Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Avoid secondary cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Remoulding soft clay sample preparation device and method based on vacuum combined electron-osmosis effect

The invention discloses a remoulding soft clay sample preparation device and a remoulding soft clay sample preparation method based on a vacuum combined electron-osmosis effect. Nonwoven geotextile, a gravel layer, a sand mat layer and an electron-osmosis cathode are sequentially paved on an osmosis drainage base; the upper and lower ends of a latex film are respectively turned outward and sleeved on a sample loading solidification cylinder and are fixed with the osmosis drainage base by a bolt through a flange; a water vapor separation cylinder is provided with an electric contact vacuum member and is connected with the osmosis drainage base and a vacuum pump respectively through an air pipe; slurry is poured into the designated height of the sample loading solidification cylinder, and an electro-osmosis anode is put in; and the electro-osmosis anode and the electro-osmosis cathode are respectively connected with a programmable direct-current power supply by wires. Under the combined effect of vacuum negative pressure and electro-osmosis, the drainage solidification speed of a soil body is increased, and the solidification stress level in a soil body sample preparation process can be adjusted. According to the device and the method disclosed by the invention, the size of a sample tank is reduced, and meanwhile, the number of sample preparation each time is increased by preparing multiple groups of soil samples; the device has a simple structure and is convenient for operation and sample taking; and the sample preparation period is short, and secondary cutting, disturbance and waste of soil samples are effectively avoided.

Owner:HOHAI UNIV

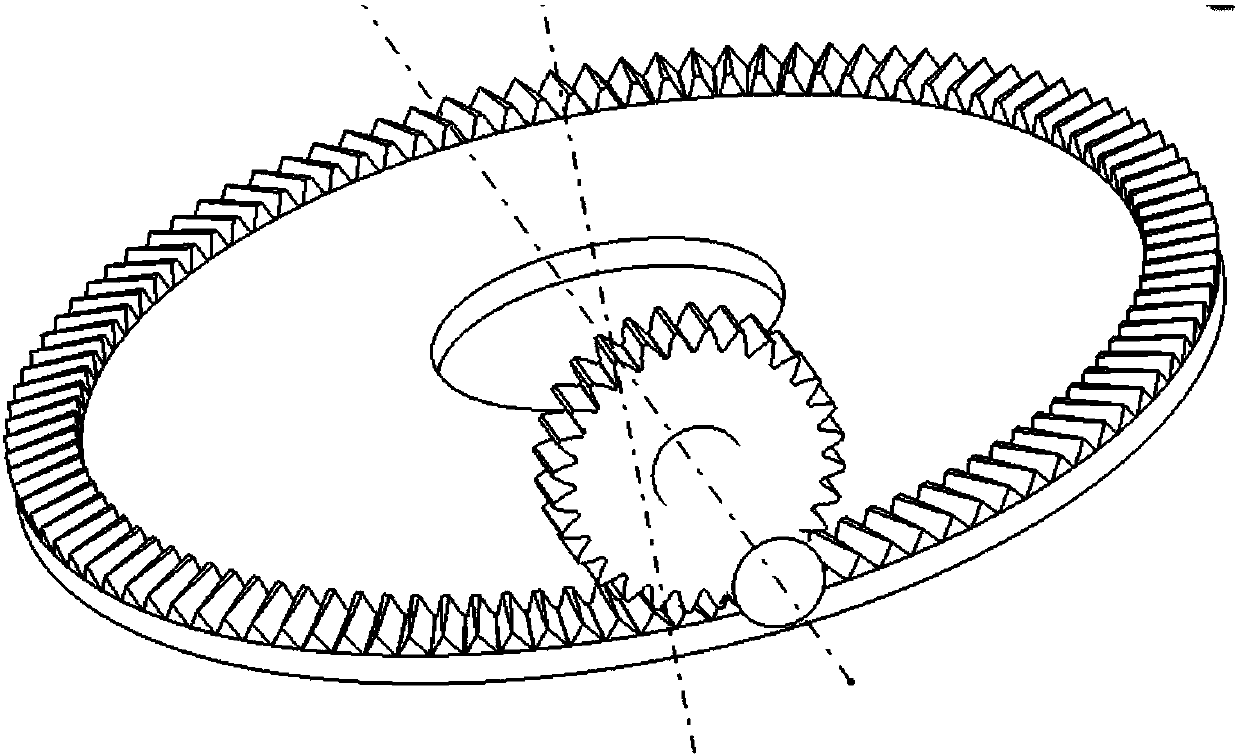

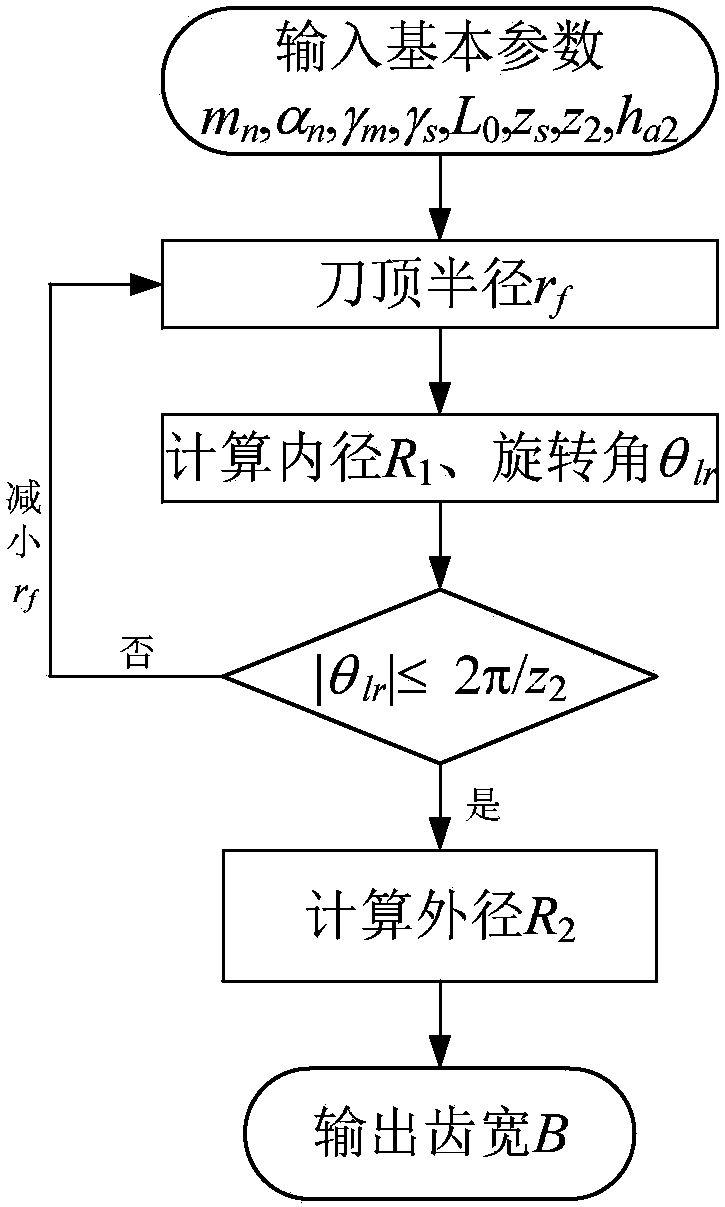

Skew line tooth surface gear transmission pair and tooth width geometric design method

InactiveCN105156637AReduce weightIncrease thrust-to-weight ratioPortable liftingGearing elementsAviationGeometric design

The invention discloses a skew line tooth surface gear transmission pair and a tooth width geometric design method. The skew line tooth surface gear transmission pair adopts an alternating axis transmission form composed of involute spur gears and skew line tooth surface gears. Each skew line tooth surface gear is formed by spreading straight tooth involute slotting cutters in a staggered mode; the skew line tooth surface gears can only mesh with the straight tooth cylindrical gears and can not mesh with the skewed tooth cylindrical gears with helix angle; and the tooth trace is approximate to a skew line and forms an oblique angle with the radius direction, thereby being very suitable for the demands of design diversification for aviation compact space. The method illuminates the gear shaping principle of the skew line gear and skew line tooth surface gear, and deduces the tooth surface equation of the skew line tooth surface gear. The margin line of the involute slotting cutters is utilized to calculate the position of the tangent point of the internal end tooth root. The condition that the outer end tooth top tooth thickness is equal to zero is utilized to obtain the sharpening condition. The condition of avoiding secondary cutting of the tooth root is combined with determine the cutter top fillet radius, thereby finally obtaining the tooth width of the skew line tooth surface gear.

Owner:CHANGAN UNIV

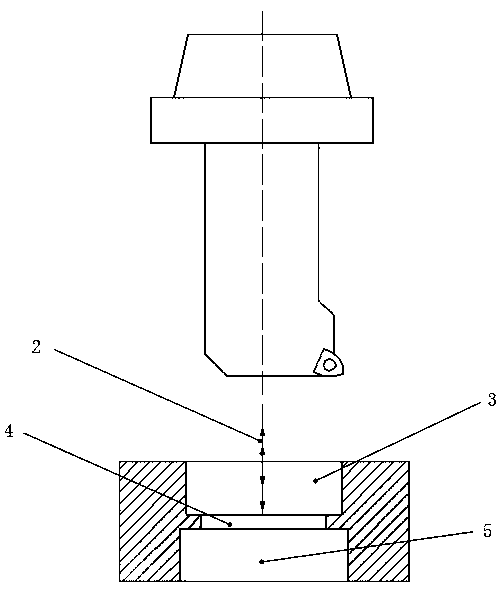

Single-face clamping hole forming method of double-side stepped hole part

The invention discloses a single-face clamping hole forming method of a double-side stepped hole part, and belongs to the technical field of hole processing. The single-face clamping hole forming method main comprises the following steps that S1, an upper counterbore, a stepped hole and a lower counterbore are subjected to rough milling; S2, the lower counterbore is subjected to milling; S3, the upper counterbore and the stepped hole are subjected to fine boring, a boring tool is mounted, the knifepoint direction of a tool bit of the boring tool is confirmed when SPOS of a machine tool is 0, the knifepoint direction is adopted as the forward direction of the X axis, then, the boring tool stretches along the Y axis into the upper counterbore and the stepped hole to perform boring, after boring, the machine tool stops, the tool bit of the boring tool still points the forward direction of the X axis, then, the boring tool retracts in the negative direction of the X axis, L1 equals to 0.1mm, and then, the boring tool retracts upwards along the Y axis; and S4, the lower counterbore is subjected to reverse boring. According to the single-face clamping hole forming method, the upper counterbore is bored to the required size in a set boring manner, the stepped hole is bored to the required size in a set boring manner, the lower counterbore is bored to the required size in a set boringand reverse boring manner, the clamping and datum transformation times is decreased, precision like surface roughness and coaxiality of to-be-processed holes is guaranteed, and hole processing efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

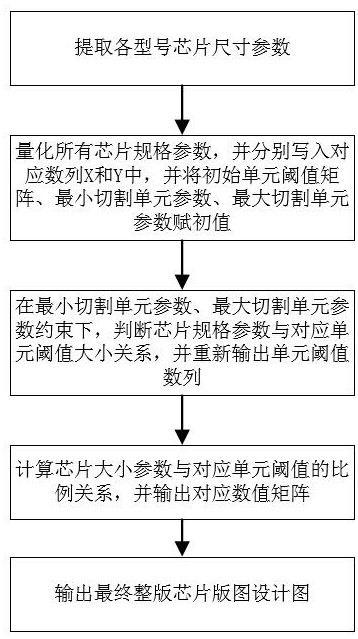

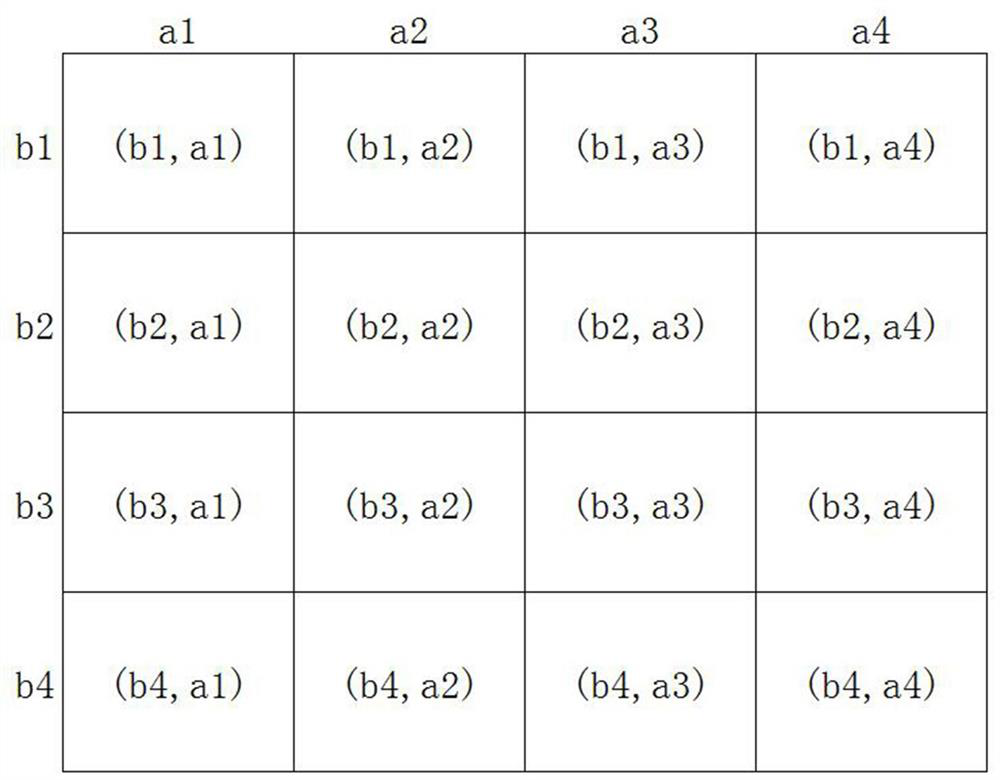

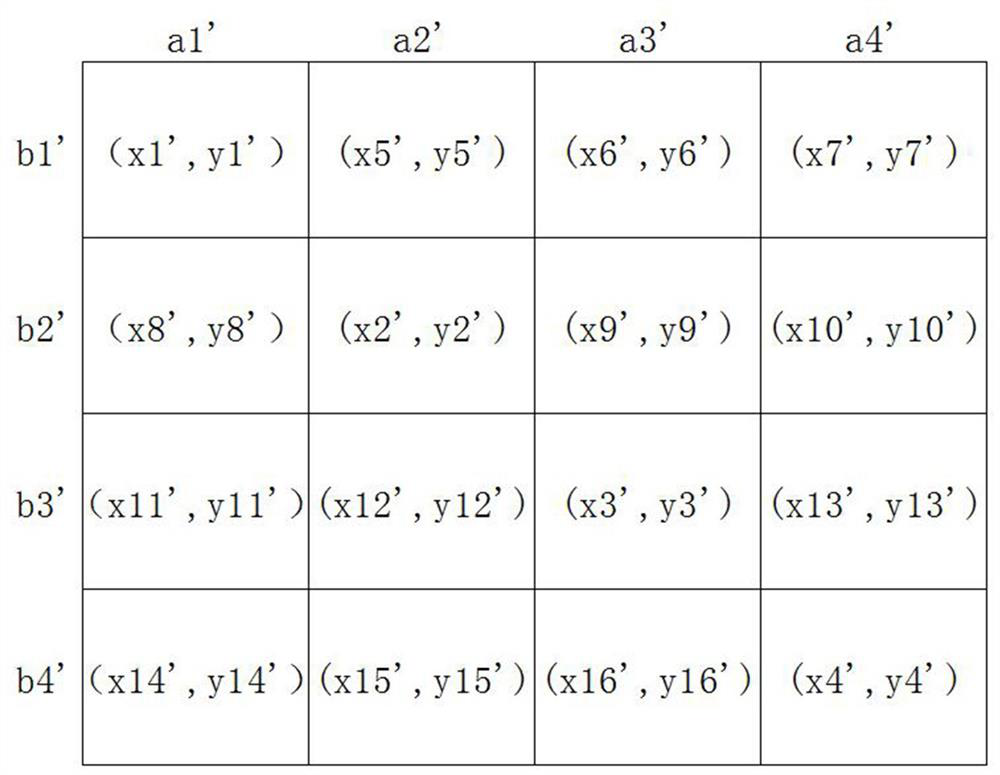

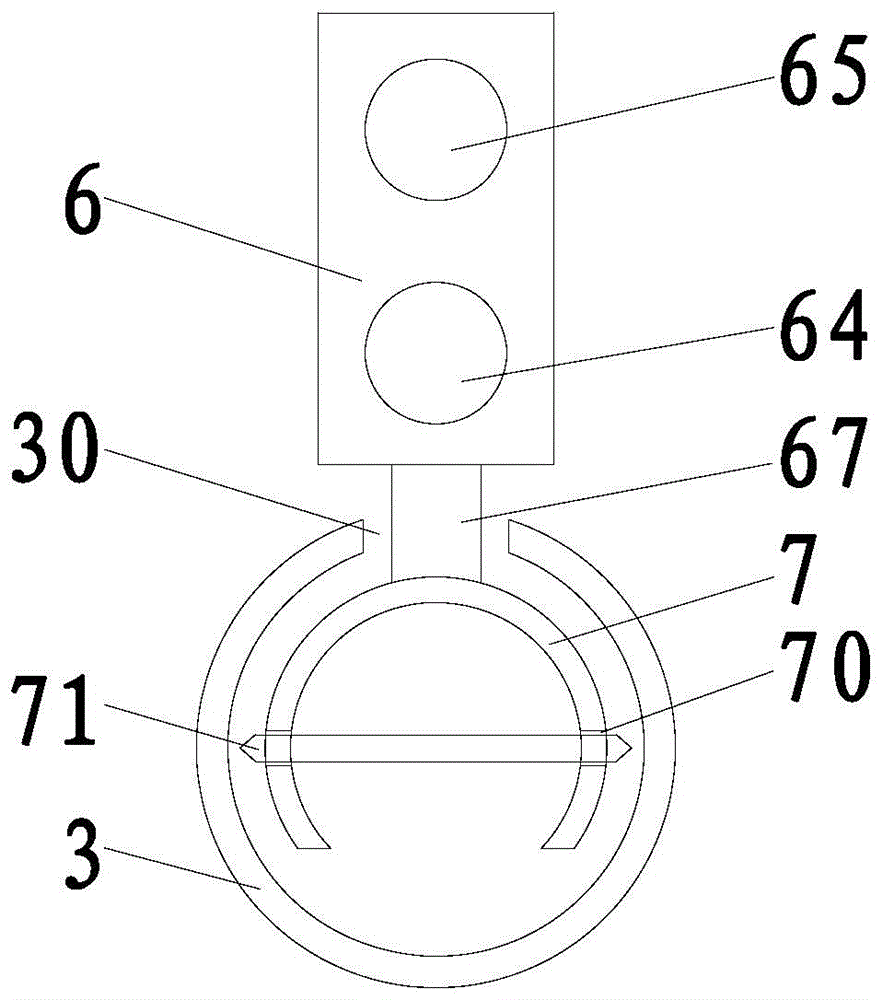

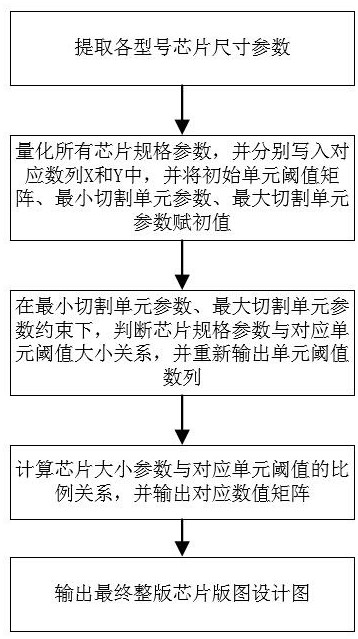

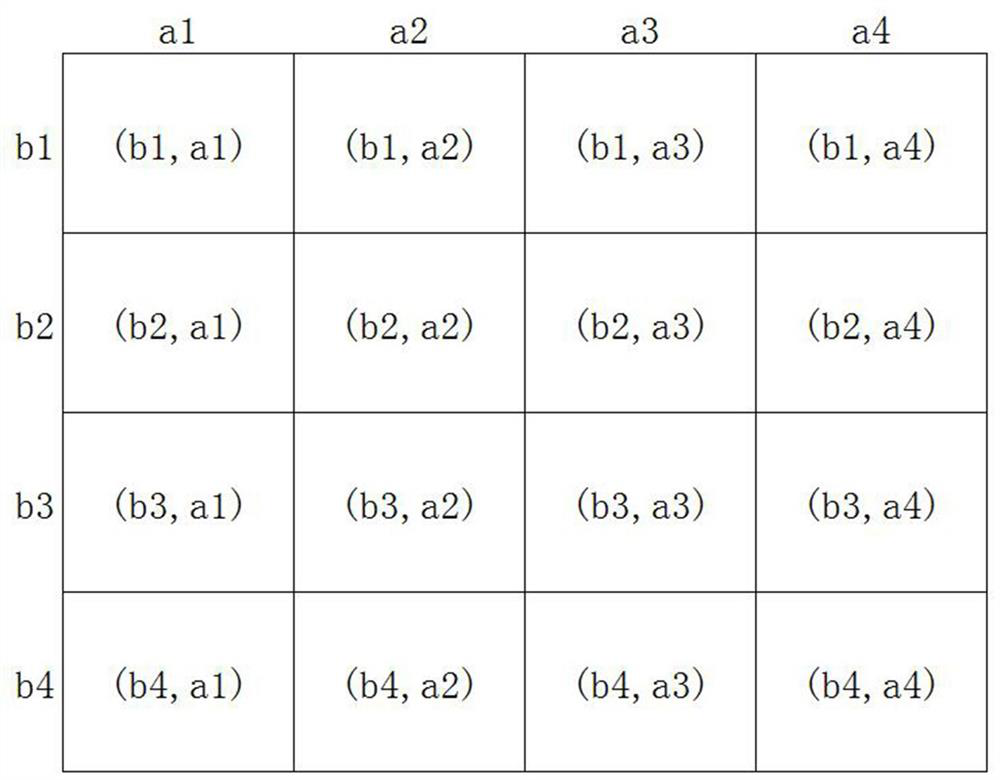

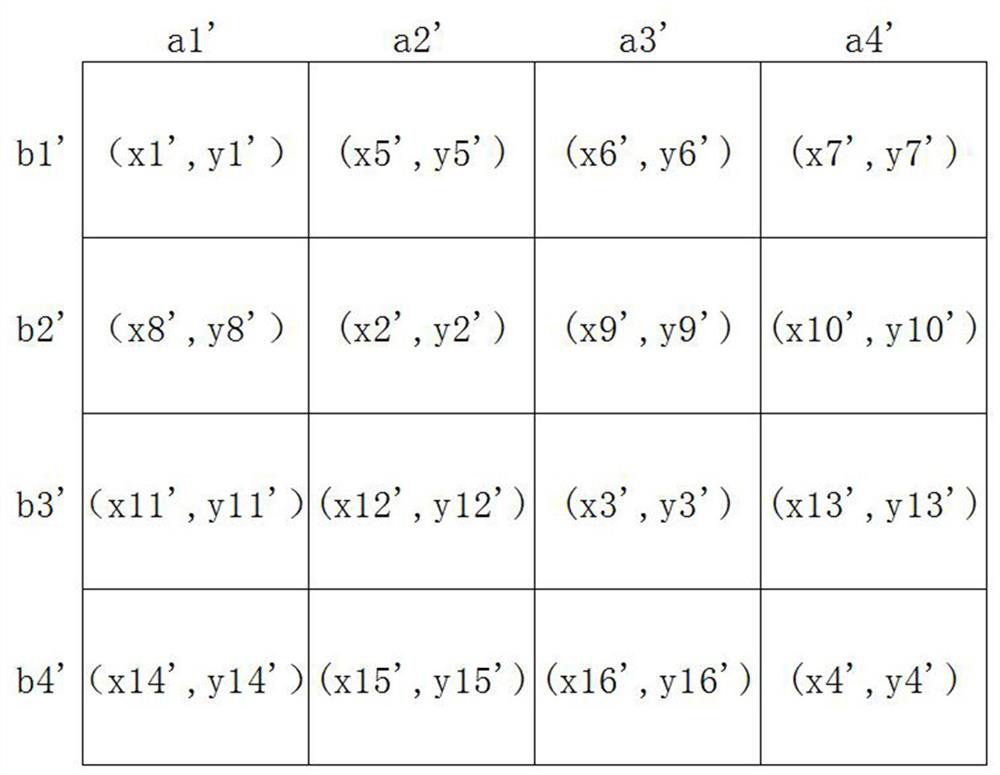

Layout design method of multi-model chip, chip prepared by layout design method and terminal

ActiveCN114548020ADesign flexible adjustmentEfficient outputSolid-state devicesComputer aided designChip sizeLayout

The invention discloses a layout design method of a multi-model chip and a chip and a terminal prepared by the layout design method, and belongs to the technical field of semiconductors, and the layout design method comprises the following steps: obtaining size parameters of each model of chip and initial values of each parameter quantity; under the constraint of the maximum cutting unit parameter and the minimum cutting unit parameter, the size relation between the chip size parameter and the corresponding initial unit threshold value is judged, and the chip unit threshold value is adjusted; and calculating a proportional relation between the threshold value of the corresponding chip unit and the chip size parameter, and outputting a layout design drawing. According to the method, the threshold values of the chip units are adjusted according to the sizes of the chips of different models, the whole layout can be quickly divided into a plurality of independent operation areas, then the proportional relation between the chips and the chip units is further calculated, the chips of the corresponding number are quickly arranged in the corresponding chip units, and in a certain threshold value range, the number of the chips is greatly reduced. The layout design can be simply, quickly and flexibly adjusted according to own chip design parameters of customers, and the layout design drawing is efficiently output.

