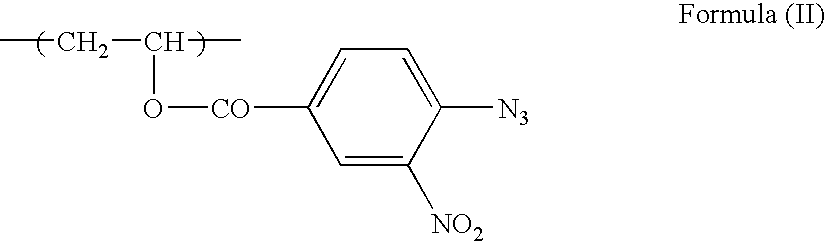

Provided is an ink containing a pigment, a water-soluble organic solvent, and a surfactant represented by the following general formula (1), and having a viscosity at 25° C. of 5 mPa·s or more. The ink has a static surface tension of 27.1 mN / m or more and 35.0 mN / m or less, which is measured at 25° C. by a Wilhelmy method. The ink also has a dynamic surface tension at a bubble life time of 150 msec of 30.5 mN / m or more and 37.0 mN / m or less, which is measured at 25° C. by a maximum bubble pressure method.

Owner:CANON KK

Ink-jet recording apparatus

ActiveUS20070030301A1Inhibit swellingSpecific dynamic surface tensionMeasurement apparatus componentsDuplicating/marking methodsWater basedVulcanization

The ink-jet recording apparatus has an ink passage into which a water based ink or a preservation solution is filled. The ink passage is formed from a rubber employing organic peroxide and zinc oxide as a vulcanization agent. The ink has a dynamic surface tension at a lifetime of 100 ms of about 35 mN / m to about 45 mN / m as measured by means of a maximum bubble pressure method at a measurement temperature of 25° C. The preservation solution has a dynamic surface tension at a lifetime of 100 ms of about 30 mN / m to about 35 mN / m as measured by means of a maximum bubble pressure method at a measurement temperature of 25° C.

Owner:BROTHER KOGYO KK

Aqueous ink, ink set, image forming method and image forming apparatus

InactiveCN101302368AImprove image qualityAvoid bleedingDuplicating/marking methodsInksImage formationReactive components

An aqueous ink used together with a black ink containing a self-dispersion pigment, wherein the aqueous ink contains a reactive component for destabilizing the dispersion state of the self-dispersion pigment, the dynamic surface tension of the aqueous ink at a lifetime of 30 milliseconds is 41 mN / m or more, and the dynamic surface tension of the aqueous ink at a lifetime of 500 milliseconds is from 28 mN / m or more to 38 mN / m or less as determined by a maximum bubble pressure method.

