Sugarcane cutting machine capable of cutting off sugarcanes uniformly

A cutting machine and sugarcane technology, applied in metal processing and other directions, can solve the problems of sugarcane pollution, unfavorable people's safe consumption, high labor intensity, etc., and achieve the effect of reducing labor intensity, convenient fixing, and avoiding secondary cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

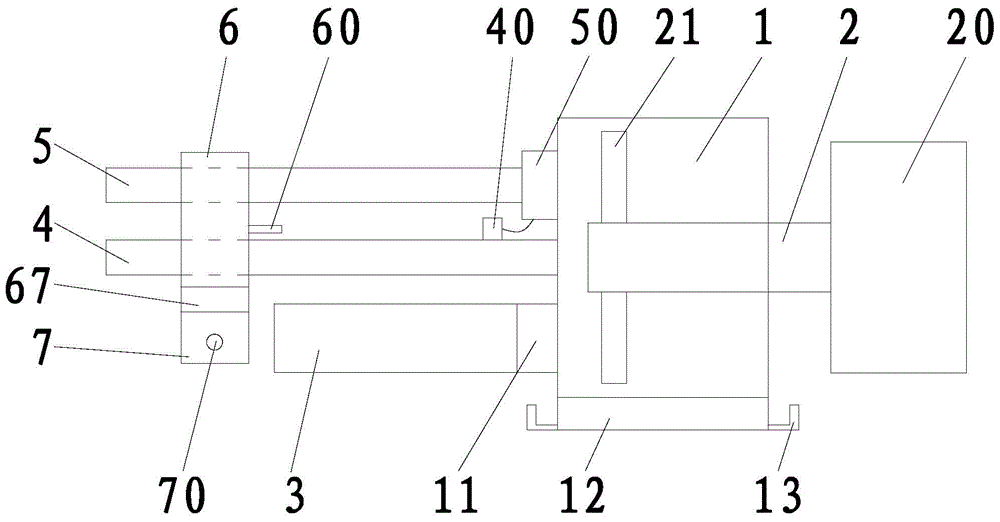

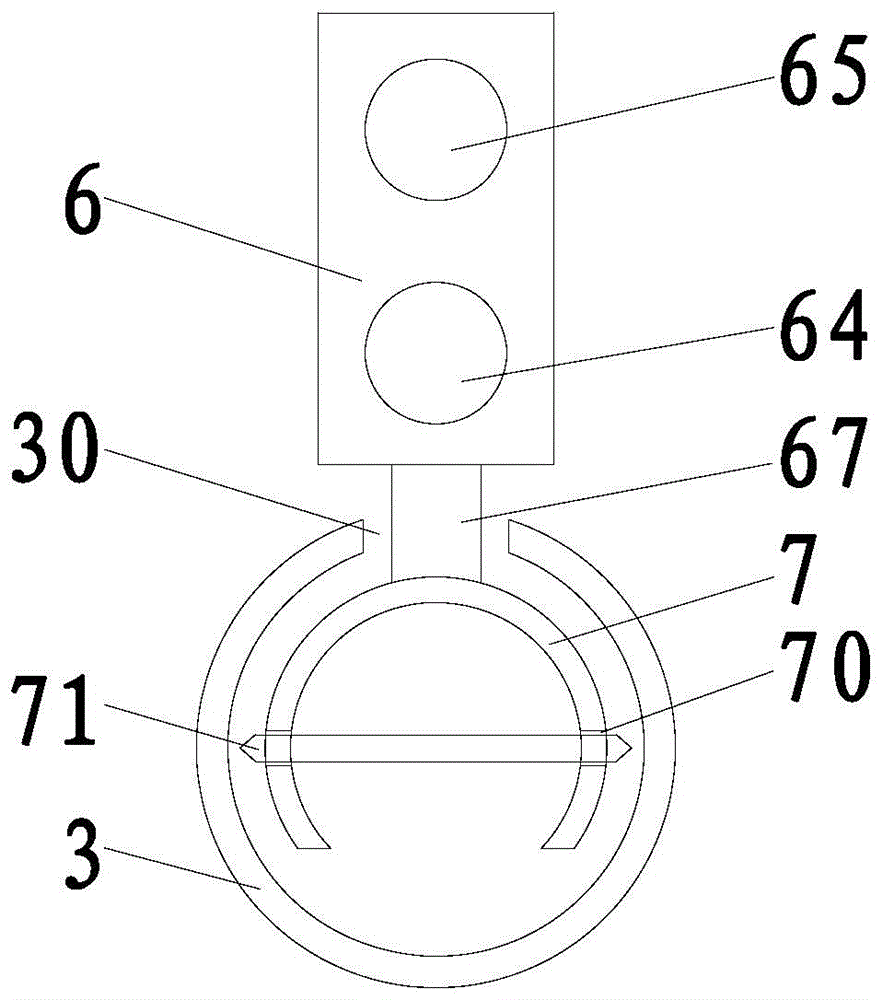

[0018] refer to figure 1 and figure 2 , a sugarcane cutting machine with uniform cutting of the present invention, comprising a cutting cylinder 1, a rotating shaft 2, a screw mandrel 5, a sliding rod 4, a slider 6, a clamping ring 7, and a conduit 3, the rotating shaft 2 goes deep into the cutting cylinder 1, A plurality of cutting knives 21 are connected on the rotating shaft 2, a first motor 20 is connected at one end of the rotating shaft 2, a discharge port 12 is provided at the bottom of the cutting cylinder 1, a feeding port 11 is provided at one side of the cutting cylinder 1, and the conduit 3 is connected to the discharge port 1. Port 12 is connected, there is a gap 30 on the top of the conduit 3, there is a slide rod 4 above the conduit 3, a screw rod 5 is above the slide rod 4, one end of the screw rod 5 is connected with the second motor 50, and one end of the slide rod 4 is connected with the cutting cylinder 1 , the slide bar 4 has an inductor 40 near the side...

Embodiment 2

[0020] In the second embodiment, on the basis of the first embodiment, several hanging hooks 13 are added, and the hanging hooks 13 are symmetrically distributed on the outer wall of the discharge port 12 .

[0021] Working process of the present invention:

[0022] In the working process of a sugarcane cutting machine with uniform cutting in the present invention, the peeled sugarcane is placed in the conduit 3, the top of the sugarcane is placed in the clamping ring 7, and the fixing rod 71 penetrates the top of the sugarcane, so that the top of the sugarcane is fixed , start the first motor 20 and the second motor 50, the sugarcane advances at a constant speed, and the sugarcane is evenly cut off during the advancement process, and falls from the discharge port 12. When the thimble 60 is pushed against the inductor 40, the second motor 50 Reverse operation, until slide block 6 is driven to initial position, unload remaining sugarcane top, put into another sugarcane. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com