Owner:成都复锦功率半导体技术发展有限公司

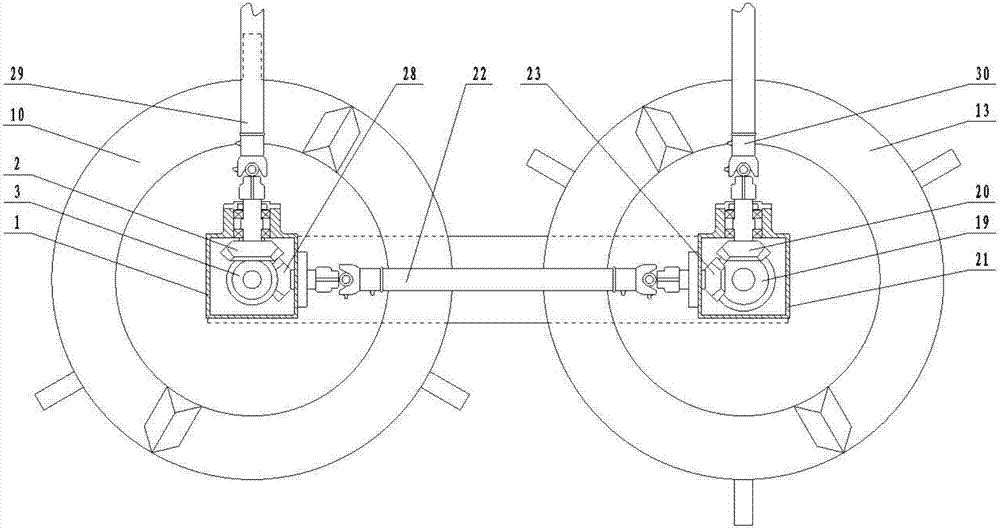

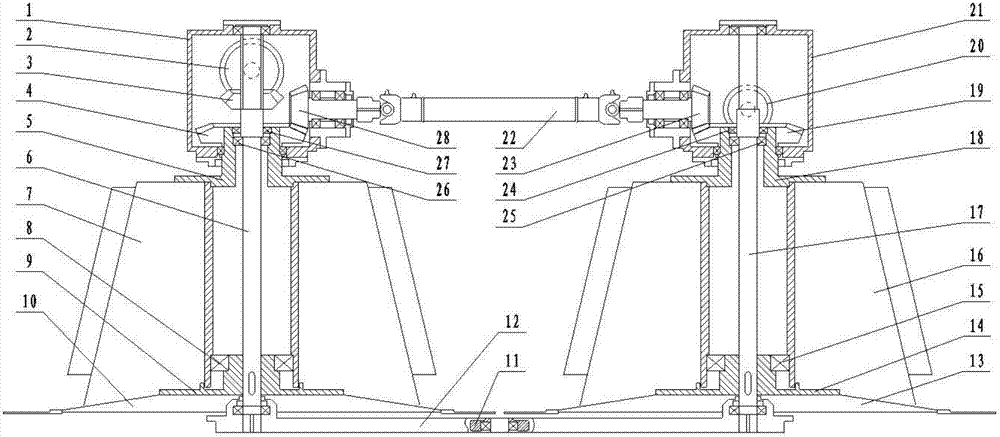

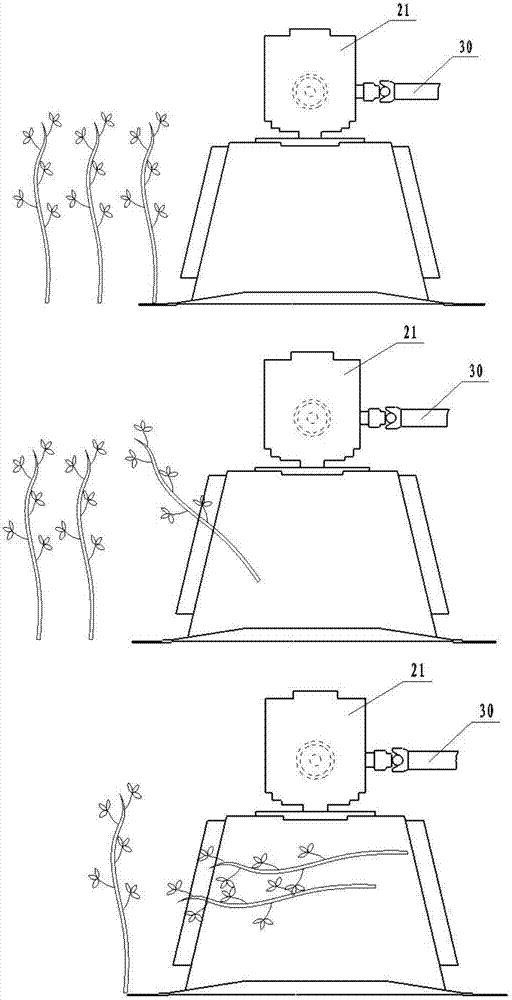

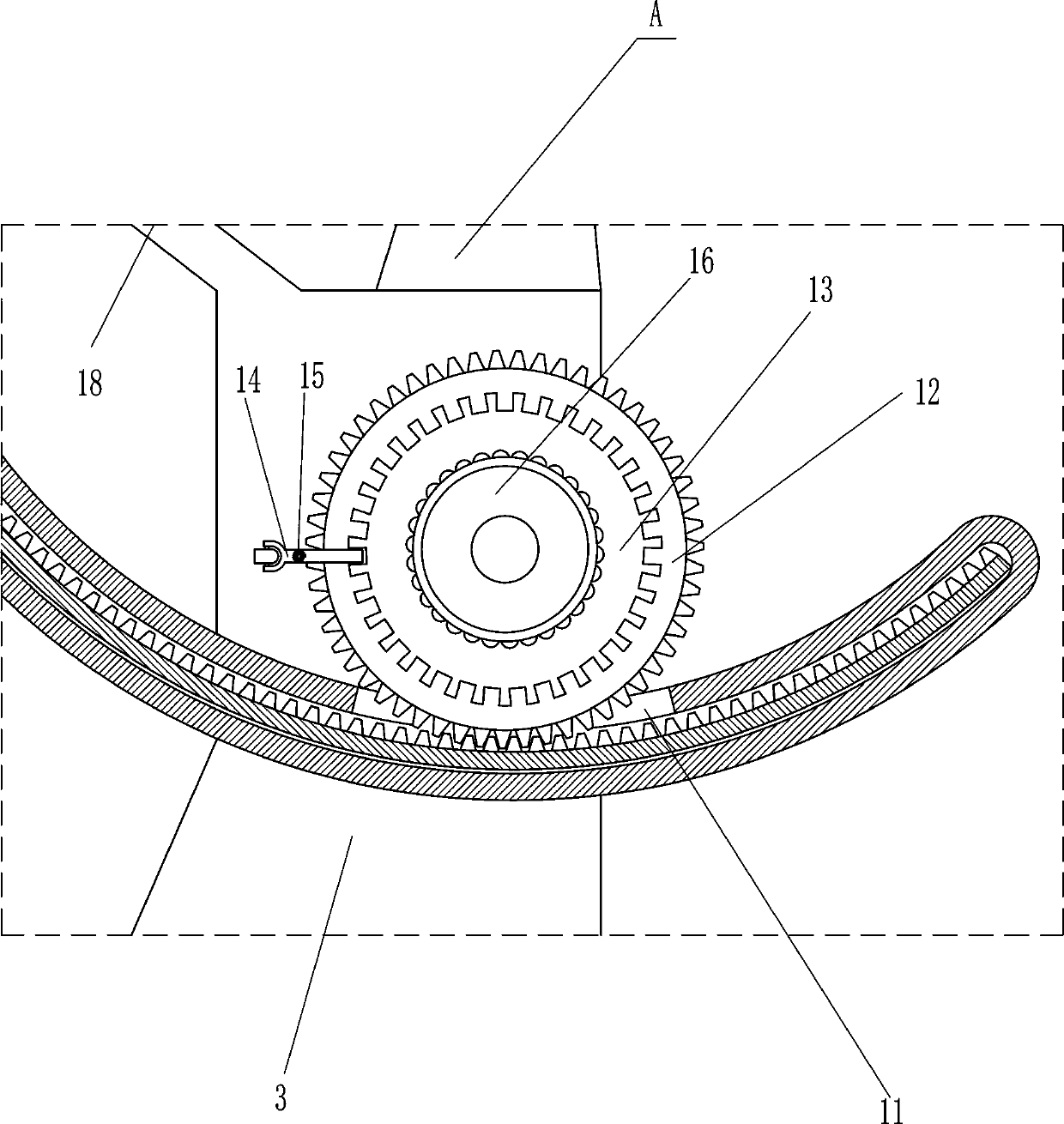

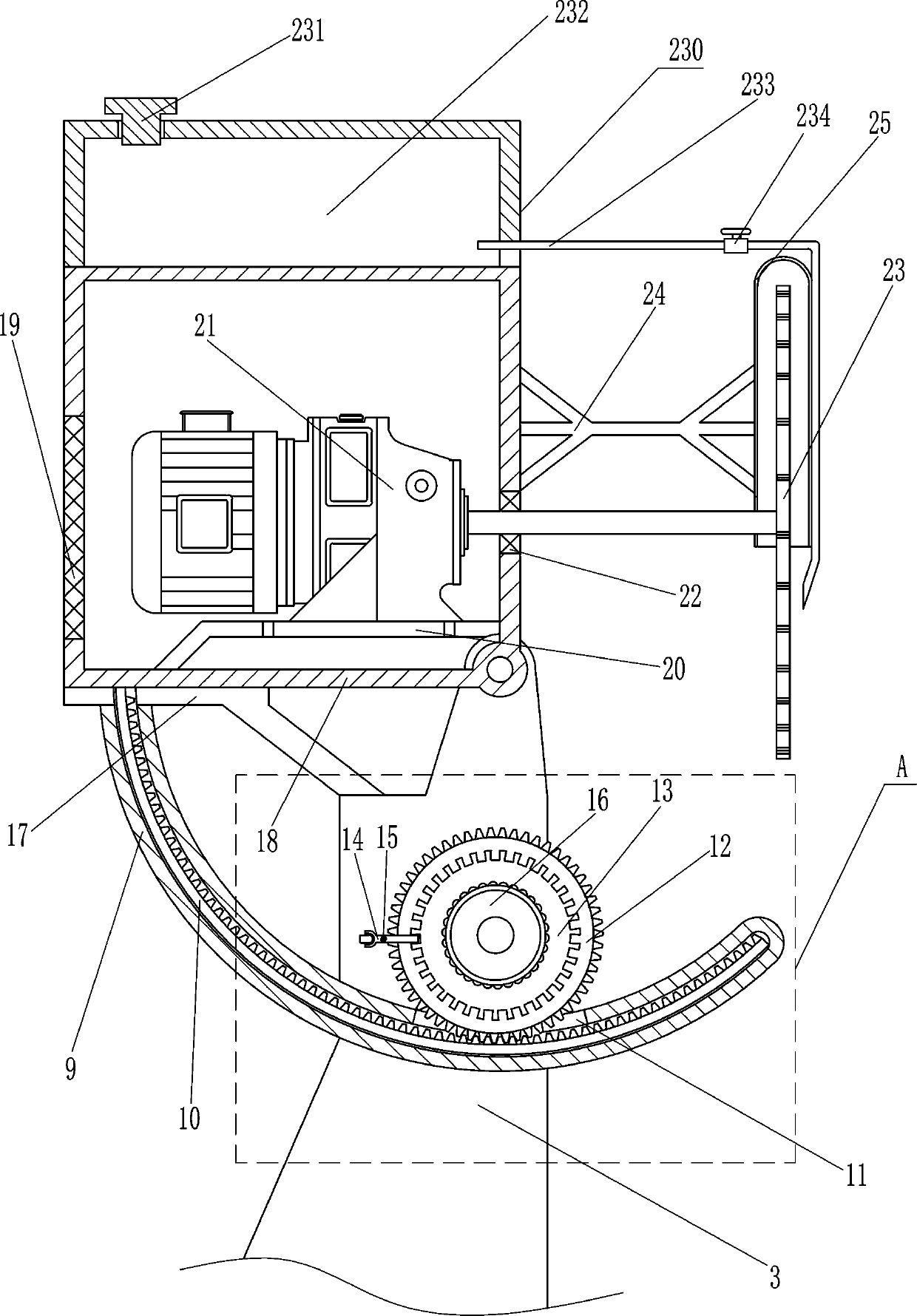

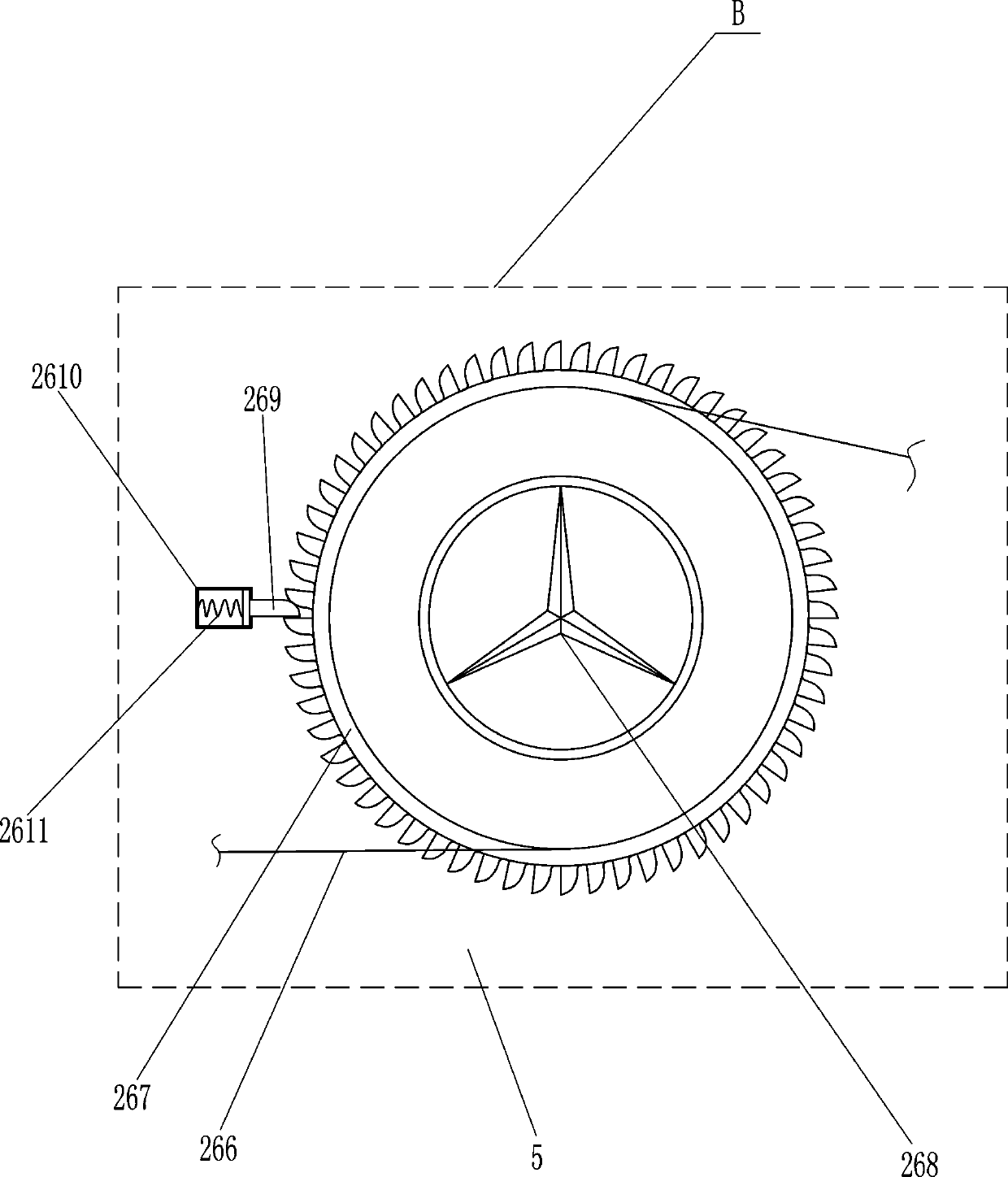

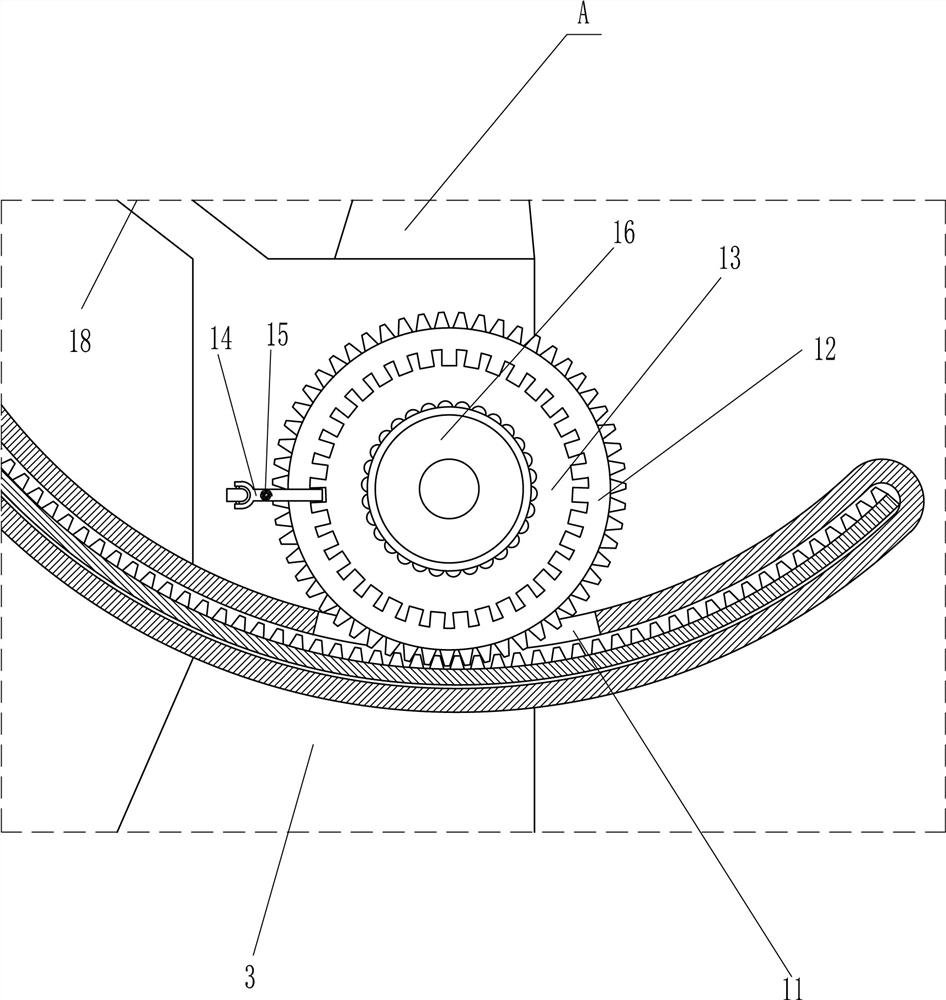

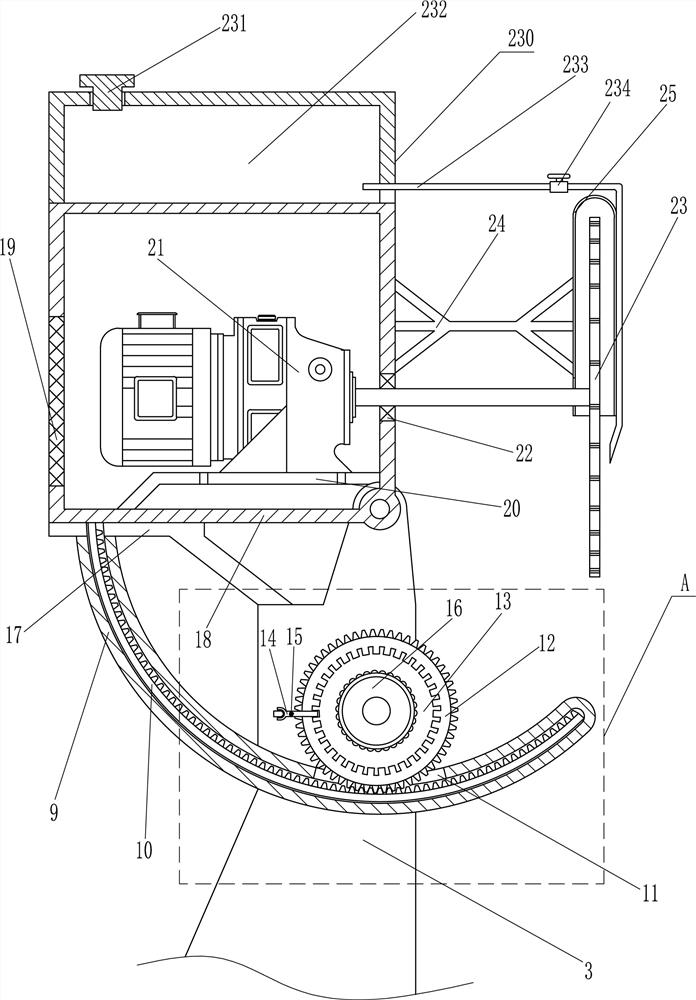

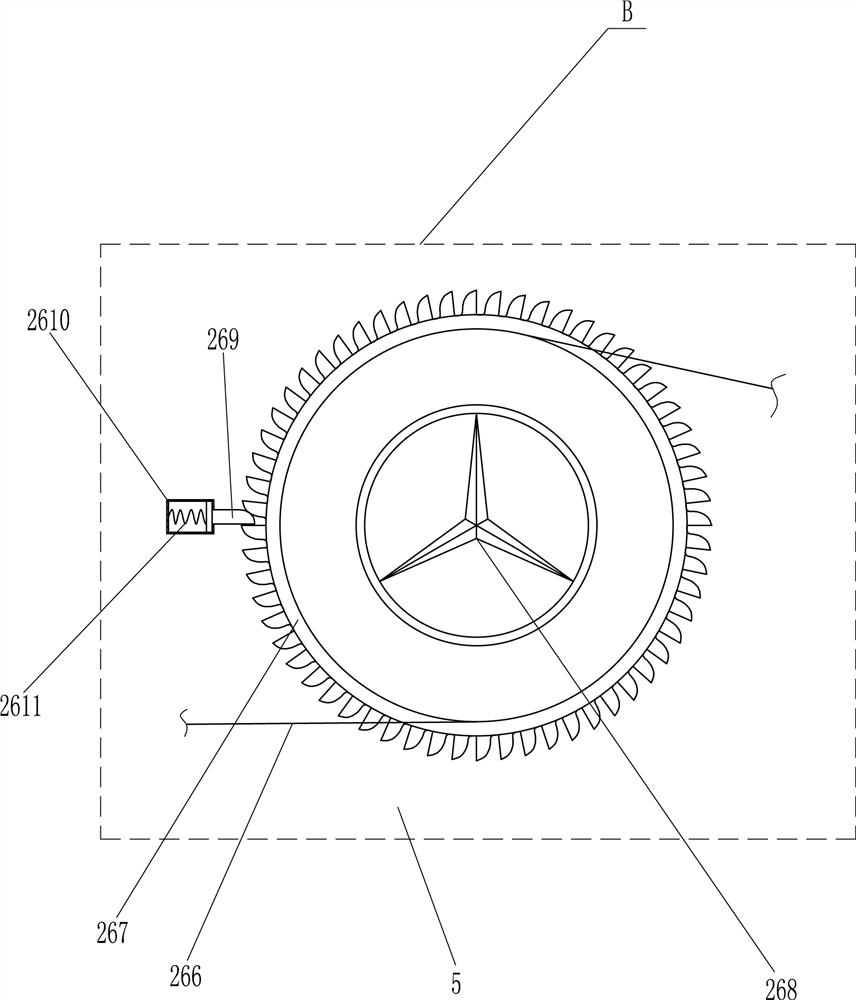

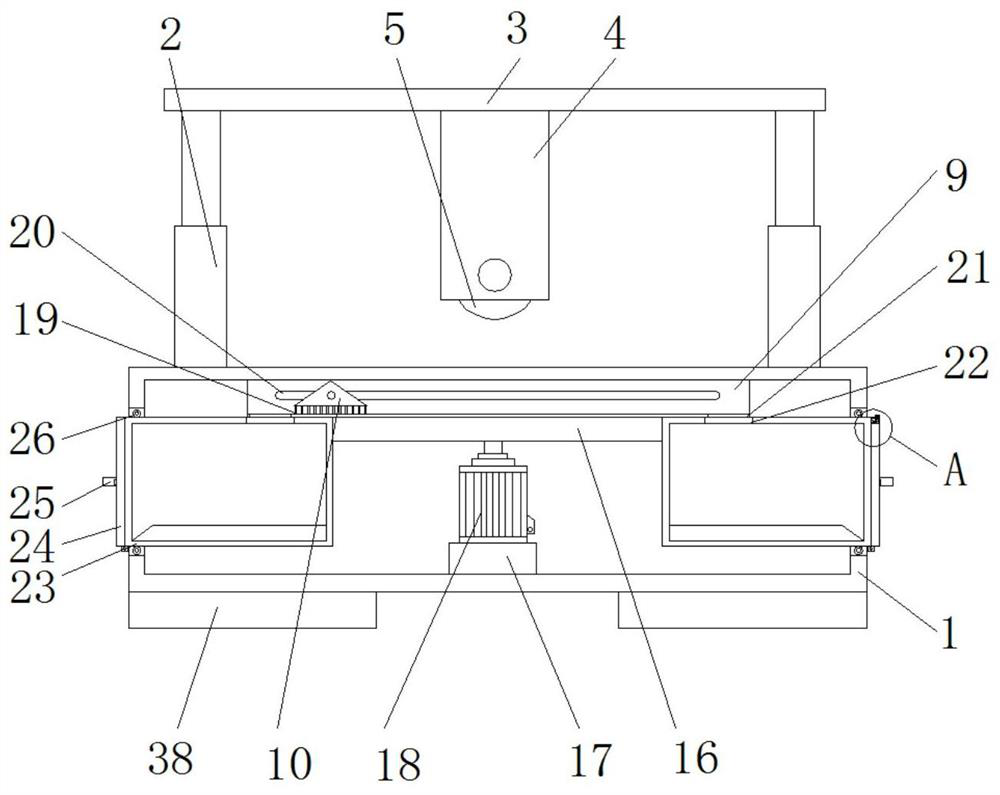

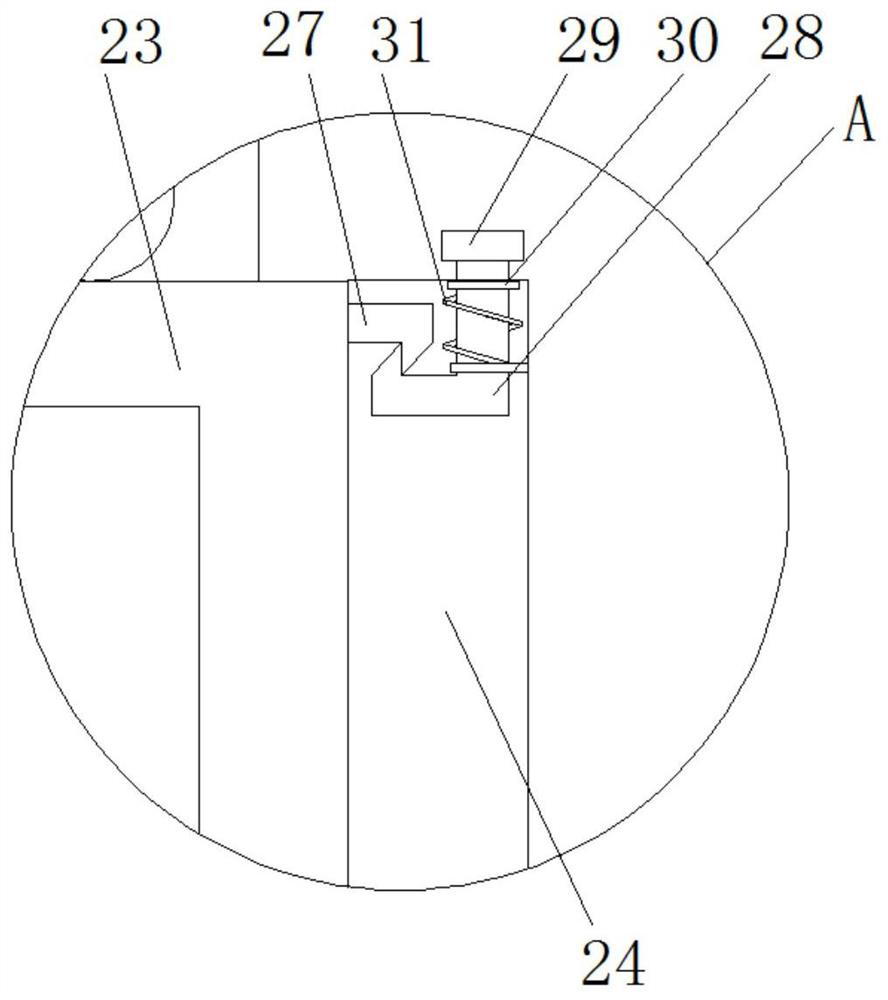

Rotatable mower header and differential feeding method

The invention relates to the technical field of agricultural machinery, in particular to a rotatable mower header and a differential feeding method. The mower header is mainly composed of a left cardan joint (29), a left gear box (1), a left material guiding cylinder (7), a left cutter disc (10), a gear box (12), a right cardan joint (30), a right gear box (21), a right material guiding cylinder (16) and a right cutter disc (13). Different revolving speeds of the cutter discs and the material guiding cylinders are achieved, and the revolving speed of the cutter discs is high so as to ensure the cutting speed, low revolving speeds of the material guiding cylinders and material drainage. With the differential feeding method, roots of mowed forage grass are arranged at the front and the following crops are conveyed backwards in order, layout of forage grass strips is in order, the following operation is convenient, and at the same time, the forge grass is prevented from tilting forwards and secondary cutting is avoided.