Owner:CANON KK

Method of forming pattern and method of producing electronic element

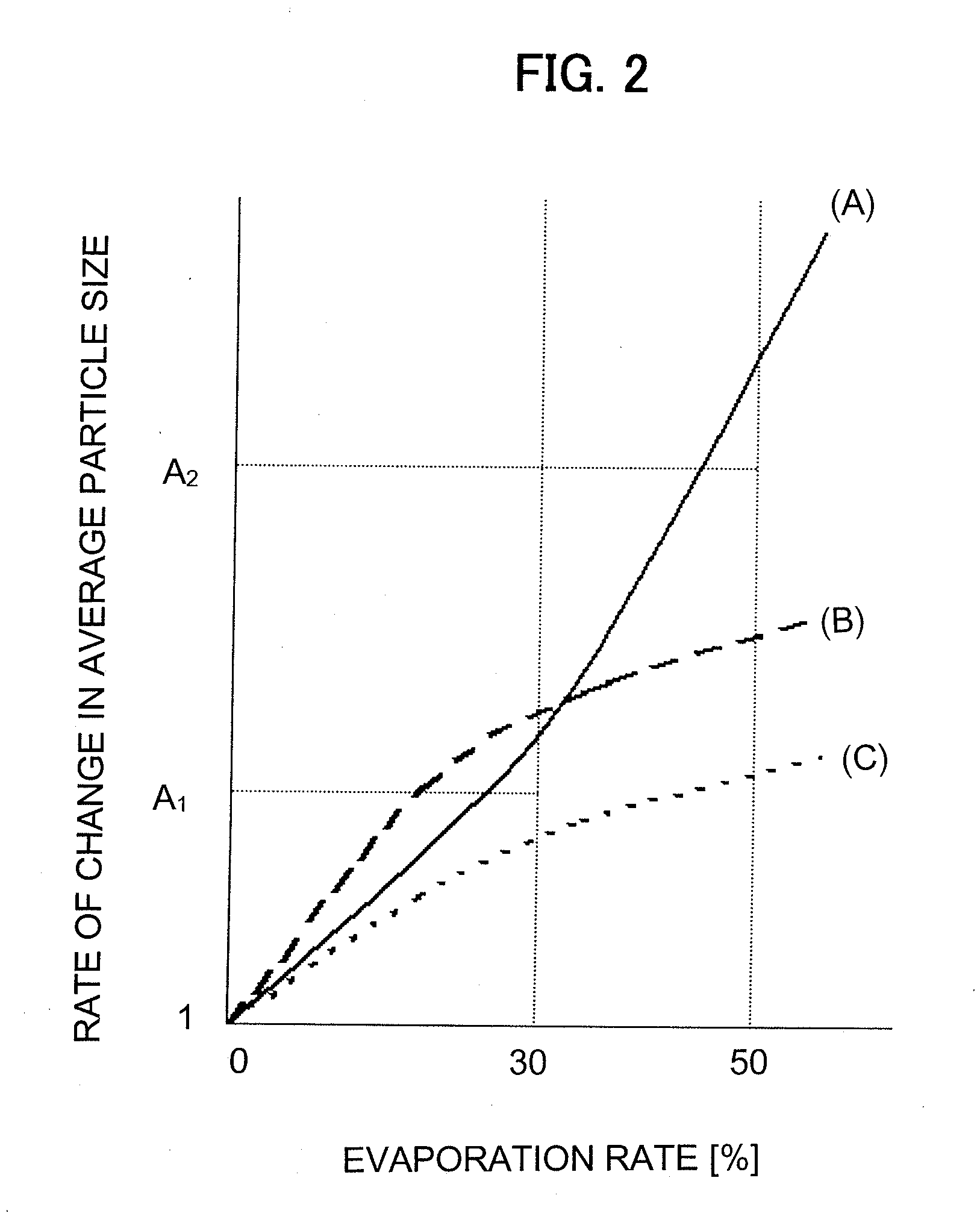

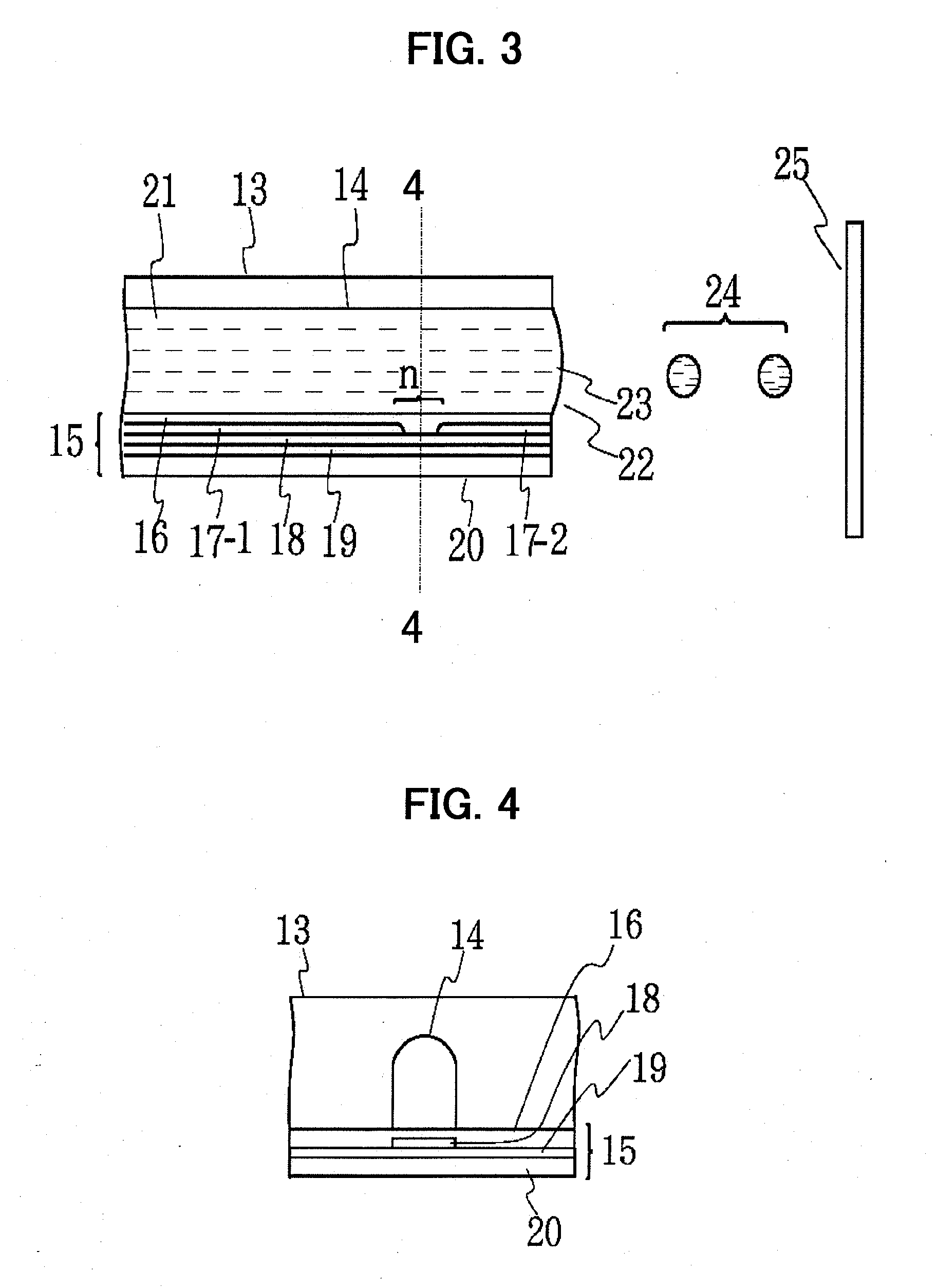

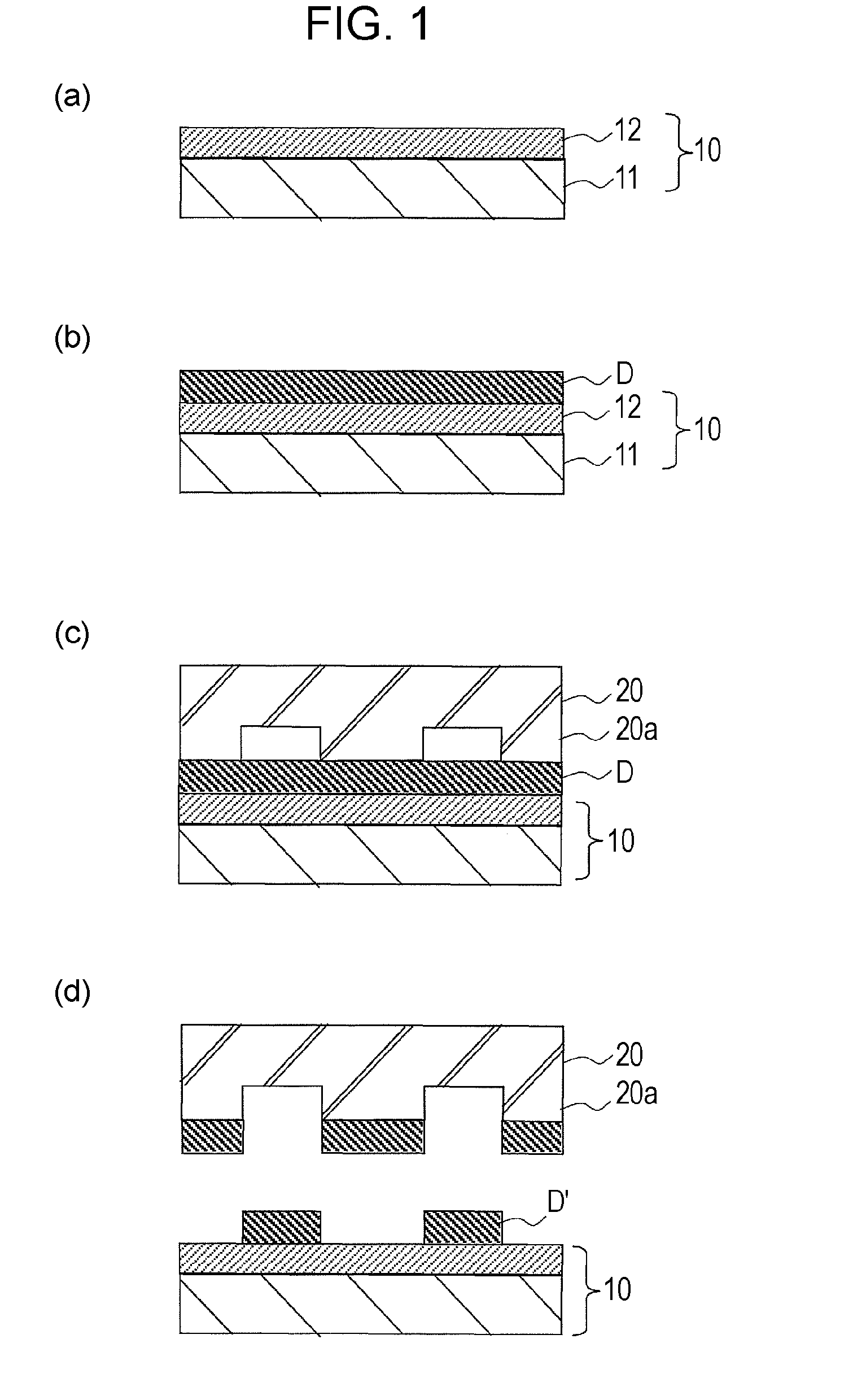

