Angle-adjustable marble cutting device

A cutting equipment and marble technology, applied in the direction of stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of inability to adjust the cutting angle, cumbersome operation procedures, easy displacement of marble, etc., to avoid displacement and reduce complexity. , to ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

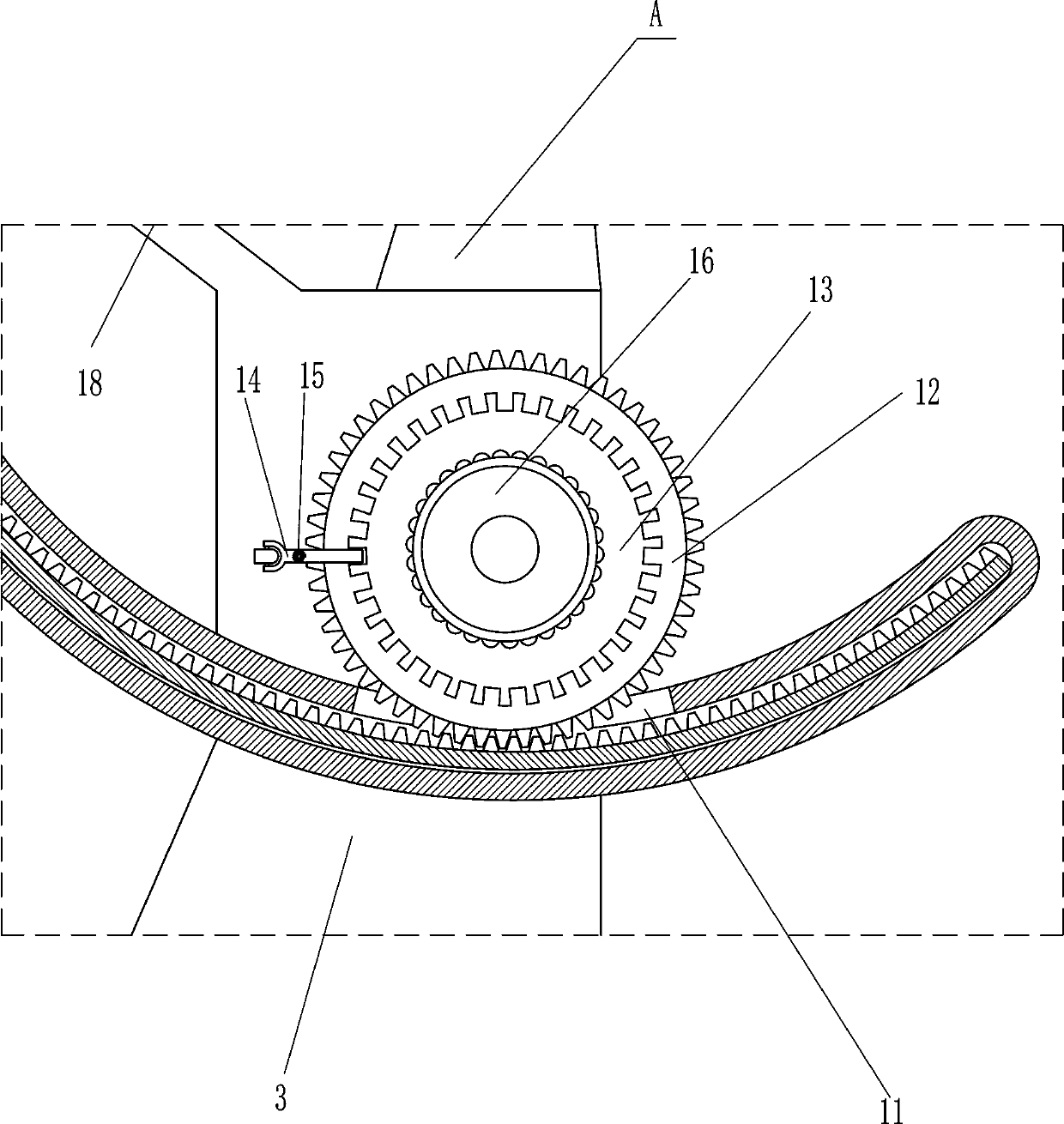

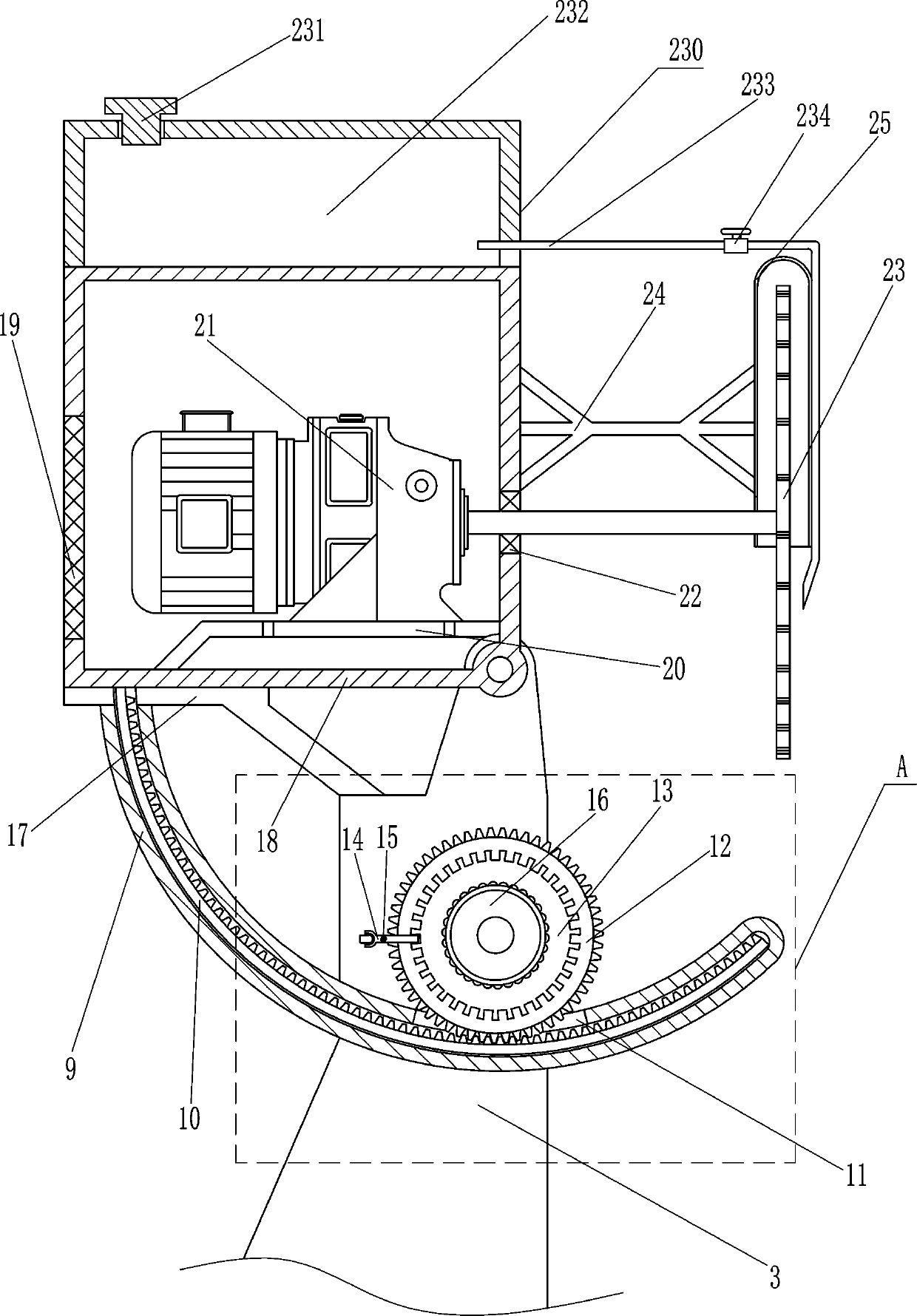

[0020] An adjustable angle marble cutting equipment such as Figure 1-3 As shown, it includes a bottom plate 1, a first bracket 2, a second bracket 3, a tapered plate 4, a first placement plate 5, a handle 8, an adjustment assembly, a support plate 17, a first frame body 18, a net plate 19, a second Two placement plate 20, motor 21, bearing seat 22, cutting piece 23, first fixed rod 24 and waterproof cover 25, bottom plate 1 top right side is symmetrically provided with first bracket 2, and bottom plate 1 is connected with the first bracket by welding 2 connection, the left side of the top of the bottom plate 1 is provided with a second support 3, the top of the first support 2 is provided with a conical plate 4, the top of the conical plate 4 is placed with a first placement plate 5, and the left and right sides of the bottom of the first placement plate 5 are both There is a tapered groove 6, and the tapered groove 6 is slidingly matched with the tapered plate 4. A handle 8 ...