Owner:CHINA AGRI UNIV

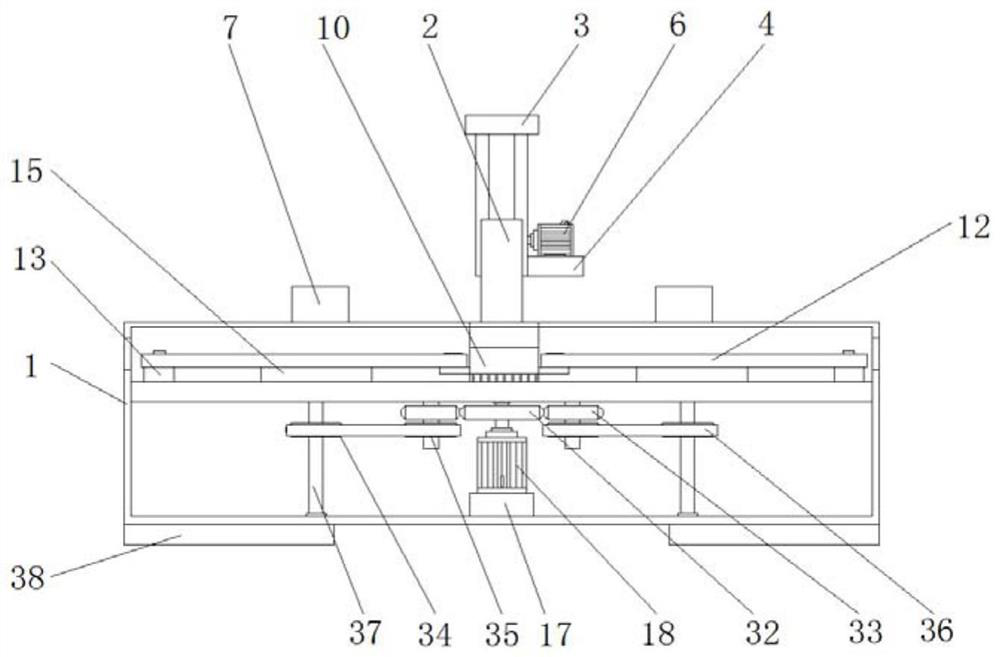

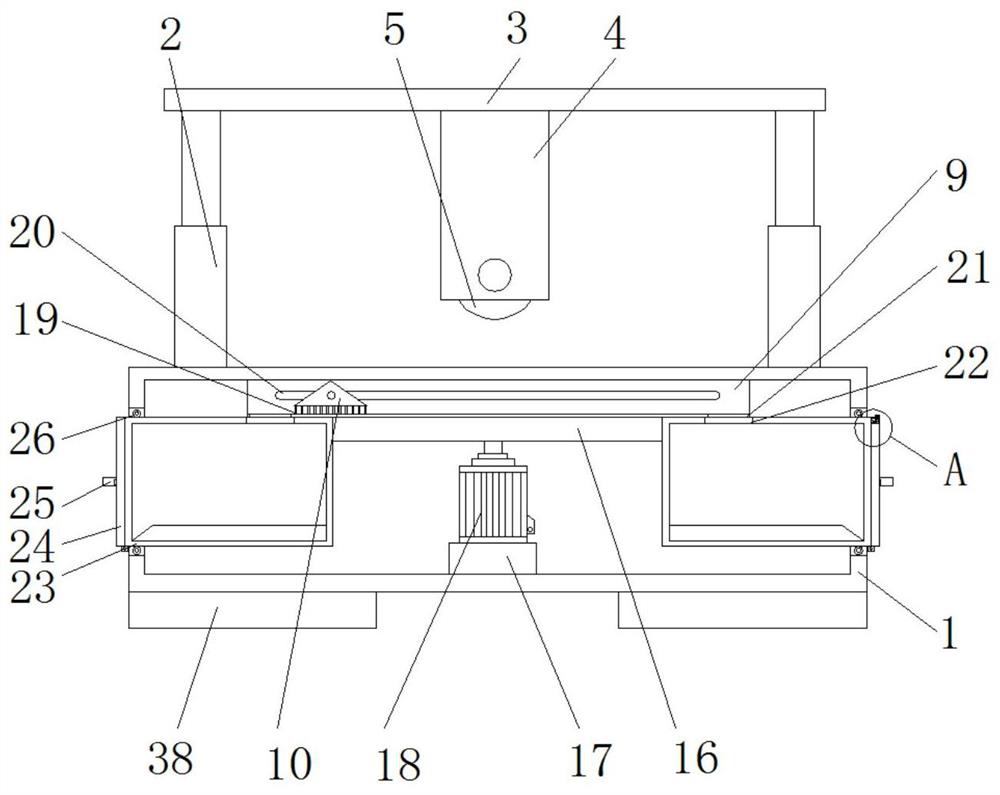

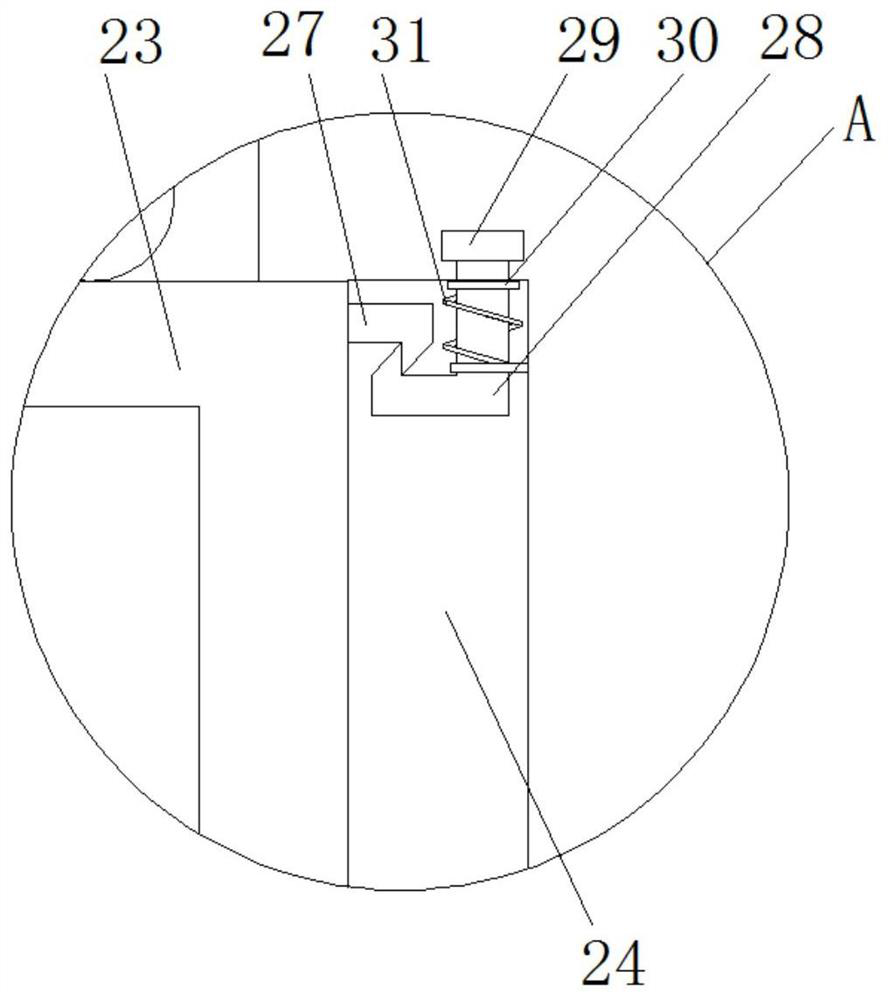

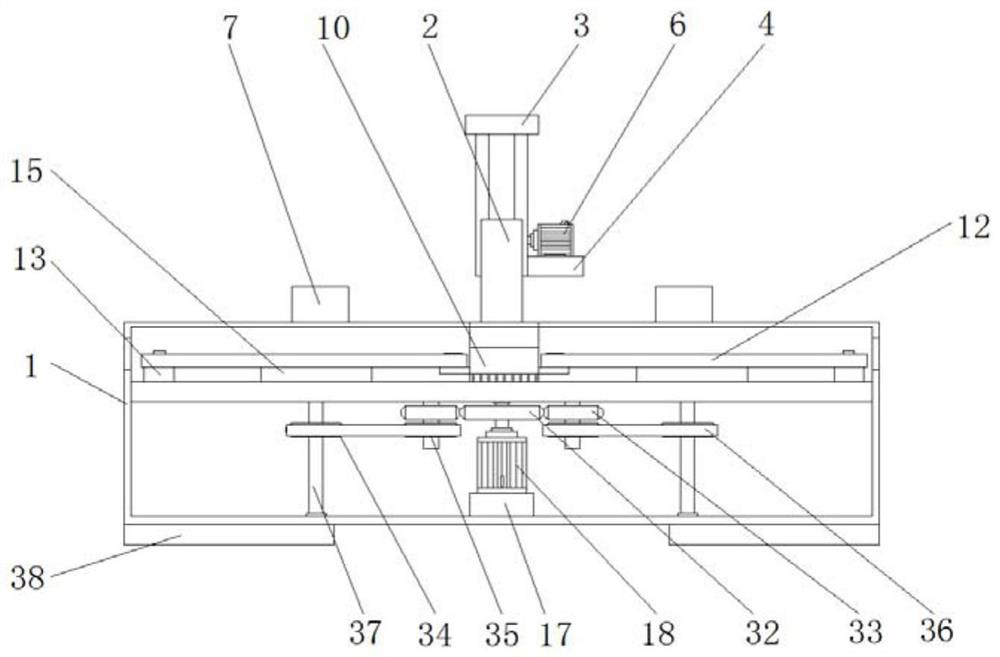

Angle-adjustable marble cutting device

ActiveCN111015971AAdjustable angleAvoid displacementWorking accessoriesStone-like material working toolsClassical mechanicsElectric machinery

The invention relates to a cutting device, in particular to an angle-adjustable marble cutting device. Therefore, the angle-adjustable marble cutting device aims to achieve the technical effects of being capable of adjusting the cutting angle, firmly fixing marble and preventing the marble from shifting during cutting. According to the technical scheme, the angle-adjustable marble cutting device comprises a bottom plate, first supports, a second support, a conical plate and the like, the first supports are symmetrically arranged on the right side of the top of the bottom plate, and the secondsupport is arranged on the left side of the top of the bottom plate. The angles of a motor and a cutting blade can be adjusted by rotating a first hand rotating wheel, so that the cutting angle of themarble is adjusted, the angle can be adjusted when the marble is cut, the operation of adjusting the angle is simple, the adjusted angle is wide, the adjustment can be carried out according to the cutting requirement, subsequent secondary cutting by using a hand grinder is avoided, the working efficiency is improved, and the operation complexity is reduced.

Owner:济南森华精密机械有限公司

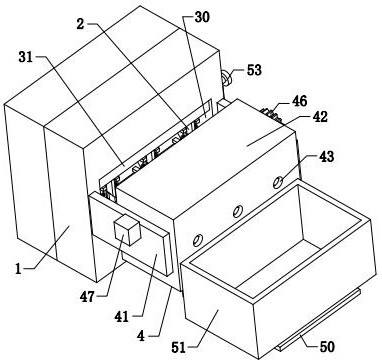

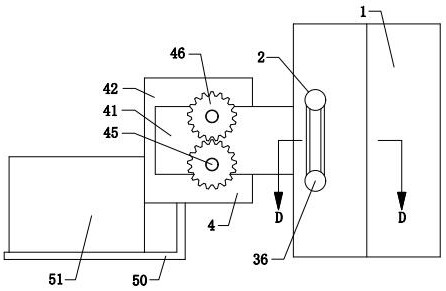

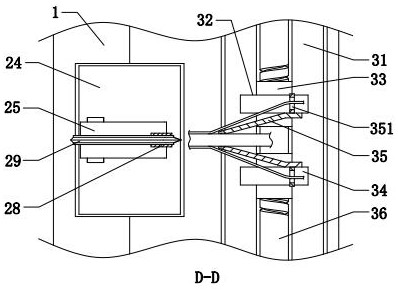

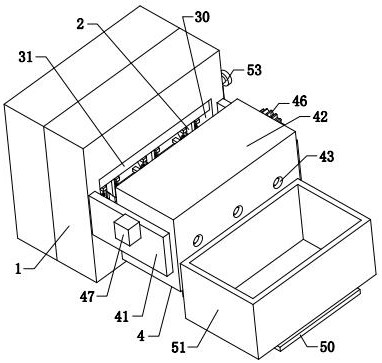

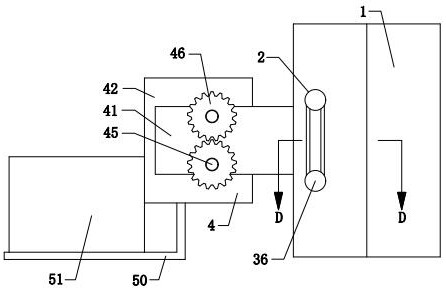

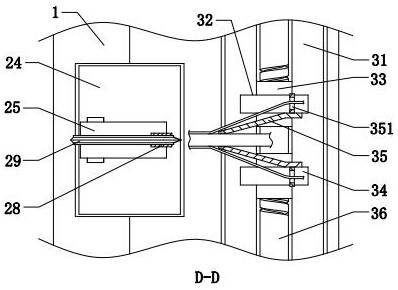

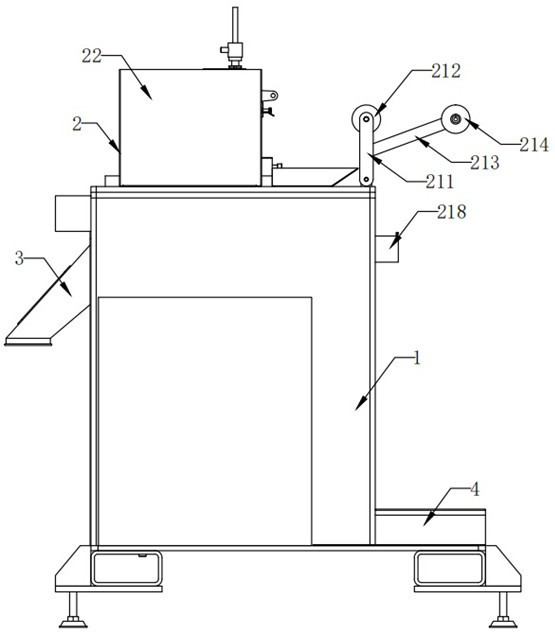

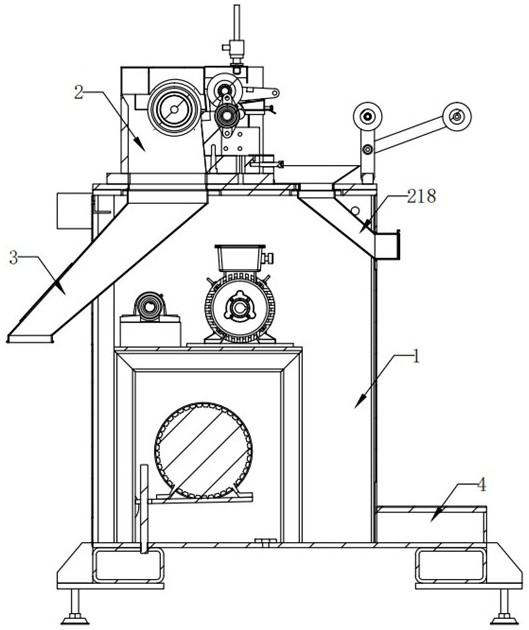

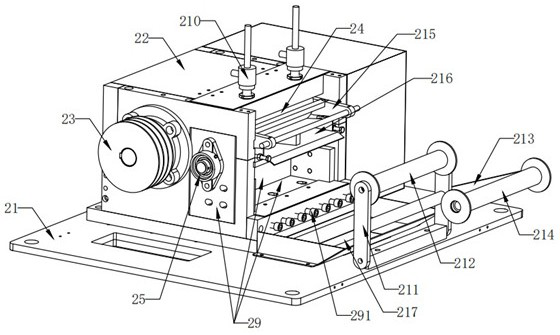

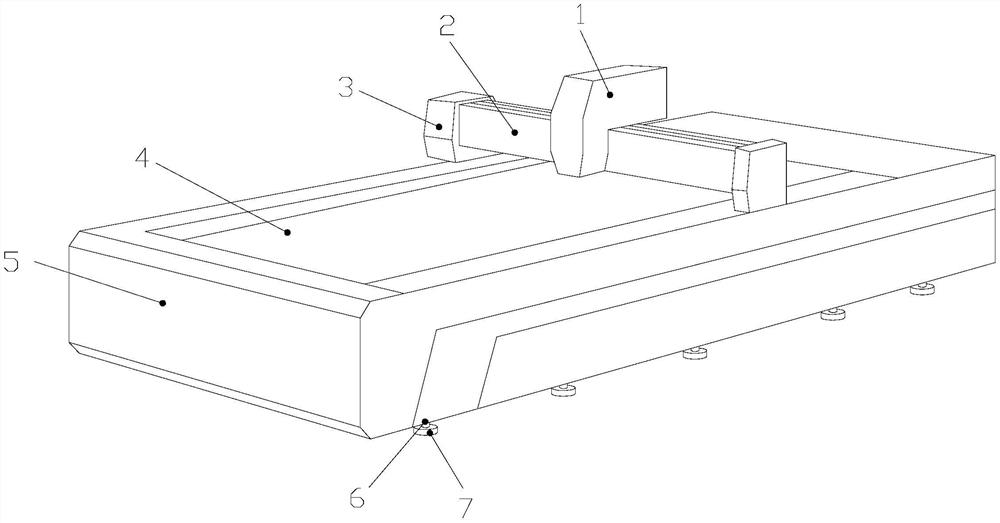

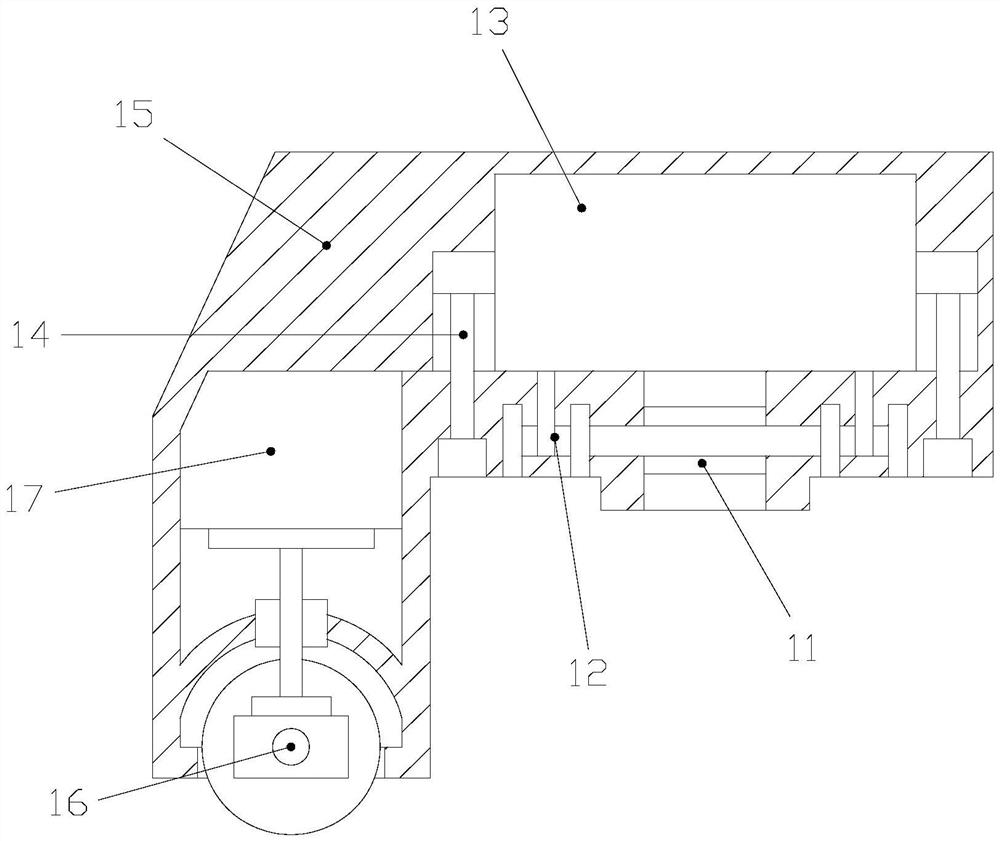

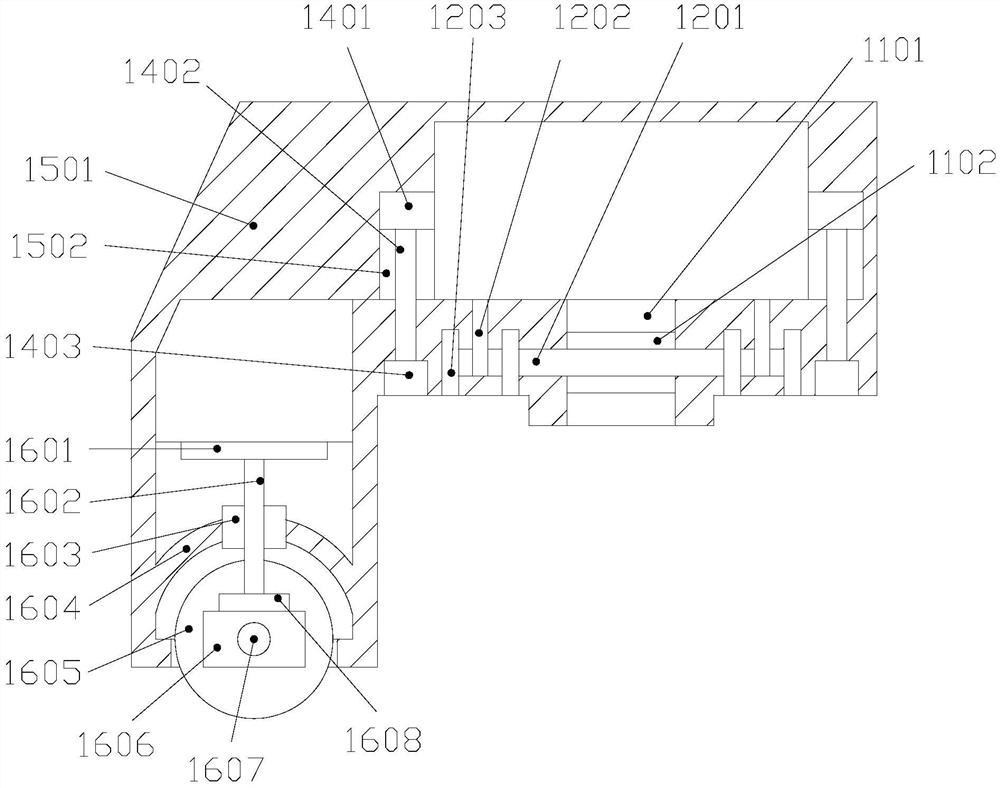

Wood automatic transverse cutting machine

The invention belongs to the technical field of wood machining equipment, and in particular, relates to a wood automatic transverse cutting machine. The machine comprises a frame, a loading module anda cutting module; the loading module comprises a pushing mechanism arranged on the frame, a side surface loading mechanism and a stop mechanism; the pushing mechanism comprises a loading channel formed in the frame, a pushing piece arranged on the loading channel, and a first driving mechanism matched and connected with the pushing piece; the side surface loading mechanism comprises a set of sidesurface loading plates and a set of elastic blocks; the stop mechanism comprises a discharge port, a pressing piece and a second driving mechanism; and the cutting module comprises a mounting base, atransverse moving driving motor, an electric wood saw and a lifting driving mechanism. Compared with the prior art, the machine is additionally provided with the lifting driving mechanism, so that the electric wood saw can automatically move down during returning to prevent secondary cutting of woods; and cut wood blocks are high in section flatness and cutting quality without needing the polishing treatment, so that higher enterprise benefit is achieved.