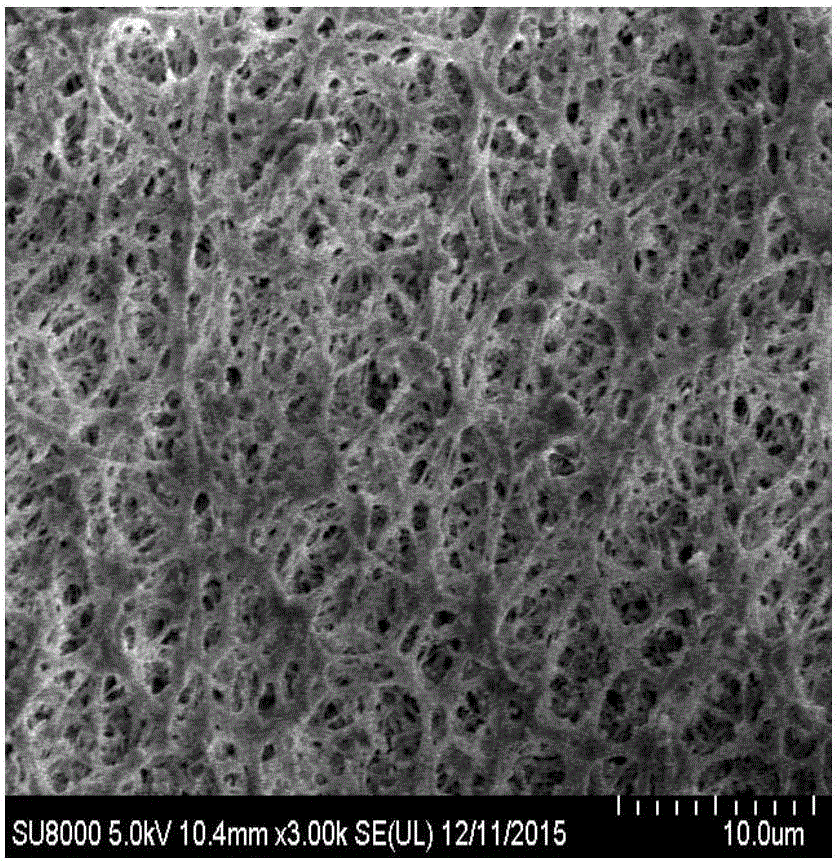

InactiveUS20100044905A1Reliable transmissionFine and precise patternSolid-state devicesWood working apparatusSheet filmEngineering