Embodiment 2

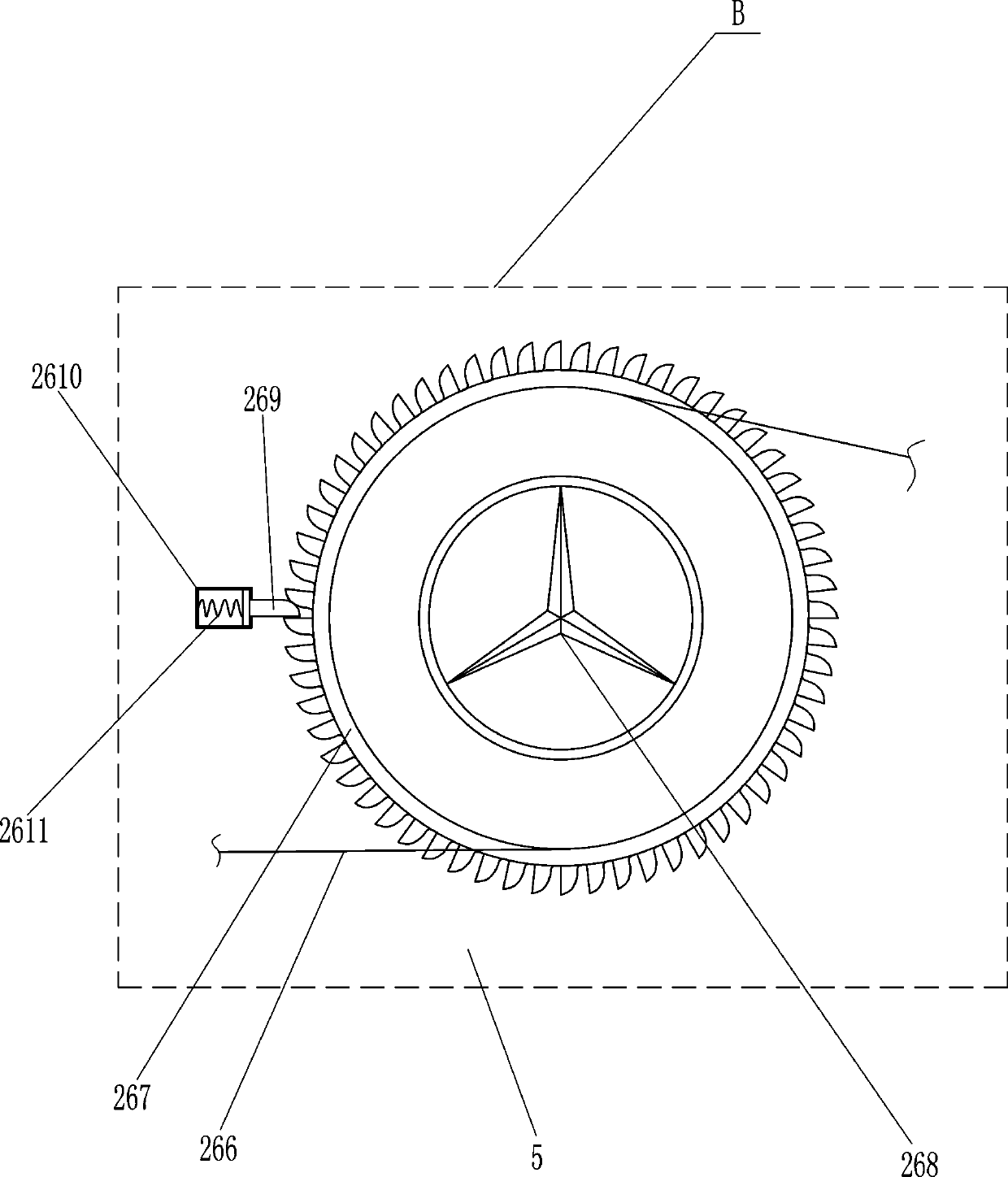

[0024]Also includes a fixing device 26, the fixing device 26 includes a housing 261, a second fixing rod 262, a first spring 263, a horizontal plate 264, a pulley 265, a stay cord 266, a ratchet 267, a second hand wheel 268, a ratchet Block 269, the second frame body 2610 and the second spring 2611, the left and right sides of the front side of the first placement plate 5 are symmetrically provided with a housing 261, the first placement plate 5 is connected with the housing 261 by welding, the housing The body 261 is slidingly provided with a second fixed rod 262, the bottom of the second fixed rod 262 is connected with a first spring 263, the lower part of the housing 261 is equipped with a horizontal plate 264, and the tail end of the first spring 263 is connected to the middle of the top of the horizontal plate 264 , a pulley 265 is installed on the lower part of the housing 261, a pulley 266 is connected to the bottom of the second fixed rod 262, a ratchet 267 is installed...

Embodiment 3

[0027] Also includes a cooling and dust reduction mechanism 230, the cooling and dust reduction mechanism 230 includes a plug 231, a water tank 232, an outlet pipe 233 and a valve 234, the top of the first frame body 18 is provided with a water tank 232, and the first frame body 18 is connected to the water tank by welding 232 connection, first frame body 18 top left side is provided with plug 231, and water tank 232 right bottom is connected with outlet pipe 233, and outlet pipe 233 tail end is positioned at waterproof cover 25 right sides, and outlet pipe 233 is provided with valve 234.

[0028] The operator opens the plug 231 to pour clean water into the water tank 232, and then plugs the plug 231. When it is necessary to reduce dust during cutting or cool down the cutting piece 23, the operator opens the valve 234, and then the water in the water tank 232 will pass through the outlet pipe 233 Drop onto cutting piece 23 and marble 7, thereby play the effect of preventing pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com