Owner:浙江世新精密机械有限公司

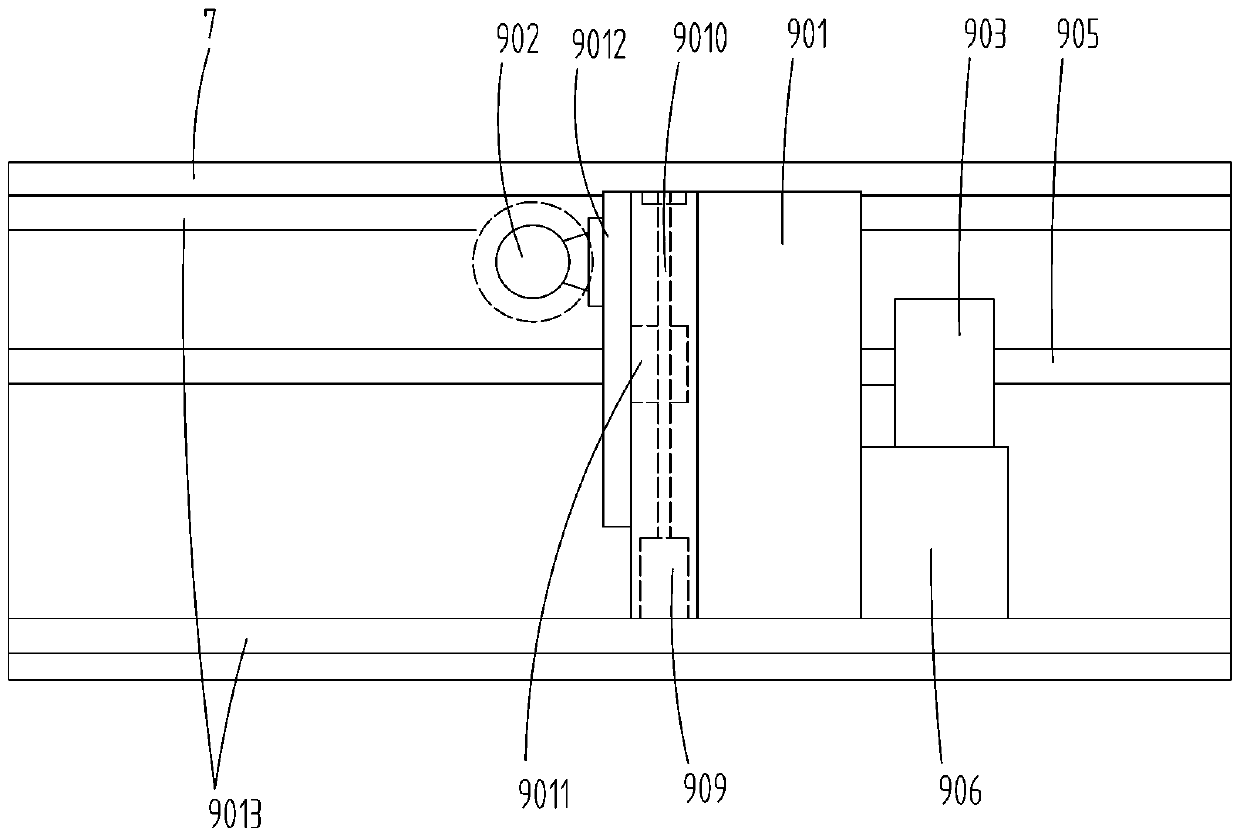

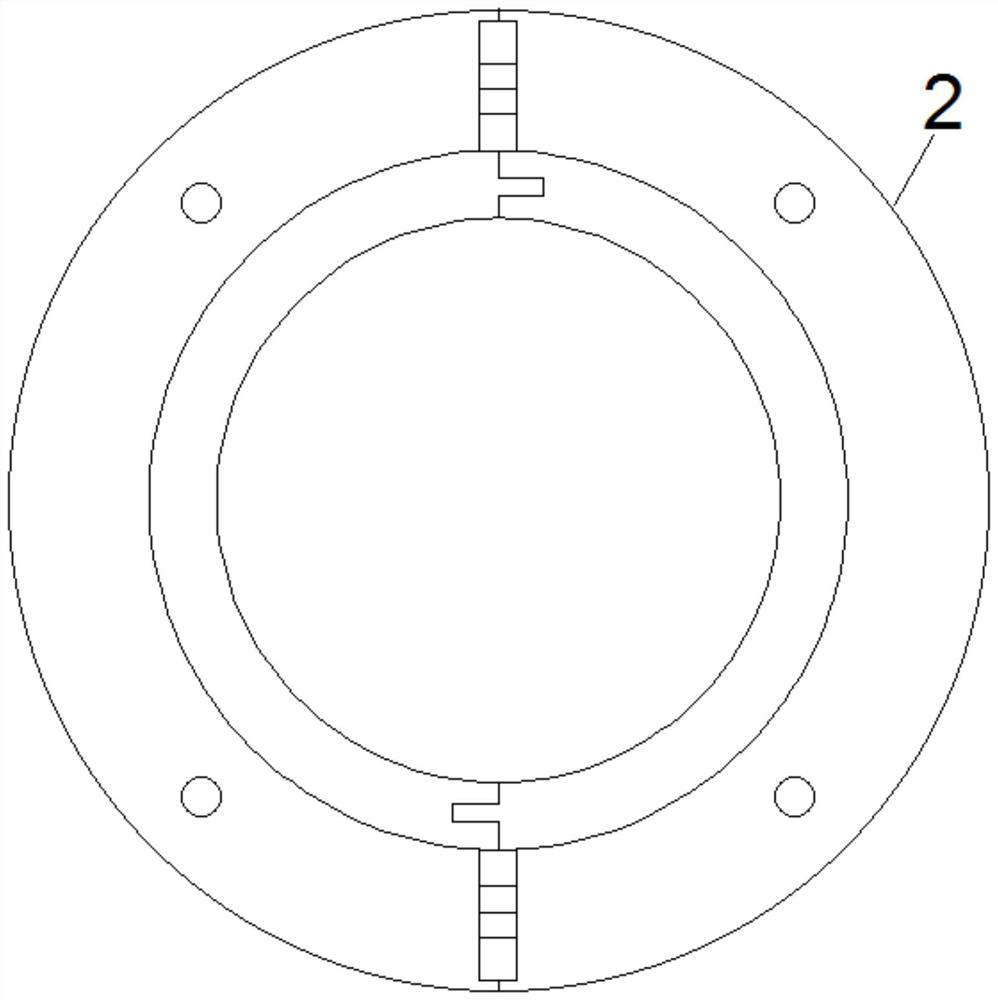

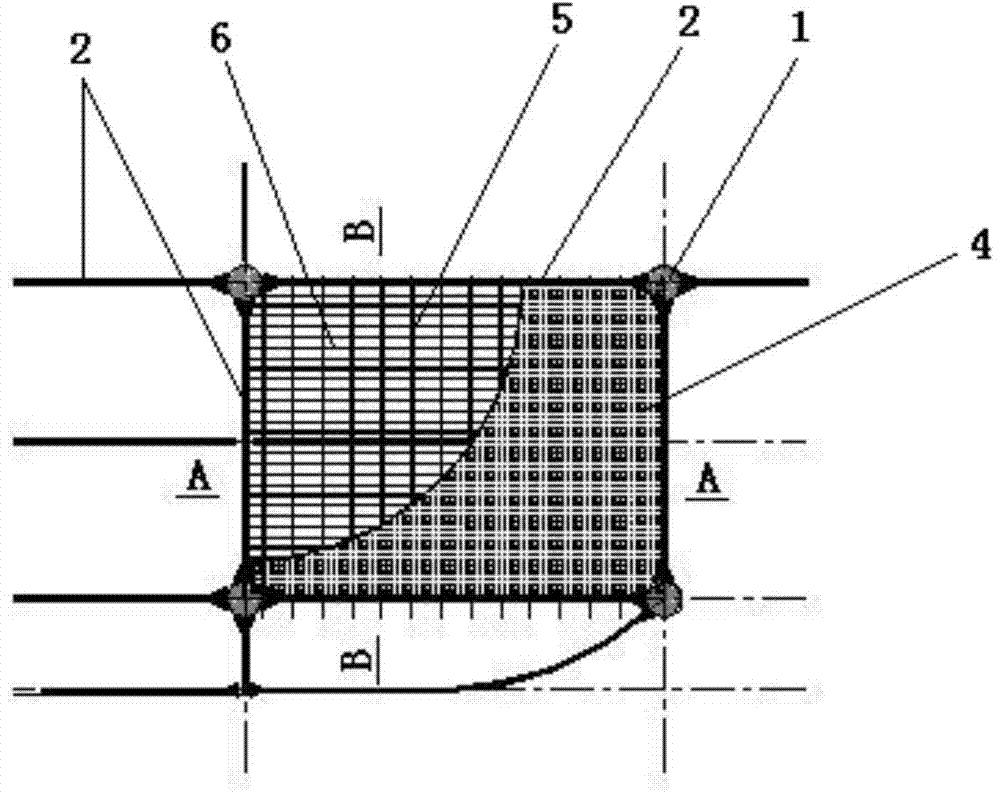

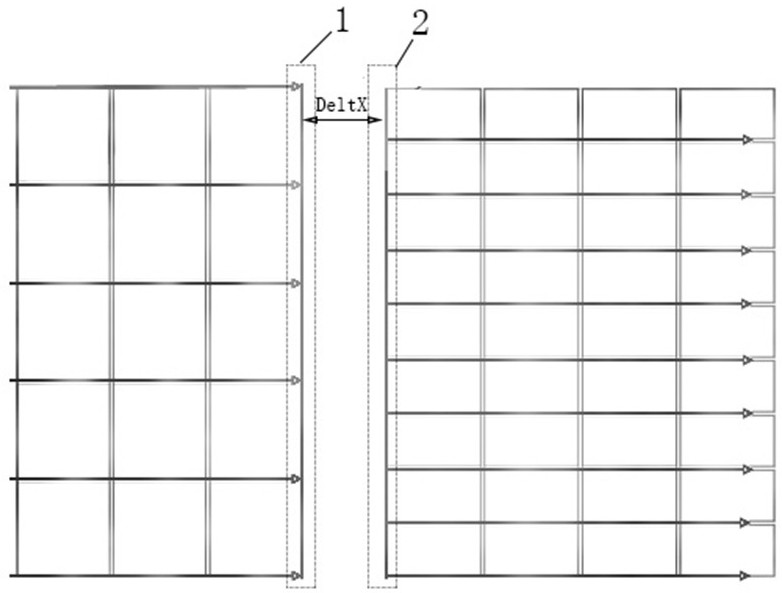

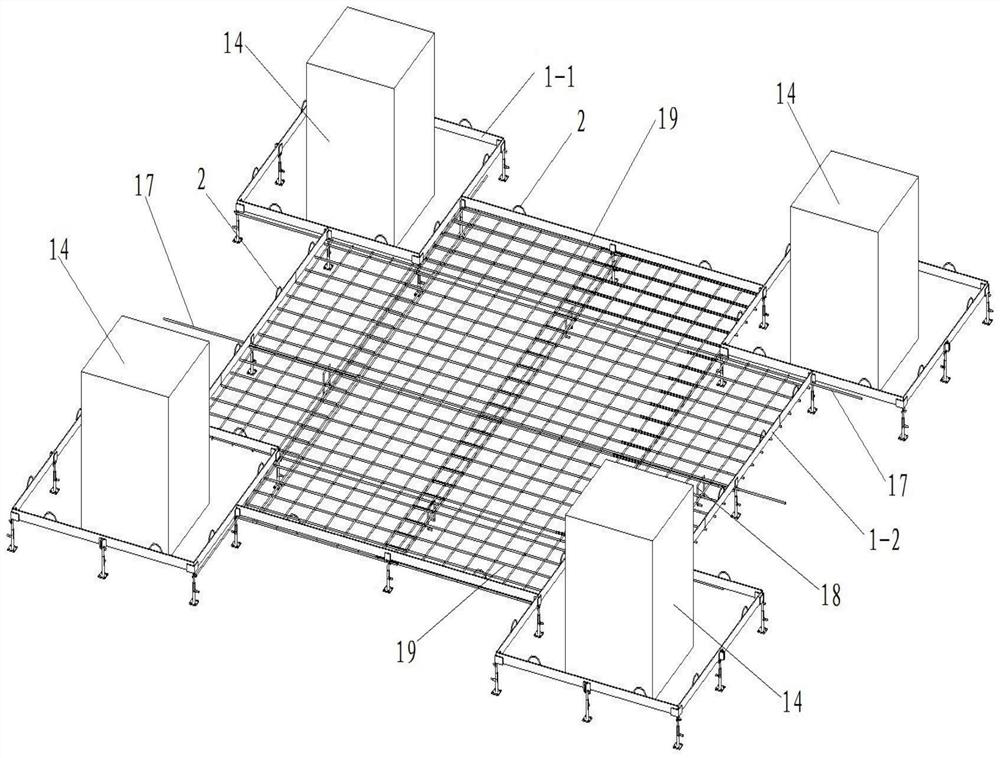

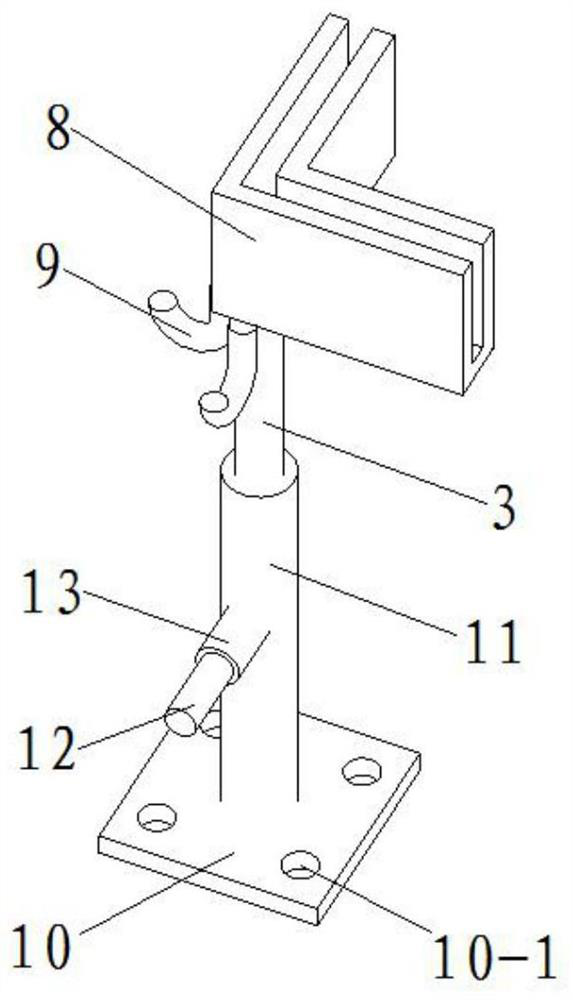

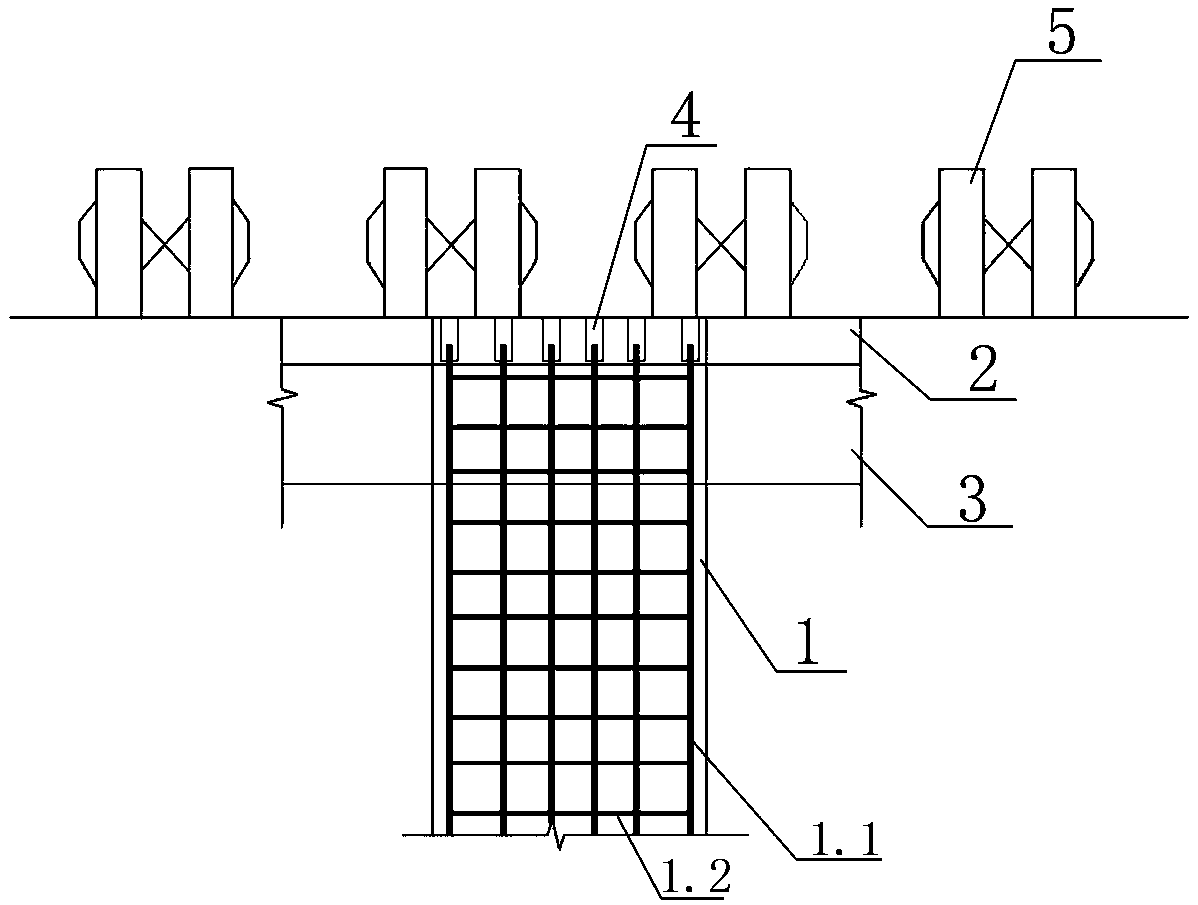

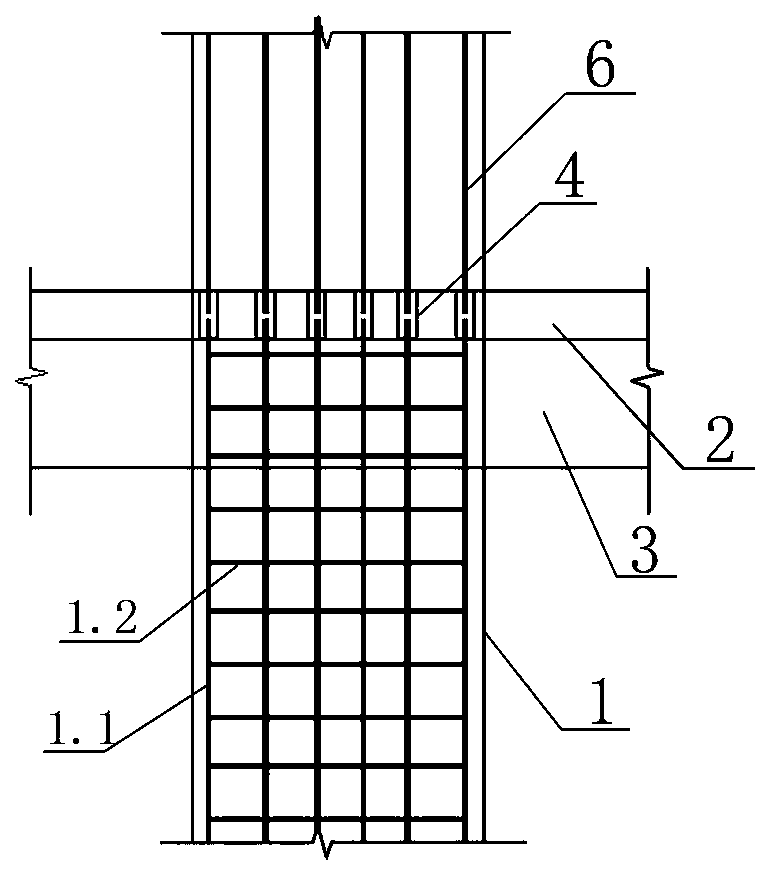

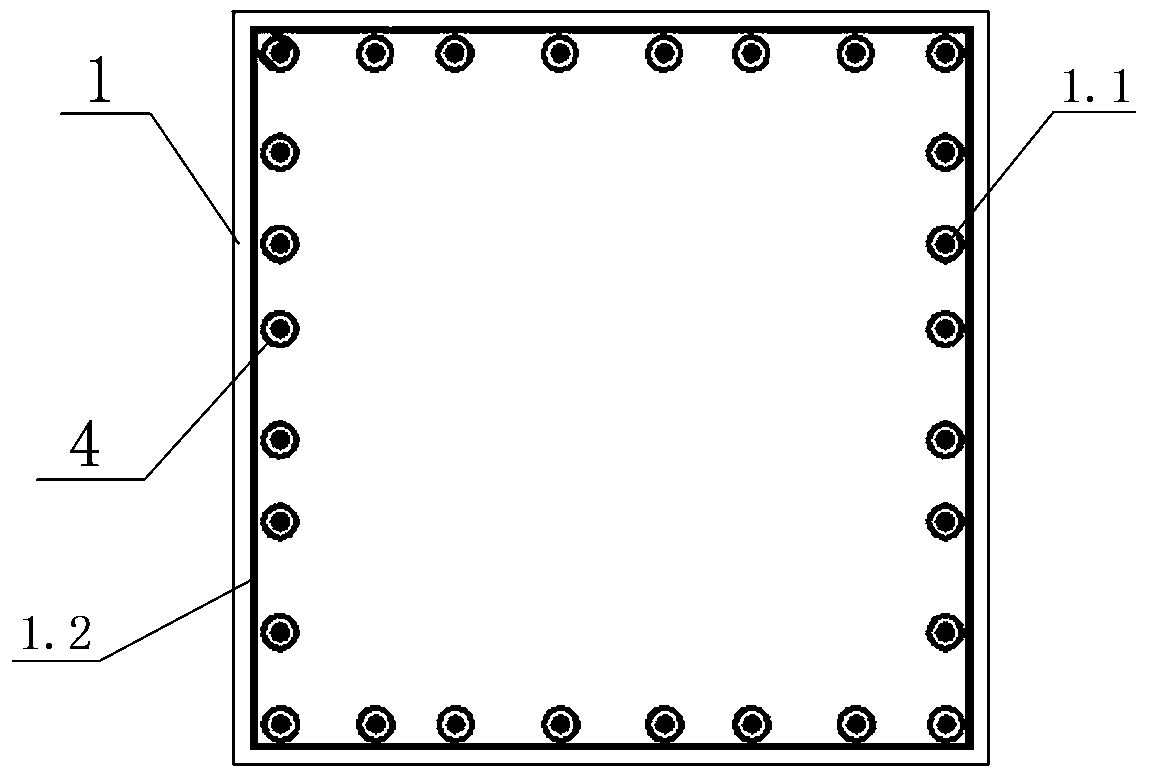

Non-slitting construction structure of concrete super-flat terrace

ActiveCN110158394AReduce uncontrollabilityImprove flatnessIn situ pavingsSingle unit pavingsSurface finishSteel bar

The invention discloses a non-slitting construction structure of a concrete super-flat terrace. The construction structure comprises a concrete terrace and a terrace foundation poured in the concreteterrace, wherein the terrace foundation comprises a partition plate network, a terrace steel bar layer, and a supporting mechanism for supporting the partition plate network and the terrace steel barlayer; the supporting mechanism comprises a plurality of supporting rings arranged in an array mode; and an auxiliary supporting frame is arranged between every two adjacent supporting rings arrangedin the same row and between every two adjacent supporting rings arranged in the same column in the supporting mechanism. According to the construction structure, the super-flat terrace is subjected tonon-slitting construction by arranging the partition plate network, the terrace steel bar layer and the supporting mechanism for supporting the partition plate network and the terrace steel bar layer; the height of main supporting frames, transition supporting frames and the auxiliary supporting frames can all be adjusted through adjustment bases so as control the elevation of the partition platenetwork; and the surface finishing operability is controlled by using the partition plate network, the uncontrollable property of concrete surface finishing is effectively reduced, and the smoothnessof the concrete surface is improved.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