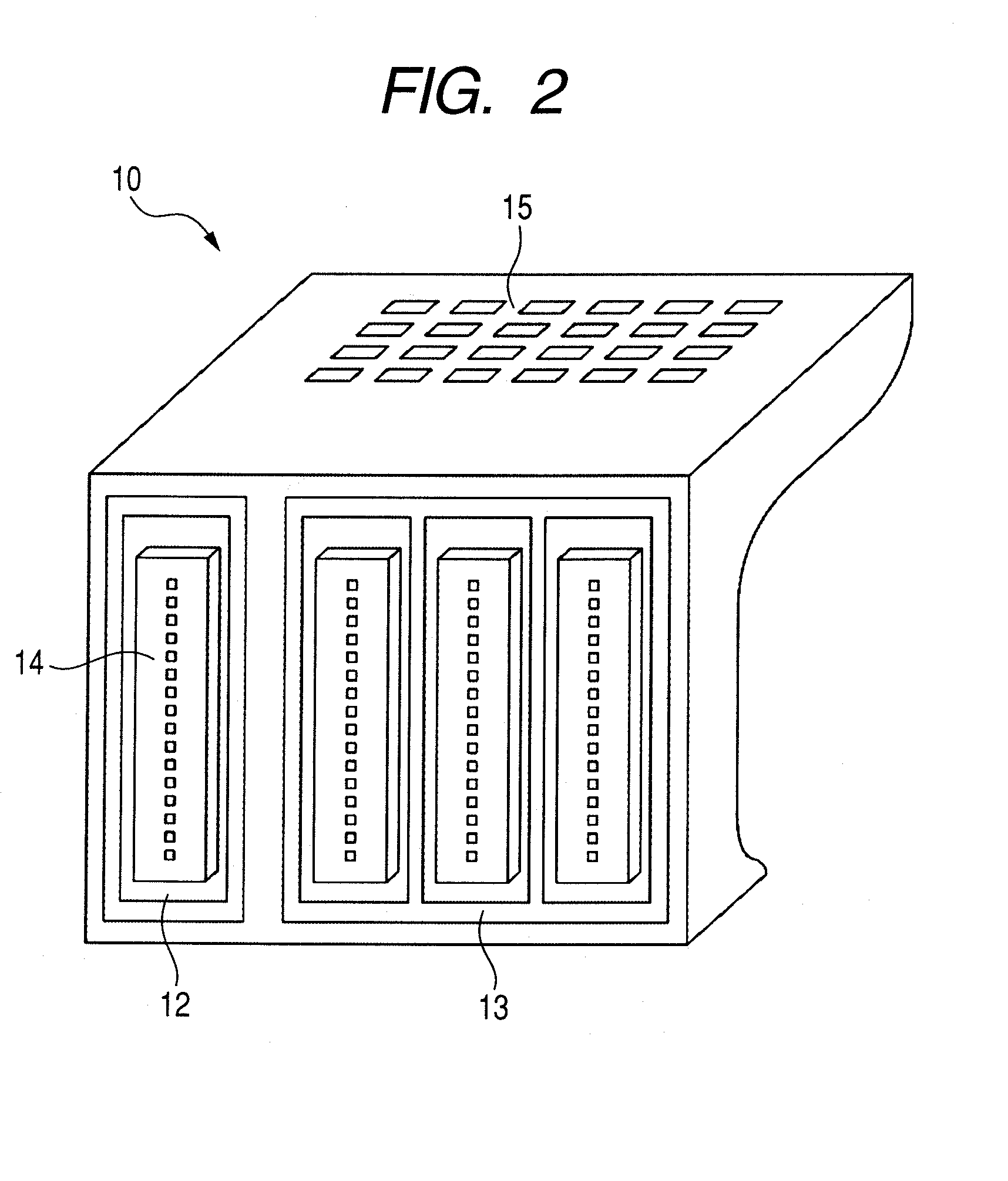

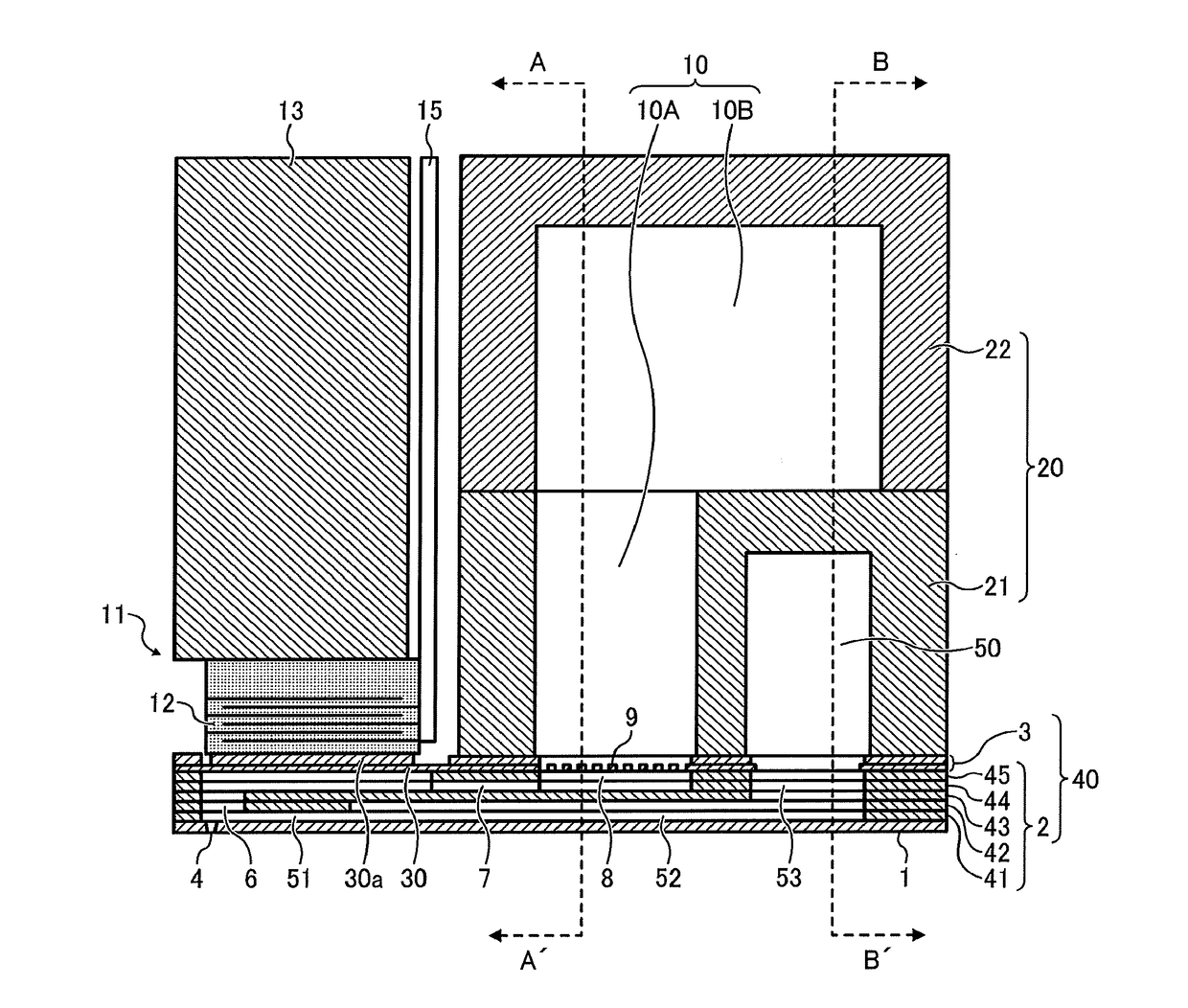

A method of forming a pattern and a method of producing an electronic element with which a fine and precise pattern is stably formed are provided. Each of the method of forming a pattern and the method of producing an electronic element includes a step of forming an electrically conductive film D by applying a liquid composition onto a first plate 10; a step of forming an electrically conductive pattern D′ on the first plate 10 by pressing a second plate 20 onto a surface side of the first plate 10, on which the electrically conductive film D is formed, to transfer an unwanted pattern of the electrically conductive film D to top faces of projections 20a of the second plate 20, thereby removing the unwanted pattern; and a step of transferring the electrically conductive pattern D′ by pressing the surface side of the first plate 10, on which the electrically conductive pattern D′ is formed, onto a surface of a transfer-receiving substrate, wherein when a surface tension of the surface of the first plate 10, onto which the liquid composition is applied, is represented by α, a dynamic surface tension of the liquid composition at 100 msec measured by a maximum bubble pressure method is represented by β, and a surface tension of the top faces of the projections 20a of the second plate 20 is represented by γ, the composition of the liquid composition or a material of the surface of the first plate 10 or the second plate 20 is set so as to satisfy γ>α≧β.

