Aqueous ink, ink set, image forming method and image forming apparatus

A water-based ink and image technology, applied in reproduction/marking methods, ink, printing, etc., can solve the problems of high surface tension, reduced image fixing ability, low permeability of recording medium, etc., and achieve high image density and excellent ejection stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

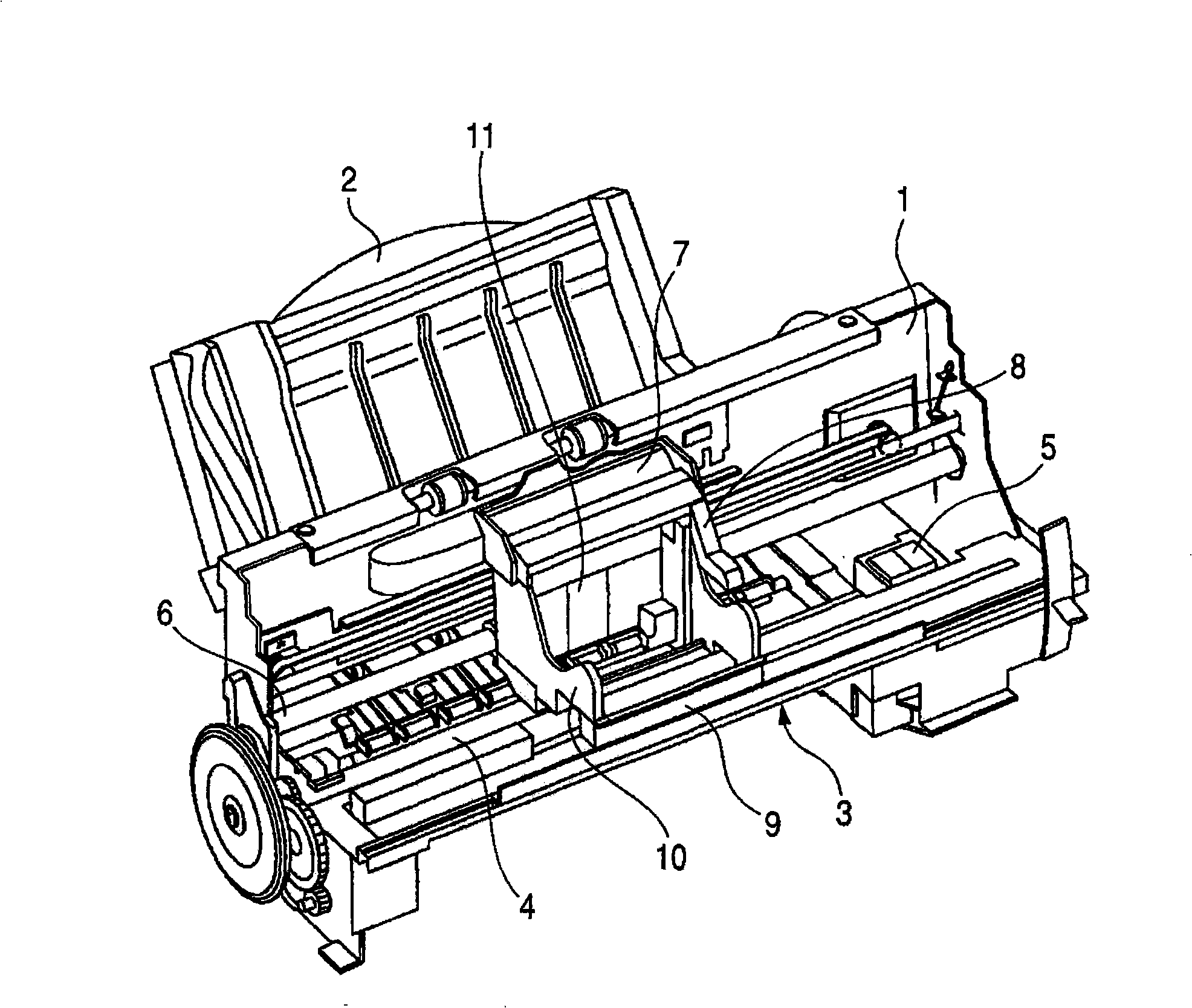

Image

Examples

Embodiment

[0143] Hereinafter, the present invention will be described more specifically by the following Examples and Comparative Examples. However, the present invention is not limited to these Examples unless exceeding the gist of the present invention. Incidentally, "%" used below is based on mass unless otherwise specified.

[0144]

[0145] (preparation of pigment dispersion solution A)

[0146] will have 10 copies with 210m 2 carbon black having a specific surface area and a DBP oil absorption value of 74 mL / 100 g, 20 parts of a polymer obtained by using a styrene-acrylic acid copolymer having an acid value of 200 and a weight-average molecular weight of 10,000 obtained in a 10 mass % sodium hydroxide aqueous solution Mix with 70 parts of water. The mixture was subjected to dispersion treatment by sand milling for 1 hour, then centrifuged to remove coarse particles, and the mixture thus treated was filtered under pressure through a microfilter (product of Fuji Photo Film Co. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com