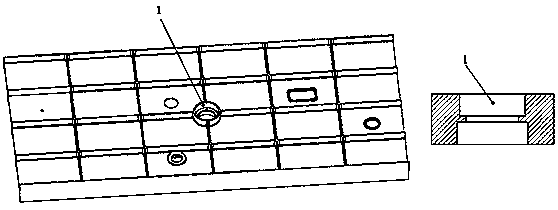

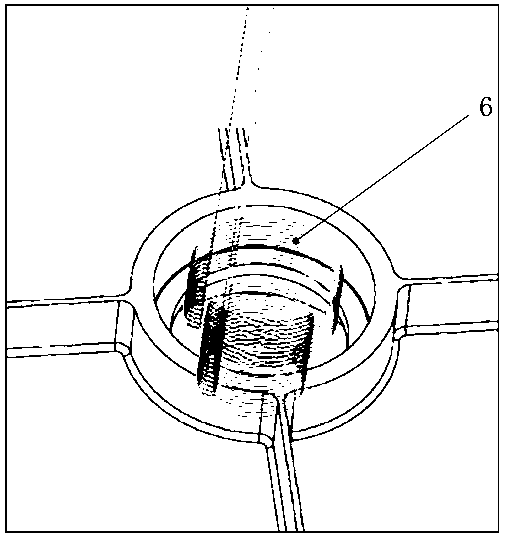

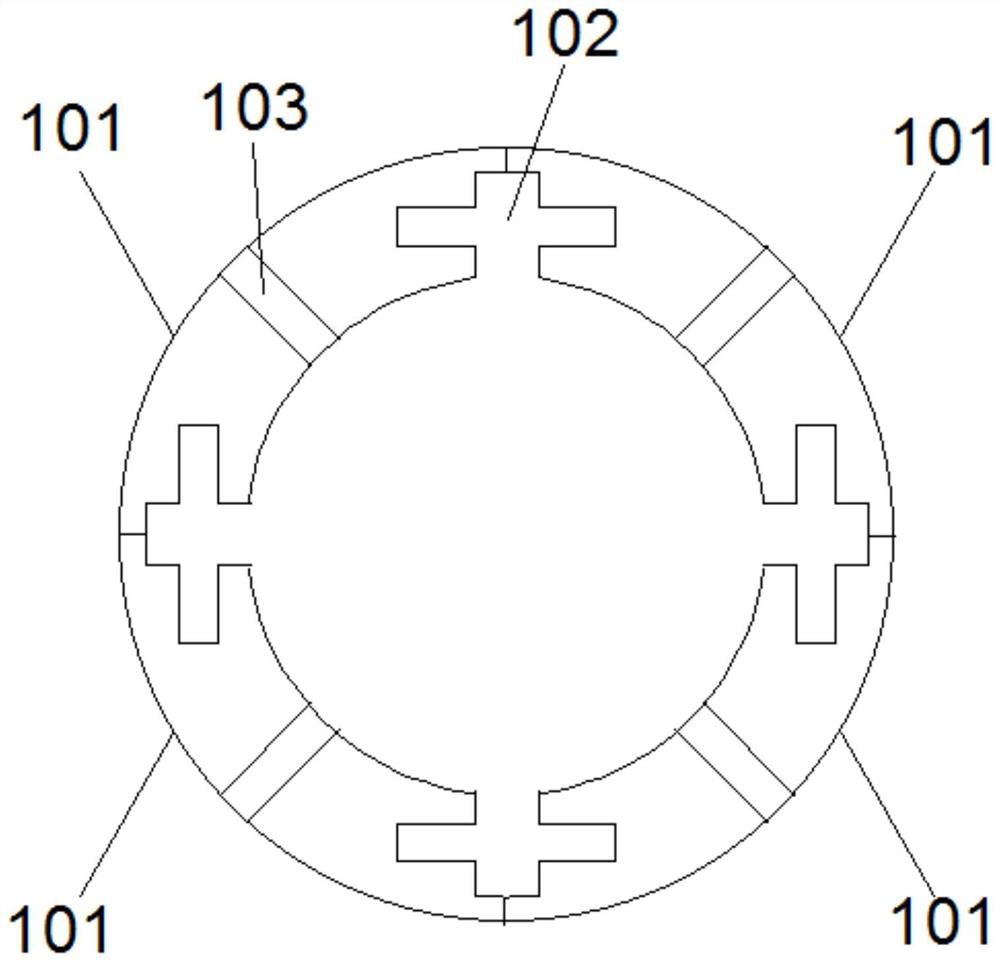

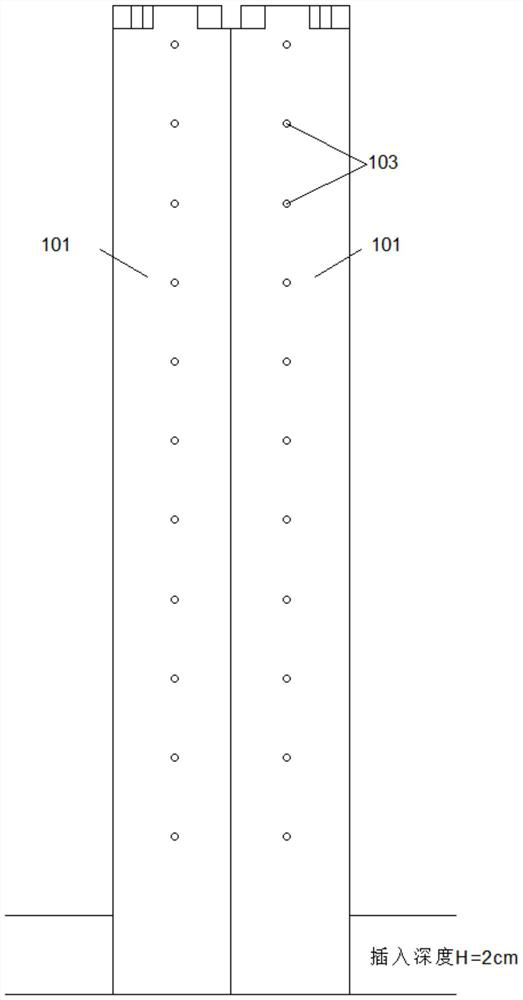

Mounting method, dismounting method and using method of hollow cylinder sample

PendingCN112985948AReduce the level of disturbanceEasy to controlPreparing sample for investigationCircular discEngineering

The invention discloses a mounting method, a dismounting method and a using method of a hollow cylinder sample. The hollow cylinder sample comprises an inner cylinder, a consolidation outer cylinder, a permeable top cover and a drainage chassis, wherein the inner cylinder comprises four inner cylinder assemblies which are arranged in an arc shape, fixing grooves and water permeable holes; the consolidation outer cylinder comprises two semi-circular consolidation outer cylinder assemblies, a fixing table, a fixing hole A, locking blocks, limiting grooves and limiting blocks; a through hole is formed in the center of the permeable top cover; the whole drainage chassis is in a disc shape and provided with water collecting holes. The installation and connection adopts a mortise and tenon buckling mode, so that a soil sample can be more accurately close to the required standard size; a vacuum bin with relatively high leakproofness is formed, so that water and gas can be conveniently discharged, and the water content can be more accurately controlled; and moreover, the disturbance degree on the soil sample during sample disassembly is effectively reduced, secondary cutting on the inner diameter and the outer diameter of the soil sample is avoided, and the possibility is provided for rapidly manufacturing the saturated hollow cylindrical sample with the inner diameter and the outer diameter of the international common standard at one time.

Owner:UNIV OF JINAN

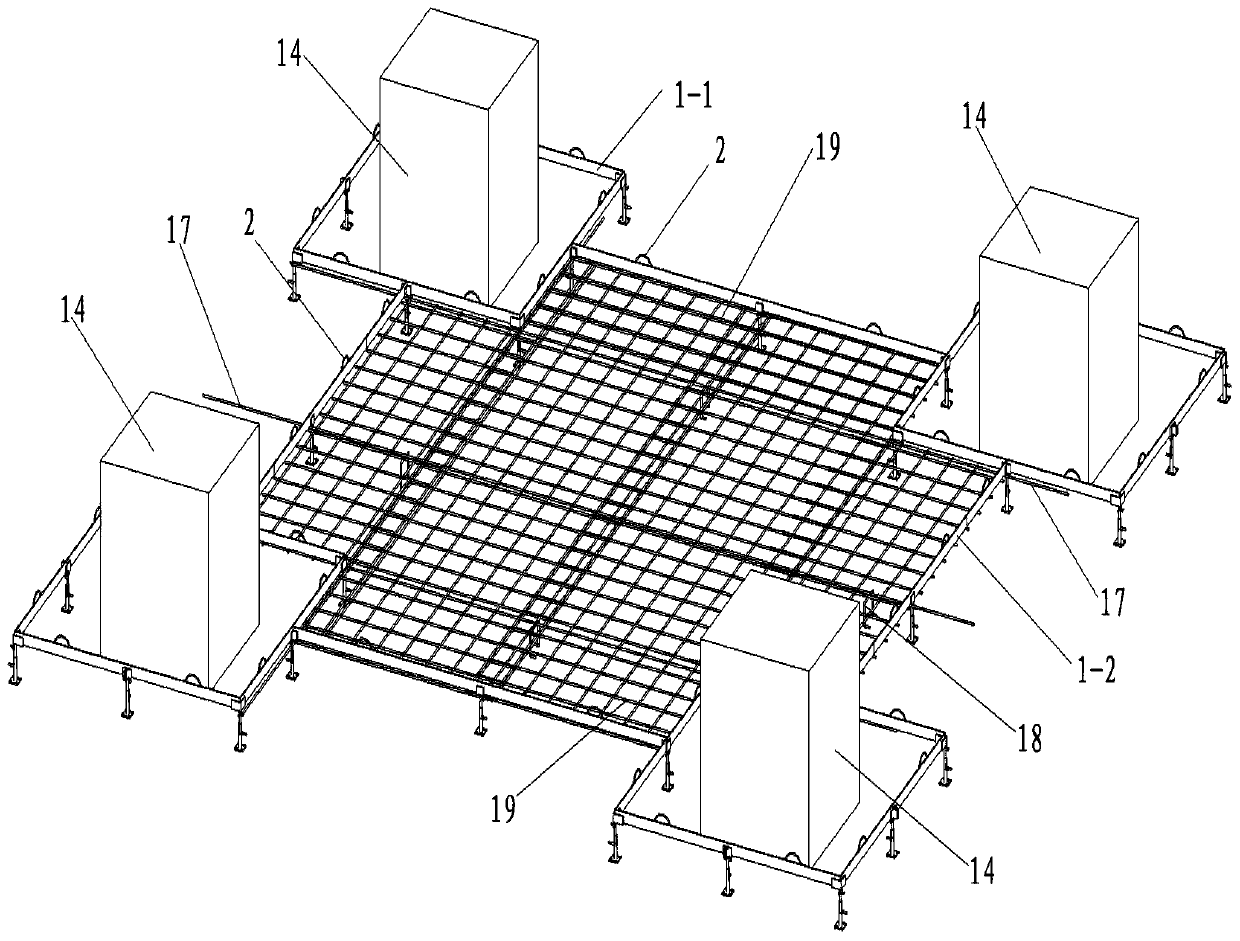

Template overhanging construction method for floor system with composite structure by utilizing profiled steel beams

InactiveCN104499715AReduce labor intensityIncrease usageBuilding material handlingSupporting systemJoist

The invention discloses a template overhanging construction method for a floor system with a composite structure by utilizing profiled steel beams. In the construction method, the profiled steel beams are utilized for overhanging templates to establish a supporting system; H-shaped steel joists are used as mail joists; the main joists are connected with the profiled steel beams through overhanging rings; a template system is suspended on the profiled steel beams, and the excellent mechanical properties of the H-shaped steel joists are sufficiently utilized to effectively transmit loads of the upper template to the profiled steel beams, so that the defects of the lower full hall scaffold supporting system of templates are overcome, the method is safe and reliable, the construction progress is greatly enhanced, and the labor intensity of workers is reduced; besides, the template system can be recycled, so that the use rate of materials is increased, and the construction cost is reduced; besides, the templates and sub-joists are made of macromolecular plastics, so that the loads of the template system are greatly reduced, and the whole stability of the supporting system is largely improved; materials are not easy to damage, so that the material turnover rate is greatly increased; the method is specially suitable for the construction of steel structural concrete floor and frame-structure concrete floor plates of high-rise buildings.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