Owner:SONY CORP

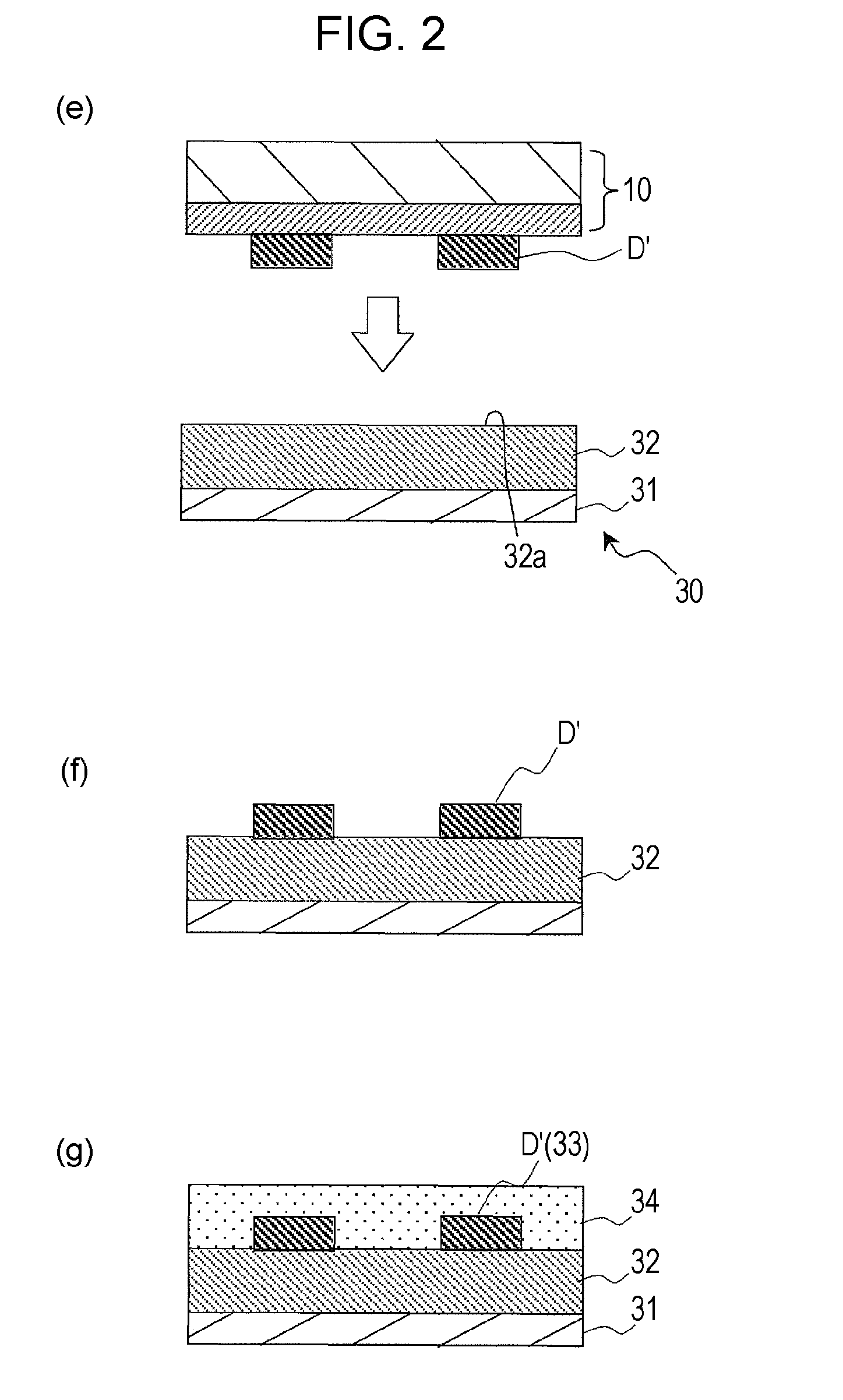

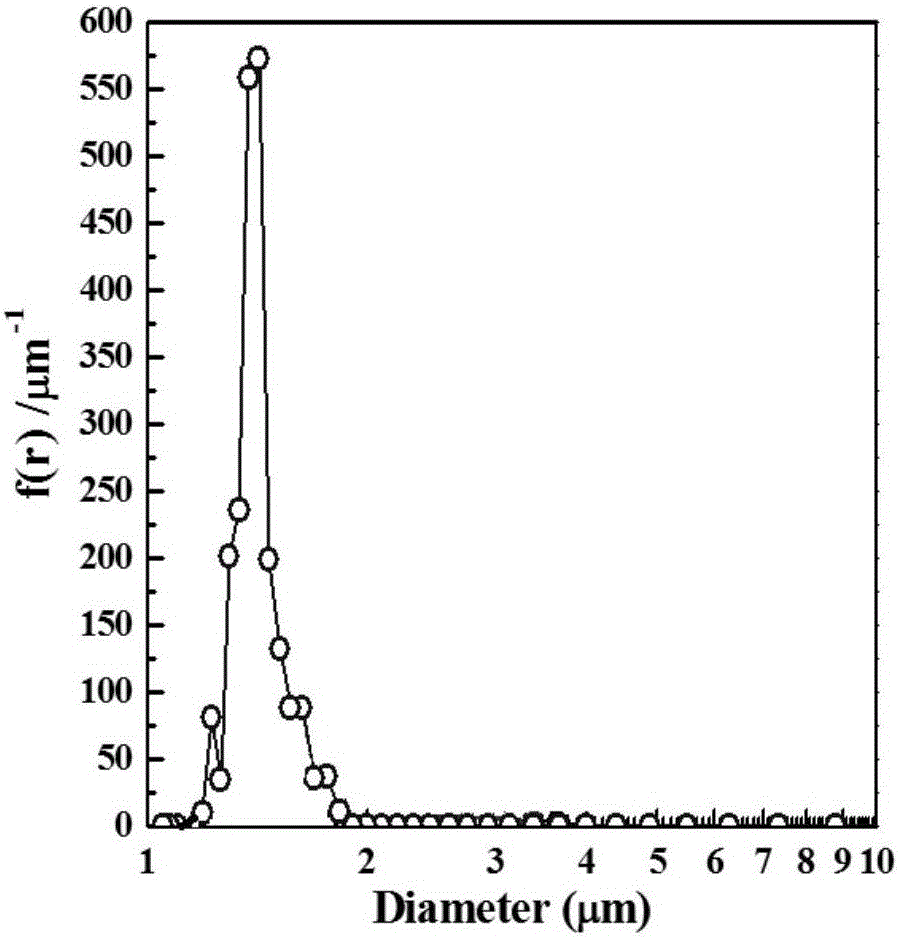

Gelled lead acid battery diaphragm pore size distribution measurement method

InactiveCN105674919ATruly reflect the porosityAccurately getUsing fluid meansColloidElectron microscope

The invention provides a gelled lead acid battery diaphragm pore size distribution measurement method, which is convenient to test and accurate in testing result. A bubble pressure method based on a capillary action principle is adopted to measure a wet curve Fw and a dry curve Fv; according to the ratio of an opened diaphragm pore area R(r)=(Fw / Fv)*100%, differentiation is carried out between the R(r) and the pore size, and a diaphragm pore size distribution function f(r)=d(R(r)) / dr is obtained. The gelled lead acid battery diaphragm pore size distribution measurement method has the beneficial effects that when the wet curve is measured, a diaphragm sample is placed in an ethanol solution for being immersed, the actually-acted pore conditions after the diaphragm is assembled in a battery can be truly reflected, the added pressure value is 0.001 to 0.01 MPa each time, and the obtained result is accurate. The method of the invention is convenient to test, the obtained pore size distribution result is accurate, and the result is consistent with results through electron microscope detection and mercury intrusion detection.

Owner:FUZHOU UNIV +1

Inkjet recording sheet, manufacturing method of inkjet recording sheet, and inkjet recording method

A inkjet recording sheet comprising a support and provided thereon, a porous ink absorptive layer containing inorganic micro-particles and a hydrophilic binder, wherein the ink absorptive layer contains 0.15-2.5 g / m2 of a surfactant having a dynamic surface tension of a 0.3% aqueous solution, which is measured by a maximum bubble pressure method, of not more than 60 mN / m at 20 m·sec under a condition of a liquid temperature of 35° C.

Owner:KONICA MINOLTA INC

Ink jet recording ink tank

ActiveUS7976146B2Easy to useReliably counter shocksMeasurement apparatus componentsInksEngineeringMechanical engineering

An ink jet recording ink tank includes: an ink retention member, which to hold ink exerts a negative pressure through capillary force; and ink, which is retained in the ink retention member, for which a dynamic surface tension in a lifetime of 50 msec, obtained by a maximum bubble pressure method, is higher than an interfacial tension of the ink retention member, a dynamic surface tension in a lifetime of 5000 msec is lower than the interfacial tension of the ink retention member, and a difference between the dynamic surface tension in the lifetime of 50 msec and the dynamic surface tension in the lifetime of 5000 msec is equal to or greater than 8 mN / m.

Owner:CANON KK

Water based ink set for ink-jet recording and inkjet recording method

ActiveUS7244297B2Improved lightfastnessIncrease resistanceMeasurement apparatus componentsDuplicating/marking methodsWater basedOrganic solvent

A water based ink set for ink-jet recording has a yellow ink, a magenta ink and a cyan ink each having at least a coloring agent, water and a water soluble organic solvent. The coloring agent of each of the black ink and the red ink is a pigment and the coloring agent of each of the yellow ink, the magenta ink and the cyan ink is a water soluble dye. The black ink and the red ink each have a dynamic surface tension at a lifetime of 100 ms of 40 mN / m or more and 45 mN / m or less as measured by a maximum bubble pressure method at 25° C.

