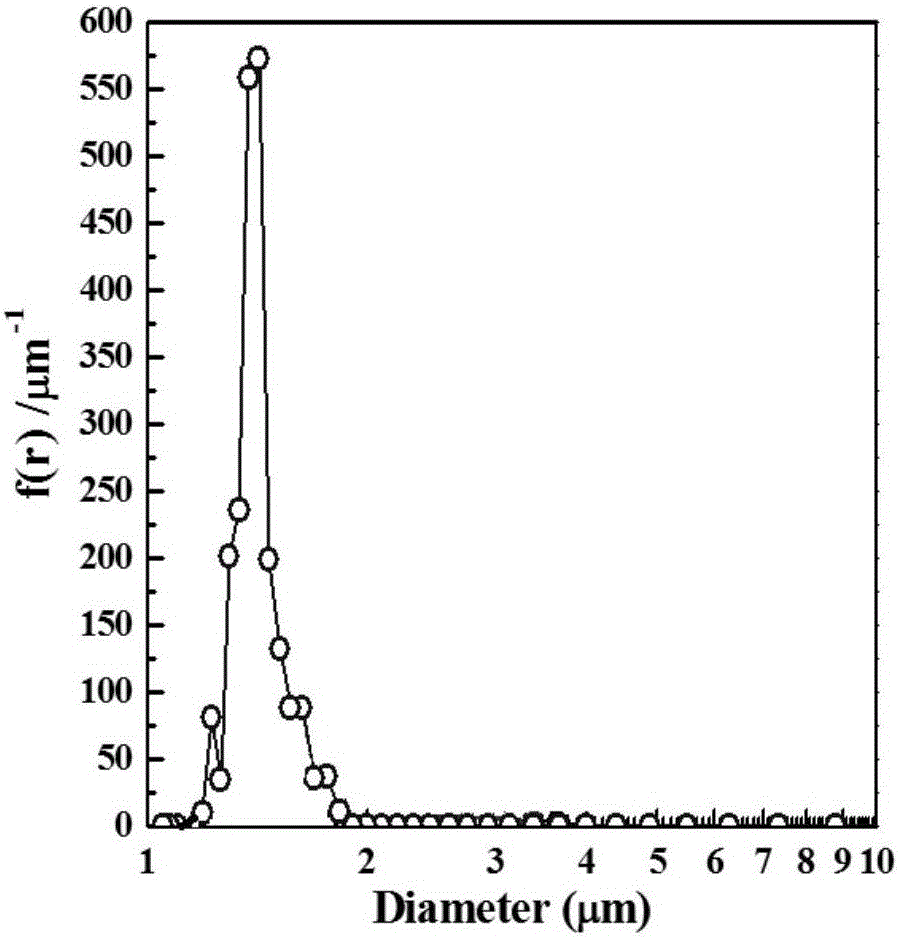

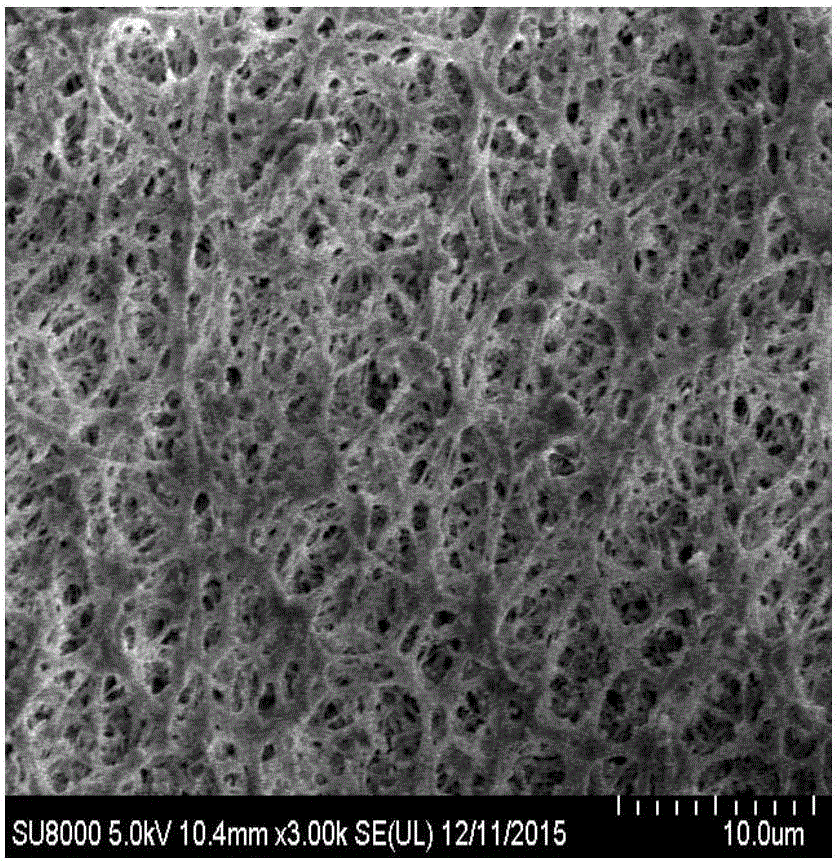

Gelled lead acid battery diaphragm pore size distribution measurement method

A technology of lead-acid battery and pore size distribution, which is applied in the direction of measuring devices, fluid utilization devices, instruments, etc., to achieve the effects of accurate pore size distribution, shortened measurement time, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of colloidal lead-acid battery separator:

[0034] Weigh 5g of PVC and dissolve it in 45g of DMF solution, add 1.2wt% stock solution of coupling agent (KH-550), heat and stir at 70°C for 2h;

[0035] Weigh 15g of 300-400 mesh diatomite and add it, and stir thoroughly at room temperature for 10 minutes;

[0036] Pour the resulting mixture into a sealed container, and place it in a constant temperature water bath at 40°C for 30 minutes for defoaming;

[0037] Scrape with a 1000μm scraper to form a sheet, and let it stand for 400s;

[0038] Put it into a 70°C aqueous solution to release the mold into pieces, take it out after 2 hours, and dry it at 60°C for 2 hours;

[0039] Place in 0.2% non-ionic surfactant TX-100 aqueous solution at 25°C, take it out after 2 hours, and dry at 60°C for 2 hours to obtain separator A;

[0040] 2, measure dividing plate aperture distribution situation with measuring method of the present invention:

[0041] Cut the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com