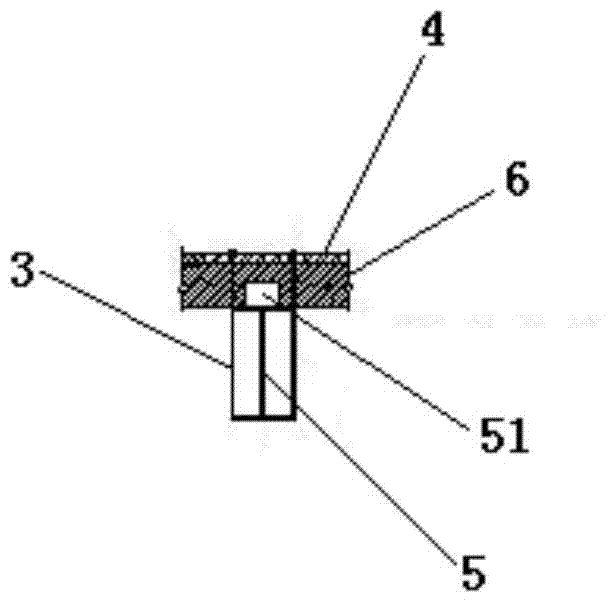

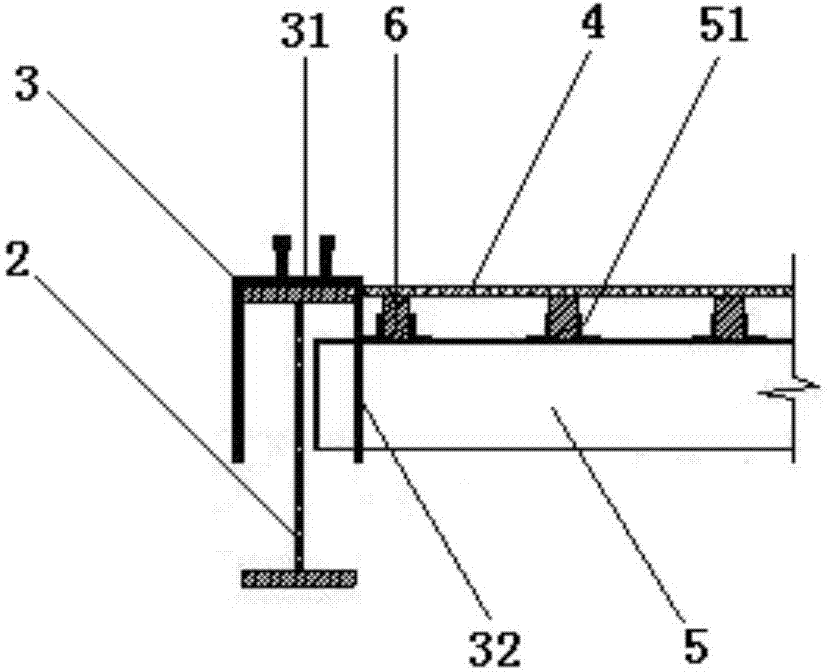

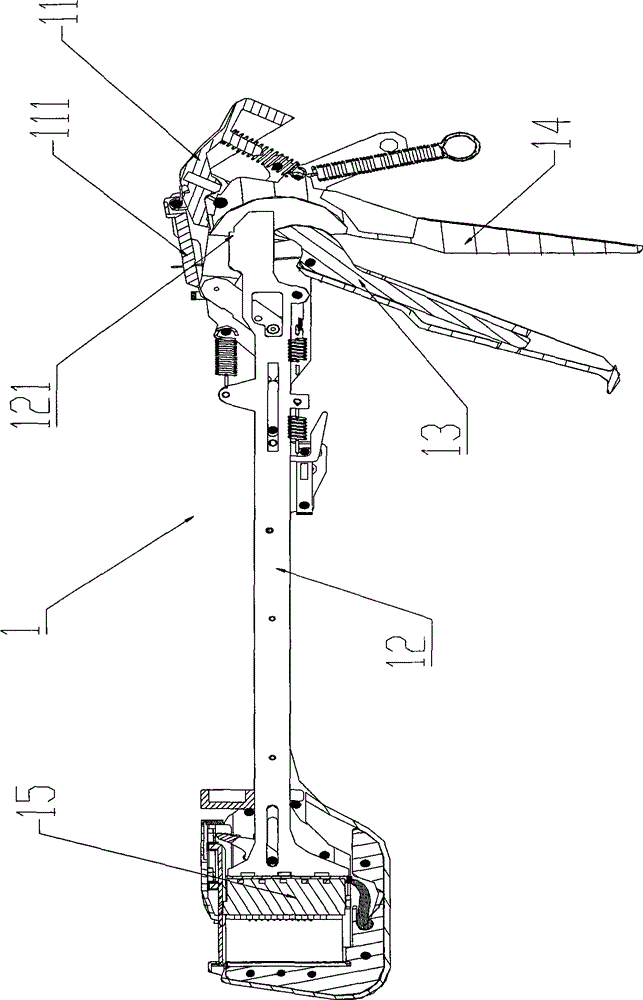

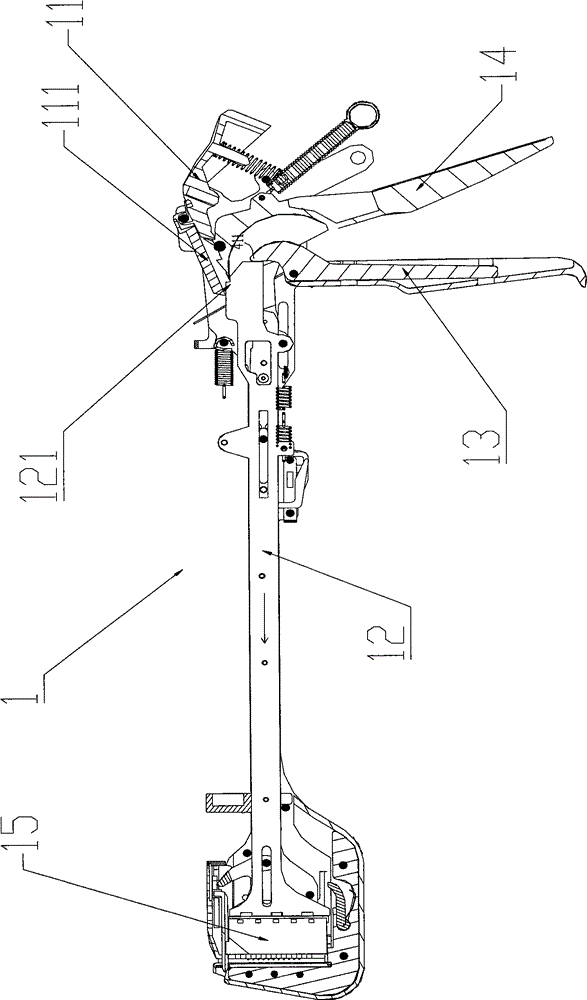

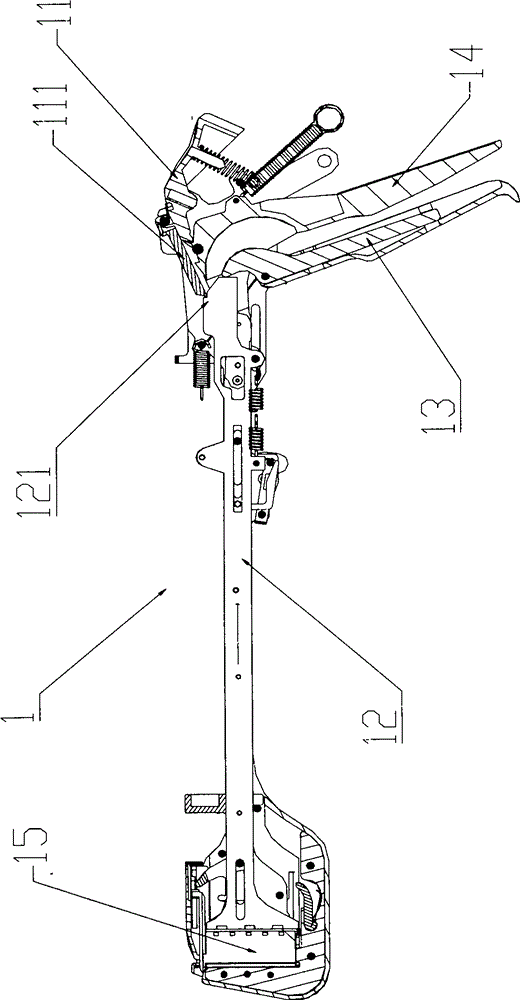

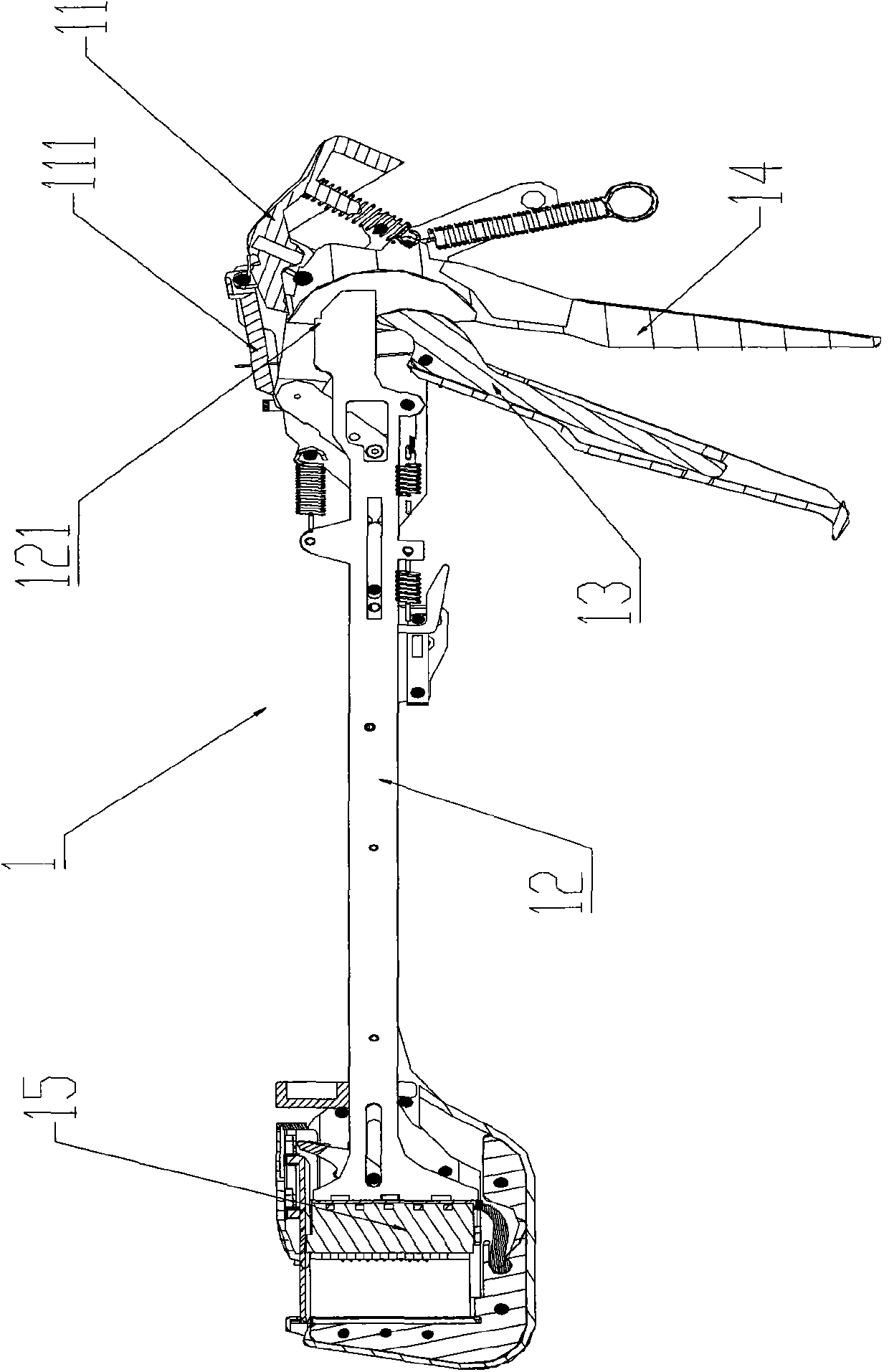

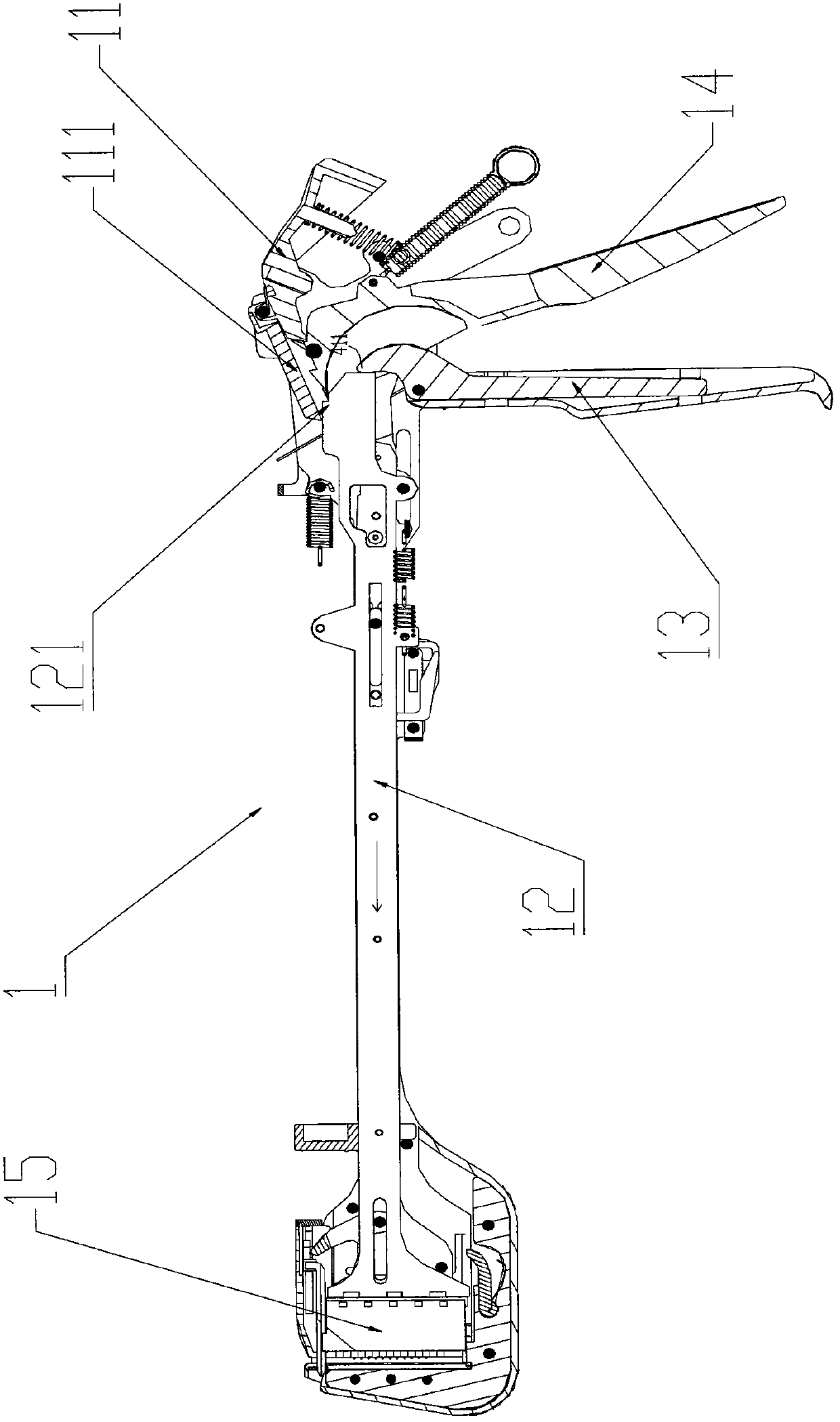

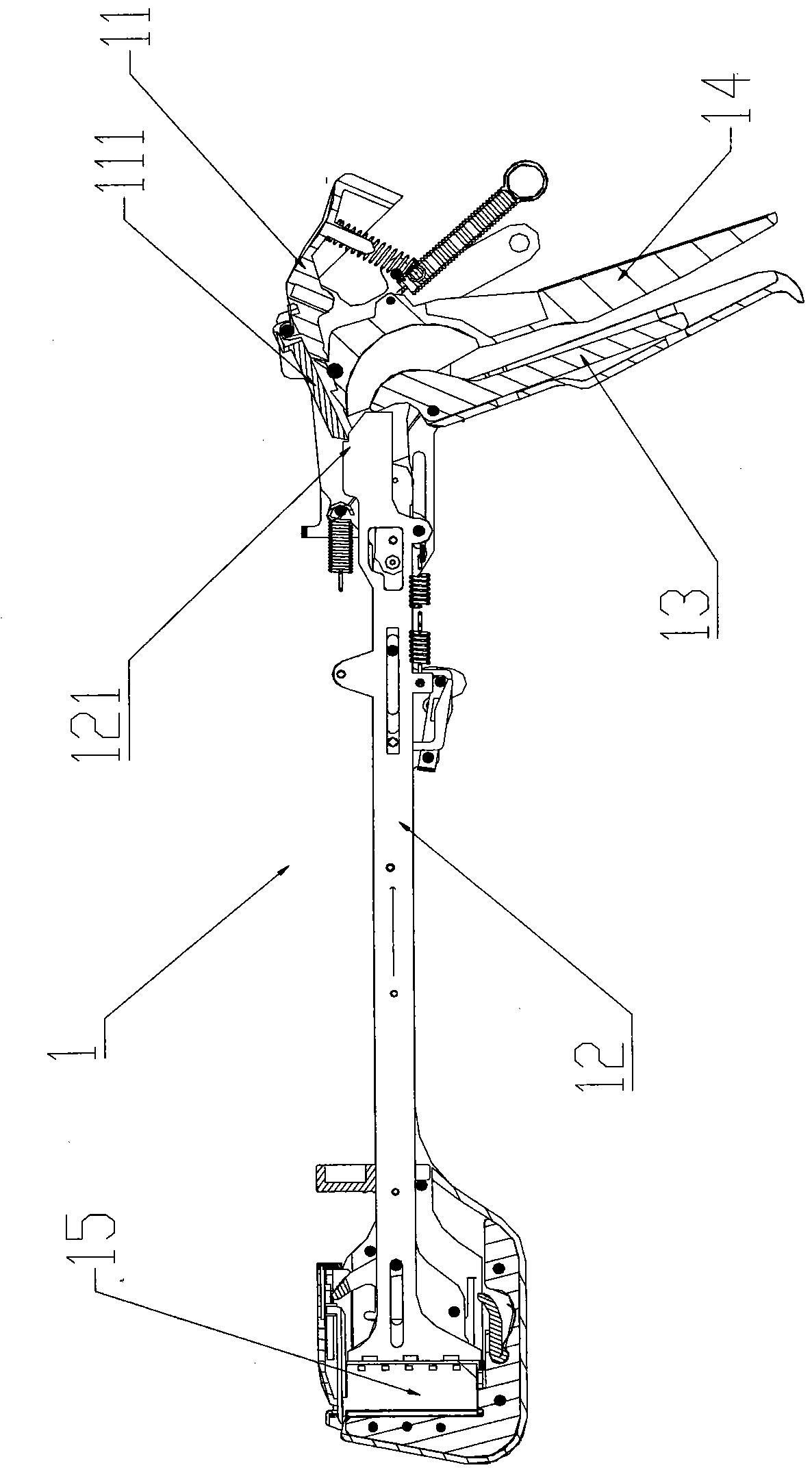

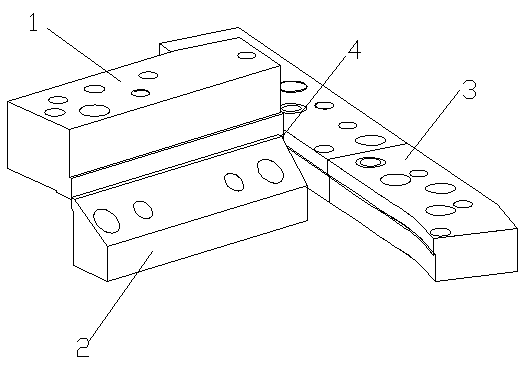

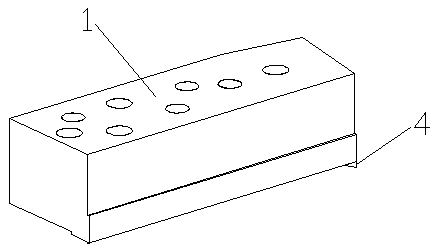

Stitching device with percussion locking unit

ActiveCN105266865APrevent secondary firingAvoid secondary cuttingSurgical staplesEngineeringLocking plate

The invention provides a stitching device with a percussion locking unit; the stitching device comprises a stitching device body, and a pin ejector board and a release button arranged on the stitching device body; the release button is provided with a pin ejector board locking plate; the pin ejector board is provided with a pin ejector board boss; the far end of the pin ejector board locking plate abuts against the pin ejector board boss. In usage, a percussion handle is held to push the pin ejector board, thus driving a cutter to finish cutting; when the cutting is finished, the far end of the pin ejector board locking plate is joint with the pin ejector board boss, so the pin ejector board cannot return to the original state; even if the doctor re-hold the percussion handle, the pin ejector board cannot be pushed, thus preventing secondary percussion of the stitching device, preventing secondary cutting of the cutter, and avoiding medical accidents.

Owner:B J ZH F PANTHER MEDICAL EQUIP

Sugarcane cutting machine capable of cutting off sugarcanes uniformly

The invention discloses a sugarcane cutting machine capable of cutting sugarcanes uniformly. The sugarcane cutting machine capable of cutting the sugarcanes uniformly comprises a cutting barrel, a rotating shaft, a lead screw, a sliding rod, a slider, a clamping ring and a guide tube, wherein the rotating shaft is connected with a plurality of cutters; one end of the rotating shaft is connected with a first motor; a discharging opening is formed in the bottom of the cutting barrel; a feeding opening is formed in one side of the cutting barrel; the guide tube is connected with the discharging opening; a notch is formed in the top of the guide tube; the sliding rod is arranged above the guide tube; the lead screw is arranged above the sliding rod; the slider is provided with a first through hole and a second through hole; the lead screw penetrates in the first through hole; the sliding rod penetrates in the second through hole; the slider is provided with an ejector pin which is matched with an inductor; the clamping ring is arranged below the slider and is connected with the slider via a connecting plate; a fixing hole is formed in the clamping ring; two sides of the clamping ring run through the fixing hole; and a fixing rod penetrates in the fixing hole. The lead screw and the sliding rod are combined to drive the clamping ring so as to drive the sugarcanes to move forwards at constant speed, the labor intensity is reduced, and lengths of cut sugarcanes are the same.

Owner:陈赢荣

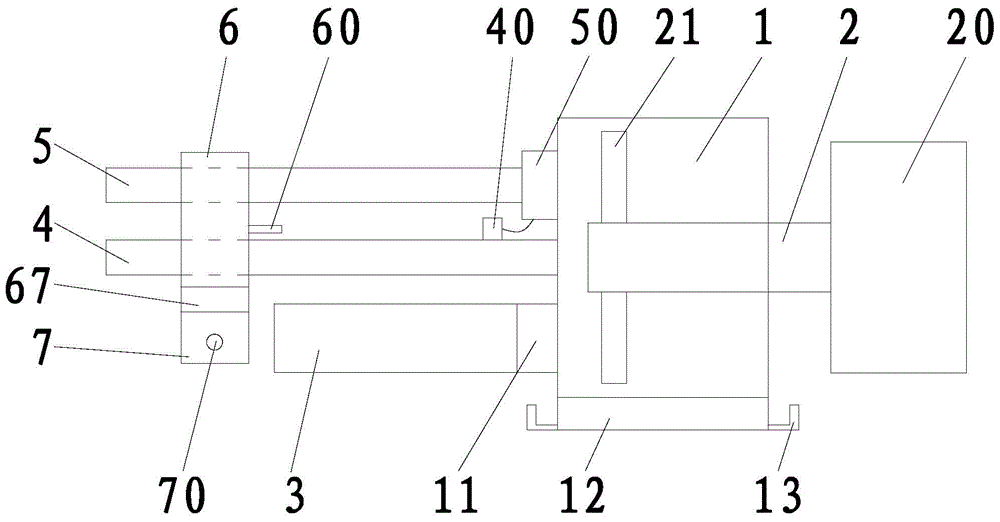

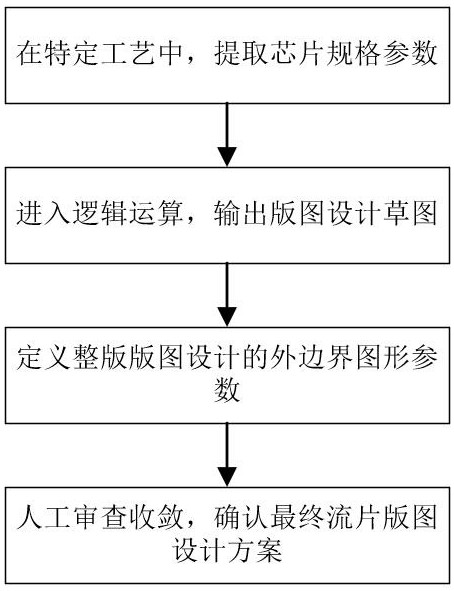

Semiconductor laser cutting mpw layout design method and chip and terminal prepared therefrom

ActiveCN114548015BAvoid dwell timeEasy to operateImage enhancementImage analysisLogical operationsLayout

Owner:CHENGDU FUJIN POWER SEMICON TECH DEV CO LTD

A high-efficiency shearing device for plate parts

ActiveCN108817501BSame displacementAvoid secondary cuttingShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention relates to the technical filed of plate machining, in particular to an efficient plate shearing device for plate pieces. Through a contact switch, shifting between driving and positioning can be achieved, and with cooperation with a limiting assembly, displacement of the plate pieces can be limited, and therefore displacement of the plate pieces are the same, and secondary cutting isavoided. The limiting assembly achieves position adjustment and positioning through an adjusting cylinder, and therefore shearing requirements of different spaces of the plate pieces can be met. An upper compression roller is arranged at the cutting end, and therefore the plate pieces can be effectively limited without influence on cutting, and the problems caused by plate body upwarp during cutting are avoided. A delayed communicating device is arranged, when the contact switch is connected with driving roll shaft power, delayed communication is carried out, enough recovery time is providedfor a cutting assembly, collision with the cutting assembly caused by plate piece forward movement is avoided, and security is high.

Owner:徐州欧美国林人造板有限公司

Synchronous stripping device for multiple strands of wires and cables

ActiveCN114268055AEasy to cutAvoid secondary cuttingApparatus for removing/armouring cablesElectronic waste recyclingStructural engineeringElectric wire

The invention relates to the technical field of wires and cables, in particular to a multi-strand wire and cable synchronous stripping device which comprises a processing box, a stripping part and a wire core conveying part, feeding ports are formed in the left end of the processing box at equal intervals in the front-back direction of the processing box, the stripping part is arranged in the processing box, and the wire core conveying part is installed at the right end of the processing box; an existing electric wire stripping machine has the following problems that the existing stripping machine cannot carry out transmission and stripping treatment on electric wires with different diameters, so that limitation exists; the stripping machine cannot segment a wire core, and the wire core needs to be subjected to secondary cutting through special cutting equipment, so that the working procedures are increased; the electric wires with different diameters can be cut through the cutting knives located on the upper and lower sides of the electric wires; according to the invention, intermittent pressing and cutting segmentation processing can be carried out on the peeled wire core while the wire is peeled, and secondary cutting of the wire core can be avoided, so that processes can be reduced.

Owner:徐州华创电子有限公司

Slicing device for processing traditional Chinese medicine decoction pieces

PendingCN113276197AUniform thicknessAvoid secondary cuttingMetal working apparatusProcess engineeringMaterials processing

The invention provides a slicing device for processing traditional Chinese medicine decoction pieces, and relates to the technical field of Chinese medicinal material processing equipment. The slicing device comprises a shell, a supporting plate, connecting pieces, a conical guide table, a material barrel, guide grooves, blanking seams, cutter mechanisms, a driving mechanism and a control panel. According to the slicing device, the thickness of decoction pieces can be kept uniform, and the sliced decoction pieces directly fall into a conical blanking bin; secondary cutting is avoided, and raw material medicines are output through the multiple guide grooves simultaneously while the slicing quality is guaranteed; and the multiple material guide grooves work in cooperation with the multiple cutter mechanisms, and the slicing efficiency is effectively improved.

Owner:THE THIRD PEOPLES HOSPITAL OF QINGDAO

A layout design method of a multi-type chip and a chip and terminal prepared therefrom

ActiveCN114548020BDesign flexible adjustmentEfficient outputSolid-state devicesComputer aided designComputer hardwareChip size

The invention discloses a layout design method of a multi-type chip and a prepared chip and a terminal, which belong to the technical field of semiconductors. Under the constraints of the cutting unit parameters, determine the size relationship between the chip size parameters and the corresponding initial cell thresholds, and adjust the chip cell thresholds; calculate the proportional relationship between the corresponding chip cell thresholds and the chip size parameters, and then output the layout design. The present invention first adjusts the chip unit thresholds by different types of chips, and can quickly divide the overall layout into multiple independent operation areas, and then further calculates the proportional relationship between chips and chip units, and then quickly arranges the corresponding number of chips on the corresponding chip units. Within a certain threshold range, the layout design can be flexibly adjusted according to the customer's own chip design parameters simply and quickly, and the layout design can be output efficiently.

Owner:成都复锦功率半导体技术发展有限公司

An adjustable angle marble cutting equipment

ActiveCN111015971BAdjustable angleAvoid displacementWorking accessoriesStone-like material working toolsClassical mechanicsElectric machinery

The invention relates to a cutting device, in particular to an angle-adjustable marble cutting device. Therefore, the technical problem of the present invention is to provide an angle-adjustable marble cutting device that can adjust the cutting angle, can fix the marble firmly, and avoid the displacement of the marble during cutting. Technical solution: An angle-adjustable marble cutting equipment, including a bottom plate, a first bracket, a second bracket, a tapered plate, etc.; the first bracket is symmetrically arranged on the right side of the top of the bottom plate, and the second bracket is arranged on the left side of the top of the bottom plate . The invention can adjust the angle of the motor and the cutting piece by turning the first hand wheel, thereby adjusting the cutting angle of the marble, so that the angle can be adjusted when the marble is cut, and the operation of adjusting the angle is relatively simple, and the angle of adjustment is relatively wide. It can be adjusted according to the cutting needs, avoiding the subsequent use of the hand grinder for secondary cutting, which improves the work efficiency and reduces the complexity of the operation.