Owner:BROTHER KOGYO KK

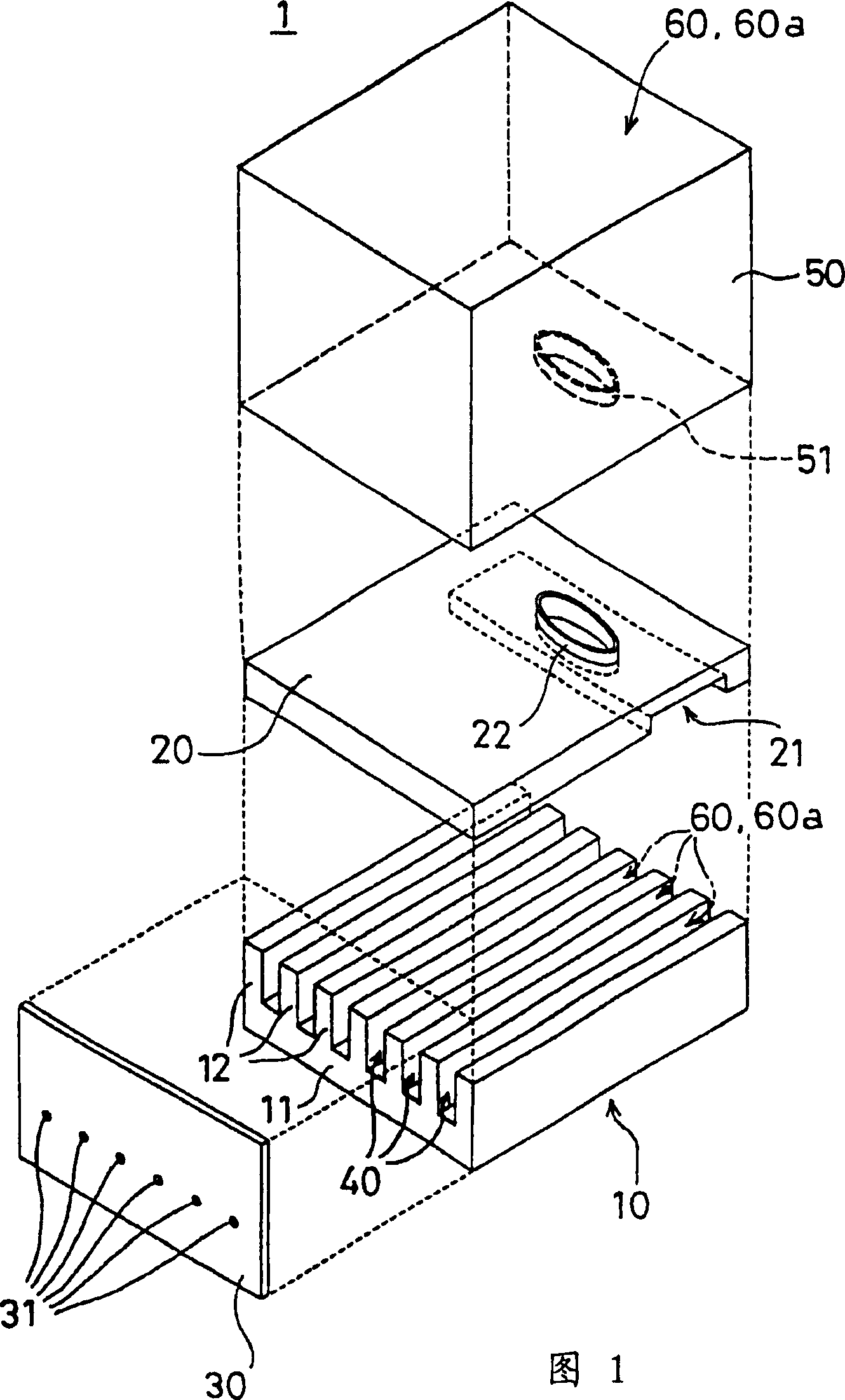

Ink composition, printing method using the same and printed image obtained using the same, and ink set and ink head

InactiveCN1782001ASlow dischargeSmooth dischargeDuplicating/marking methodsInksEngineeringMaximum bubble pressure method