Owner:济南森华精密机械有限公司

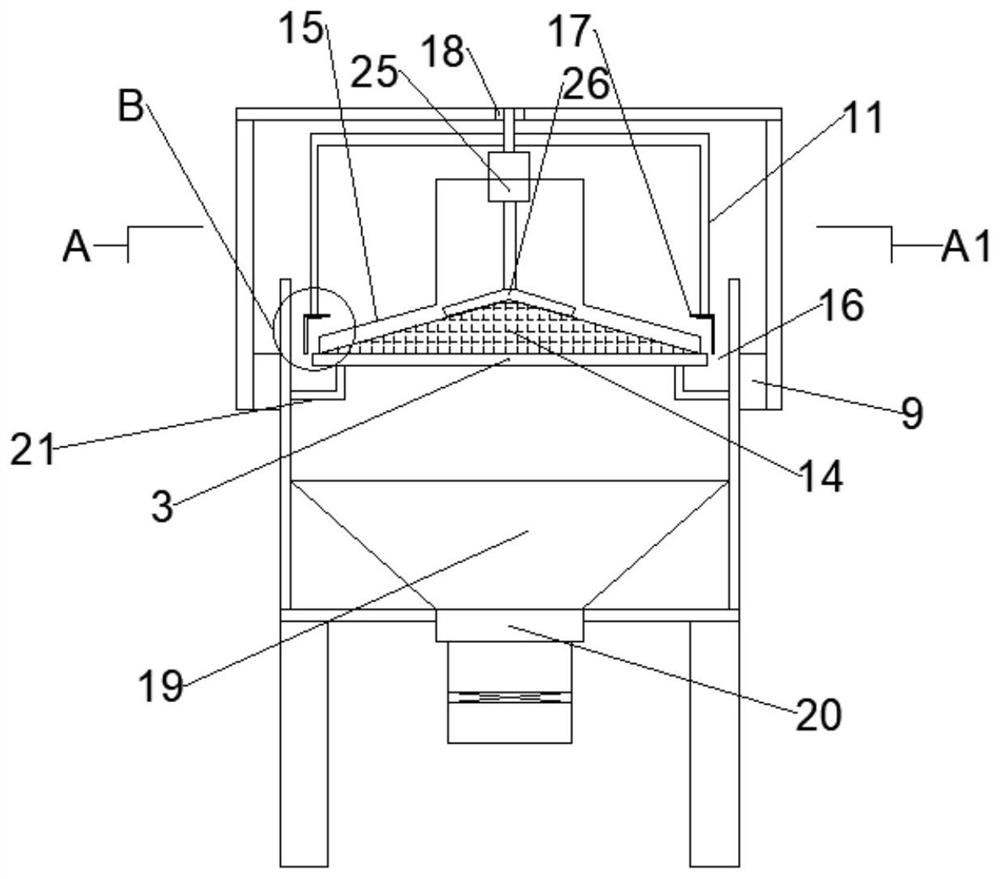

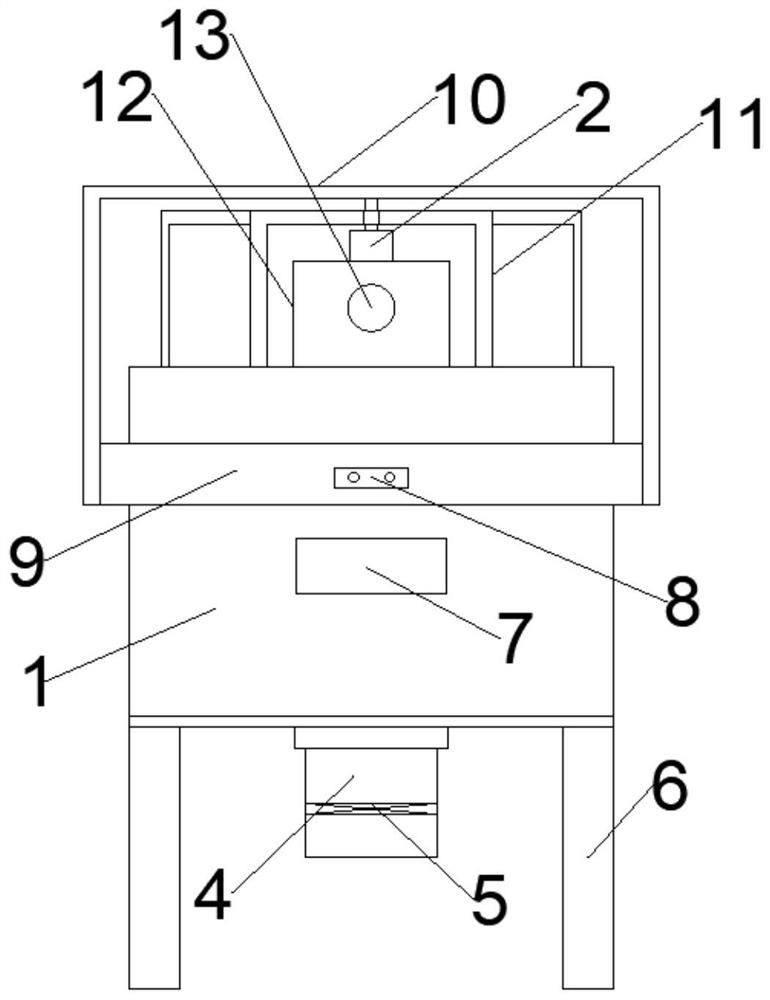

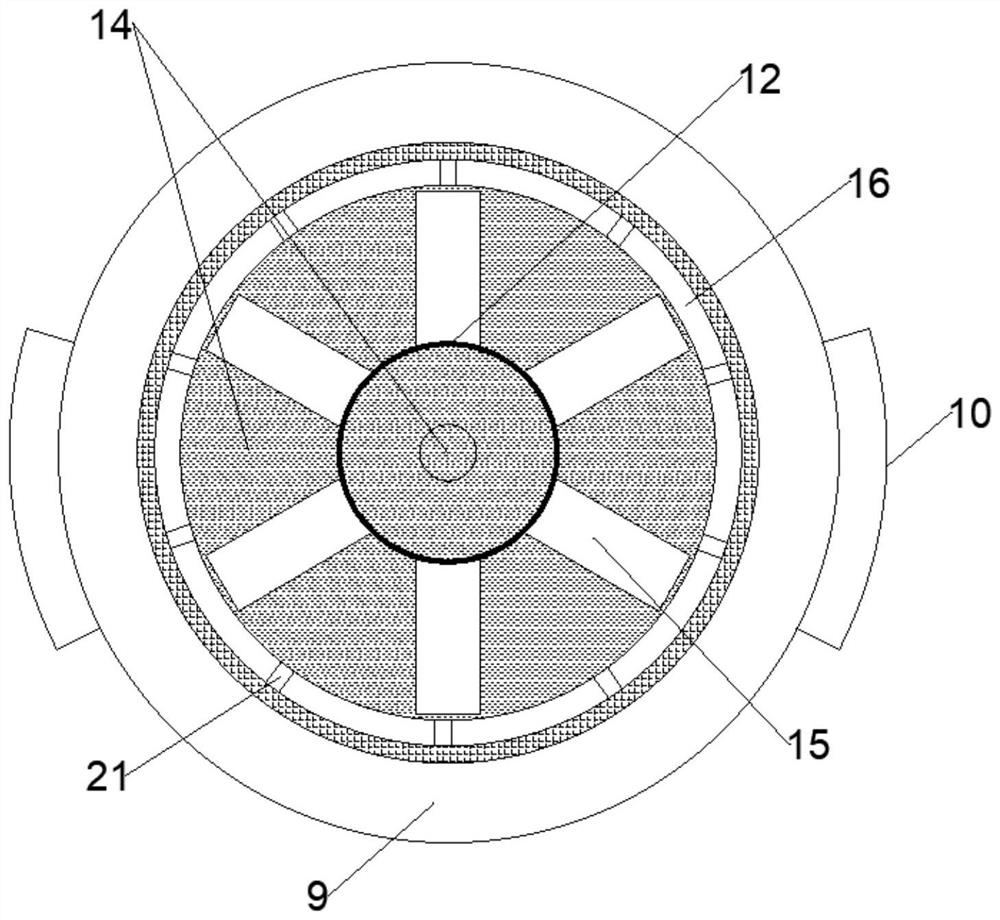

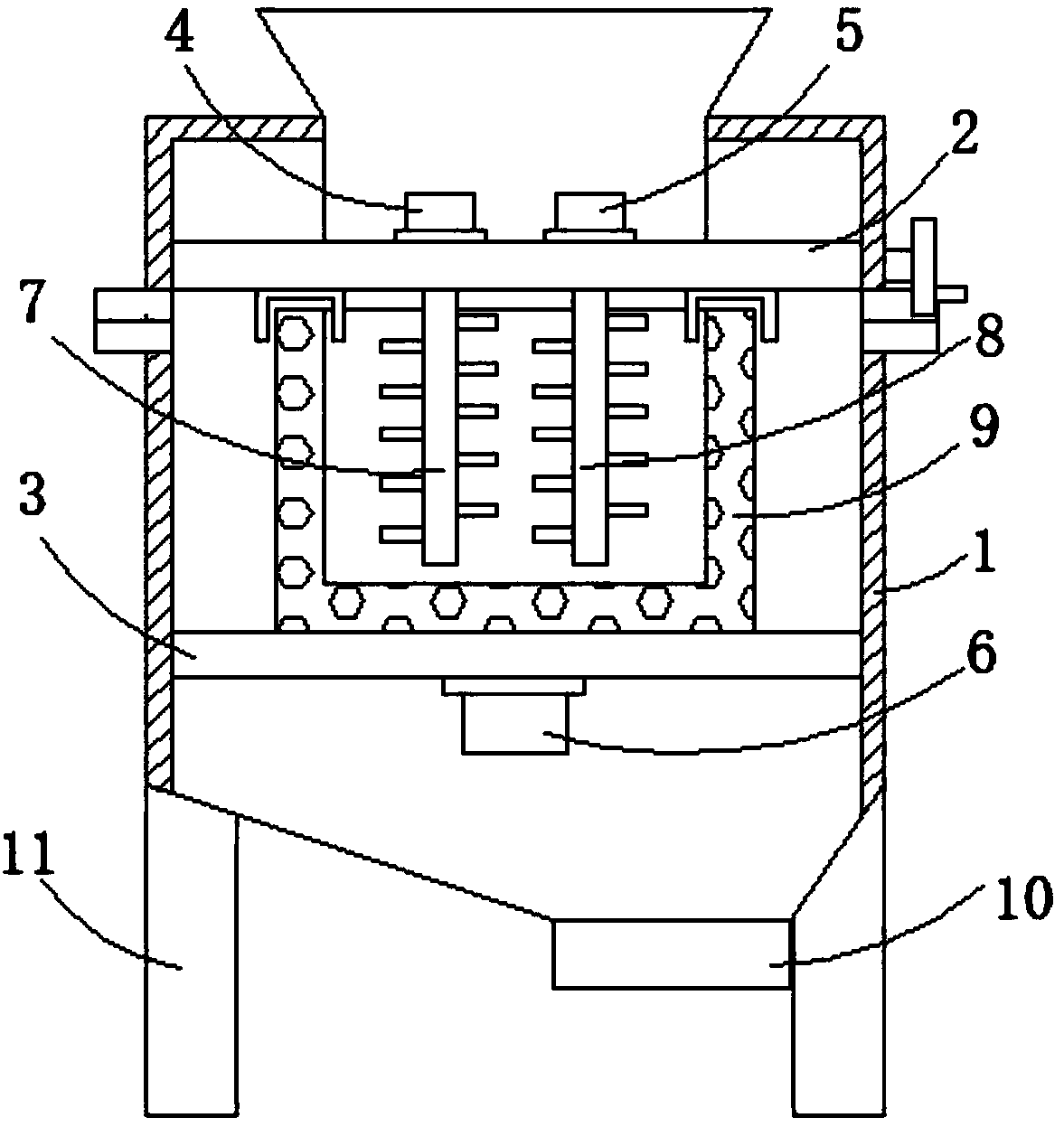

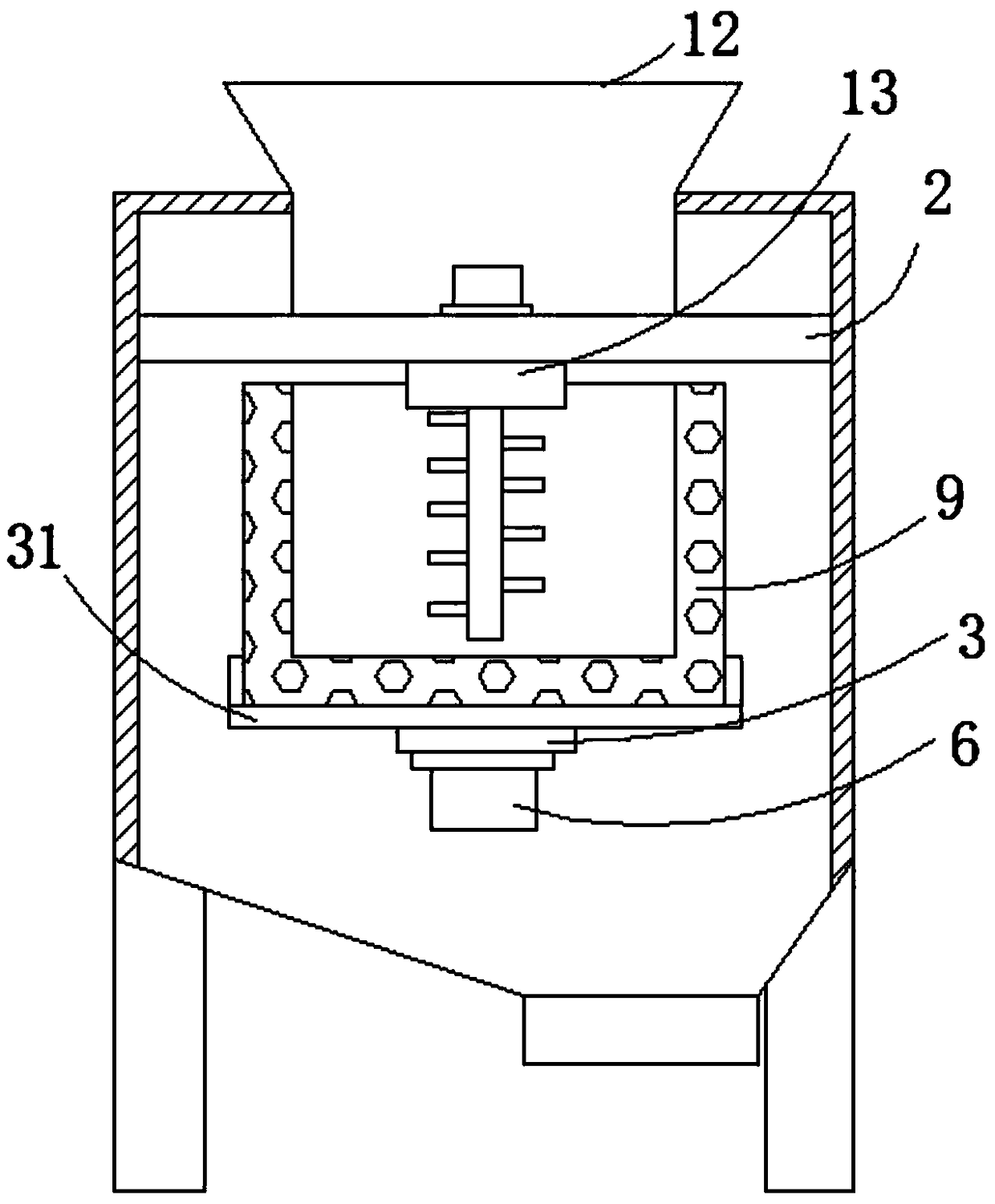

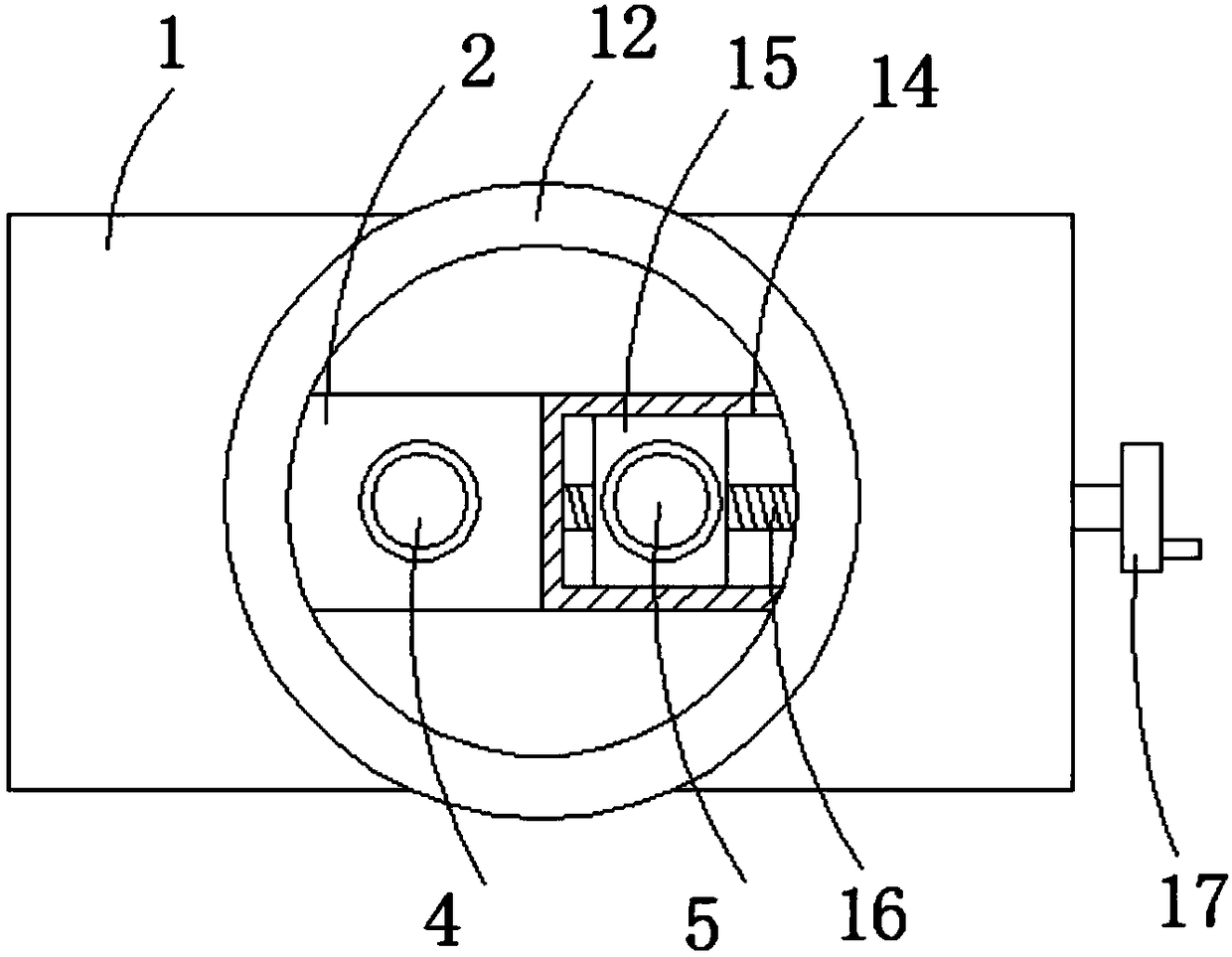

Production equipment for ceramic fiber granulated wool

The invention discloses production equipment for ceramic fiber granulated wool in the technical field of fiber wool production equipment. The production equipment comprises a box, a first supporting frame and a second supporting frame are fixedly installed on the upper and lower sides of an inner cavity of the box respectively, a first cutting motor and a second cutting motor are installed on thetwo sides of the top of the first supporting frame, a screening motor is installed in the middle of the bottom of the second supporting frame, a screening cylinder is rotationally connected between the first supporting frame and the second supporting frame, a first cutting frame and a second cutting frame are arranged on the two sides of the bottom of the first supporting frame, and a dischargingbarrel is arranged at the bottom of the box. Ceramic fiber wool is cut under the mutual effect of the first cutting frame and the second cutting frame, and screening is performed by the screening cylinder in the cutting process to separate out small residual balls and guarantee the forming quality of granulated wool; the distance between the first cutting frame and the second cutting frame can beadjusted, so the size of ceramic fiber grains can be changed for cutting, and the application range is wide.

Owner:CHANGXING RUIHONG REFRACTORY MATERIAL CO LTD

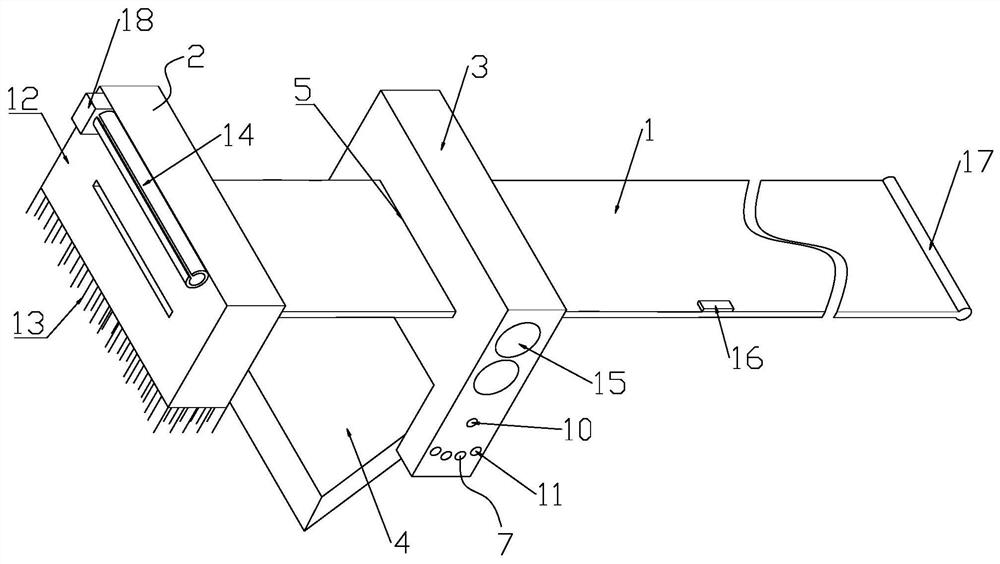

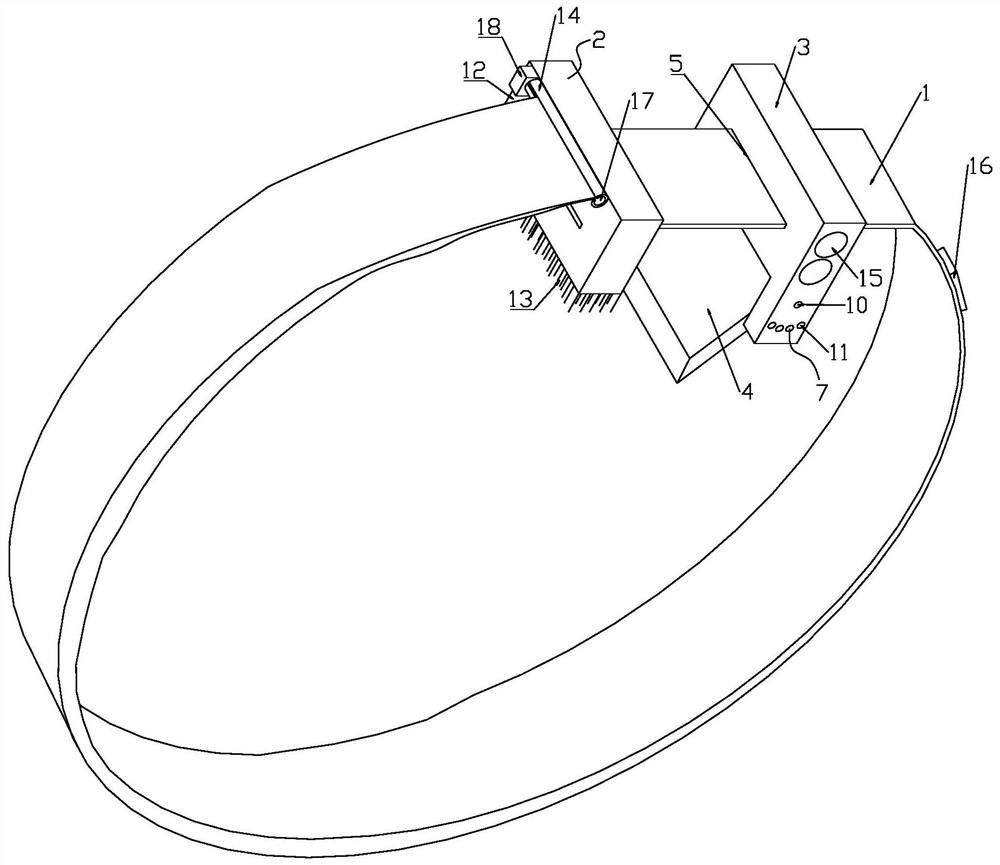

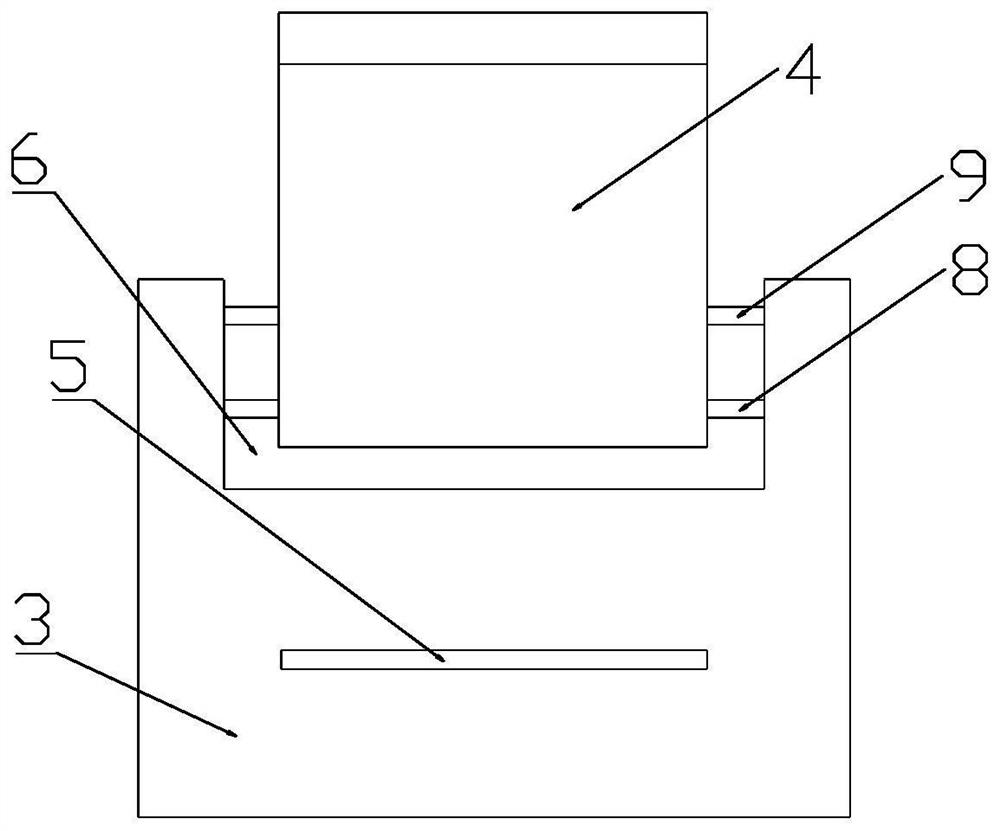

Cutting device and method for promoting flowering and fruiting of larch

PendingCN113366985AAvoid irregularitiesAvoid secondary cuttingCuttersCutting implementsTree trunkLarch tree

The invention relates to the technical field of plant breeding, and provides a cutting device. The cutting device comprises a belt-shaped soft belt, a tool apron and a cutting knife, wherein a limiting device is arranged at one end of the belt-shaped soft belt and is used for fixing the belt-shaped soft belt to a tree trunk, the other end of the belt-shaped soft belt is used for being connected with the limiting device, and a tension sensor is arranged on the belt-shaped soft belt; the tool apron is arranged on the belt-shaped soft belt in a sliding manner; and the cutting knife is arranged on the tool apron. According to the cutting device, the problems that in the prior art, most larch trunks are irregular, some parts are not prone to being in contact with the cutting knife, and secondary cutting needs to be carried out are solved.

Owner:河北省林业和草原科学研究院

A Concrete Ultra-flat Floor Cut-Free Construction Structure

ActiveCN110158394BReduce uncontrollabilityImprove flatnessIn situ pavingsSingle unit pavingsSurface finishArchitectural engineering

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

A multi-strand wire and cable synchronous stripping device

ActiveCN114268055BEasy to cutAvoid secondary cuttingApparatus for removing/armouring cablesElectronic waste recyclingStructural engineeringElectric wire

The invention relates to the technical field of electric wires and cables, in particular to a synchronous peeling device for multi-strand electric wires and cables, which includes a processing box, a peeling part and a wire core conveying part. There is a peeling part in the box, and a wire core delivery part is installed at the right end of the processing box; the existing wire stripping machine has the following problems: the existing stripping machine cannot transmit and strip the wires of different diameters, so there are limitations; The stripping machine cannot segment the wire core, and needs to use special cutting equipment to cut the wire core twice, thereby increasing the process; the invention can cut wires of different diameters through the cutting knives located on the upper and lower sides of the wire; The invention can intermittently press and cut the stripped wire core into sections while stripping the wire, avoiding secondary cutting of the wire core, thereby reducing the process.

Owner:徐州华创电子有限公司

Ultra-precision thermoplastic composite material granulator

The invention discloses an ultra-precision thermoplastic composite material granulator. The ultra-precision thermoplastic composite material granulator comprises a rack and a granulating device arranged on the rack, the granulating device comprises a bottom plate, a housing, a rotary knife roll, an upper press roll and a lower press roll, the bottom plate is fixed on the rack, the housing is arranged on the bottom plate, and the rotary knife roll, the upper press roll and the lower press roll are all arranged in the housing. The upper press roller and the lower press roller are both located on one side of the rotary knife roller and are distributed up and down, a knife holder is further arranged between the rotary knife roller and the lower press roller, a fixed knife is arranged on the knife holder and is of a cuboid structure, and two faces of the fixed knife are concave towards the center. A gap between one concave face of the fixed knife and the outer wall of the rotary knife roller is a discharging gap, a discharging barrel is further arranged at the bottom of the bottom plate, and the discharging barrel extends out of the rack.

Owner:无锡麦科机械有限公司

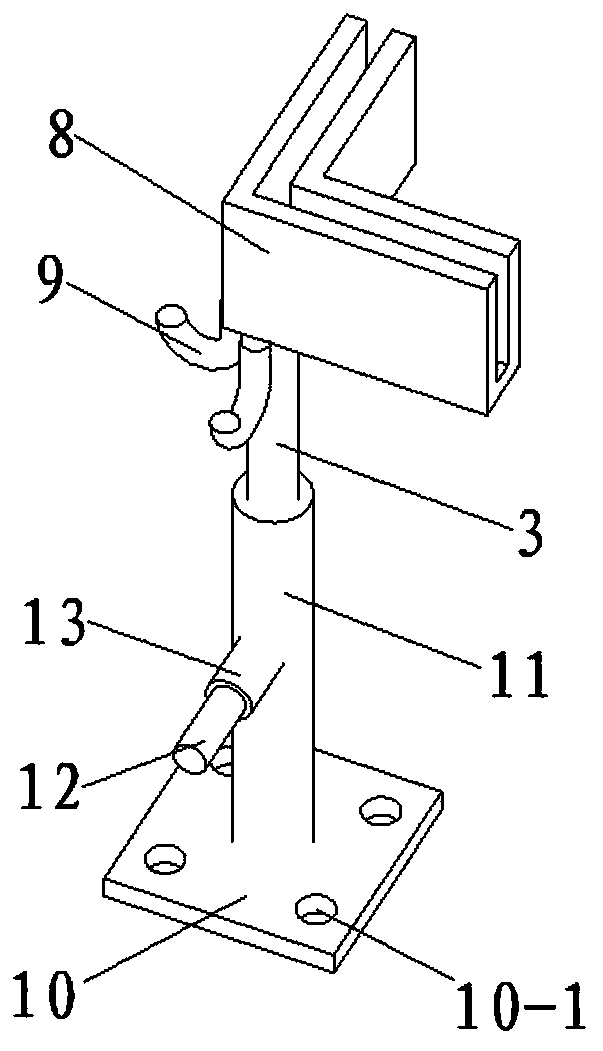

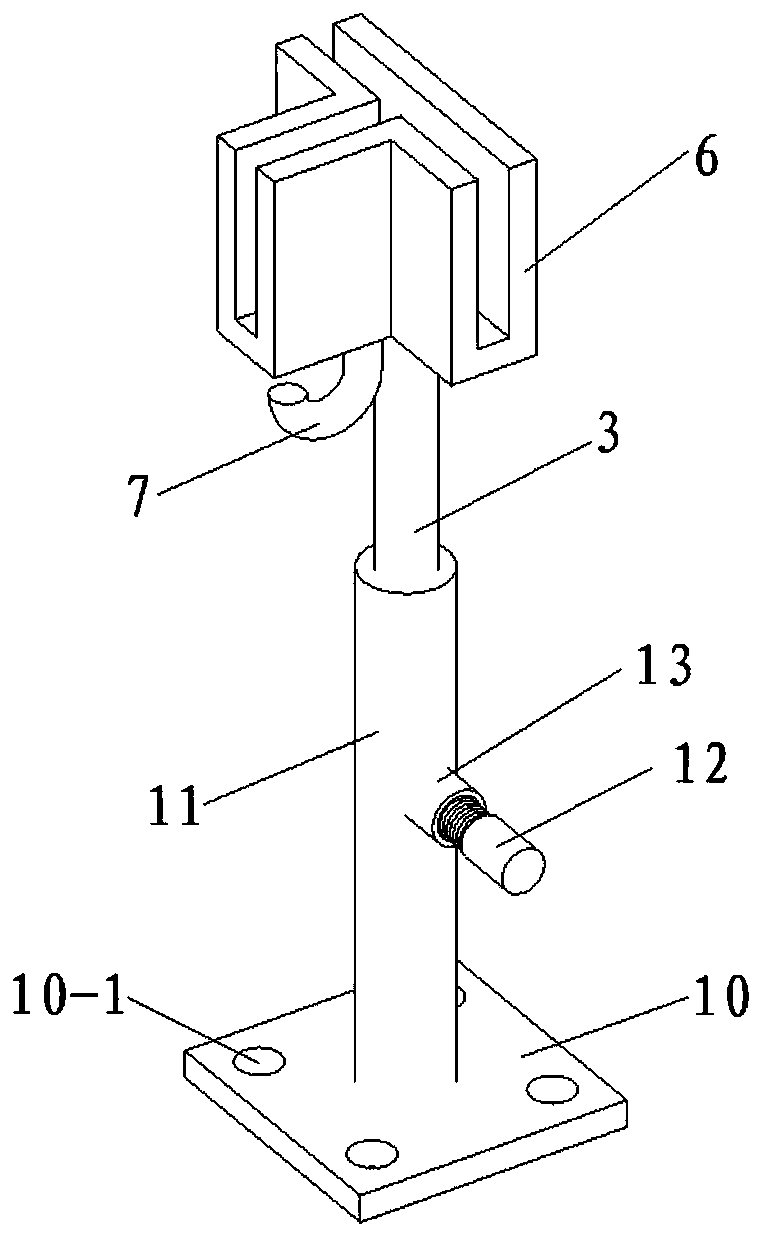

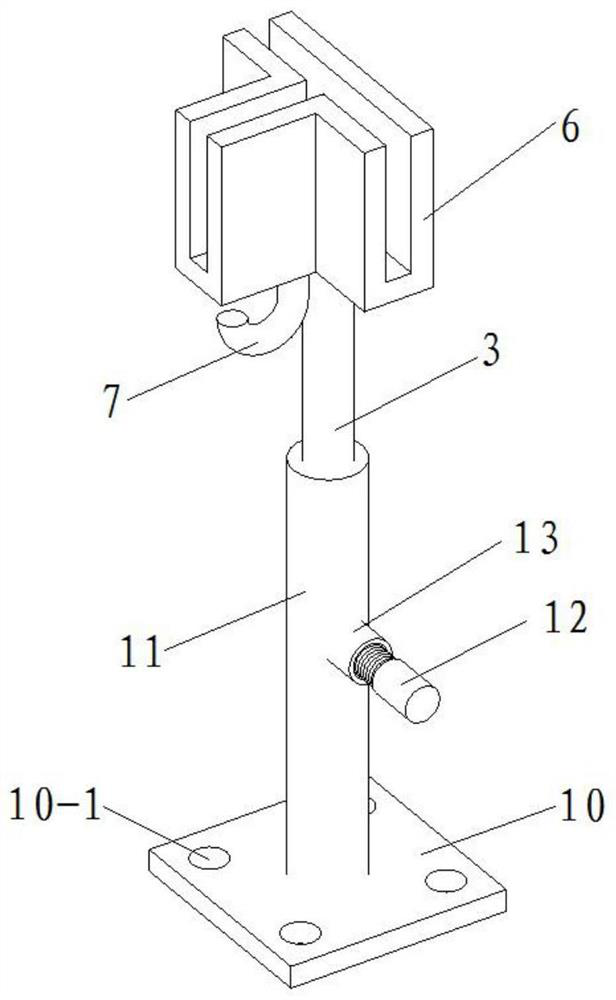

Supporting structure for building translation and construction method thereof

ActiveCN109610882AAvoid secondary cuttingMove smoothly into placeBuilding repairsBasementStructural engineering

The invention discloses a supporting structure for building translation and a construction method thereof. The supporting structure for building translation is arranged at the top of a foundation raftor an independent foundation. The supporting structure comprises supporting columns and a basement top plate; the top surfaces of the supporting columns are flush with the top surface of the basementtop plate; the top ends of main ribs in the supporting columns are lower than the top surface of the supporting column, and the top end of each main rib is sleeved with a sleeve; and the elevation ofthe top end of each sleeve matches the elevation of the top surface of the basement top plate. The construction method solves the technical problem that normal migration cannot be conducted due to the fact that a driving path is obstructed in an existing building migration in-place process through a traditional construction method.

Owner:BEIJING FOURTH CONSTR & ENG

Waste recovery device for steel pipe cutting-off machining

ActiveCN112643123AReduce labor levelGuaranteed tightnessTube shearing machinesMaintainance and safety accessoriesElectric machineryProcess engineering

The invention discloses a waste recovery device for steel pipe cutting-off machining. The waste recovery device comprises an operation table, the lower end of an air cylinder is fixed to the upper surface of the operation table, the upper end of the air cylinder is fixed to the lower surface of a top cover, a fixing table is fixed to the lower surface of the top cover, a first motor is fixed to the upper surface of the fixing table, the top end of the first motor is in shaft connection with a cutting knife, the cutting knife is in shaft connection into the fixing table, a clamping device is fixed to the upper surface of the operation table, a fixing device is in threaded connection into the clamping device, a placing plate is fixed in the operation table, and the lower surface of the placing plate is in shaft connection with a second motor. According to the waste recovery device for steel pipe cutting-off machining, generated waste can be swept after a steel pipe is cut, the swept waste can fall into a collector through a falling hole, and therefore the waste in the collector can be directly dumped, and the waste generated after the steel pipe is cut can be recovered.

Owner:芜湖博威机械制造有限公司

Waste recovery device for steel pipe cutting and processing

ActiveCN112643123BReduce labor levelGuaranteed tightnessTube shearing machinesMaintainance and safety accessoriesElectric machinePipe

The invention discloses a waste recycling device for steel pipe cutting and processing, which comprises an operating table, the upper surface of the operating table is fixed with the lower end of the cylinder, and the upper end of the air cylinder is fixed on the lower surface of the top cover, and the lower surface of the top cover A fixed table is fixed, and the upper surface of the fixed table is fixed with a first motor, the top shaft of the first motor is connected with a cutting knife, and the cutting knife shaft is connected inside the fixed table, and the upper surface of the operation table is fixed with a A clamper, and the inside of the clamper is threadedly connected with a fixer, the inside of the operating table is fixed with a placement plate, and the lower surface of the placement plate is shaft-connected with a second motor. The waste recovery device for steel pipe cutting and processing can clean the waste produced after the steel pipe is cut, and the cleaned waste can fall into the collector through the drop hole, so that the waste in the collector can be dumped directly. Thereby finishing the waste material after steel pipe cutting is recycled.

Owner:芜湖博威机械制造有限公司

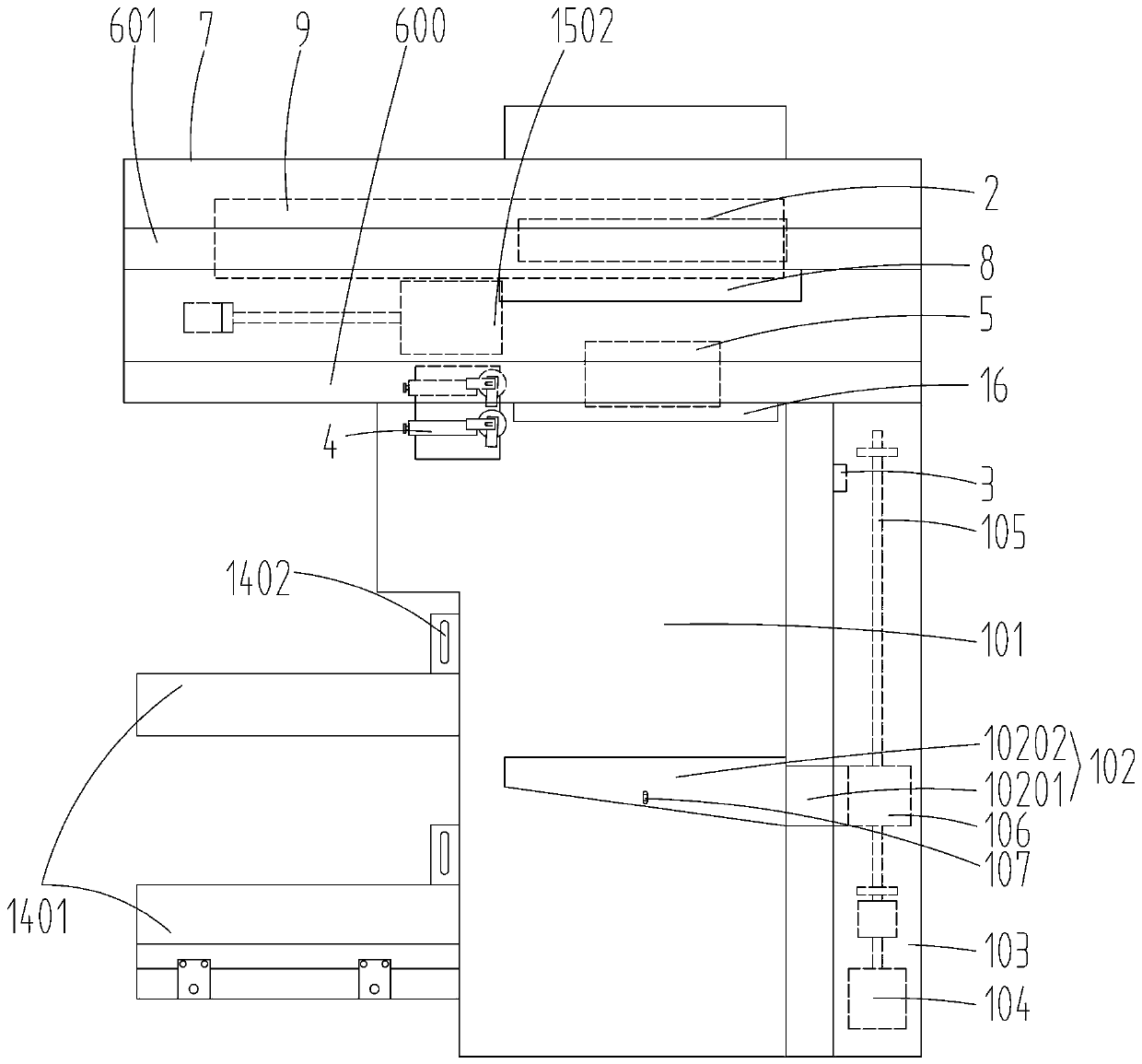

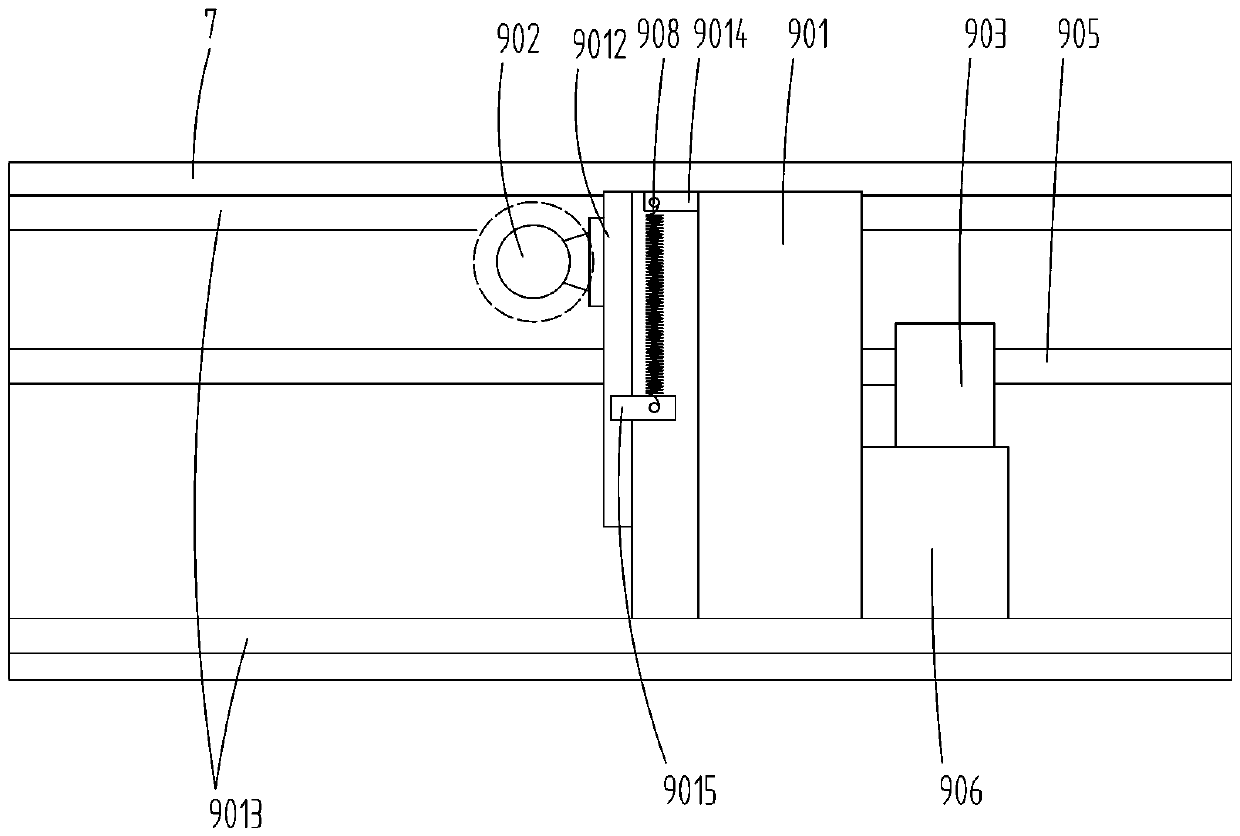

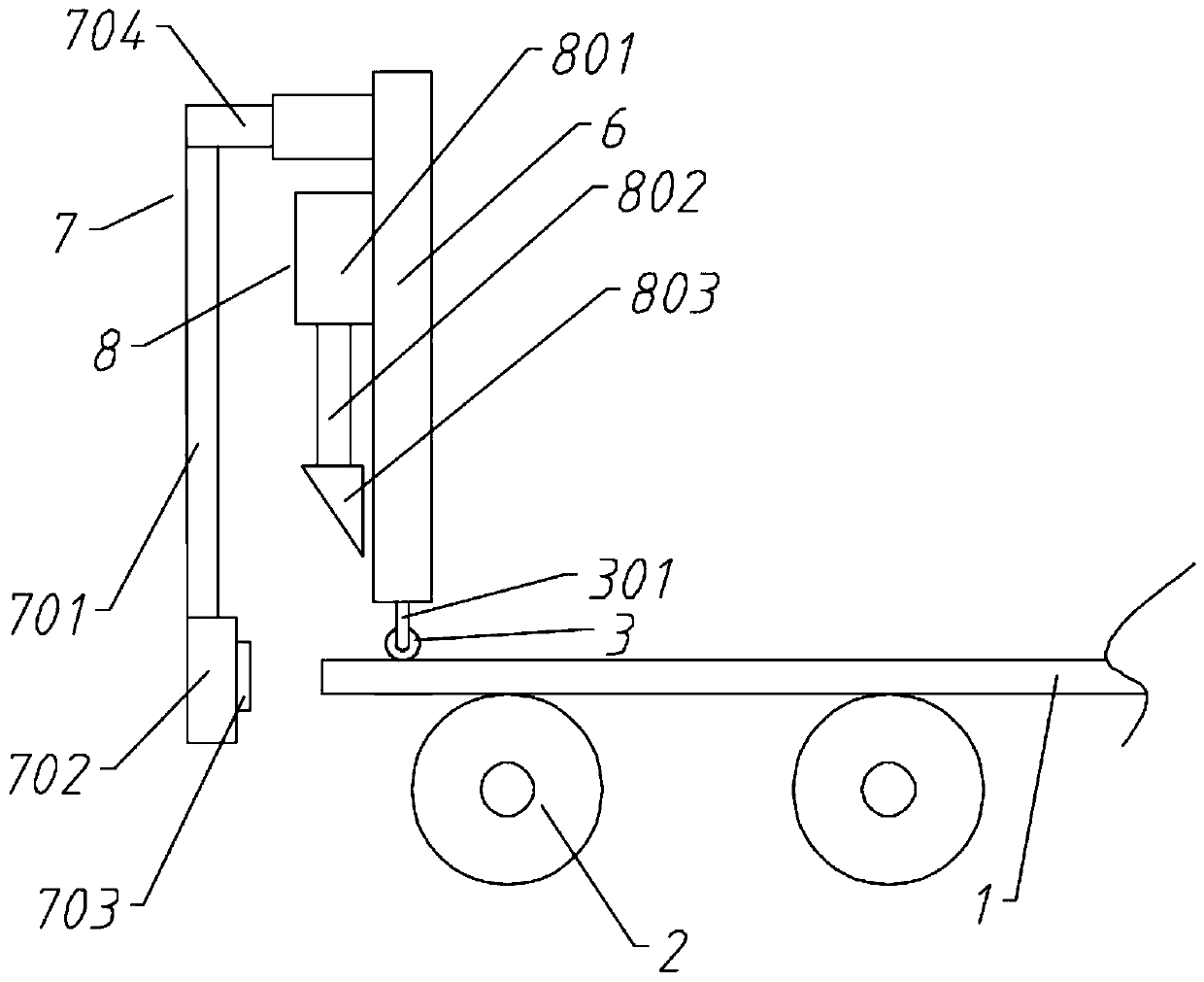

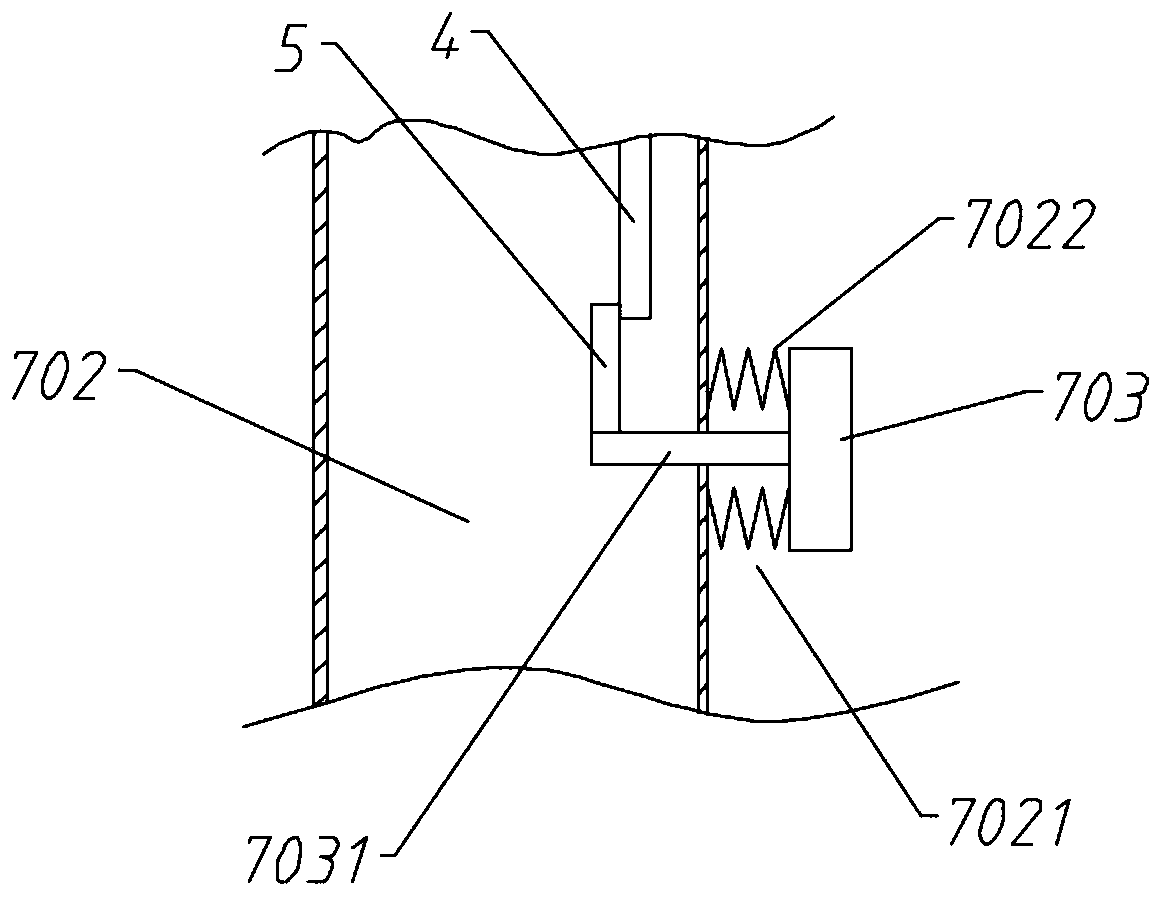

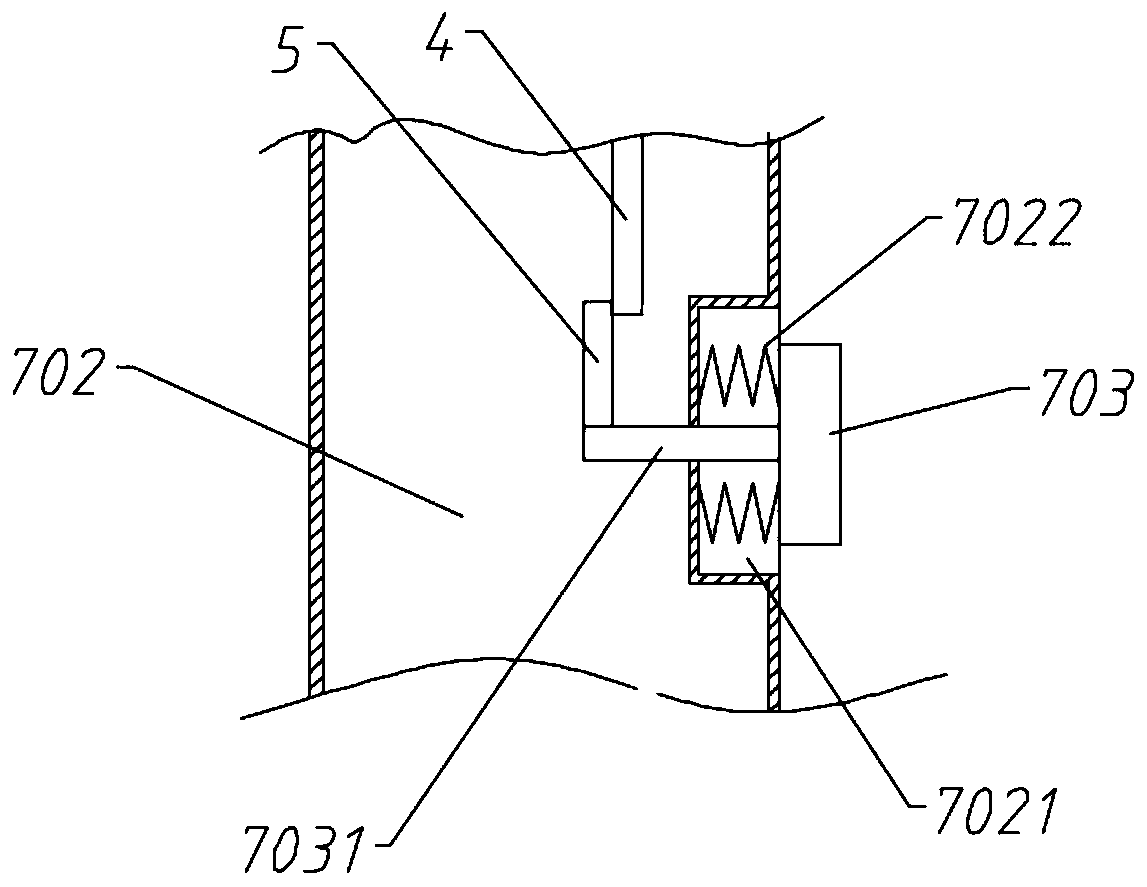

An automatic feeding type leather goods cutting machine

ActiveCN110004253BAvoid secondary cuttingAvoid displacementLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusStructural engineeringMachine

The invention discloses an automatic feeding type leatherware cutting machine. The automatic feeding type leatherware cutting machine structurally comprises an automatic adjusting type high-precisioncutting device, a transverse moving driving machine frame, a longitudinal moving driving machine frame, a material conveying belt, an equipment machine table, connecting supporting columns and connecting supporting blocks, the automatic adjusting type high-precision cutting device is arranged at the upper end of the transverse moving driving machine frame and is connected with the transverse moving driving machine frame in a transmission fit mode, and the transverse moving driving machine frame is located above the material conveying belt. The automatic feeding type leatherware cutting machineis provided with a structure capable of automatically limiting the cutting machine after the cutting machine moves so that the situation that a cutting machine body moves due to vibration generated by the cutting machine, so that the deviation of cutting of leatherware is caused can be effectively prevented, meanwhile, a structure capable of automatically and finely adjusting the position of a cutting piece is arranged so that the situation that the leatherware needs to undergo secondary cutting, so that the influence on cutting work is caused can be prevented.

Owner:嘉兴市华染新能源有限公司

A stapler with firing locking device

ActiveCN105266865BPrevent secondary firingAvoid secondary cuttingSurgical staplesEngineeringLocking plate

Owner:B J ZH F PANTHER MEDICAL EQUIP

Novel blanking die waste cut-off tool structure

InactiveCN111451358AAvoid it happening againAvoid double cutVehicle componentsStructural engineeringWaste material

The invention discloses a novel blanking die waste cut-off tool structure. The novel blanking die waste cut-off tool structure comprises a waste upper die tool block, a waste lower die tool block anda blanking tool block, wherein the waste upper die tool block is provided with a length-direction cutting edge and a width-direction cutting edge; the length-direction cutting edge is matched with a cutting edge of the waste lower die tool block; the blanking tool block is arranged on the side edge of the waste lower die tool block; a cutting edge of the blanking tool block is matched with the width-direction cutting edge on the waste upper die tool block; a pointed cone-shaped cutting edge protruding downwards is arranged at the intersection of the length-direction cutting edge and the width-direction cutting edge of the waste upper die tool block; and a space for the pointed cone-shaped cutting edge to descend is arranged between the waste lower die tool block and the blanking tool block. By the adoption of the novel blanking die waste cut-off tool structure, scrap iron can be avoided, the die repairing frequency is reduced, the production efficiency is improved, and the quality of ablanking piece product is improved.

Owner:柳州宝钢汽车零部件有限公司

A kind of oblique tooth surface gear transmission pair and tooth width geometric design method

InactiveCN105156637BReduce weightIncrease thrust-to-weight ratioPortable liftingGearing elementsAviationEngineering

The invention discloses a helical tooth surface gear transmission pair and a tooth width geometric design method. The helical flank gear is staggered with a straight-tooth involute shaper. This kind of helical flank gear can only mesh with the spur gear, but cannot mesh with the helical gear with a helical angle. The tooth line is approximately an oblique line and forms an oblique angle with the radial direction, which is very suitable for the design diversification of the aviation compact space. The invention clarifies the tooth-shaping principle of the helical tooth surface gear of the helical gear, deduces the tooth surface equation of the helical tooth surface gear; uses the limit line of the involute gear shaper to find the position of the tangent point of the root of the inner end tooth ; Through the condition that the tooth thickness of the outer end tip is equal to zero, the condition of sharpening is obtained; then combined with the condition of avoiding the secondary cutting of the tooth root, the radius of the tip fillet is determined, and the tooth width of the helical flank gear is finally obtained.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com