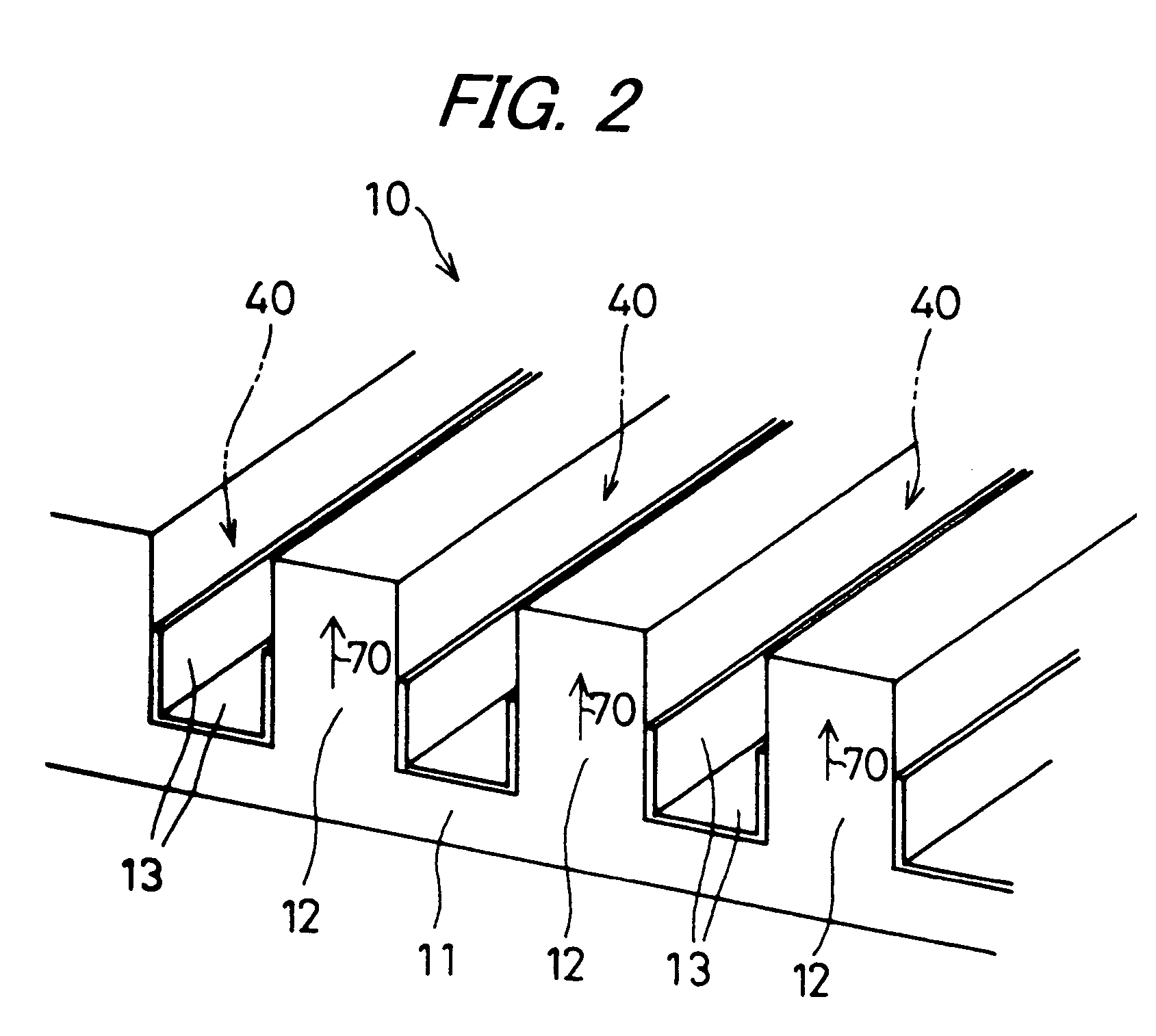

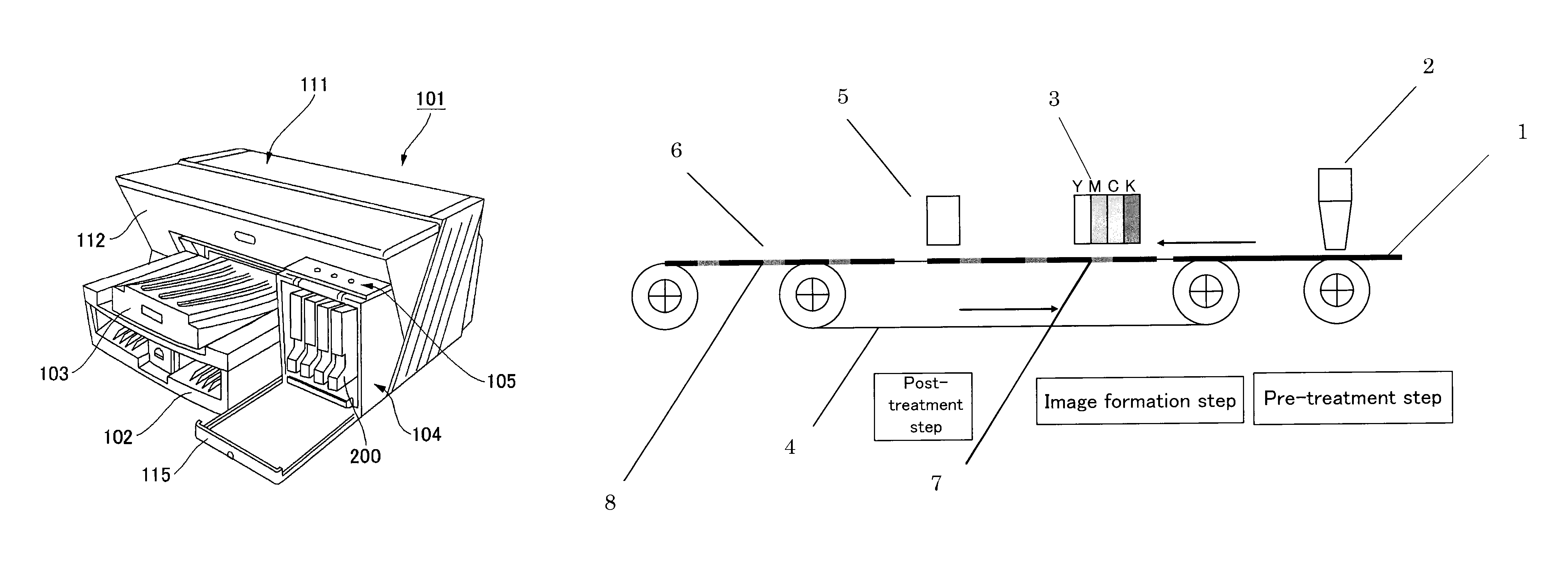

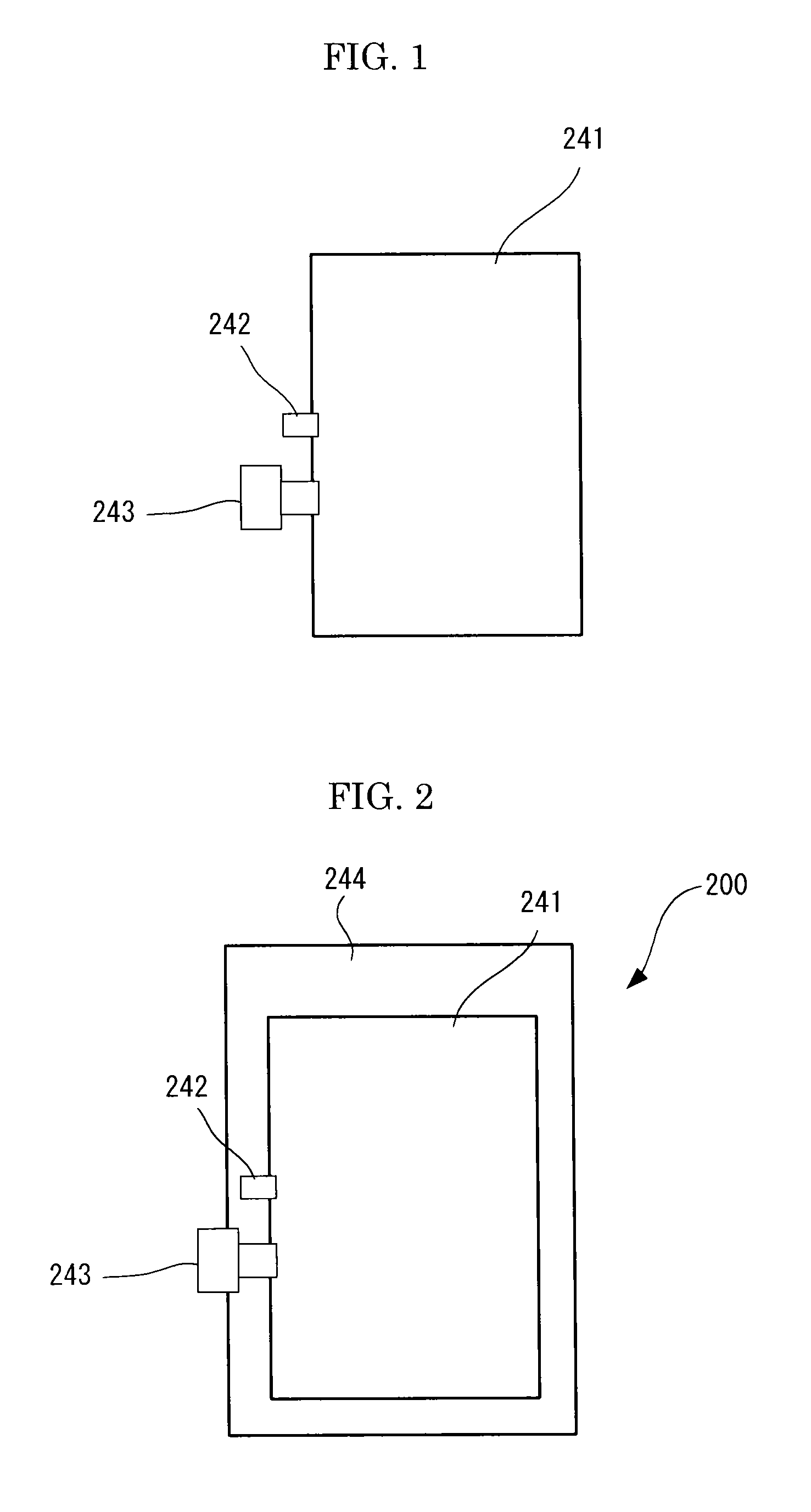

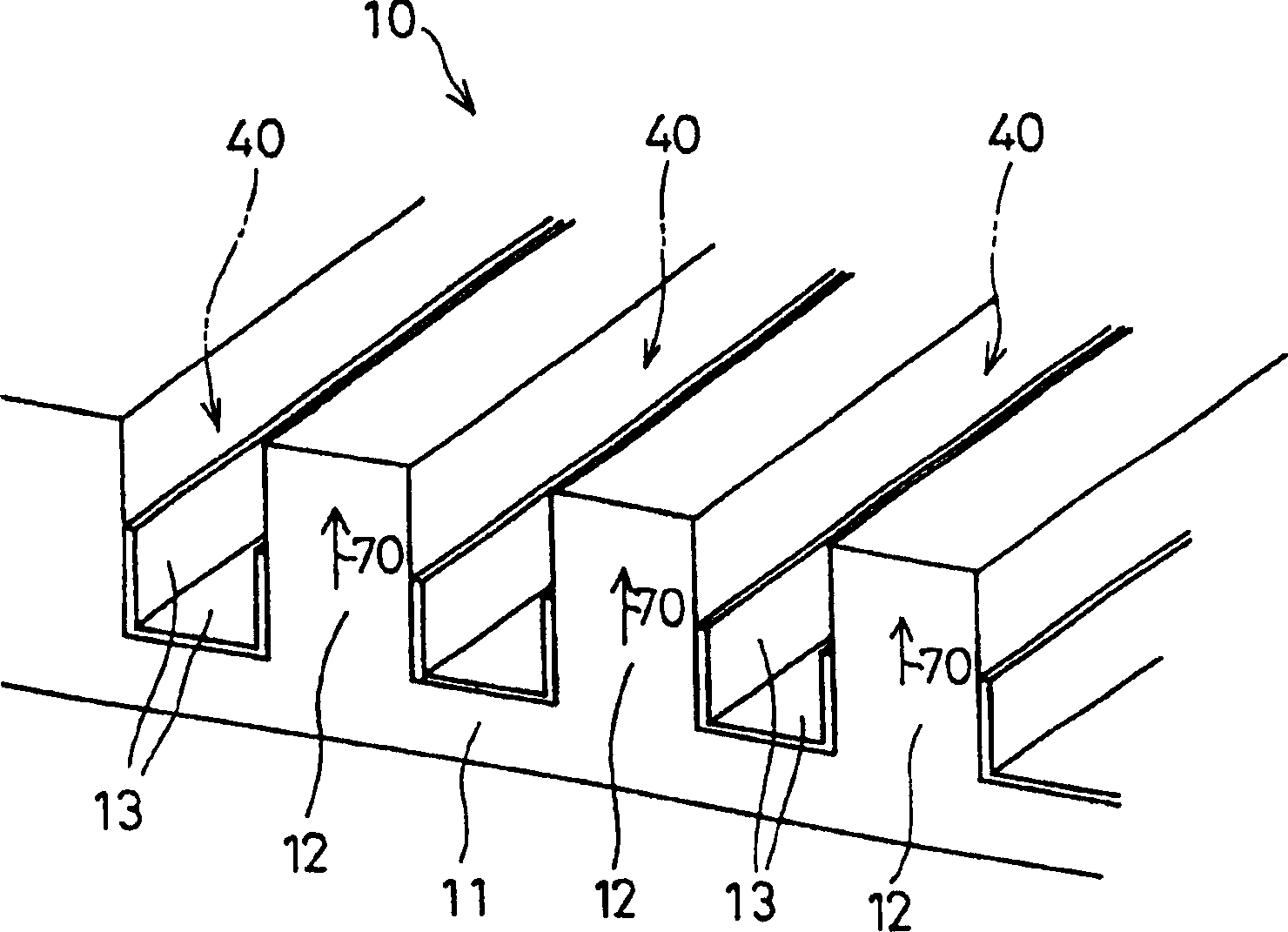

An object of the present invention is to provide an ink composition capable of obtaining high-quality recorded images with excellent discharge stability when using an inkjet recording method, a recording method using the composition, a recorded image, an ink set, and an inkjet head. . The difference between the dynamic surface tension (mN / m) and the static surface tension (mN / m) of the ink composition (60) measured by the maximum bubble pressure method at a temperature of 24 to 26°C is 0 to 7 (mN / m). The ink composition is stored in the inkjet tank (50) of the inkjet head (1), and the ink composition is supplied from the ink tank (50) to the ink cartridge (40) having the discharge port (31), and a voltage is applied to the inkjet tank (50) of the inkjet head (1). On the partition (12) made of piezoelectric material, the partition (12) applies pressure to the ink composition (60) stored in the ink tank (40), so that the ink composition (60) is discharged from the discharge port (31). 60) Liquid droplets attached to the recording material to record images.

Owner:SHARP KK

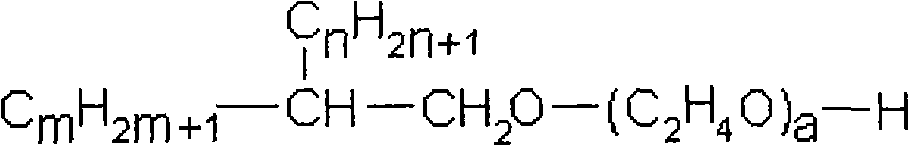

Sizing agent for reinforcement fiber and application thereof

ActiveUS20150018451A1Improve performanceExcellent splittabilityCarbon fibresSynthetic resin layered productsMethacrylatePolymer science

The present invention aims to provide a sizing agent for a reinforcement fiber used for reinforcing thermoplastic matrix resins. The sizing agent uniformly spreads on reinforcement fiber surface and imparts, to a reinforcement fiber, both excellent splittability and bonding performance to thermoplastic matrix resins.The sizing agent for a reinforcement fiber of the present invention comprises essentially an ester compound (A) having a vinyl ester group, acrylate group or methacrylate group bonded to at least one of the chain ends of the main chain of the ester compound (A), and of a polyoxyalkylene alkyl ether (B) which is an adduct between an alkylene oxide and a C4-14 monohydric alcohol. When water is added to the sizing agent thereby producing a mixture with a nonvolatile content of 1 weight %, the mixture exhibits a dynamic surface tension ranging from 40 to 55 mN / m determined by the maximum bubble pressure method when bubbles are blown into the mixture at the rate of one bubble per 100 milliseconds.

Owner:MATSUMOTO YUSHI SEIYAKU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com